Manufacturing Options for Activated Carbons with Selected Synthetic Polymers as Binders

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Sodium carboxymethylhydrocellulose (CMHC) (Ashland, OR, USA) is refined, water-soluble, high viscosity (1500–2500 mPa*s) anionic polymer that acts as a thickening agent, rheological modifier, binding agent, stabilizer, protective colloid, film-forming agent and water retaining agent. It is patented (Patent No. 4,919,711) as bonding agent for metal ore in metallurgy. CMHC is widely used in toothpastes as a water-binding thickener to prevent syneresis and to impart a semi-fluid state to various paste and ointment formulations. CMHC is also used in creams and adhesive powders for dental prostheses. The preparatory steps for this work assumed the use of CMHC with a high fineness and its uniform wet mixing with carbon [26].

- Poly[1-(2-oxo-1-pyrrolidinyl)ethylene] (POPE) (Ashland, OR, USA) is a water-soluble polymer made from N-vinylpyrrolidone monomer by free radical polymerization. POPE’s varied solubility in aqueous and organic solvent systems, combined with its non-toxic nature, are key properties that provide POPE with excellent flexibility. It is mainly used in the pharmaceutical and cosmetic industries as a filler, increasing the volume of the cosmetic product. As a binder, it ensures the binding of cosmetic product ingredients and tablet formation. Its non-toxic and supports corneal and conjunctival treatment in ophthalmology. Not previously used in the production of activated carbons [27].

- Methyl-hydroxypropyl cellulose (enriched)—MHPC (Ashland, OR, USA) has higher molecular weight than construction binders containing crystalline cellulose. Used as a versatile binder in protective coatings and for clays granulation and extrusion of ceramics. Its use in the molding of bulk products allows it to maintain the shape of molds, e.g., extruded ceramic products. It is also an effective water retaining agent [16,28].

Methods of Solution Preparation

2.2. Manufacturing Process

- Grinding of hard coal and pulverization in industrial mills. The same grinding equipment was used in laboratory and industrial tests.

- Molding of the binder-and-coal-dust paste (prepared in the previous stage); the process was carried out in industrial mixers. The same grinding equipment was used in laboratory and industrial tests.

- Granulation, granules were formed from coal-binder paste; process was carried out in industrial granulators using extrusion elements allowing to obtain granules with a diameter of 4.2 mm. The same grinding equipment was used in laboratory and industrial tests.

- Having dried the granules and pre-hardened their surface, the shaped granules were sent directly to a rotary drum dryer heated by the gas from the carbonization furnaces. Drying was performed at temperatures of 200–400 °C. The same drying equipment was used in laboratory and industrial tests.

- Carbonization of the dried granules was carried out in a laboratory carbonization furnace (lab tests) and in industrial rotary carbonization furnace (technological tests). Carbonization was carried out at a temperature of 800 °C for a period of 60 min. The rotational speed of the furnace was programmed to take 1 rotation for 30–35 s.

- Activation was carried out in laboratory and industrial activation furnaces. Primary activation process was performed only in laboratory conditions in temperature 900 °C and time 120 min. The activating agent was carbon dioxide produced in the activation furnace which was recycled from emitted fumes. An activation in industrial condition was tested as double-stage activation process. The first stage was completed at 900 °C and the second at and 600 °C. The activation time for both stages was 120 min. The activating agents in the process were water steam (H2O) and carbon dioxide (CO2). CO2 was supplied to the furnace as a waste product from the carbonization furnace.

- -

- POPE and MHPC were added to mixer in a dose: 30, 150, 240 g/3 kg of coal,

- -

- CMHC was tested in doses: 30, 150, 240, 360, 450 g/3 kg of coal.

2.3. Analytical Methods

Sample Imaging Using a Scanning Microscope

3. Results and Discussion

3.1. Granulation Process

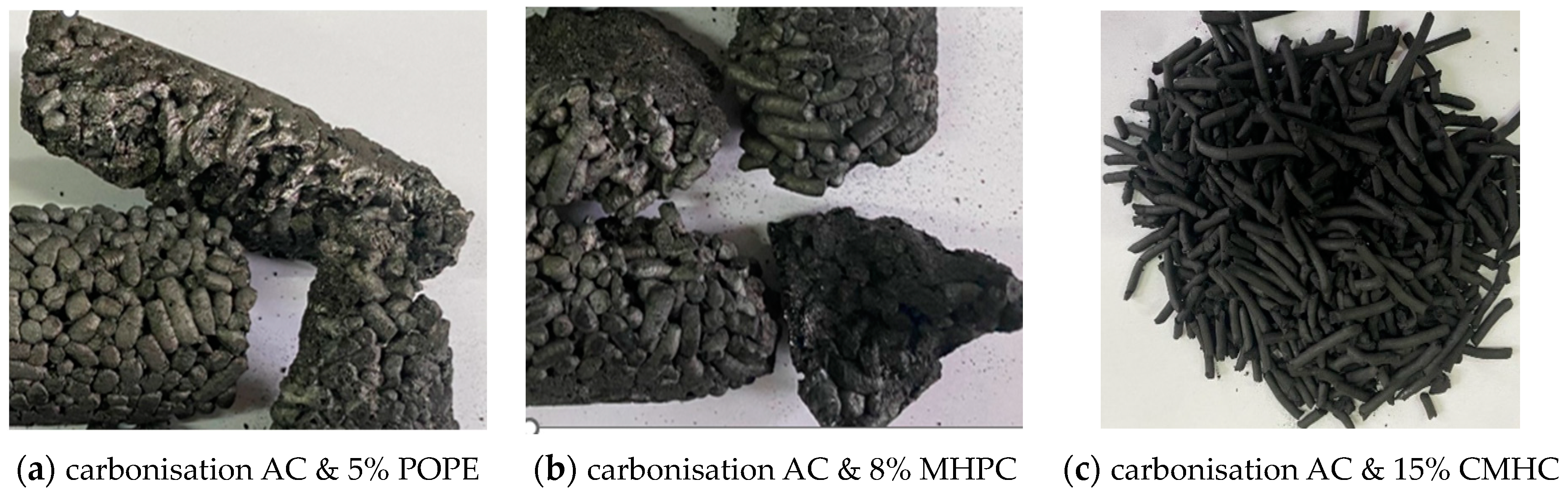

3.2. Carbonization Process

3.3. Activation Process

4. Conclusions

- Until now most granulated AC production was based on the sugar beet molasse as a binder. However, recently, due to inflation and difficult supplies other binders had to be considered. In conducted research there were chosen polymeric binders CMHC, POPE, MHPC used so far for construction or pharmaceutical industry. They have not yet been applied in AC manufacturing.

- It was observed that the formed AC granules, using concentrations of 1% and 5% of tested polymers, were shapeless, short, fragile, deformed quickly and self-agglomerated into larger agglomerates. Only higher concentrations of polymers allowed granules to be formed. With 8, 12 and 15% CMHC, the granules were long, but stable after granulation.

- During the carbonization tests, there was no depolymerization of the AC containing POPE- and MHPC and the granules become fluidized and then agglomerated. Only samples with 8, 12 and 15% CMHC had a high mechanical strength of approx. 99.9% and could be subjected to the activation process.

- The first activation trials were carried out at 900 °C for 120 min. Some of the granules with 15% CMHC were incinerated, so activation of this batch was repeated at the same temperature but shorter time of 90 min. Similar parameters to 15% CMHC reaches also AC with 8% CMHC. To industrial phase of experiments there was chosen AC with 8% CMHC because of economical efficiency. Higher concentration generates a higher investment cost, which are important factor in professional manufacturing.

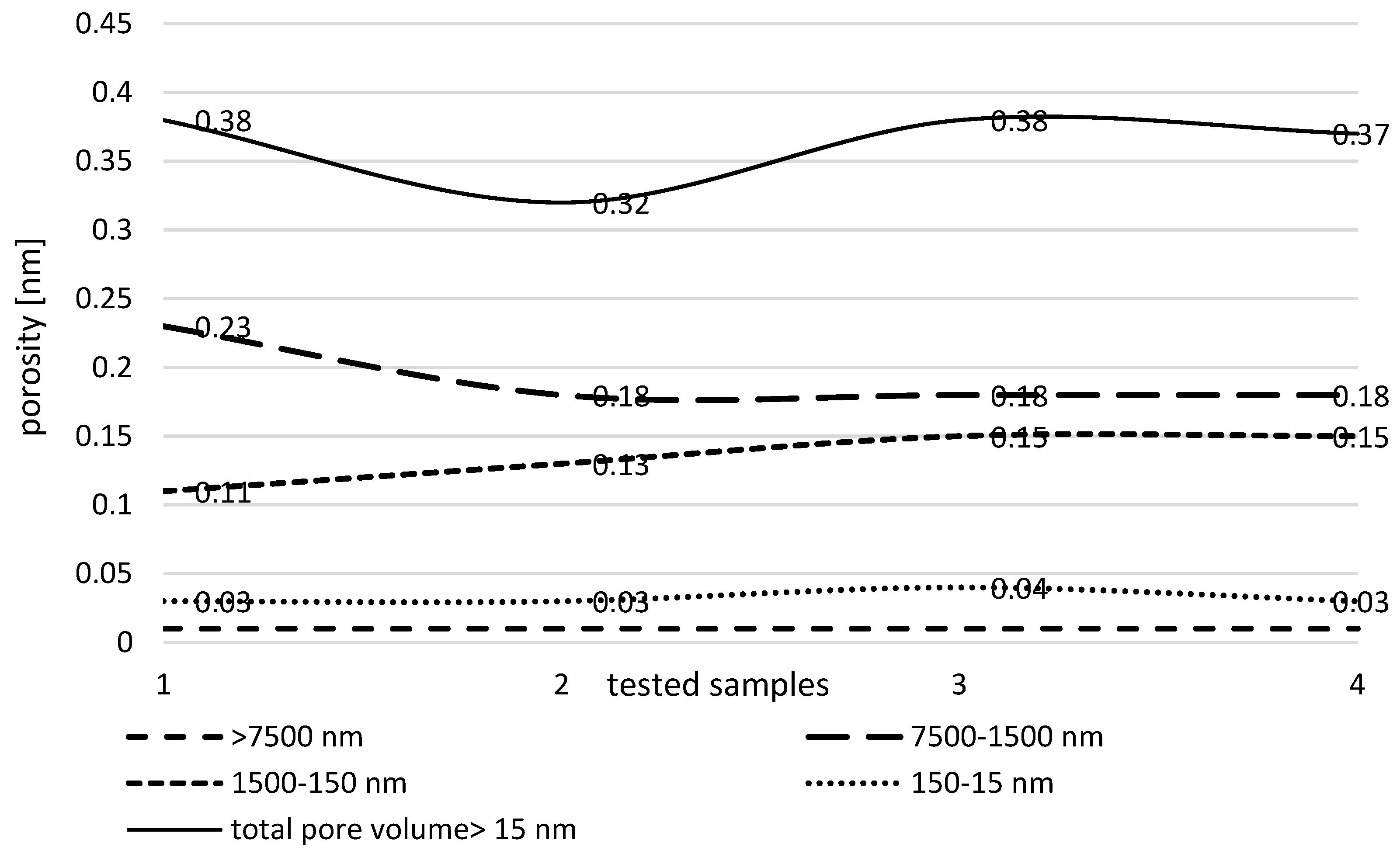

- Tests with single- and double activation of AC with 8% CMHC showed significant increase in the specific surface area and pore volume: BET changed from 774 to 968 m2/g and pore volume form 0.63 to 0.82 cm3/g. Better results were reached for double-stage activation.

- It was observed that, as a result of the modification of the activation process, an increase in the diameter of the internal pores and, consequently, a reduction in the proportion of micropores to 50–70% was observed for the studied granular carbon. However, based on the obtained results, it can be observed that there was an overall increase in the total adsorption capacity, compared to the single-stage activation. It made possible to recognize 8% CMHC as an effective AC’s binder which let to achieve high adsorption and mechanical strength parameters.

- Chemical analyses of the investigated AC surface showed large rate of mineral ions: calcium, silicon and aluminum. Additionally groups with acidic character were recognized: phosphates—0.22%, sulphates—0.20% and chlorides ions 16%. Basic character had only potassium. Acidic groups were reduced in comparison to raw hard coal.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Available online: www.cbt-carbon.com (accessed on 29 December 2023).

- Available online: www.filterpol.com (accessed on 30 December 2023).

- Available online: www.waterfilters.net (accessed on 29 December 2023).

- Xia, Y.; Zuo, H.; Lv, J.; Wei, S.; Yao, Y.; Liu, Z.; Lin, Q.; Yu, Y.; Yu, W.; Huang, Y. Preparation of multi-layered microcapsule-shaped activated biomass carbon with ultrahigh surface area from bamboo parenchyma cells for energy storage and cationic dyes removal. J. Clean. Prod. 2023, 396, 136517. [Google Scholar] [CrossRef]

- Abbas, Q.; Pajak, D.; Frąckowiak, E.; Béguin, F. Effect of binder on the performance of carbon/carbon symmetric capacitors in salt aqueous electrolyte. Electrochim. Acta 2014, 140, 132–138. [Google Scholar] [CrossRef]

- Avantaggiato, G.; Havenaar, R.; Visconti, A. Evaluation of the intestinal absorption of deoxynivalenol and nivalenol by an in vitro gastrointestinal model, and the binding efficacy of activated carbon and other adsorbent materials. Food Chem. Toxicol. 2004, 42, 817–824. [Google Scholar] [CrossRef]

- Chmiola, J.; Yushin, G.; Dash, R.; Gogotsi, Y. Effect of pore size and surface area of carbide derived carbons on specific capacitance. J. Power Sources 2006, 158, 765–772. [Google Scholar] [CrossRef]

- Jjagwe, J.; Wilberforce Olupot, P.; Menya, E.; Mpagi Kalibbala, H. Synthesis and Application of Granular Activated Carbon from Biomass Waste Materials for Water Treatment: A Review. J. Bioresour. Bioprod. 2021, 6, 292–322. [Google Scholar] [CrossRef]

- Suárez-Ruiz, I.; Crelling, J.C. (Eds.) Chapter 8-Coal-Derived Carbon Materials. In Applied Coal Petrology; Academic Press: Cambridge, MA, USA, 2008; pp. 193–225. [Google Scholar] [CrossRef]

- Esfandiari, A.; Kaghazchi, T.; Soleimani, M. Preparation and evaluation of activated carbons obtained by physical activation of polyethyleneterephthalate (PET) wastes. J. Taiwan Inst. Chem. Eng. 2012, 43, 631–637. [Google Scholar] [CrossRef]

- Choma, J.; Czubaszek, M.; Jaroniec, M. Adsorption of dyes from aqueous solutions on active carbons. Ochr. Sr. 2015, 37, 3–14. [Google Scholar]

- Pogorzelska, I. Activated carbon–properties and application. Filtry Plus Filtreon 2019, 17–20. [Google Scholar]

- Li, J.; Ding, X.; Guo, Y.; Wang, L.; Rong, C.; Qu, Y.; Ma, X.; Wang, Z. A simple and highly effective process for the preparation of activated carbons with high surface area. Mater. Chem. Phys. 2011, 127, 495–500. [Google Scholar] [CrossRef]

- Pacheco, F.; Torgal, I.W.; Jonkers, H. Biopolymers and Biotech Admixtures for Eco-Efficient Construction Materials; Woodhead Publishing Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Shanmugam, S. Granulation techniques and technologies: Recent progresses. Bioimpacts 2015, 5, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Iveson, S.M.; Litster, J.D.; Hapgood, K.; Ennis, B.J. Nucleation, growth and breakage phenomena in agitated wet granulation processes: A review. Powder Technol. 2001, 117, 3–39. [Google Scholar] [CrossRef]

- Dürig, T.; Karan, K. Chapter 9-Binders in Wet Granulation. In Handbook of Pharmaceutical Wet Granulation; Narang, A.S., Badawy, S.I.F., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 317–349. [Google Scholar] [CrossRef]

- Batra, A.; Desai, D.; Serajuddin, A.T.M. Investigating the Use of Polymeric Binders in Twin Screw Melt Granulation Process for Improving Compactibility of Drugs. J. Pharm. Sci. 2017, 106, 140–150. [Google Scholar] [CrossRef]

- Thakore, S.D.; Reddy, K.V.; Dantuluri, A.K.; Patel, D.; Kumawat, A.; Sihorkar, V.; Ghoroi, C.; Bansal, A.K. Application of Twin-Screw Melt Granulation to Overcome the Poor Tabletability of a High Dose Drug. Pharm. Res. 2022, 39, 3241–3257. [Google Scholar] [CrossRef] [PubMed]

- Argalis, P.; Jerane, I.; Zhurinsh, A.; Vegerem, K. Assessment of Different Binders for Activated Carbon Granulation for the Use in CO2 Adsorption. Environ. Clim. Technol. 2021, 25, 1086–1100. [Google Scholar] [CrossRef]

- Llamas-Unzueta, R.; Ramírez-Montoya, L.A.; Menéndez, J.A.; Montes-Morán, M.A. Customised Microporous Carbon 3D Structures with Good Mechanical Properties and High Nitrogen Content Obtained from Whey Powders. C 2023, 9, 100. [Google Scholar] [CrossRef]

- Patel, N.G.; Banella, S.; Serajuddin, A.T.M. Moisture Sorption by Polymeric Excipients Commonly Used in Amorphous Solid Dispersions and its Effect on Glass Transition Temperature: II. Cellulosic Polymers. J. Pharm. Sci. 2022, 111, 3114–3129. [Google Scholar] [CrossRef] [PubMed]

- Skoczko, I.; Gumiński, R.; Bos, E.; Zgłobicka, I. Impact of chemical activation on selected adsorption features of powdered activated carbon. Desalination Water Treat. 2021, 243, 165–179. [Google Scholar] [CrossRef]

- Bühler, V. Excipients for Pharmaceuticals-Povidone, Crospovidone and Copovidone; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2005; pp. 1–4. ISBN 978-3-540-23412. [Google Scholar]

- Ducheyne, P. Comprehensive Biomaterials; University of Pennsylvania: Philadelphia, PA, USA, 2011. [Google Scholar]

- Banyai, B.E.; LaSota, D.E.; Struck, D.L. US Patent for Binder for Metal-Containing Ores Patent. U.S. Patent # 4919711, 24 April 1990. [Google Scholar]

- Adamo, A.J.; Hamm, J.D.; Islam, M.; White, K.L.; Vona, S.A., Jr. Methyl Ethyl Hydroxyethyl Cellulose For Personal Care Applications. European Patent EP2651387, 23 October 2013. [Google Scholar]

- Skoczko, I.; Guminski, R. Tests on the Application of Various Types of Biomass for Activated Carbon Production. J. Ecol. Eng. 2024, 25, 285–302. [Google Scholar] [CrossRef]

- Neimark, A.V.; Lin, Y.; Ravikovitch, P.; Thommes, M. Quenched solid density functional theory and pore size analysis of micro-mesoporous carbons. Carbon 2009, 47, 1617–1628. [Google Scholar] [CrossRef]

- Mills, P.J.T.; Seville, J.P.K.; Knight, P.C.; Adams, M.J. The effect of binder viscosity on particle agglomeration in a low shear mixer/agglomerator. Powder Technol. 2000, 113, 140–147. [Google Scholar] [CrossRef]

- Rajniak, P.; Mancinelli, C.; Chern, R.T.; Stepanek, F.; Farber, L.; Hill, B.T. Experimental study of wet granulation in fluidized bed: Impact of the binder properties on the granule morphology. Int. J. Pharm. 2007, 334, 92–102. [Google Scholar] [CrossRef] [PubMed]

- Mahmodi, G.; Zarrintaj, P.; Taghizadeh, A.; Saeb, M.R. From microporous to mesoporous mineral frameworks: An alliance between zeolite and chitosan. Carbohydr. Res. 2020, 489, 107930. [Google Scholar] [CrossRef] [PubMed]

- Plavniece, A.; Dobele, G.; Volperts, A.; Zhurinsh, A. Hydrothermal Carbonization vs. Pyrolysis: Effect on the Porosity of the Activated Carbon Materials. Sustainability 2022, 14, 15982. [Google Scholar] [CrossRef]

- Sultana, M.; Rownok, M.H.; Sabrin, M.; Rahaman, M.H.; Alam, S.N. A review on experimental chemically modified activated carbon to enhance dye and heavy metals adsorption. Clean. Eng. Technol. 2022, 6, 100382. [Google Scholar] [CrossRef]

- Hokkanen, S.; Bhatnagar, A.; Sillanpää, M. A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res. 2016, 91, 156–173. [Google Scholar] [CrossRef] [PubMed]

- Shkolin, A.V.; Men’shchikov, I.E.; Khozina, E.V. Isotropic and anisotropic properties of adsorption-induced deformation of porous carbon materials. Adsorption 2023, 29, 237–253. [Google Scholar] [CrossRef]

- Fomkin, A.A.; Shkolin, A.V.; Pulin, A.L. Adsorption-Induced Deformation of Adsorbents. Colloid J. 2018, 80, 578–586. [Google Scholar] [CrossRef]

- Klosowicz, S.; Zielinski, J.; Raszewski, Z. Mesomorfic state and types of mesophases. Bull. WAT 2022, 71, 115–135. [Google Scholar] [CrossRef]

- Ruiz, I.B.; Parra, J.B.; Pajares, J.A.; Pis, J.J. Effect of coal pre-oxidation on the optical texture and porosity of pyrolysis chars. J. Anal. Appl. Pyrolysis 2005, 75, 27–32. [Google Scholar] [CrossRef]

- Bansal, R.C.; Goyal, M. Activated Carbon Adsorption; Taylor & Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Pourhakkak, P.; Taghizadeh, M.; Taghizadeh, A.; Ghaedi, M. Chapter 2-Adsorbent. In Interface Science and Technology; Ghaedi, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 33, pp. 71–210. [Google Scholar] [CrossRef]

- Skoczko, I.; Guminski, R. Research on the Development of Technologies for the Production of Granulated Activated Carbons Using Various Binders. Materials 2020, 13, 5180. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, R. A review on production and application of activated carbon from discarded plastics in the context of ‘waste treats waste’. J. Environ. Manag. 2023, 325 Pt B, 116613. [Google Scholar] [CrossRef]

- Sych, N.V.; Kartel, N.T.; Nikolaichuk, A.D. Integrated processing of anthracite into sorption materials. Russ. J. Appl. Chem. 2006, 79, 722–726. [Google Scholar] [CrossRef]

- Chul, L.H.; Byamba-Ochir, N.; Shim, W.G.; Balathanigaimani, M.S.; Moon, H. High-performance super capacitors based on activated anthracite with controlled porosity. J. Power Sources 2015, 275, 668–674. [Google Scholar] [CrossRef]

- Yuan, X.; Lee, J.G.; Yun, H.; Deng, S.; Kim, Y.J.; Lee, J.E.; Kwak, S.K.; Lee, K.B. Solving two environmental issues simultaneously: Waste polyethylene terephthalate plastic bottle-derived microporous carbons for capturing CO2. Chem. Eng. J. 2020, 397, 125350. [Google Scholar] [CrossRef]

- Czepirski, L.; Szczurowski, J.; Bałys, M.; Ciesińska, W.; Makomaski, G.; Zieliński, J. Pore structure of activated carbons from waste polymers. Environ. Eng. Prot. 2013, 16, 353–359. [Google Scholar]

- Mendoza-Carrasco, R.; Cuerda-Correa, E.M.; Alexandre-Franco, M.F.; Fernández-González, C.; Gómez-Serrano, V. Preparation of high-quality activated carbon from polyethyleneterephthalate (PET) bottle waste. Its use in the removal of pollutants in aqueous solution. J. Environ. Manag. 2016, 181, 522–535. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Quinlivan, P.A.; Knappe, D.R. Effects of activated carbon surface chemistry and pore structure on the adsorption of organic contaminants from aqueous solution. Carbon 2002, 40, 2085–2100. [Google Scholar] [CrossRef]

- Daud, W.M.A.W.; Houshamnd, A.H. Textural characteristics, surface chemistry and oxidation of activated carbon. J. Nat. Gas Chem. 2010, 19, 267–279. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhao, Y. Effects of activation conditions on BET specific surface area of activated carbon nanotubes. Microporous Mesoporous Mater. 2004, 76, 215–219. [Google Scholar] [CrossRef]

- Siipola, V.; Pflugmacher, S.; Romar, H.; Wendling, L.; Koukkari, P. Low-Cost Biochar Adsorbents for Water Purification Including Microplastics Removal. Appl. Sci. 2020, 10, 788. [Google Scholar] [CrossRef]

- Zuo, H.; Xia, Y.; Liu, H.; Liu, Z.; Huang, Y. Preparation of activated carbon with high nitrogen content from agro-industrial waste for efficient treatment of chromium (VI) in water. Ind. Crops Prod. 2023, 194, 116403. [Google Scholar] [CrossRef]

- Kumar, A.; Jena, H.M. Preparation and characterization of high surface area activated carbon from Fox nut (Euryale ferox) shell by chemical activation with H3PO4. Results Phys. 2016, 6, 651–658. [Google Scholar] [CrossRef]

- Bubanale, S.; Shivashankar, M. History, Method of Production, Structure and Applications of Activated Carbon. Int. J. Eng. Res. 2017, 6, 495–498. [Google Scholar]

- Slasli, A.M.; Jorge, M.; Stoeckli, F.; Seaton, N.A. Modelling of water adsorption by activated carbons: Effects of microporous structure and oxygen content. Carbon 2004, 42, 1947–1952. [Google Scholar] [CrossRef]

| CMHC | POPE | MHPC | |

|---|---|---|---|

| Molecular formula | [C6H7O2(OH)2OCH2COONa]n | (C6H9NO)n | C56H108O30 |

| Molecular weight g/mol | 250,000 | 35,000 | 6.1 × 105 |

| pH | 6.5–8.5 | 3–7 | 5–8 |

| Density g/cm3 | 750 | 1.2 | 0.410 |

| Viscosity mPa*s | 2000 | 5000 | 20,000 |

| Melting point °C | 274 | 180 | 250 |

| Appearance | white fibrous powder | yellowish hygroscopic amorphous powder | white powder |

| Pulp | Raw Materials for AC Processing |

|---|---|

| 1. | 3 kg ground coal, 800 mL water, 30 g CMHC (1%) |

| 2. | 3 kg ground coal, 800 mL water, 30 g POPE (1%) |

| 3. | 3 kg ground coal, 900 mL water, 150 g CMHC (5%) |

| 4. | 3 kg ground coal, 900 mL water, 150 g POPE (5%) |

| 5. | 3 kg ground coal, 1000 mL water, 0.2 kg molasse, 150 g CMHC (5%) |

| 6. | 3 kg ground coal, 1200 mL water, 450 g CMHC (15%) |

| 7. | 3 kg ground coal, 1200 mL water,150 g MHPC -2 (5%) |

| 8. | 3 kg ground coal, 900 mL water, 240 g CMHC (8%) |

| 9. | 3 kg ground coal, 1100 mL water, 360 g CMHC (12%) |

| 10. | 3 kg ground coal, 900 mL water, 240 g POPE (8%) |

| 11. | 3 kg ground coal, 900 mL water, 240 g MHPC-2 (8%) |

| Parameter | Standard [28] | |

|---|---|---|

| 1. | Bulk Density (BD) | PN-74/C-97554 |

| 2. | Water Absorption (WA) | PN-74/C-97554 |

| 3. | Specific Surface Area (SSA) | PN-74/C-97554 |

| 4. | Volatile Matter (VM) | PN-EN 1860-2:2006 |

| 5. | Elemental carbon (C) | PN-EN 1860-2:2006 |

| 6. | Ash (A) | PN-84/C-97555/08 |

| 7. | Moisture (M) | PN-84/C-97555/09 |

| 8. | Methylene Numbe (MNo)r | PN-82/C-97555.03 |

| 9. | Iodine Number (INo) | PN-83/C-97555.04 |

| 10. | BET surface | PN-ISO 9277 |

| 11. | Sieve analysis (SA) | PN-87/C-97555.01 |

| 12. | Pore volume * (PV) | Company own instruction manual |

| 13. | Mechanical Strength | Company own instruction manual; PN-90/C-97554 |

| 14. | Abrasion | PN-90/C-97554; PN-EN 12915-1 |

| Batch Weight [g] | Yield [g] | Efficiency [%] | BD [g/dm3] | Ash [%] | VM [%] | Flash Point [°C] | Mech. Strength [%] | |

|---|---|---|---|---|---|---|---|---|

| 1 | 660 | granules agglomerated | ||||||

| 2 | 660 | granules agglomerated | ||||||

| 3 | 660 | granules agglomerated | ||||||

| 4 | 660 | granules agglomerated | ||||||

| 5 | 660 | granules agglomerated | ||||||

| 6 | 500 | 327 | 65.4 | 520 | 7.59 | 3.45 | 318 | 95.9 |

| 7 | 660 | granules agglomerated | ||||||

| 8 | 500 | 338 | 67.6 | 570 | 6.89 | 2.77 | 330 | 97.9 |

| 9 | 500 | 330 | 66 | 539 | 7.66 | 2.34 | 339 | 99.9 |

| 10 | 500 | granules agglomerated | ||||||

| 11 | 500 | granules agglomerated |

| Parameter | 120 min | 90 min | ||

|---|---|---|---|---|

| CMHC (15%) | CMHC (12%) | CMHC (8%) | CMHC (15%) | |

| Batch weight [g] | 450 | 450 | 450 | 450 |

| Yield [g] | 122 | 157 | 162 | 159 |

| Efficiency [%] | 27.1 | 34.8 | 36 | 35.3 |

| Density [g/dm3] | 394 | 428 | 430 | 428 |

| Ash [%] | 35.83 | 12.84 | 11.78 | 15.95 |

| Water absorption [cm3/g] | 0.37 | 0.44 | 0.41 | 0.57 |

| Abrasion [%] | 0.25 | 0.2 | 0.1 | 0.2 |

| Granule diameter [mm] | 1.54 | 1.88 | 1.74 | 1.84 |

| Granule contraction rel.to dryied [%] | 10.58 | 7.02 | 6.11 | 8.58 |

| Volitile matter [%} | 44.5 | 21.7 | 18.6 | 18.8 |

| INo [mg/g] | 843 | 853 | 854 | 823 |

| Mech. Strenght [%] | 98.3 | 98.5 | 99.9 | 99.9 |

| BET surface [m2/g] | 722.5 | 764.9 | 782.6 | 788.1 |

| Pores volume [cm3/g] | 0.58 | 0.52 | 0.54 | 0.53 |

| Sieve analysis (residues) [%] | ||||

| 3.5 mm | 0.7 | 0.6 | 0.6 | 0.6 |

| 2.75 mm | 19.6 | 18.6 | 16.8 | 17.6 |

| 2.0 mm | 59.7 | 60.01 | 61.23 | 60.7 |

| 1.5 mm | 18.4 | 19.7 | 20.05 | 19.2 |

| <1.0 | 1.6 | 1.09 | 1.32 | 1.9 |

| 1-Stage Activation | 2-Stage Activation | |

|---|---|---|

| Batch weight [g] | 450 | 162 |

| Yield [g] | 162 | 135 |

| Efficiency [%] | 36 | 83.1 |

| Density [g/dm3] | 669 | 428 |

| Ash [%] | 18.15 | 12.84 |

| Water absorption [cm3/g] | 0.42 | 0.48 |

| Abrasion [%] | 0.1 | 0.2 |

| Granule diameter [mm] | 1.88 | 1.72 |

| Granule contraction rel.to dryied [%] | 8.13 | 7.02 |

| Volitile matter [%} | 18.15 | 9.91 |

| INo [mg/g] | 811 | 862 |

| Mech. Strenght [%] | 99.7 | 99.9 |

| BET surface [m2/g] | 774.3 | 968.1 |

| Pores volume [cm3/g] | 0.63 | 0.82 |

| Sieve analysis (residues) {%} | ||

| 3.5 mm | 0.6 | 0.3 |

| 2.75 mm | 16.8 | 13.6 |

| 2.0 mm | 61.23 | 68.01 |

| 1.5 mm | 20.05 | 17.14 |

| <1.0 | 1.32 | 0.95 |

| Element | Net Counts | Weight % | Atom % |

|---|---|---|---|

| C | 868,222 | 47.30 | 55.57 |

| O | 262,984 | 48.15 | 42.46 |

| Mg | 3174 | 0.12 | 0.07 |

| Al | 9260 | 0.27 | 0.14 |

| Si | 61,313 | 1.61 | 0.81 |

| P | 8980 | 0.22 | 0.10 |

| S | 8413 | 0.20 | 0.09 |

| Cl | 5690 | 0.16 | 0.06 |

| K | 4327 | 0.14 | 0.05 |

| Ca | 51,794 | 1.85 | 0.65 |

| Total | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skoczko, I.; Szatyłowicz, E.; Tabor, A.; Gumiński, R. Manufacturing Options for Activated Carbons with Selected Synthetic Polymers as Binders. Materials 2024, 17, 1753. https://doi.org/10.3390/ma17081753

Skoczko I, Szatyłowicz E, Tabor A, Gumiński R. Manufacturing Options for Activated Carbons with Selected Synthetic Polymers as Binders. Materials. 2024; 17(8):1753. https://doi.org/10.3390/ma17081753

Chicago/Turabian StyleSkoczko, Iwona, Ewa Szatyłowicz, Adam Tabor, and Remigiusz Gumiński. 2024. "Manufacturing Options for Activated Carbons with Selected Synthetic Polymers as Binders" Materials 17, no. 8: 1753. https://doi.org/10.3390/ma17081753

APA StyleSkoczko, I., Szatyłowicz, E., Tabor, A., & Gumiński, R. (2024). Manufacturing Options for Activated Carbons with Selected Synthetic Polymers as Binders. Materials, 17(8), 1753. https://doi.org/10.3390/ma17081753