Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites

Abstract

1. Introduction

2. Experimental Program

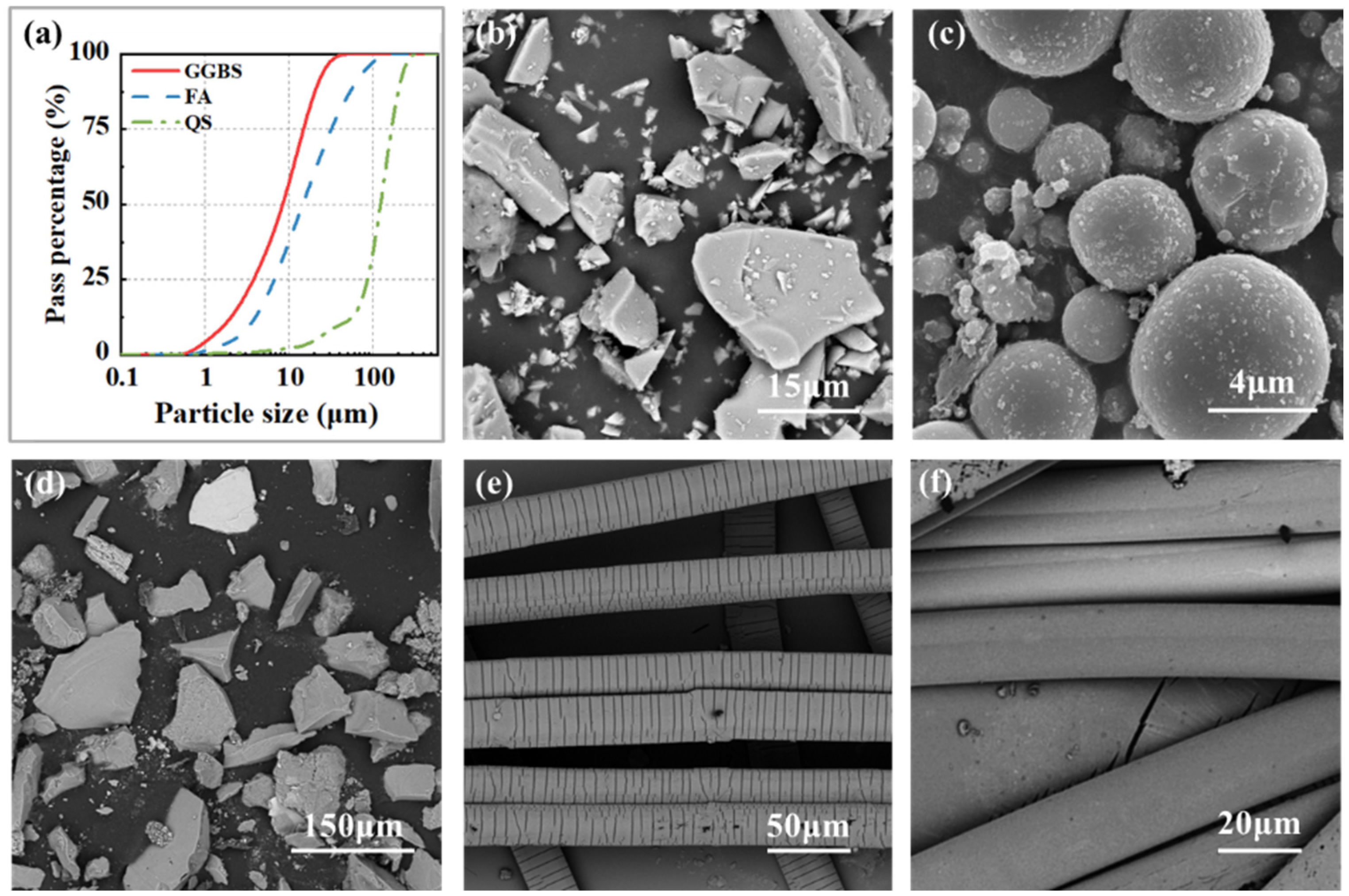

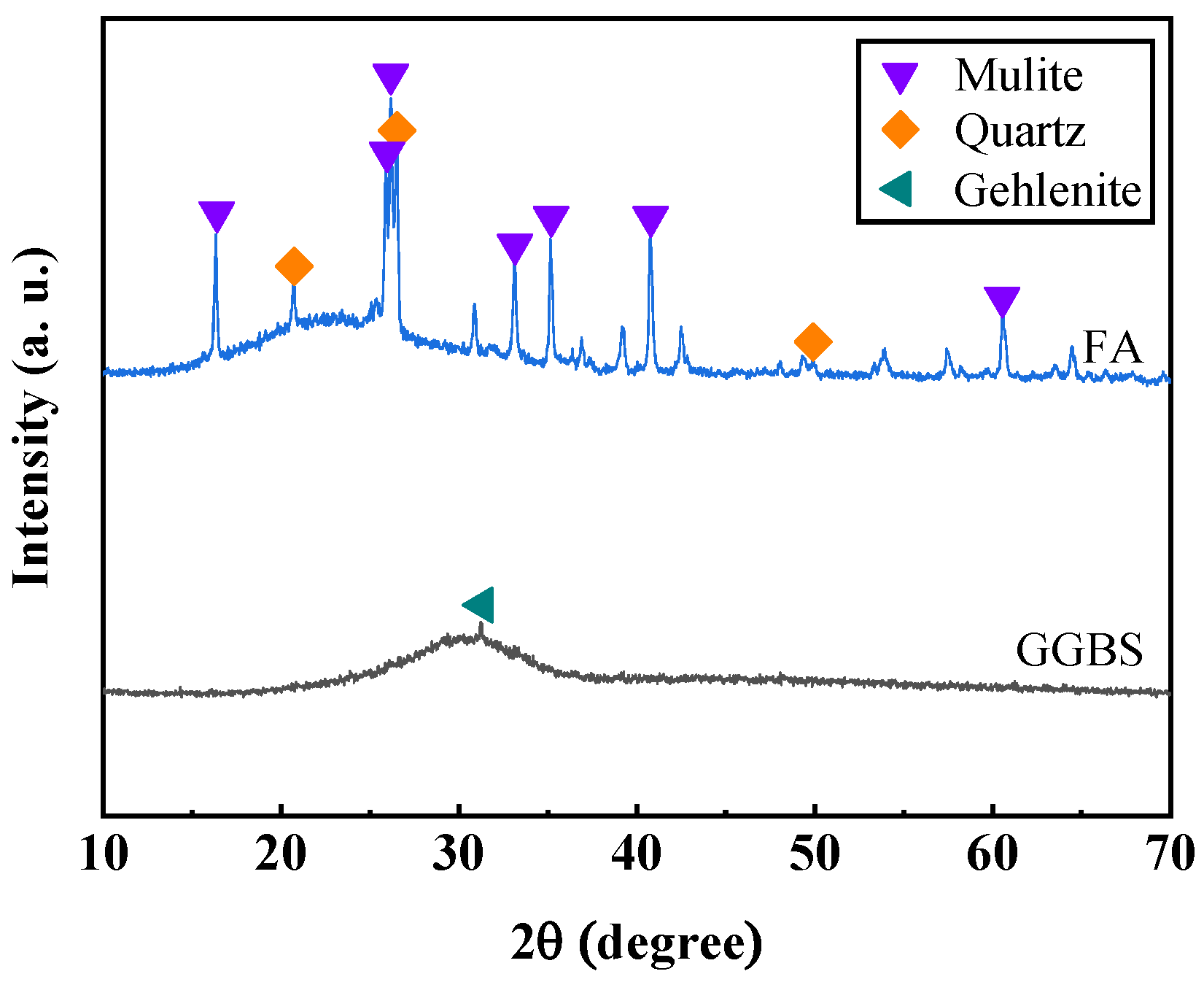

2.1. Materials

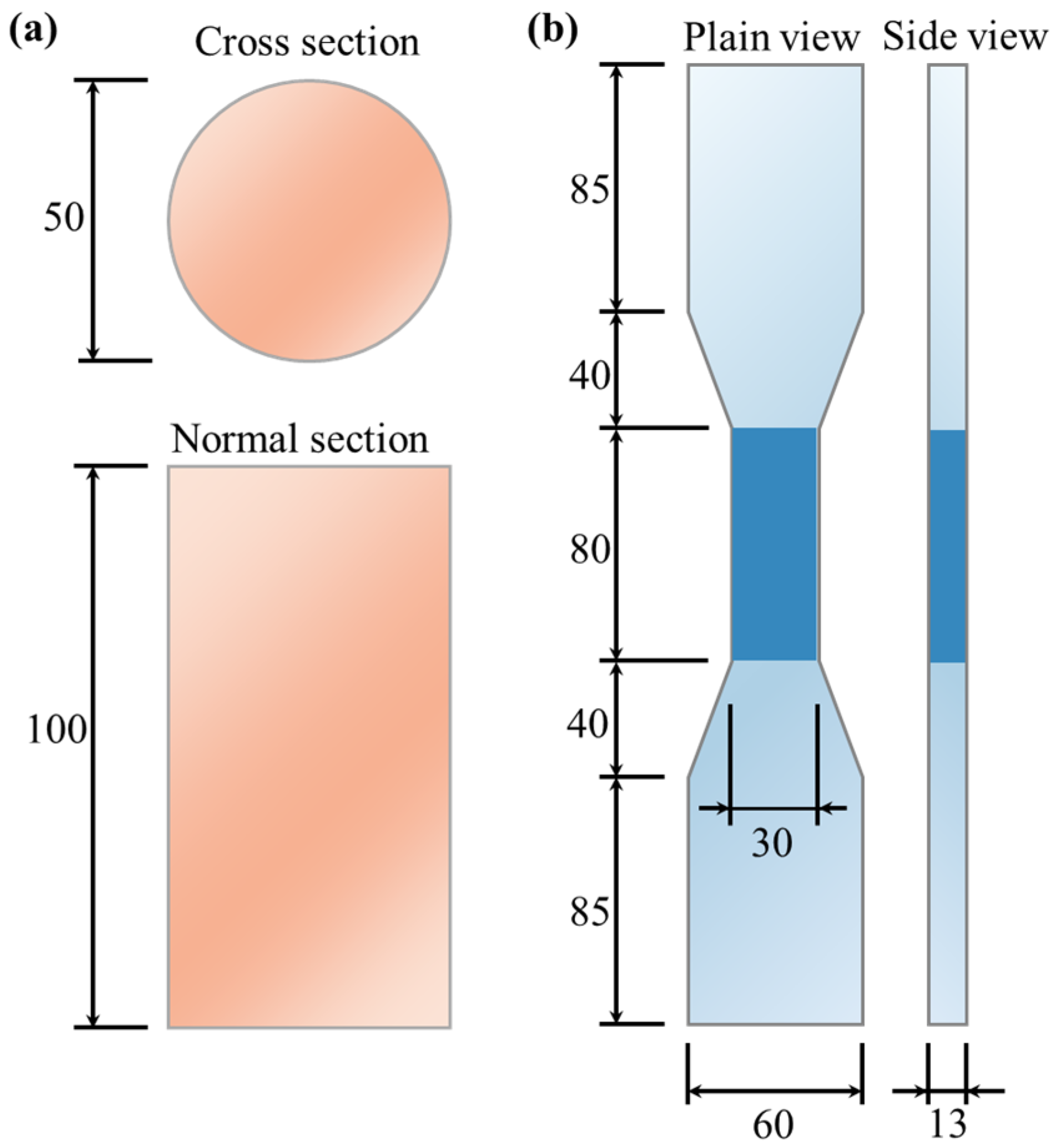

2.2. Mix Proportions and Specimens

2.3. Test Methods

3. Results and Discussion

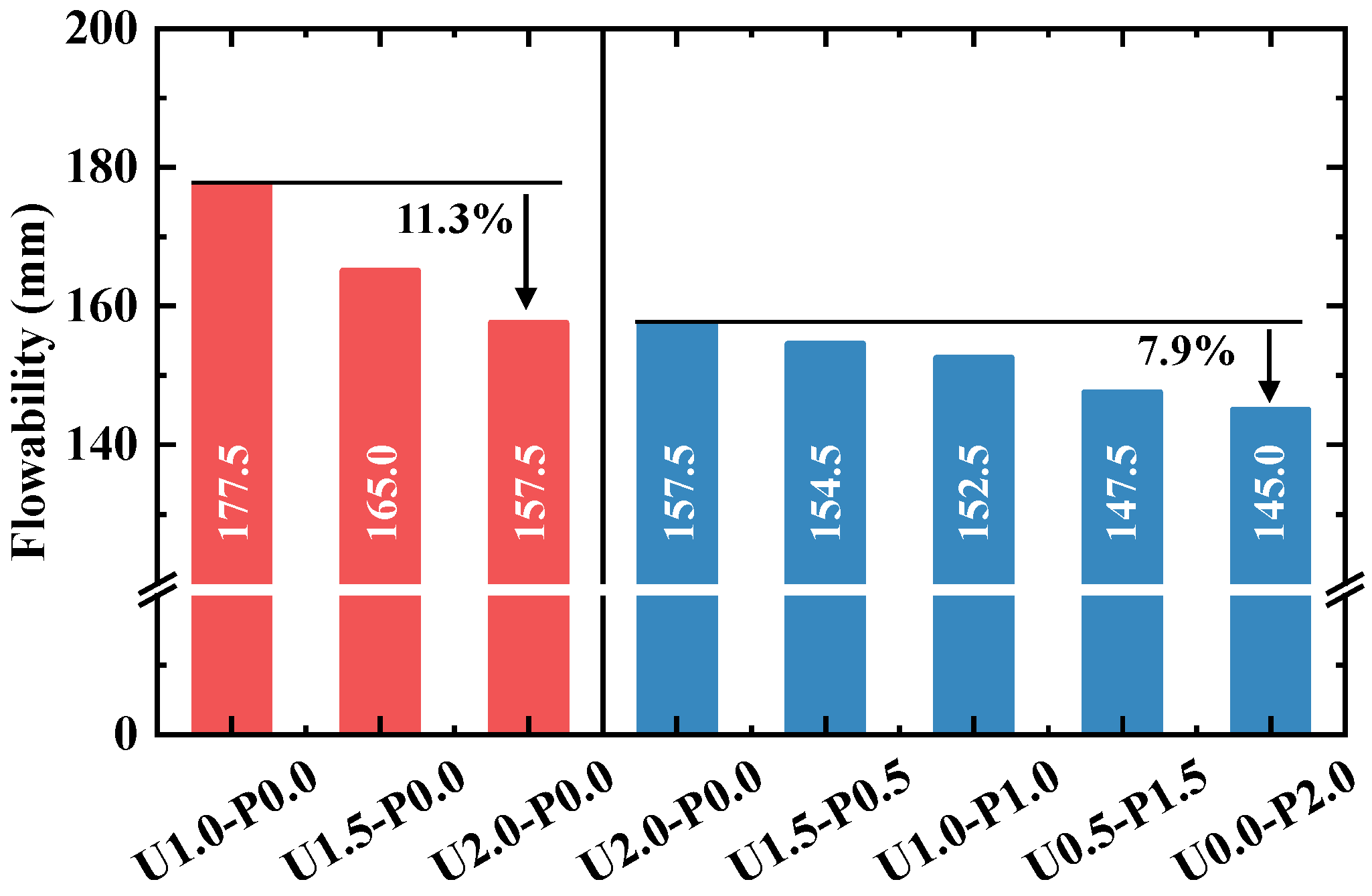

3.1. Flowability

3.2. Compressive Behavior

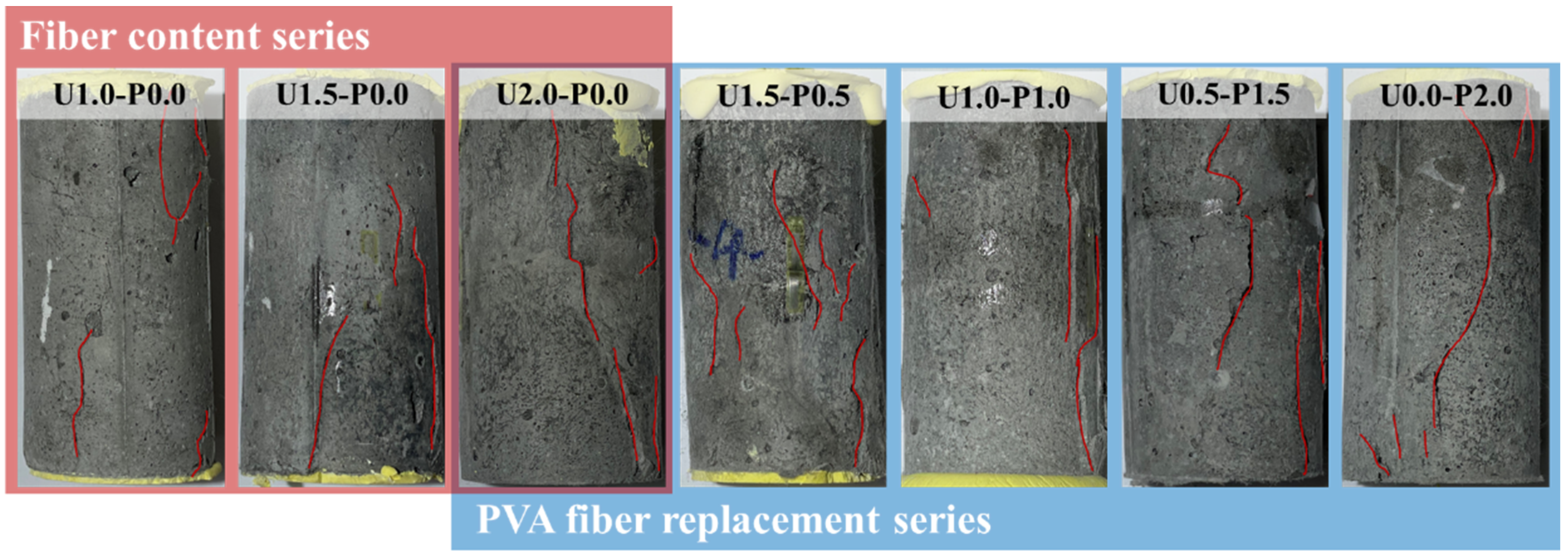

3.2.1. Failure Mode of Compressive Specimens

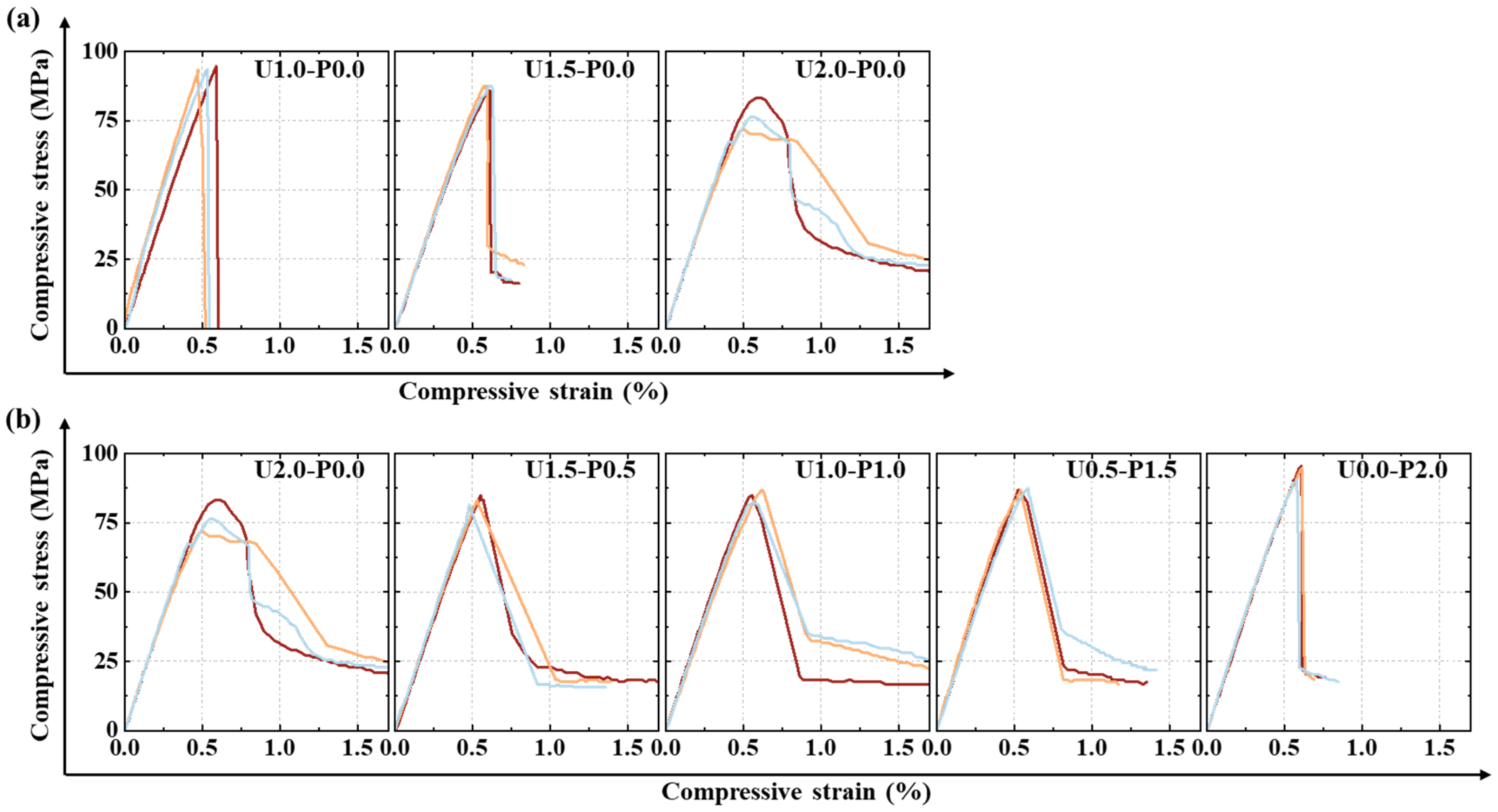

3.2.2. Compressive Stress–Strain Curves

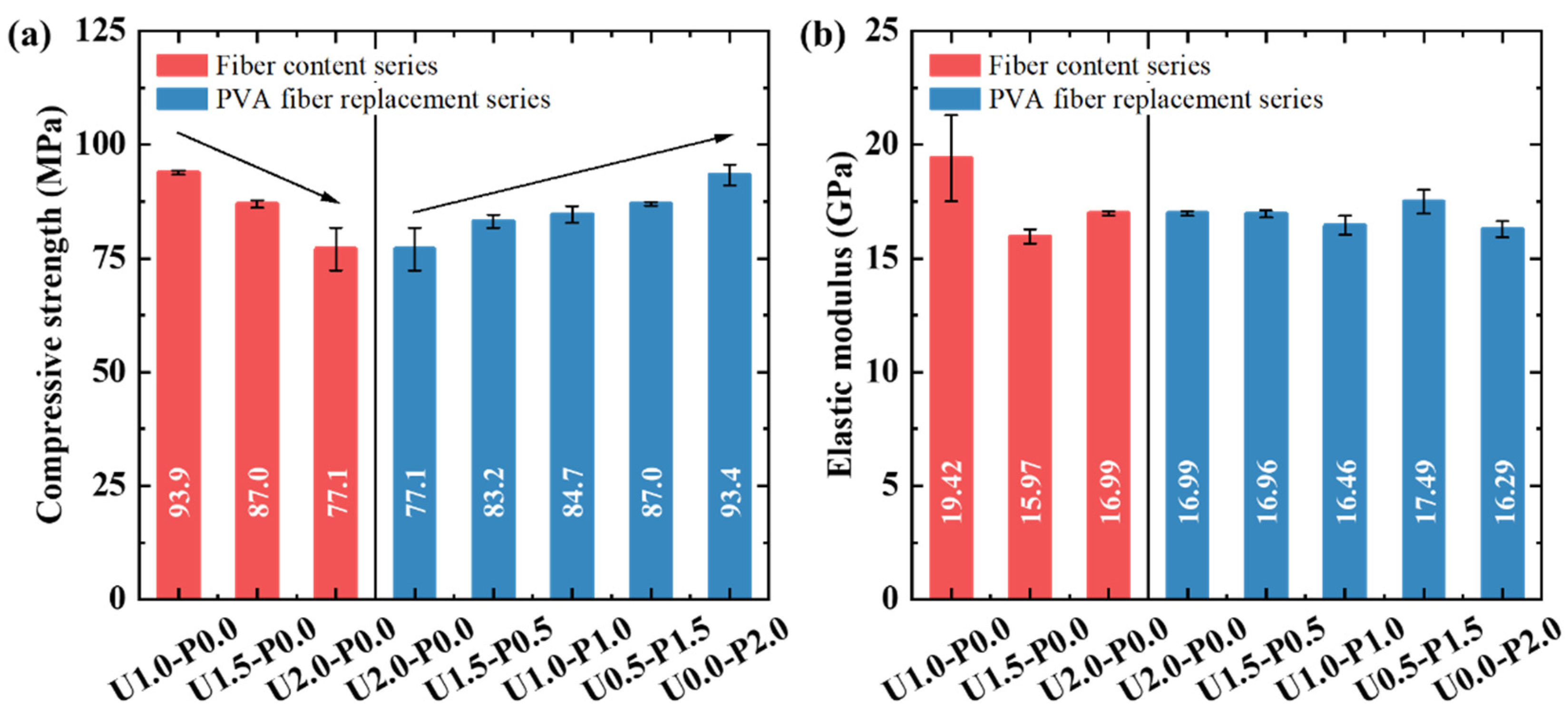

3.2.3. Compressive Properties

3.3. Tensile Behavior

3.3.1. Failure Mode of Tensile Specimens

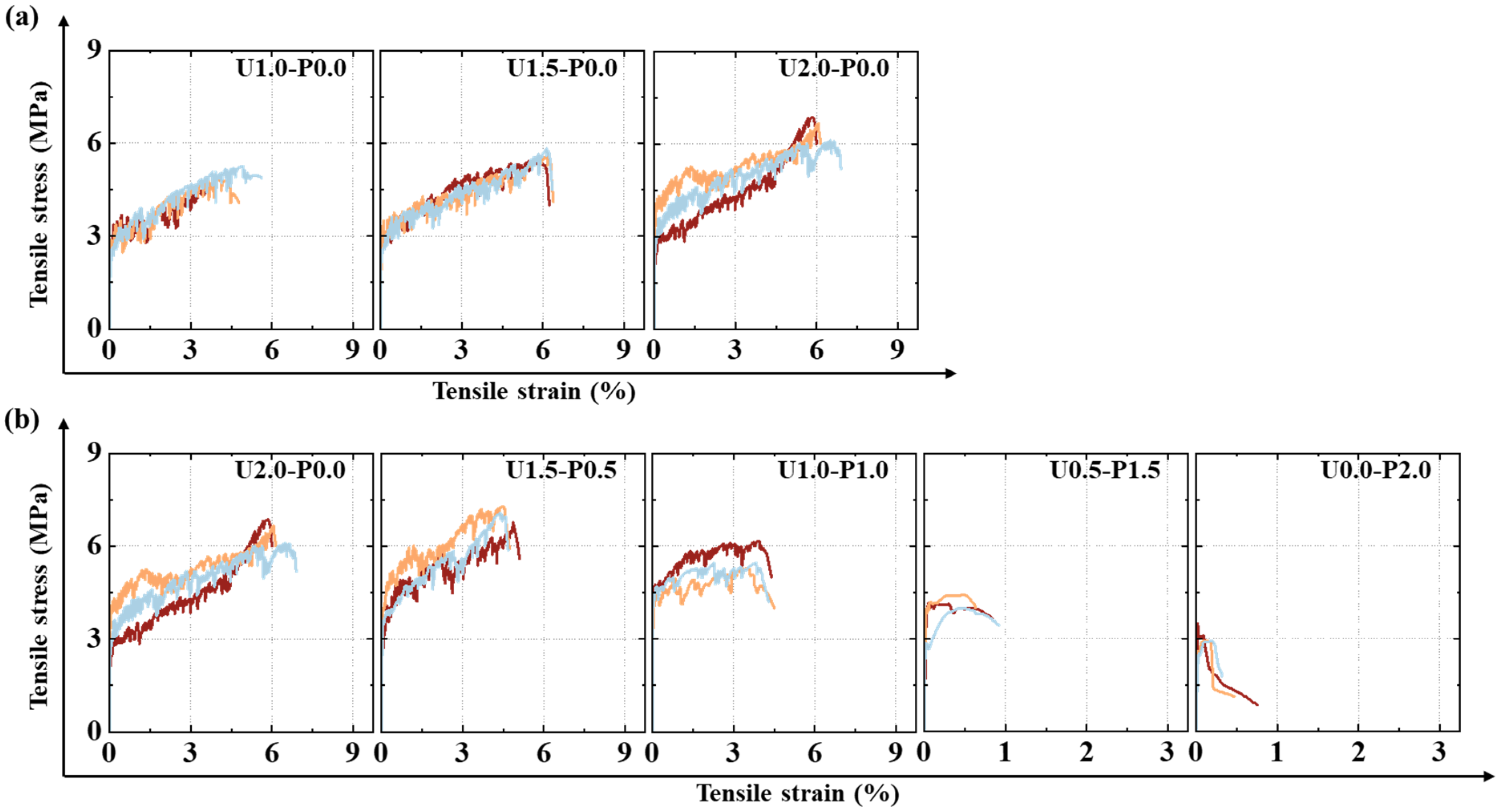

3.3.2. Tensile Stress–Strain Curves

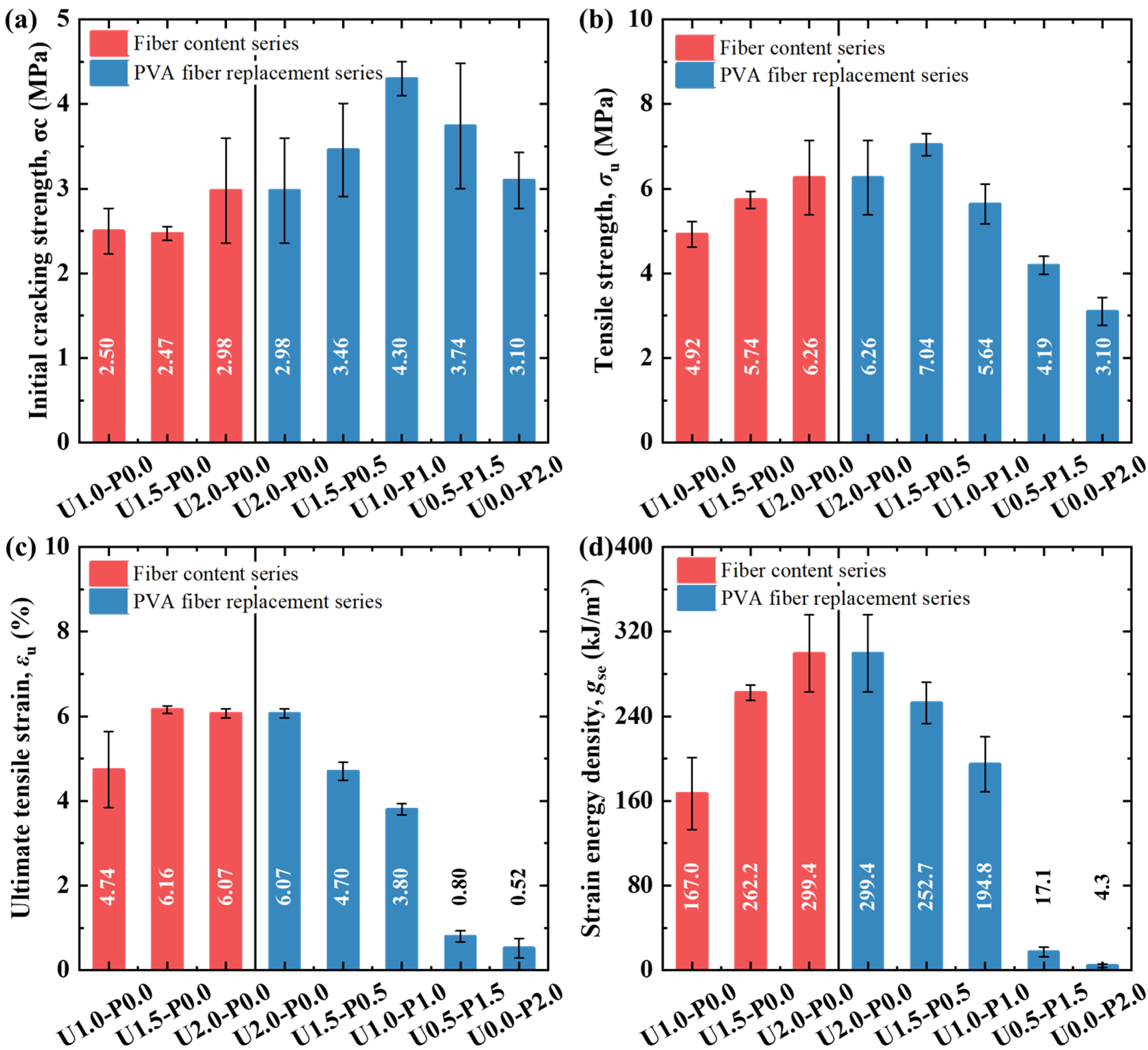

3.3.3. Tensile Properties

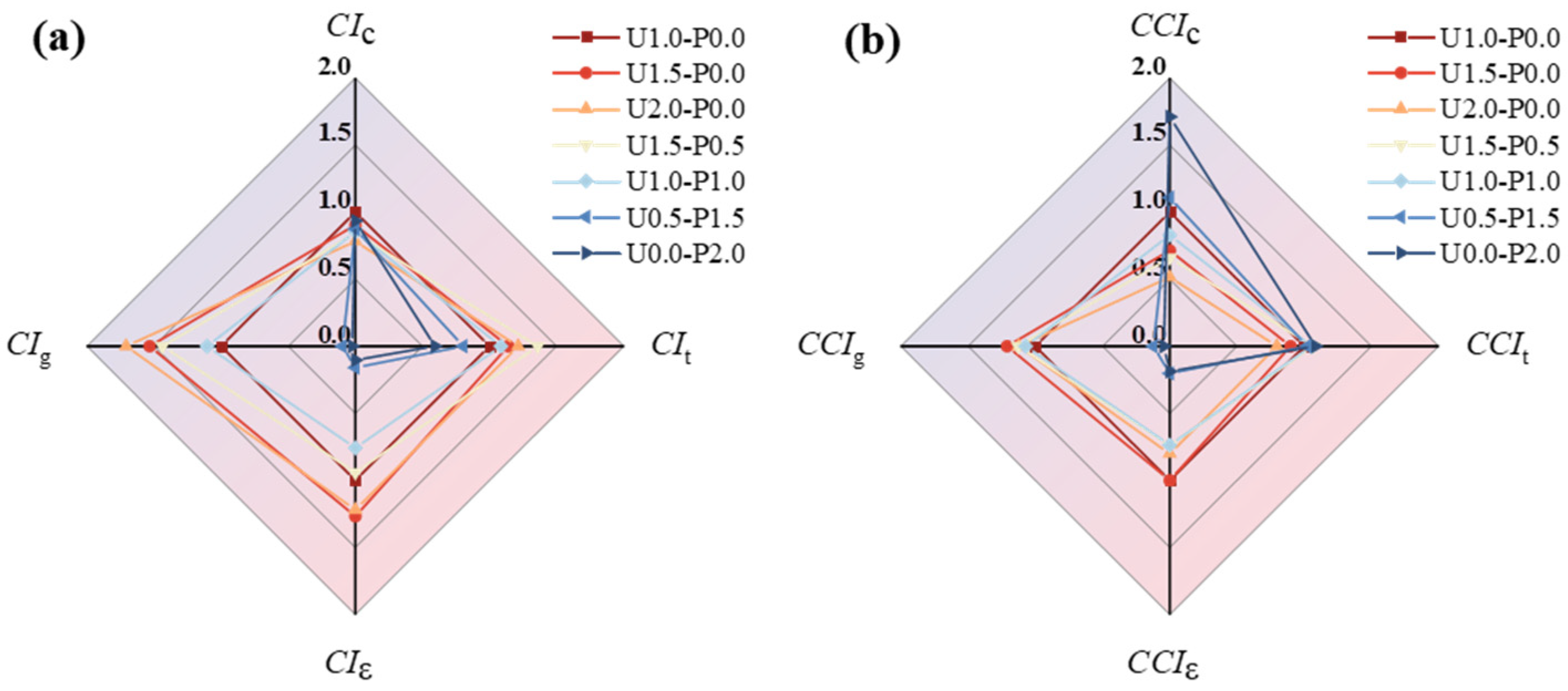

3.4. Economic and Environmental Analyses

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ostovari, H.; Müller, L.; Skocek, J.; Bardow, A. From Unavoidable CO2 Source to CO2 Sink? A Cement Industry Based on CO2 Mineralization. Environ. Sci. Technol. 2021, 55, 5212–5223. [Google Scholar] [CrossRef] [PubMed]

- Rootzén, J.; Johnsson, F. Managing the costs of CO2 abatement in the cement industry. Clim. Policy 2016, 17, 781–800. [Google Scholar] [CrossRef]

- Winnefeld, F.; Leemann, A.; German, A.; Lothenbach, B. CO2 storage in cement and concrete by mineral carbonation. Curr. Opin. Green Sustain. Chem. 2022, 38, 100672. [Google Scholar] [CrossRef]

- Rees, C.A.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S. The mechanism of geopolymer gel formation investigated through seeded nucleation. Colloids Surfaces A Physicochem. Eng. Asp. 2008, 318, 97–105. [Google Scholar] [CrossRef]

- Zakira, U.; Zheng, K.; Xie, N.; Birgisson, B. Development of high-strength geopolymers from red mud and blast furnace slag. J. Clean. Prod. 2023, 383, 135439. [Google Scholar] [CrossRef]

- Lin, J.-X.; Liu, R.-A.; Liu, L.-Y.; Zhuo, K.-Y.; Chen, Z.-B.; Guo, Y.-C. High-strength and high-toughness alkali-activated composite materials: Optimizing mechanical properties through synergistic utilization of steel slag, ground granulated blast furnace slag, and fly ash. Constr. Build. Mater. 2024, 422, 135811. [Google Scholar] [CrossRef]

- Gharzouni, A.; Vidal, L.; Essaidi, N.; Joussein, E.; Rossignol, S. Recycling of geopolymer waste: Influence on geopolymer formation and mechanical properties. Mater. Des. 2016, 94, 221–229. [Google Scholar] [CrossRef]

- Lingyu, T.; Dongpo, H.; Jianing, Z.; Hongguang, W. Durability of geopolymers and geopolymer concretes: A review. Rev. Adv. Mater. Sci. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- Hu, W.; Nie, Q.; Huang, B.; Shu, X. Investigation of the strength development of cast-in-place geopolymer piles with heating systems. J. Clean. Prod. 2019, 215, 1481–1489. [Google Scholar] [CrossRef]

- Kim, Y.; Chae, T. Effect of addition of as-received IGCC slag in making geopolymer. J. Ceram. Process. Res. 2018, 19, 378–382. [Google Scholar]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Chen, G.; Zhuo, K.-X.; Luo, R.-H.; Lai, H.-M.; Cai, Y.-J.; Xie, B.-X.; Lin, J.-X. Fracture behavior of environmentally friendly high-strength concrete using recycled rubber powder and steel fibers: Experiment and modeling. Case Stud. Constr. Mater. 2024, 21, e03501. [Google Scholar] [CrossRef]

- Zhang, P.; Sha, D.; Li, Q.; Zhao, S.; Ling, Y. Effect of Nano Silica Particles on Impact Resistance and Durability of Concrete Containing Coal Fly Ash. Nanomaterials 2021, 11, 1296. [Google Scholar] [CrossRef]

- Golewski, G.L. Enhancement fracture behavior of sustainable cementitious composites using synergy between fly ash (FA) and nanosilica (NS) in the assessment based on digital image processing procedure. Theor. Appl. Fract. Mech. 2024, 131, 104442. [Google Scholar] [CrossRef]

- Xiao, S.-H.; Liao, S.-J.; Zhong, G.-Q.; Guo, Y.-C.; Lin, J.-X.; Xie, Z.-H.; Song, Y. Dynamic properties of PVA short fiber reinforced low-calcium fly ash—Slag geopolymer under an SHPB impact load. J. Build. Eng. 2021, 44, 103220. [Google Scholar] [CrossRef]

- Brugaletta, F.; Becher, A.F.; Rostagno, D.L.; Kim, J.; Medina, J.I.F.; Ziejewska, C.; Marczyk, J.; Korniejenko, K. The Different Properties of Geopolymer Composites Reinforced with Flax Fibers and Carbon Fibers. Materials 2024, 17, 2633. [Google Scholar] [CrossRef] [PubMed]

- Kanda, T.; Li, V. A New Micromechanics Design Theory for Pseudo Strain Hardening; University of Michigan: Ann Arbor, MI, USA, 2003. [Google Scholar]

- Li, V. From Micromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. Doboku Gakkai Ronbunshu 1993, 471, 1–12. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites—Tailored Composites Through Micromechanical Modeling. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Su, J.-Y.; Chen, G.; Pan, H.-S.; Lin, J.-X.; Zhang, J.; Zhuo, K.-X.; Chen, Z.-B.; Guo, Y.-C. Rubber modified high strength-high ductility concrete: Effect of rubber replacement ratio and fiber length. Constr. Build. Mater. 2023, 404, 133243. [Google Scholar] [CrossRef]

- de Oliveira, A.M.; Silva, F.d.A.; Fairbairn, E.d.M.R.; Filho, R.D.T. Coupled temperature and moisture effects on the tensile behavior of strain hardening cementitious composites (SHCC) reinforced with PVA fibers. Mater. Struct. 2018, 51, 65. [Google Scholar] [CrossRef]

- Li, J.; Weng, J.; Yang, E.-H. Stochastic model of tensile behavior of strain-hardening cementitious composites (SHCCs). Cem. Concr. Res. 2019, 124, 105856. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Deflection hardening behaviour of short fibre reinforced fly ash based geopolymer composites. Mater. Des. 2013, 50, 674–682. [Google Scholar] [CrossRef]

- Zhang, S.; Li, V.C.; Ye, G. Micromechanics-guided development of a slag/fly ash-based strain-hardening geopolymer composite. Cem. Concr. Compos. 2020, 109, 103510. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Curosu, I.; Liebscher, M.; Mechtcherine, V.; Silva, F.d.A. On the mechanical performance of K- and Na-based strain-hardening geopolymer composites (SHGC) reinforced with PVA fibers. Constr. Build. Mater. 2020, 248, 118558. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Zhang, M. Effect of sand content on engineering properties of fly ash-slag based strain hardening geopolymer composites. J. Build. Eng. 2021, 34, 101951. [Google Scholar] [CrossRef]

- Nematollahi, B.; Qiu, J.; Yang, E.-H.; Sanjayan, J. Micromechanics constitutive modelling and optimization of strain hardening geopolymer composite. Ceram. Int. 2017, 43, 5999–6007. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Constr. Build. Mater. 2014, 57, 163–168. [Google Scholar] [CrossRef]

- Lao, J.-C.; Huang, B.-T.; Xu, L.-Y.; Khan, M.; Fang, Y.; Dai, J.-G. Seawater sea-sand Engineered Geopolymer Composites (EGC) with high strength and high ductility. Cem. Concr. Compos. 2023, 138, 104998. [Google Scholar] [CrossRef]

- Trindade, A.C.C.; Heravi, A.A.; Curosu, I.; Liebscher, M.; de Andrade Silva, F.; Mechtcherine, V. Tensile behavior of strain-hardening geopolymer composites (SHGC) under impact loading. Cem. Concr. Compos. 2020, 113, 103703. [Google Scholar] [CrossRef]

- Lin, J.-X.; Chen, G.; Pan, H.-S.; Wang, Y.-C.; Guo, Y.-C.; Jiang, Z.-X. Analysis of stress-strain behavior in engineered geopolymer composites reinforced with hybrid PE-PP fibers: A focus on cracking characteristics. Compos. Struct. 2023, 323, 117437. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Effect of recycled tyre polymer fibre on engineering properties of sustainable strain hardening geopolymer composites. Cem. Concr. Compos. 2021, 122, 104167. [Google Scholar] [CrossRef]

- Li, V.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar]

- Zhang, Z.; Zhang, Q. Matrix tailoring of Engineered Cementitious Composites (ECC) with non-oil-coated, low tensile strength PVA fiber. Constr. Build. Mater. 2018, 161, 420–431. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bianco, A.; Blasi, E.; Cappello, M.; Caputo, D.; Chougan, M.; Coffetti, D.; Coppola, B.; et al. New Materials and Technologies for Durability and Conservation of Building Heritage. Materials 2023, 16, 1190. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-X.; Su, J.-Y.; Pan, H.-S.; Peng, Y.-Q.; Guo, Y.-C.; Chen, W.-S.; Sun, X.-L.; Yuan, B.-X.; Liu, G.-T.; Lan, X.-W. Dynamic compression behavior of ultra-high performance concrete with hybrid polyoxymethylene fiber and steel fiber. J. Mater. Res. Technol. 2022, 20, 4473–4486. [Google Scholar] [CrossRef]

- Lin, J.-X.; Song, Y.; Xie, Z.-H.; Guo, Y.-C.; Yuan, B.; Zeng, J.-J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.K.; Leung, C.K.Y.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Peng, Y.-Q.; Zheng, D.-P.; Pan, H.-S.; Yang, J.-L.; Lin, J.-X.; Lai, H.-M.; Wu, P.-Z.; Zhu, H.-Y. Strain hardening geopolymer composites with hybrid POM and UHMWPE fibers: Analysis of static mechanical properties, economic benefits, and environmental impact. J. Build. Eng. 2023, 76, 107315. [Google Scholar] [CrossRef]

- Lin, J.-X.; Luo, R.-H.; Su, J.-Y.; Guo, Y.-C.; Chen, W.-S. Coarse synthetic fibers (PP and POM) as a replacement to steel fibers in UHPC: Tensile behavior, environmental and economic assessment. Constr. Build. Mater. 2024, 412, 134654. [Google Scholar] [CrossRef]

- Li, V. Engineered Cementitious Composites (ECC)—Material, Structural, and Durability Performance; University of Michigan: Ann Arbor, MI, USA, 2011. [Google Scholar]

- GB/T-18046; Ground Granulated Blast Furnace Slag Used for Cement, Mortar and Concrete. China Architecture and Building Press: Beijing, China, 2017. (In Chinese)

- ASTM-C618; Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2012.

- ASTM-C1437; Flow of Hydraulic Cement Mortar. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2013.

- ASTM-C109/C109M; Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2020.

- Yokota, H.; Rokugo, K.; Sakata, N. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composite with Multiple Fine Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008; pp. 1–16. [Google Scholar]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T.Q. Fresh and rheological characteristics of fiber reinforced concrete—A review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Kong, H.-J.; Bike, S.G.; Li, V.C. Constitutive rheological control to develop a self-consolidating engineered cementitious composite reinforced with hydrophilic poly(vinyl alcohol) fibers. Cem. Concr. Compos. 2003, 25, 333–341. [Google Scholar] [CrossRef]

- ASTM C469/C469M-22; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S. Microstructural characterisation of cementitious composite incorporating polymeric fibre: A comprehensive review. Constr. Build. Mater. 2022, 335, 127497. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Sakulich, A.R.; Li, V.C. Nanoscale characterization of engineered cementitious composites (ECC). Cem. Concr. Res. 2011, 41, 169–175. [Google Scholar] [CrossRef]

- Lei, D.-Y.; Guo, L.-P.; Chen, B.; Curosu, I.; Mechtcherine, V. The connection between microscopic and macroscopic properties of ultra-high strength and ultra-high ductility cementitious composites (UHS-UHDCC). Compos. Part B Eng. 2019, 164, 144–157. [Google Scholar] [CrossRef]

- Lee, S.K.; Oh, T.; Banthia, N.; Yoo, D.-Y. Optimization of fiber aspect ratio for 90 MPa strain-hardening geopolymer composites (SHGC) with a tensile strain capacity over 7.5%. Cem. Concr. Compos. 2023; 139, 105055. [Google Scholar] [CrossRef]

- Wang, Y.; Zhong, H.; Zhang, M. Experimental study on static and dynamic properties of fly ash-slag based strain hardening geopolymer composites. Cem. Concr. Compos. 2022, 129, 104481. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Xu, L.-Y.; Qian, L.-P.; Huang, B.-T.; Dai, J.-G. Development of artificial one-part geopolymer lightweight aggregates by crushing technique. J. Clean. Prod. 2021, 315, 128200. [Google Scholar] [CrossRef]

- Shoji, D.; He, Z.; Zhang, D.; Li, V.C. The greening of engineered cementitious composites (ECC): A review. Constr. Build. Mater. 2022, 327, 126701. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Song, Y.; Hou, M.; Xu, Y. Development of low-cost engineered cementitious composites using Yellow River silt and unoiled PVA fiber. Constr. Build. Mater. 2024, 425, 136063. [Google Scholar] [CrossRef]

| Materials | Al2O3 | SiO2 | CaO | Fe2O3 | K2O | SO3 | MgO | TiO2 | Other |

|---|---|---|---|---|---|---|---|---|---|

| FA | 31.14 | 53.96 | 4.01 | 4.16 | 2.03 | 0 | 1.01 | 1.13 | 2.53 |

| GGBS | 17.70 | 34.50 | 34.00 | 1.03 | 0 | 1.64 | 6.01 | 0 | 5.12 |

| Fiber Type | Density (g/cm3) | Strength (MPa) | Elastic Modulus (GPa) | Length (mm) | Diameter (μm) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| PE | 0.97 | 2500 | 120 | 12 | 20 | 3.7 |

| PVA | 1.29 | 1830 | 40 | 12 | 15 | 6.9 |

| Mix IDs | GGBS | FA | Quartz Sand | Alkali-Activator | Water | BaCl2 | PE Fiber (%) | PVA Fiber (%) |

|---|---|---|---|---|---|---|---|---|

| U1.0-P0.0 | 849.7 | 364.1 | 242.8 | 242.8 | 72.8 | 12.1 | 1.0 | 0.0 |

| U1.5-P0.0 | 1.5 | 0.0 | ||||||

| U2.0-P0.0 | 2.0 | 0.0 | ||||||

| U1.5-P0.5 | 1.5 | 0.5 | ||||||

| U1.0-P1.0 | 1.0 | 1.0 | ||||||

| U0.5-P1.5 | 0.5 | 1.5 | ||||||

| U0.0-P2.0 | 0.0 | 2.0. |

| Mix IDs | Compressive Strength (MPa) | Peak Strain (%) | Elastic Modulus (GPa) |

|---|---|---|---|

| U1.0-P0.0 | 93.9 (0.49) | 0.532 (0.05) | 19.42 (1.90) |

| U1.5-P0.0 | 87.0 (0.83) | 0.606 (0.01) | 15.97 (0.32) |

| U2.0-P0.0 | 77.1 (4.69) | 0.565 (0.05) | 16.99 (0.10) |

| U1.5-P0.5 | 83.2 (1.43) | 0.565 (0.02) | 16.96 (0.16) |

| U1.0-P1.0 | 84.7 (1.80) | 0.578 (0.03) | 16.46 (0.42) |

| U0.5-P1.5 | 87.0 (0.41) | 0.552 (0.03) | 17.49 (0.52) |

| U0.0-P2.0 | 93.4 (2.30) | 0.598 (0.01) | 16.29 (0.35) |

| Mix IDs | (MPa) | (%) | (MPa) | (%) | (kJ/m3) |

|---|---|---|---|---|---|

| U1.0-P0.0 | 2.50 (0.27) | 0.024 (0.017) | 4.92 (0.30) | 4.74 (0.90) | 167.0 (34.2) |

| U1.5-P0.0 | 2.47 (0.08) | 0.027 (0.007) | 5.74 (0.20) | 6.16 (0.09) | 262.2 (7.3) |

| U2.0-P0.0 | 2.98 (0.62) | 0.069 (0.009) | 6.26 (0.88) | 6.07 (0.11) | 299.4 (36.5) |

| U1.5-P0.5 | 3.46 (0.55) | 0.057 (0.026) | 7.04 (0.26) | 4.70 (0.21) | 252.7 (19.5) |

| U1.0-P1.0 | 4.30 (0.20) | 0.050 (0.034) | 5.64 (0.47) | 3.80 (0.13) | 194.8 (26.2) |

| U0.5-P1.5 | 3.74 (0.74) | 0.032 (0.017) | 4.19 (0.21) | 0.80 (0.13) | 17.1 (4.6) |

| U0.0-P2.0 | 3.10 (0.33) | 0.025 (0.016) | 3.10 (0.33) | 0.52 (0.23) | 4.3 (1.6) |

| Materials | GGBS | FA | NaOH | Na2SiO3 | BaCl2 | QS | PE Fibers | PVA Fibers | Water |

|---|---|---|---|---|---|---|---|---|---|

| Cost (USD/t) | 48.7 | 26.4 | 2783.4 | 417.5 | 3340.1 | 55.7 | 55,667.6 | 6262.6 | 0.42 |

| Carbon emission factor (kg CO2/kg) | 0.019 [56] | 0.009 [56] | 1.915 [56] | 0.804 [57] | - | 0.010 [56] | 2.000 [58] | 1.710 [59] | 0.8 [59] |

| Mix IDs | Cost | CE | CIc | CIt | CIε | CIg | CCIc | CCIt | CCIε | CCIg |

|---|---|---|---|---|---|---|---|---|---|---|

| U1.0-P0.0 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| U1.5-P0.0 | 1.30 | 1.02 | 0.90 | 1.14 | 1.27 | 1.53 | 0.90 | 1.00 | 1.21 | 0.90 |

| U2.0-P0.0 | 1.60 | 1.05 | 0.78 | 1.21 | 1.22 | 1.71 | 0.80 | 0.80 | 1.12 | 0.80 |

| U1.5-P0.5 | 1.34 | 1.05 | 0.84 | 1.36 | 0.94 | 1.44 | 1.07 | 0.74 | 1.13 | 1.07 |

| U1.0-P1.0 | 1.09 | 1.06 | 0.85 | 1.08 | 0.76 | 1.10 | 1.05 | 0.74 | 1.07 | 1.05 |

| U0.5-P1.5 | 0.84 | 1.06 | 0.87 | 0.80 | 0.16 | 0.10 | 1.02 | 0.20 | 0.12 | 1.02 |

| U0.0-P2.0 | 0.58 | 1.06 | 0.94 | 0.59 | 0.10 | 0.02 | 1.08 | 0.19 | 0.04 | 1.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Shi, J.; Wang, L.; Huang, C.; Tao, X.; Li, C.; Chen, Z. Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites. Materials 2024, 17, 4356. https://doi.org/10.3390/ma17174356

Guo J, Shi J, Wang L, Huang C, Tao X, Li C, Chen Z. Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites. Materials. 2024; 17(17):4356. https://doi.org/10.3390/ma17174356

Chicago/Turabian StyleGuo, Jingen, Ji Shi, Liuhuo Wang, Chengyong Huang, Xiongwu Tao, Chaosen Li, and Zhanbiao Chen. 2024. "Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites" Materials 17, no. 17: 4356. https://doi.org/10.3390/ma17174356

APA StyleGuo, J., Shi, J., Wang, L., Huang, C., Tao, X., Li, C., & Chen, Z. (2024). Evaluation of Axial Compressive and Tensile Properties of PE/PVA Hybrid Fiber Reinforced Strain-Hardening Geopolymer Composites. Materials, 17(17), 4356. https://doi.org/10.3390/ma17174356