Carbon Emission Optimization of Ultra-High-Performance Concrete Using Machine Learning Methods

Abstract

:1. Introduction

2. Machine Learning Methods

2.1. ANN

2.2. Gradient Descent Method

2.3. GA

- (1)

- Initialization: In genetic algorithms, the initial population consists of a set of randomly selected potential solutions. The effectiveness of genetic algorithms is strongly influenced by the initial population. Since the parameters of the solution cannot be handled directly by genetic algorithms, the solved problem must be encoded to become an individual in the genetic space. Binary encoding, octal encoding, hexadecimal encoding, real encoding, tree encoding, permutation encoding, etc. are some of the common encoding techniques. For different types of computational problems, specific forms of transformations play an important role. Although binary encoding can speed up crossover and mutation operations, it is unsuitable for some sophisticated engineering design issues. The use of hexadecimal and octal encoding is not widely used. Real number encoding works better for some more difficult issues, particularly those involving neural networks. Tree encoding can be applied with any encoding language and is appropriate for use in constantly evolving programs or expressions.

- (2)

- Individual evaluation (fitness calculation): The fitness function, which can be single- or multi-objective, is a crucial part of genetic algorithms. The objective function is a function that assesses how well a group of parameters—individuals who make up the population—perform. When creating a fitness function for a practical situation, care should be taken to ensure that it is non-negative, continuous, single-valued, logical, and consistent. Based on specific challenges, the fitness function should be easy to understand and computationally efficient. The iterative convergence of genetic algorithms is directly influenced by the fitness function’s design’s rationality, which also has an impact on the effectiveness of optimization outcomes.

- (3)

- Selection operation: Selection operation controls whether an individual participates in population reproduction, and it also affects how quickly genetic algorithms converge. The Boltzmann algorithm, ranking algorithm, roulette wheel algorithm, random traversal sampling method, etc. are some of the frequently used selection methods. For the selection processes in this study, a roulette wheel algorithm is utilized.

- (4)

- Cross operation: In order to complete the recombination of genetic information and create a new generation of individuals in the population, cross operation simulates chromosomal exchange in biology. The population can be continuously optimized through selection operations when new individuals change in terms of their fitness value. The commonly used crossover operators include single-point crossover, two-point crossover, k-point crossover, uniform crossover, etc.

- (5)

- Mutation operation: Crossover operation produces new individuals with the same alleles as their parents, which will have a detrimental effect on population variety. The goal of mutation operation is to maintain population diversity. The alleles of offspring are changed at random by the mutation operation, and the mutation probability should be as low as feasible or else the genetic algorithm will be identical to the random search algorithm. Exchange mutation, inversion mutation, random shuffling mutation, etc. are some of the frequently utilized mutation operators.

- (6)

- Termination condition judgment: Three criteria need to be met for a genetic algorithm to be judged to have met its termination requirement. The genetic algorithm’s default iteration, which is typically set to 100 to 500, is the first. The genetic algorithm’s iteration process ends, and the ideal individual is produced after the predetermined number of iterations has been reached. The second is to set the fitness function threshold, which allows the genetic algorithm to skip iterations and output the best candidate if an individual satisfies the objective function’s requirements and the required fitness value during the iteration process. The third criterion is that the genetic algorithm has achieved the convergence threshold and cannot achieve the optimization effect through further iterations if the population’s fitness function value is not increasing during the genetic algorithm’s iteration process. As a result, it is possible to finish the iteration and produce the optimal individual.

2.4. K-Fold Cross Validation Method

3. Materials and Experiments

3.1. Materials

3.2. Experiments

4. Machine Learning Optimization

4.1. Database

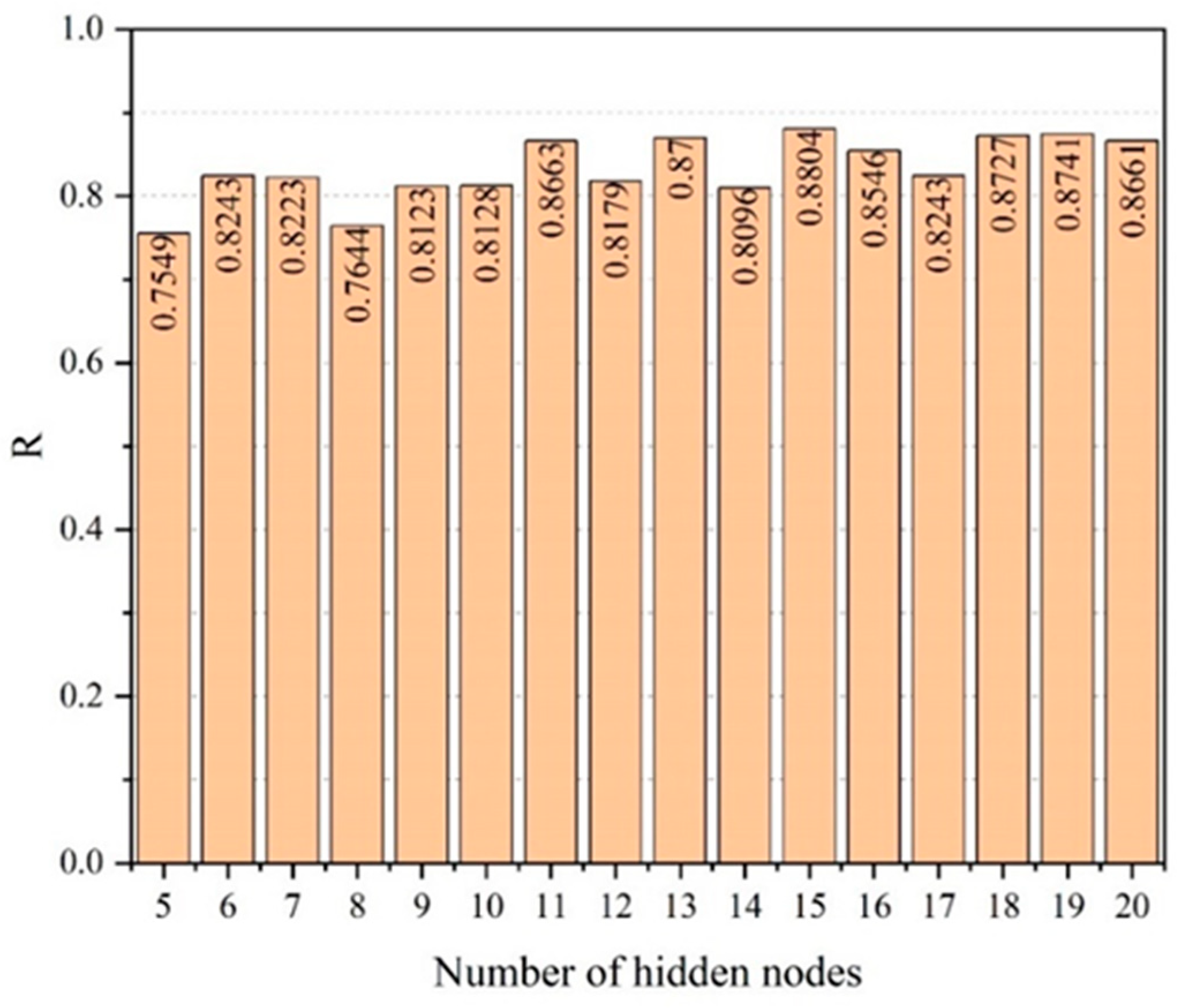

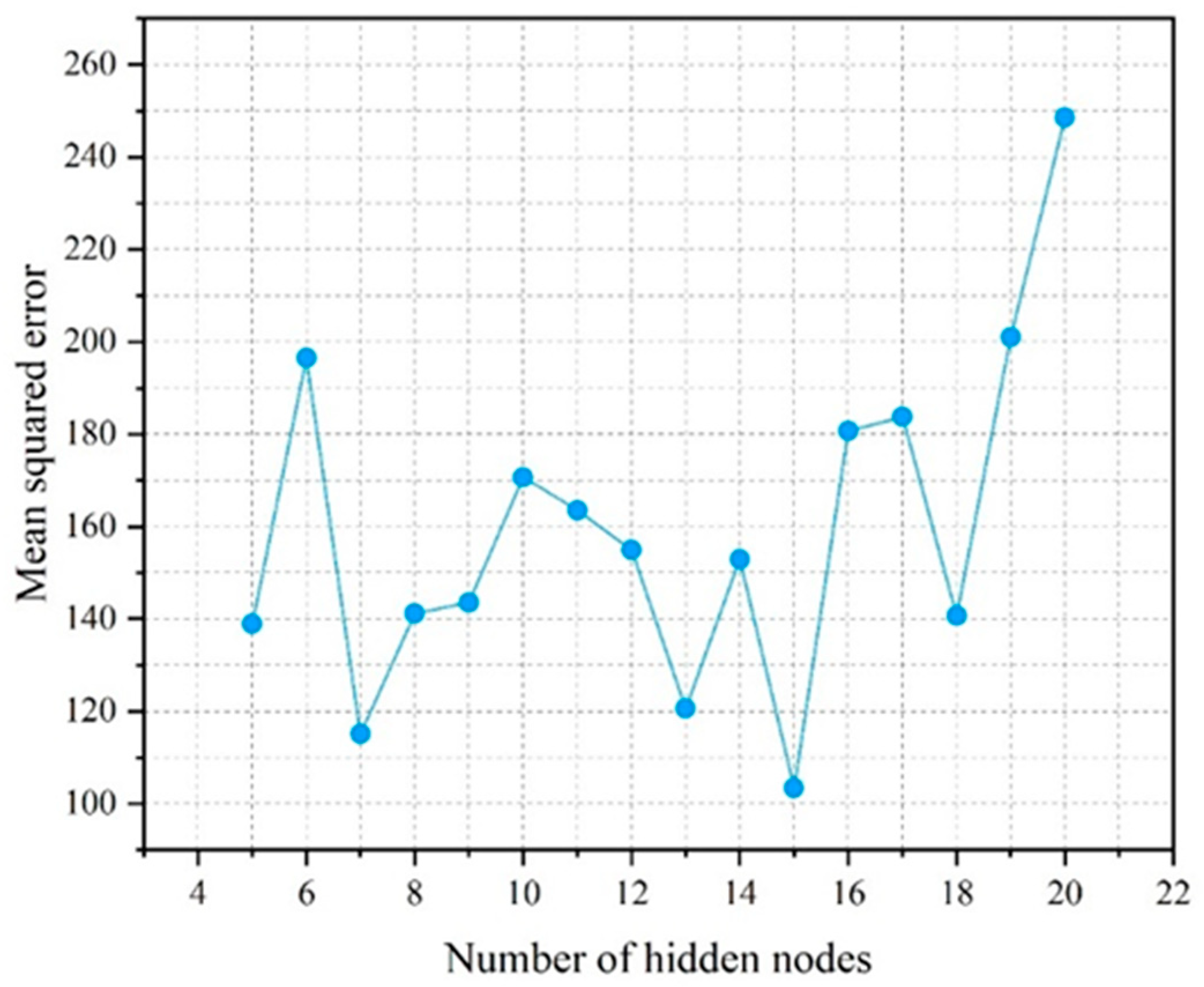

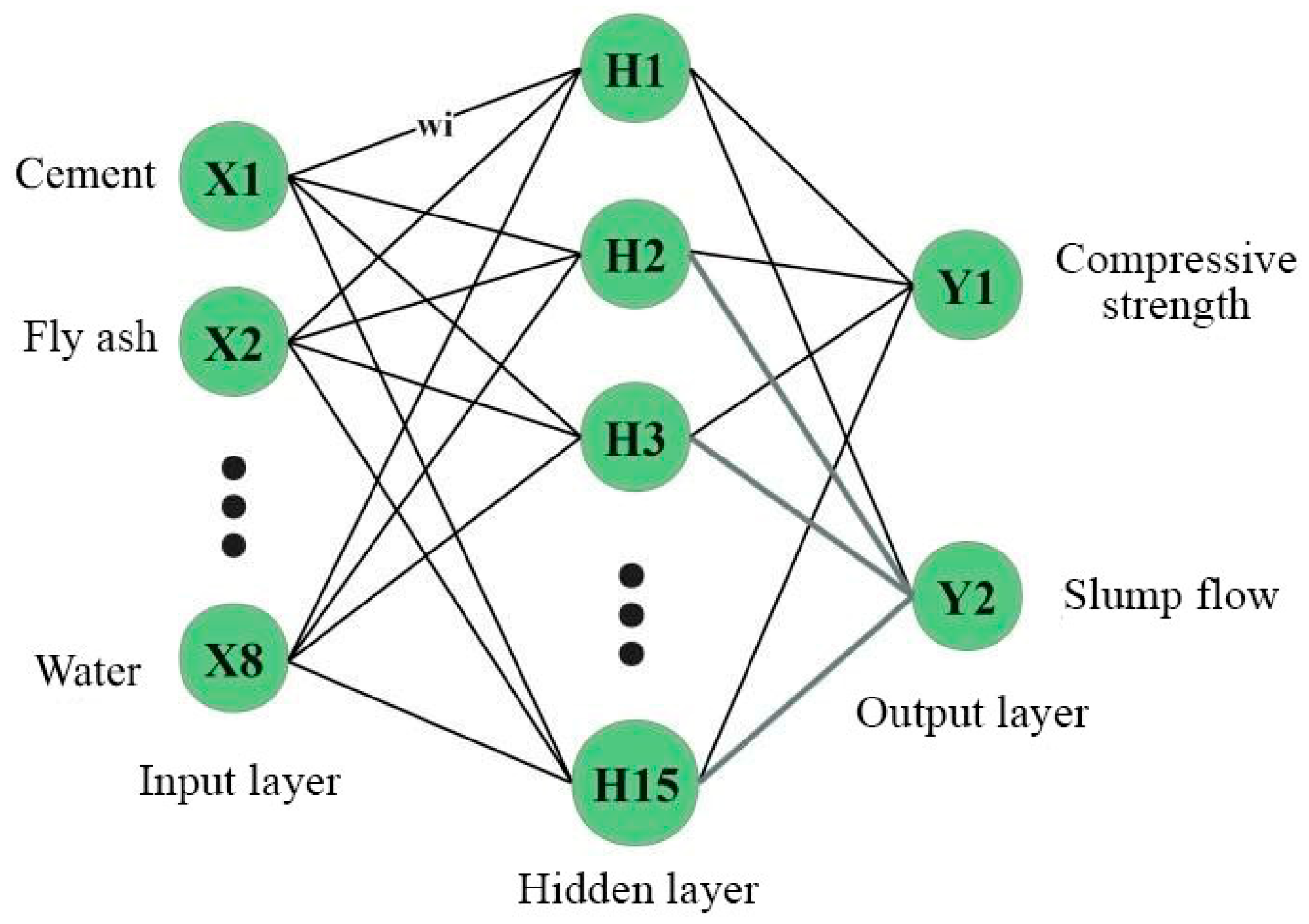

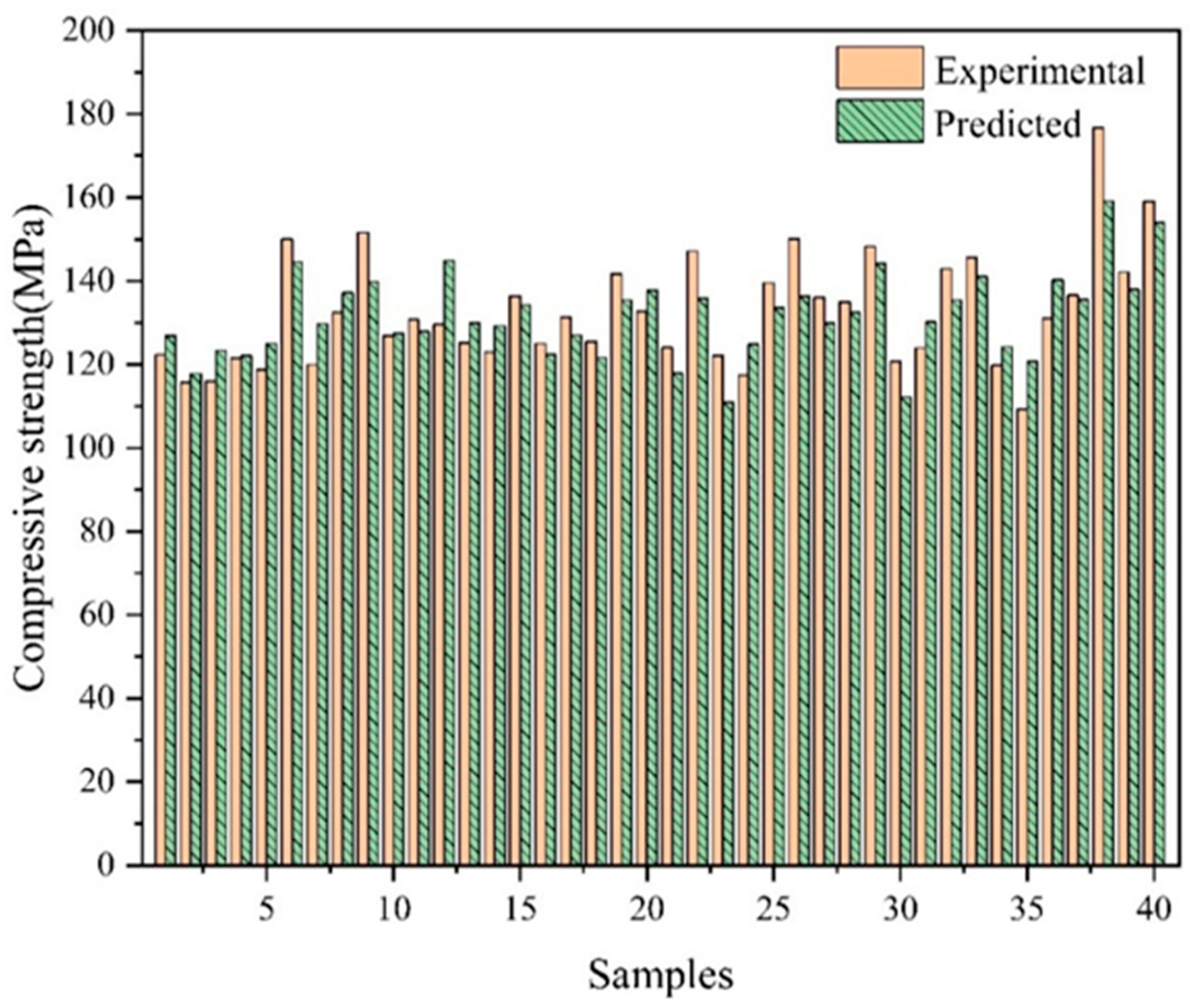

4.2. ANN Prediction Model

4.3. GA Optimization Process

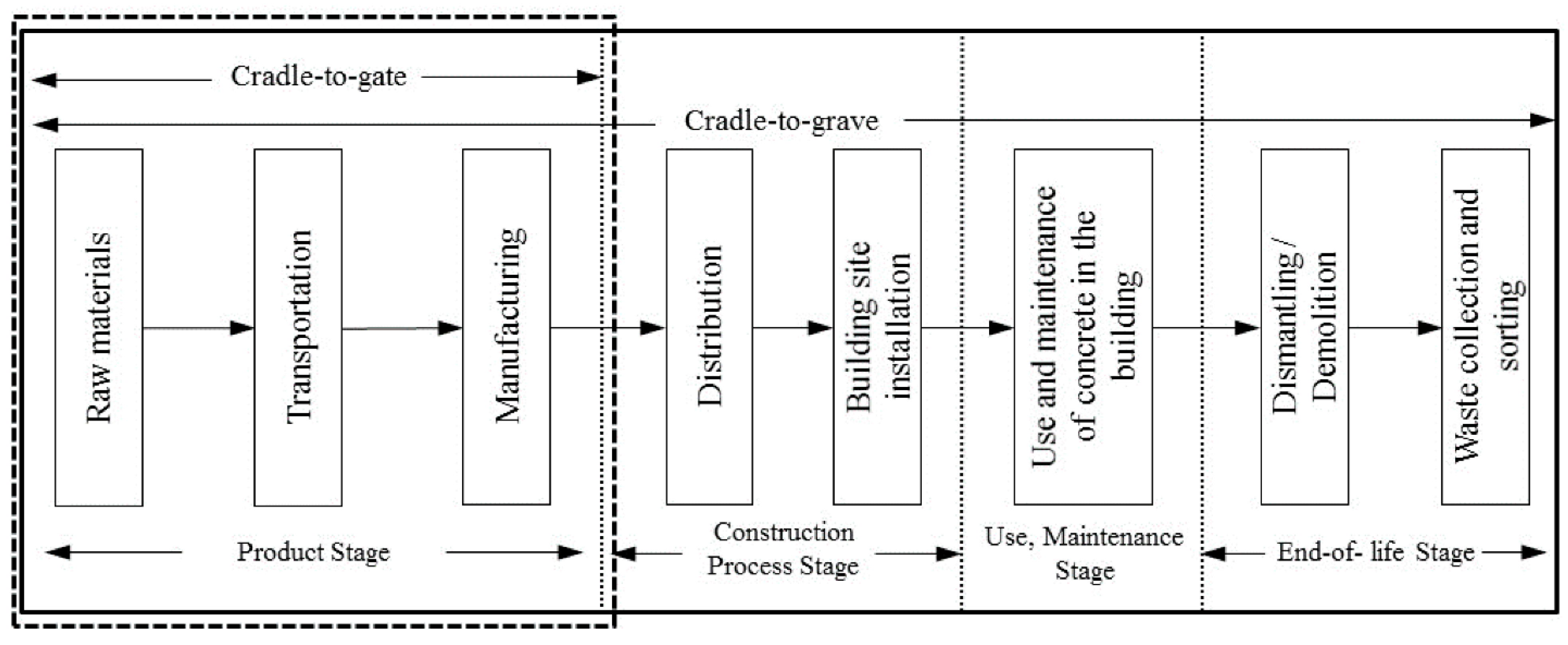

4.3.1. Calculation Method of Carbon Emissions

Raw Material Stage

Transportation Stage

Manufacturing Stage

4.3.2. Optimization Objective Function

4.3.3. Constraint Condition

- (1)

- Compressive strength. The 28 day compressive strength estimated by the ANN model for UHPC should be higher than the strength required. Equation (10) illustrates the strength constraint:Among them, (28) is the ANN predicted value of the 28 day compressive strength of UHPC. (28) is the required value for the 28 day compressive strength of UHPC, which needs to be selected according to the requirements in actual engineering. Considering the basic mechanical properties of UHPC, (28) is taken as 120 MPa in this study [55].

- (2)

- Slump flow. The ANN prediction value of the slump flow of fresh UHPC should be higher than the required slump flow. Equation (11) displays the slump flow constraints:where Slump is the ANN-predicted value of the workability of fresh UHPC. Slumpr is the required workability of fresh UHPC, which needs to be selected according to the requirements of actual engineering. Considering the basic working performance of UHPC, Slumpr is taken as 600 mm in this study [56].

- (3)

- Component content. The optimized UHPC component content should be within a reasonable range, and this study uses the data range in the dataset as the component content constraint. The component content constraint is shown in Equation (12), and some statistical parameters of the dataset are illustrated in Table 5.where Comp represents the component content, including cement, fly ash, GGBS, silica fume, fine aggregate, steel fiber, water-reducing agent, and water. Lower and Upper are the lower and upper limits for each component content.

- (4)

- Component proportion. Some components in UHPC are related, and the proportion of some components should be constrained. This study has considered the water–cement ratio, water–binder ratio, and cement–sand ratio. We still use the proportion range in the dataset as a component proportion constraint. The detailed constraint of composition ratio is shown in Equations (13)–(15). Some statistical parameters of water–cement ratio, water–binder ratio, and cement–sand ratio in the data set are provided in Table 6.where Rw/c, Rw/b, and Rb/fa are the water–cement ratio, water–binder ratio and cement–sand ratio, respectively. Rl and Ru are the lower and upper limits of each composition ratio, respectively.

- (5)

- Absolute volume. The absolute volume of UHPC is calculated by Equation (16), which means that the total volume of all components in a 1 m3 UHPC should equal 1 m3.where WC, WFl, WGGBS, WSi, WFA, WSF, WSP, and WW represent the masses of cement, fly ash, GGBS, silica fume, fine aggregate, steel fiber, water-reducing agent, and water in 1 m3 UHPC, respectively. ρC, ρFl, ρGGBS, ρSi, ρFA, ρSF, ρSP, and ρW represent the densities of cement, fly ash, GGBS, silica fume, fine aggregate, steel fiber, water-reducing agent, and water, respectively. The densities of cementitious materials are given in Table 1. The densities of fine aggregate, steel fiber, water-reducing agent, and water are 2630 kg/m3, 7800 kg/m3, 1190 kg/m3, and 1000 kg/m3, respectively.

4.3.4. Implementation of Carbon Emission Optimization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Zhou, S. The prediction of self-healing capacity of bacteria-based concrete using machine learning approaches. Cmc-Comput. Mater. Contin. 2019, 59, 57–77. [Google Scholar] [CrossRef]

- Karolczuk, A.; Skibicki, D.; Pejkowski, L. Gaussian process for machine learning-based fatigue life prediction model under multiaxial stress-strain conditions. Materials 2022, 15, 7797. [Google Scholar] [CrossRef]

- Imran, H.; Al-Abdaly, N.M.; Shamsa, M.H.; Shatnawi, A.; Ibrahim, M.; Ostrowski, K.A. Development of prediction model to predict the compressive strength of Eco-Friendly Concrete using multivariate polynomial regression combined with stepwise method. Materials 2022, 15, 317. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Ahmad, A. A systematic review of the research development on the application of machine learning for concrete. Materials 2022, 15, 4512. [Google Scholar] [CrossRef]

- Mortazavi, B.; Shahrokhi, M.; Shojaei, F.; Rabczuk, T.; Zhuang, X.; Shapeev, A.V. A first-principles and machine-learning investigation on the electronic, photocatalytic, mechanical and heat conduction properties of nanoporous C5N monolayers. Nanoscale 2022, 14, 4324–4333. [Google Scholar] [CrossRef]

- Dung Nguyen, K.; Zhuang, X. A deep neural network-based algorithm for solving structural optimization. J. Zhejiang Univ.-Sci. A 2021, 22, 609–620. [Google Scholar]

- Mortazavi, B.; Javvaji, B.; Shojaei, F.; Rabczuk, T.; Shapeev, A.V.; Zhuang, X. Exceptional piezoelectricity, high thermal conductivity and stiffness and promising photocatalysis in two-dimensional MoSi2N4 family confirmed by first-principles. Nano Energy 2021, 82, 105716. [Google Scholar] [CrossRef]

- Biswas, R.; Kumar, M.; Singh, R.K.; Alzara, M.; El Sayed, S.B.A.; Abdelmongy, M.; Yosri, A.M.; Yousef, S. A novel integrated approach of RUNge Kutta optimizer and ANN for estimating compressive strength of self-compacting concrete. Case Stud. Constr. Mater. 2023, 18, e02163. [Google Scholar] [CrossRef]

- Ly, H.; Nguyen, T.; Pham, B.; Nguyen, M. A hybrid machine learning model to estimate self-compacting concrete compressive strength. Front. Struct. Civ. Eng. 2022, 16, 990–1002. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, X.; Luo, Y.; Jia, Y.; Wang, C.; Fang, Z.; Zhuang, X.; Zhou, S. Prediction of early compressive strength of Ultrahigh-Performance Concrete using machine learning methods. Int. J. Comput. Methods 2023, 20, 2141023. [Google Scholar] [CrossRef]

- Sobolev, K.; Amirjanov, A. Application of genetic algorithm for modeling of dense packing of concrete aggregates. Constr. Build. Mater. 2010, 24, 1449–1455. [Google Scholar] [CrossRef]

- Chiniforush, A.A.; Gharehchaei, M.; Nezhad, A.A.; Castel, A.; Moghaddam, F.; Keyte, L.; Hocking, D.; Foster, S. Minimising risk of early-age thermal cracking and delayed ettringite formation in concrete—A hybrid numerical simulation and genetic algorithm mix optimisation approach. Constr. Build. Mater. 2021, 299, 124280. [Google Scholar] [CrossRef]

- Latif, I.; Banerjee, A.; Surana, M. Explainable machine learning aided optimization of masonry infilled reinforced concrete frames. Structures 2022, 44, 1751–1766. [Google Scholar] [CrossRef]

- Ghahremani, B.; Rizzo, P. Multi-gene genetic programming for the prediction of the compressive strength of concrete mixtures. Comput. Concr. 2022, 30, 225–236. [Google Scholar]

- Zhang, X.Y.; Yu, R.; Zhang, J.J.; Shui, Z.H. A low-carbon alkali activated slag based ultra-high performance concrete (UHPC): Reaction kinetics and microstructure development. J. Clean. Prod. 2022, 363, 132416. [Google Scholar] [CrossRef]

- Sun, C.; Wang, K.; Liu, Q.; Wang, P.J.; Pan, F. Machine-learning-based comprehensive properties prediction and mixture design optimization of Ultra-High-Performance Concrete. Sustainability 2023, 15, 15338. [Google Scholar] [CrossRef]

- Suwarno, R.H.; Yuwono, A.S.; Erizal. On the performance analysis and environmental impact of concrete with coal fly ash and bottom ash. Int. J. Eng. Technol. Innov. 2023, 13, 86–97. [Google Scholar] [CrossRef]

- Mohamed, K.; Mateus, R.; Bragança, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar]

- Hossain, U.; Sun, C.; Hong, Y.; Xuan, D. Evaluation of environmental impact distribution methods for supplementary cementitious materials. Renew. Sustain. Energy Rev. 2018, 82, 597–608. [Google Scholar] [CrossRef]

- Gettu, R.; Patel, A.; Rathi, V.; Prakasan, S.; Basavaraj, A.S.; Palaniappan, S.; Maity, S. Influence of supplementary cementitious materials on the sustainability parameters of cements and concretes in the Indian context. Mater. Struct. 2019, 52, 10. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Butera, A.; Le, K.N.; Li, W. Utilising CO2 technologies for recycled aggregate concrete: A critical review. Constr. Build. Mater. 2020, 250, 118903. [Google Scholar] [CrossRef]

- Thomas, C.; de Brito, J.; Cimentada, A.; Sainz-Aja, J.A. Macro- and micro- properties of multi-recycled aggregate concrete. J. Clean. Prod. 2020, 245, 118843. [Google Scholar] [CrossRef]

- Miller, S.A. Supplementary cementitious materials to mitigate greenhouse gas emissions from concrete: Can there be too much of a good thing? J. Clean. Prod. 2018, 178, 587–598. [Google Scholar] [CrossRef]

- Liu, G.W.; Hua, J.M.; Wang, N.; Deng, W.J.; Xue, X.Y. Material alternatives for concrete structures on remote islands: Based on Life-Cycle-Cost Analysis. Adv. Civ. Eng. 2022, 2022, 7329408. [Google Scholar] [CrossRef]

- Paredes, J.A.; Gálvez, J.C.; Enfedaque, A.; Alberti, M.G. Matrix optimization of Ultra High Performance Concrete for improving strength and durability. Materials 2021, 14, 6944. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Li, Z.; Zhou, Y.; Xie, Q.; Peng, H.; Zhou, S.; Wang, C. Effect of stray current and sulfate attack on cementitious materials in soil. Constr. Build. Mater. 2023, 408, 133723. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Stone, M. Cross-validatory choice and assessment of statistical predictions. J. R. Stat. Soc. Ser. B-Stat. Methodol. 1974, 36, 111–147. [Google Scholar] [CrossRef]

- Chen, S.Z.; Zhou, M.M.; Shi, X.Y.; Huang, J.D. A novel MBAS-RF approach to predict mechanical properties of geopolymer-based compositions. Gels 2023, 9, 434. [Google Scholar] [CrossRef] [PubMed]

- Deeb, R.; Karihaloo, B.L. Mix proportioning of self-compacting normal and high-strength concretes. Mag. Concr. Res. 2013, 65, 546–556. [Google Scholar] [CrossRef]

- Wang, X.P.; Yu, R.; Shui, Z.H.; Song, Q.L.; Zhang, Z.H. Mix design and characteristics evaluation of an eco-friendly Ultra-High Performance Concrete incorporating recycled coral based materials. J. Clean. Prod. 2017, 165, 70–80. [Google Scholar] [CrossRef]

- Ayira, F.; John, O. Investigating the Properties of Reactive Powder Concrete (RPC)-Compressive and Flexural Strength; Universiti Teknologi Petronas: Seri Iskandar, Malaysia, 2013. [Google Scholar]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, L.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra-high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Nie, J.; Li, C.; Qian, G.; Pan, R.; Fei, B.; Deng, S. Effect of shape and content of steel fiber on workability and mechanical properties of Ultra-High Performance Concrete UHPC. Cailiao Daobao/Mater. Rep. 2021, 35, 04042–04052. [Google Scholar]

- Pyo, S.; Kim, H.K. Fresh and hardened properties of ultra-high performance concrete incorporating coal bottom ash and slag powder. Constr. Build. Mater. 2017, 131, 459–466. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Meszoely, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- El-Helou, R.G.; Haber, Z.B.; Graybeal, B.A. Mechanical behavior and design properties of Ultra-High-Performance Concrete. Aci Mater. J. 2022, 119, 181–194. [Google Scholar]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-art review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef] [PubMed]

- Li, Y. Study on Property of Non-Steam Curing Ultra-High Performance Concrete. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. (In Chinese). [Google Scholar]

- Wen, C. Study on Workability and Mechanical Properties and Microstructure of Ultra High Performance Concrete. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2020. (In Chinese). [Google Scholar]

- Yang, Z. Study on Mechanical Properties of Reactive Powder Concrete. Master’s Thesis, Dalian Jiaotong University, Dalian, China, 2008. (In Chinese). [Google Scholar]

- Nie, J. Research on Key Influencing Factors of Mechanical Properties and Expansion of Ultra High Performance Concrete. Master’s Thesis, Changsha University of Science and Technology, Changsha, China, 2020. (In Chinese). [Google Scholar]

- Zheng, W.; Shui, Z.H.; Xu, Z.Z.; Gao, X.; Zhang, S. Multi-objective optimization of concrete mix design based on machine learning. J. Build. Eng. 2023, 76, 107396. [Google Scholar] [CrossRef]

- Sameer, H.; Weber, V.; Mostert, C.; Bringezu, S.; Fehling, E.; Wetzel, A. Environmental assessment of Ultra-High-Performance Concrete using carbon, material, and water footprint. Materials 2019, 12, 851. [Google Scholar] [CrossRef] [PubMed]

- Lei, B.; Yu, L.J.; Chen, Z.Y.; Yang, W.Y.; Deng, C.; Tang, Z. Carbon emission evaluation of recycled fine aggregate concrete based on life cycle assessment. Sustainability 2022, 14, 14448. [Google Scholar] [CrossRef]

- Wang, X.Y. Simulation for optimal mixture design of low-CO2 high-volume fly ash concrete considering climate change and CO2 uptake. Cem. Concr. Compos. 2019, 104, 103408. [Google Scholar] [CrossRef]

- Wang, X.Y.; Lee, H.S. Effect of global warming on the proportional design of low CO2 slag-blended concrete. Constr. Build. Mater. 2019, 225, 1140–1151. [Google Scholar] [CrossRef]

- Li, Y.; Wu, B.; Wang, R. Critical review and gap analysis on the use of high-volume fly ash as a substitute constituent in concrete. Constr. Build. Mater. 2022, 341, 127889. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Ménaché, J.; O’Moore, L.M. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef]

- Yepes-Bellver, L.; Brun-Izquierdo, A.; Alcalá, J.; Yepes, V. CO2-optimization of post-tensioned concrete slab-bridge decks using surrogate modeling. Materials 2022, 15, 4776. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Tae, S.H.; Suk, S.J.; Ford, G.; Yang, K.H. An optimization system for concrete life cycle cost and related CO2 emissions. Sustainability 2016, 8, 361. [Google Scholar] [CrossRef]

- Roberti, F.; Cesari, V.F.; De Matos, P.R.; Pelisser, F.; Pilar, R. High- and ultra-high-performance concrete produced with sulfate-resisting cement and steel microfiber: Autogenous shrinkage, fresh-state, mechanical properties and microstructure characterization. Constr. Build. Mater. 2021, 268, 121092. [Google Scholar] [CrossRef]

- Shin, T.Y.; Kim, J.H.; Koh, K.T.; Ryu, G.S.; Wang, K. Placement of ultra-high performance concrete for inclined-surface pavement. Road Mater. Pavement Des. 2022, 23, 1667–1680. [Google Scholar] [CrossRef]

- Yang, K.H.; Jung, Y.B.; Cho, M.S.; Tae, S.H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

| SiO2 (%) | Al2O3 (%) | CaO (%) | MgO (%) | Na2O (%) | K2O (%) | Fe2O3 (%) | TiO2 (%) | SO3 (%) | P2O5 (%) | Density (kg/m3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P.C | 21.39 | 5.15 | 61.04 | 2.82 | 0.64 | 0.62 | 3.86 | 0.85 | 3.1 | 0.10 | 3190 |

| FA | 48.54 | 27.12 | 3.19 | 11.08 | 1.63 | 2270 | |||||

| GGBS | 26.74 | 12.36 | 41.34 | 4.56 | 3.89 | 0.03 | 2750 | ||||

| SF | 94.57 | 0.67 | 0.34 | 0.23 | 0.82 | 0.15 | 2.07 | 0.90 | 2310 |

| Cement/kg | FA/kg | GGBS/kg | SF/kg | Fine Aggregates/kg | Steel Fibers/% | Superplasticizer/% | Water/kg |

|---|---|---|---|---|---|---|---|

| 565 | 154 | 154 | 154 | 1141 | 2.0 | 1.8 | 164 |

| 569 | 155 | 155 | 155 | 1034 | 2.0 | 1.8 | 165 |

| 582 | 48 | 194 | 145 | 1212 | 2.0 | 1.8 | 165 |

| 632 | 0 | 0 | 158 | 1316 | 2.0 | 1.8 | 223 |

| 642 | 0 | 0 | 148 | 1185 | 2.0 | 1.8 | 158 |

| 653 | 201 | 0 | 151 | 1008 | 4.0 | 1.8 | 161 |

| 675 | 125 | 0 | 115 | 1179 | 0.0 | 2.0 | 180 |

| 679 | 48 | 97 | 145 | 1212 | 2.0 | 1.8 | 155 |

| 690 | 212 | 0 | 159 | 1061 | 3.0 | 1.8 | 191 |

| 692 | 0 | 0 | 148 | 1185 | 2.0 | 1.8 | 158 |

| 692 | 0 | 99 | 148 | 1333 | 2.0 | 1.8 | 134 |

| 703 | 151 | 0 | 151 | 1005 | 4.0 | 1.8 | 161 |

| 718 | 0 | 0 | 127 | 1352 | 2.0 | 1.8 | 152 |

| 736 | 0 | 0 | 156 | 1182 | 2.0 | 1.8 | 173 |

| 741 | 198 | 0 | 148 | 1185 | 2.0 | 1.8 | 158 |

| 750 | 125 | 0 | 115 | 1104 | 0.0 | 2.0 | 180 |

| 754 | 0 | 157 | 136 | 1047 | 3.0 | 1.8 | 209 |

| 763 | 191 | 0 | 106 | 1079 | 2.0 | 1.8 | 173 |

| 775 | 0 | 161 | 136 | 1072 | 2.0 | 1.8 | 193 |

| 776 | 48 | 0 | 145 | 1212 | 2.0 | 1.8 | 165 |

| 777 | 0 | 0 | 108 | 1079 | 2.0 | 1.8 | 173 |

| 790 | 0 | 105 | 158 | 1053 | 3.0 | 1.8 | 189 |

| 800 | 176 | 0 | 150 | 650 | 2.0 | 1.8 | 165 |

| 808 | 0 | 0 | 143 | 1189 | 2.0 | 2.0 | 175 |

| 811 | 0 | 0 | 143 | 1192 | 2.0 | 1.8 | 191 |

| 817 | 0 | 0 | 144 | 1202 | 2.0 | 1.8 | 180 |

| 820 | 0 | 107 | 145 | 1072 | 2.0 | 1.8 | 214 |

| 840 | 0 | 0 | 148 | 1185 | 2.0 | 1.8 | 158 |

| 847 | 0 | 0 | 150 | 997 | 4.0 | 1.8 | 179 |

| 850 | 176 | 0 | 150 | 650 | 2.0 | 1.8 | 165 |

| 857 | 0 | 0 | 151 | 1008 | 4.0 | 1.8 | 191 |

| 861 | 0 | 0 | 152 | 1125 | 2.0 | 1.8 | 202 |

| 865 | 0 | 54 | 153 | 1072 | 2.0 | 1.8 | 193 |

| 868 | 0 | 0 | 153 | 1021 | 3.0 | 2.0 | 183 |

| 870 | 0 | 0 | 154 | 1024 | 3.0 | 2.0 | 189 |

| 875 | 0 | 0 | 154 | 1144 | 2.0 | 1.8 | 206 |

| 890 | 0 | 0 | 157 | 1047 | 3.0 | 1.8 | 209 |

| 900 | 0 | 0 | 100 | 1350 | 0.4 | 2.5 | 170 |

| 903 | 0 | 0 | 159 | 1062 | 2.0 | 1.8 | 204 |

| 1000 | 0 | 0 | 0 | 1350 | 0.4 | 2.5 | 170 |

| Materials | Carbon Emission (kg/ton) | References |

|---|---|---|

| P.C | 931 | [48] |

| FA | 19.6 | [48] |

| GGBS | 26.5 | [49] |

| SF | 14 | [50] |

| Fine aggregate | 1.3 | [48] |

| Steel fiber | 1496.5 | [51] |

| Water-reducing agent | 250 | [48] |

| Water | 0.196 | [48] |

| Type of Transport | Emission Factor kg CO2−e t−1km−1 | ||

|---|---|---|---|

| Road | 0.071 | ||

| Rail | 0.0166 | ||

| Sea | 0.0146 | - | - |

| Min | Max | Average | Range | |

|---|---|---|---|---|

| Cement (kg/m3) | 490 | 1000 | 754.3 | 510 |

| FA (kg/m3) | 0 | 275 | 156.8 | 275 |

| GGBS (kg/m3) | 0 | 275 | 144.6 | 275 |

| SF (kg/m3) | 30 | 210 | 150.2 | 180 |

| Fine aggregate (kg/m3) | 940 | 1408 | 1085.7 | 468 |

| Steel fiber (%) | 1 | 3.5 | 2.11 | 2.5 |

| Water-reducing agent (%) | 0.4 | 2.0 | 1.10 | 1.6 |

| Water (kg/m3) | 142 | 282 | 185.9 | 140 |

| Slump flow (mm) | 300 | 920 | 543.1 | 620 |

| Compressive strength (MPa) | 100.2 | 190.8 | 135.7 | 90.6 |

| Min | Max | Average | Range | |

|---|---|---|---|---|

| 0.140 | 0.477 | 0.239 | 0.337 | |

| 0.120 | 0.300 | 0.171 | 0.180 | |

| 0.65 | 1.60 | 1.03 | 0.95 |

| P.C (kg) | FA (kg) | GGBS (kg) | SF (kg) | Sand (kg) | Steel Fiber (%) | Superplasticizer (%) | Water (kg) | CO2−eM (kg) | CO2−e (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Before optimization | 582 | 145 | 97 | 145 | 1212 | 0.02 | 0.01 | 165 | 788 | 798 |

| Optimized | 512.4 | 216.8 | 180.3 | 165.5 | 923.8 | 1.57 | 1.65 | 222.3 | 678 | 688 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Du, M.; Jia, Y.; Chang, C.; Zhou, S. Carbon Emission Optimization of Ultra-High-Performance Concrete Using Machine Learning Methods. Materials 2024, 17, 1670. https://doi.org/10.3390/ma17071670

Wang M, Du M, Jia Y, Chang C, Zhou S. Carbon Emission Optimization of Ultra-High-Performance Concrete Using Machine Learning Methods. Materials. 2024; 17(7):1670. https://doi.org/10.3390/ma17071670

Chicago/Turabian StyleWang, Min, Mingfeng Du, Yue Jia, Cheng Chang, and Shuai Zhou. 2024. "Carbon Emission Optimization of Ultra-High-Performance Concrete Using Machine Learning Methods" Materials 17, no. 7: 1670. https://doi.org/10.3390/ma17071670