Study on Characteristics of Failure and Energy Evolution of Different Moisture-Containing Soft Rocks under Cyclic Disturbance Loading

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

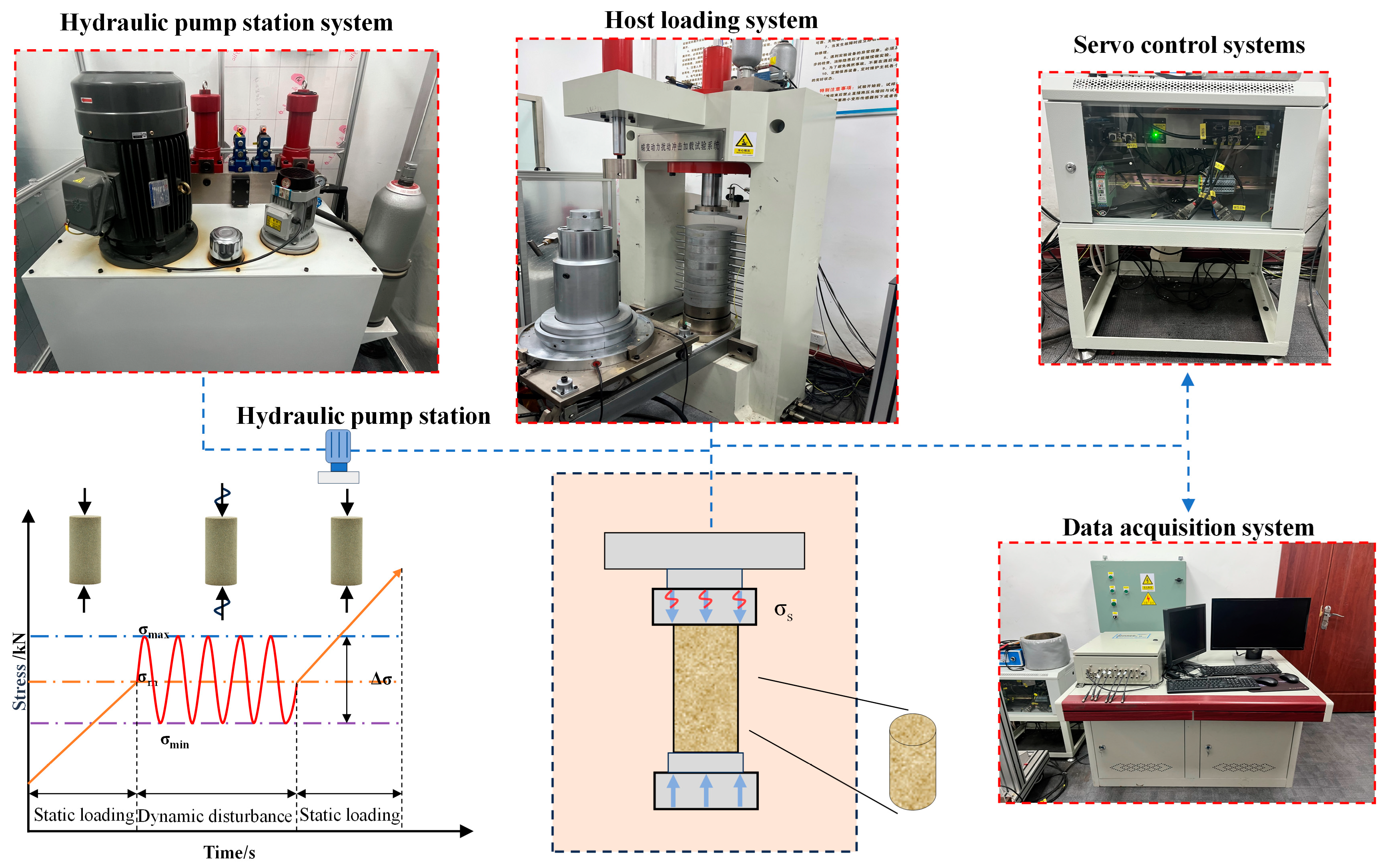

2.2. Experimental Equipment and Protocol

3. Analysis of Experimental Results

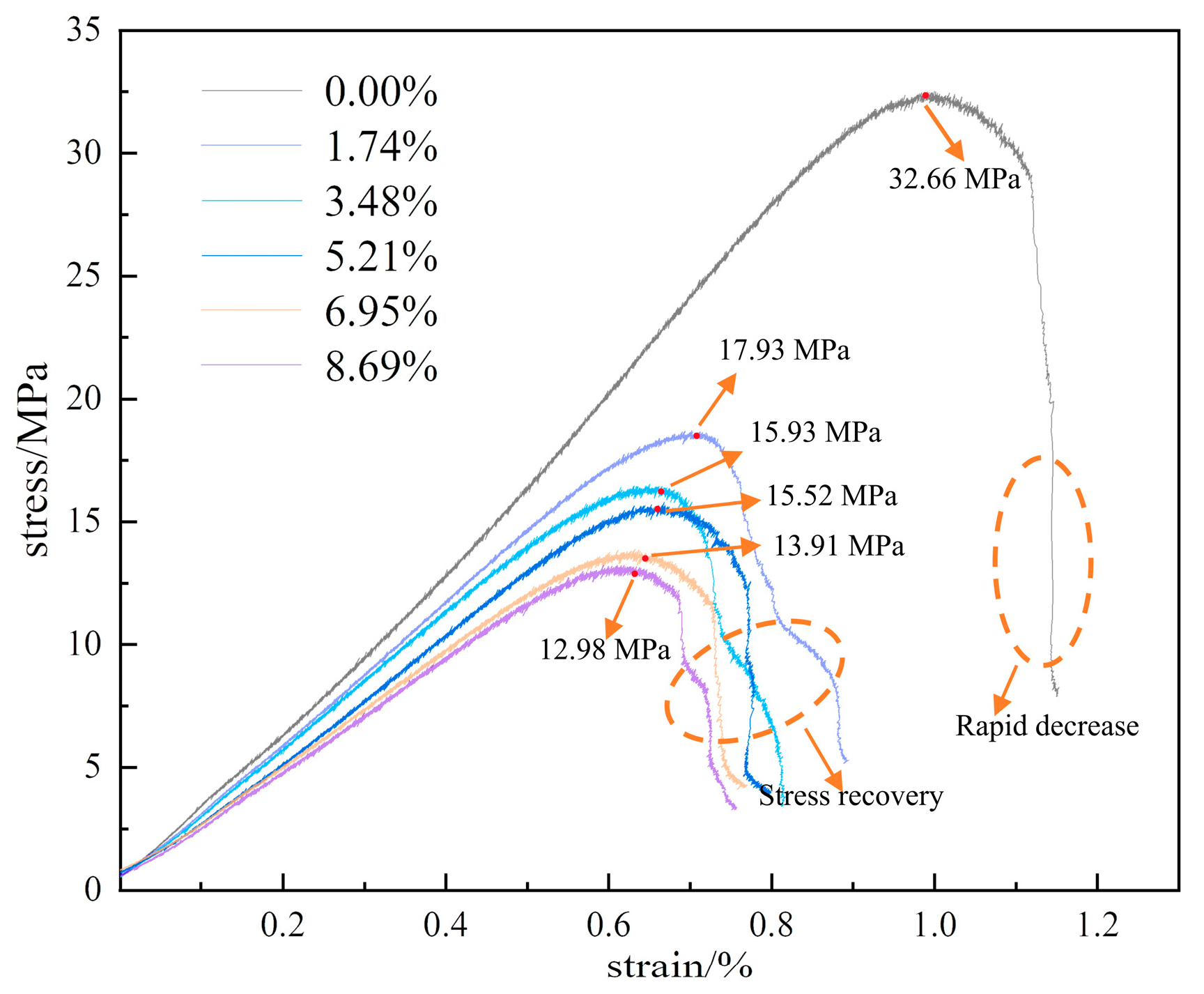

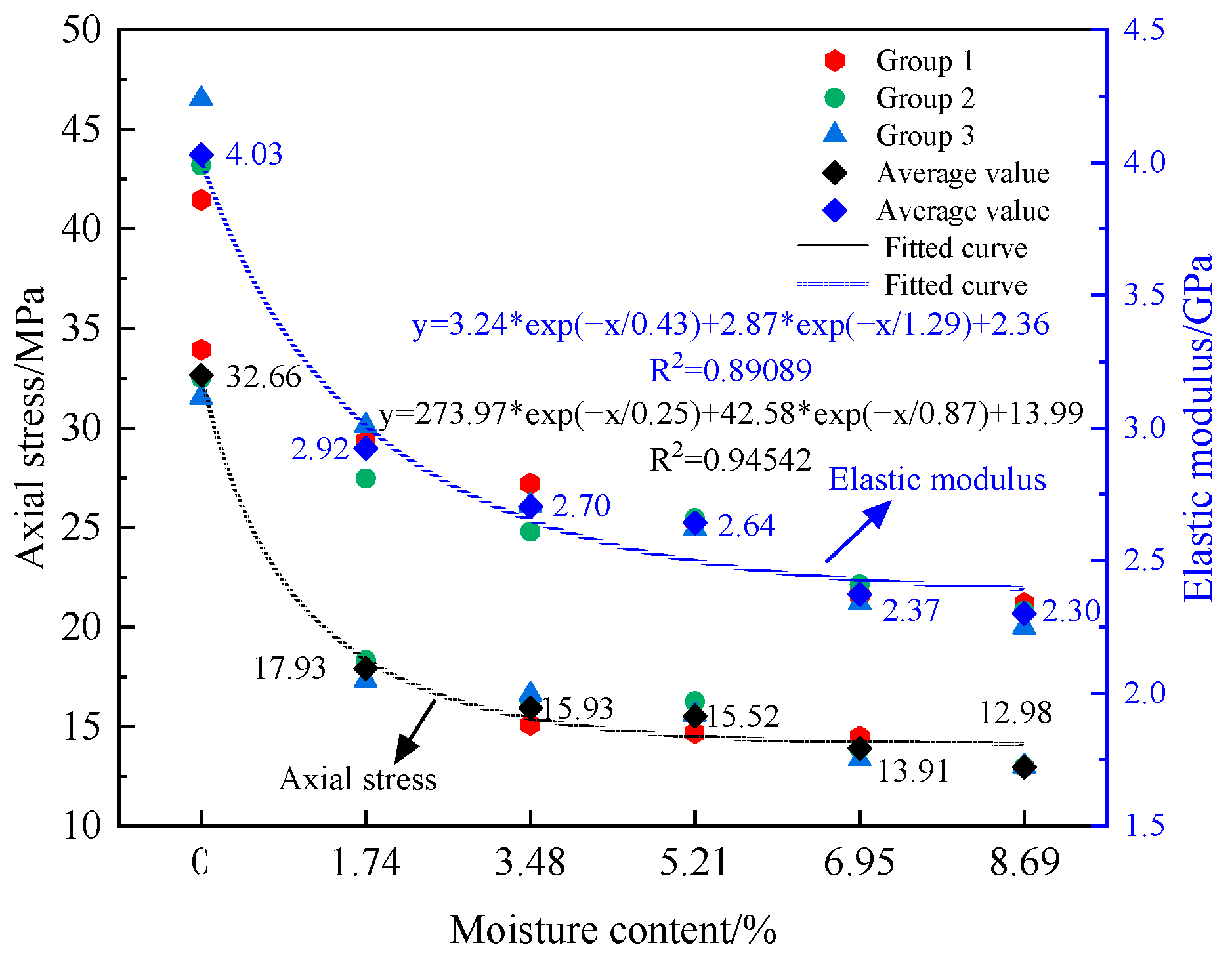

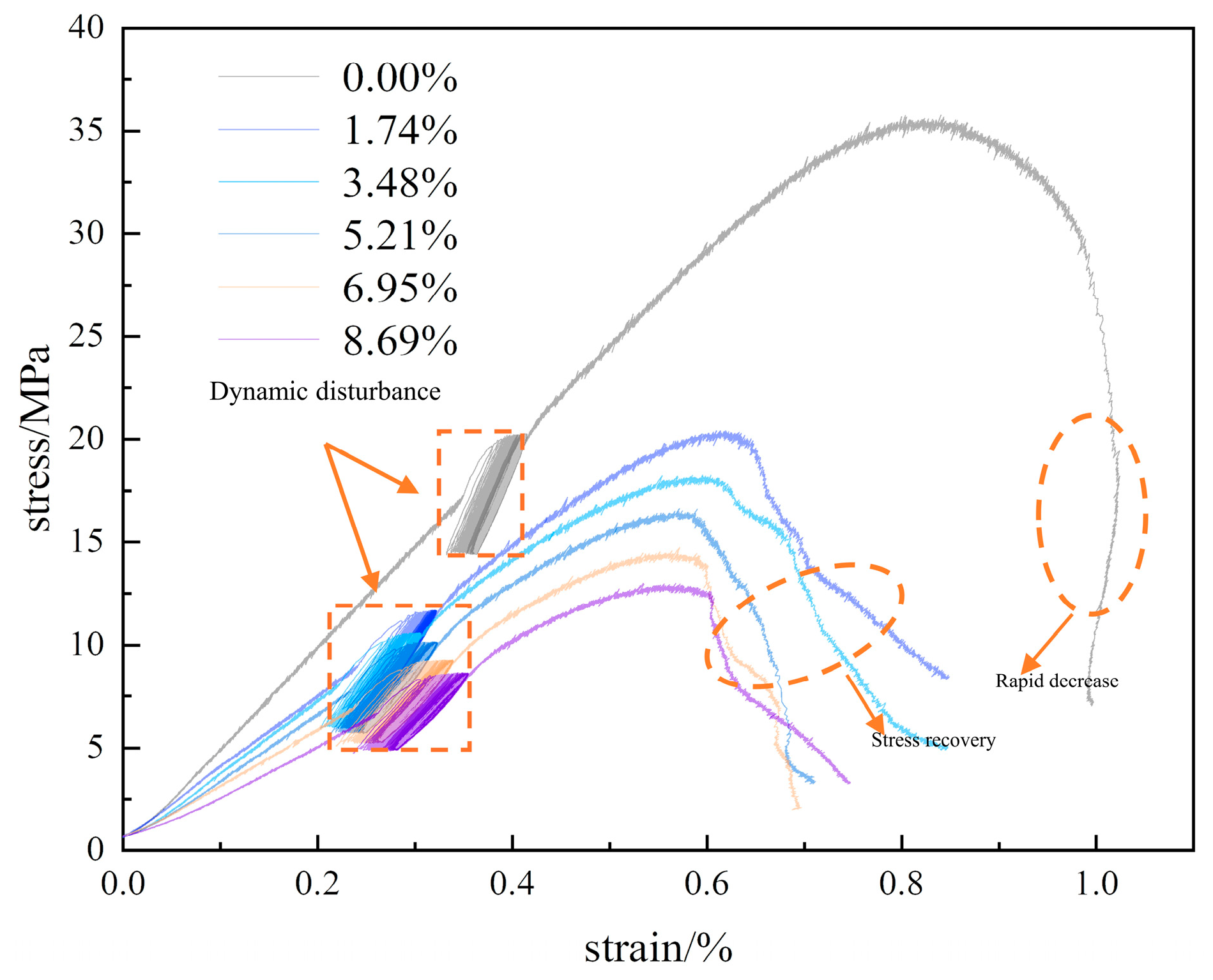

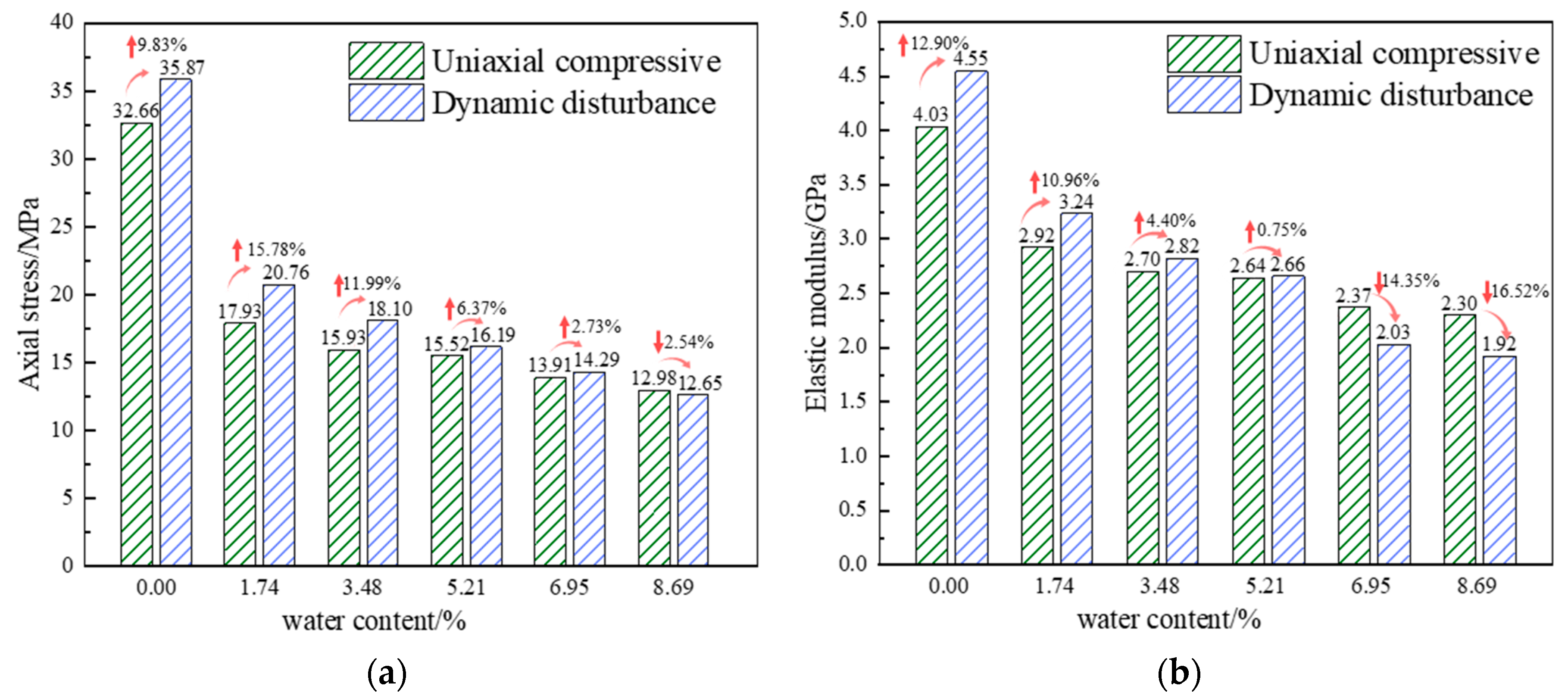

3.1. Mechanical Properties Analysis

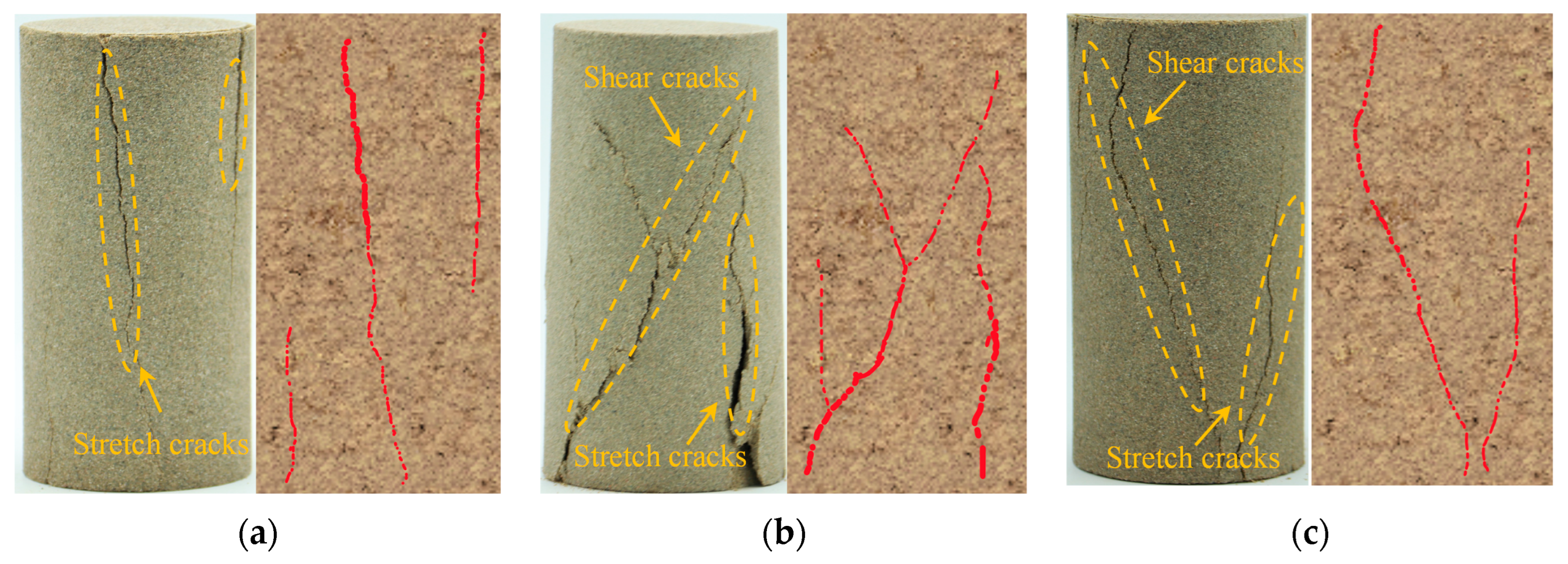

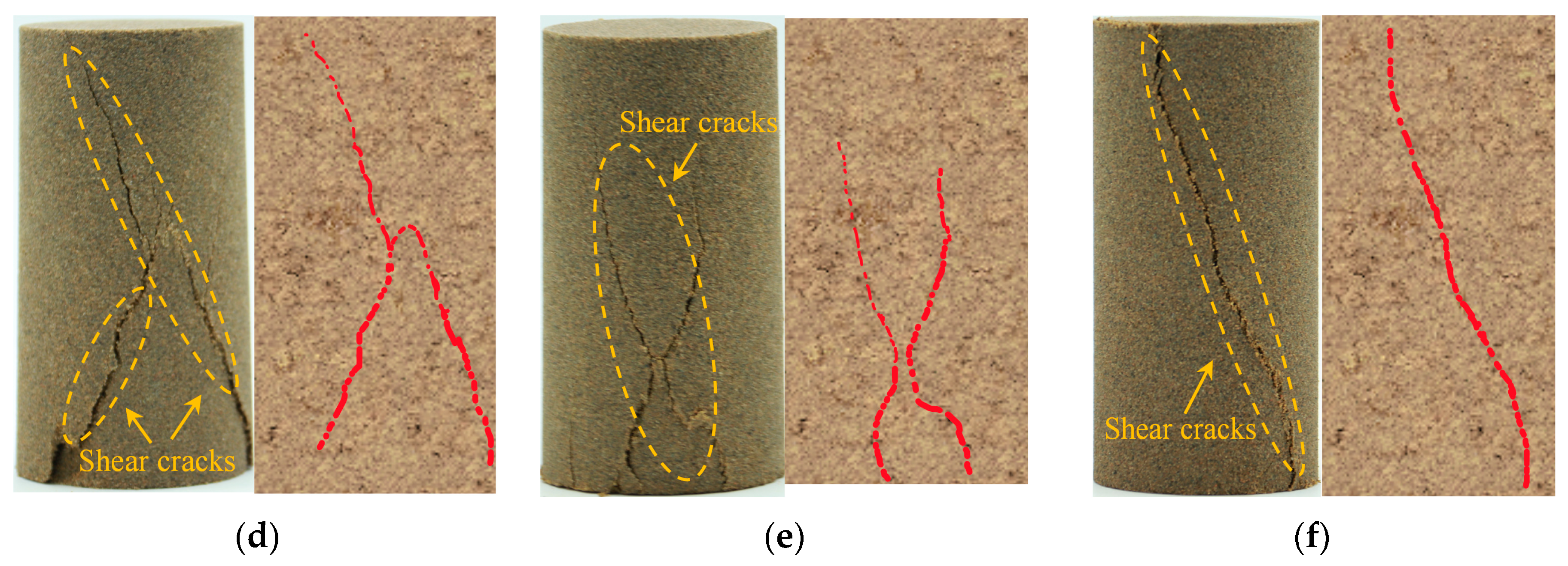

3.2. Macro-Destructive Features

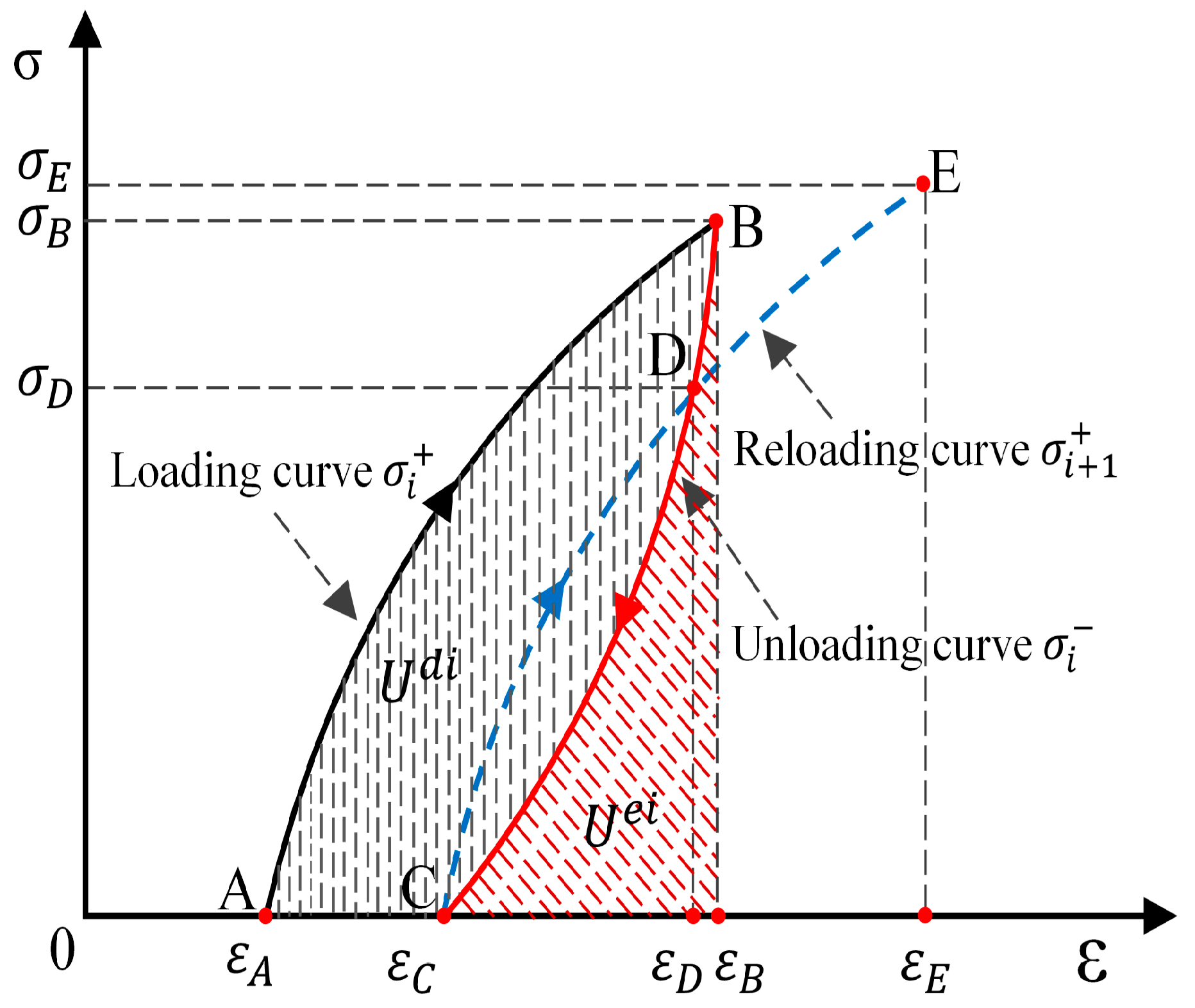

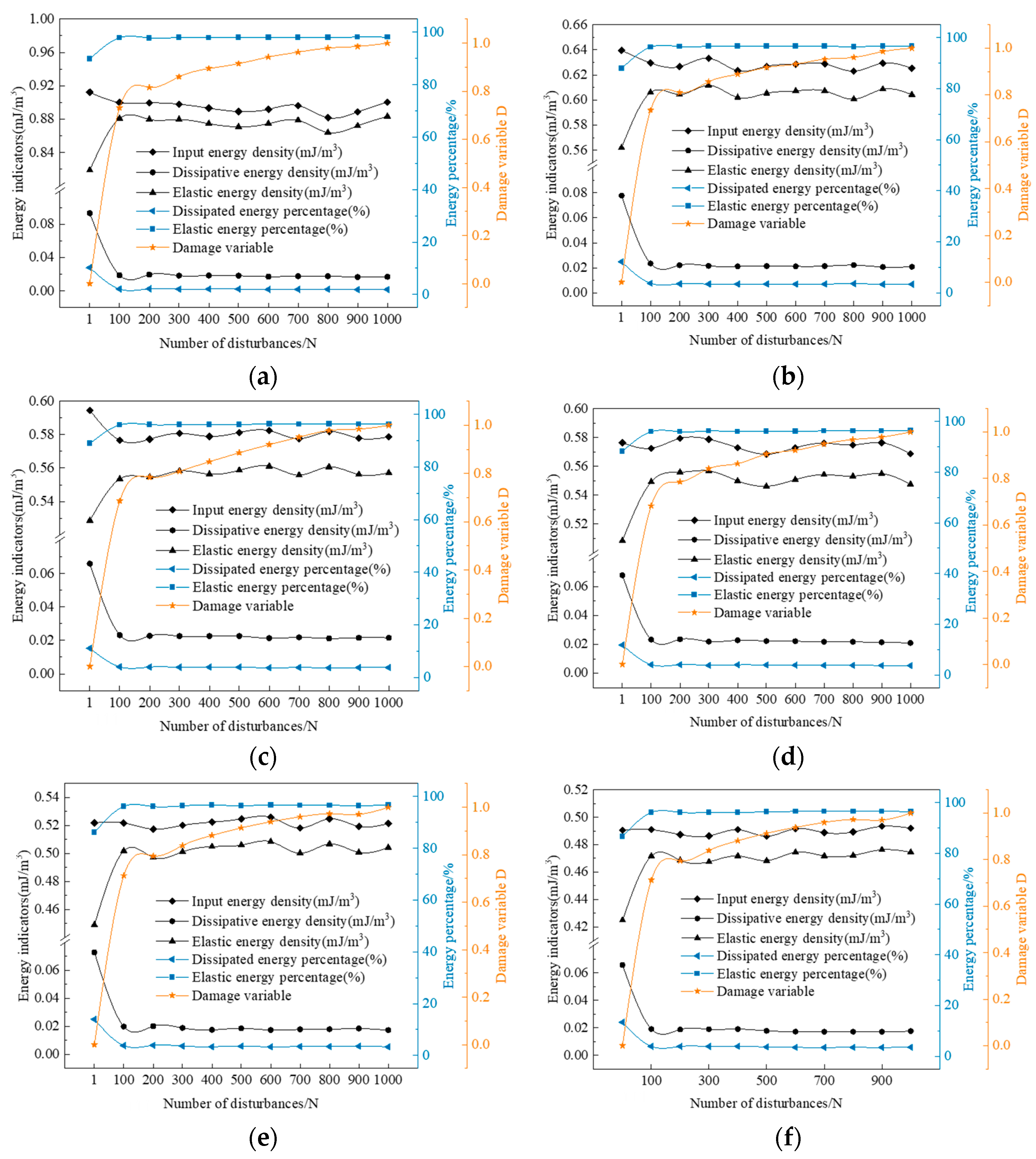

3.3. Characteristics of Energy Evolution

4. Discussion

5. Conclusions

- (1)

- Mudstone is significantly influenced by its water content. The uniaxial compressive strength of mudstone decreases from 32.66 MPa to 12.98 MPa, resulting in a softening coefficient of 0.397. The elastic modulus decreases from 4.03 GPa to 2.30 GPa, with a coefficient of 0.571. In the samples, peak strength and elastic modulus exhibit an exponential decrease with increasing water content.

- (2)

- In cyclic disturbance experiments, compressive strengths of unsaturated samples generally increase to varying degrees, while saturated samples decrease in strength. The elastic modulus of the samples shows a strengthening effect under cyclic disturbance loading at 6.95% in the saturated water state but exhibits a weakening effect in other cases. Cyclic disturbance loading does not change the failure mode of the samples; that is, dry samples become brittle while wet samples fail in a plastic manner.

- (3)

- All samples adapt to external disturbance loading within the first 100 cycles and then maintain relative stability. An inverse relationship is observed between energy indicators and water content. The variation trends of energy indicators for different water-containing samples are nearly identical, with a turning point occurring near 100 cycles. During the cyclic disturbance loading, energy is mainly stored as elastic energy within the samples. The evolution of damage in different water-containing soft rocks can be divided into two, an accelerating and a stable accumulation phase. Damage accumulation accelerates from the 1st to the 100th cycle, then stabilizes after 100 cycles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.P.; Gao, F.; Ju, Y.; Gao, M.Z.; Zhang, R.; Gao, Y.N.; Liu, J.F.; Xie, L.Z. Quantitative definition and investigation of deep mining. J. Chin. Coal Soc. 2015, 40, 1–10. [Google Scholar] [CrossRef]

- Wang, X.F.; Chen, X.Y.; Wang, J.Y.; Chang, Z.C.; Qin, D.D.; Hang, Q.X. Study on creep failure mechanism and control of the deep soft rock roadway in pingdingshan mining area. J. Min. Saf. Eng. 2023, 40, 1139–1150. [Google Scholar] [CrossRef]

- Hang, B.X.; Zhang, N.; Jing, H.W.; Kan, J.G.; Meng, B.; Li, N.; Xie, W.B.; Jiao, J.B. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. Chin. Coal Soc. 2020, 45, 911–926. [Google Scholar]

- Braunagel, M.J.; Griffith, W.A. The Effect of Dynamic Stress Cycling on the Compressive Strength of Rocks. Geophys. Res. Lett. 2019, 46, 6479–6486. [Google Scholar] [CrossRef]

- Aydan, Ö.; Kodate, S.; Iwata, N. The effect of aspect ratio of rock samples on the dynamic characteristics of rocks under shock loads. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 042063. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S. Numerical studies of floor heave mechanism and the effectiveness of grouting reinforcement of roadway in soft rock containing the mine water. Int. J. Rock Mech. Min. Sci. 2023, 170, 105484. [Google Scholar] [CrossRef]

- Moghaddam, R.H.; Golshani, A. Fatigue behavior investigation of artificial rock under cyclic loading by using discrete element method. Eng. Fail. Anal. 2024, 160, 108105. [Google Scholar] [CrossRef]

- Gegenhuber, N.; Krueger, M. Linking static and dynamic mechanical properties for metamorphic rocks from Austria including their anisotropic effect. Acta Geophys. 2021, 69, 539–546. [Google Scholar] [CrossRef]

- Heierli, J. The critical pressures for crack closure, crack reopening and crack instability in hydraulic fracturing. Int. J. Rock Mech. Min. Sci. 2024, 176, 105680. [Google Scholar] [CrossRef]

- Noël, C.; Baud, P.; Violay, M. Effect of water on sandstone’s fracture toughness and frictional parameters: Brittle strength constraints. Int. J. Rock Mech. Min. Sci. 2021, 147, 104916. [Google Scholar] [CrossRef]

- Ozoji, T.M.; Zhang, Z.X.; Aladejare, A.E.; Zhang, N.B.; Paasovaara, N.; Arrieta, M.R. Effect of strain rate on specific fracture energy and micro-fracture surface properties of rock specimen under dynamic uniaxial compression. Eng. Fract. Mech. 2024, 295, 109763. [Google Scholar] [CrossRef]

- Villalobos, F.A.; Rodríguez, P.A.; Vera, M. Study of the anisotropic tensile and compressive strength of a foliated phyllite. Proc. Inst. Civ. Eng. Geotech. Eng. 2023, 176, 15–26. [Google Scholar] [CrossRef]

- Driouch, A.; Ouadif, L.; Lahmili, A.; Belmi, M.A. Evaluation of the Compression Potential of Serpentine Rock Masses of the Bou Azzer Mining District in the Central Anti-Atlas of Morocco. Min. Met. Explor. 2022, 39, 189–200. [Google Scholar] [CrossRef]

- Padmanabha, V.; Schäfer, F.; Rae, A.S.P.; Kenkmann, T. Dynamic Split Tensile Strength of Basalt, Granite, Marble and Sandstone: Strain Rate Dependency and Fragmentation. Rock Mech. Rock Eng. 2023, 56, 109–128. [Google Scholar] [CrossRef]

- Stavropoulou, M.; Xiroudakis, G. Fracture Frequency and Block Volume Distribution in Rock Masses. Rock Mech. Rock Eng. 2020, 53, 4673–4689. [Google Scholar] [CrossRef]

- Alneasan, M.; Alzo’ubi, A.K.; Ibrahim, F. A comparison between conventional and generalized fracture criteria to predict fracture parameters in clay rich rocks (Mudstone) under temperature effect. Constr. Build. Mater. 2024, 416, 135168. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Liang, B.; Wang, D.; Luan, H.J.; Zhang, G.C.; Dong, L.; Chen, L.G. Experimental study on failure mechanical properties and acoustic emission characteristics of soft rock–coal combination under dynamic disturbance. Eng. Fail. Anal. 2024, 158, 108016. [Google Scholar] [CrossRef]

- Dehghanipoodeh, M.; Baghbanan, A.; Hashemolhosseini, H.; Laghaei, M.; Salimian, M.H. Investigating the deformability of grouted rock mass under static and dynamic loading conditions. Bull. Eng. Geol. Environ. 2019, 78, 4549–4566. [Google Scholar] [CrossRef]

- Malik, A.; Chakraborty, T.; Rao, K.S. Strain rate effect on the mechanical behavior of basalt: Observations from static and dynamic tests. Thin-Walled Struct. 2018, 126, 127–137. [Google Scholar] [CrossRef]

- Dong, L.; Wang, D.; Sun, X.M.; Jiang, Y.J.; Luan, H.J.; Zhang, G.C.; Zhou, G.L.; Liang, B. Experimental Study on the Mechanical Properties and Acoustic Emission Characteristics of Deep Soft Rocks under Low-Frequency Dynamic Disturbance. Appl. Sci. 2023, 13, 6399. [Google Scholar] [CrossRef]

- Arora, K.; Chakraborty, T.; Rao, K.S. Experimental Study on Stiffness Degradation of Rock Under Uniaxial Cyclic Sinusoidal Compression Loading. Rock Mech. Rock Eng. 2019, 52, 4785–4797. [Google Scholar] [CrossRef]

- Roy, D.G.; Singh, T.N.; Kodikara, J.; Das, R. Effect of Water Saturation on the Fracture and Mechanical Properties of Sedimentary Rocks. Rock Mech. Rock Eng. 2017, 50, 2585–2600. [Google Scholar]

- Manogharan, P.; Wood, C.; Marone, C.; Elsworth, D.; Rivière, J.; Shokouhi, P. Nonlinear elastodynamic behavior of intact and fractured rock under in-situ stress and saturation conditions. J. Mech. Phys. Solids 2021, 153, 104491. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Peter, M. Effects of saturation medium and pressure on strength parameters of Latrobe Valley brown coal: Carbon dioxide, water and nitrogen saturations. Energy 2011, 36, 6941–6947. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.J.; Han, Z.Y.; Naser, G.; Liang, P.; Xie, Z.W. Influence of moisture content and intermediate principal stress on cracking behavior of sandstone subjected to true triaxial unloading conditions. Eng. Fail. Anal. 2023, 248, 109265. [Google Scholar] [CrossRef]

- Sun, X.M.; Jiang, M.; Wang, X.B.; Zang, J.C.; Gang, X.; Miao, C.Y. Experimental study on creep mechanical properties of sandstone with different water contents in Wanfu coal mine. Rock Soil. Mech. 2023, 44, 624–636. [Google Scholar]

- Zhang, Z.N.; Chi, X.L.; Yang, K.; Lyu, X.; Wang, Y. Studies on the Deformation and Macro–Micro-Damage Characteristics of Water-Bearing Sandstone under Cyclic Loading and Unloading Tests. ACS Omega 2023, 8, 19843–19852. [Google Scholar] [CrossRef]

- Ullah, B.; Zhou, Z.L.; Cai, X.; Lu, J.Y.; Zhao, C.C. Failure prediction and microcracks development based on acoustic emission and energy evolution for different rocks treated with freeze–thaw weathering. Bull. Eng. Geol. Environ. 2023, 82, 471. [Google Scholar] [CrossRef]

- Meng, Q.B.; Liu, J.F.; Pu, H.; Huang, B.X.; Zhang, Z.Z.; Wu, J.Y. Effects of cyclic loading and unloading rates on the energy evolution of rocks with different lithology. Geomech. Energy Environ. 2023, 34, 100455. [Google Scholar] [CrossRef]

- Tarasov, B.G.; Stacey, T.R. Features of the Energy Balance and Fragmentation Mechanisms at Spontaneous Failure of Class I and Class II Rocks. Rock Mech. Rock Eng. 2017, 50, 2563–2584. [Google Scholar] [CrossRef]

- Hu, S.C.; Zhang, C.X.; Ru, W.K.; Han, J.M.; Guo, S.H.; Zhou, X.D.; Yang, L. Creep properties and energy evolution characteristics of weakly cemented rock under step loading. Int. J. Rock Mech. Min. Sci. 2023, 170, 105428. [Google Scholar] [CrossRef]

- Xiao, J.Q.; Ding, D.X.; Jiang, F.L.; Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock Mech. Min. Sci. 2010, 47, 461–468. [Google Scholar] [CrossRef]

| Rock Sample Number | Average Water Content (%) | σm (MPa) | Δσ (kN) | Frequency (Hz) | Number of Disturbances/N |

|---|---|---|---|---|---|

| R0-1 | 0 | 16.33 | 10 | 5 | 1000 |

| R0-2 | 10 | 5 | 1000 | ||

| R0-3 | 10 | 5 | 1000 | ||

| R2-1 | 1.74 | 8.97 | 10 | 5 | 1000 |

| R2-2 | 10 | 5 | 1000 | ||

| R2-3 | 10 | 5 | 1000 | ||

| R4-1 | 3.48 | 7.97 | 10 | 5 | 1000 |

| R4-2 | 10 | 5 | 1000 | ||

| R4-3 | 10 | 5 | 1000 | ||

| R6-1 | 5.21 | 7.76 | 10 | 5 | 1000 |

| R6-2 | 10 | 5 | 1000 | ||

| R6-3 | 10 | 5 | 1000 | ||

| R8-1 | 6.95 | 6.96 | 10 | 5 | 1000 |

| R8-2 | 10 | 5 | 1000 | ||

| R8-3 | 10 | 5 | 1000 | ||

| R10-1 | 8.68 | 6.49 | 10 | 5 | 1000 |

| R10-2 | 10 | 5 | 1000 | ||

| R10-3 | 10 | 5 | 1000 |

| Moisture Content (%) | Number of Disturbances (N) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

| 0.00 | 0.9122 | 0.8998 | 0.8994 | 0.8980 | 0.8932 | 0.8891 | 0.8918 | 0.8963 | 0.8817 | 0.8886 | 0.9004 |

| 1.74 | 0.6396 | 0.6296 | 0.6266 | 0.6333 | 0.6234 | 0.6269 | 0.6286 | 0.6288 | 0.6230 | 0.6294 | 0.6252 |

| 3.48 | 0.5945 | 0.5767 | 0.5773 | 0.5808 | 0.5789 | 0.5813 | 0.5824 | 0.5776 | 0.5819 | 0.5778 | 0.5787 |

| 5.21 | 0.5765 | 0.5726 | 0.5795 | 0.5788 | 0.5729 | 0.5685 | 0.5729 | 0.5761 | 0.5749 | 0.5764 | 0.5687 |

| 6.95 | 0.5219 | 0.5218 | 0.5174 | 0.5201 | 0.5224 | 0.5247 | 0.5258 | 0.5181 | 0.5248 | 0.5193 | 0.5215 |

| 8.69 | 0.4907 | 0.4909 | 0.4874 | 0.4864 | 0.4909 | 0.4862 | 0.4917 | 0.4888 | 0.4893 | 0.4934 | 0.4920 |

| Moisture Content (%) | Number of Disturbances (N) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

| 0.00 | 0.0934 | 0.0189 | 0.0197 | 0.0184 | 0.0186 | 0.0183 | 0.0172 | 0.0177 | 0.0178 | 0.0167 | 0.0171 |

| 1.74 | 0.0777 | 0.0236 | 0.0222 | 0.0216 | 0.0213 | 0.0215 | 0.0213 | 0.0215 | 0.0223 | 0.0208 | 0.0209 |

| 3.48 | 0.0659 | 0.0232 | 0.0227 | 0.0225 | 0.0225 | 0.0226 | 0.0213 | 0.0218 | 0.0212 | 0.0216 | 0.0216 |

| 5.21 | 0.0680 | 0.0233 | 0.0235 | 0.0219 | 0.0229 | 0.0223 | 0.0221 | 0.0218 | 0.0217 | 0.0214 | 0.0210 |

| 6.95 | 0.0729 | 0.0199 | 0.0202 | 0.0189 | 0.0175 | 0.0187 | 0.0174 | 0.0179 | 0.018 | 0.0185 | 0.0173 |

| 8.69 | 0.0658 | 0.0191 | 0.0188 | 0.0189 | 0.0191 | 0.0178 | 0.0172 | 0.017 | 0.0171 | 0.0171 | 0.0175 |

| Moisture Content (%) | Number of Disturbances (N) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

| 0.00 | 0.8188 | 0.8809 | 0.8797 | 0.8796 | 0.8746 | 0.8708 | 0.8746 | 0.8786 | 0.8639 | 0.8719 | 0.8833 |

| 1.74 | 0.5619 | 0.606 | 0.6044 | 0.6117 | 0.6021 | 0.6054 | 0.6073 | 0.6073 | 0.6007 | 0.6086 | 0.6043 |

| 3.48 | 0.5286 | 0.5535 | 0.5546 | 0.5583 | 0.5564 | 0.5587 | 0.5611 | 0.5558 | 0.5607 | 0.5562 | 0.5571 |

| 5.21 | 0.5085 | 0.5493 | 0.5560 | 0.5569 | 0.5500 | 0.5462 | 0.5508 | 0.5543 | 0.5532 | 0.5550 | 0.5477 |

| 6.95 | 0.4490 | 0.5019 | 0.4972 | 0.5012 | 0.5049 | 0.5060 | 0.5084 | 0.5002 | 0.5068 | 0.5008 | 0.5042 |

| 8.69 | 0.4249 | 0.4718 | 0.4686 | 0.4675 | 0.4718 | 0.4684 | 0.4745 | 0.4718 | 0.4722 | 0.4763 | 0.4745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.; Tang, X.; Chen, L.; Wang, D.; Jiang, Y. Study on Characteristics of Failure and Energy Evolution of Different Moisture-Containing Soft Rocks under Cyclic Disturbance Loading. Materials 2024, 17, 1770. https://doi.org/10.3390/ma17081770

Cao X, Tang X, Chen L, Wang D, Jiang Y. Study on Characteristics of Failure and Energy Evolution of Different Moisture-Containing Soft Rocks under Cyclic Disturbance Loading. Materials. 2024; 17(8):1770. https://doi.org/10.3390/ma17081770

Chicago/Turabian StyleCao, Xuewen, Xuhui Tang, Lugen Chen, Dong Wang, and Yujing Jiang. 2024. "Study on Characteristics of Failure and Energy Evolution of Different Moisture-Containing Soft Rocks under Cyclic Disturbance Loading" Materials 17, no. 8: 1770. https://doi.org/10.3390/ma17081770

APA StyleCao, X., Tang, X., Chen, L., Wang, D., & Jiang, Y. (2024). Study on Characteristics of Failure and Energy Evolution of Different Moisture-Containing Soft Rocks under Cyclic Disturbance Loading. Materials, 17(8), 1770. https://doi.org/10.3390/ma17081770