Application of Phosphogypsum in Ultra-High-Performance Concrete (UHPC) Matrix for Strength Enhancement and Shrinkage Reduction

Abstract

:1. Introduction

2. Experimental Schemes

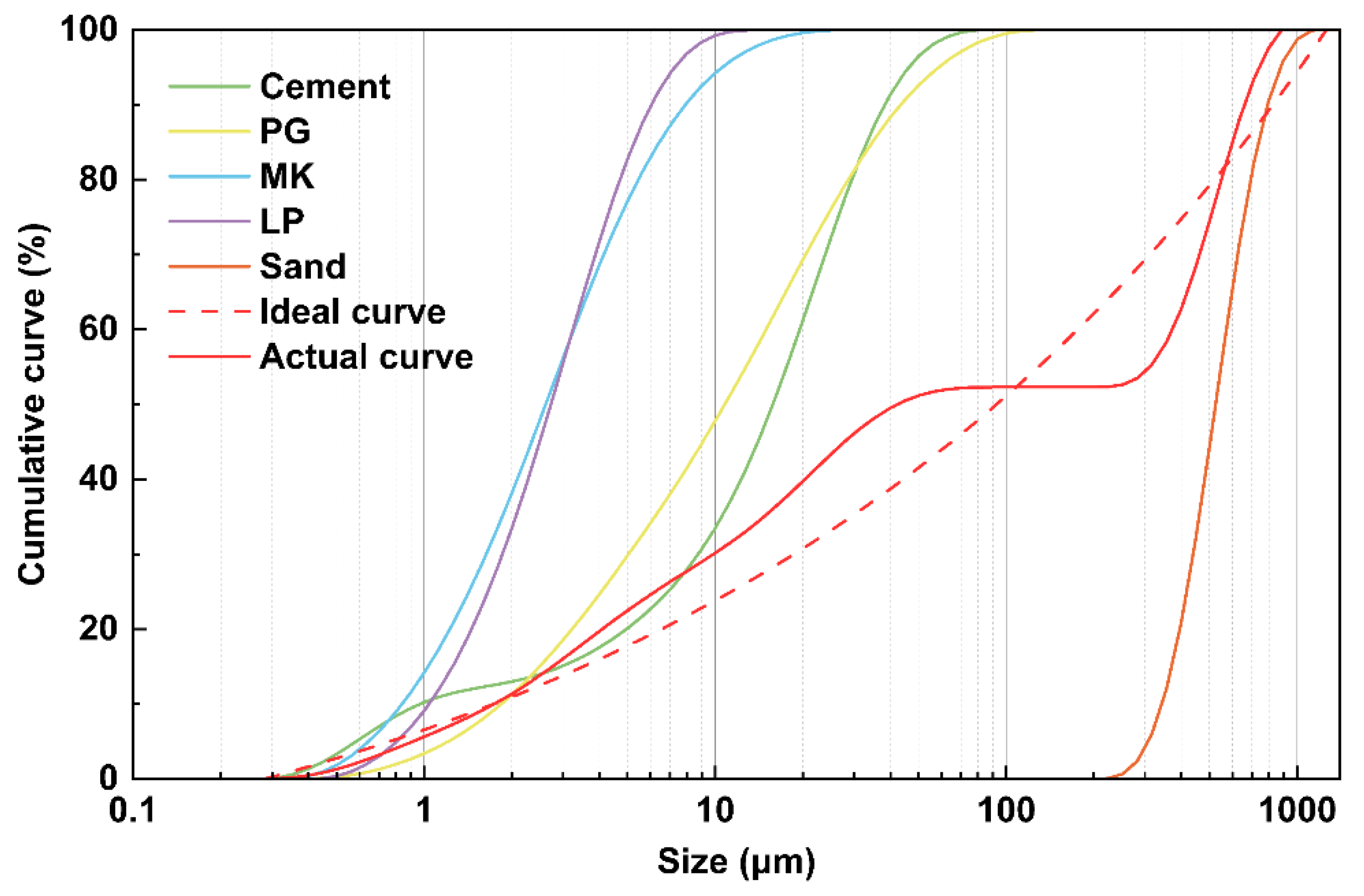

2.1. Raw Material

2.2. Mix Design and Specimen Preparation

2.3. Compressive Strength

2.4. Setting Time

2.5. Shrinkage Test

2.6. Hydration Kinetics

2.7. TG–DTG

2.8. X-Ray Diffraction

3. Results and Discussion

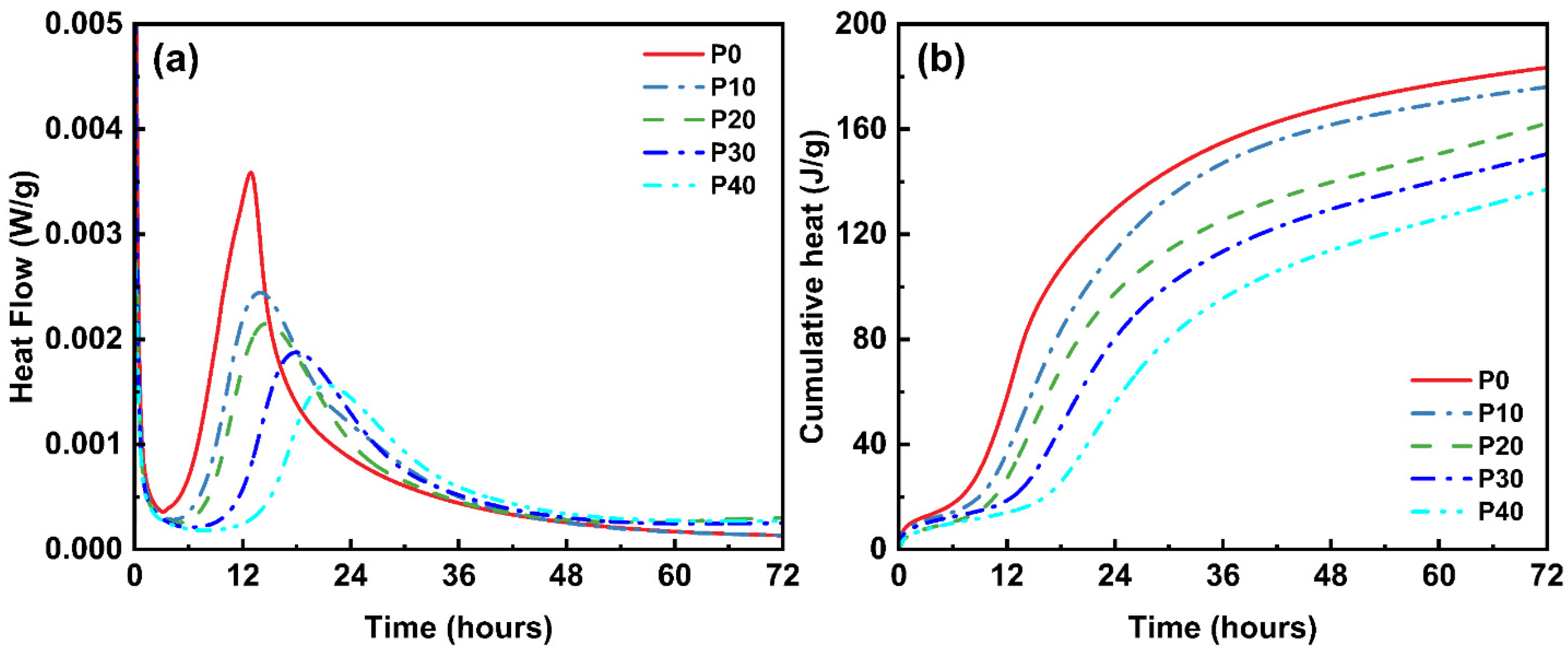

3.1. Heat of Hydration Analysis

3.2. XRD Analysis

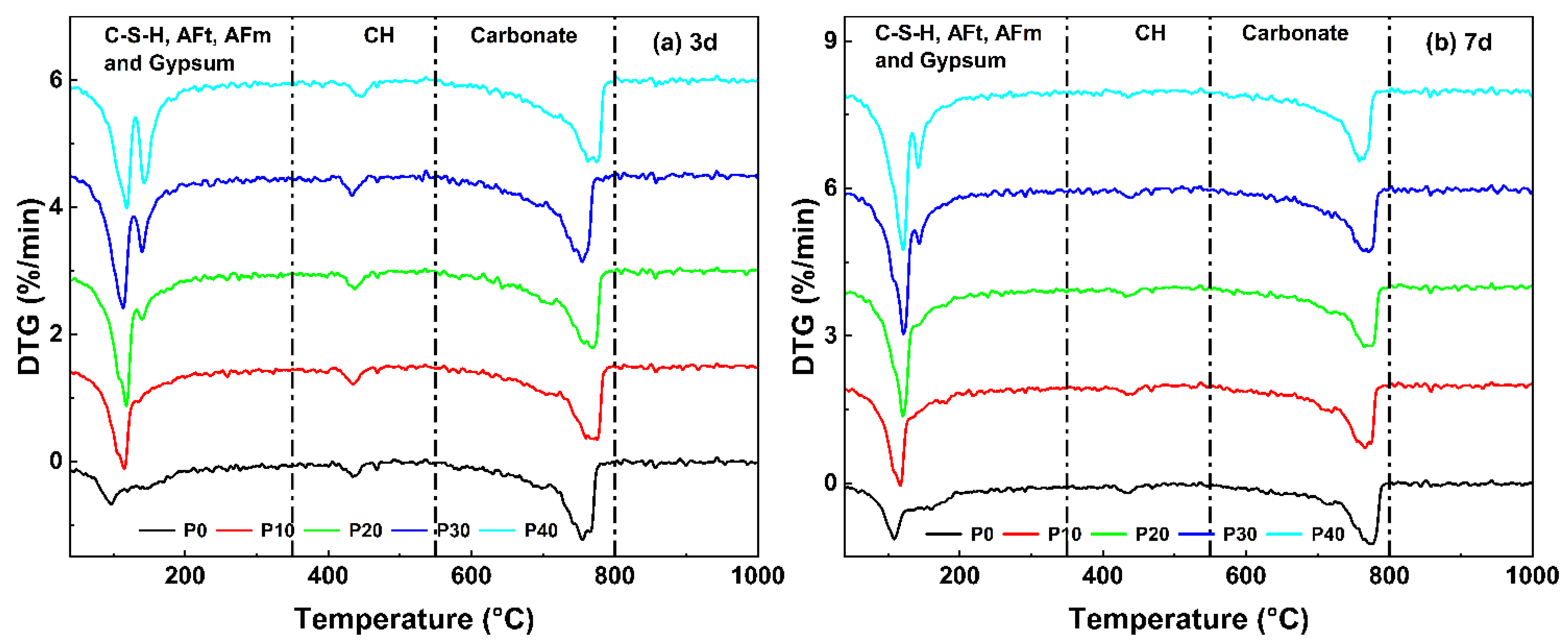

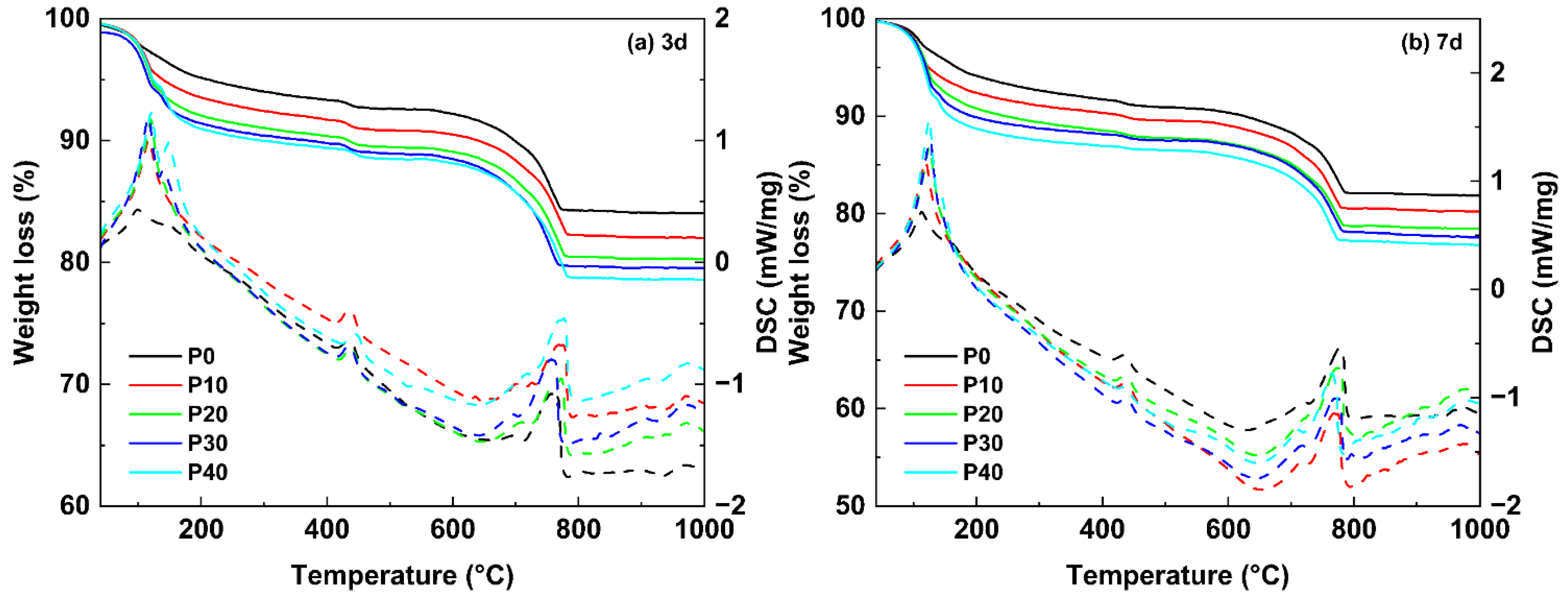

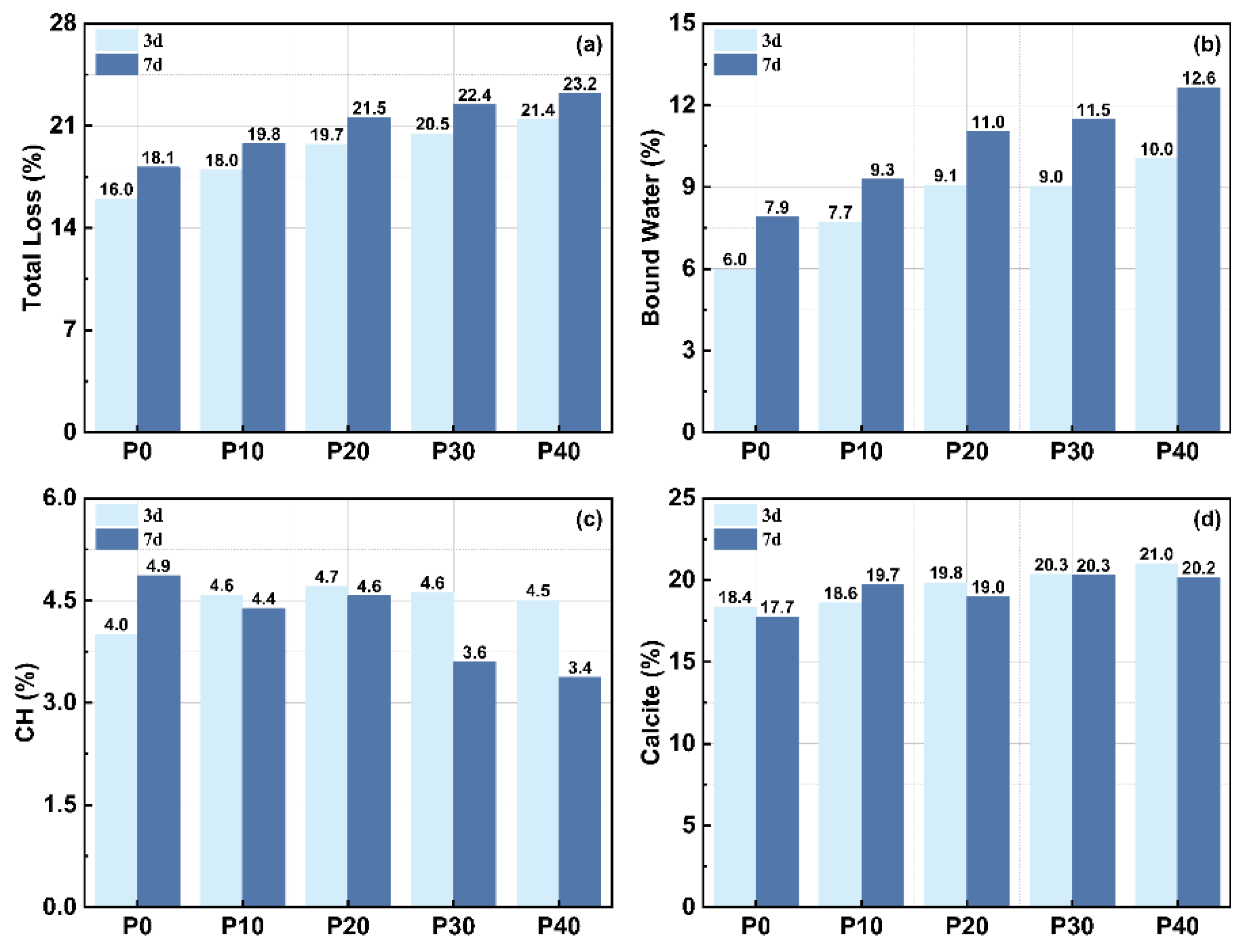

3.3. Thermal Analysis

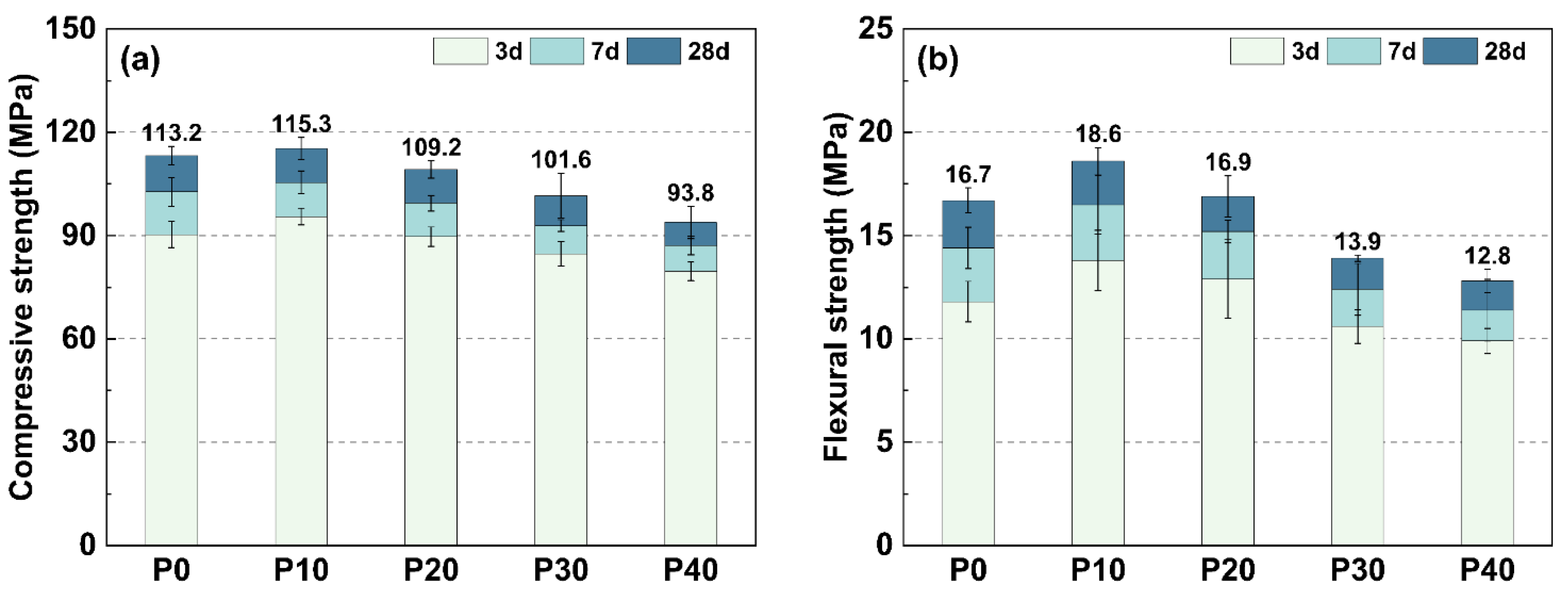

3.4. Mechanical Properties

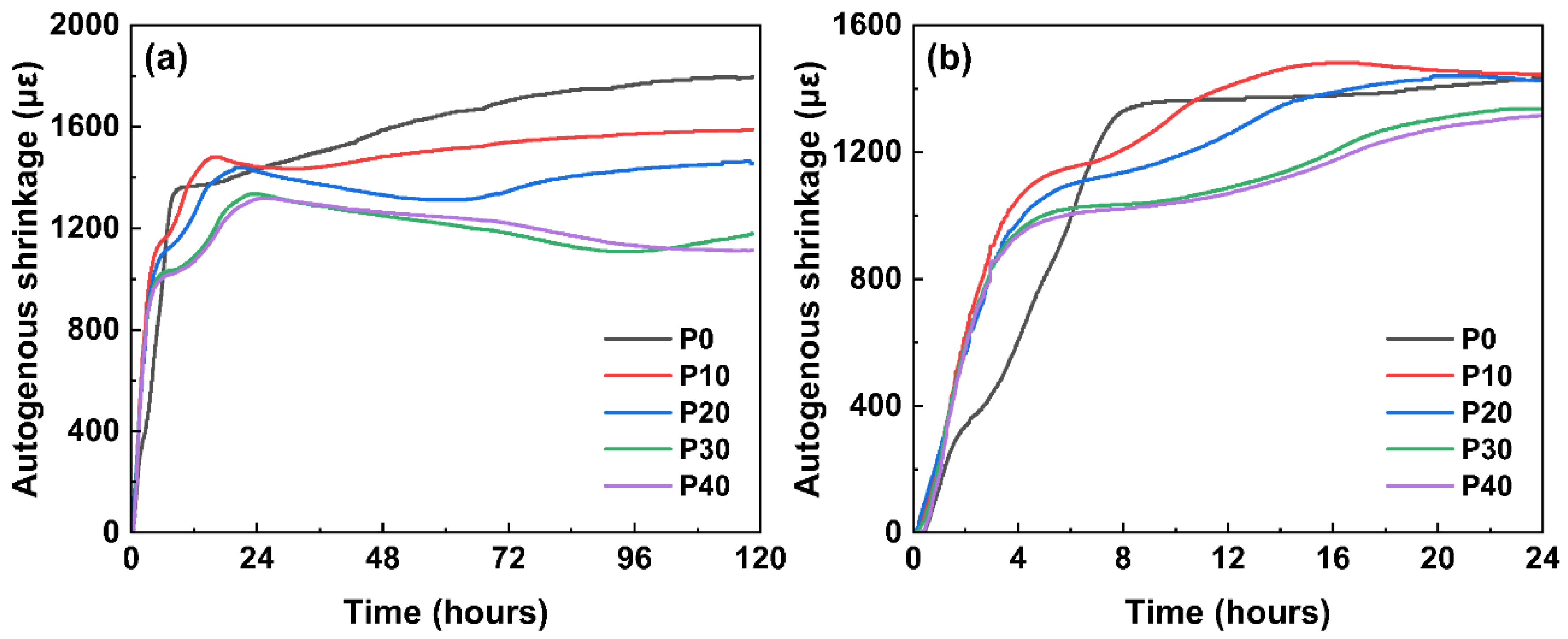

3.5. Autogenous Shrinkage

4. Conclusions

- Hydration process: The results of isothermal calorimetry showed that an increasing PG content delays hydration, which is reflected in the extended induction period and the hydration peak time. This delay is attributed to the sulfate regulation of C3A hydration, which prevents the cement from setting rapidly and improves volume stability.

- Phase evolution: XRD and TG results confirmed that, under room temperature conditions, PG alters the formation of hydration products, with the formation of AFt increasing at early stages and secondary hydration reactions consuming CH over time, resulting in microstructure refinement.

- Mechanical properties: The compressive and flexural strength tests showed that although strength development at an early age was hindered by the retarding effect of PG, mechanical performance remained comparable or even better in the long term with moderate replacement quantities. The results suggest that a PG substitute (≤10–20%) optimizes both processability and long-term strength, whereas excessive replacement results in a decrease in strength.

- Autogenous shrinkage and volume stability: PG significantly reduces shrinkage at an early age, with a PG replacement of 10 to 40% reducing shrinkage by 11.6–38.0% within 5 days. This is attributed to the micro-expansion effect of PG in early hydration phases. In addition, the limestone powder in the system prevents the conversion of AFt to AFm, further improving shrinkage resistance and volume stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, T.; Wang, X.; Maimaitituersun, N.; Dong, S.; Li, L.; Han, B. Synergistic effects of steel fibers and steel wires on uniaxial tensile mechanical and self-sensing properties of UHPC. Constr. Build. Mater. 2024, 416, 134991. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2020, 268, 121112. [Google Scholar] [CrossRef]

- Kim, S.; Yoo, D.-Y.; Kim, M.-J.; Banthia, N. Self-healing capability of ultra-high-performance fiber-reinforced concrete after exposure to cryogenic temperature. Cem. Concr. Compos. 2019, 104, 103335. [Google Scholar] [CrossRef]

- Zhuang, W.; Li, S.; Wang, Z.; Zhang, Z.; Yu, Q. Impact of micromechanics on dynamic compressive behavior of ultra-high performance concrete containing limestone powder. Compos. Part B-Eng. 2022, 243, 110160. [Google Scholar] [CrossRef]

- Wang, J.; Dong, S.; Pang, S.D.; Yu, X.; Han, B.; Ou, J. Tailoring Anti-Impact Properties of Ultra-High Performance Concrete by Incorporating Functionalized Carbon Nanotubes. Engineering 2022, 18, 232–245. [Google Scholar] [CrossRef]

- Lu, J.-X.; Shen, P.; Sun, Y.; Poon, C.S. Strategy for preventing explosive spalling and enhancing material efficiency of lightweight ultra high-performance concrete. Cem. Concr. Res. 2022, 158, 106842. [Google Scholar] [CrossRef]

- Mo, K.H.; Johnson Alengaram, U.; Jumaat, M.Z.; Yap, S.P. Feasibility study of high volume slag as cement replacement for sustainable structural lightweight oil palm shell concrete. J. Clean. Prod. 2015, 91, 297–304. [Google Scholar] [CrossRef]

- Jin, Z.; Ma, B.; Su, Y.; Lu, W.; Qi, H.; Hu, P. Effect of calcium sulphoaluminate cement on mechanical strength and waterproof properties of beta-hemihydrate phosphogypsum. Constr. Build. Mater. 2020, 242, 118198. [Google Scholar] [CrossRef]

- Raheem, A.A.; Abdulwahab, R.; Kareem, M.A. Incorporation of metakaolin and nanosilica in blended cement mortar and concrete—A review. J. Cleaner Prod. 2021, 290, 125852. [Google Scholar] [CrossRef]

- Saidin, S.S.; Kudus, S.A.; Jamadin, A.; Anuar, M.A.; Amin, N.M.; Ibrahim, Z.; Zakaria, A.B.; Sugiura, K. Operational modal analysis and finite element model updating of ultra-high-performance concrete bridge based on ambient vibration test. Case Stud. Constr. Mater. 2022, 16, e01117. [Google Scholar] [CrossRef]

- Guo, M.; Hu, B.; Xing, F.; Zhou, X.; Sun, M.; Sui, L.; Zhou, Y. Characterization of the mechanical properties of eco-friendly concrete made with untreated sea sand and seawater based on statistical analysis. Constr. Build. Mater. 2020, 234, 117339. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Zhou, Y.; Min, C.; Shi, Y. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill. J. Hazard. Mater. 2020, 399, 122993. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, D.; You, L.; Luo, H.; Xu, W. Recycling phosphogypsum in subbase of pavement: Treatment, testing, and application. Constr. Build. Mater. 2022, 342, 127948. [Google Scholar] [CrossRef]

- Wei, Z.; Deng, Z. Research hotspots and trends of comprehensive utilization of phosphogypsum: Bibliometric analysis. J. Environ. Radioact. 2022, 242, 106778. [Google Scholar] [CrossRef]

- Chuan, L.M.; Zheng, H.G.; Zhao, J.J.; Wang, A.L.; Sun, S.F. Phosphogypsum production and utilization in China. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 22099. [Google Scholar] [CrossRef]

- Wang, C.; Chen, S.; Huang, D.; Huang, Q.; Li, X.; Shui, Z. Safe environmentally friendly reuse of red mud modified phosphogypsum composite cementitious material. Constr. Build. Mater. 2023, 368, 130348. [Google Scholar] [CrossRef]

- Xie, Y.; Sun, T.; Shui, Z.; Ding, C.; Li, W. The impact of carbonation at different CO2 concentrations on the microstructure of phosphogypsum-based supersulfated cement paste. Constr. Build. Mater. 2022, 340, 127823. [Google Scholar] [CrossRef]

- Wang, Z.; Shui, Z.; Sun, T.; Li, X.; Zhang, M. Recycling utilization of phosphogypsum in eco excess-sulphate cement: Synergistic effects of metakaolin and slag additives on hydration, strength and microstructure. J. Clean. Prod. 2022, 358, 131901. [Google Scholar] [CrossRef]

- Contreras Llanes, M.; Pérez López, R.; Gázquez González, M.J.; Morales Flórez, V.; Santos, A.; Esquivias, L.; Bolívar Raya, J.P. Fractionation and fluxes of metals and radionuclides during the recycling process of phosphogypsum wastes applied to mineral CO2 sequestration. Waste Manag. 2015, 45, 412–419. [Google Scholar] [CrossRef]

- Neto, J.S.A.; Bersch, J.D.; Silva, T.S.; Rodríguez, E.D.; Suzuki, S.; Kirchheim, A.P. Influence of phosphogypsum purification with lime on the properties of cementitious matrices with and without plasticizer. Constr. Build. Mater. 2021, 299, 123935. [Google Scholar] [CrossRef]

- Wang, J.; Tan, H.; He, X.; Zhang, J.; Jian, S.; Du, C.; Deng, X. Influence of wet grinded slag on the hydration of phosphogypsum-slag based cement and its application in backfill tailings. Constr. Build. Mater. 2022, 360, 129509. [Google Scholar] [CrossRef]

- Huang, X.; Li, J.; Jiang, W.; Chen, Z.; Wan, Y.; Xue, Q.; Liu, L.; Poon, C.S. Recycling of phosphogypsum and red mud in low carbon and green cementitious materials for vertical barrier. Sci. Total Environ. 2022, 838, 155925. [Google Scholar] [CrossRef]

- Cao, J.; Wang, Z.; Ma, X.; Yang, X.; Zhang, X.; Pan, H.; Wu, J.; Xu, M.; Lin, L.; Zhang, Y. Promoting coordinative development of phosphogypsum resources reuse through a novel integrated approach: A case study from China. J. Cleaner Prod. 2022, 374, 134078. [Google Scholar] [CrossRef]

- Akın Altun, İ.; Sert, Y. Utilization of weathered phosphogypsum as set retarder in portland cement. Cem. Concr. Res. 2004, 34, 677–680. [Google Scholar] [CrossRef]

- Kacimi, L.; Simon-Masseron, A.; Ghomari, A.; Derriche, Z. Reduction of clinkerization temperature by using phosphogypsum. J. Hazard. Mater. 2006, 137, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Enamorado, S.; Abril, J.M.; Delgado, A.; Más, J.L.; Polvillo, O.; Quintero, J.M. Implications for food safety of the uptake by tomato of 25 trace-elements from a phosphogypsum amended soil from SW spain. J. Hazard. Mater. 2014, 266, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Zhang, Q.; Li, X. Crystallization kinetics of α-hemihydrate gypsum prepared by hydrothermal method in atmospheric salt solution medium. Crystals 2021, 11, 843. [Google Scholar] [CrossRef]

- Diouri, C.; Echehbani, I.; Lahlou, K.; Omari, K.E.; Alaoui, A. Valorization of moroccan phosphogypsum in road engineering: Parametric study. Mater. Today Proc. 2022, 58, 1054–1058. [Google Scholar] [CrossRef]

- Meskini, S.; Samdi, A.; Ejjaouani, H.; Remmal, T. Valorization of phosphogypsum as a road material: Stabilizing effect of fly ash and lime additives on strength and durability. J. Cleaner Prod. 2021, 323, 129161. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Lachemi, M. Benefits of using blended waste coarse lightweight aggregates in structural lightweight aggregate concrete. J. Cleaner Prod. 2016, 119, 108–117. [Google Scholar] [CrossRef]

- Zhang, L.; Mo, K.H.; Yap, S.P.; Gencel, O.; Ling, T.-C. Mechanical strength, water resistance and drying shrinkage of lightweight hemihydrate phosphogypsum-cement composite with ground granulated blast furnace slag and recycled waste glass. Constr. Build. Mater. 2022, 345, 128232. [Google Scholar] [CrossRef]

- Ding, C.; Sun, T.; Shui, Z.; Xie, Y.; Ye, Z. Physical properties, strength, and impurities stability of phosphogypsum-based cold-bonded aggregates. Constr. Build. Mater. 2022, 331, 127307. [Google Scholar] [CrossRef]

- Pinto, S.R.; Angulski da Luz, C.; Munhoz, G.S.; Medeiros-Junior, R.A. Durability of phosphogypsum-based supersulfated cement mortar against external attack by sodium and magnesium sulfate. Cem. Concr. Res. 2020, 136, 106172. [Google Scholar] [CrossRef]

- Li, H.; Xu, F.; Li, B.; Sun, T.; Huang, X.; Zhu, J.; Peng, C.; Lin, J.; Chen, Z. Investigation on mechanical properties of excess-sulfate phosphogypsum slag cement: From experiments to molecular dynamics simulation. Constr. Build. Mater. 2022, 315, 125685. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, M. Long-term evolution of delayed ettringite and gypsum in portland cement mortars under sulfate erosion. Constr. Build. Mater. 2009, 23, 812–816. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, L.; He, X.; Su, Y.; Miao, W.; Strnadel, B.; Huang, X. Hydration and rheology of activated ultra-fine ground granulated blast furnace slag with carbide slag and anhydrous phosphogypsum. Cem. Concr. Compos. 2022, 133, 104727. [Google Scholar] [CrossRef]

- Peng, Y.; Li, X.; Liu, Y.; Zhan, B.; Xu, G. Optimization for mix proportion of reactive powder concrete containing phosphorous slag by using packing model. J. Adv. Concr. Technol. 2020, 18, 481–492. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, J.; Liu, J.; Ke, J.; Wang, F. Properties and microstructure of reactive powder concrete having a high content of phosphorous slag powder and silica fume. Constr. Build. Mater. 2015, 101, 482–487. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, G.; Yang, R.; Yu, R.; Xiao, R.; Wang, Z.; Xie, G.; Cheng, J. Hydration kinetics and microstructure development of ultra-high performance concrete (UHPC) by high volume of phosphorus slag powder. Cem. Concr. Compos. 2023, 138, 104978. [Google Scholar] [CrossRef]

- Rui, Y.; Rui, Y.; Zhonghe, S.; Xu, G.; Xunguang, X.; Xiangbin, Z.; Yunyao, W.; Yongjia, H. Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag. J. Cleaner Prod. 2019, 240, UNSP 118157. [Google Scholar]

- Chen, G.; Huang, Y.; Yang, R.; Yu, R.; Xiao, R.; Wang, Z.; Ke, X.; Xie, G.; Cheng, J.; Bao, M. Comparative study on mechanical properties and microstructure development of ultra-high performance concrete incorporating phosphorous slag under different curing regimes. Constr. Build. Mater. 2023, 392, 131963. [Google Scholar] [CrossRef]

- Shi, Y.; Matsui, I.; Feng, N. Effect of compound mineral powders on workability and rheological property of HPC. Cem. Concr. Res. 2002, 32, 71–78. [Google Scholar] [CrossRef]

- Liu, Z.; Qi, X.; Shui, Z.; Lv, Y. The preparation, property and hydration mechanism of ultra high performance concrete with metakaolin substitution for silica fume. J. Build. Eng. 2024, 94, 109927. [Google Scholar] [CrossRef]

- Liu, Z.; Qi, X.; Yu, Z.; Gao, X.; Shui, Z. Development and properties of cost-effective self-sensing Ultra-High Performance Fiber-Reinforced Concrete (UHPFRC) incorporating steel slags. Constr. Build. Mater. 2024, 449, 138502. [Google Scholar] [CrossRef]

- EN 196-1:2016 Standard; Methods of Testing Cement—Part 1: Determination of Strength. British Standards Institution-BSI and CEN European Committee for Standardization: London, UK, 2016.

- EN 196-3:2016 Standard; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. British Standards Institution-BSI and CEN European Committee for Standardization: London, UK, 2016.

- ASTM C1698-09; Standard Test Method for Autogenous Strain of Cement Paste and Mortar. ASTM International: West Conshohocken, PA, USA, 2014.

| Materials | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | MgO | SO3 | TiO2 | L.O.I. |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 61.91 | 20.17 | 5.09 | 3.68 | 0.16 | 0.85 | 2.41 | 0.29 | 5.46 |

| PG | 36.07 | 5.34 | 0.83 | 0.41 | 0.30 | 0.77 | 32.05 | 0.11 | 24.12 |

| MK | 0.23 | 49.43 | 46.57 | 0.76 | 0.18 | 0.15 | 0.04 | 1.23 | 1.42 |

| LP | 56.55 | 0.49 | 0.07 | - | - | 0.29 | - | - | 42.6 |

| Group | Cement | PG | LP | MK | Sand | w/b | SP |

|---|---|---|---|---|---|---|---|

| P0 | 1015 | 0 | 271 | 258 | 1315 | 0.2 | 10.8 |

| P10 | 914 | 101 | 271 | 258 | 1315 | 0.2 | 10.8 |

| P20 | 812 | 203 | 271 | 258 | 1315 | 0.2 | 10.8 |

| P30 | 711 | 304 | 271 | 258 | 1315 | 0.2 | 10.8 |

| P40 | 609 | 406 | 271 | 258 | 1315 | 0.2 | 10.8 |

| tA | (dQ/dt)A | QA | tB | (dQ/dt)B | QB | QT | |

|---|---|---|---|---|---|---|---|

| (h) | (mW/g) | (J/g) | (h) | (mW/g) | (J/g) | (J/g) | |

| P0 | 3.20 | 0.3570 | 12.9 | 12.91 | 3.5863 | 69.0 | 183.5 |

| P10 | 4.27 | 0.2840 | 12.4 | 13.96 | 2.4457 | 52.7 | 176.1 |

| P20 | 4.67 | 0.2524 | 9.4 | 14.72 | 2.1529 | 45.9 | 162.3 |

| P30 | 6.27 | 0.2118 | 12.7 | 17.98 | 1.8768 | 46.6 | 150.6 |

| P40 | 7.84 | 0.1842 | 11.2 | 21.37 | 1.5633 | 42.4 | 137.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Qi, X.; Lv, Y.; Shui, Z. Application of Phosphogypsum in Ultra-High-Performance Concrete (UHPC) Matrix for Strength Enhancement and Shrinkage Reduction. Materials 2025, 18, 1135. https://doi.org/10.3390/ma18051135

Liu Z, Qi X, Lv Y, Shui Z. Application of Phosphogypsum in Ultra-High-Performance Concrete (UHPC) Matrix for Strength Enhancement and Shrinkage Reduction. Materials. 2025; 18(5):1135. https://doi.org/10.3390/ma18051135

Chicago/Turabian StyleLiu, Zhijie, Xibo Qi, Yuanhang Lv, and Zhonghe Shui. 2025. "Application of Phosphogypsum in Ultra-High-Performance Concrete (UHPC) Matrix for Strength Enhancement and Shrinkage Reduction" Materials 18, no. 5: 1135. https://doi.org/10.3390/ma18051135

APA StyleLiu, Z., Qi, X., Lv, Y., & Shui, Z. (2025). Application of Phosphogypsum in Ultra-High-Performance Concrete (UHPC) Matrix for Strength Enhancement and Shrinkage Reduction. Materials, 18(5), 1135. https://doi.org/10.3390/ma18051135