Study on Salt-Frost Damage Durability of High-Performance Concrete with Polypropylene Fiber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Flexural Strength Test

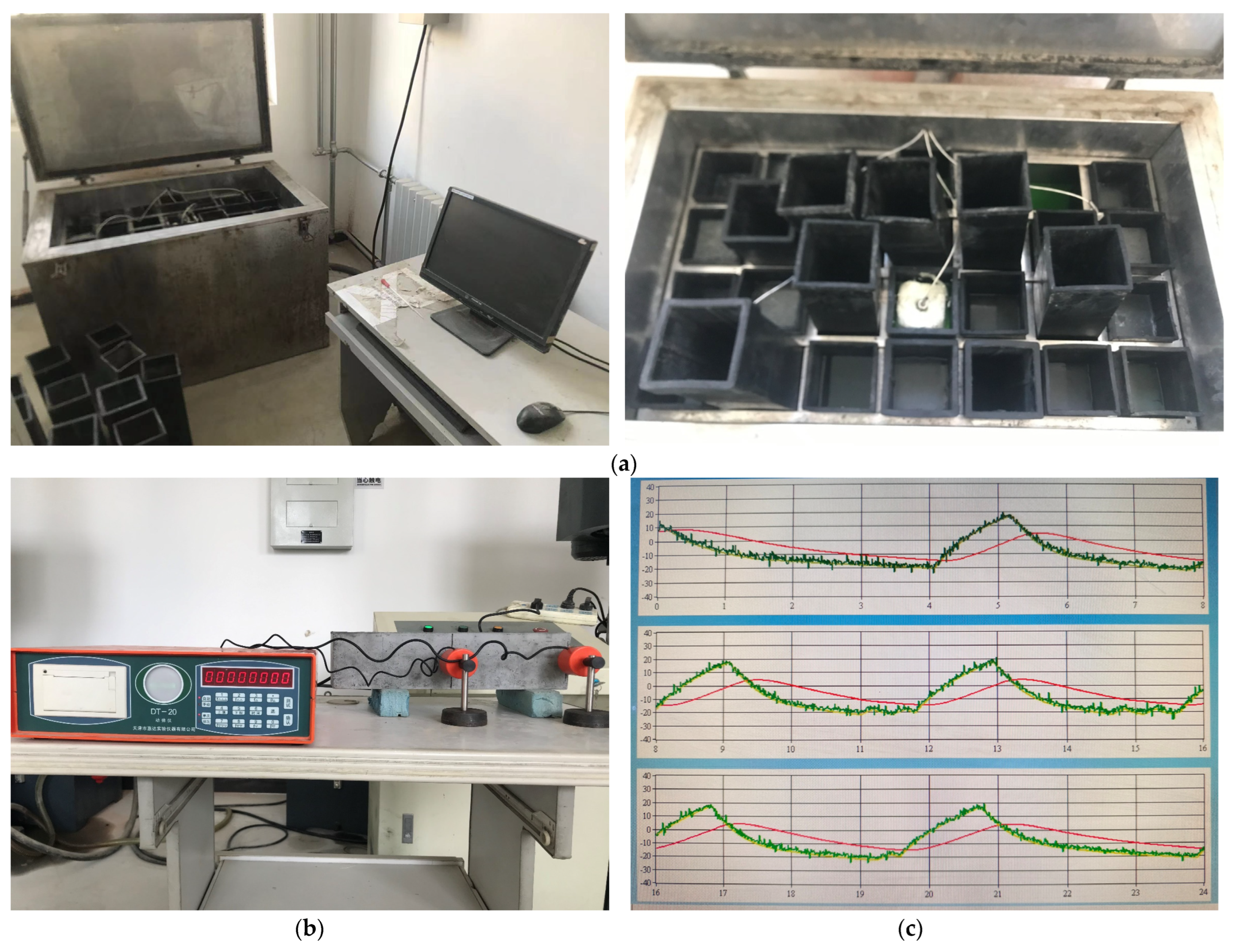

2.2.2. Freeze–Thaw Test

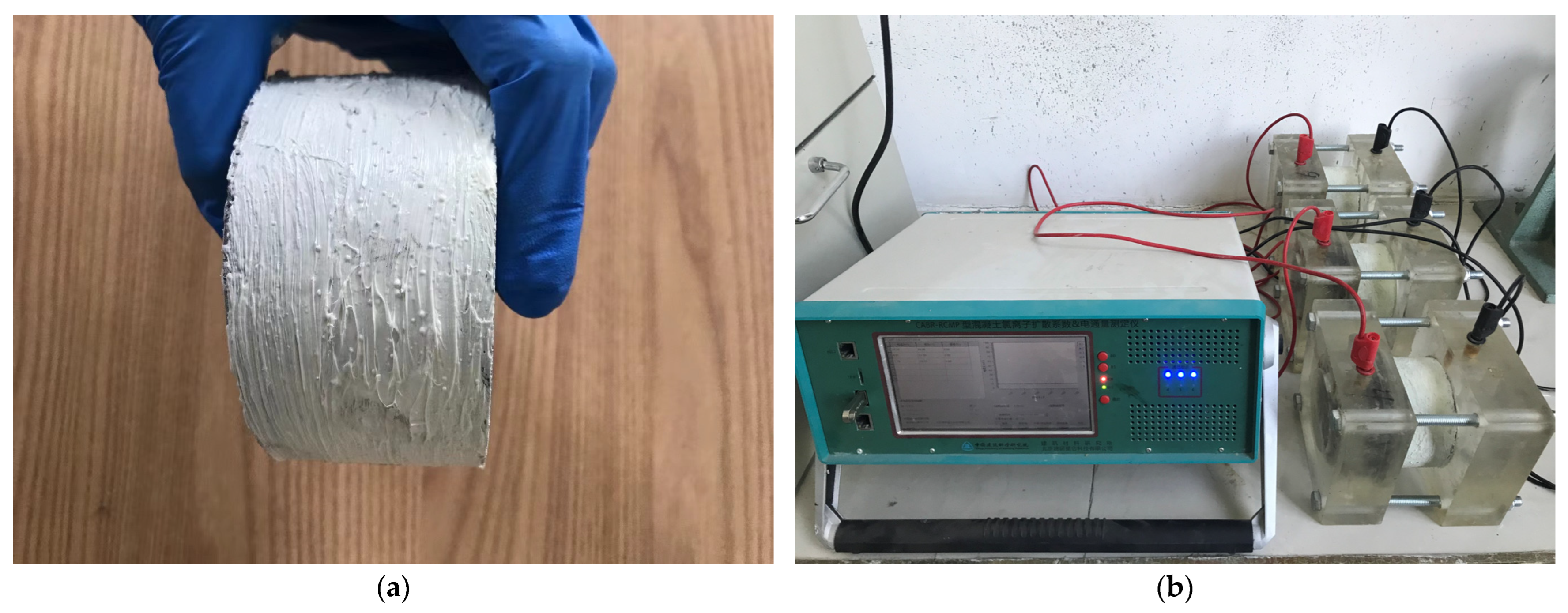

2.2.3. Chloride Ion Penetration Resistance Test

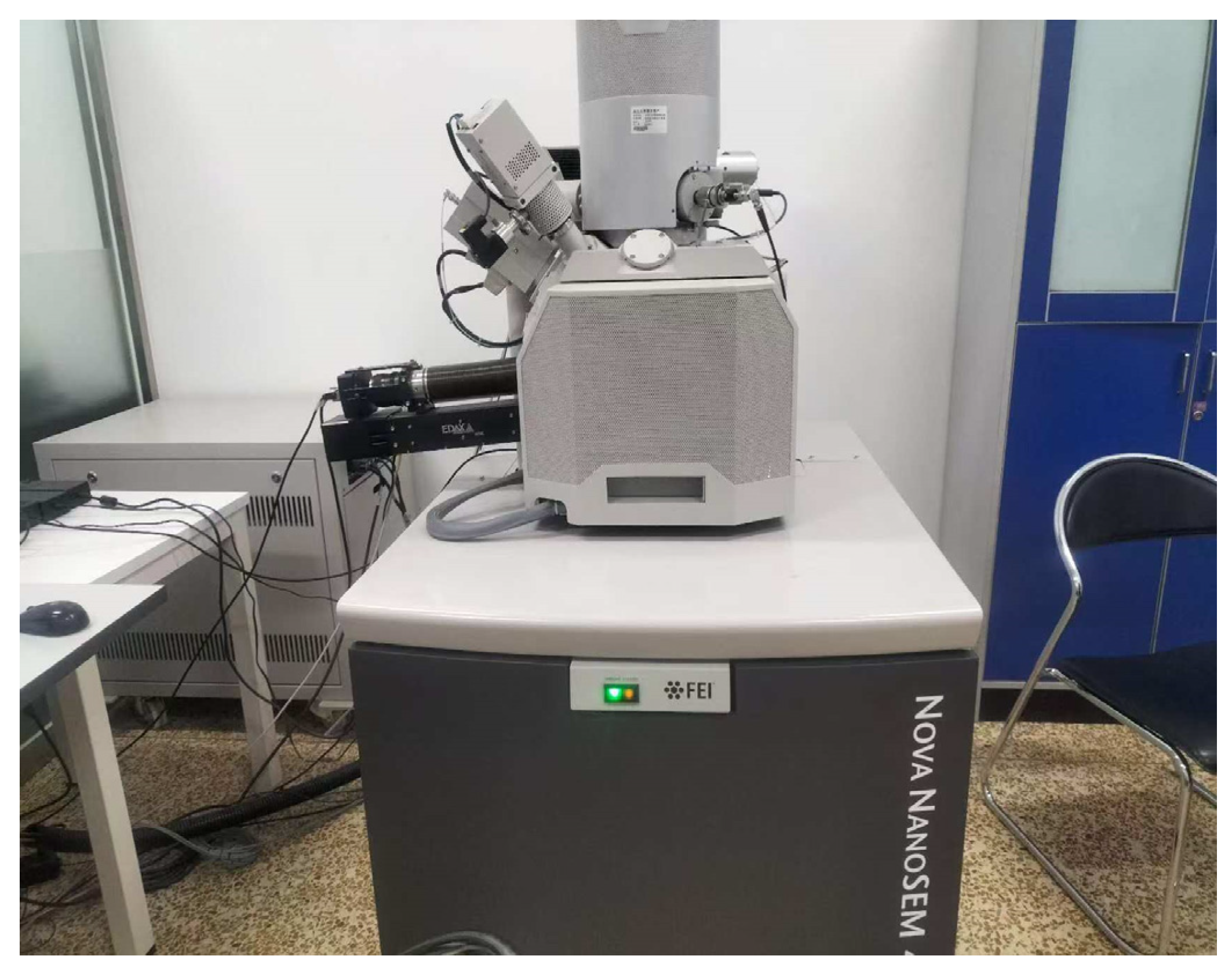

2.2.4. SEM Test

3. Results and Discussion

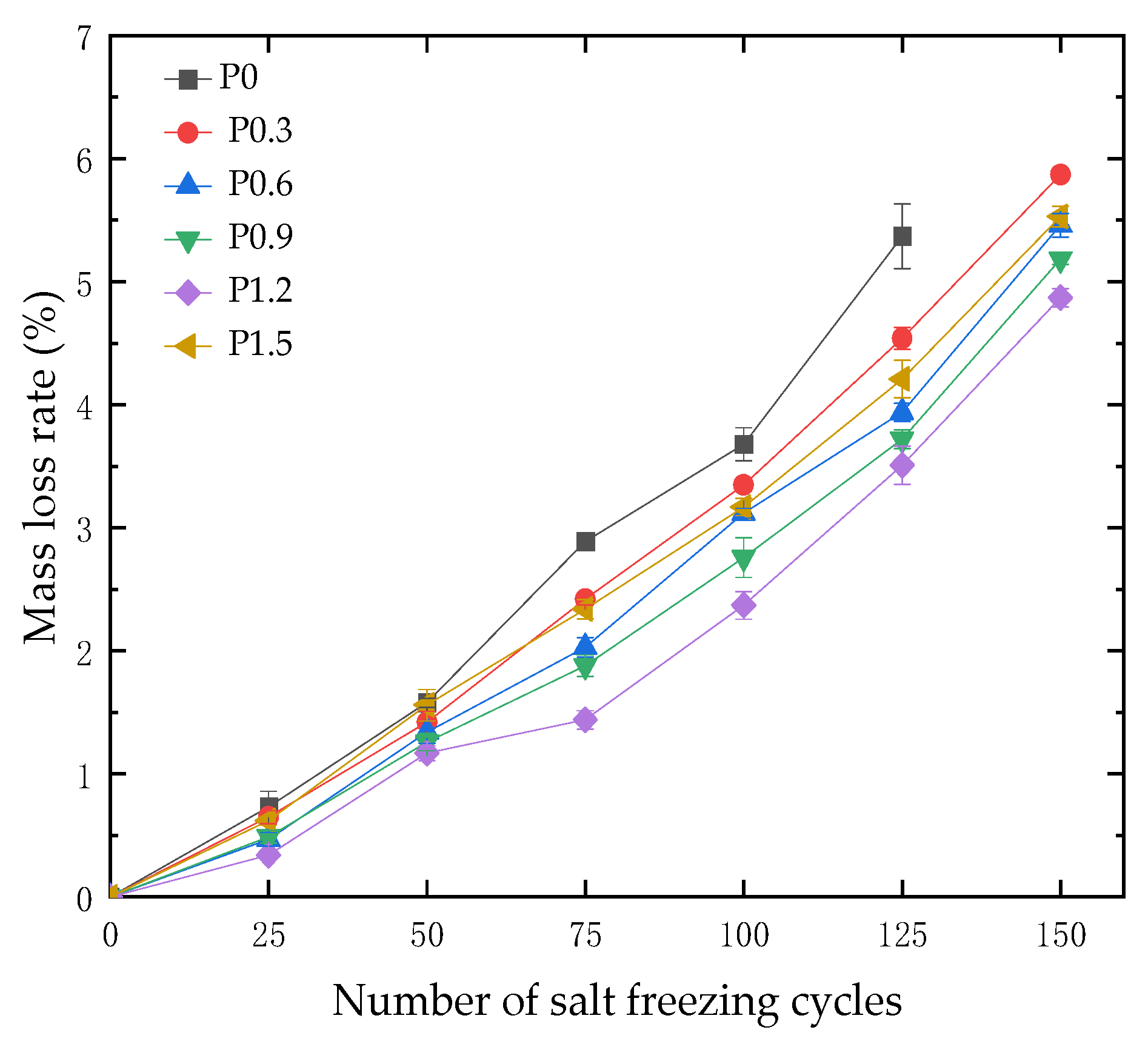

3.1. Mass Loss Rate

3.2. Relative Dynamic Elastic Modulus

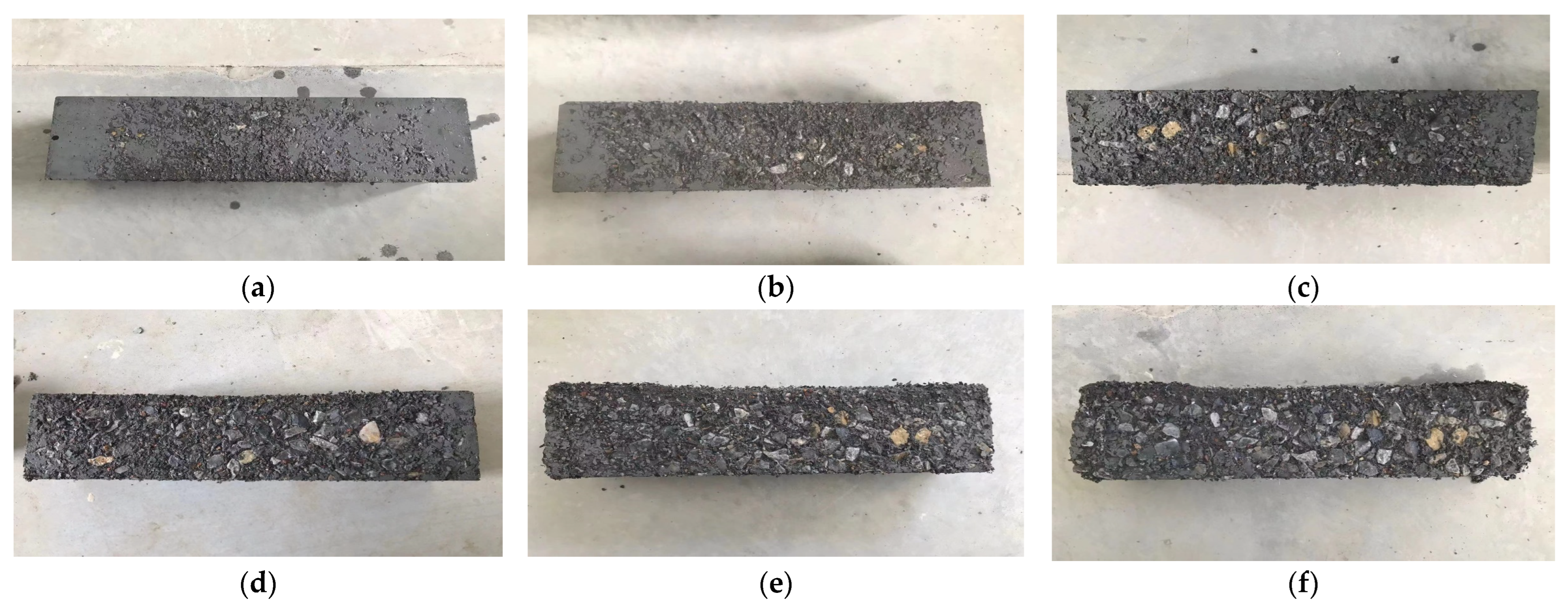

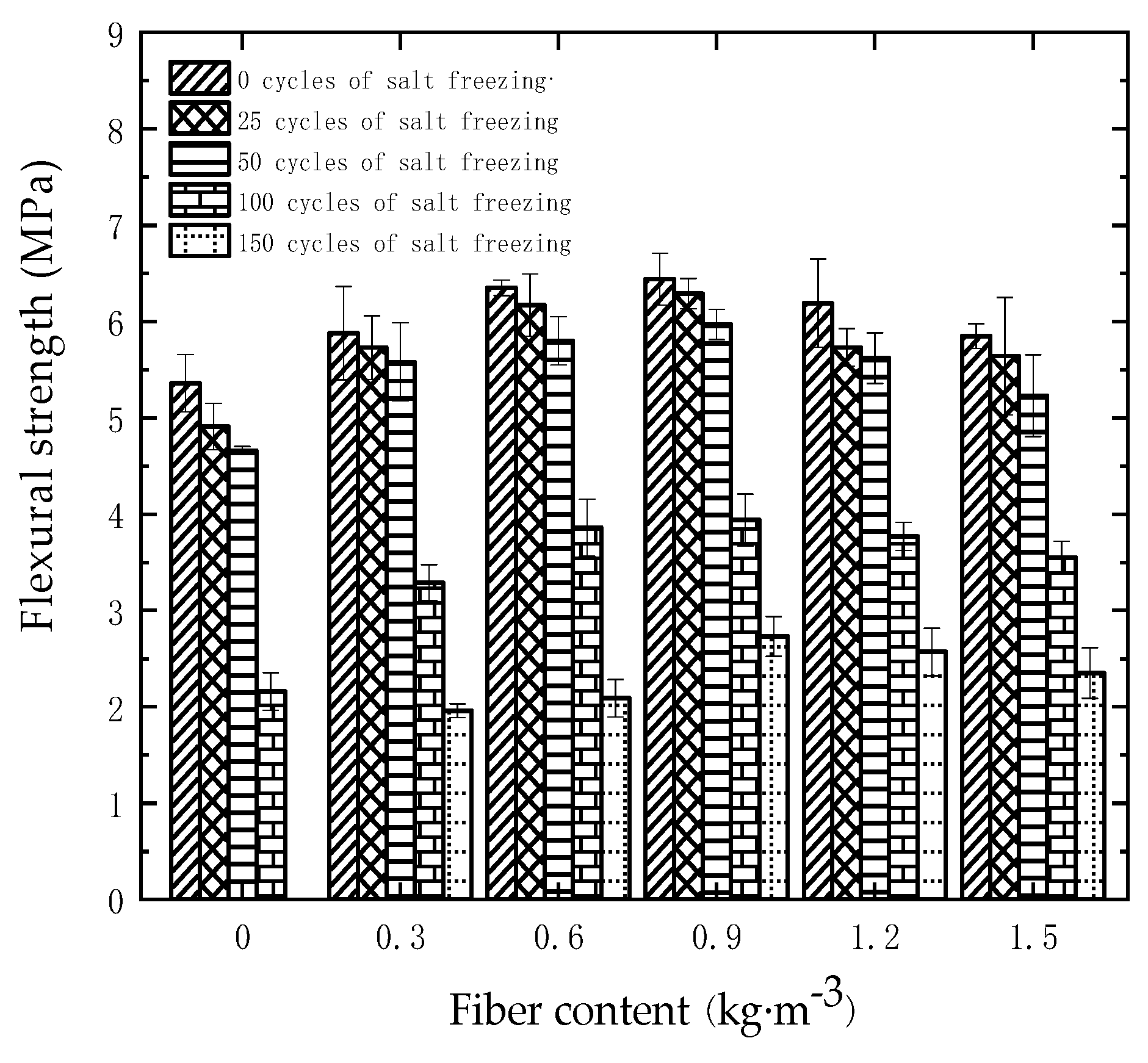

3.3. Flexural Strength

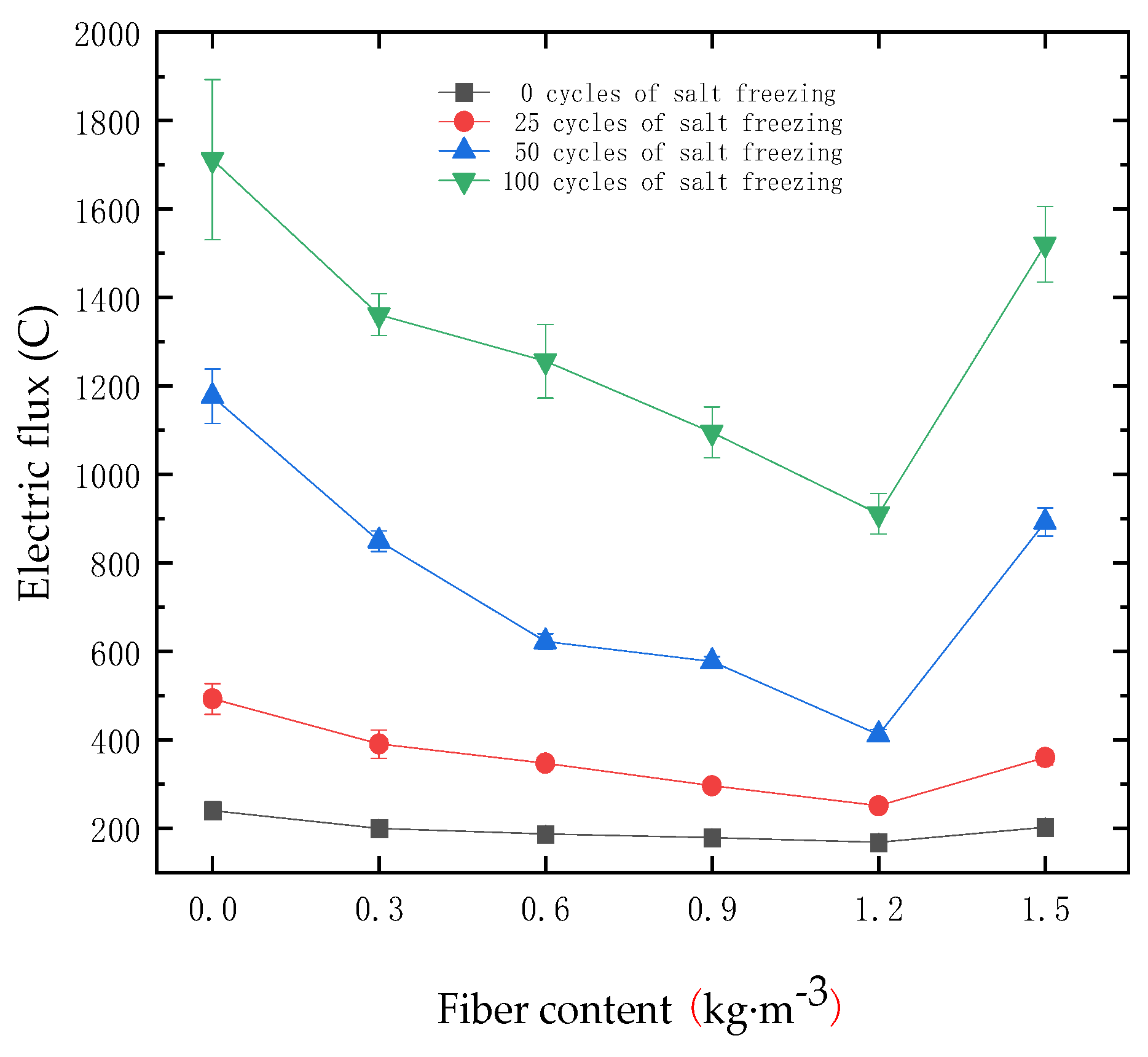

3.4. Resistance to Chloride Ion Penetration

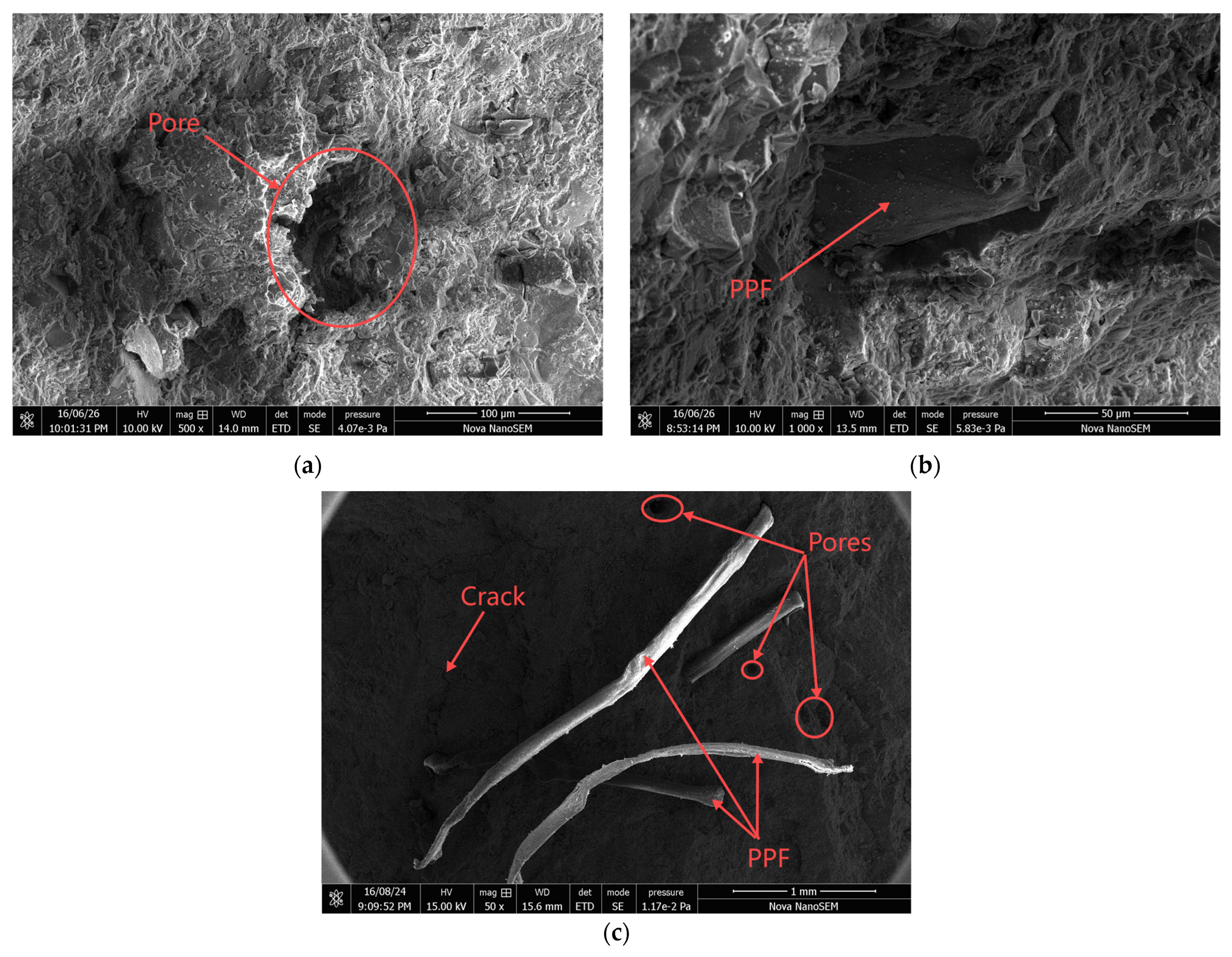

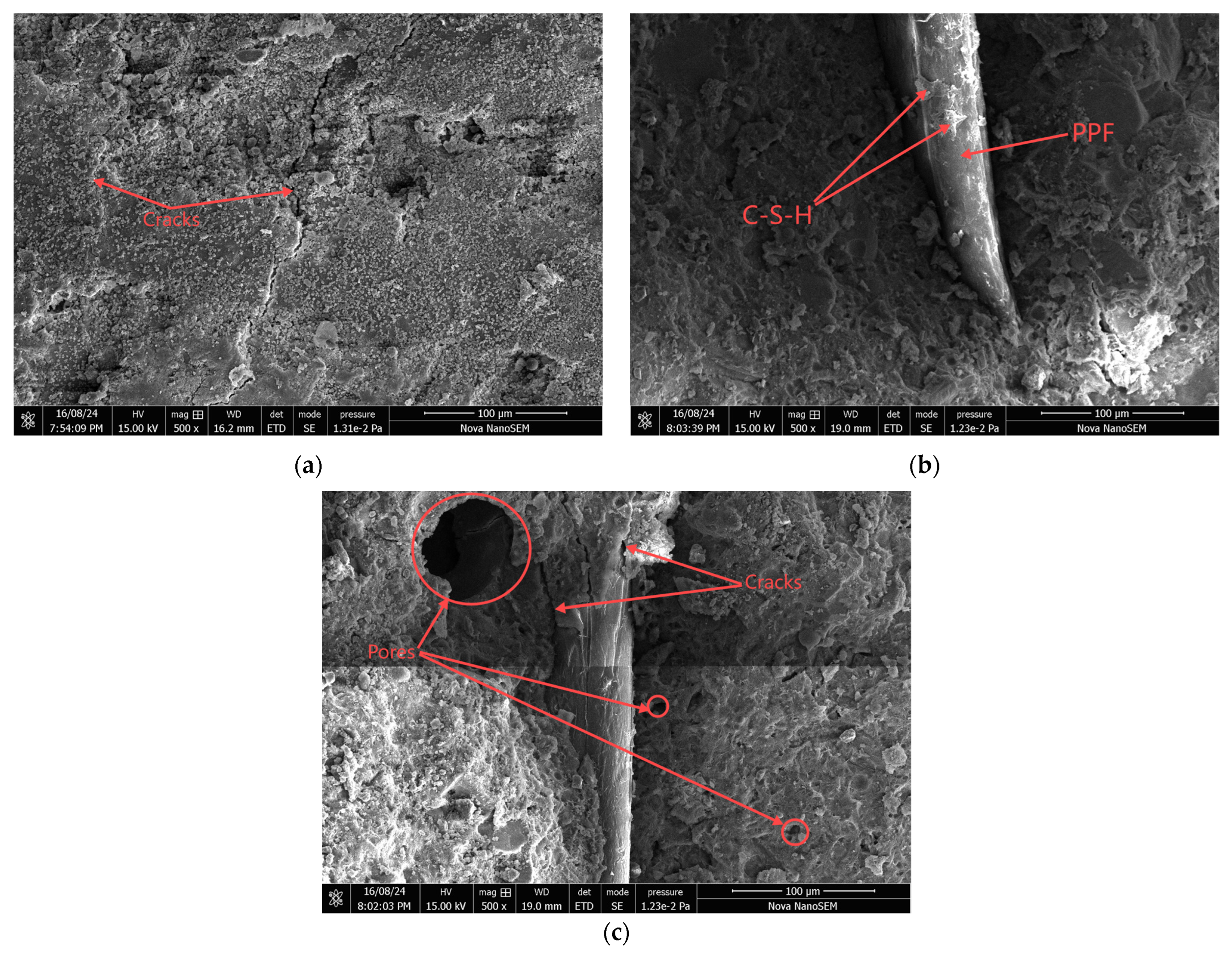

3.5. Microscopic Analysis

4. Mechanism Analysis

5. Conclusions

- (1)

- The flexural strength of the concrete was effectively improved when the fiber content increased from 0 to 0.9 kg/m3. This improvement is due to the network structure formed by the fibers in the concrete, which tightly integrates with the cementitious materials, enhancing the ductility and flexural strength of the concrete. However, when the fiber content exceeds 0.9 kg/m3, the flexural strength of the concrete decreases. This is because the excessive fiber content leads to uneven fiber distribution, forming clusters, and introduces more air during the concrete preparation process, which increases the porosity of the concrete and negatively affects its flexural strength.

- (2)

- The incorporation of polypropylene fibers effectively improves the salt-freezing resistance of concrete. Compared to the P0 group, after 100 salt freezing cycles, the relative dynamic modulus of elasticity of the P1.2 group concrete specimens increased by 4.7%, while the mass loss rate and electrical flux decreased by 35.6% and 46.78%, respectively. The random distribution of fibers forms a network structure that blocks the connection of tiny pores within the concrete, inhibiting the development of microcracks caused by salt freezing damage. However, when the fiber content exceeds 1.2 kg/m3, the excessive amount of fibers increases the porosity of the concrete, making it easier for harmful substances, such as chloride ions, to penetrate, which accelerates deterioration under freeze–thaw conditions.

- (3)

- In the early stages of salt freezing, chloride hydrates and chloride salt crystals enter the high-performance concrete, effectively improving the internal density of the concrete and slowing the rate of salt freezing damage. However, as the number of salt freezing cycles increases, the chloride hydrates and chloride salt crystals within the high-performance concrete continue to expand, generating crystallization pressure, which accelerates the internal damage of the concrete.

- (4)

- The durability damage of polypropylene fiber high-performance concrete gradually increases with the number of salt freezing cycles. The appropriate amount of fiber incorporation improves the durability of the concrete. However, when the fiber content exceeds 1.2 kg/m3, as the number of salt freezing cycles increases, the internal porosity of the concrete increases. The continuous detachment of the cement mortar and fibers from the concrete surface allows harmful agents to penetrate more easily. Additionally, temperature stress, osmotic pressure, and crystallization pressure exacerbate the internal damage of the concrete, leading to a continuous decline in the durability of the polypropylene fiber high-performance concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abousnina, R.; Premasiri, S.; Anise, V.; Lokuge, W.; Vimonsatit, V.; Ferdous, W.; Alajarmeh, O. Mechanical properties of macro polypropylene fibre-reinforced concrete. Polymers 2021, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Ji, Y.; Wang, J.; Wang, Z.; Yu, B.; Zhang, S. Experimental and modeling analysis of polypropylene fiber reinforced concrete subjected to alkali attack and freeze–thaw cycling effect. Materials 2024, 17, 4529. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Du, G.; Li, Y. Synergistic effects of polypropylene fiber and basalt fiber on the mechanical properties of concrete incorporating fly ash ceramsite after freeze-thaw cycles. J. Build. Eng. 2024, 91, 109593. [Google Scholar] [CrossRef]

- Gaayathri, K.K.; Jessie, J.A.; Yarramsetty, J.; Ashok, B.A. A study on mechanical properties of rubberized concrete with polypropylene fibres. Interactions 2024, 245, 202. [Google Scholar] [CrossRef]

- Ponraj Sankar, L.; Aruna, G.; Krishna Rao, A.; Srinivas Kadrekar, K. Studies on drying shrinkage and water permeability of fine fly ash high performance concrete. Mater. Today Proc. 2021, 46, 930–933. [Google Scholar] [CrossRef]

- Zhang, K.; Lin, W.; Lan, Q.; Zhang, Q. Compressive properties of polypropylene fiber reinforced seawater sea-sand recycled aggregate concrete under different strain rate loading. Constr. Build. Mater. 2024, 452, 138968. [Google Scholar] [CrossRef]

- Letsosa, C.M.; Dada, O.R.; Ikotun, B.D. The effects of different curing conditions on the polypropylene fibre reinforcement concrete. J. Phys. Conf. Ser. 2024, 2888, 012022. [Google Scholar] [CrossRef]

- Ramírez, W.; Mayacela, M.; Contreras, L.; Shambi, A.; Ramírez, F.; Chacón, J. Mechanical properties of permeable concrete reinforced with polypropylene fibers for different water–cement ratios. Buildings 2024, 14, 2935. [Google Scholar] [CrossRef]

- Xu, L.; Niu, L. Effect of polypropylene fiber on frost resistance of cemented soil. Mater. Plast. 2019, 57, 78–86. [Google Scholar] [CrossRef]

- Liang, N.; Hu, G.; Zhou, K.; Liu, X.; Zhou, X. Study on early-age cracking resistance of multi-scale polypropylene fiber reinforced concrete in restrained ring tests. J. Sustain. Cem. Based Mater. 2024, 13, 1050–1062. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Q.; Lin, Y. Effect of fibers on permeability and crack relaxation of cracked concrete. J. Acta Mater. Compos. Sin. 2017, 34, 1853–1861. [Google Scholar] [CrossRef]

- Akid, A.S.M.; Hossain, S.; Munshi, M.I.U.; Elahi, M.M.A.; Sobuz, M.H.R.; Tam, V.W.Y.; Islam, M.S. Assessing the influence of fly ash and polypropylene fiber on fresh, mechanical and durability properties of concrete. J. King Saud Univ.-Eng. Sci. 2021, 33, 474–484. [Google Scholar] [CrossRef]

- Xu, F.; Li, T.; Li, C.; Li, Z.; Wang, S.; Zhao, N. Compressive behavior, microstructural properties, and freeze–thaw behavior of tailing recycled aggregate concrete with waste polypropylene fiber addition. Materials 2021, 14, 6712. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fan, X.; Zhu, Y.; Luo, J.; Wang, X.; Guo, J.; Li, F.; Zhang, Z. Study on the effect of polypropylene fiber shape and admixture on the mechanical properties of concrete. J. Phys. Conf. Ser. 2024, 2808, 012088. [Google Scholar] [CrossRef]

- Al-Lebban, M.F.; Khazaly, A.I.; Shabbar, R.; Jabal, Q.A.; Al Asadi, L.A.R. Effect of polypropylene fibers on some mechanical properties of concrete and durability against freezing and thawing cycles. Key Eng. Mater. 2021, 895, 130–138. [Google Scholar] [CrossRef]

- He, Z.; Zhang, L.; Cheng, C.; Chen, Y.; Jin, Y. Study on mechanical properties and microcosmic morphology of polypropylene fiber reinforced recycled concrete after freeze–thaw cycles. Eur. J. Environ. Civ. Eng. 2024, 28, 3412–3434. [Google Scholar] [CrossRef]

- Luo, S.; Bai, T.; Guo, M.; Wei, Y.; Ma, W. Impact of freeze–thaw cycles on the long-term performance of concrete pavement and related improvement measures: A review. Materials 2022, 15, 4568. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, W.; Wang, Q.; Li, M.; Zhang, L.; Tong, Y. Influence of polypropylene fiber on concrete permeability under freeze-thaw conditions and mechanical loading. Materials 2024, 17, 2945. [Google Scholar] [CrossRef]

- Zhao, R.; Shi, C.; Zhang, R.; Wang, W.; Zhu, H.; Luo, J. Study on the freeze-thaw resistance of concrete pavements in seasonally frozen regions. Materials 2024, 17, 1902. [Google Scholar] [CrossRef]

- Lu, J.; Liu, J.; Yang, H.; Wan, X.; Gao, J.; Zhang, J.; Li, P. Experimental investigation on the mechanical properties and pore structure deterioration of fiber-reinforced concrete in different freeze-thaw media. Constr. Build. Mater. 2022, 350, 128887. [Google Scholar] [CrossRef]

- Li, Z.; Gao, W.; Li, K.; Wang, Q.; Yang, J.; Su, C. Effect of mineral admixture and fiber on the frost resistance of concrete in cold region. IOP Conf. Ser. Earth Environ. Sci. 2019, 304, 052085. [Google Scholar] [CrossRef]

- Xu, L.; Lai, Y.; Ma, D.; Wang, J.; Li, M.; Li, L.; Gao, Z.; Liu, Y.; He, P.; Zhang, Y. Effects of fiber and surface treatment on airport pavement concrete against freeze–thawing and salt freezing. Materials 2022, 15, 7528. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Sun, C.; Wang, X. Study on the effect of fly ash on mechanical properties and seawater freeze–thaw resistance of seawater sea sand concrete. Buildings 2024, 14, 2191. [Google Scholar] [CrossRef]

- Huang, G.; Su, L.; Xue, C.; Zhang, Y.; Qiao, H.; Wang, C. Study on the deterioration mechanism of hybrid basalt-polypropylene fiber-reinforced concrete under sulfate freeze-thaw cycles. Constr. Build. Mater. 2024, 449, 138560. [Google Scholar] [CrossRef]

- Ren, J.; Lai, Y. Study on the durability and failure mechanism of concrete modified with nanoparticles and polypropylene fiber under freeze-thaw cycles and sulfate attack. Cold Reg. Sci. Technol. 2021, 188, 103301. [Google Scholar] [CrossRef]

- Gong, L.; Yu, X.; Liang, Y.; Gong, X.; Du, Q. Multi-scale deterioration and microstructure of polypropylene fiber concrete by salt freezing. Case Stud. Constr. Mater. 2023, 18, e01762. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standard Press of China: Beijing, China, 2021.

- CECS 207-2006; Technical Specificatioe for Application of High Performance Concrete. China Planning Press: Beijing, China, 2006.

- Erdoğdu, Ş.; Arslantürk, C.; Kurbetci, Ş. Influence of fly ash and silica fume on the consistency retention and compressive strength of concrete subjected to prolonged agitating. Constr. Build. Mater. 2011, 25, 1277–1281. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Zhang, H. Combined effect of polypropylene fiber and silica fume on mechanical properties of concrete composite containing fly ash. J. Reinf. Plast. Compos. 2011, 30, 1349–1358. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. Part B 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- JTS/T 236-2019; Technical Specification for Concrete Testing of Port and Waterway Engineering. China Communications Press Co., Ltd.: Beijing, China, 2019.

- GB/T 50082-2024; Standard for Test Methods of Long-Term Performance and Durability of Concrete. China Architecture & Building Press: Beijing, China, 2024.

| Cementitious Materials | Chemical Composition Ratio/% | ||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | TiO2 | Cl− | |

| Cement | 17.32 | 4.04 | 3.32 | 59.74 | 0.90 | 0.30 | 0.03 |

| Fly ash | 49.30 | 28.37 | 5.81 | 3.08 | 2.67 | 1.28 | 0.12 |

| Silica fume | 96.31 | 0.19 | 0.12 | 0.12 | 0.01 | 0.02 | 0.07 |

| Sample | Mix Ratio/(kg·m−3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Water | Cement | Fly Ash | Silica Fume | Sand | Gravel | Water Reducing Agent | Polypropylene Fiber | |

| P0 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 0 |

| P0.3 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 0.3 |

| P0.6 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 0.6 |

| P0.9 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 0.9 |

| P1.2 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 1.2 |

| P1.5 | 185 | 320 | 155 | 40 | 615 | 1195 | 13.75 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Z.; Liu, Y.; Zhang, W. Study on Salt-Frost Damage Durability of High-Performance Concrete with Polypropylene Fiber. Materials 2025, 18, 1007. https://doi.org/10.3390/ma18051007

Qi Z, Liu Y, Zhang W. Study on Salt-Frost Damage Durability of High-Performance Concrete with Polypropylene Fiber. Materials. 2025; 18(5):1007. https://doi.org/10.3390/ma18051007

Chicago/Turabian StyleQi, Zongao, Yan Liu, and Wei Zhang. 2025. "Study on Salt-Frost Damage Durability of High-Performance Concrete with Polypropylene Fiber" Materials 18, no. 5: 1007. https://doi.org/10.3390/ma18051007

APA StyleQi, Z., Liu, Y., & Zhang, W. (2025). Study on Salt-Frost Damage Durability of High-Performance Concrete with Polypropylene Fiber. Materials, 18(5), 1007. https://doi.org/10.3390/ma18051007