Random Forest Algorithm for the Mechanical Strength Prediction of Green Cement-Based Materials Incorporating Waste Materials Under Fire Condition

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sample Preparation Method

2.3. High Temperature Treatment

2.4. Mechanical Strength Test

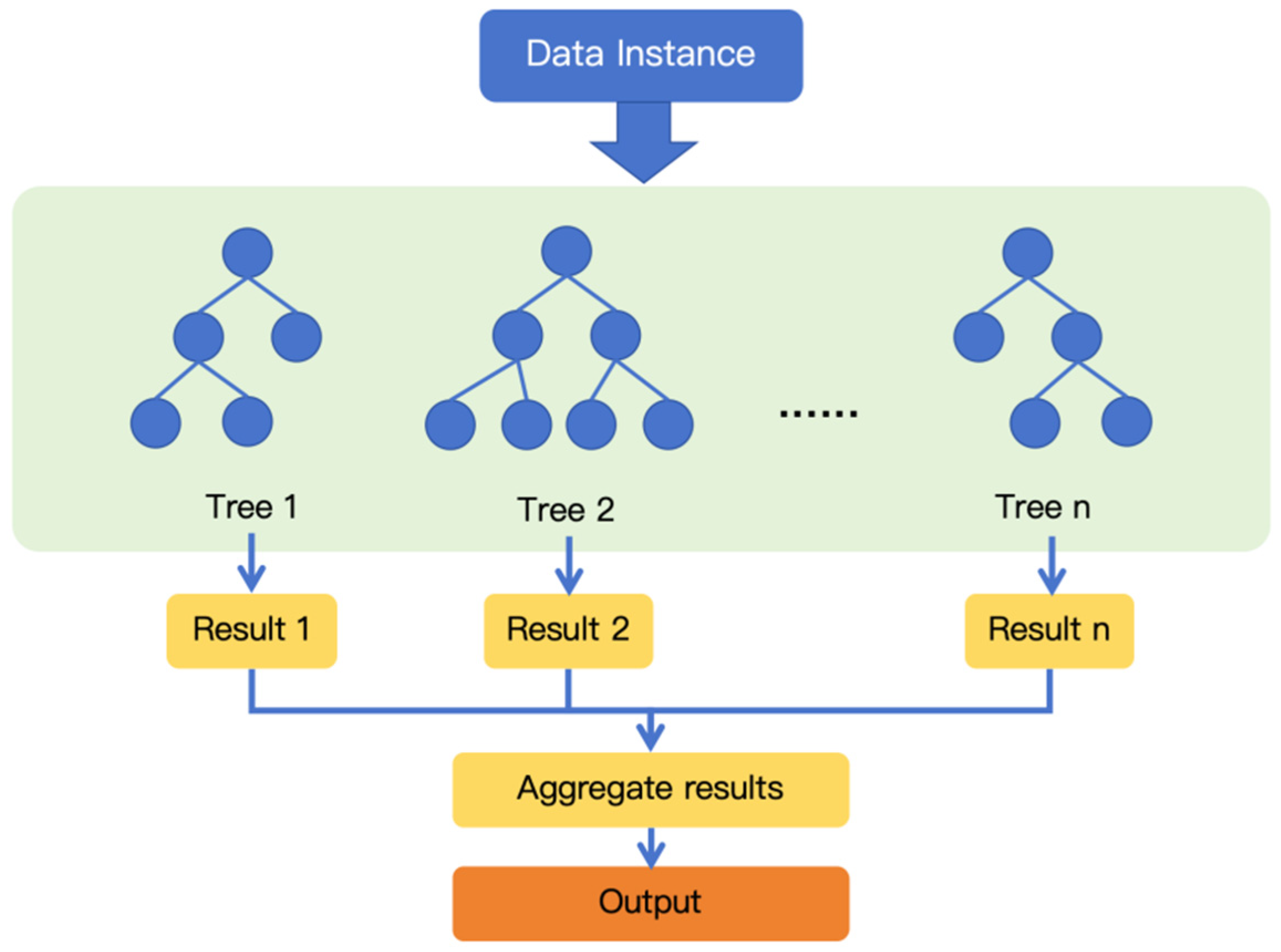

2.5. Algorithm Impementation

- (1)

- Bootstrap sampling: Construct a dataset by randomly sampling m instances (with replacement) from the original dataset .

- (2)

- Building an individual decision tree: Train a decision tree by spliting the data recursively at each node based on dataset . The splitting is repeated until a stopping condition is met (e.g., Squared Error). At every internal node of , a subset of attributes is randomly selected, and the best attribute form the subset is selected, which achieves the maximum reduction in error to split the data. In general, the number of attributes in the subset is smaller than the total number of attributes in the dataset .

- (3)

- Repeat steps (1) and (2) until all decision trees are trained.

- (4)

- Aggregating predictions: Once all decision trees have been constructed, the average prediction of trees is used as the final prediction of the random forest.

3. Results and Discussion

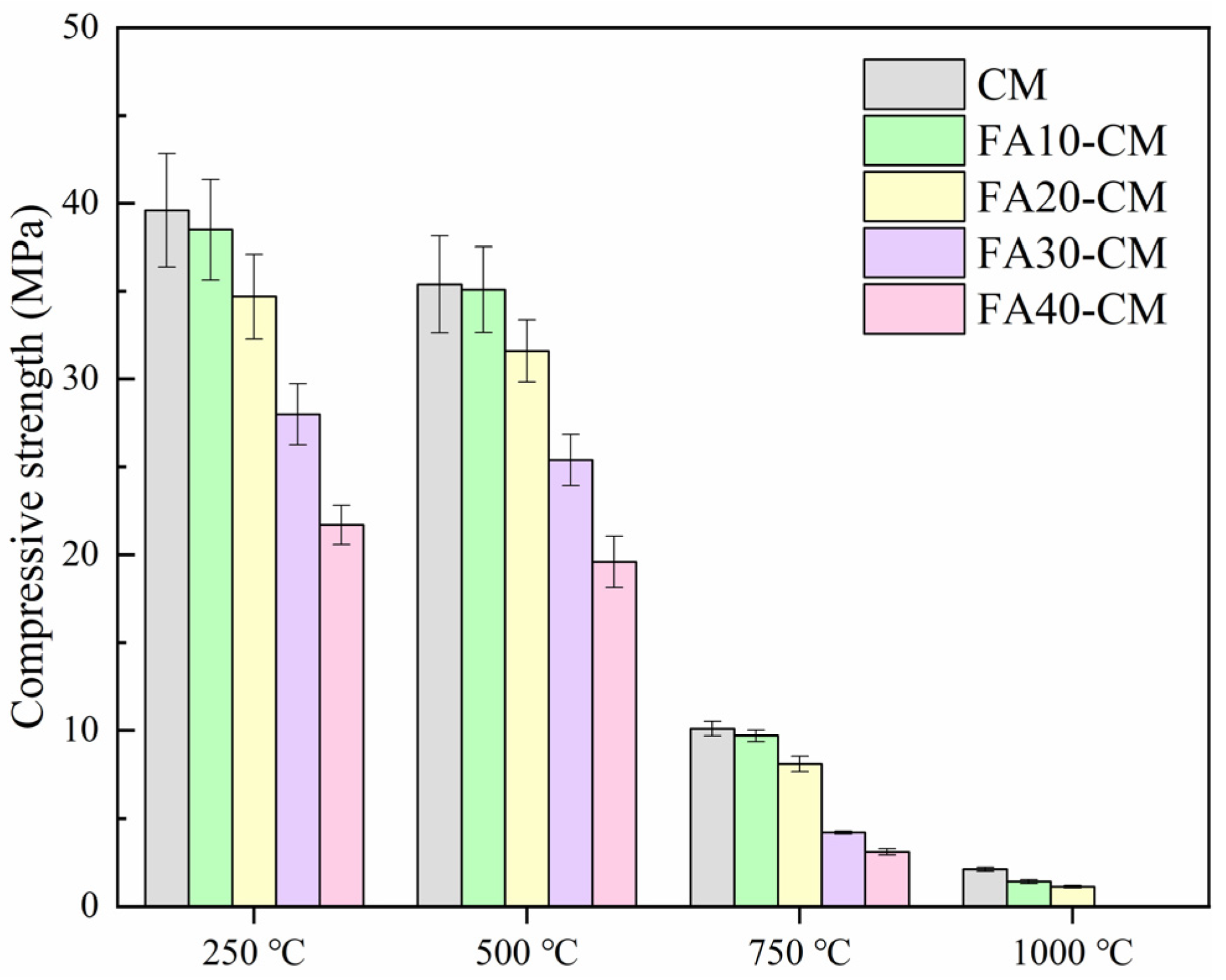

3.1. Mechanical Strength Development of Cement Mortar Incorporating FA

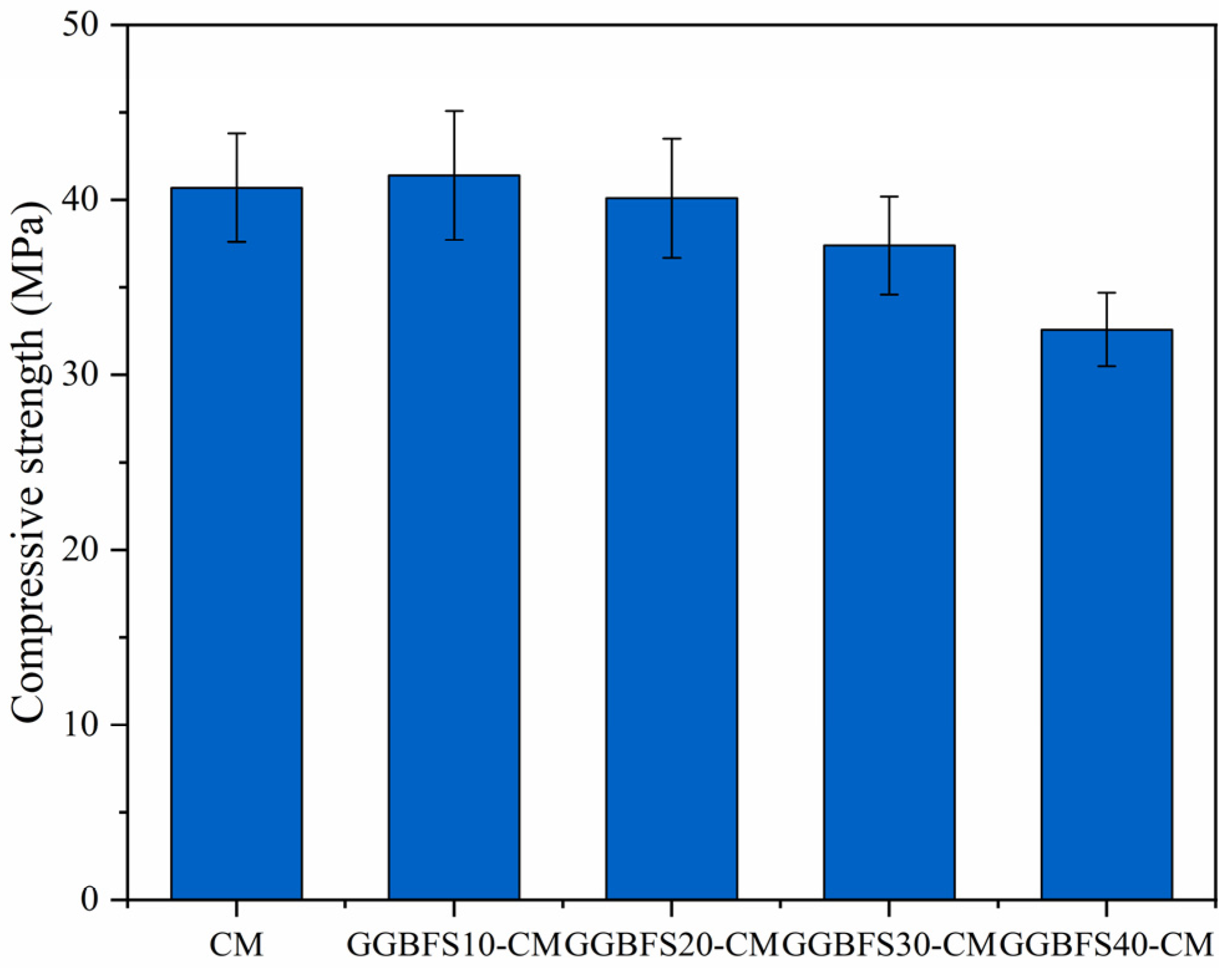

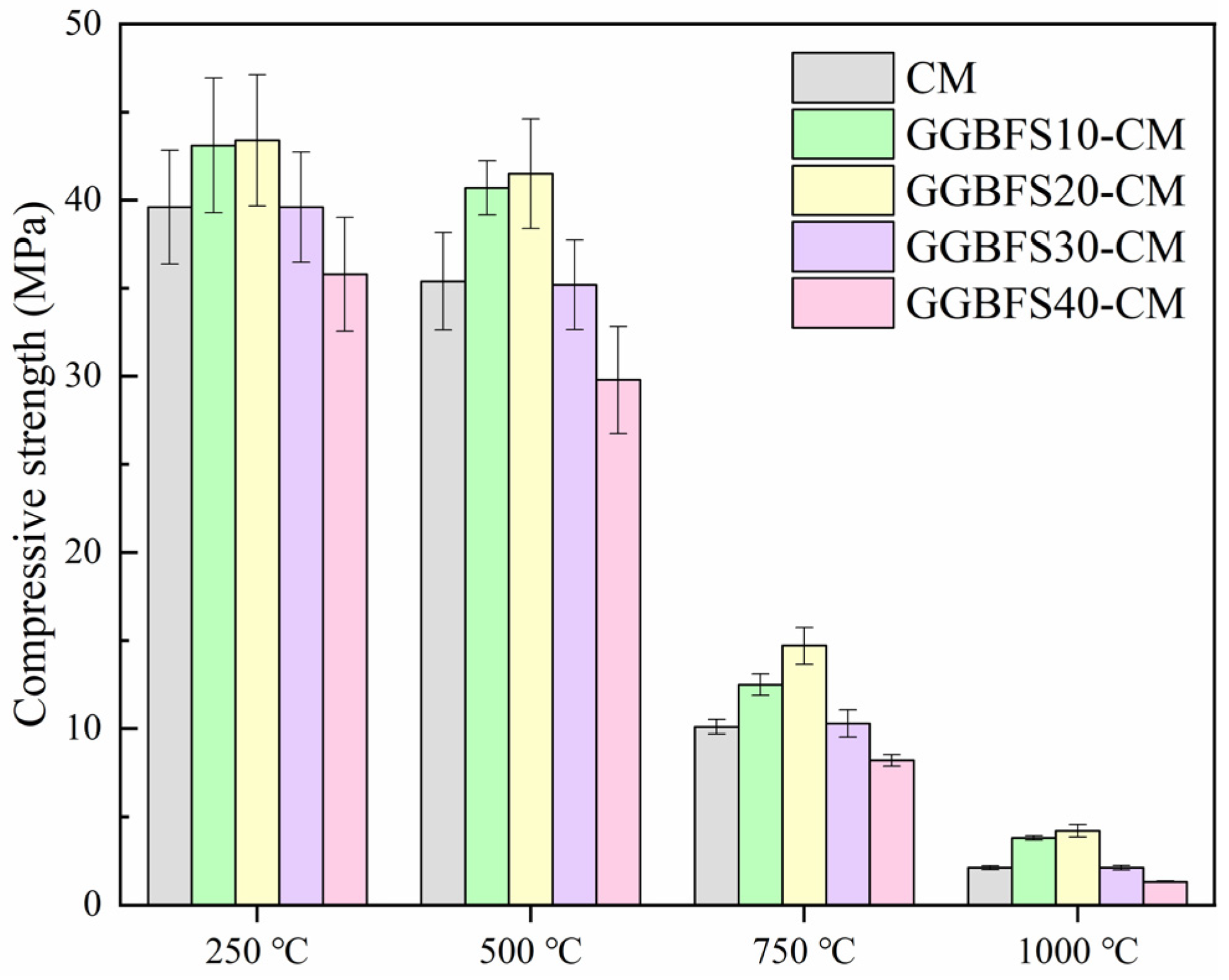

3.2. Mechanical Strength Development of Cement Mortar Containing GGBFS

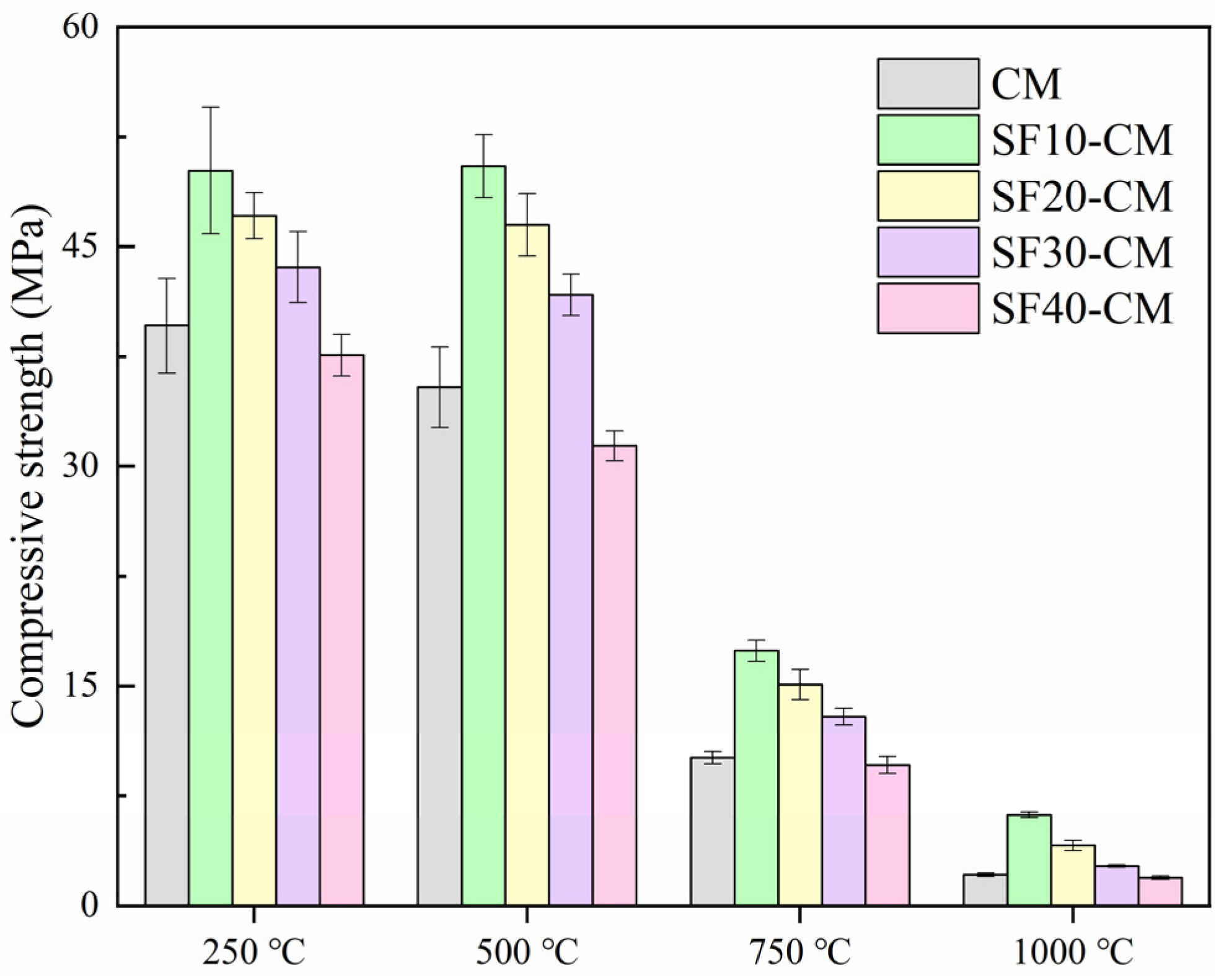

3.3. Mechanical Strength Development of Cement Mortar Containing SF

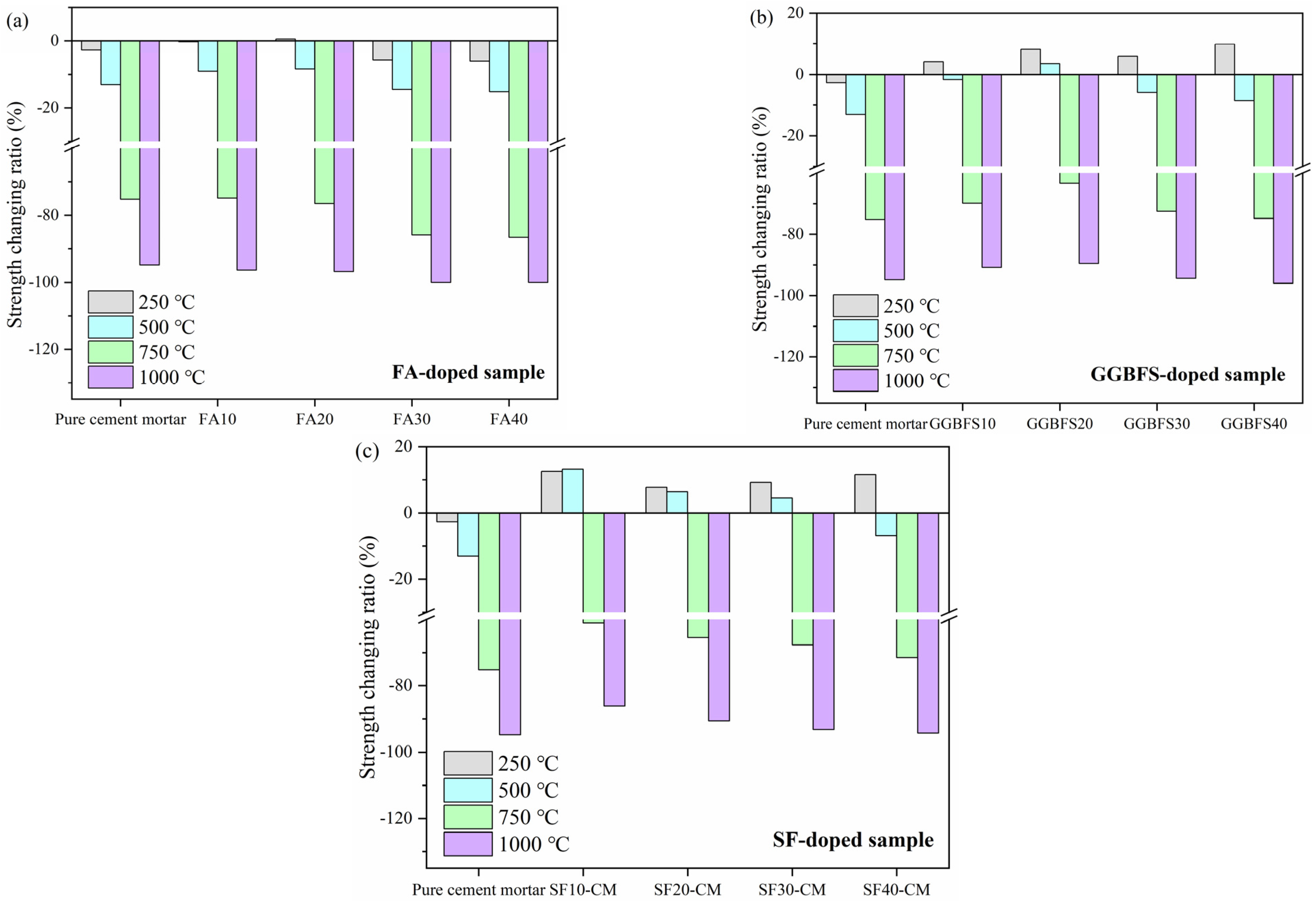

3.4. Discussion over the Strengh Development of the Cement Morater After High Temperature Treatment

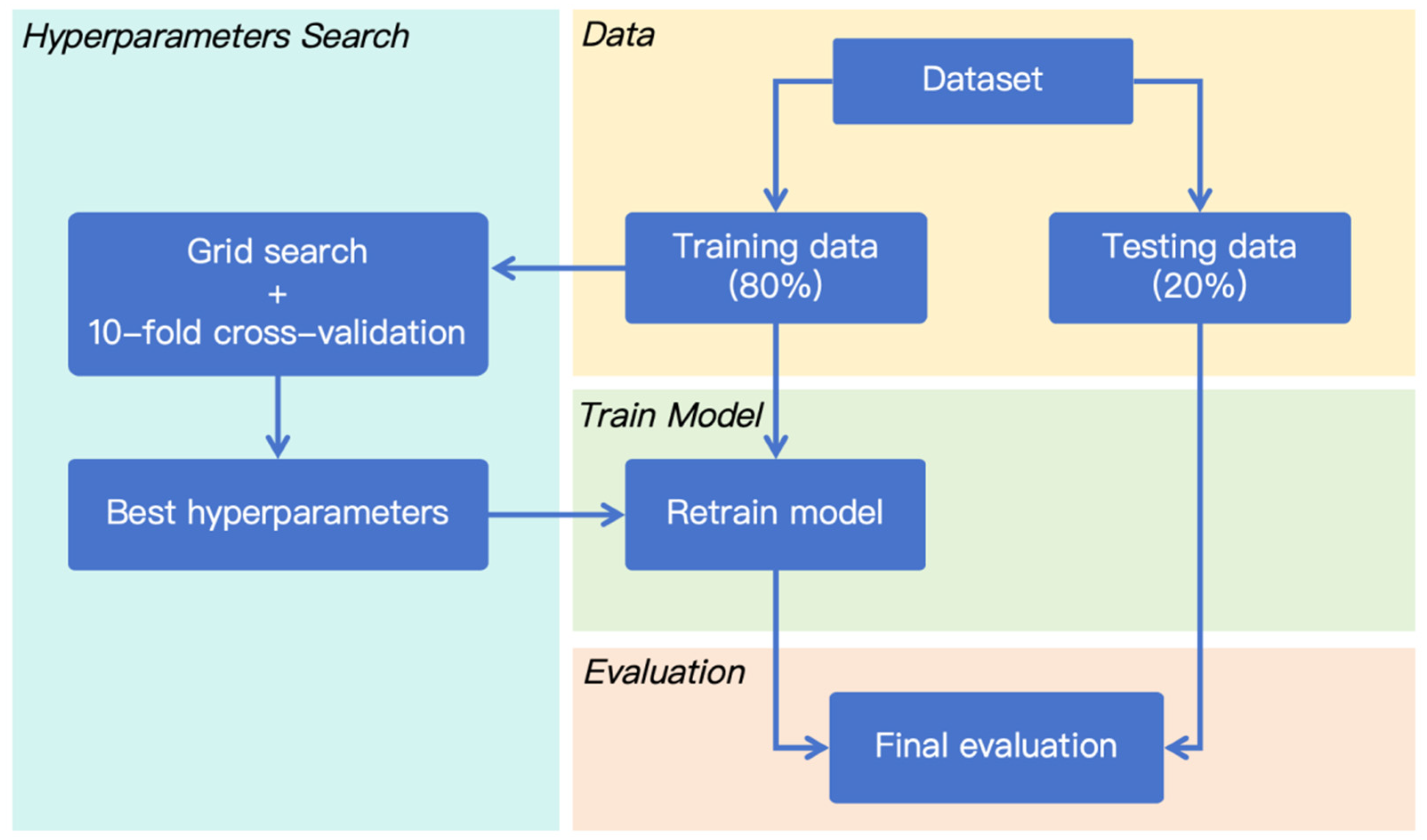

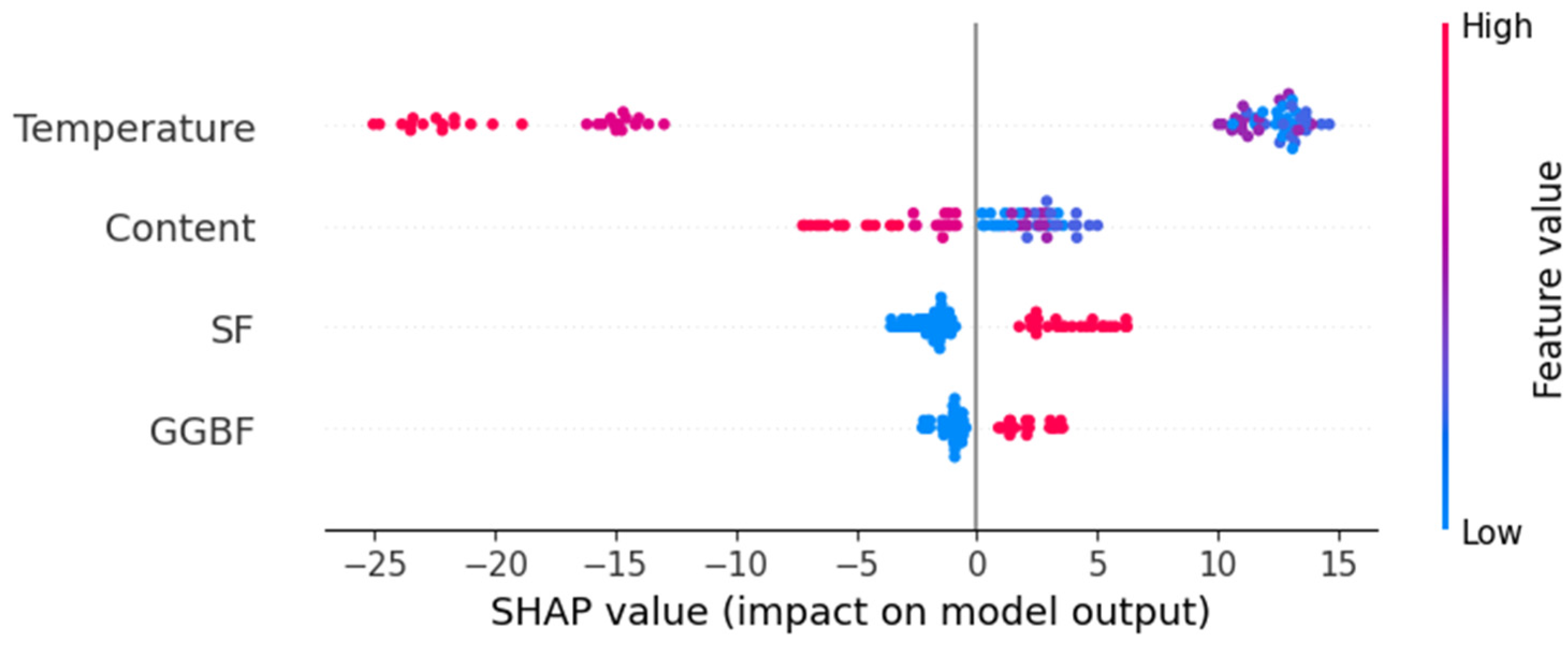

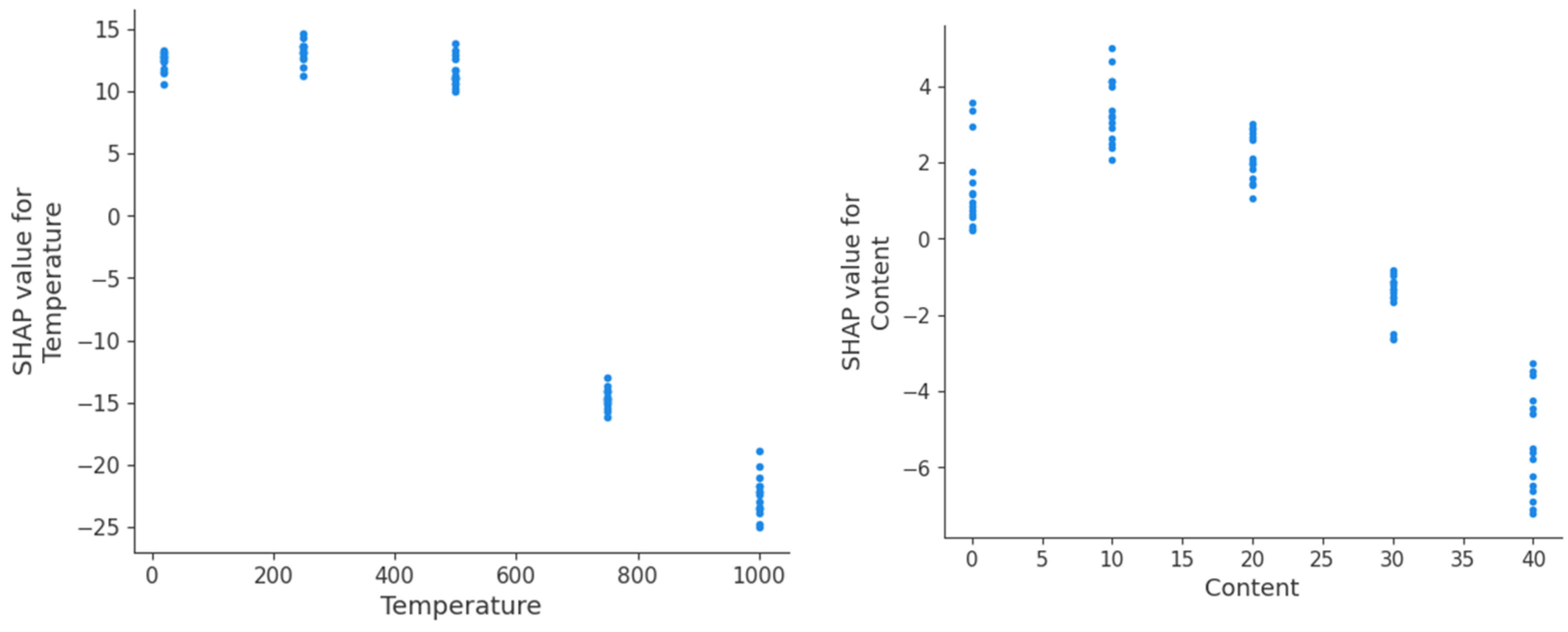

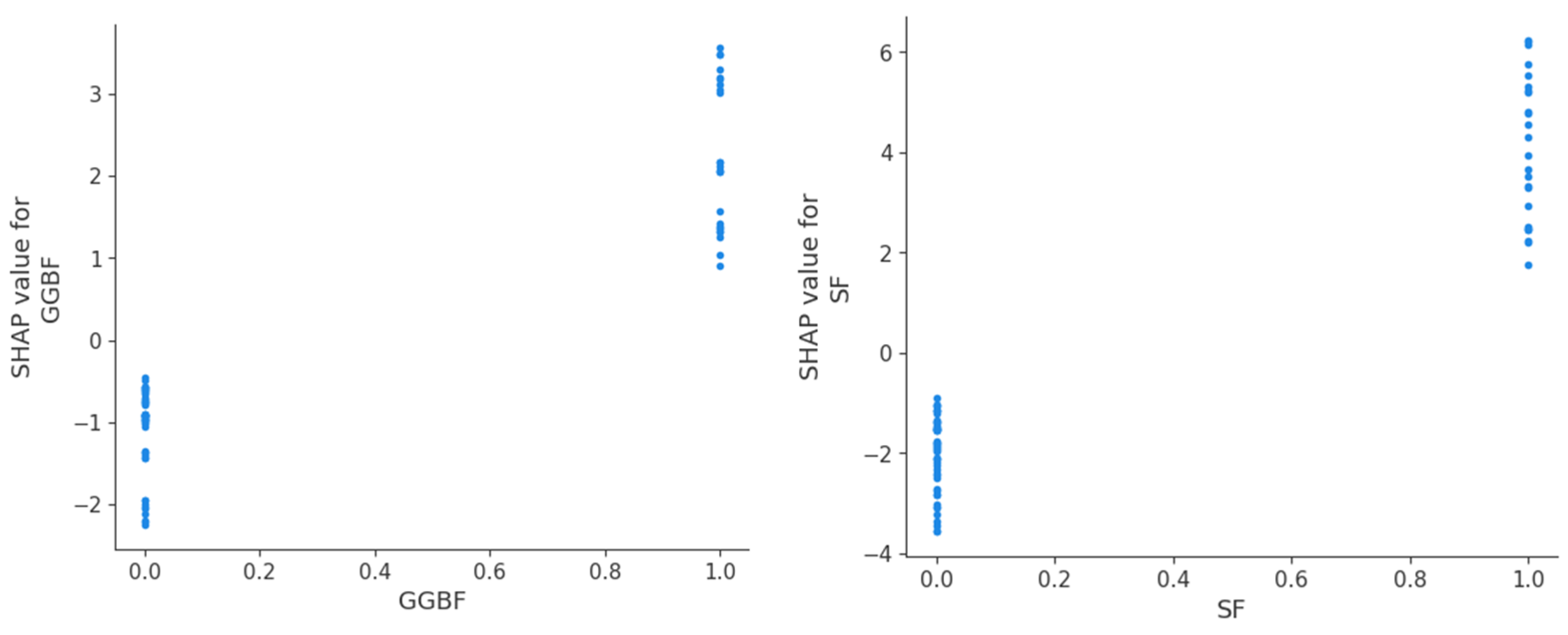

3.5. Algorithm Implementation of RFR to Predict the Compressive Strength of Blended Samples

3.5.1. The Establishment of RFR Model

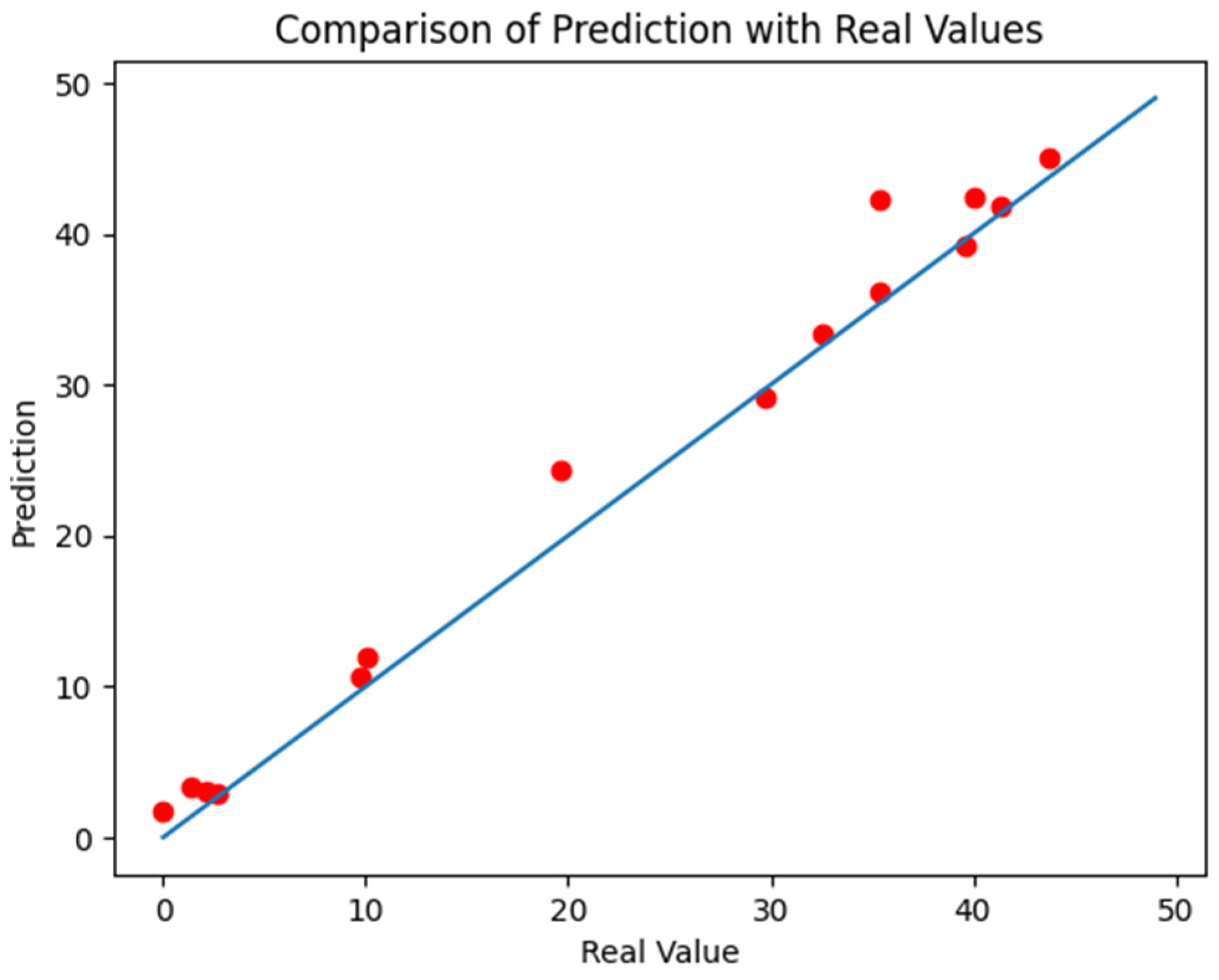

3.5.2. Model Training and Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ouyang, M.; Tian, W.; Liu, Y.; Wang, W. Gradient Power Modified Ohmic Heating Curing to Prepare Hybrid Carbon Fibers/High Performance Concrete under Deep-Freeze Low Temperature. Constr. Build. Mater. 2022, 330, 127279. [Google Scholar] [CrossRef]

- Tian, W.; Qi, B.; Liu, Y.; Liu, K.; Wang, W. Early Frost Resistance and Permeability Properties of Carbon Fiber/Cement-Based Composite Cured by Ohmic Heating under Ultra-Low Temperature. Constr. Build. Mater. 2021, 282, 122729. [Google Scholar] [CrossRef]

- Li, L.; Shi, L.; Wang, Q.; Liu, Y.; Dong, J.; Zhang, H.; Zhang, G. A Review on the Recovery of Fire-Damaged Concrete with Post-Fire-Curing. Constr. Build. Mater. 2020, 237, 117564. [Google Scholar] [CrossRef]

- Kodur, V.; Banerji, S. Modeling the Fire-Induced Spalling in Concrete Structures Incorporating Hydro-Thermo-Mechanical Stresses. Cem. Concr. Compos. 2021, 117, 103902. [Google Scholar] [CrossRef]

- Cree, D.; Green, M.; Noumowé, A. Residual Strength of Concrete Containing Recycled Materials after Exposure to Fire: A Review. Constr. Build. Mater. 2013, 45, 208–223. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, D.; Tan, K.H. On Measuring Techniques of Pore Pressure in Concrete at Elevated Temperature. Cem. Concr. Compos. 2020, 114, 103737. [Google Scholar] [CrossRef]

- Li, Y.; Pimienta, P.; Pinoteau, N.; Tan, K.H. Effect of Aggregate Size and Inclusion of Polypropylene and Steel Fibers on Explosive Spalling and Pore Pressure in Ultra-High-Performance Concrete (UHPC) at Elevated Temperature. Cem. Concr. Compos. 2019, 99, 62–71. [Google Scholar] [CrossRef]

- Liu, Y.; Zhuge, Y.; Chow, C.W.K.; Keegan, A.; Li, D.; Pham, P.N.; Yao, Y.; Kitipornchai, S.; Siddique, R. Effect of Alum Sludge Ash on the High-Temperature Resistance of Mortar. Resour. Conserv. Recycl. 2022, 176, 105958. [Google Scholar] [CrossRef]

- Tang, W.C.; Lo, T.Y. Mechanical and Fracture Properties of Normal-and High-Strength Concretes with Fly Ash after Exposure to High Temperatures. Mag. Concr. Res. 2009, 61, 323–330. [Google Scholar] [CrossRef]

- Aydin, S.; Baradan, B. Effect of Pumice and Fly Ash Incorporation on High Temperature Resistance of Cement Based Mortars. Cem. Concr. Res. 2007, 37, 988–995. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, Y.; Xiao, Y.; Yu, Z. Performance of Cement Pastes Containing Sewage Sludge Ash at Elevated Temperatures. Constr. Build. Mater. 2019, 211, 785–795. [Google Scholar] [CrossRef]

- Coviello, C.G.; Mansour, R.; Rizzo, F.; Foti, D. An experimental study on the mechanical and thermal properties of graphene-reinforced screeds. In Proceedings of the 3rd fib Italy YMG Symposium on Concrete and Concrete Structures, Torino, Italy, 9–10 November 2023. [Google Scholar]

- Poon, C.S.; Azhar, S.; Anson, M.; Wong, Y.L. Comparison of the Strength and Durability Performance of Normal- and High-Strength Pozzolanic Concretes at Elevated Temperatures. Cem. Concr. Res. 2001, 31, 1291–1300. [Google Scholar] [CrossRef]

- Schneider, U. Concrete at High Temperatures—A General Review. Fire Saf. J. 1988, 13, 55–68. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Murphy, T.; Wuhrer, R. High Temperature Performance of Mortars Containing Fine Glass Powders. J. Clean. Prod. 2017, 162, 16–26. [Google Scholar] [CrossRef]

- Li, B.; Ling, T.-C.; Yu, J.-G.; Wu, J.; Chen, W. Cement Pastes Modified with Recycled Glass and Supplementary Cementitious Materials: Properties at the Ambient and High Temperatures. J. Clean. Prod. 2019, 241, 118155. [Google Scholar] [CrossRef]

- Frías, M.; Martínez-Ramírez, S.; de la Villa, R.V.; García-Giménez, R.; de Rojas, M.S. New Scientific Evidence of the Effect of High Temperatures and Long Curing Times on MK-Blended Cement Paste Mineralogy. Cem. Concr. Res. 2022, 152, 106657. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Effect of Waste Glass Fine Aggregate on the Strength, Durability and High Temperature Resistance of Alkali-Activated Fly Ash and GGBFS Blended Mortar. Constr. Build. Mater. 2020, 263, 120177. [Google Scholar] [CrossRef]

- Cudjoe, D.; Wang, H.; Zhu, B. Assessment of the Potential Energy and Environmental Benefits of Solid Waste Recycling in China. J. Environ. Manag. 2021, 295, 113072. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zhao, L.; Gao, X.; Li, L.; Qin, L. Modification of Carbonation-Cured Cement Mortar Using Biochar and Its Environmental Evaluation. Cem. Concr. Compos. 2022, 134, 104764. [Google Scholar] [CrossRef]

- Coviello, C.G.; La Scala, A.; Sabbà, M.F.; Carnimeo, L. On the Cementitious Mixtures Reinforced with Waste Polyethylene Terephthalate. Materials 2024, 17, 5351. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Li, G.; Leung, C.K.Y. Hydration and Physical Characteristics of Ultrahigh-Volume Fly Ash-Cement Systems with Low Water/Binder Ratio. Constr. Build. Mater. 2018, 161, 509–518. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Li, K.; Hao, T.; Li, Z.; Li, L.; Ran, B.; Du, H. New Insights on Dehydration at Elevated Temperature and Rehydration of GGBS Blended Cement. Cem. Concr. Compos. 2023, 139, 105068. [Google Scholar] [CrossRef]

- Lou, Y.; Khan, K.; Amin, M.N.; Ahmad, W.; Deifalla, A.F.; Ahmad, A. Performance Characteristics of Cementitious Composites Modified with Silica Fume: A Systematic Review. Case Stud. Constr. Mater. 2023, 18, e01753. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Interpretable Machine Learning-Based Analysis of Hydration and Carbonation of Carbonated Reactive Magnesia Cement Mixes. J. Clean. Prod. 2024, 434, 140054. [Google Scholar] [CrossRef]

- Zhao, J.; Fan, C.; Huang, G.; Guo, Y.; Arachchilage, C.B.; Gupta, R.; Liu, W.V. Machine Learning-Assisted Characterization of the Thermal Conductivity of Cement-Based Grouts for Borehole Heat Exchangers. Constr. Build. Mater. 2024, 449, 138506. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Ubysz, A. Comparative Analysis of Cement Grade and Cement Strength as Input Features for Machine Learning-Based Concrete Strength Prediction. Case Stud. Constr. Mater. 2024, 21, e03557. [Google Scholar] [CrossRef]

- Noaman, M.F.; Haq, M.; Khan, M.A.; Ali, K.; Kamyab, H. Geotechnical and Microstructural Analysis of High-Volume Fly Ash Stabilized Clayey Soil and Machine Learning Application. Case Stud. Constr. Mater. 2024, 21, e03628. [Google Scholar] [CrossRef]

- Shahrokhishahraki, M.; Malekpour, M.; Mirvalad, S.; Faraone, G. Machine Learning Predictions for Optimal Cement Content in Sustainable Concrete Constructions. J. Build. Eng. 2024, 82, 108160. [Google Scholar] [CrossRef]

- Cui, Y.; Ye, L.; Yao, Z.; Gu, X.; Wang, X. Performance Optimization of Cement Calciner Based on CFD Simulation and Machine Learning Algorithm. Energy 2024, 302, 131926. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Liu, G.; Xu, H. A Robust Optimization Approach of Well Placement for Doublet in Heterogeneous Geothermal Reservoirs Using Random Forest Technique and Genetic Algorithm. Energy 2022, 254, 124427. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, D.H.; Mendoza, J.A.; Lee, M.Y. Applying Machine Learning Random Forest (RF) Method in Predicting the Cement Products with a Co-Processing of Input Materials: Optimizing the Hyperparameters. Environ. Res. 2024, 248, 118300. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Xu, P.; Zaman, A.; Alomayri, T.; Houda, M.; Alaskar, A.; Javed, M.F. Compressive Strength Prediction of Concrete Blended with Carbon Nanotubes Using Gene Expression Programming and Random Forest: Hyper-Tuning and Optimization. J. Mater. Res. Technol. 2023, 24, 7198–7218. [Google Scholar] [CrossRef]

- Fujii, T.; Sako, M.; Ishihama, K.; Kohno, Y.; Makino, T.; Yasuo, N.; Kawauchi, S. Prediction of CO2 Absorbing Performance of Amine Aqueous Solution Using Random Forest Models. Gas Sci. Eng. 2024, 129, 205417. [Google Scholar] [CrossRef]

- Kim, T.K.; Hwang, S.H.; Kim, J.; Jung, W.T.; Yoon, J. Analysis of Bond Strength of CFRP Cables with Concrete Using Random Forest Model. J. Build. Eng. 2024, 96, 110658. [Google Scholar] [CrossRef]

- Long, K.; Guo, D.; Deng, L.; Shen, H.; Zhou, F.; Yang, Y. Cross-Combination Analyses of Random Forest Feature Selection and Decision Tree Model for Predicting Intraoperative Hypothermia in Total Joint Arthroplasty. J. Arthroplast. 2024, 40, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Onyelowe, K.C.; Gnananandarao, T.; Ebid, A.M. Estimation of the Erodibility of Treated Unsaturated Lateritic Soil Using Support Vector Machine-Polynomial and -Radial Basis Function and Random Forest Regression Techniques. Clean. Mater. 2022, 3, 100039. [Google Scholar] [CrossRef]

- Tian, W.; Wang, M.; Liu, Y.; Wang, W. Ohmic Heating Curing of High Content Fly Ash Blended Cement-Based Composites towards Sustainable Green Construction Materials Used in Severe Cold Region. J. Clean. Prod. 2020, 276, 123300. [Google Scholar] [CrossRef]

- Narmluk, M.; Nawa, T. Effect of Fly Ash on the Kinetics of Portland Cement Hydration at Different Curing Temperatures. Cem. Concr. Res. 2011, 41, 579–589. [Google Scholar] [CrossRef]

- Lv, W.; Sun, Z.; Su, Z. Study of Seawater Mixed One-Part Alkali Activated GGBFS-Fly Ash. Cem. Concr. Compos. 2020, 106, 103484. [Google Scholar] [CrossRef]

- Cong, X.; Zhou, W.; Elchalakani, M. Experimental Study on the Engineering Properties of Alkali-Activated GGBFS/FA Concrete and Constitutive Models for Performance Prediction. Constr. Build. Mater. 2020, 240, 117977. [Google Scholar] [CrossRef]

- Consoli, N.C.; de Oliveira, J.P.; Lotero, A.; Filho, H.C.S.; Nuñéz, V. One-Part Alkali-Activated GGBFS as a Cement for Enhancing Compacted Filtered Iron Ore Tailings Disposal by Stacking. Transp. Geotech. 2024, 48, 101306. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Ouyang, P.; Yang, Y. Hydration of the Silica Fume-Portland Cement Binary System at Lower Temperature. Constr. Build. Mater. 2015, 93, 919–925. [Google Scholar] [CrossRef]

- Shi, C.; Wang, D.; Wu, L.; Wu, Z. The Hydration and Microstructure of Ultra High-Strength Concrete with Cement-Silica Fume-Slag Binder. Cem. Concr. Compos. 2015, 61, 44–52. [Google Scholar] [CrossRef]

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | |

|---|---|---|---|---|---|

| Cement | 22.13 | 63.47 | 6.32 | 3.56 | 1.77 |

| FA | 48.41 | 8.45 | 17.88 | 3.96 | 0.89 |

| GGBFS | 35.23 | 27.41 | 15.38 | 13.12 | 7.79 |

| SF | 95.42 | 0.38 | 0.41 | 0.32 | 0.25 |

| SCMs | Temperature | Content | Strength |

|---|---|---|---|

| SF | 250 | 10 | 50.2 |

| SF | 750 | 20 | 15.1 |

| FA | 20 | 10 | 38.6 |

| GGBFS | 1000 | 40 | 1.3 |

| Hyperparameter | Description | Search Space | Optimal Value |

|---|---|---|---|

| max_depth | The maximum depth of the tree. | [2, 3, 4, …, 9] | 8 |

| min_samples_leaf | The minimum number of samples required to be at a leaf node. | [1, 2, 3, …, 9] | 1 |

| n_estimators | The number of trees in the forest. | [10, 20, 30, …, 100] | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Qiu, R.; Xie, J.; Liu, X.; Fu, Q.; Li, Y. Random Forest Algorithm for the Mechanical Strength Prediction of Green Cement-Based Materials Incorporating Waste Materials Under Fire Condition. Materials 2025, 18, 1025. https://doi.org/10.3390/ma18051025

Zhang L, Qiu R, Xie J, Liu X, Fu Q, Li Y. Random Forest Algorithm for the Mechanical Strength Prediction of Green Cement-Based Materials Incorporating Waste Materials Under Fire Condition. Materials. 2025; 18(5):1025. https://doi.org/10.3390/ma18051025

Chicago/Turabian StyleZhang, Lei, Ruipeng Qiu, Jiabin Xie, Xianglong Liu, Qiang Fu, and Yanli Li. 2025. "Random Forest Algorithm for the Mechanical Strength Prediction of Green Cement-Based Materials Incorporating Waste Materials Under Fire Condition" Materials 18, no. 5: 1025. https://doi.org/10.3390/ma18051025

APA StyleZhang, L., Qiu, R., Xie, J., Liu, X., Fu, Q., & Li, Y. (2025). Random Forest Algorithm for the Mechanical Strength Prediction of Green Cement-Based Materials Incorporating Waste Materials Under Fire Condition. Materials, 18(5), 1025. https://doi.org/10.3390/ma18051025