Improvement of Superconducting Joint Properties for GdBa2Cu3Ox Bulk Superconductors Joined with ErBa2Cu3Ox Superconductor Using Local Melt-Growth Method

Abstract

:1. Introduction

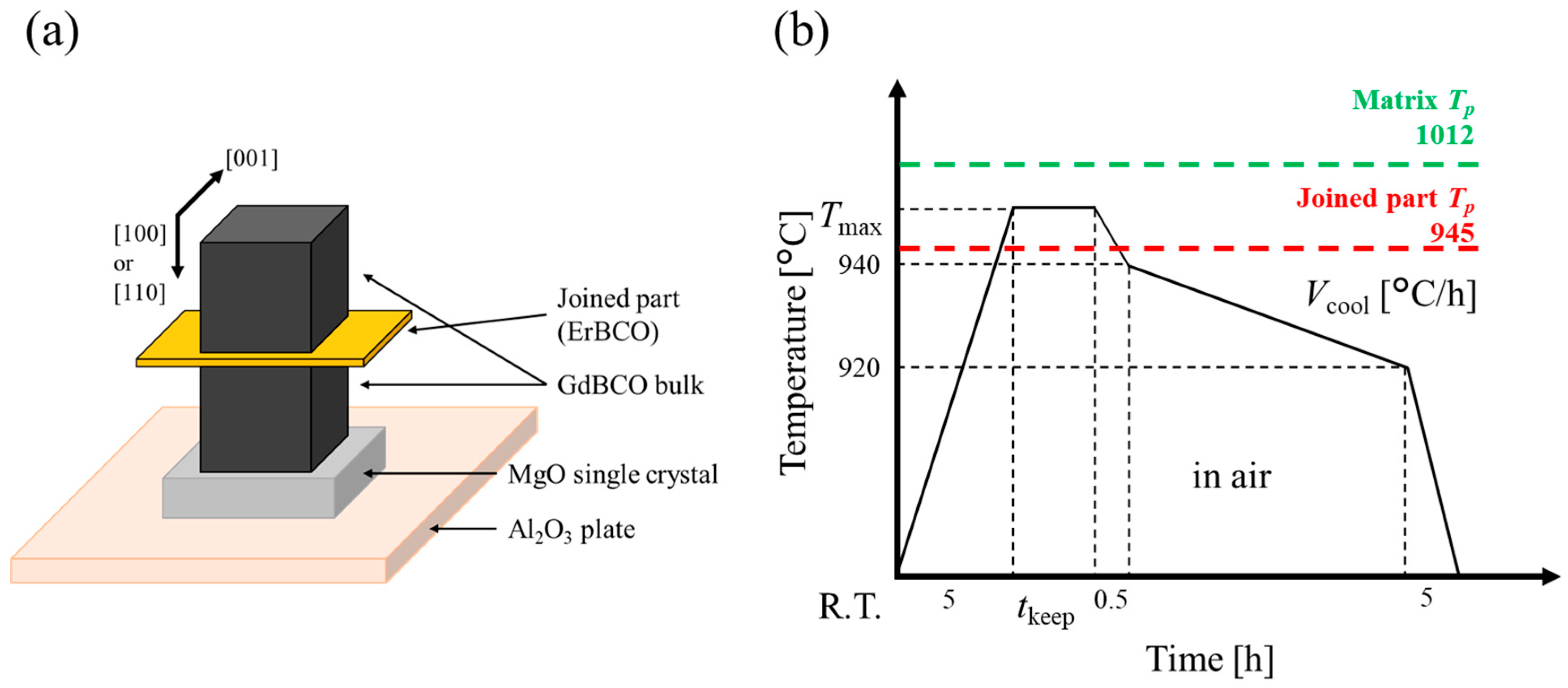

2. Materials and Methods

3. Results

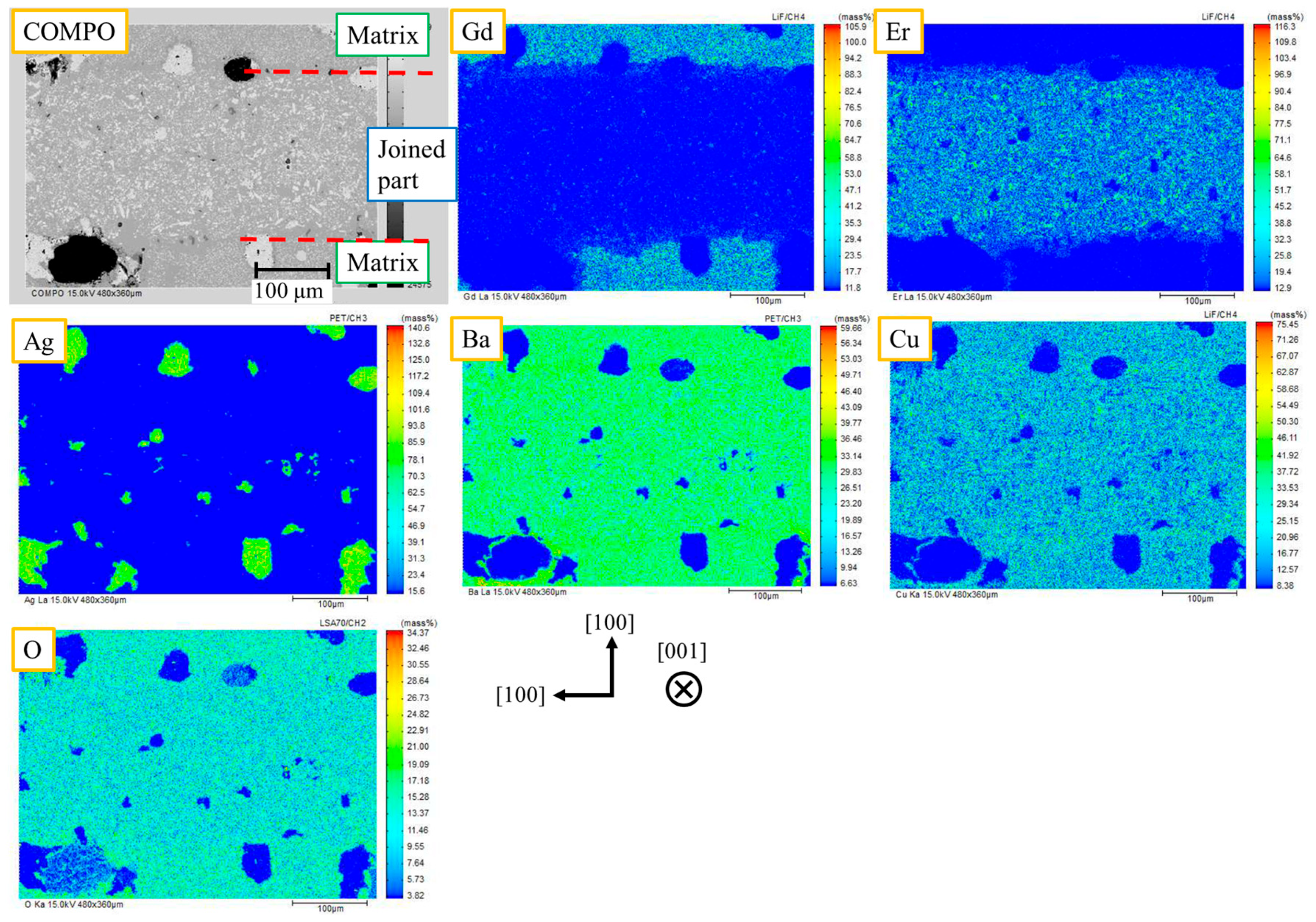

3.1. Microstructural Observation and Elemental Distribution of Joined Samples by EPMA

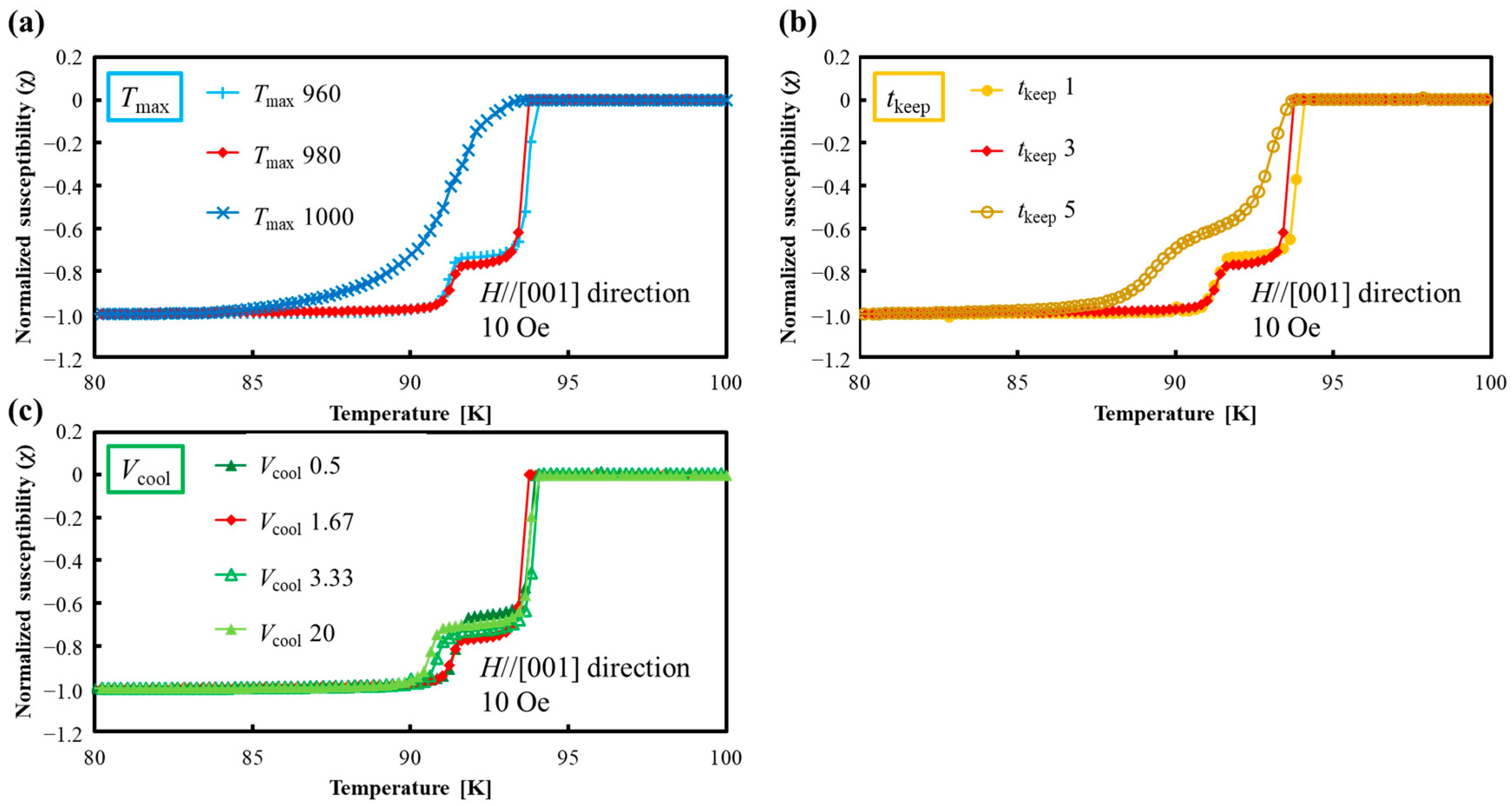

3.2. Superconductivity Properties of Joined Samples

4. Conclusions

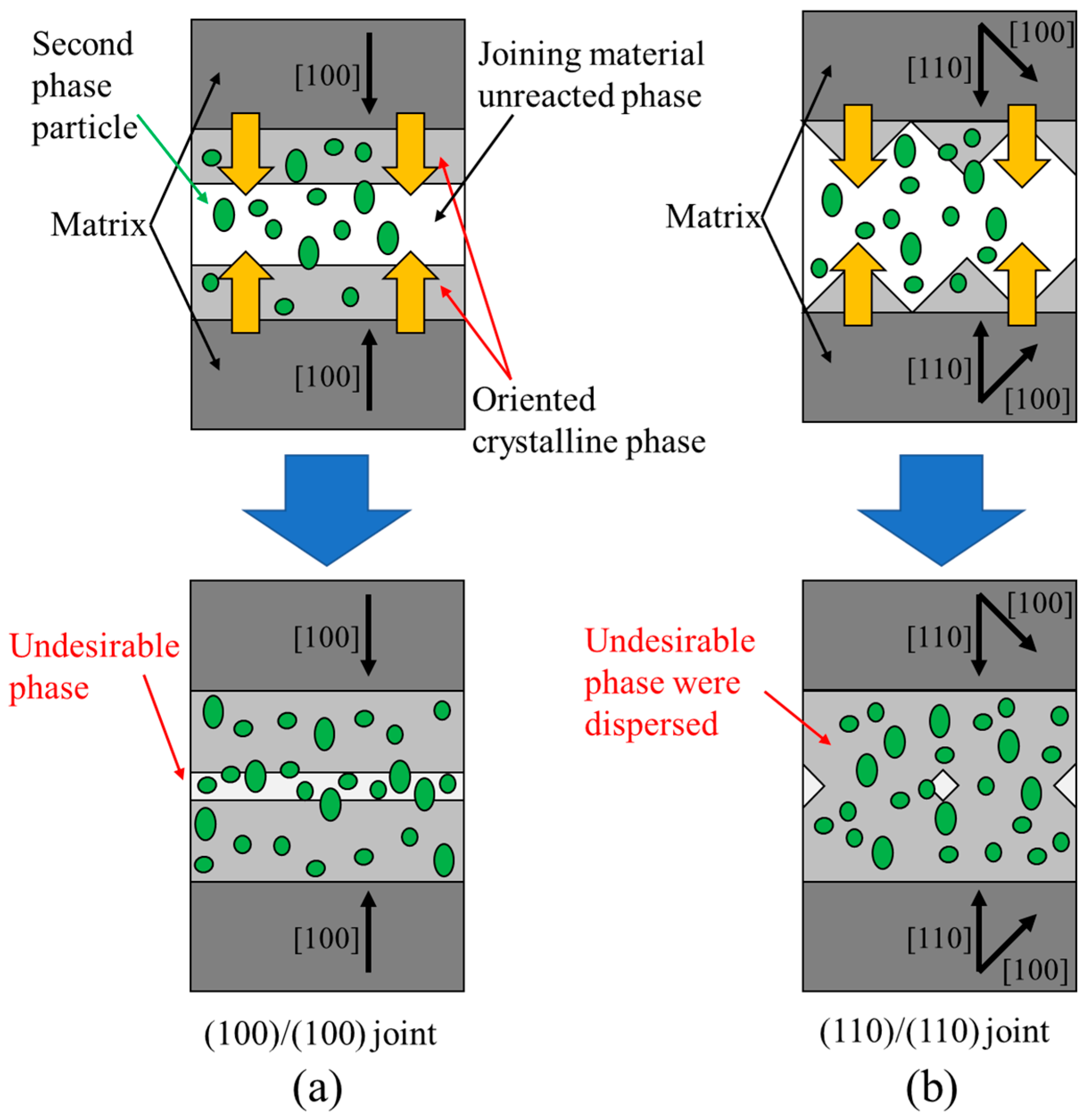

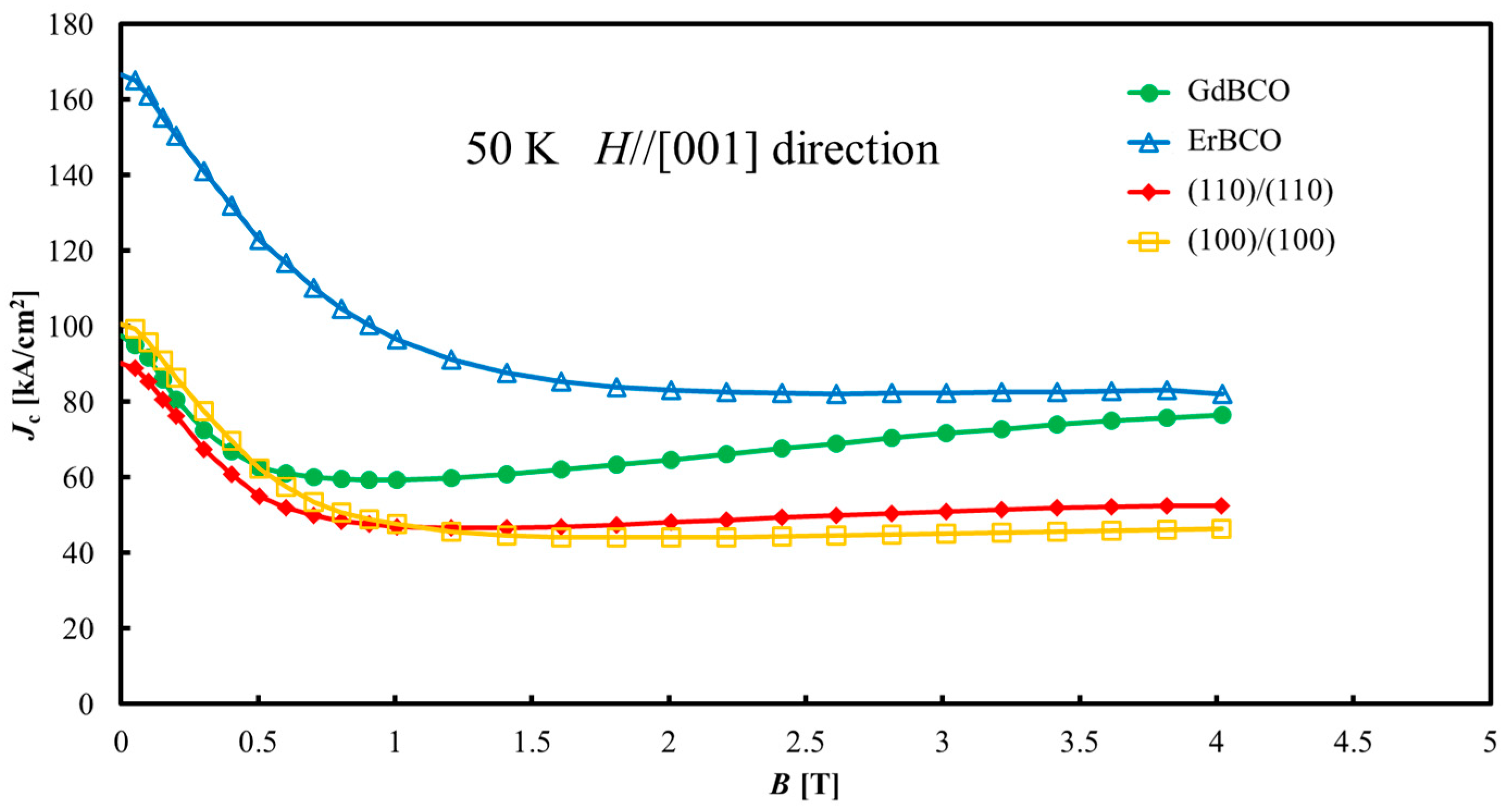

- A good superconducting joint was successfully obtained in the (100)/(100) joint, which was almost the same as that in the (110)/(110) joint. In previous reports, a good superconducting joint could not be obtained in the (100)/(100) joint due to degradation caused by impurity segregation. Still, by employing a faster cooling rate, the segregation of impurities was suppressed.

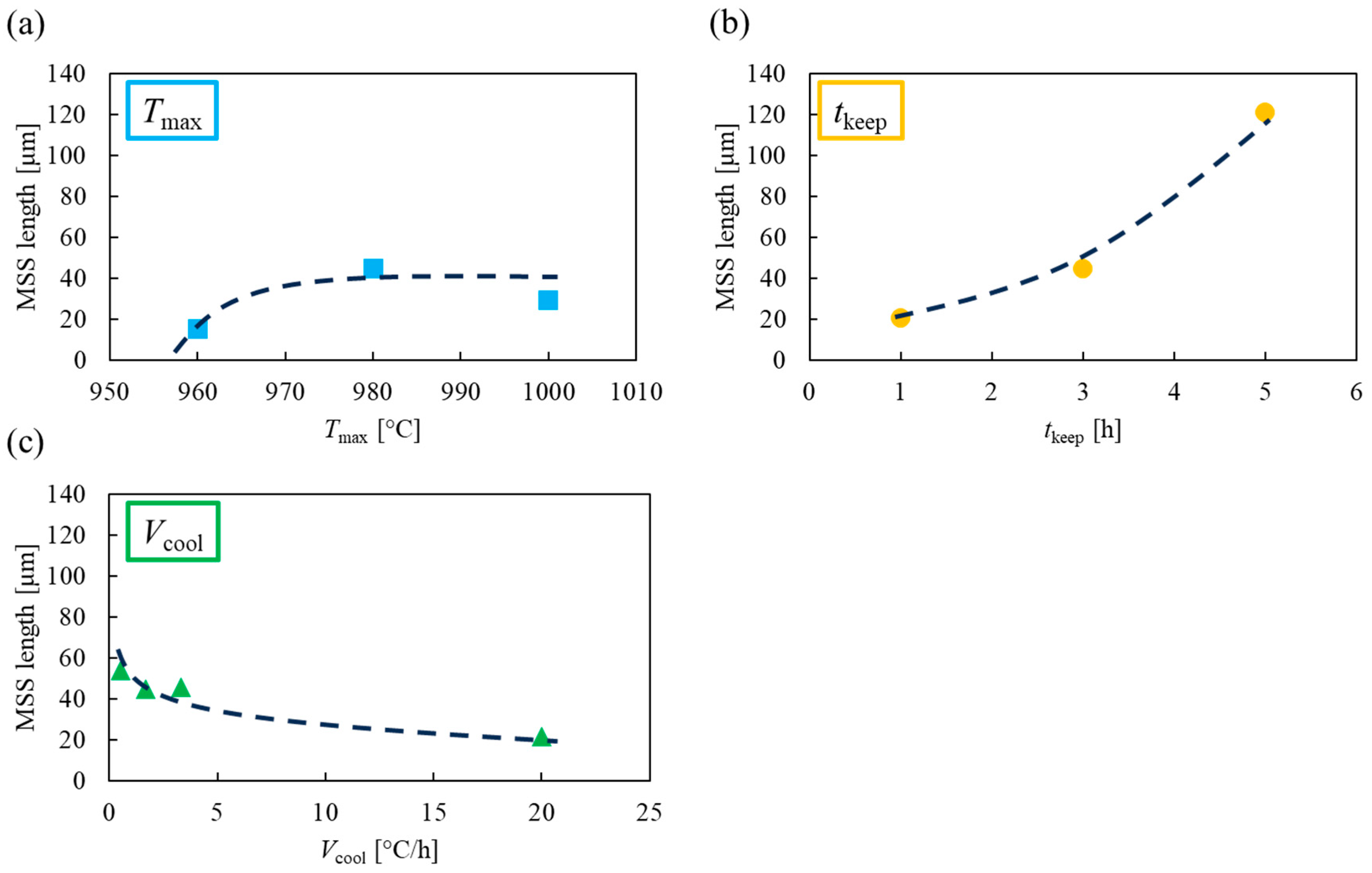

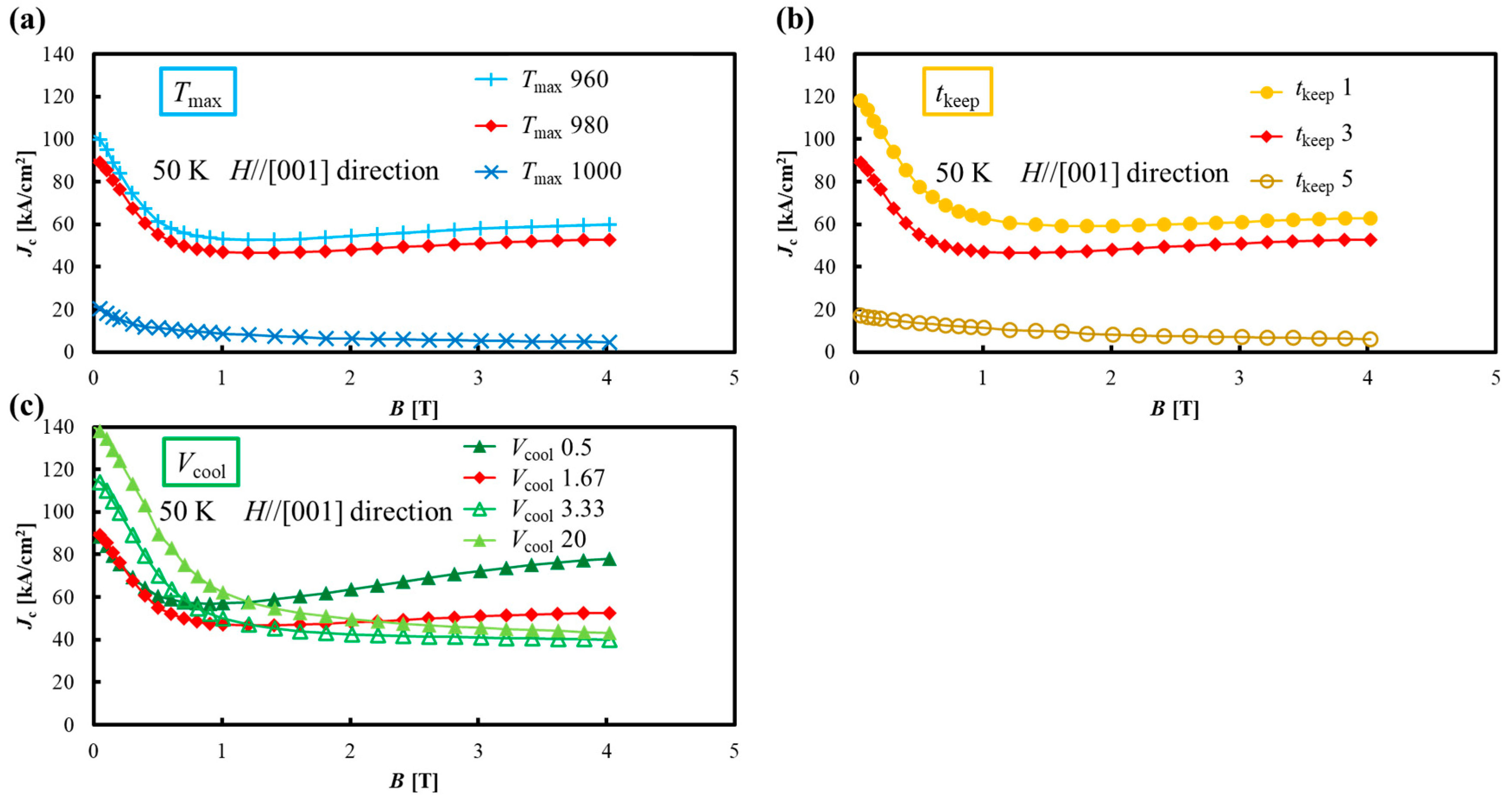

- The formation of the solid solution in the Gd/Er/Ba site sometimes resulted in the degradation of Jc. The MSS (mutual solid solution) length indicates the amount of back-melting in the matrix, and the formation is solid solutions; therefore, longer MSS lengths possibly correlate with decreased superconducting properties. EPMA line analysis revealed that the MSS length in the joined part varied depending on the joining thermal conditions. It was possible to decrease the MSS length in the joined part by lowering Tmax, shortening tkeep, and making Vcool faster.

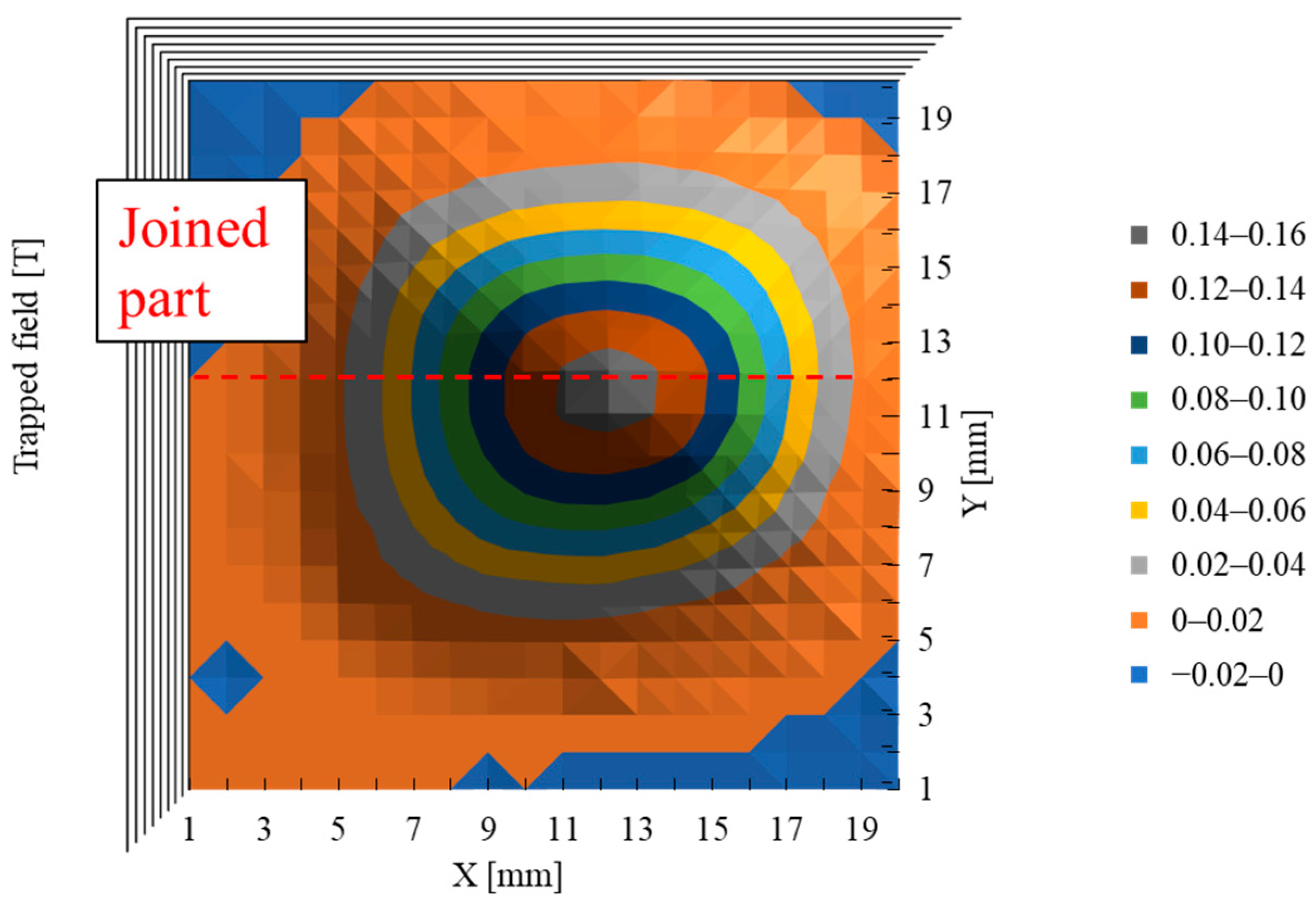

- The results of Tc and Jc-B characteristics showed little difference depending on the joining direction, especially in the low field region of Jc-B, which was equivalent to that of matrix GdBCO. In addition, the superconducting properties of the “(110)/(110)” were very good in the results of the trapped magnetic field distribution obtained by FCM, and it was confirmed that the joined part does not become defective when used as a bulk.

- Tc and Jc-B results with different joining thermal conditions show that the local melt-growth method can be significantly degraded by the joining thermal conditions. Additionally, a good superconducting joint can be obtained by lowering Tmax, shortening tkeep and making Vcool faster.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tomita, M.; Murakami, M. High-temperature superconductor bulk magnets that can trap magnetic fields of over 17 tesla at 29 K. Nature 2003, 421, 517–520. [Google Scholar] [CrossRef] [PubMed]

- Durrell, J.H.; Ainslie, M.D.; Zhou, D.; Vanderbemden, P.; Bradshaw, T.; Speller, S.; Filipenko, M.; Cardwell, D.A. Bulk superconductors: A roadmap to applications. Supercond. Sci. Technol. 2018, 31, 103501. [Google Scholar] [CrossRef]

- Murakami, M. Processing and applications of bulk RE-Ba-Cu-O superconductors. Int. J. Appl. Ceram. Technol. 2007, 4, 225–241. [Google Scholar] [CrossRef]

- Koshizuka, N. R&D of superconducting bearing technologies for flywheel energy storage systems. Phys. C Supercond. 2006, 445–448, 1103–1108. [Google Scholar]

- Nakagawa, Y. Research and development of a high-temperature superconducting flywheel energy storage system Research and development of the new sunshine program. Teion Kogaku 1999, 34, 541–548. (In Japanese) [Google Scholar] [CrossRef]

- Koyama, F.; Akiyama, S.; Murakami, M. Developments of superconducting mixers for medical applications. Supercond. Sci. Technol. 2006, 19, S572–S574. [Google Scholar] [CrossRef]

- Hayashi, H.; Tsutsumi, K.; Saho, N.; Nishizima, N.; Asano, K. Study on a mobile-type magnetic separator applying high-Tc bulk superconductors. Phys. C Supercond. 2003, 392–396, 745–748. [Google Scholar] [CrossRef]

- Nakamura, T.; Tamada, D.; Yanagi, Y.; Itoh, Y.; Nemoto, T.; Utumi, H.; Kose, K. Development of a superconducting bulk magnet for NMR and MRI. J. Magn. Reason. Imaging 2015, 259, 68–75. [Google Scholar] [CrossRef]

- Matsuzaki, H.; Kimura, Y.; Ohtani, I.; Izumi, M.; Ida, T.; Akita, Y.; Sugimoto, H.; Miki, M.; Kitano, M. An axial gap-type HTS bulk synchronous motor excited by pulsed-field magnetization with vortex-type armature copper windings. IEEE Trans. Appl. Supercond. 2005, 15, 2222–2225. [Google Scholar] [CrossRef]

- Zhou, D.; Izumi, M.; Miki, M.; Felder, B.; Ida, T.; Kitano, M. An overview of rotating machine systems with high-temperature bulk superconductors. Supercond. Sci. Technol. 2012, 25, 103001. [Google Scholar] [CrossRef]

- Koshizuka, N.; Matsunaga, K.; Yamachi, N.; Kawaji, A.; Hirabayashi, H.; Murakami, M.; Tomita, M.; Une, S.; Saito, S.; Isono, M.; et al. Construction of the stator installed in the superconducting magnetic bearing for a 10 kWh flywheel. Phys. C Supercond. 2004, 412–414, 756–760. [Google Scholar] [CrossRef]

- Dimos, D.; Chaudhari, P.; Mannhart, J. Superconducting transport properties of grain boundaries in YBa2Cu3O7 bicrystals. Phys. Rev. B 1990, 41, 4038–4049. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Gough, M.; Dennis, A.R.; Durrell, J.H.; Cardwell, D.A. Distribution of the superconducting critical current density within a Gd-Ba-Cu-O single grain. Supercond. Sci. Technol. 2020, 33, 044009. [Google Scholar] [CrossRef]

- Kim, C.J.; Kim, H.J.; Jee, Y.A.; Hong, G.W.; Joo, J.H.; Han, S.C.; Han, Y.H.; Sung, T.H.; Kim, S.J. Multiseeding with “(100)/(100)” grain junctions in top-seeded melt growth processed YBCO superconductors. Phys. C 2000, 338, 205–212. [Google Scholar] [CrossRef]

- Wongsatanawarid, A.; Seki, H.; Murakami, M. Growth of large bulk Y–Ba–Cu–O with multi-seeding. Supercond. Sci. Technol. 2010, 23, 045022. [Google Scholar] [CrossRef]

- Werfel, F.N.; Floegel-Delor, U.; Riedel, T.; Goebel, B.; Rothfeld, R.; Schirrmeister, P.; Wippich, D. Large-scale HTS bulks for magnetic application. Phys. C Supercond. 2013, 484, 6–11. [Google Scholar] [CrossRef]

- Almalki, A.; Namburi, D.K.; Ba-Abbad, M.; Dennis, A.R.; Huang, K.Y.; Almutairi, A.; Durrell, J.H.; Cardwell, D.A. Processing and Properties of Bar-Shaped Single-Seeded and Multi-Seeded YBCO Bulk Superconductors by a Top-Seeded Melt Growth Technique. J. Supercond. Nov. Magn. 2017, 30, 1397–1403. [Google Scholar] [CrossRef]

- Dorget, R.; Nouailhetas, Q.; Colle, A.; Berger, K.; Sudo, K.; Ayat, S.; Lévêque, J.; Koblischka, M.R.; Sakai, N.; Oka, T.; et al. Review on the use of superconducting bulks for magnetic screening in electrical machines for aircraft applications. Materials 2021, 14, 2847. [Google Scholar] [CrossRef]

- Salama, K.; Selvamanickam, V. Joining of high current bulk Y-Ba-Cu-O superconductors. Appl. Phys. 1992, 60, 898–900. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.M.; Mahadev, N.; Sengupta, S. Microstructural and spectroscopic analyses of a strongly-linked joint formed in a superconductor. Phys. C Supercond. 2000, 329, 95–101. [Google Scholar] [CrossRef]

- Harnois, C.; Desgardin, G.; Laffez, I.; Chaud, X.; Bourgault, D. High quality weld of melt textured YBCO using Ag doped YBCO junctions. Phys. C Supercond. 2002, 383, 269–278. [Google Scholar] [CrossRef]

- Yoshioka, J.; Iida, K.; Sakai, N.; Murakami, M. The crystallization in the welding region for Y–Ba–Cu–O bulk superconductors. Phys. C Supercond. 2003, 386, 495–499. [Google Scholar] [CrossRef]

- Takemura, K.; Sudo, K.; Dorget, R.; Dadiel, J.L.; Sakafuji, M.; Yokoyama, K.; Oka, T.; Murakami, M.; Sakai, N. Pulsed field magnetizing behavior of Gd-Ba-Cu-O bulk superconductor with a superconducting joint. IEEE Trans. Appl. Supercond. 2023, 33, 6800305. [Google Scholar] [CrossRef]

- Morita, M.; Tanaka, M.; Takebayashi, S.; Kimura, K.; Miyamoto, K.; Miyamoto, K.; Sawano, K. Effect of Pt Addition on Melt-Processed YBaCuO Superconductors. Jpn. J. Appl. Phys. 1991, 30, L813. [Google Scholar] [CrossRef]

- Nishio, T.; Itoh, Y.; Ogasawara, F.; Suganuma, M.; Yamada, Y.; Mizutani, U. Superconducting and mechanical properties of YBCO-Ag composite superconductors. J. Mater. Sci. 1989, 24, 3228–3234. [Google Scholar] [CrossRef]

- Murakami, M. Melt Processed High-Temperature Superconductors; World Scientific: Singapore, 1992. [Google Scholar]

- Gyorgy, E.M.; van Dover, R.B.; Jackson, K.A.; Schneemeyer, L.F.; Waszczak, J.V. Anisotropic critical currents in Ba2YCu3O7 analyzed using an extended Bean model. Appl. Phys. Lett. 1989, 55, 283–285. [Google Scholar] [CrossRef]

- Kambara, M.; Yoshizumi, M.; Umeda, T.; Miyake, K.; Murata, K.; Izumi, T.; Shiohara, Y. Role of the primary phase particles during the peritectic solidification of Y-123 superconducting oxides. J. Mater. Res. 2001, 16, 22. [Google Scholar] [CrossRef]

- Murakami, M.; Sakai, N.; Higuchi, T.; Yoo, S.I. Melt-processed light rare earth element-Ba-Cu-O. Supercond. Sci. Technol. 1996, 9, 1015. [Google Scholar] [CrossRef]

- Murakami, M. Processing of bulk YBaCuO. Supercond. Sci. Technol. 1992, 5, 185. [Google Scholar] [CrossRef]

- Diko, P.; Volochová, D.; Radušovská, M.; Zmorayová, K.; Šefčiková, M.; Antal, V.; Jurek, K.; Jirsa, M.; Kováč., J. Influence of preparation conditions on 211 particle refinement in YBCO bulk superconductors with Ce addition. Phys. C Supercond. 2013, 494, 31–35. [Google Scholar] [CrossRef]

| Sample Name | (110)/(110) | (100)/(100) | Tmax 960 | Tmax 1000 | tkeep 1 | tkeep 5 | Vcool 0.5 | Vcool 3.33 | Vcool 20 |

|---|---|---|---|---|---|---|---|---|---|

| Direction | [110] | [100] | [110] | [110] | [110] | [110] | [110] | [110] | [110] |

| Tmax [°C] | 980 | 980 | 960 | 1000 | 980 | 980 | 980 | 980 | 980 |

| tkeep [h] | 3 | 3 | 3 | 3 | 1 | 5 | 3 | 3 | 3 |

| Vcool [°C/h] | 1.67 | 1.67 | 1.67 | 1.67 | 1.67 | 1.67 | 0.5 | 3.33 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takemura, K.; Sudo, K.; Sakafuji, M.; Yokoyama, K.; Oka, T.; Sakai, N. Improvement of Superconducting Joint Properties for GdBa2Cu3Ox Bulk Superconductors Joined with ErBa2Cu3Ox Superconductor Using Local Melt-Growth Method. Materials 2024, 17, 484. https://doi.org/10.3390/ma17020484

Takemura K, Sudo K, Sakafuji M, Yokoyama K, Oka T, Sakai N. Improvement of Superconducting Joint Properties for GdBa2Cu3Ox Bulk Superconductors Joined with ErBa2Cu3Ox Superconductor Using Local Melt-Growth Method. Materials. 2024; 17(2):484. https://doi.org/10.3390/ma17020484

Chicago/Turabian StyleTakemura, Kento, Kimiaki Sudo, Masaki Sakafuji, Kazuya Yokoyama, Tetsuo Oka, and Naomichi Sakai. 2024. "Improvement of Superconducting Joint Properties for GdBa2Cu3Ox Bulk Superconductors Joined with ErBa2Cu3Ox Superconductor Using Local Melt-Growth Method" Materials 17, no. 2: 484. https://doi.org/10.3390/ma17020484

APA StyleTakemura, K., Sudo, K., Sakafuji, M., Yokoyama, K., Oka, T., & Sakai, N. (2024). Improvement of Superconducting Joint Properties for GdBa2Cu3Ox Bulk Superconductors Joined with ErBa2Cu3Ox Superconductor Using Local Melt-Growth Method. Materials, 17(2), 484. https://doi.org/10.3390/ma17020484