Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate

Abstract

1. Introduction

2. Materials and Methods

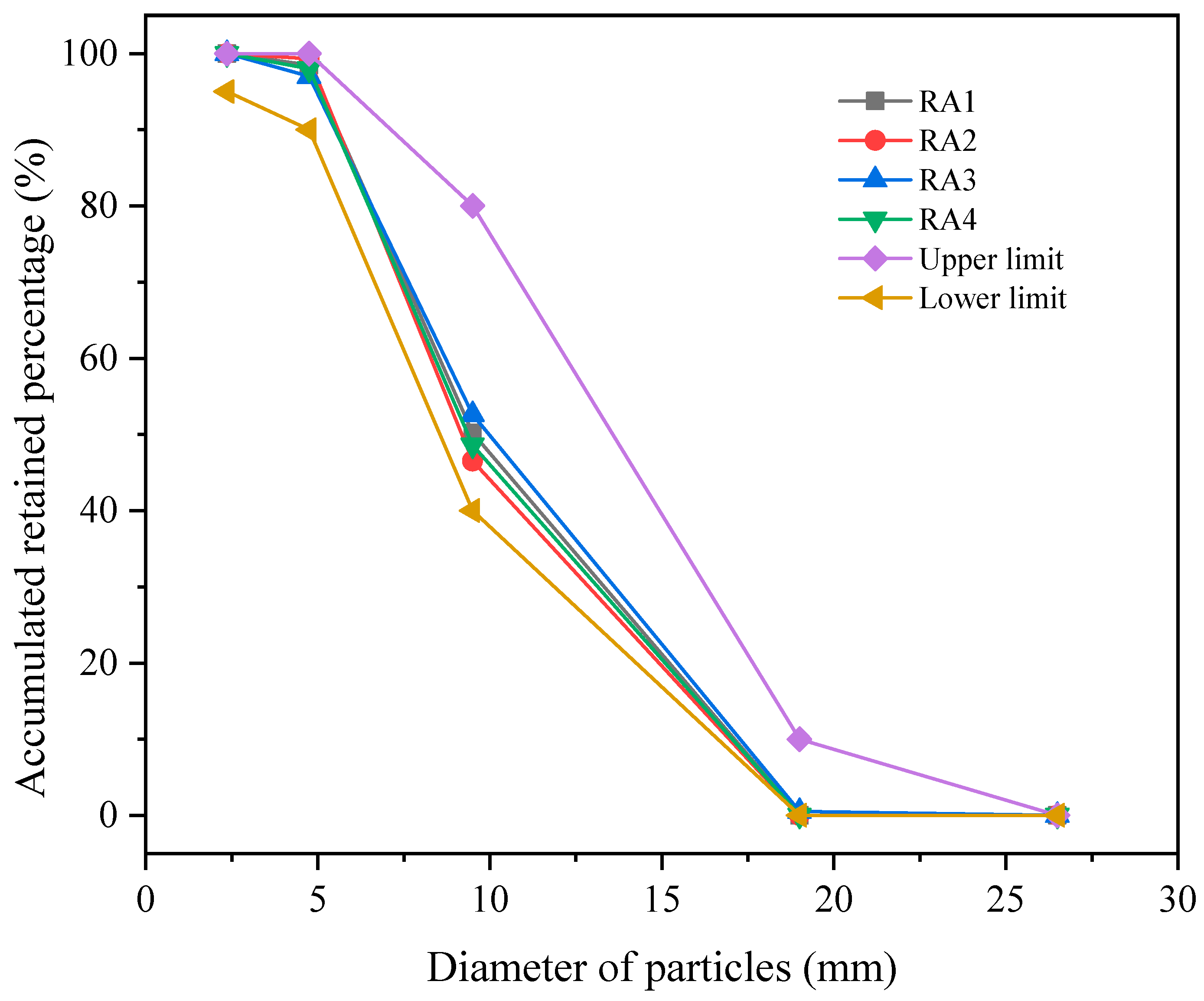

2.1. Materials

2.2. Methodology

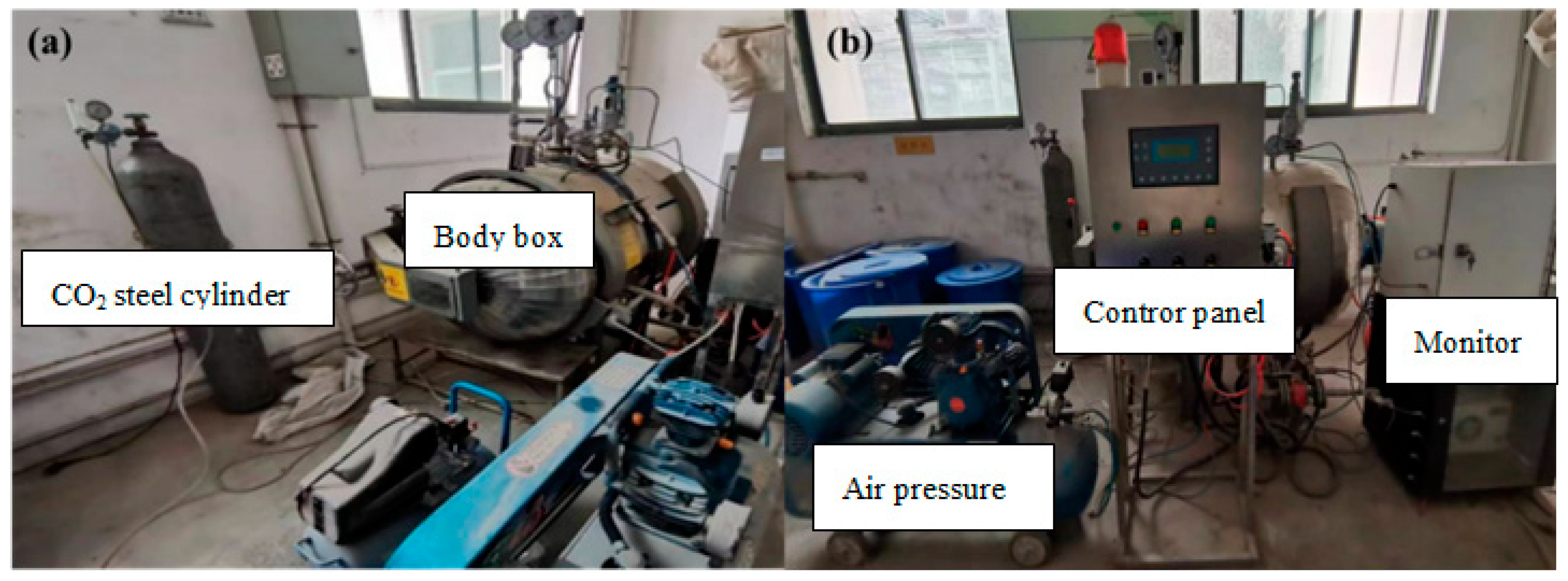

Carbonation Modification

2.3. Measurement

3. Results and Discussion

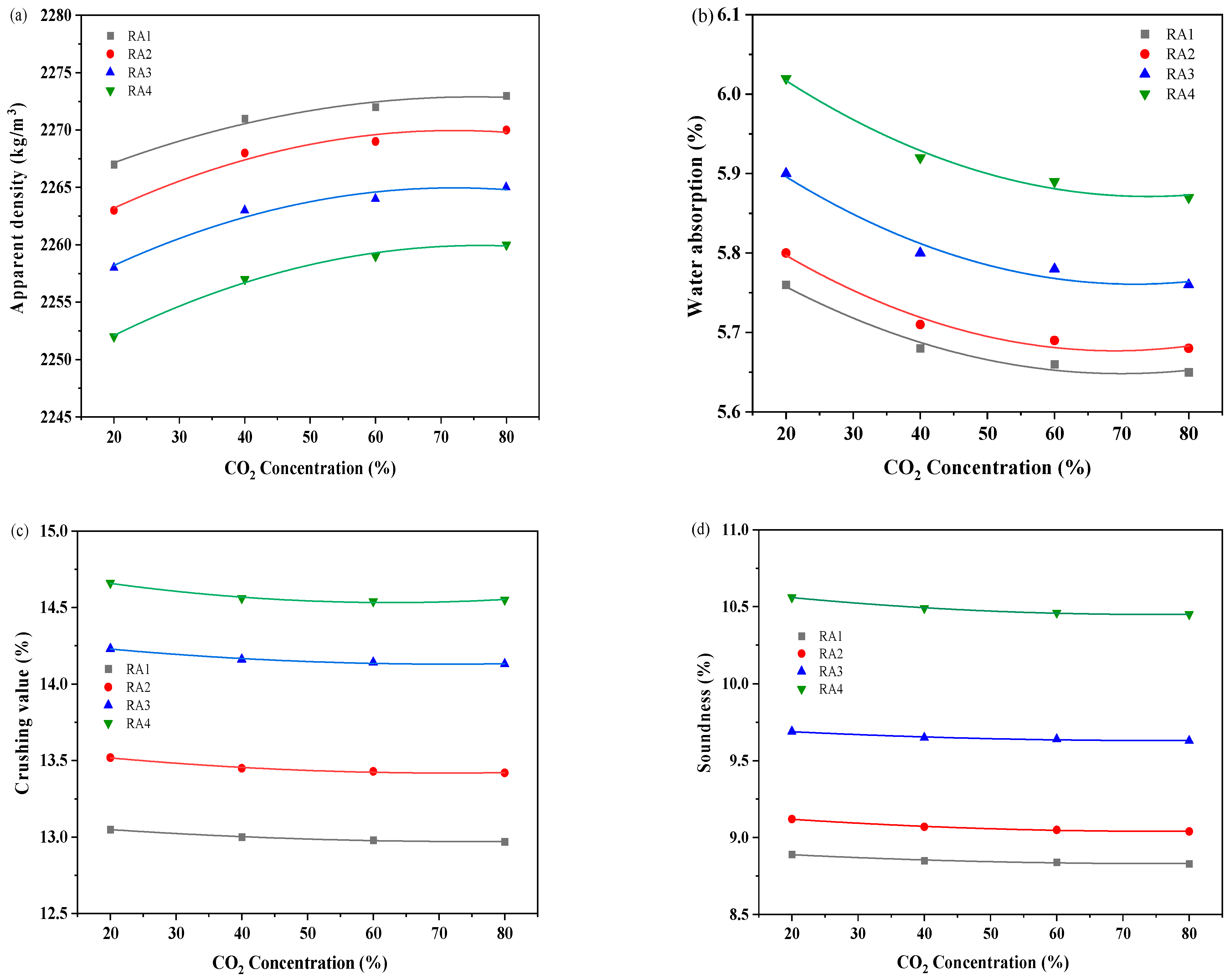

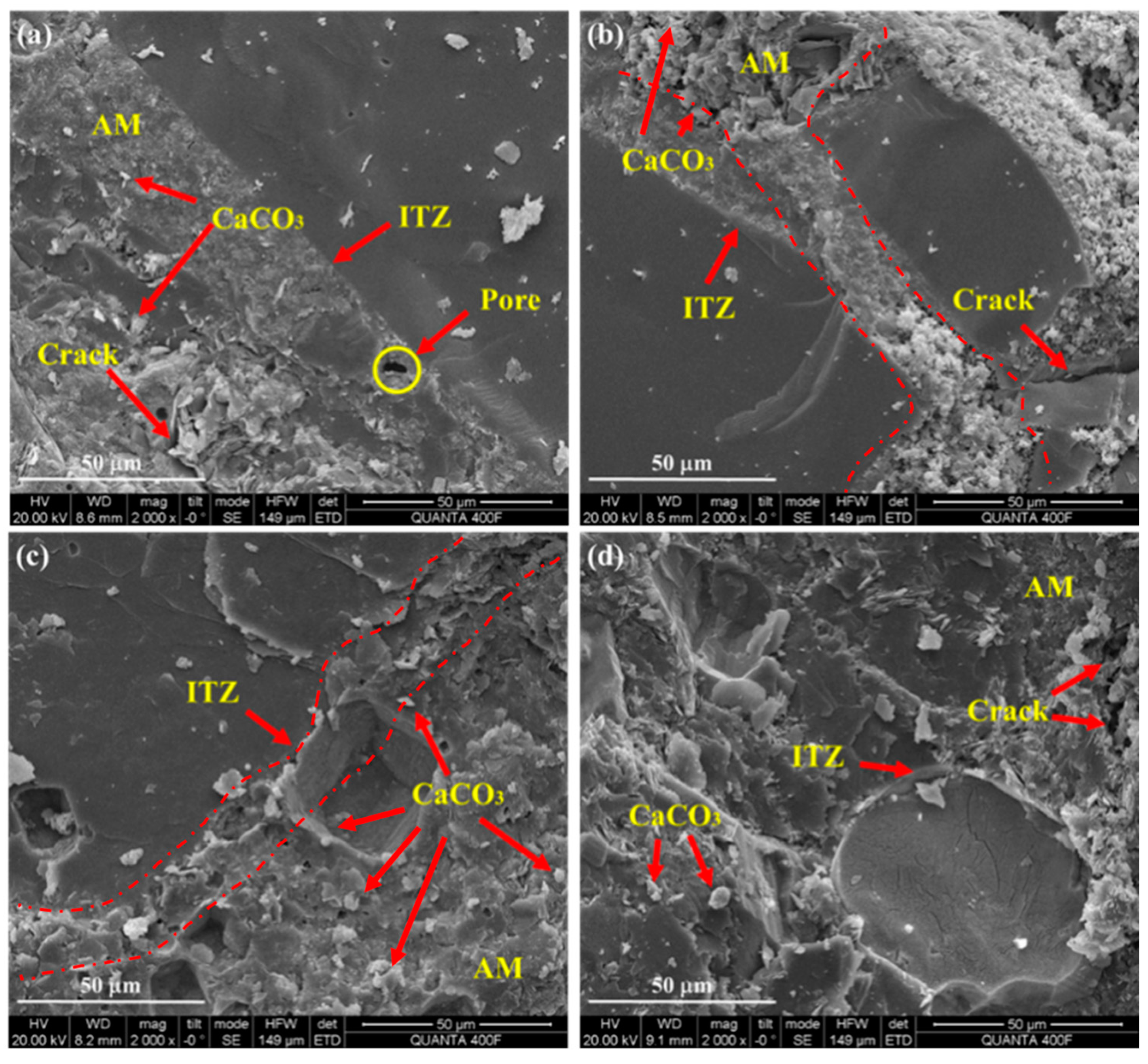

3.1. Effect of CO2 Concentration on Physical Properties of RA

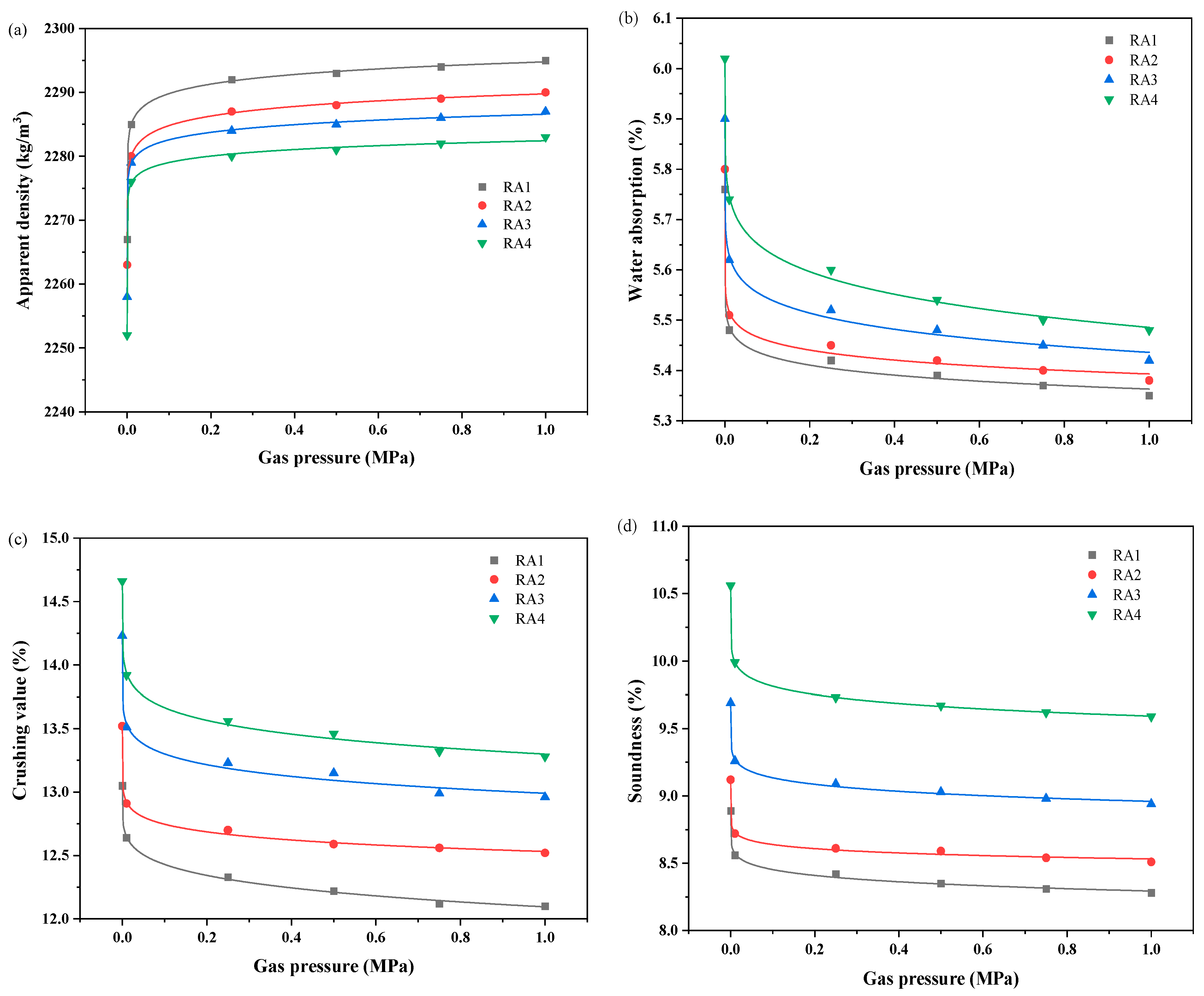

3.2. Effect of Carbonation Pressure on the Physical Properties of RA

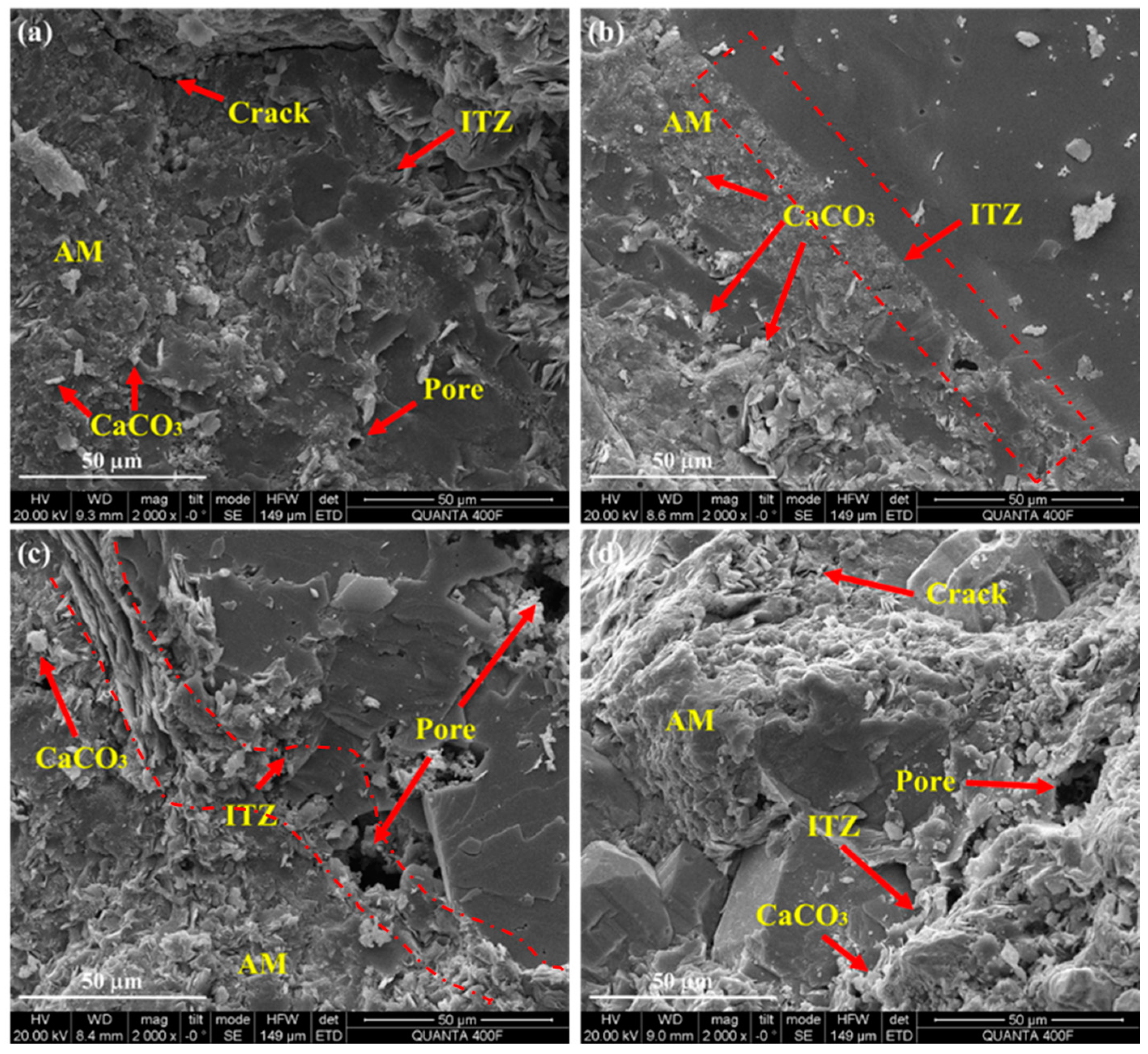

3.3. Effect of Moisture Content on the Physical Properties of RA

4. Conclusions

- (a)

- With the increase in CO2 concentration, the apparent density of RA gradually increased, and the water absorption, crushing value, and soundness gradually decreased. When the CO2 concentration increases from 20% to 60%, CO2 can enter the interior of RA through pores and react with calcium ions, so high porosity will accelerate the carbonation reaction of RA. When the CO2 concentration is further increased to 80%, the cracks on the surface of AM are filled with carbonation products and become regular, which prevents further carbonation reaction to a certain extent;

- (b)

- The carbonation reaction between the hydration products in AM and CO2 was accelerated when the gas pressure increased to 0.01 MPa; consequently, the physical properties of RA were enhanced significantly. The performance of RA was partially improved when the gas pressure exceeded 0.5 MPa; the CaCO3 flakes appeared in the attached mortar of RA, and the ITZ between the mortar and the original aggregate was no longer visible. Therefore, excessive gas pressure does not play a significant role in the degree of carbonation modification of RA;

- (c)

- In the carbonation opposite evaluation, the effect of RA moisture content on the physical properties of RA is significant, and the optimal moisture content range of RA carbonation modification is 3.2–3.4%. However, the quality performance of RA decreased when the moisture content of RA increased from 3.4% to 3.8%. This is because when the moisture content of RA exceeds the optimal value, the diffusion rate of CO2 decreases, and the carbonation reaction rate decreases, accordingly;

- (d)

- In general, it is recommended to maintain a CO2 concentration between 40% and 60% during the carbonation modification process. The carbonation effectiveness increases with pressure, and from an economic perspective, a carbonation pressure of 0.01 MPa is suggested. The moisture content of the recycled aggregates is ideally within the range of 3.2–3.4%; excessively high moisture content can hinder CO2 diffusion and reduce carbonation efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tu, K.; Wu, J.; Wang, Y.; Deng, H.; Zhang, R. Uniaxial Compressive Stress–Strain Relation of Recycled Coarse Aggregate Concrete with Different Carbonation Depths. Materials 2022, 15, 5429. [Google Scholar] [CrossRef] [PubMed]

- Meraj, G.; Kanga, S.; Kranjčić, N.; Đurin, B.; Singh, S.K. Role of Natural Capital Economics for Sustainable Management of Earth Resources. Earth 2021, 2, 622–634. [Google Scholar] [CrossRef]

- Ding, Y.; Wu, J.; Xu, P.; Zhang, X.; Fan, Y. Treatment Methods for the Quality Improvement of Recycled Concrete Aggregate (Rca)—A Review. J. Wuhan Univ. Technol. Mater. Sci. Ed 2021, 36, 77–92. [Google Scholar] [CrossRef]

- Li, L.; Ziyabek, N.; Jiang, Y.; Xiao, J.; Poon, C.S. Effect of Carbonation Duration on Properties of Recycled Aggregate Concrete. Case Stud. Constr. Mater. 2023, 19, e02640. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pacheco-Torgal, F.; Lopes, A. Advantages and Shortcomings of the Utilization of Recycled Wastes as Aggregates in Structural Concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Marvila, M.; de Matos, P.; Rodríguez, E.; Monteiro, S.N.; de Azevedo, A.R. Recycled Aggregate: A Viable Solution for Sustainable Concrete Production. Materials 2022, 15, 5276. [Google Scholar] [CrossRef]

- Xiao, J.; Poon, C.S.; Wang, Y.; Zhao, Y.; Ding, T.; Geng, Y.; Ye, T.; Li, L. Fundamental Behaviour of Recycled Aggregate Concrete–Overview I: Strength and Deformation. Mag. Concr. Res. 2022, 74, 999–1010. [Google Scholar] [CrossRef]

- Kępniak, M.; Łukowski, P. Multicriteria Analysis of Cement Mortar with Recycled Sand. Sustainability 2024, 16, 1773. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.S. Enhancing the Durability Properties of Concrete Prepared with Coarse Recycled Aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Long-Term Mechanical and Durability Properties of Recycled Aggregate Concrete Prepared with the Incorporation of Fly Ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of Recycled Aggregate Concrete–a Review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing Recycled Concrete Containing High Volume of Fly Ash in Terms of the Embodied Energy and Chloride Ion Resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Zhang, J.; Liu, F.; Lin, X.; Ji, T. A New Look at the Resistance of Recycled Aggregate Concrete (Rac) to the External Sulfate Attacks: The Influence of the Multiple Mesoscopic Material Phases. J. Build. Eng. 2023, 64, 105653. [Google Scholar] [CrossRef]

- Memon, S.A.; Bekzhanova, Z.; Murzakarimova, A. A Review of Improvement of Interfacial Transition Zone and Adherent Mortar in Recycled Concrete Aggregate. Buildings 2022, 12, 1600. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Tang, Y.; Duan, Z.; Poon, C.-S. Long-Term Shrinkage and Mechanical Properties of Fully Recycled Aggregate Concrete: Testing and Modelling. Cem. Concr. Compos. 2022, 130, 104527. [Google Scholar] [CrossRef]

- Ren, P.; Li, B.; Yu, J.-G.; Ling, T.-C. Utilization of Recycled Concrete Fines and Powders to Produce Alkali-Activated Slag Concrete Blocks. J. Clean. Prod. 2020, 267, 122115. [Google Scholar] [CrossRef]

- Xiao, J.; Lei, B.; Zhang, C. On Carbonation Behavior of Recycled Aggregate Concrete. Sci. China Technol. Sci. 2012, 55, 2609–2616. [Google Scholar] [CrossRef]

- Trivedi, S.S.; Snehal, K.; Das, B.; Barbhuiya, S. A Comprehensive Review Towards Sustainable Approaches on the Processing and Treatment of Construction and Demolition Waste. Constr. Build. Mater. 2023, 393, 132125. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Scientometric Analysis Approach to Analyze the Present Research on Recycled Aggregate Concrete. J. Build. Eng. 2022, 46, 103679. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-Modified Cement Mortars: Their Enhanced Properties, Applications, Prospects, and Challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A Review on Different Treatment Methods for Enhancing the Properties of Recycled Aggregates for Sustainable Construction Materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Göswein, V.; Gonçalves, A.B.; Silvestre, J.D.; Freire, F.; Habert, G.; Kurda, R. Transportation Matters–Does It? Gis-Based Comparative Environmental Assessment of Concrete Mixes with Cement, Fly Ash, Natural and Recycled Aggregates. Resour. Conserv. Recycl. 2018, 137, 1–10. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregate–A Review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Zhang, M.; Tan, S.; Pan, Z.; Hao, D.; Zhang, X.; Chen, Z. The Spatial Spillover Effect and Nonlinear Relationship Analysis between Land Resource Misallocation and Environmental Pollution: Evidence from China. J. Environ. Manag. 2022, 321, 115873. [Google Scholar] [CrossRef]

- Anderson, J.O.; Thundiyil, J.G.; Stolbach, A. Clearing the Air: A Review of the Effects of Particulate Matter Air Pollution on Human Health. J. Med. Toxicol. 2012, 8, 166–175. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.-S.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregates through Carbonation. J. Mater. Civ. Eng. 2015, 27, 04015029. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Zhang, G.; Li, L. Interfacial Properties of Modeled Recycled Aggregate Concrete Modified by Carbonation. Constr. Build. Mater. 2016, 105, 307–320. [Google Scholar] [CrossRef]

- Pu, Y.; Li, L.; Wang, Q.; Shi, X.; Luan, C.; Zhang, G.; Fu, L.; Abomohra, A.E.-F. Accelerated Carbonation Technology for Enhanced Treatment of Recycled Concrete Aggregates: A State-of-the-Art Review. Constr. Build. Mater. 2021, 282, 122671. [Google Scholar] [CrossRef]

- Kangni-Foli, E.; Poyet, S.; Le Bescop, P.; Charpentier, T.; Bernachy-Barbé, F.; Dauzères, A.; L’Hôpital, E.; de Lacaillerie, J.-B.D.E. Carbonation of Model Cement Pastes: The Mineralogical Origin of Microstructural Changes and Shrinkage. Cem. Concr. Res. 2021, 144, 106446. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, P.; Garcia-Troncoso, N.; Mo, K.H.; Ling, T.-C. Roles of Enhanced Itz in Improving the Mechanical Properties of Concrete Prepared with Different Types of Recycled Aggregates. J. Build. Eng. 2022, 60, 105197. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Y.; Zhu, P.; Yang, J.; Li, H.; Wang, F.; Yan, X. Improvement of Mechanical Properties and Carbonation Durability of Recycled Fine Aggregate Engineered Cementitious Composites for Structural Strengthening. J. Build. Eng. 2023, 76, 107277. [Google Scholar] [CrossRef]

- Li, L.; Xiao, J.; Xuan, D.; Poon, C.S. Effect of Carbonation of Modeled Recycled Coarse Aggregate on the Mechanical Properties of Modeled Recycled Aggregate Concrete. Cem. Concr. Compos. 2018, 89, 169–180. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability of Crushed Fine Recycled Aggregate Concrete Assessed by Permeability-Related Properties. Mag. Concr. Res. 2019, 71, 1142–1150. [Google Scholar] [CrossRef]

- Bian, H.; Chai, L.; Liu, Y.; Duan, P.; Shi, W.; Chen, J.; Zhang, H.; Ge, Z. Prediction Model for Time-Dependent Drying Shrinkage of Recycled Coarse and Fine Aggregate Concrete Based on Internal Relative Humidity. Constr. Build. Mater. 2024, 439, 137426. [Google Scholar] [CrossRef]

- Liang, C.; Ma, H.; Pan, Y.; Ma, Z.; Duan, Z.; He, Z. Chloride Permeability and the Caused Steel Corrosion in the Concrete with Carbonated Recycled Aggregate. Constr. Build. Mater. 2019, 218, 506–518. [Google Scholar] [CrossRef]

- Huang, H.; Ren, X.; Liu, Z.; Wang, F. Development of Low-Carbon and Cost-Effective Ultra-High Performance Concrete Using Carbonated Recycled Fine Aggregate. Constr. Build. Mater. 2023, 399, 132575. [Google Scholar] [CrossRef]

- Tam, V.W.; Butera, A.; Le, K.N. Carbon-Conditioned Recycled Aggregate in Concrete Production. J. Clean. Prod. 2016, 133, 672–680. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, H.; Chen, K.; Sun, C.; Li, W.; Jiao, S.; Tam, V.W. Improving Industrial Drying Process of Recycled Fine Aggregates as a Means of Carbonation to Improve the Mechanical Properties and Plastic Shrinkage of Self-Leveling Mortar. Constr. Build. Mater. 2023, 403, 133001. [Google Scholar] [CrossRef]

- Jamil, S.; Shi, J.; Idrees, M. Effect of Various Parameters on Carbonation Treatment of Recycled Concrete Aggregate Using the Design of Experiment Method. Constr. Build. Mater. 2023, 382, 131339. [Google Scholar] [CrossRef]

- Farahani, H.S.; Zadeh, A.H.; Hu, J.; Hawkins, C.; Kim, S. Carbonation reaction of recycled concrete aggregates (RCA): CO2 mass consumption under various treatment conditions. Clean. Mater. 2025, 15, 100296. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, D.; Zuo, J.; Miller, T.R.; Duan, H.; Schiller, G. Potential for CO2 mitigation and economic benefits from accelerated carbonation of construction and demolition waste. Renew. Sustain. Energy Rev. 2022, 169, 112920. [Google Scholar] [CrossRef]

- Li, L.; Wu, M. An Overview of Utilizing CO2 for Accelerated Carbonation Treatment in the Concrete Industry. J. CO2 Util. 2022, 60, 102000. [Google Scholar] [CrossRef]

- Chen, K.-Y.; Xia, J.; Wu, R.-J.; Shen, X.-Y.; Chen, J.-J.; Zhao, Y.-X.; Jin, W.-L. An Overview on the Influence of Various Parameters on the Fabrication and Engineering Properties of CO2-Cured Cement-Based Composites. J. Clean. Prod. 2022, 366, 132968. [Google Scholar] [CrossRef]

- GB/T 25177-2010; Recycled Coarse Aggregate for Concrete. China National Standardization Administration Committee: Beijing, China, 2010.

- Zhu, P.; Li, H.; Liu, H.; Yan, X.; Wang, X.; Chen, C. Effect of CO2 Curing on the Physical Properties of Recycled Coarse Aggregate with Different Attached Mortar Contents. J. Wuhan. Univ. Technol. 2022, 37, 905–911. [Google Scholar] [CrossRef]

- GB/T 14685-2022; Pebble and Crushed Stone for Construction. China National Standardization Administration Committee: Beijing, China, 2022.

- Zhu, P.; Chen, X.; Liu, H.; Wang, Z.; Chen, C.; Li, H. Recycling of Waste Recycled Aggregate Concrete in Freeze-Thaw Environment and Emergy Analysis of Concrete Recycling System. J. Build. Eng. 2024, 96, 110377. [Google Scholar] [CrossRef]

- Pepe, M.; Filho, R.D.T.; Koenders, E.A.; Martinelli, E. Alternative Processing Procedures for Recycled Aggregates in Structural Concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Gholizadeh-Vayghan, A.; Bellinkx, A.; Snellings, R.; Vandoren, B.; Quaghebeur, M. The Effects of Carbonation Conditions on the Physical and Microstructural Properties of Recycled Concrete Coarse Aggregates. Constr. Build. Mater. 2020, 257, 119486. [Google Scholar] [CrossRef]

- Zeng, X. Progress in the Research of Carbonation Resistance of Rac. Constr. Build. Mater. 2020, 230, 116976. [Google Scholar] [CrossRef]

- Shuvo, A.K.; Sarker, P.K.; Shaikh, F.U.A. Efficacy of Various Accelerated Carbonation Techniques to Improve Recycled Concrete Aggregates: A Comprehensive Review. J. Build. Eng. 2024, 95, 110257. [Google Scholar] [CrossRef]

- Pu, Y.; Li, L.; Shi, X.; Wang, Q.; Abomohra, A. Improving Recycled Concrete Aggregates Using Flue Gas Based on Multicyclic Accelerated Carbonation: Performance and Mechanism. Constr. Build. Mater. 2022, 361, 129621. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Liang, J.; Meng, Y.; Rong, H.; Li, D.; Chen, Y.; Lv, J.; Jiang, Y.; Liu, Y. Straightening Methods for Rca and Rac—A Review. Cem. Concr. Compos. 2023, 141, 105145. [Google Scholar] [CrossRef]

- Feng, Y.; Li, J.; Zhang, B.; Fu, H.; Chen, W.; Xue, Z.; Lu, Z.; Yang, J.; Xie, J. Concrete Improvement Incorporating Recycled Powder and Aggregates Treated Via a Combination of Calcination and Carbonation: The Impact Behaviors. J. Clean. Prod. 2023, 418, 138069. [Google Scholar] [CrossRef]

- Qian, R.; Wan-Wendner, L.; Yang, C.; Zhao, R.; Ye, Z.; Kong, D.; Zhang, Y. Investigations on Carbon-Sequestration Optimization of Recycled Coarse-Aggregate and Its Effects on Concrete Performances. J. Build. Eng. 2024, 90, 109453. [Google Scholar] [CrossRef]

- Wu, K.; Luo, S.; Zheng, J.; Yan, J.; Xiao, J. Influence of Carbonation Treatment on the Properties of Multiple Interface Transition Zones and Recycled Aggregate Concrete. Cem. Concr. Compos. 2022, 127, 104402. [Google Scholar] [CrossRef]

- Pla, C.; Cuezva, S.; Martinez-Martinez, J.; Fernandez-Cortes, A.; Garcia-Anton, E.; Fusi, N.; Crosta, G.B.; Cuevas-Gonzalez, J.; Cañaveras, J.C.; Sanchez-Moral, S. Role of Soil Pore Structure in Water Infiltration and Co2 Exchange between the Atmosphere and Underground Air in the Vadose Zone: A Combined Laboratory and Field Approach. Catena 2017, 149, 402–416. [Google Scholar] [CrossRef]

| Type | Apparent Density kg/m3 | Water Absorption % | Crushing Value % | Soundness % |

|---|---|---|---|---|

| RA1 | 2231 | 6.38 | 14.36 | 9.86 |

| RA2 | 2226 | 6.44 | 14.91 | 10.15 |

| RA3 | 2219 | 6.57 | 15.74 | 10.82 |

| RA4 | 2212 | 6.72 | 16.24 | 11.81 |

| Condition | CO2 Concentration (%) | Gas Pressure (MPa) | Moisture Content (%) |

|---|---|---|---|

| 1 | 20, 40, 60, 80 | 0.01 | 3.4 |

| 2 | 20 ± 3 | 0, 0.01, 0.5, 1.0 | 3.4 |

| 3 | 20 ± 3 | 0.01 | 3.2, 3.4, 3.6, 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehmood, N.; Zhu, P.; Liu, H.; Li, H.; Zhu, X. Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate. Materials 2025, 18, 901. https://doi.org/10.3390/ma18040901

Mehmood N, Zhu P, Liu H, Li H, Zhu X. Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate. Materials. 2025; 18(4):901. https://doi.org/10.3390/ma18040901

Chicago/Turabian StyleMehmood, Nasir, Pinghua Zhu, Hui Liu, Haichao Li, and Xudong Zhu. 2025. "Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate" Materials 18, no. 4: 901. https://doi.org/10.3390/ma18040901

APA StyleMehmood, N., Zhu, P., Liu, H., Li, H., & Zhu, X. (2025). Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate. Materials, 18(4), 901. https://doi.org/10.3390/ma18040901