Investigating and Evaluating Novel Fly Ash-Based Proppant Compressive Strength Under Various Environmental Conditions

Abstract

:1. Introduction

2. Experimental Description

2.1. Experiment Materials

- Type F fly ash (FA), a commercially obtained gray powder that chemically consists mainly of silicon oxide (SiO2), alumina oxide (Al2O3), and iron oxide (Fe2O3) with low calcium oxide (CaO), from Sika (Baar, Switzerland).

- Tap water from New Cairo, Cairo, Egypt.

- Sodium metasilicate (Na2SiO3), used as an alkaline binder, which is an industrial white granule material, commercially obtained, from Sigma-Aldrich (St. Louis, MO, USA).

- Hydrochloric acid (HCl), from Sisco Research Laboratories (Mumbai, India).

- Sodium hydroxide (NaOH), from Sisco Research Laboratories (Mumbai, India).

- Sodium chloride (NaCl),from Sisco Research Laboratories (Mumbai, India).

- Crude oil: A highly viscous liquid form of a mixture of hydrocarbons.

- Distilled water (DI Water).

- Heated water bath.

- Carbon dioxide gas (CO2).

2.2. Experiment Methodology (Formulation and Procedure)

2.2.1. Mix Design

- B20W25: binder 20% weight ratio and water 25% weight ratio.

- B22W25: binder 22% weight ratio and water 25% weight ratio.

- B25W25: binder 25% weight ratio and water 25% weight ratio.

2.2.2. Mixing, Sample Formation, and Curing Process

2.3. Experimental Scope

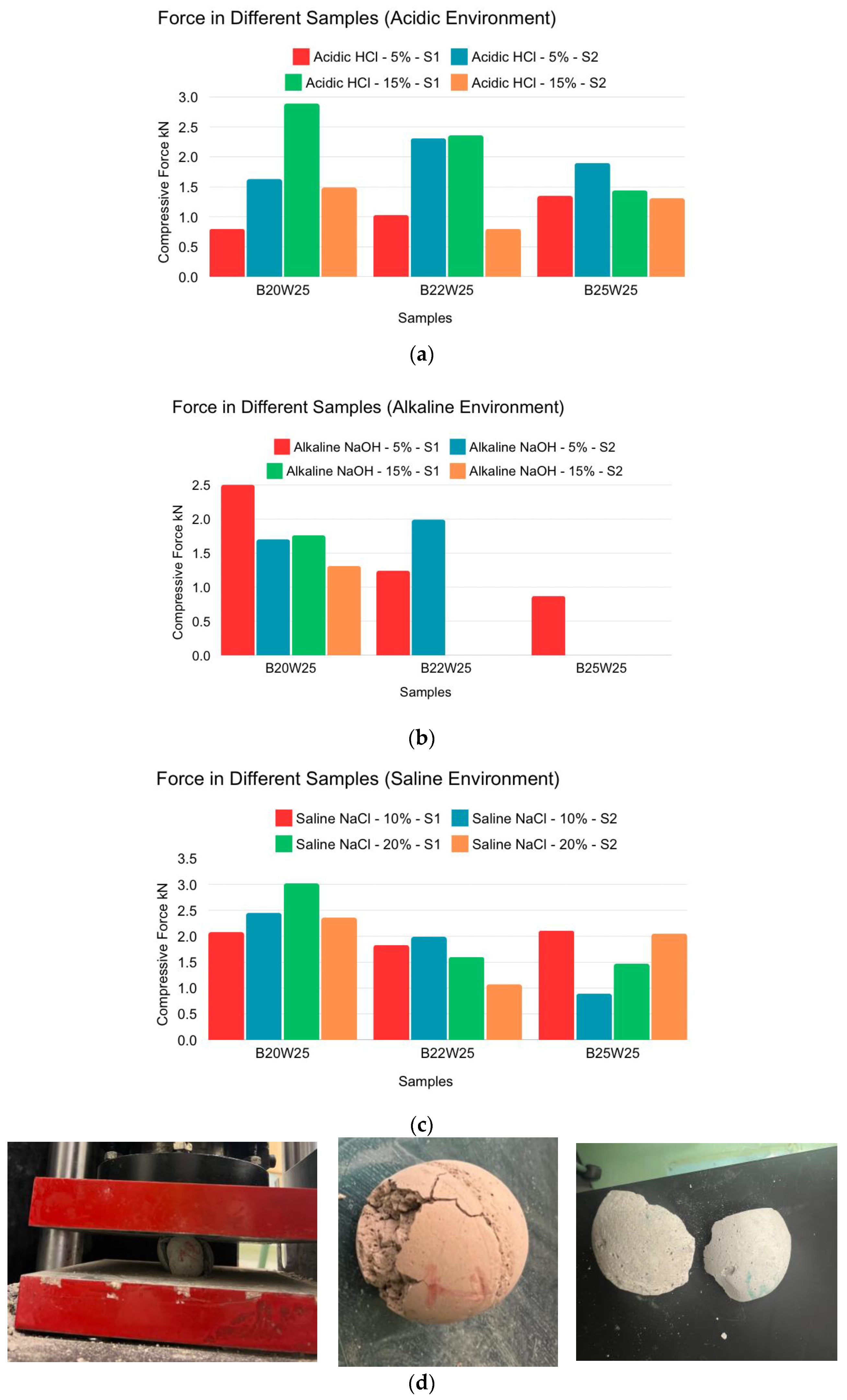

3. Results

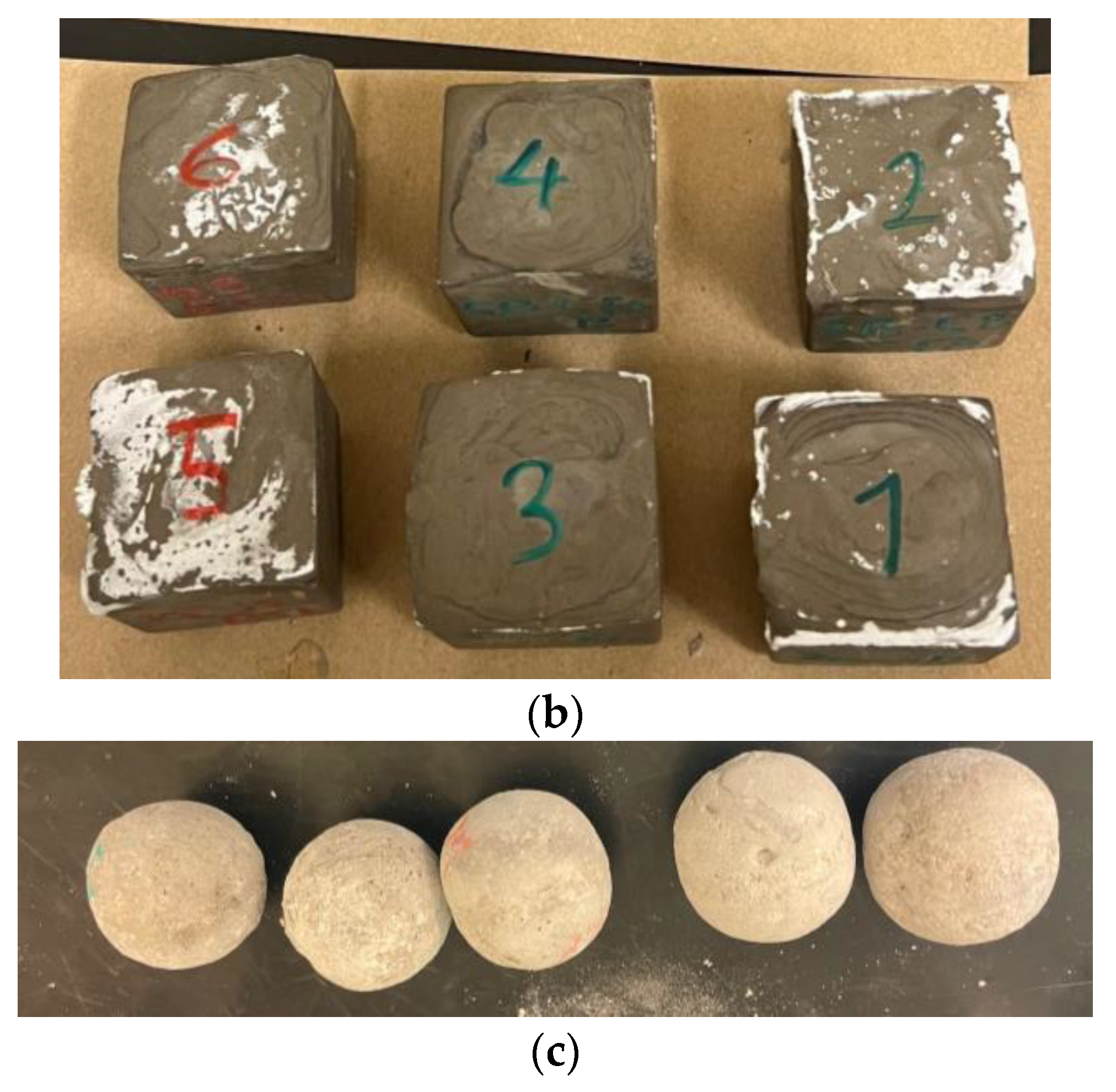

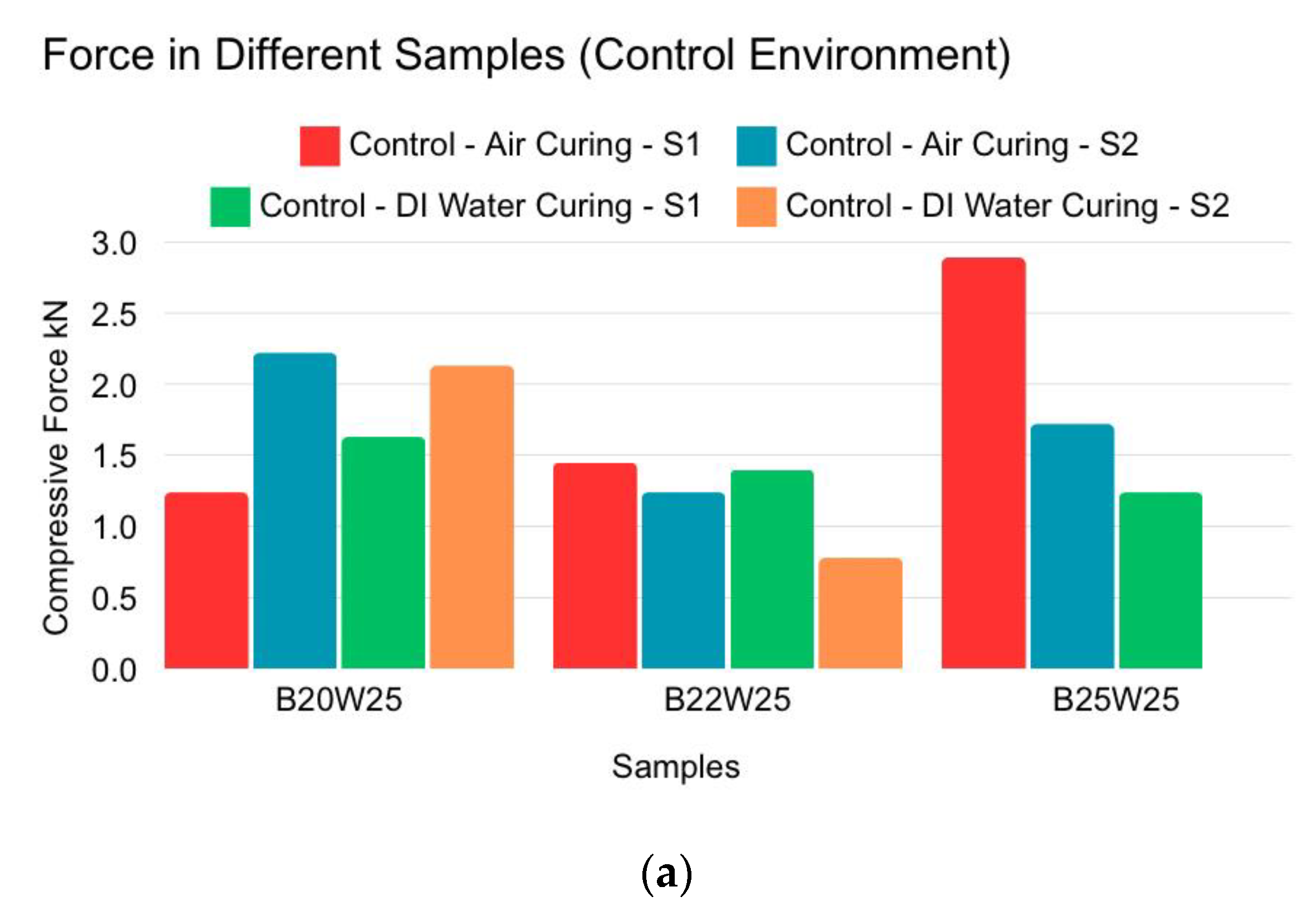

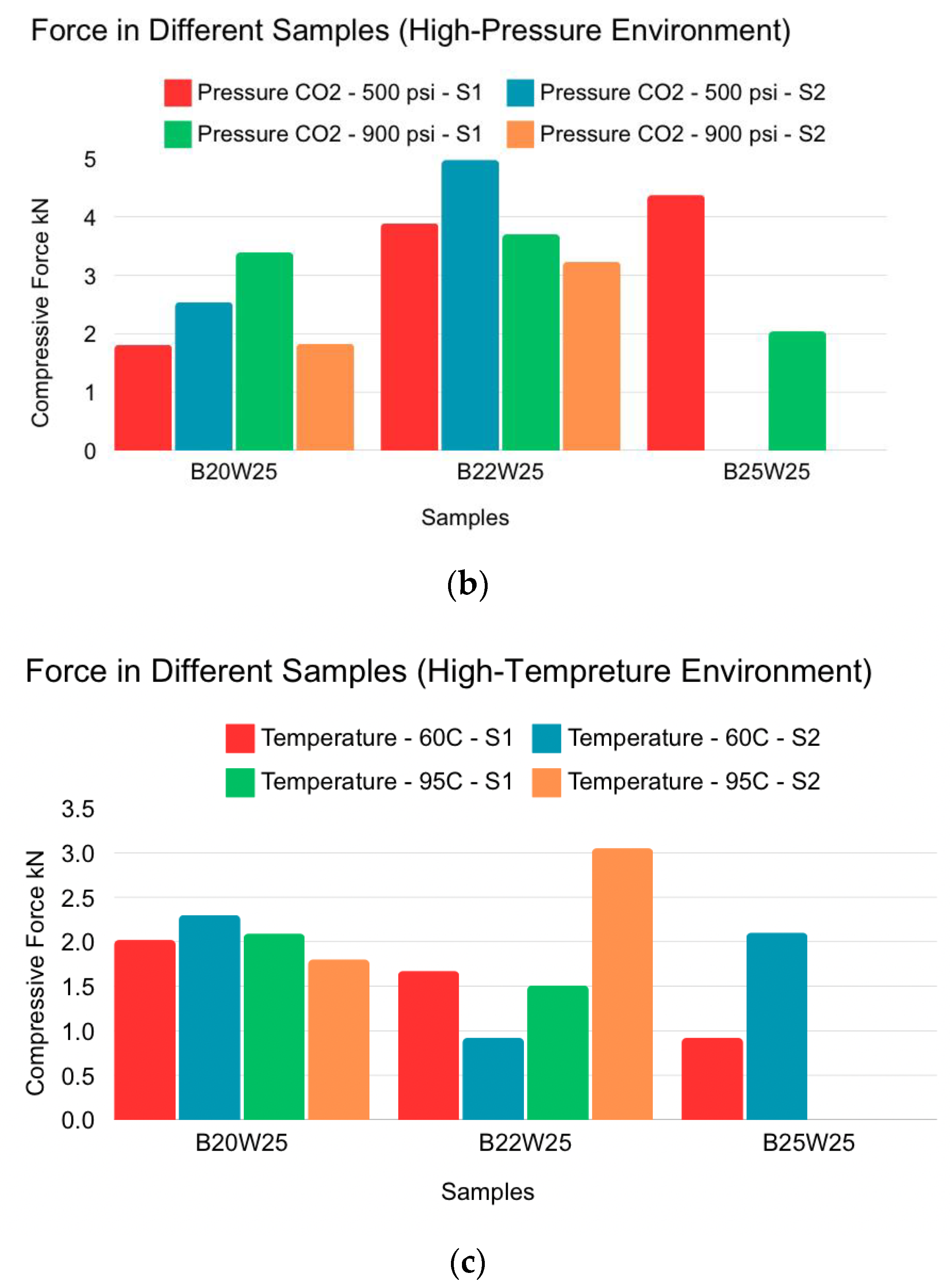

3.1. Cubical Samples

3.2. Spherical Samples

4. Discussion

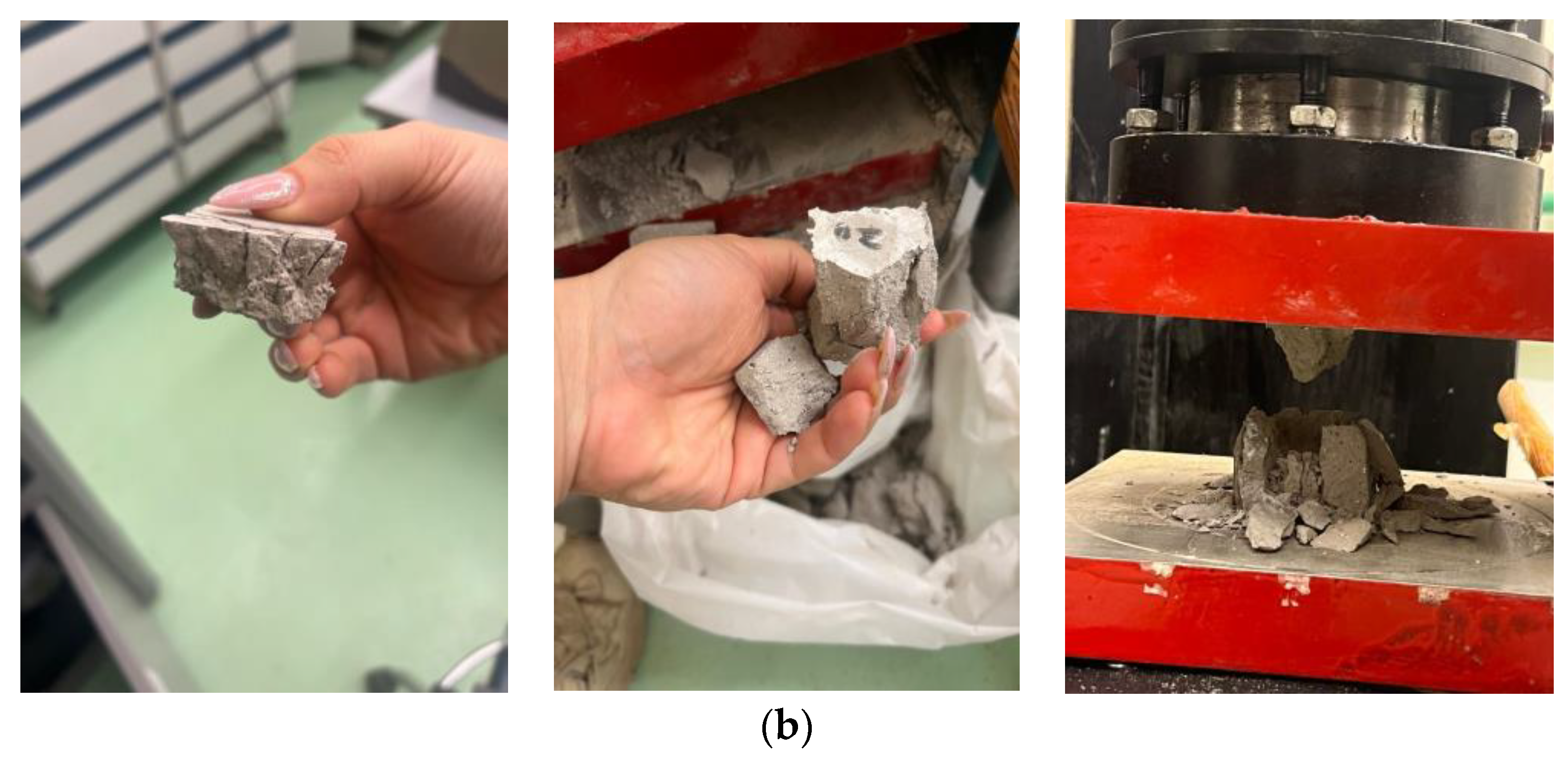

4.1. Compression Test

4.2. Future Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FA | Fly ash |

| B | Binder |

| W | Water |

| B20W25 | Binder 20% weight ratio and water 25% weight ratio |

| B22W25 | Binder 22% weight ratio and water 25% weight ratio |

| B25W25 | Binder 25% weight ratio and water 25% weight ratio |

| SiO₂ | Silicon dioxide |

| Al₂O₃ | Alumina oxide |

| Fe₂O₃ | Iron oxide |

| CaO | Calcium oxide |

| Na₂SiO₃ | Sodium metasilicate |

| HCl | Hydrochloric acid |

| NaOH | Sodium hydroxide |

| NaCl | Sodium chloride |

| CO₂ | Carbon dioxide |

References

- Chen, T.; Gao, J.; Zhao, Y.; Liang, T.; Hu, G.; Han, X. Progress of Polymer Application in Coated Proppant and Ultra-Low Density Proppant. Polymers 2022, 14, 5534. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Huang, B. A new permeability model of fracture containing proppants. J. Nat. Gas Sci. Eng. 2022, 104, 104661. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, C.; Zhou, L. Experimental Study of Proppant Placement Characteristics in Curving Fractures. Energies 2022, 15, 7169. [Google Scholar] [CrossRef]

- Dilireba, T.; Wang, J. Effect of Proppant Damages on Fracture Conductivity and Long-Term Recovery in Shale Gas Reservoirs. Energy Fuels 2024, 38, 11695–11705. [Google Scholar] [CrossRef]

- Ding, X.; Wang, T.; Dong, M.; Chen, N. Influence of Proppant Size on the Proppant Embedment Depth. ACS Omega 2022, 7, 35044–35054. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Guo, B.; Liu, X.; Tan, X. Chapter 14—Hydraulic Fracturing. In Petroleum Production Engineering, 2nd ed.; Gulf Professional Publishing: Boston, MA, USA, 2017; Chapter 14; pp. 389–501. [Google Scholar] [CrossRef]

- Zheng, W.; Silva, S.C.; Tannant, D.D. Crushing characteristics of four different proppants and implications for fracture conductivity. J. Nat. Gas Sci. Eng. 2018, 53, 125–138. [Google Scholar] [CrossRef]

- Xu, F.; Yao, K.; Li, D.; Xu, D.; Yang, H. Study on the Effect of Acid Corrosion on Proppant Properties. Energies 2022, 15, 8368. [Google Scholar] [CrossRef]

- Underdown, D.R.; Das, K. New Proppant for Deep Hydraulic Fracturing. J. Pet. Technol. 1985, 37, 98–104. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Y.; Yang, T.; Song, Y. A study on a new type of high-performance resin-coated sand for petroleum fracturing proppants. Coatings 2023, 13, 1841. [Google Scholar] [CrossRef]

- Haydar, R.; Fakher, S. Harsh Environmental Effects on Low Density Fly Ash Proppants. In Proceedings of the Mediterranean Offshore Conference, Alexandria, Egypt, 20–22 October 2024. [Google Scholar] [CrossRef]

- Liao, Z.; Rabiee, H.; Ge, L.; Li, X.; Yang, Z.; Xue, Q.; Shen, C.; Wang, H. Revealling pore microstructure impacts on the compressive strength of porous proppant based on finite and discrete element method. J. Mater. Sci. Technol. 2024, 211, 72–81. [Google Scholar] [CrossRef]

- Pangilinan, K.D.; de Leon, A.C.C.; Advincula, R.C. Polymers for proppants used in hydraulic fracturing. J. Pet. Sci. Eng. 2016, 145, 154–160. [Google Scholar] [CrossRef]

- Kc, B.; Ghazanfari, E.; McLennan, J.; Frash, L.P.; Meng, M. Evaluation of sintered bauxite proppant for binary enhanced geothermal systems. Géoméch. Geophys. Geo-Energy Geo-Resour. 2024, 10, 21. [Google Scholar] [CrossRef]

- Rickards, A.R.; Brannon, H.D.; Wood, W.D.; Stephenson, C.J. High Strength, Ultralightweight Proppant Lends New Dimensions to Hydraulic Fracturing Applications. SPE Prod. Oper. 2006, 21, 212–221. [Google Scholar] [CrossRef]

- Helmy, Y.; Fakher, S. Evaluating the Performance of Class F Fly Ash Compared to Class G Cement for Hydrocarbon Wells Cementing: An Experimental Investigation. Materials 2024, 17, 2710. [Google Scholar] [CrossRef]

- Permatasari, R.; Sodri, A.; Gustina, H.A. Utilization of Fly Ash Waste in the Cement Industry and its Environmental Impact: A Review. J. Penelit. Pendidik. IPA 2023, 9, 569–579. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. Coal-Based fly ash. Handbook of Fly Ash 2022; Elsevier: Oxford, UK, 2022; Chapter 1; pp. 5–9. [Google Scholar] [CrossRef]

- Sanjuán, M.; Argiz, C. Fineness of Coal Fly Ash for Use in Cement and concrete. Fuels 2021, 2, 471–486. [Google Scholar] [CrossRef]

- Menéndez, E.; Argiz, C.; Recino, H.; Sanjuán, M. Characterization of Mortars Made with Coal Ashes Identified as a Way Forward to Mitigate Climate Change. Crystals 2022, 12, 557. [Google Scholar] [CrossRef]

- Sanjuán, M.; Suarez-Navarro, J.A.; Argiz, C.; Estévez, E. Radiation dose calculation of fine and coarse coal fly ash used for building purposes. J. Radioanal. Nucl. Chem. 2021, 327, 1045–1054. [Google Scholar] [CrossRef]

- Menéndez, E.; Argiz, C.; Sanjuán, M. Reactivity of Ground Coal Bottom Ash to Be Used in Portland Cement. J 2021, 4, 223–232. [Google Scholar] [CrossRef]

- Wu, X.; Huo, Z.; Ren, Q.; Li, H.; Lin, F.; Wei, T. Preparation and characterization of ceramic proppants with low density and high strength using fly ash. J. Alloys Compd. 2017, 702, 442–448. [Google Scholar] [CrossRef]

- Ding, S.; Jow, J. Low-Density and High-Strength Fracking Proppant Made by High-Alumina Fly Ash. Coal Combust. Gasif. Prod. 2022. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, M.; Zhang, Y.; Liu, C.; Zhu, W.; Liu, G.; Yang, Y.; Sun, G.; Yang, L. The solidification and volatilization behavior of heavy metal ions in ceramic proppant made from fly ash. Ceram. Int. 2023, 49, 28326–28336. [Google Scholar] [CrossRef]

- Haydar, R.R.; Fakher, S. Development of a Low Cost Environmentally Friendly Proppant with High Buoyancy for Hydraulic Fracturing Operations. In Proceedings of the 57th U.S. Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023. [Google Scholar] [CrossRef]

- Ren, Q.; Ren, Y.; Li, H.; Wu, X.; Bai, W.; Zheng, J.; Hai, O. Preparation and characterization of high silicon ceramic proppants using low grade bauxite and fly ash. Mater. Chem. Phys. 2019, 230, 355–361. [Google Scholar] [CrossRef]

- Ahmad, S.; Alam Ghazi, M.S.; Syed, M.; Al-Osta, M.A. Utilization of fly ash with and without secondary additives for stabilizing expansive soils: A review. Results Eng. 2024, 22, 102079. [Google Scholar] [CrossRef]

- Nomani, M.; Shaquib, O.; Lone, A.A. Environmental Implications of Fly Ash Management and Utilization: A Review of Laws, Policies, and Practices. Curr. World Environ. J. 2024, 19, 634–650. [Google Scholar] [CrossRef]

- Das, D.; Rout, P.K. A Review of Coal Fly Ash Utilization to Save the Environment. Water Air Soil Pollut. 2023, 234, 128. [Google Scholar] [CrossRef]

- Suppiah, R.R.; Rahman, S.H.A.; Irawan, S.; Shafiq, N. Development of New Formulation of Geopolymer Cement for Oil Well Cementing. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 14–16 November 2016. [Google Scholar] [CrossRef]

- Singh, N.B. Fly Ash-Based Geopolymer Binder: A Future Construction Material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef]

- Haruna, S.; Mohammed, B.S.; Wahab, M.M.A.; Kankia, M.U.; Amran, M.; Gora, A.M. Long-Term Strength Development of Fly Ash-Based One-Part Alkali-Activated Binders. Materials 2021, 14, 4160. [Google Scholar] [CrossRef]

- ASTM Standard C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

| Proppant Type | Density (g/cm³) | Compressive Strength (psi) | Environmental Durability |

|---|---|---|---|

| Sand | 2.65 | Max 5800 | Poor |

| Resin-Coated Sand | >2.65 | 6000–7000 | Good |

| Ceramic | 2.55–3.9 | 7000–15,000 | Excellent |

| Novel Fly Ash | 1.33–1.36 | 1180 | Very Good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haydar, R.; Fakher, S. Investigating and Evaluating Novel Fly Ash-Based Proppant Compressive Strength Under Various Environmental Conditions. Materials 2025, 18, 399. https://doi.org/10.3390/ma18020399

Haydar R, Fakher S. Investigating and Evaluating Novel Fly Ash-Based Proppant Compressive Strength Under Various Environmental Conditions. Materials. 2025; 18(2):399. https://doi.org/10.3390/ma18020399

Chicago/Turabian StyleHaydar, Raz, and Sherif Fakher. 2025. "Investigating and Evaluating Novel Fly Ash-Based Proppant Compressive Strength Under Various Environmental Conditions" Materials 18, no. 2: 399. https://doi.org/10.3390/ma18020399

APA StyleHaydar, R., & Fakher, S. (2025). Investigating and Evaluating Novel Fly Ash-Based Proppant Compressive Strength Under Various Environmental Conditions. Materials, 18(2), 399. https://doi.org/10.3390/ma18020399