Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials

Abstract

:1. Introduction

| Different materials and methods |  |  |  |  |

| SMA | Pneumatic flexible gripper | Dielectric elastomers | MR materials | |

| Material properties | Shape memory effect, Superelasticity, Wear resistant | Higher output forces, Fast response time, Low cost | Low power consumption, Fast response time, Small volume | Higher output forces, Good controllability, Low cost |

| Material disadvantage | High energy consumption, Unstable response time, Limited lifespan | High energy consumption, Large size, Loud noise | Low output forces, Poor stability, Limited lifespan | High sealing requirements |

2. Flexible Robotic Gripper

2.1. Shape Memory Alloy (SMA)

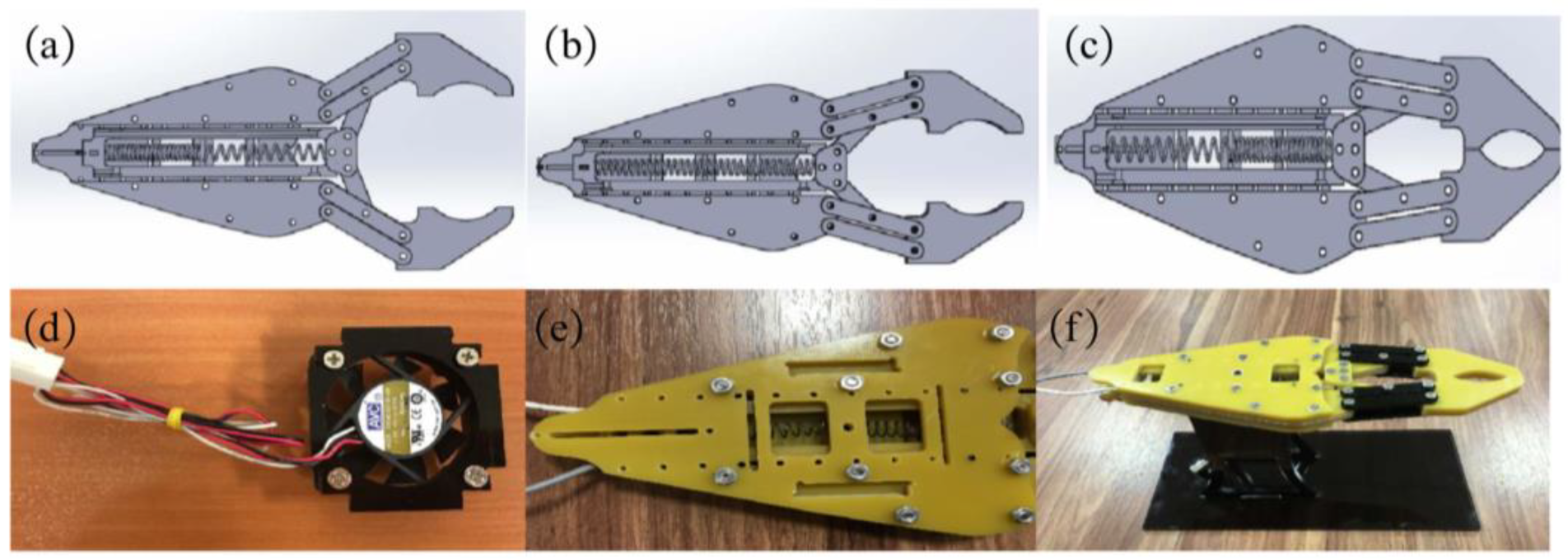

2.2. Pneumatic Flexible Gripper

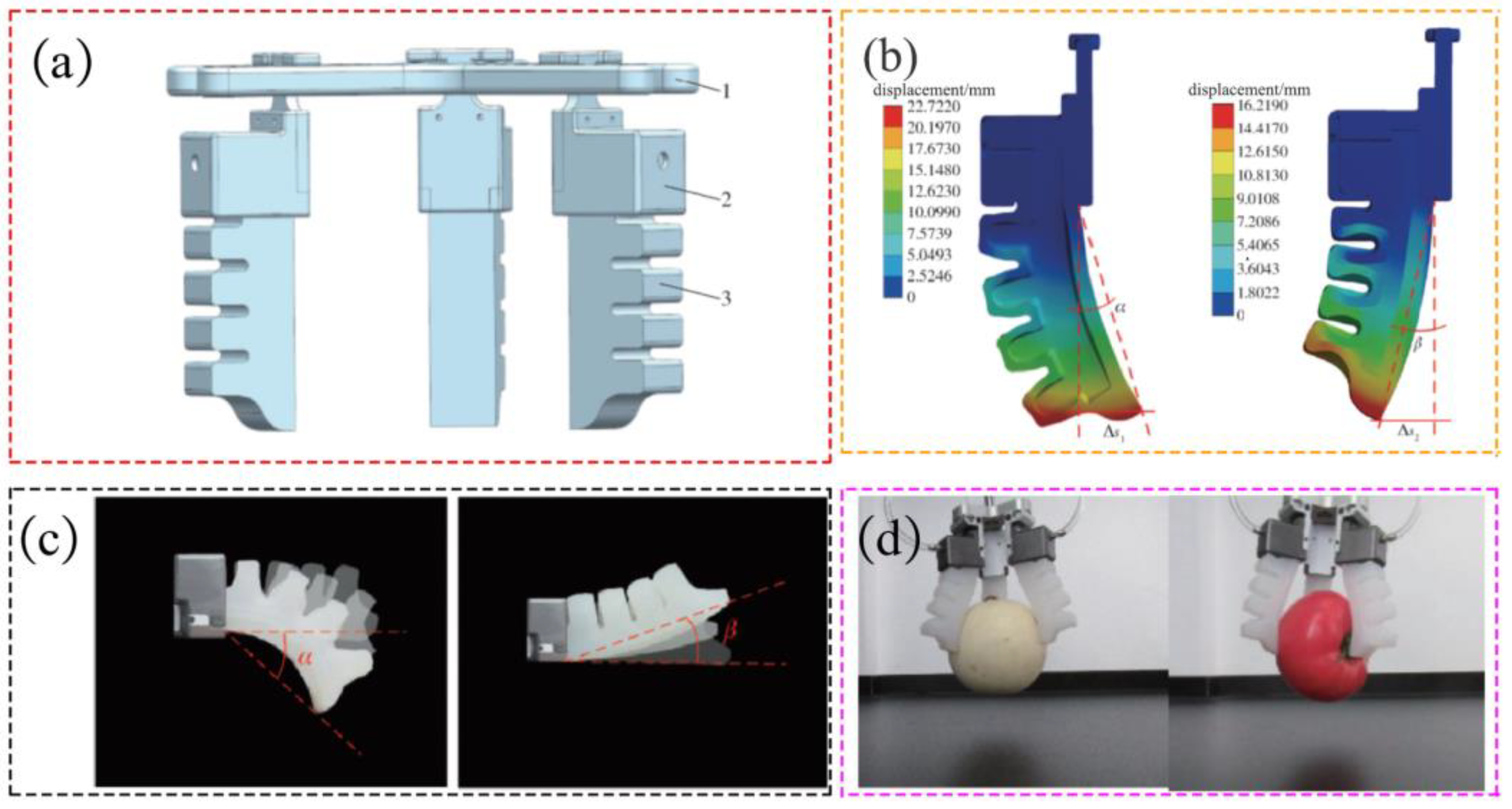

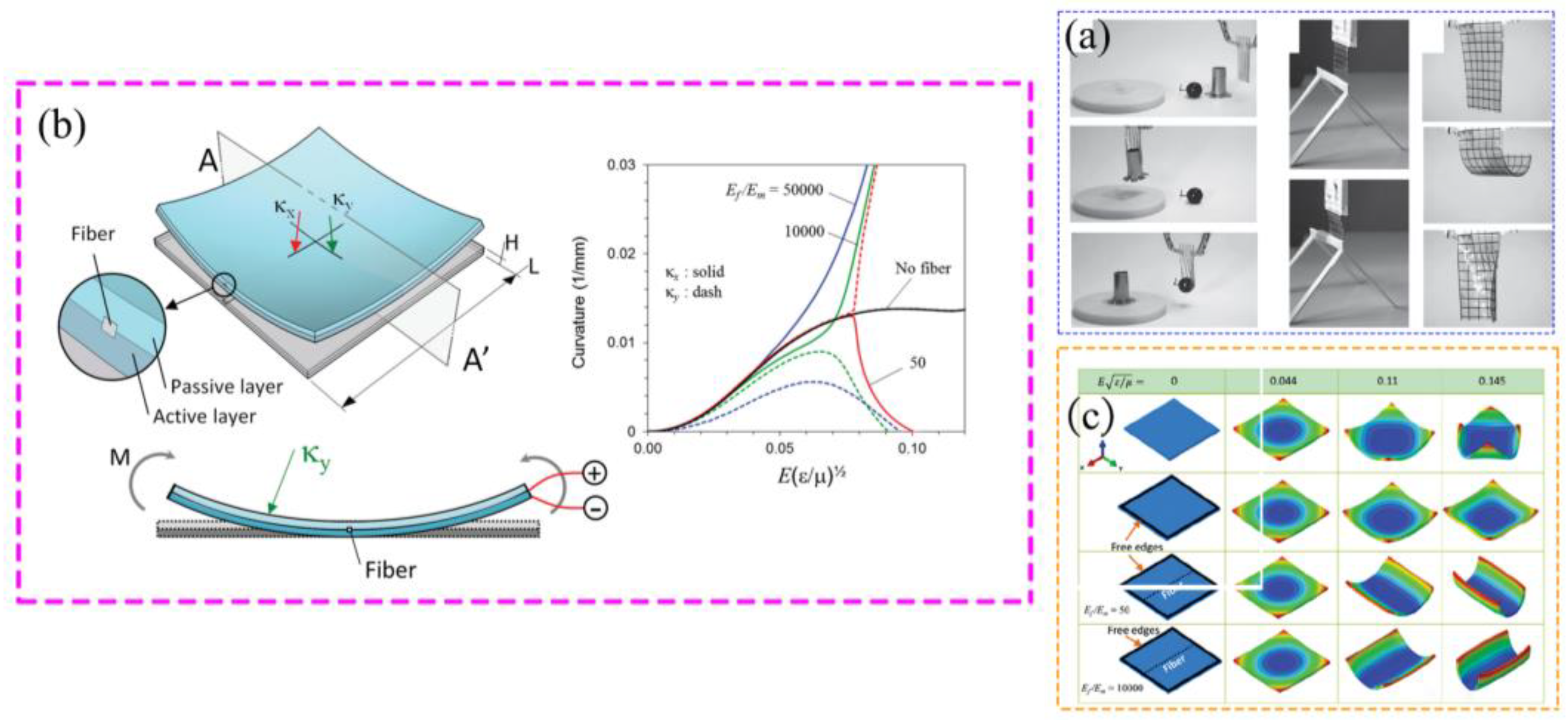

2.3. Dielectric Elastomer

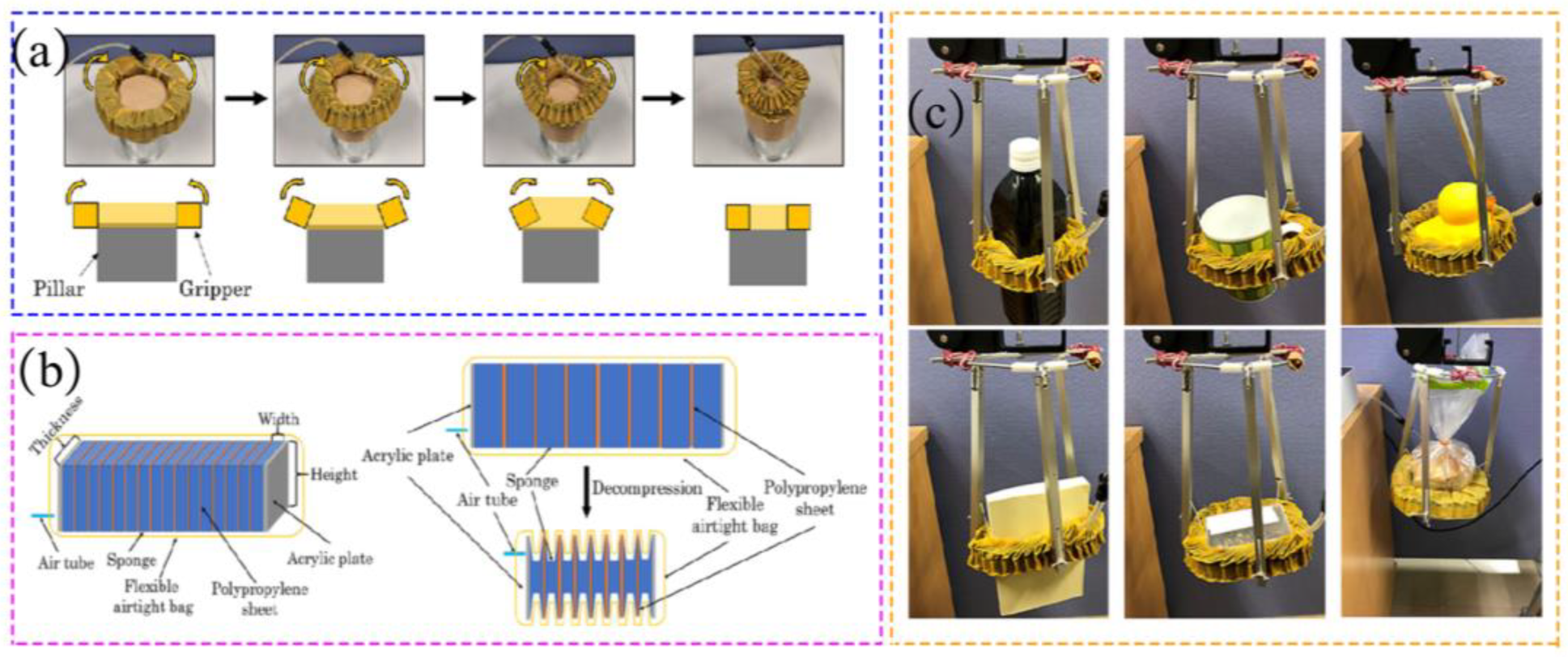

3. Magnetorheological Grippers

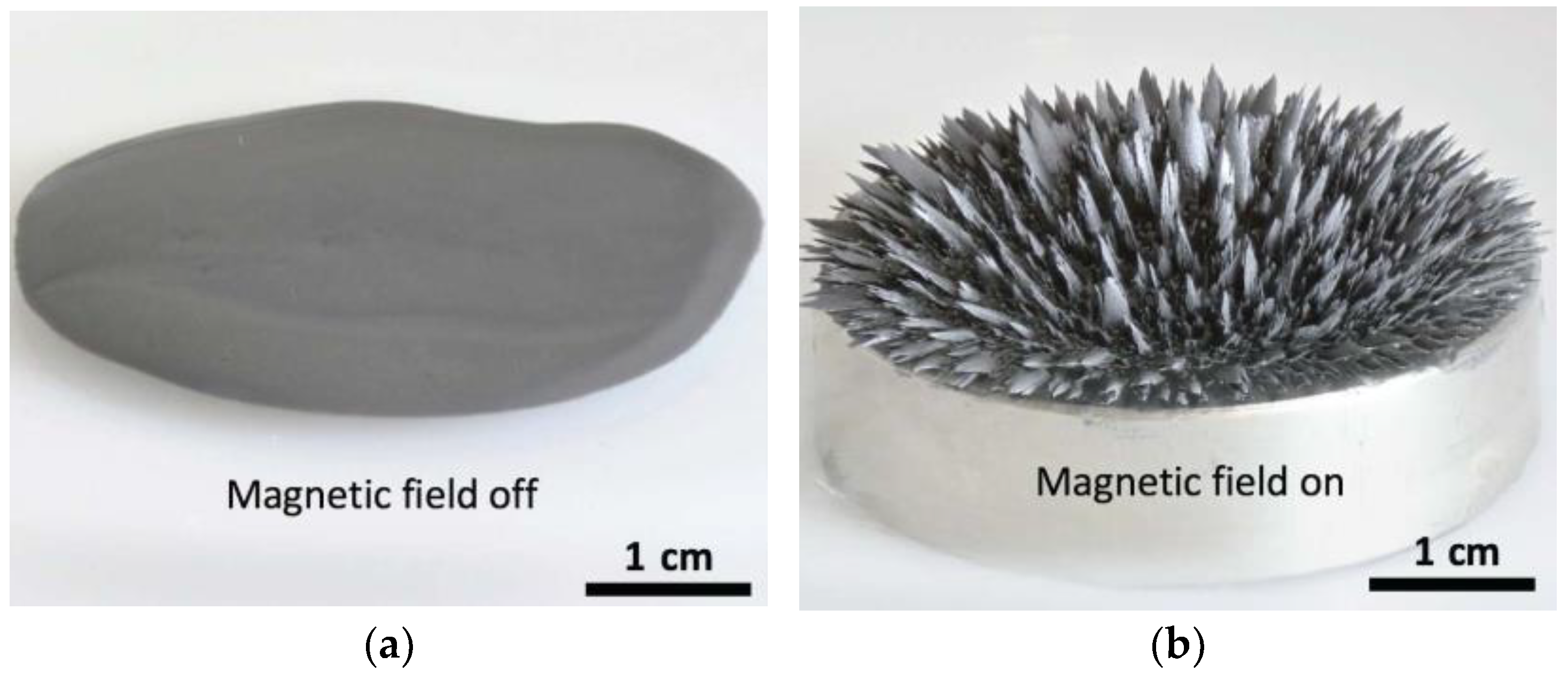

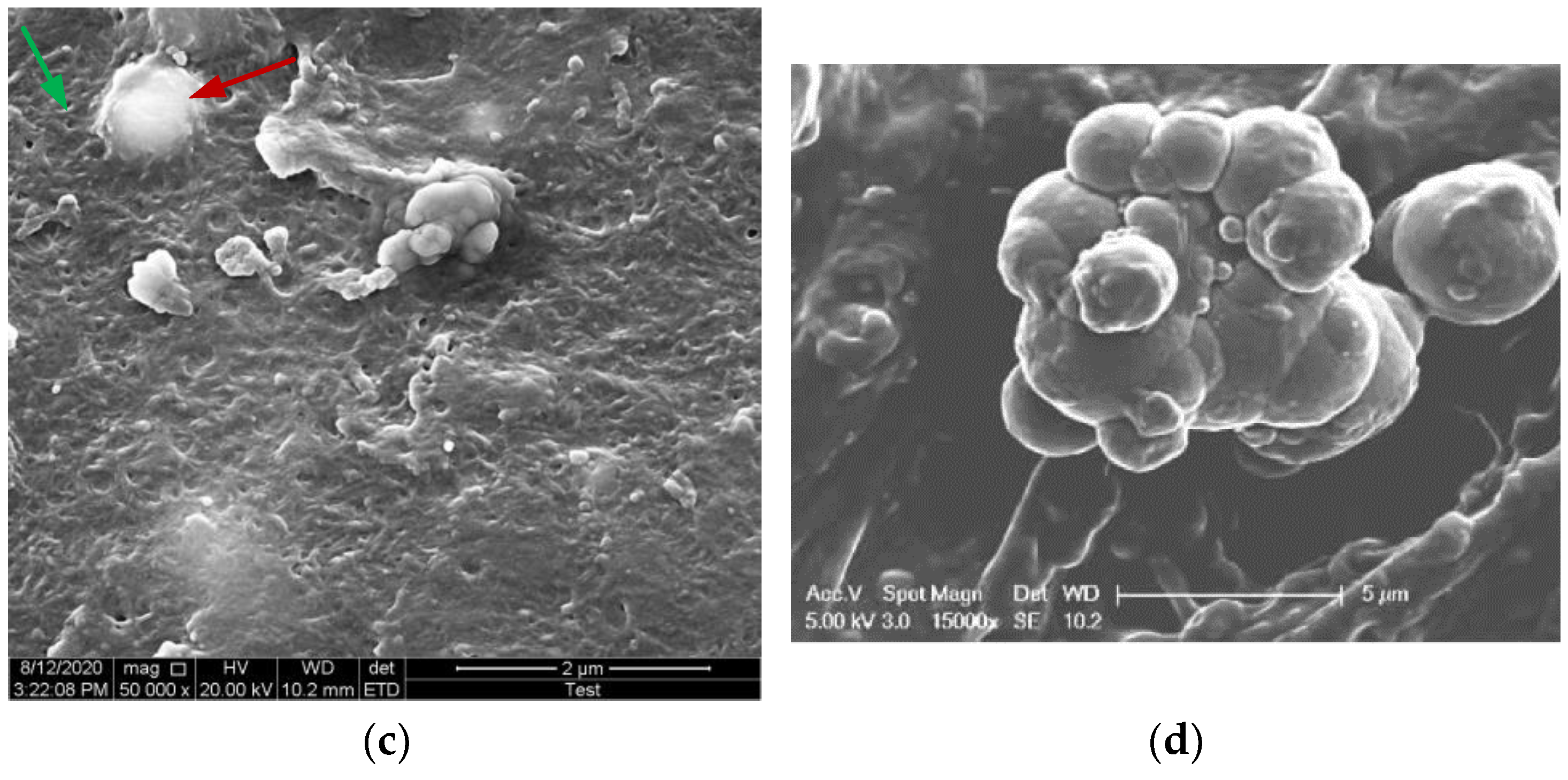

3.1. Magnetorheological Materials

3.2. Magnetorheological Flexible Gripper

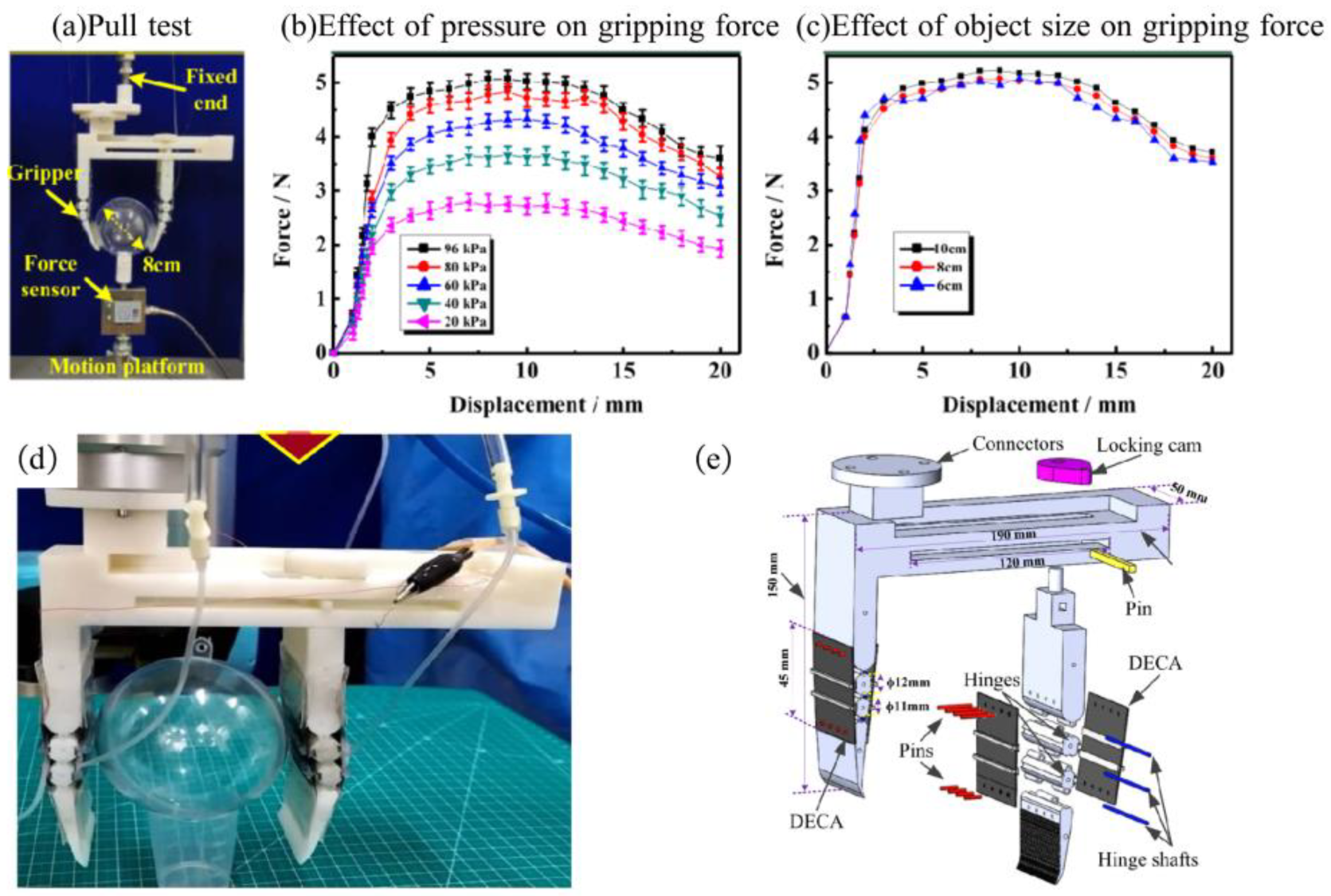

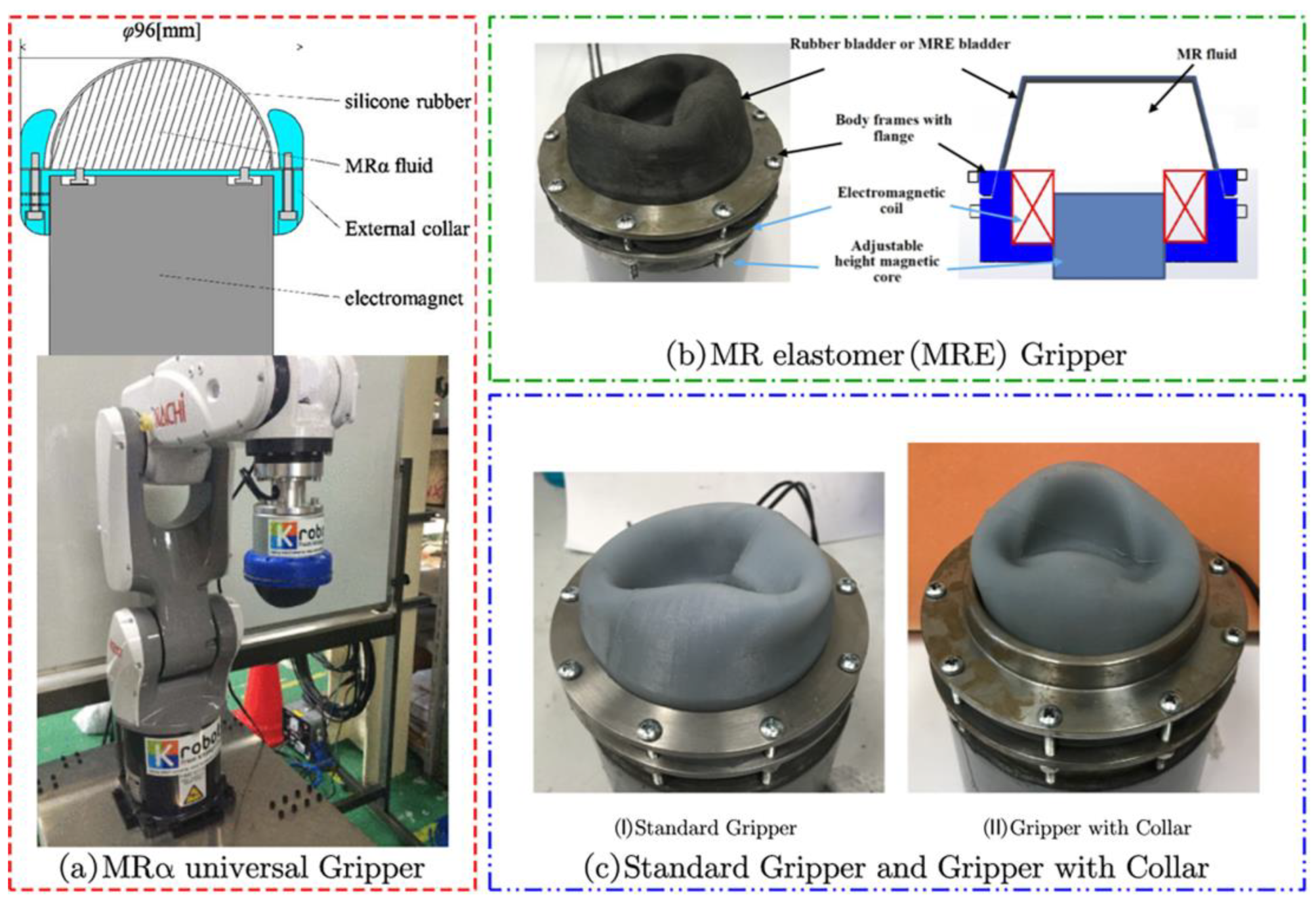

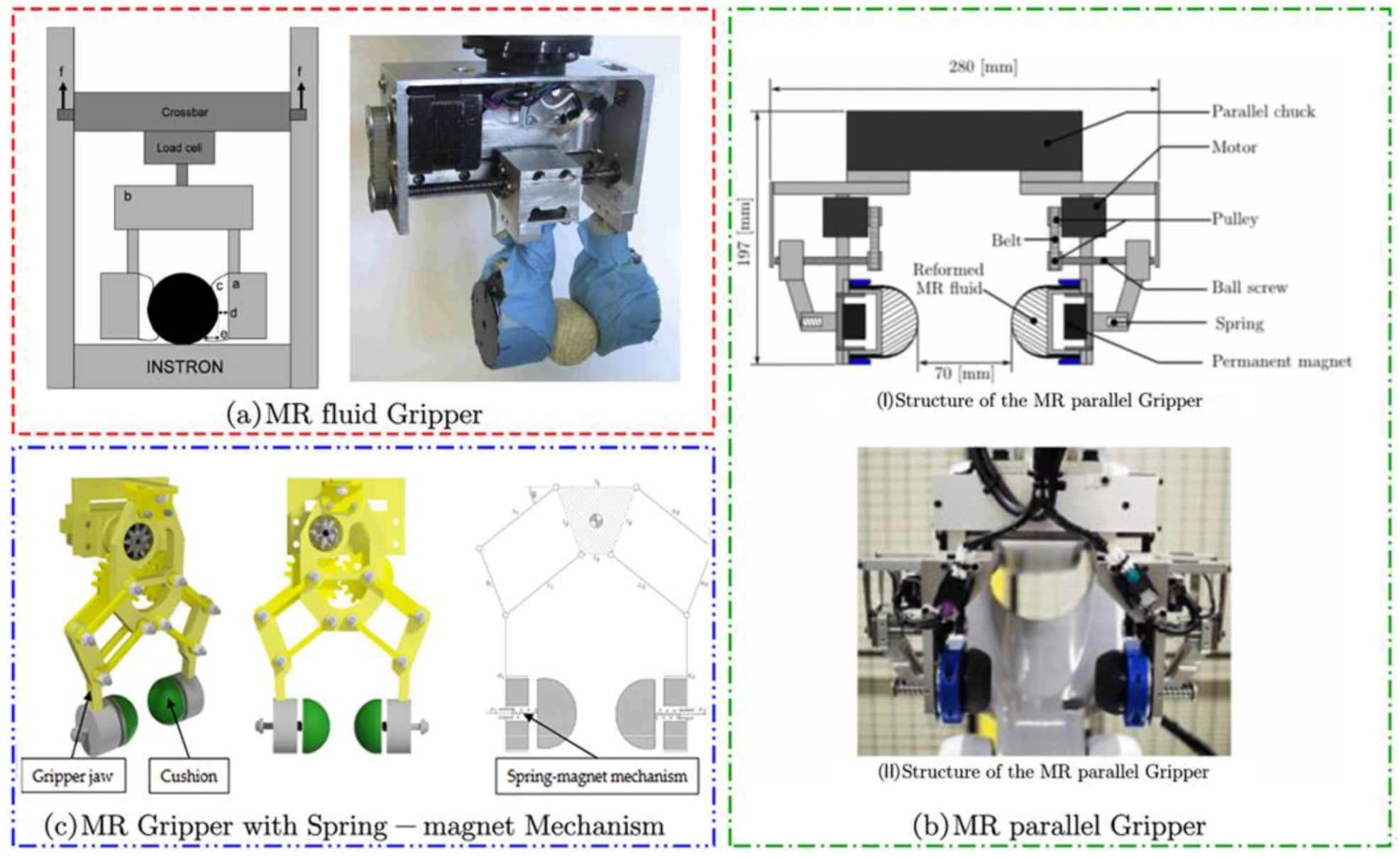

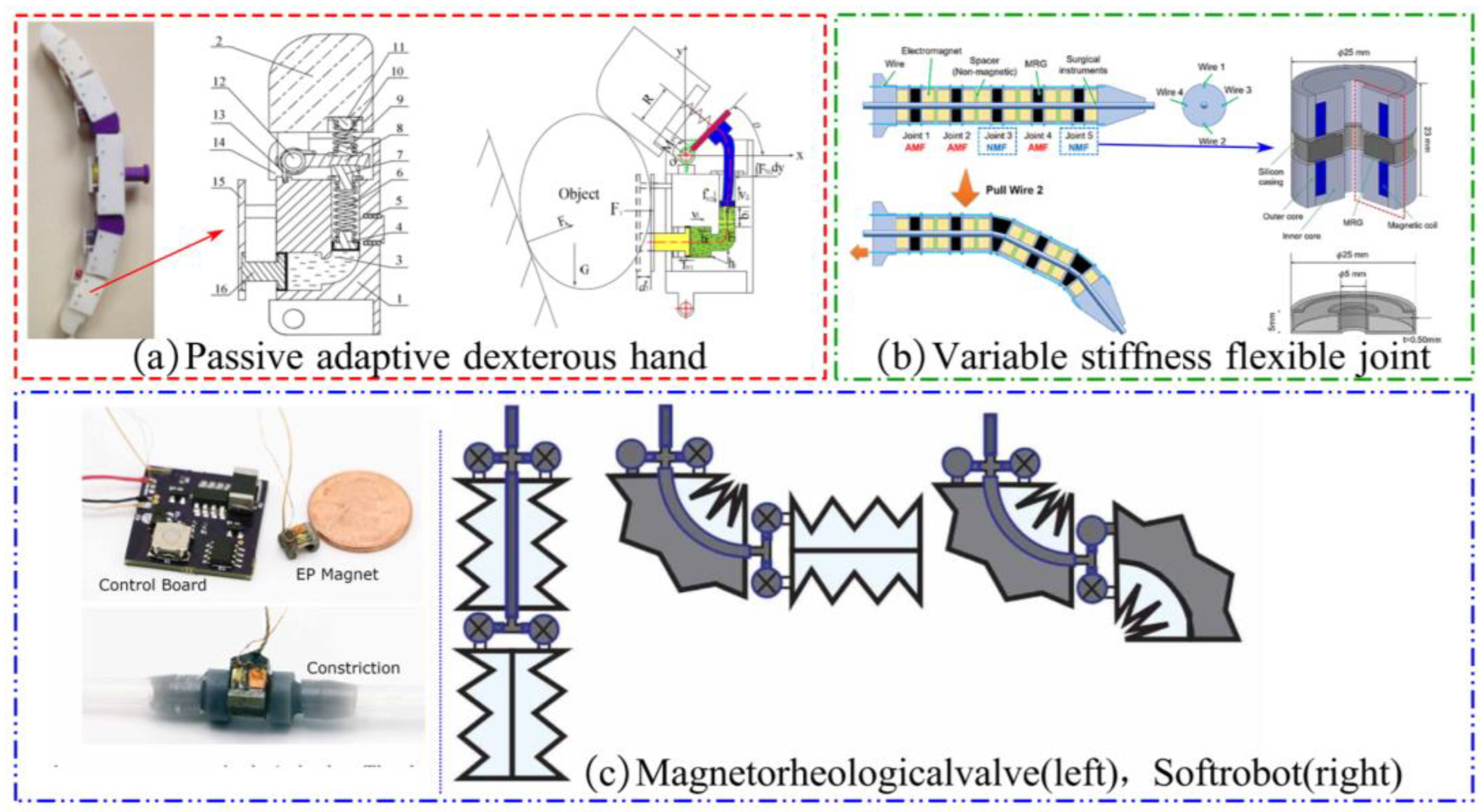

3.2.1. The Viscosity/Stiffness Change Type

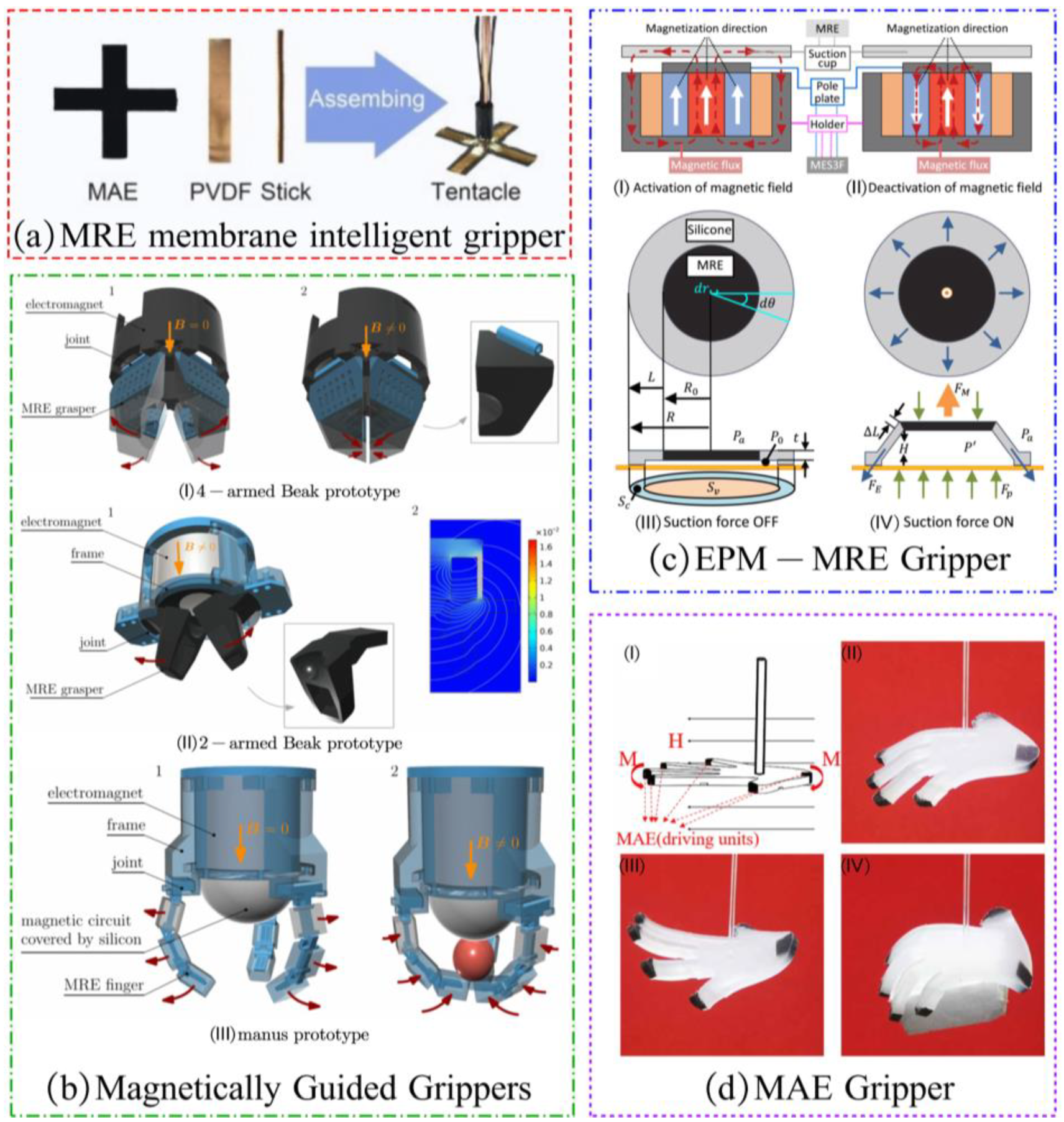

3.2.2. The Magnet-Driven Type

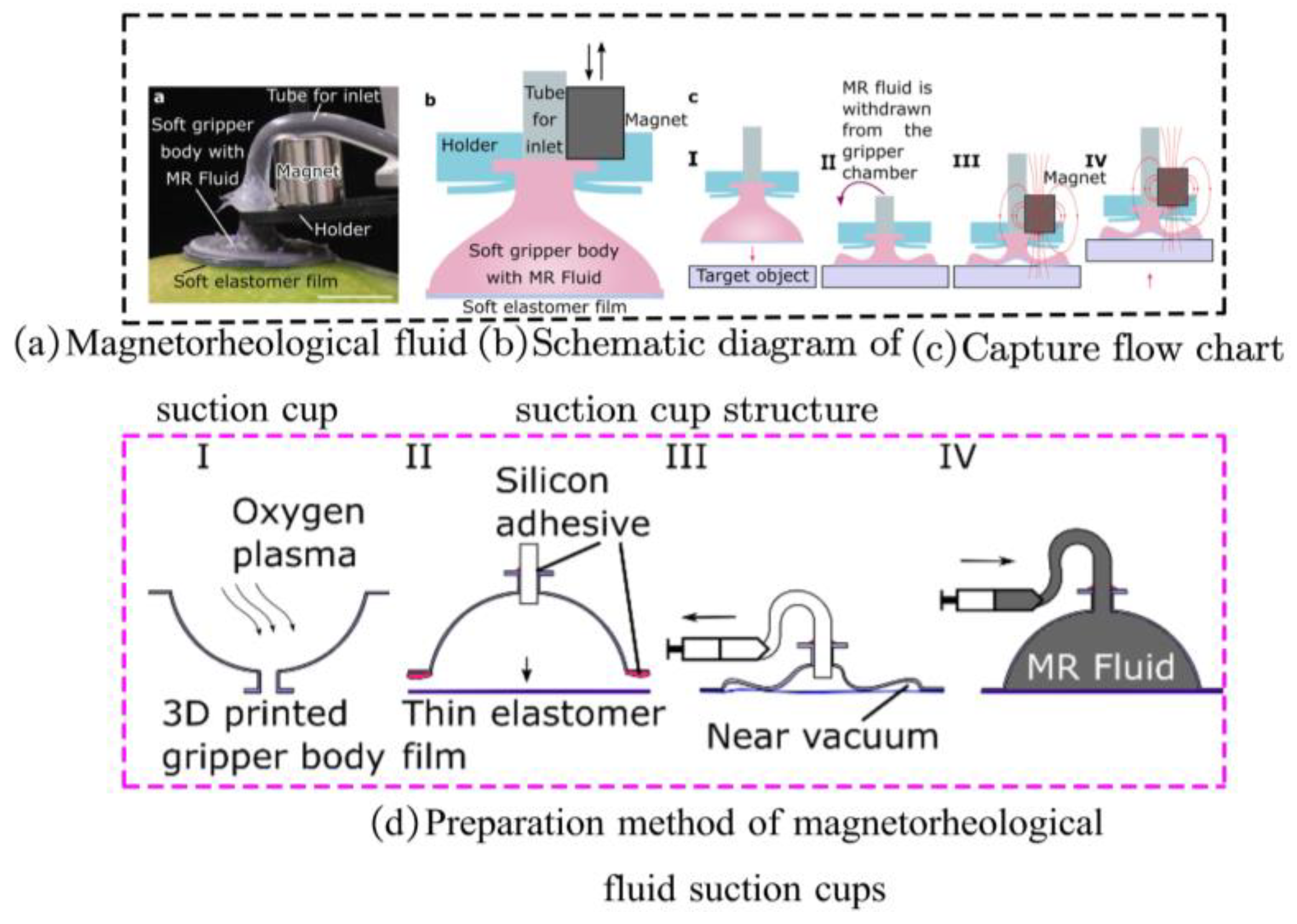

3.2.3. The Adhesion Force Type

4. Conclusions

- Flexible grippers have high adaptability and flexibility and satisfy the task of grip-ping objects of various shapes and materials. In medical applications, a 6 mm diameter pin SMA actuator can operate on a circular plane with a diameter of about 20 mm. In robotic applications, the pneumatic flexible gripper can realize the adaptive grasp of 564 g fruits with a diameter of about 100 mm. It is worth noting that the material and structure of the flexible gripper will change according to the weight and size of the grasping object.

- The application of MR materials in flexible grippers has a broad development prospect. By controlling the strength of the magnetic field, the viscosity and stiffness of MR materials can be regulated, thus realizing flexible control of the grippers.

- MR flexible grippers can achieve high precision and fast gripping action by magnetic drive. Due to the high response speed and good reversibility of MR material, the manipulator has high accuracy and stability in the gripping process.

- Adhesive force is a crucial attribute of flexible grippers, and MR materials enable the regulation of adhesive force through control of the magnetic field distribution. Although the adhesive force is relatively small, this feature holds significant implications for handling objects with irregular shapes.

- Flexible grippers based on MR materials have been proven usable and well-controllable by researchers. Next, MR flexible grippers should be developed in the direction of low power consumption and easy production. In the near future, it is believed that flexible grippers can achieve good applications in the industrial field.

Author Contributions

Funding

Conflicts of Interest

References

- Volpe, R.; Khosla, P. A Theoretical and Experimental Investigation of Impact Control for Manipulators. Int. J. Robot. Res. 1993, 12, 351–365. [Google Scholar] [CrossRef]

- Pandian, S.R.; Kawamura, S. Hybrid Force/Position Control for Robot Manipulators Based on a D-Type Learning Law. Robotica 1996, 14, 51–59. [Google Scholar] [CrossRef]

- Diks, J.; Jaspers, J.E.N.; Wisselink, W.; de Mol, B.a.M.J.; Grimbergen, C.A. The Mechanical Master-Slave Manipulator: An Instrument Improving the Performance in Standardized Tasks for Endoscopic Surgery. Surg. Endosc. 2007, 21, 1025–1031. [Google Scholar] [CrossRef]

- Yigit, A.; Perozo, M.A.; Cuvillon, L.; Durand, S.; Gangloff, J. Novel Omnidirectional Aerial Manipulator With Elastic Suspension: Dynamic Control and Experimental Performance Assessment. IEEE Robot. Autom. Lett. 2021, 6, 612–619. [Google Scholar] [CrossRef]

- Kang, C.; Chunxiang, M.; Maoqi, Z.; Feng, G. Optimization and Mechanical Accuracy Reliability of a New Type of Forging Manipulator. Chin. J. Mech. Eng. 2015, 28, 236–248. [Google Scholar] [CrossRef]

- Jayaswal, K.; Palwalia, D.K.; Kumar, S. Analysis of Robust Control Method for the Flexible Manipulator in Reliable Operation of Medical Robots during COVID-19 Pandemic. Microsyst. Technol. 2021, 27, 2103–2116. [Google Scholar] [CrossRef] [PubMed]

- Bian, Y.; Gao, Z.; Lv, X.; Fan, M. Theoretical and Experimental Study on Vibration Control of Flexible Manipulator Based on Internal Resonance. J. Vib. Control 2018, 24, 3321–3337. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, R.; Ju, F.; Zhao, J.; Chen, B.; Wu, H. A Light Cable-Driven Manipulator Developed for Aerial Robots: Structure Design and Control Research. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420926425. [Google Scholar] [CrossRef]

- Wu, Q.; Shao, X. Design and Control of Compound Driven Two-Finger Flexible Manipulator. J. Zhejiang Univ. Eng. Sci. 2023, 56, 1845–1855. [Google Scholar] [CrossRef]

- Kim, H.-I.; Han, M.-W.; Song, S.-H.; Ahn, S.-H. Soft Morphing Hand Driven by SMA Tendon Wire. Compos. Pt. B Eng. 2016, 105, 138–148. [Google Scholar] [CrossRef]

- Wang, W.; Ahn, S.-H. Shape Memory Alloy-Based Soft Gripper with Variable Stiffness for Compliant and Effective Grasping. Soft Robot. 2017, 4, 379–389. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Yu, C.Y.; Serrano, P.A.A.; Ahn, S.-H. Shape Memory Alloy-Based Soft Finger with Changeable Bending Length Using Targeted Variable Stiffness. Soft Robot. 2020, 7, 283–291. [Google Scholar] [CrossRef] [PubMed]

- McMahan, W.; Jones, B.A.; Walker, I.D. Design and Implementation of a Multi-Section Continuum Robot: Air-Octor. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; IEEE: New York, NY, USA, 2005; Volumes 1–4, pp. 3345–3352. [Google Scholar]

- McMahan, W.; Chitrakaran, V.; Csencsits, M.; Dawson, D.; Walker, I.D.; Jones, B.A.; Pritts, M.; Dienno, D.; Grissom, M.; Rahn, C.D. Field Trials and Testing of the OctArm Continuum Manipulator. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation (icra), Orlando, FL, USA, 15–19 May 2006; IEEE: New York, NY, USA, 2006; Volumes 1–10, p. 2336. [Google Scholar]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal Robotic Gripper Based on the Jamming of Granular Material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Amend, J.R.; Brown, E.; Rodenberg, N.; Jaeger, H.M.; Lipson, H. A Positive Pressure Universal Gripper Based on the Jamming of Granular Material. IEEE Trans. Robot. 2012, 28, 341–350. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic Networks for Soft Robotics That Actuate Rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Reljic, V.; Bajci, B.; Sulc, J.; Seslija, D.; Dudic, S. Remote Control of Pneumatic Circular Manipulator Using CEyeClon Platform. In Proceedings of the Proceedings of 2017 4th Experiment@international Conference (exp.at’17), Faro, Portugal, 6–8 June 2017; IEEE: New York, NY, USA, 2017; pp. 103–104. [Google Scholar]

- Zhu, H.; Jin, Y.; Zhang, L.; Liu, S. Remote Control System of Pneumatic Manipulator Based on nRF905. Mech. Electr. Eng. Mag. 2010, 27, 40–43. [Google Scholar]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Versatile Soft Grippers with Intrinsic Electroadhesion Based on Multifunctional Polymer Actuators. Adv. Mater. 2016, 28, 231–238. [Google Scholar] [CrossRef]

- Zhou, F.; He, J.; Zhang, M.; Xiao, Y.; Chen, Z.; Wong, T.-W.; Li, T.; Xu, Z.; Luo, Y. Electromechanical Model-Based Adaptive Control of Multilayered Dielectric Elastomer Bending Actuator. J. Appl. Mech.-Trans. ASME 2021, 88, 111006. [Google Scholar] [CrossRef]

- Wu, M.; Zheng, X.; Liu, R.; Hou, N.; Afridi, W.H.; Afridi, R.H.; Guo, X.; Wu, J.; Wang, C.; Xie, G. Glowing Sucker Octopus (Stauroteuthis Syrtensis)-Inspired Soft Robotic Gripper for Underwater Self-Adaptive Grasping and Sensing. Adv. Sci. 2022, 9, 2104382. [Google Scholar] [CrossRef]

- Chen, F.-Y.; Ren, Z.-X.; Lau, G.-K. Maximal Strengths of Dielectric Elastomer Fingers for a Passive Grip. Smart Mater. Struct. 2022, 31, 045014. [Google Scholar] [CrossRef]

- Lanzetta, M.; Iagnemma, K. Gripping by Controllable Wet Adhesion Using a Magnetorheological Fluid. CIRP Ann. Manuf. Technol. 2013, 62, 21–25. [Google Scholar] [CrossRef]

- Tsugami, Y.; Barbie, T.; Tadakuma, K.; Nishida, T. Development of Universal Parallel Gripper Using Reformed Magnetorheological Fluid. In Proceedings of the 2017 11th Asian Control Conference (ascc), Gold Coast, Australia, 17–20 December 2017; IEEE: New York, NY, USA, 2017; pp. 778–783. [Google Scholar]

- Kitano, S.; Komatsuzaki, T.; Suzuki, I.; Nogawa, M.; Naito, H.; Tanaka, S. Development of a Rigidity Tunable Flexible Joint Using Magneto-Rheological Compounds-Toward a Multijoint Manipulator for Laparoscopic Surgery. Front. Robot. AI 2020, 7, 59. [Google Scholar] [CrossRef]

- Choi, D.-S.; Kim, T.-H.; Lee, S.-H.; Pang, C.; Bae, J.W.; Kim, S.-Y. Beyond Human Hand: Shape-Adaptive and Reversible Magnetorheological Elastomer-Based Robot Gripper Skin. ACS Appl. Mater. Interfaces 2020, 12, 44147–44155. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.T.; Hartzell, C.M.; Leps, T.; Wereley, N.M. Gripping Characteristics of an Electromagnetically Activated Magnetorheological Fluid-Based Gripper. AIP Adv. 2018, 8, 056701. [Google Scholar] [CrossRef]

- Skrivan, V.; Sodomka, O.; Mach, F. Magnetically Guided Soft Robotic Grippers. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (Robosoft 2019), Seoul, Republic of Korea, 14–18 April 2019; IEEE: New York, NY, USA, 2019; pp. 126–130. [Google Scholar]

- Bernat, J.; Gajewski, P.; Kapela, R.; Marcinkowska, A.; Superczyńska, P. Design, Fabrication and Analysis of Magnetorheological Soft Gripper. Sensors 2022, 22, 2757. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.S.; Ning, D.H.; Yang, J.; Du, H.; Zhang, S.W.; Li, W.H. A Seat Suspension with a Rotary Magnetorheological Damper for Heavy Duty Vehicles. Smart Mater. Struct. 2016, 25, 105032. [Google Scholar] [CrossRef]

- Ma, T.; Li, T.; Jing, G.; Liu, H.; Bi, F. Development of a Novel Seat Suspension Based on the Cubic Stewart Parallel Mechanism and Magnetorheological Fluid Damper. Appl. Sci. 2022, 12, 11437. [Google Scholar] [CrossRef]

- Xiong, C.; Yu, L.; Abi, L.; Lu, Z. Step-Control and Vibration Characteristics of a Hybrid Vehicle Suspension System Considering Energy Consumption. Veh. Syst. Dyn. 2022, 60, 1531–1554. [Google Scholar] [CrossRef]

- Choi, S.B.; Lee, B.K.; Nam, M.H.; Cheong, C.C. Vibration Control of a MR Seat Damper for Commercial Vehicles. J. Intell. Mater. Syst. Struct. 2000, 11, 936–944. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, S.; Kang, B. Research on Circular Plate MR Fluids Brake. J. Cent. South Univ. Technol. 2007, 14, 257–259. [Google Scholar] [CrossRef]

- Sarkar, C.; Hirani, H. Synthesis and Characterization of Antifriction Magnetorheological Fluids for Brake. Def. Sci. J. 2013, 63, 408–412. [Google Scholar] [CrossRef]

- Hung, N.Q.; Bok, C.S. Optimal Design of a T-Shaped Drum-Type Brake for Motorcycle Utilizing Magnetorheological Fluid. Mech. Based Des. Struct. Mech. 2012, 40, 153–162. [Google Scholar] [CrossRef]

- Kumbhar, B.K.; Patil, S.R.; Sawant, S.M. Synthesis and Characterization of Magneto-Rheological (MR) Fluids for MR Brake Application. Eng. Sci. Technol. Int. J. 2015, 18, 432–438. [Google Scholar] [CrossRef]

- Park, J.-Y.; Kim, G.-W.; Oh, J.-S.; Kim, Y.-C. Hybrid Multi-Plate Magnetorheological Clutch Featuring Two Operating Modes: Fluid Coupling and Mechanical Friction. J. Intell. Mater. Syst. Struct. 2021, 32, 1537–1549. [Google Scholar] [CrossRef]

- Wang, D.; Zi, B.; Zeng, Y.; Xie, F.; Hou, Y. An Investigation of Thermal Characteristics of a Liquid-Cooled Magnetorheological Fluid-Based Clutch. Smart Mater. Struct. 2015, 24, 055020. [Google Scholar] [CrossRef]

- Thakur, M.K.; Sarkar, C. Thermal and Tribological Performance of Graphite Flake-Based Magnetorheological Fluid Under Shear Mode Clutch. J. Tribol. Trans. ASME 2021, 143, 121806. [Google Scholar] [CrossRef]

- Neelakantan, V.A.; Washington, G.N. Modeling and Reduction of Centrifuging in Magnetorheological (MR) Transmission Clutches for Automotive Applications. J. Intell. Mater. Syst. Struct. 2005, 16, 703–711. [Google Scholar] [CrossRef]

- Weber, F.; Maslanka, M. Frequency and Damping Adaptation of a TMD with Controlled MR Damper. Smart Mater. Struct. 2012, 21, 055011. [Google Scholar] [CrossRef]

- Liu, M.; Sethi, V.; Song, G.; Li, H. Investigation of Locking Force for Stay Cable Vibration Control Using Magnetorheological Fluid Damper. J. Vib. Acoust. Trans. ASME 2008, 130, 054504. [Google Scholar] [CrossRef]

- Li, H.; Liu, M.; Li, J.; Guan, X.; Ou, J. Vibration Cantol of Stay Cables of the Shandong Binzhou Yellow River Highway Bridge Using Magnetorheological Fluid Dampers. J. Bridge Eng. 2007, 12, 401–409. [Google Scholar] [CrossRef]

- Jung, H.J.; Spencer, B.F.; Lee, I.W. Control of Seismically Excited Cable-Stayed Bridge Employing Magnetorheological Fluid Dampers. J. Struct. Eng. 2003, 129, 873–883. [Google Scholar] [CrossRef]

- Vezys, J.; Dragasius, E.; Volkovas, V.; Mystkowski, A.; Korobko, E. The Sedimentation of Magneto-Rheological Fluid Monitoring System Based on Resistivity Measuring. Mechanika 2016, 22, 449–452. [Google Scholar] [CrossRef]

- Zhu, W.; Dong, X.; Huang, H.; Qi, M. Enhanced Magnetorheological Effect and Sedimentation Stability of Bimodal Magnetorheological Fluids Doped with Iron Nanoparticles. J. Intell. Mater. Syst. Struct. 2021, 32, 1271–1277. [Google Scholar] [CrossRef]

- Park, B.O.; Park, B.J.; Hato, M.J.; Choi, H.J. Soft Magnetic Carbonyl Iron Microsphere Dispersed in Grease and Its Rheological Characteristics under Magnetic Field. Colloid Polym. Sci. 2011, 289, 381–386. [Google Scholar] [CrossRef]

- Mao, R.; Wang, X.; Cai, S.; Zhang, G.; Wang, J. Strain Dependent Magneto-Mechanical Property of Magnetorheological Gel Composite: Rheological Measurement and Model Establishment. Compos. Sci. Technol. 2022, 227, 109612. [Google Scholar] [CrossRef]

- Yun, G.; Tang, S.-Y.; Sun, S.; Yuan, D.; Zhao, Q.; Deng, L.; Yan, S.; Du, H.; Dickey, M.D.; Li, W. Liquid Metal-Filled Magnetorheological Elastomer with Positive Piezoconductivity. Nat. Commun. 2019, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Xuan, S.; Xu, Y.; Liu, T.; Gong, X. Recent Progress on the Magnetorheological Plastomers. Int. J. Smart Nano Mater. 2015, 6, 135–148. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Matsui, R.; Takeda, K.; Tobushi, H.; Pieczyska, E.A. Mechanical Properties and Advanced Subjects in Shape Memory Alloys and Polymers. J. Theor. Appl. Mech. 2018, 56, 447–456. [Google Scholar] [CrossRef]

- Shin, B.H.; Jang, T.; Ryu, B.-J.; Kim, Y. A Modular Torsional Actuator Using Shape Memory Alloy Wires. J. Intell. Mater. Syst. Struct. 2016, 27, 1658–1665. [Google Scholar] [CrossRef]

- Karimi, S.; Konh, B. Self-Sensing Feedback Control of Multiple Interacting Shape Memory Alloy Actuators in a 3D Steerable Active Needle. J. Intell. Mater. Syst. Struct. 2020, 31, 1524–1540. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, L.; Penney, N.; Barr, T.; Lee, H.-J.; Arnold, S. Design and Control of a Proof-of-Concept Active Jet Engine Intake Using Shape Memory Alloy Actuators. Smart Struct. Syst. 2011, 7, 1–13. [Google Scholar] [CrossRef]

- Song, G.; Ma, N. Robust Control of a Shape Memory Alloy Wire Actuated Flap. Smart Mater. Struct. 2007, 16, N51–N57. [Google Scholar] [CrossRef]

- Rad, N.F.; Yousefi-Koma, A.; Rezaei, H.; Bazrafshani, M.A. Design and Fabrication of a Gripper Actuated by Shape Memory Alloy Spring. In Proceedings of the 2016 4th Rsi International Conference on Robotics and Mechatronics (icrom), Tehran, Iran, 26–28 October 2016; IEEE: New York, NY, USA, 2016; pp. 455–458. [Google Scholar]

- Liu, M.; Hao, L.; Zhang, W.; Zhao, Z. A Novel Design of Shape-Memory Alloy-Based Soft Robotic Gripper with Variable Stiffness. Int. J. Adv. Robot. Syst. 2020, 17, 172988142090781. [Google Scholar] [CrossRef]

- Mikuriya, S.; Nakahara, T.; Tobushi, H.; Watanabe, H. The Estimation of Temperature Rise in Low-Cycle Fatigue of TiNi Shape-Memory Alloy. JSME Int. J. Ser. A Solid Mech. Mat. Eng. 2000, 43, 166–172. [Google Scholar] [CrossRef]

- Lin, P.H.; Tobushi, H.; Hashimoto, T.; Shimeno, Y.; Takata, K. Fatigue Properties of TiNi Shape Memory Alloy. Mater. Sci. Res. Int. 2001, 7, 103–110. [Google Scholar] [CrossRef] [PubMed]

- Guilemany, J.M.; Fernández, J. Relationships between Structure and Hardness Developed during the High Temperature Ageing of a Smart Cu-Based Alloy. J. Mater. Sci. 1996, 31, 4981–4984. [Google Scholar] [CrossRef]

- Tachoire, H.; Isalgue, A.; Torra, V. Smart materials: Predictable time-behavior of Cu-Zn-Al shape memory alloys. J. Chim. Phys. Chim. Biol. 1997, 94, 1069–1080. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Xu, W. Energy Consumption of Flexible Gripper during Contraction and Expansion. J. Beijing Univ. Aeronaut. Astronaut. 2021, 47, 2208–2214. [Google Scholar]

- Suzumori, K. Flexible Microactuator: 1st Report, static Characteristics of 3 DOF Actuator. Trans. Jpn. Soc. Mech. Eng. Ser. C 1989, 55, 2547. [Google Scholar] [CrossRef]

- PI, J.; LIU, J.; XU, L. Structure Design and Experiment of Three Finger Flexible Pneumatic Gripper. Trans. Chin. Soc. Agric. Mach. 2020, 51, 93–101. [Google Scholar]

- Yamada, K.; Mitsuda, T. A Vacuum-Driven Rubber-Band Gripper. Robomech J. 2021, 8, 16. [Google Scholar] [CrossRef]

- Luo, H.P.; Qiu, F.C.; Sun, Q.H.; Cao, J.B.; Ju, E.S.; Chen, J.J. Experimental Research on Dielectric Elastomer Power Generation. Key Eng. Mater. 2012, 522, 927–930. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.B.; Joseph, J. High-Speed Electrically Actuated Elastomers with Strain Greater than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef] [PubMed]

- Larson, C.; Peele, B.; Li, S.; Robinson, S.; Totaro, M.; Beccai, L.; Mazzolai, B.; Shepherd, R. Highly Stretchable Electroluminescent Skin for Optical Signaling and Tactile Sensing. Science 2016, 351, 1071–1074. [Google Scholar] [CrossRef] [PubMed]

- Wilson, K.E.; Henke, E.-F.M.; Slipher, G.A.; Anderson, I.A. Rubbery Logic Gates. Extrem. Mech. Lett. 2016, 9, 188–194. [Google Scholar] [CrossRef]

- O’Brien, B.M.; McKay, T.G.; Gisby, T.A.; Anderson, I.A. Rotating Turkeys and Self-Commutating Artificial Muscle Motors. Appl. Phys. Lett. 2012, 100, 074108. [Google Scholar] [CrossRef]

- Garnell, E.; Doare, O.; Rouby, C. Coupled Vibro-Acoustic Modeling of a Dielectric Elastomer Loudspeaker. J. Acoust. Soc. Am. 2020, 147, 1812–1821. [Google Scholar] [CrossRef]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric Elastomer Based “Grippers” for Soft Robotics. Adv. Mater. 2015, 27, 6814. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, J.; Cai, Y.; Li, B.; Liu, G.; Li, P. Stiffness-Tunable Robotic Gripper Driven by Dielectric Elastomer Composite Actuators. Smart Mater. Struct. 2020, 29, 125013. [Google Scholar] [CrossRef]

- Ahamed, R.; Choi, S.-B.; Ferdaus, M.M. A State of Art on Magneto-Rheological Materials and Their Potential Applications. J. Intell. Mater. Syst. Struct. 2018, 29, 2051–2095. [Google Scholar] [CrossRef]

- Rankin, P.J.; Horvath, A.T.; Klingenberg, D.J. Magnetorheology in Viscoplastic Media. Rheol. Acta 1999, 38, 471–477. [Google Scholar] [CrossRef]

- Wilson, M.J.; Fuchs, A.; Gordaninejad, F. Development and Characterization of Magnetorheological Polymer Gels. J. Appl. Polym. Sci. 2002, 84, 2733–2742. [Google Scholar] [CrossRef]

- Carlson, J.D.; Jolly, M.R. MR Fluid, Foam and Elastomer Devices. Mechatronics 2000, 10, 555–569. [Google Scholar] [CrossRef]

- de Vicente, J.; Klingenberg, D.J.; Hidalgo-Alvarez, R. Magnetorheological Fluids: A Review. Soft Matter 2011, 7, 3701–3710. [Google Scholar] [CrossRef]

- Dai, J. Investigation of the Relationship among the Microstructure, Rheological Properties of MR Grease and the Speed Reduction Performance of a Rotary Micro-Brake. Mech. Syst. Signal Process. 2019, 116, 741–750. [Google Scholar] [CrossRef]

- Roman, C.; Valencia, C.; Franco, J.M. AFM and SEM Assessment of Lubricating Grease Microstructures: Influence of Sample Preparation Protocol, Frictional Working Conditions and Composition. Tribol. Lett. 2016, 63, 20. [Google Scholar] [CrossRef]

- Ahuré Powell, L.A.; Choi, Y.T.; Hu, W.; Wereley, N.M. Nonlinear Modeling of Adaptive Magnetorheological Landing Gear Dampers under Impact Conditions. Smart Mater. Struct. 2016, 25, 115011. [Google Scholar] [CrossRef]

- Wei, Y.; Lv, J.; Tang, Z.; Yang, L.; Wu, M.; Zhao, T.; Yin, H. A Universal Rheological Constitutive Equation of Magnetorheological Fluids with a Wide Shear Rate Range. J. Magn. Magn. Mater. 2022, 563, 169811. [Google Scholar] [CrossRef]

- Hu, G.; Ying, S.; Qi, H.; Yu, L.; Li, G. Design, Analysis and Optimization of a Hybrid Fluid Flow Magnetorheological Damper Based on Multiphysics Coupling Model. Mech. Syst. Signal Process. 2023, 205, 110877. [Google Scholar] [CrossRef]

- Shiga, T.; Okada, A.; Kurauchi, T. Magnetroviscoelastic Behavior of Composite Gels. J. Appl. Polym. Sci. 1995, 58, 787–792. [Google Scholar] [CrossRef]

- Sun, S.; Yang, J.; Yildirim, T.; Ning, D.; Zhu, X.; Du, H.; Zhang, S.; Nakano, M.; Li, W. A Magnetorheological Elastomer Rail Damper for Wideband Attenuation of Rail Noise and Vibration. J. Intell. Mater. Syst. Struct. 2020, 31, 220–228. [Google Scholar] [CrossRef]

- Zhao, C.; Ren, Z.; Tang, C.; Zhang, T. The Application of Magnetorheological Damper in Machining the Impeller Blades of High Temperature Alloy. In Materials Science Forum; Liu, Z.Q., Wan, Y., Song, Q.H., Shi, Z.Y., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 723, pp. 358–361. [Google Scholar]

- Yarra, S.; Gordaninejad, F.; Behrooz, M.; Pekcan, G.; Itani, A.M.; Publicover, N. Performance of a Large-Scale Magnetorheological Elastomer-Based Vibration Isolator for Highway Bridges. J. Intell. Mater. Syst. Struct. 2018, 29, 3890–3901. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Samali, B. Development and Characterization of a Magnetorheological Elastomer Based Adaptive Seismic Isolator. Smart Mater. Struct. 2013, 22, 035005. [Google Scholar] [CrossRef]

- Nishida, T.; Okatani, Y.; Tadakuma, K. Development of Universal Robot Gripper Using MR Alpha Fluid. Int. J. Humanoid Robot. 2016, 13, 1650017. [Google Scholar] [CrossRef]

- Hartzell, C.M.; Choi, Y.T.; Wereley, N.M.; Leps, T.J.G. Performance of a Magnetorheological Fluid-Based Robotic End Effector. Smart Mater. Struct. 2019, 28, 035030. [Google Scholar] [CrossRef]

- Pettersson, A.; Davis, S.; Gray, J.O.; Dodd, T.J.; Ohlsson, T. Design of a Magnetorheological Robot Gripper for Handling of Delicate Food Products with Varying Shapes. J. Food Eng. 2010, 98, 332–338. [Google Scholar] [CrossRef]

- Bialek, M.; Jedryczka, C.; Milecki, A. Investigation of Thermoplastic Polyurethane Finger Cushion with Magnetorheological Fluid for Soft-Rigid Gripper. Energies 2021, 14, 6541. [Google Scholar] [CrossRef]

- Koivikko, A.; Drotlef, D.-M.; Sitti, M.; Sariola, V. Magnetically Switchable Soft Suction Grippers. Extrem. Mech. Lett. 2021, 44, 101263. [Google Scholar] [CrossRef]

- Liu, Q.; Jing, T.; Mo, A.; Xu, X.; Zhang, W. A Novel Robot Hand with the Magneto-Rheological Fluid Solidification. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (Robio), Zhuhai, China, 6–9 December 2015; IEEE: New York, NY, USA, 2015; pp. 2495–2500. [Google Scholar]

- Leps, T.; Glick, P.E.; Ruffatto, D.; Parness, A.; Tolley, M.T.; Hartzell, C. A Low-Power, Jamming, Magnetorheological Valve Using Electropermanent Magnets Suitable for Distributed Control in Soft Robots. Smart Mater. Struct. 2020, 29, 105025. [Google Scholar] [CrossRef]

- Feng, J.; Xuan, S.; Lv, Z.; Pei, L.; Zhang, Q.; Gong, X. Magnetic-Field-Induced Deformation Analysis of Magnetoactive Elastomer Film by Means of DIC, LDV, and FEM. Ind. Eng. Chem. Res. 2018, 57, 3246–3254. [Google Scholar] [CrossRef]

- Feng, J.; Xuan, S.; Ding, L.; Gong, X. Magnetoactive Elastomer/PVDF Composite Film Based Magnetically Controllable Actuator with Real-Time Deformation Feedback Property. Compos. Pt. A Appl. Sci. Manuf. 2017, 103, 25–34. [Google Scholar] [CrossRef]

- Zhang, P.; Kamezaki, M.; He, Z.; Sakamoto, H.; Sugano, S. EPM-MRE: Electropermanent Magnet-Magnetorheological Elastomer for Soft Actuation System and Its Application to Robotic Grasping. IEEE Robot. Autom. Lett. 2021, 6, 8181–8188. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Sun, M.; Wu, H.; Zhou, Y.; Wu, H.; Jiang, S. A Magneto-Active Soft Gripper with Adaptive and Controllable Motion. Smart Mater. Struct. 2021, 30, 015024. [Google Scholar] [CrossRef]

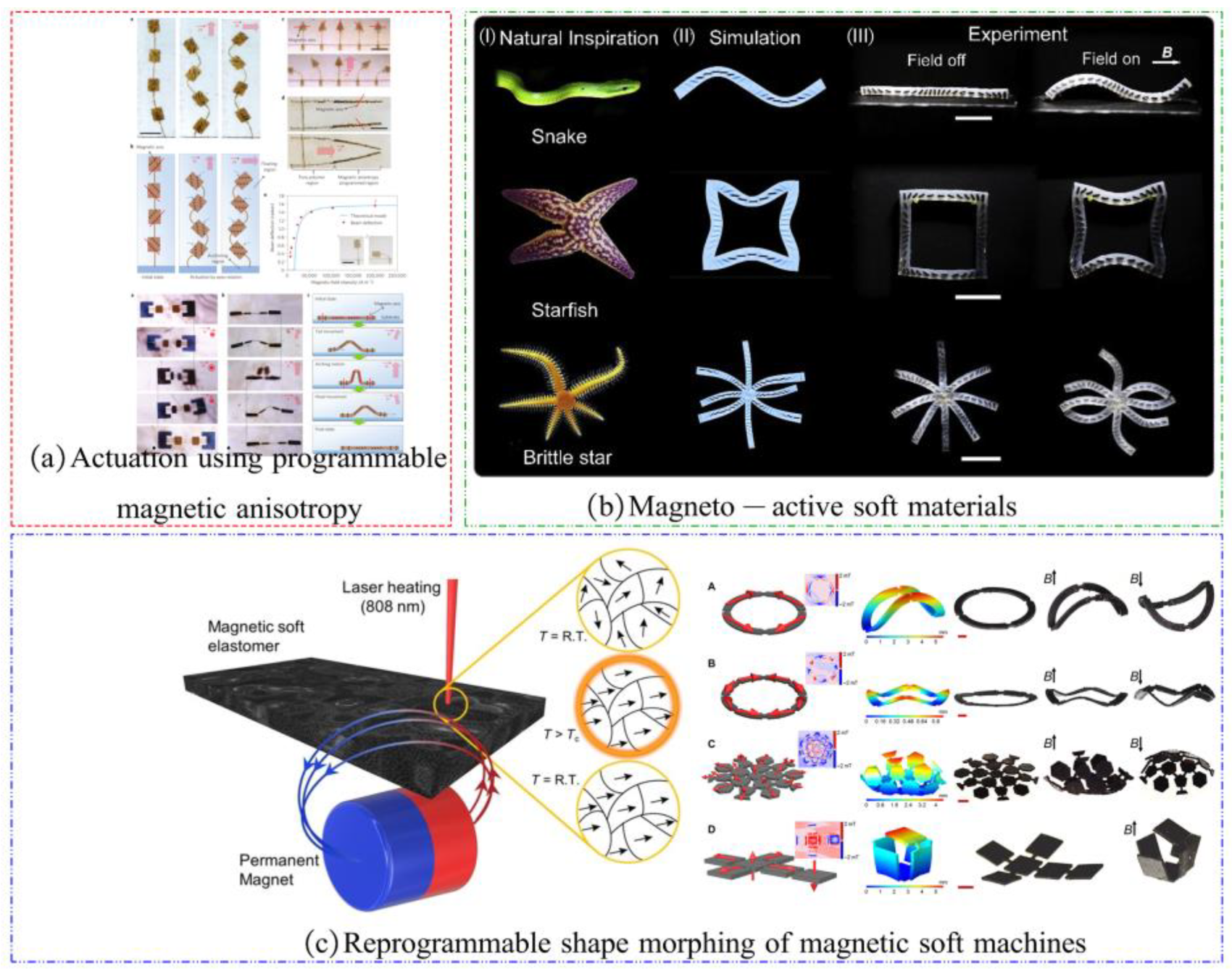

- Kim, J.; Chung, S.E.; Choi, S.-E.; Lee, H.; Kim, J.; Kwon, S. Programming Magnetic Anisotropy in Polymeric Microactuators. Nat. Mater. 2011, 10, 747–752. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Guo, H.; Fu, J.; Xie, Y.; Zhu, M.; Yu, M. 3D Printed Shape-Programmable Magneto-Active Soft Matter for Biomimetic Applications. Compos. Sci. Technol. 2020, 188, 107973. [Google Scholar] [CrossRef]

- Alapan, Y.; Karacakol, A.C.; Guzelhan, S.N.; Isik, I.; Sitti, M. Reprogrammable Shape Morphing of Magnetic Soft Machines. Sci. Adv. 2020, 6, eabc6414. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Kim, B.-C.; Lim, D.-W.; Shin, B.-C. Control of Adhesion Force for Micro LED Transfer Using a Magnetorheological Elastomer. J. Mech. Sci. Technol. 2019, 33, 5321–5325. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Liu, Y.; Li, J.; Xu, F.; Huang, X.; Yue, X. Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials. Materials 2024, 17, 4858. https://doi.org/10.3390/ma17194858

Xu M, Liu Y, Li J, Xu F, Huang X, Yue X. Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials. Materials. 2024; 17(19):4858. https://doi.org/10.3390/ma17194858

Chicago/Turabian StyleXu, Meng, Yang Liu, Jialei Li, Fu Xu, Xuefeng Huang, and Xiaobin Yue. 2024. "Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials" Materials 17, no. 19: 4858. https://doi.org/10.3390/ma17194858

APA StyleXu, M., Liu, Y., Li, J., Xu, F., Huang, X., & Yue, X. (2024). Review of Flexible Robotic Grippers, with a Focus on Grippers Based on Magnetorheological Materials. Materials, 17(19), 4858. https://doi.org/10.3390/ma17194858