Evaluation of Selected Quality Characteristics of Thin-Walled Models Manufactured Using Powder Bed Fusion Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

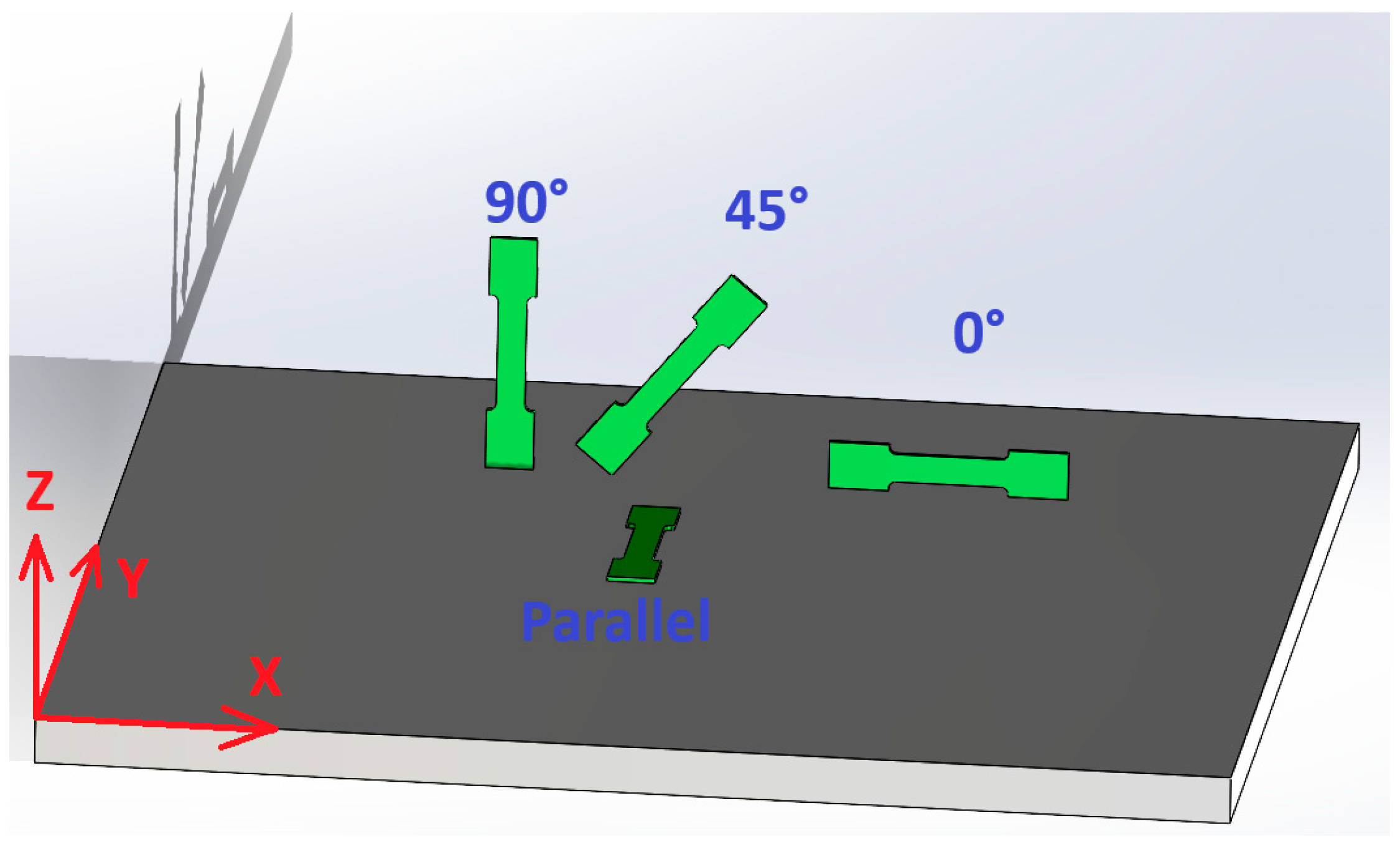

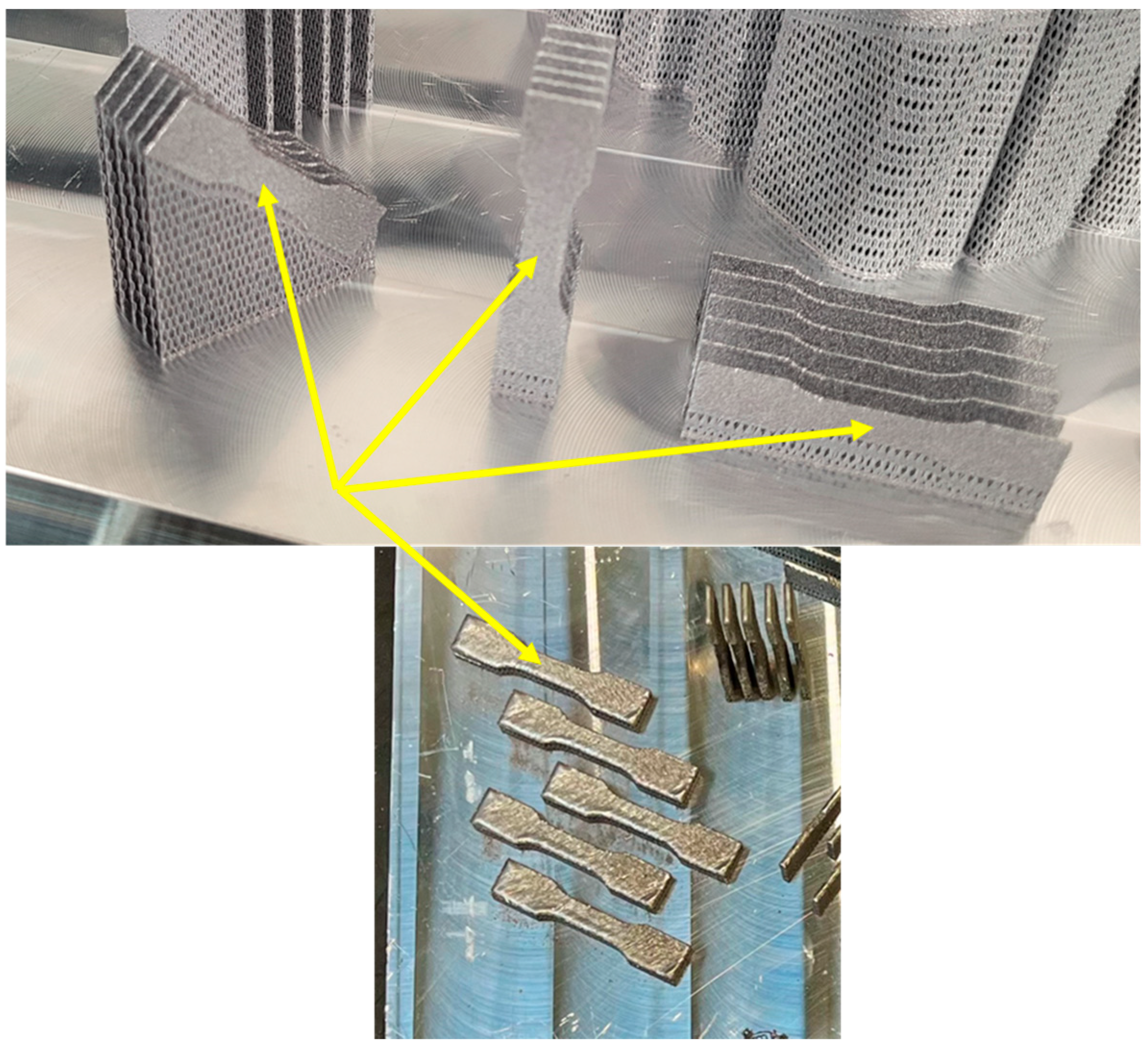

2.2. Methods

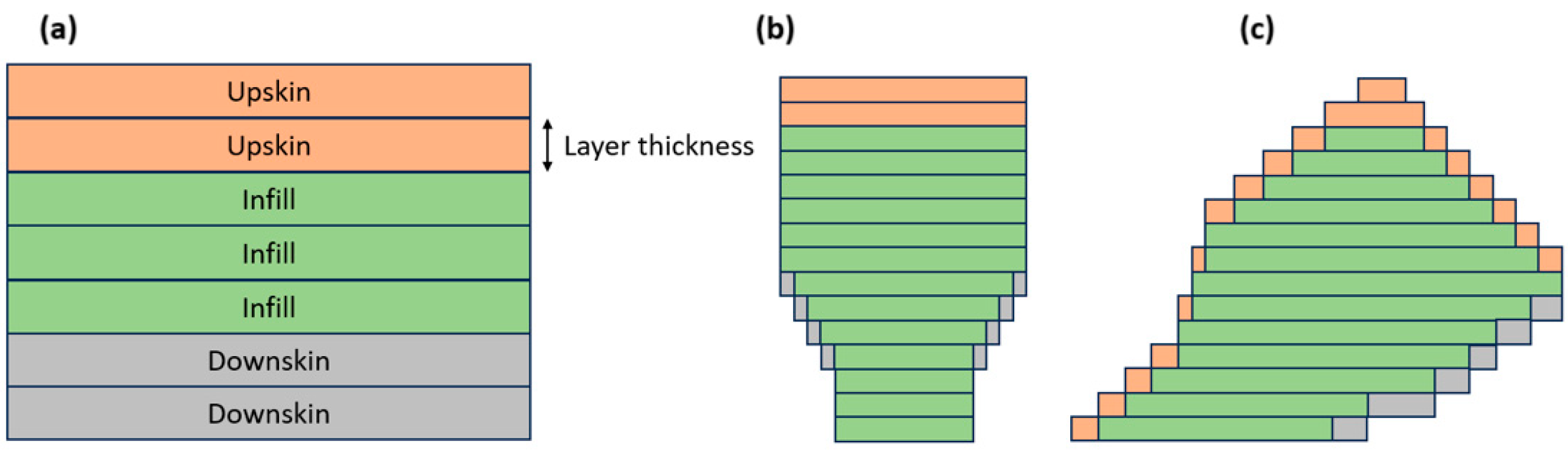

2.2.1. PBF Technology

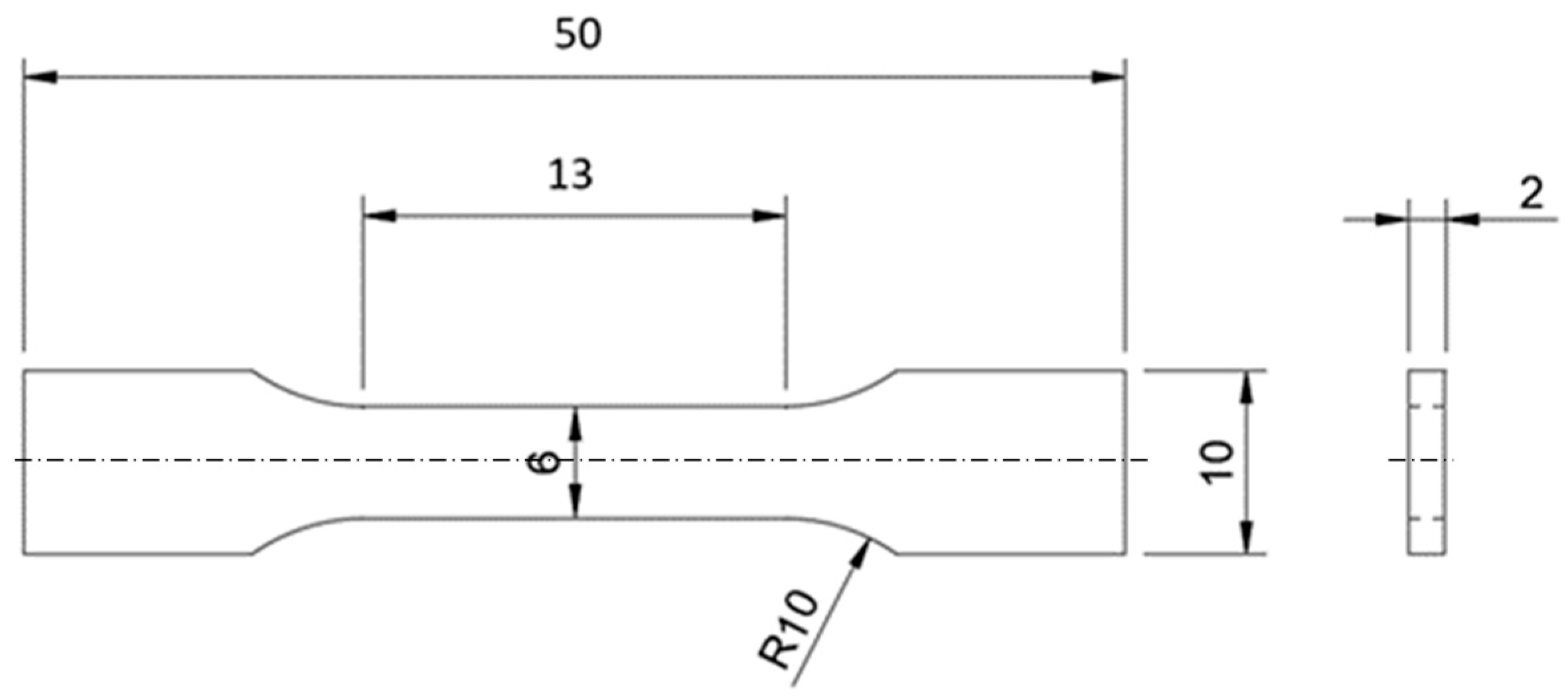

2.2.2. Tensile Test

2.2.3. Surface Texture Measurement

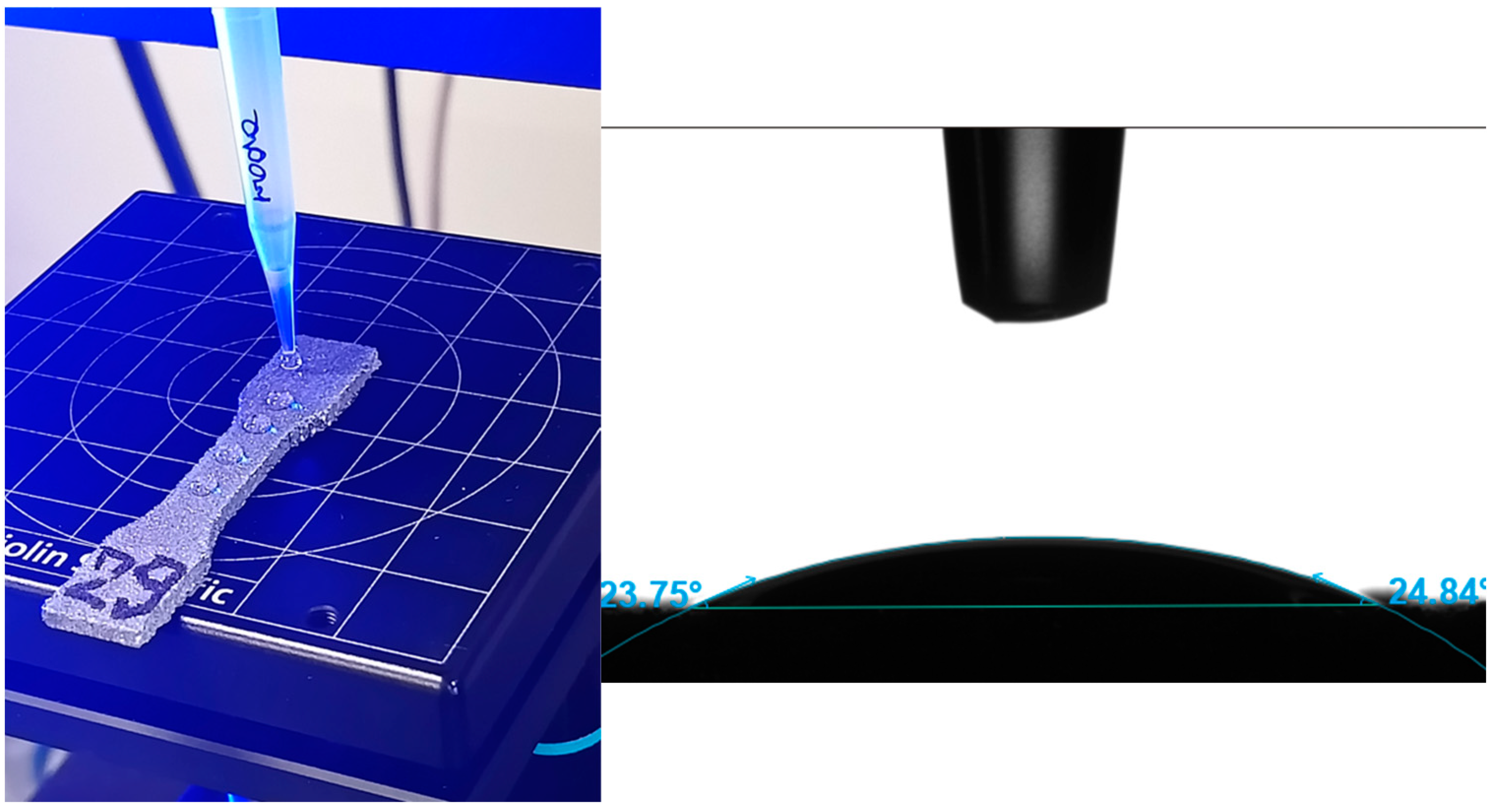

2.2.4. Contact Angle Measurement

2.2.5. Microstructure Analysis

3. Results and Discussion

3.1. Dimensional Accuracy

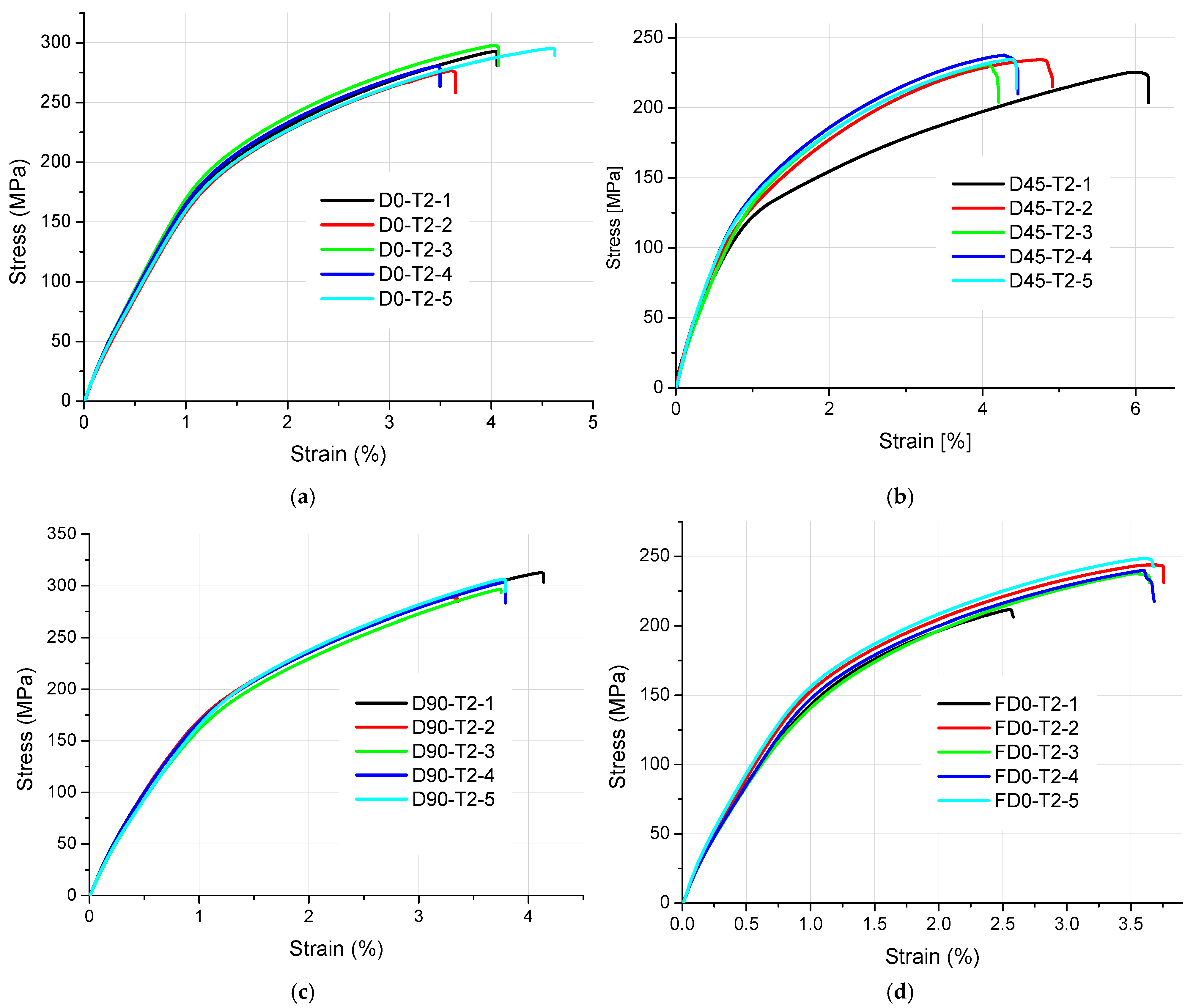

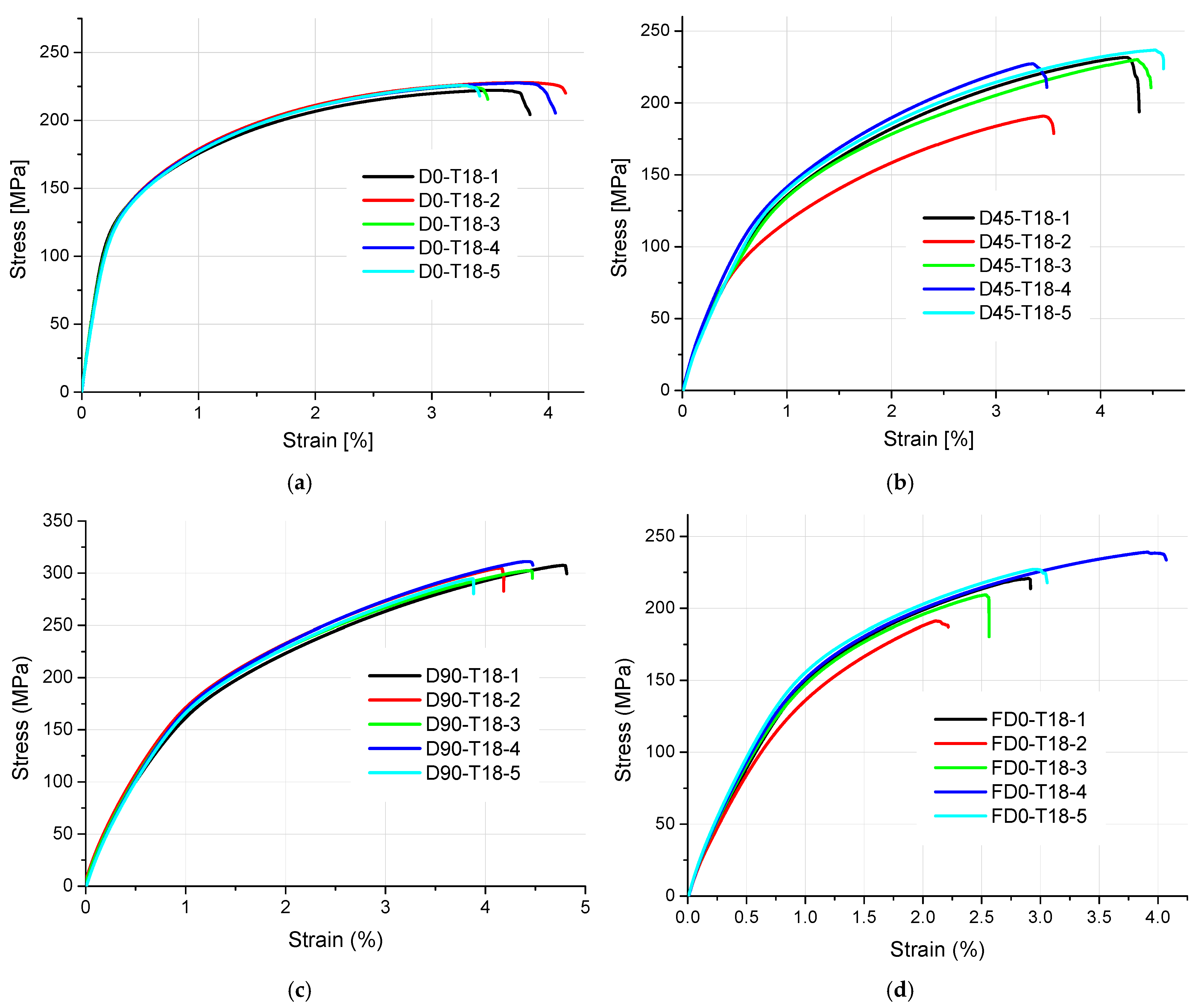

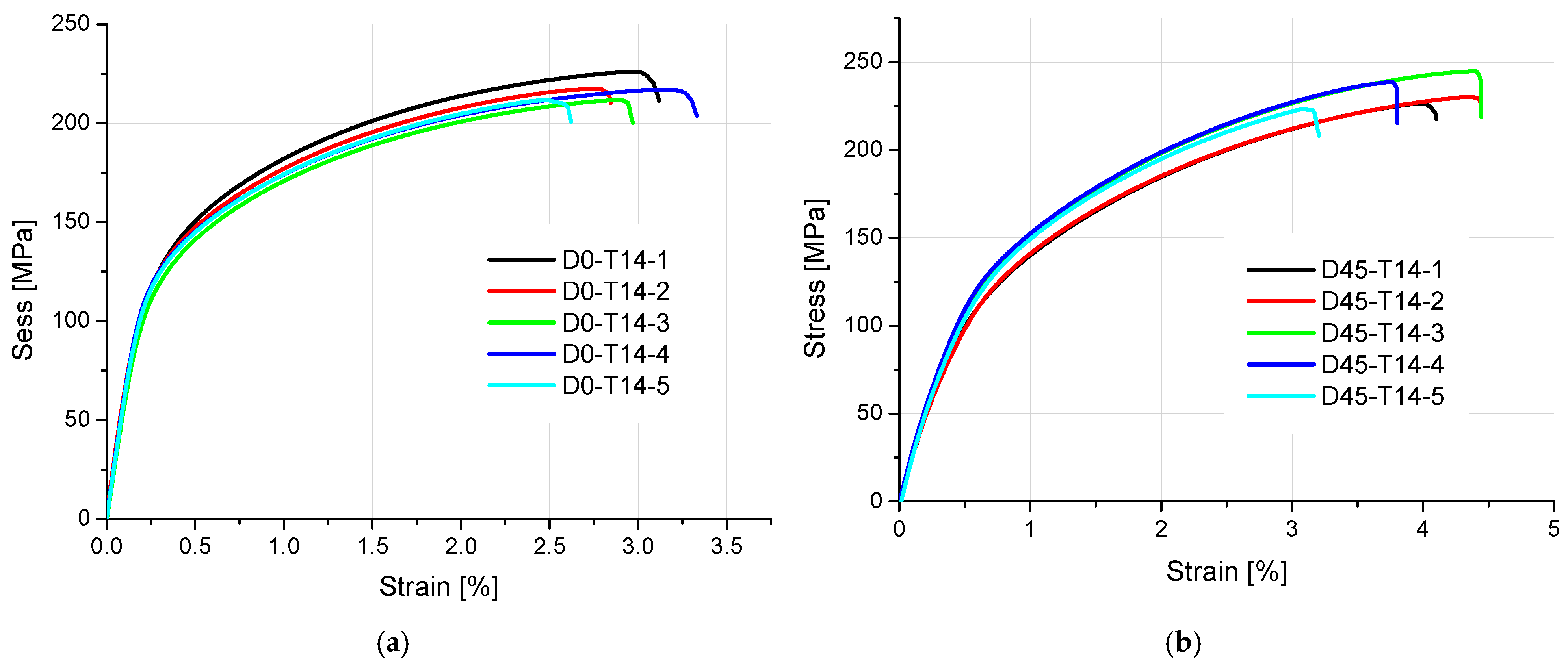

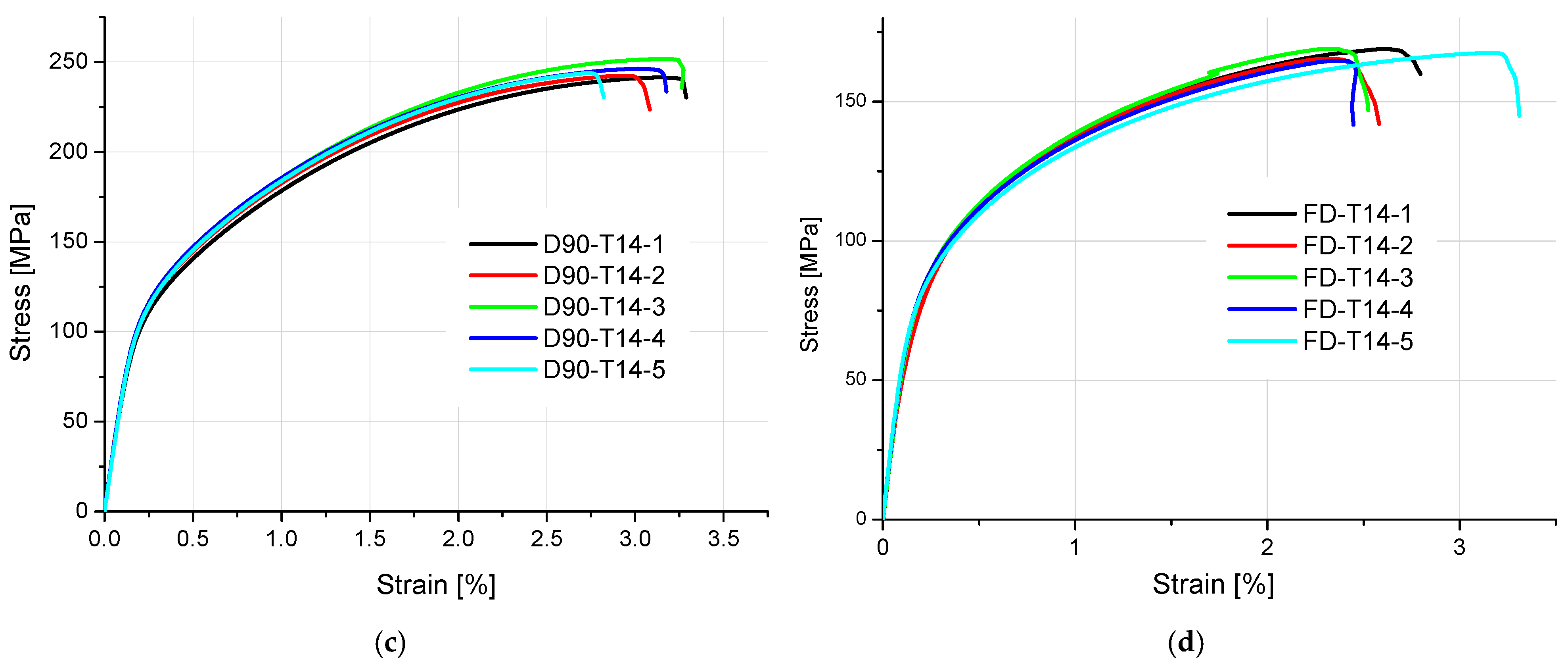

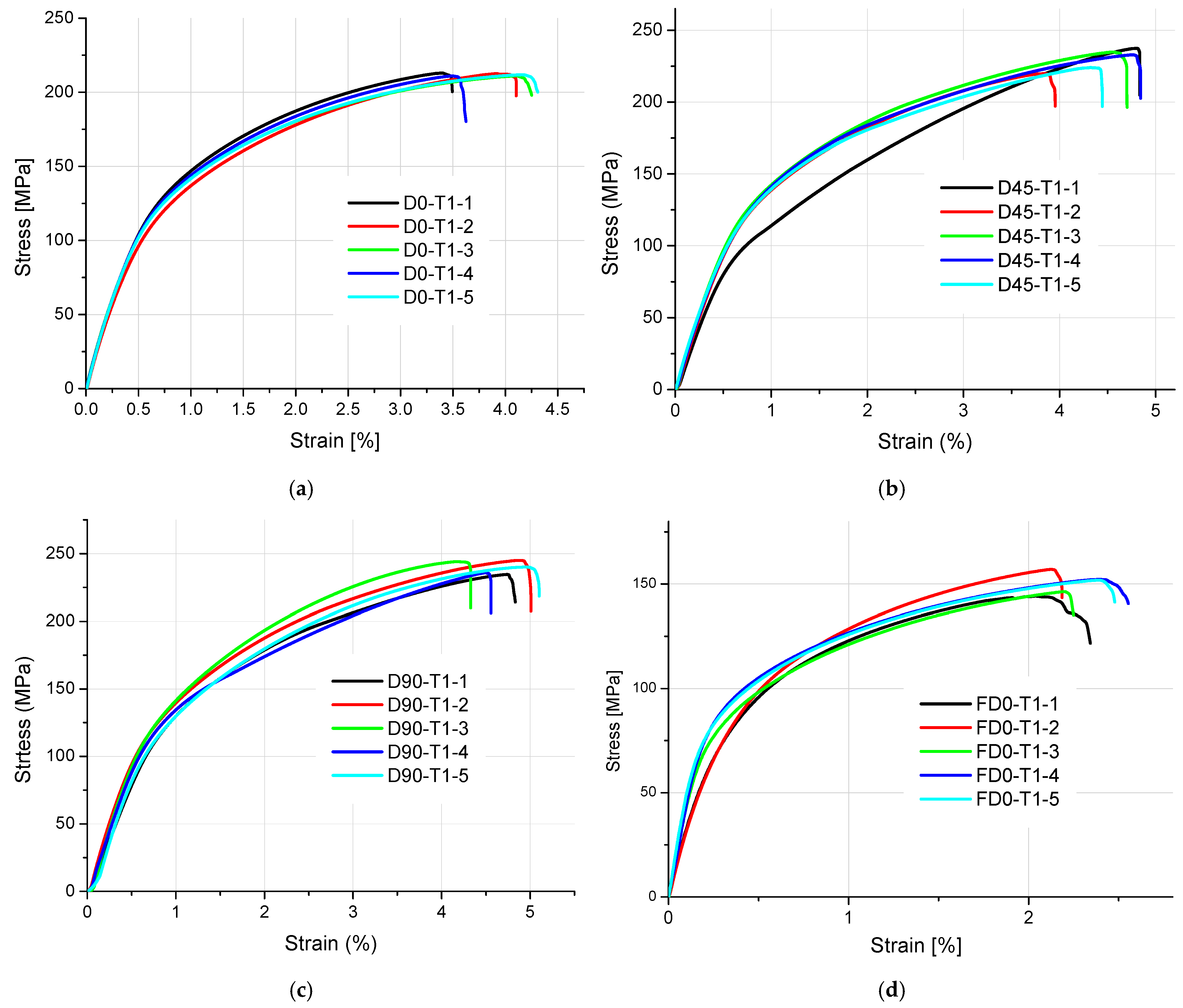

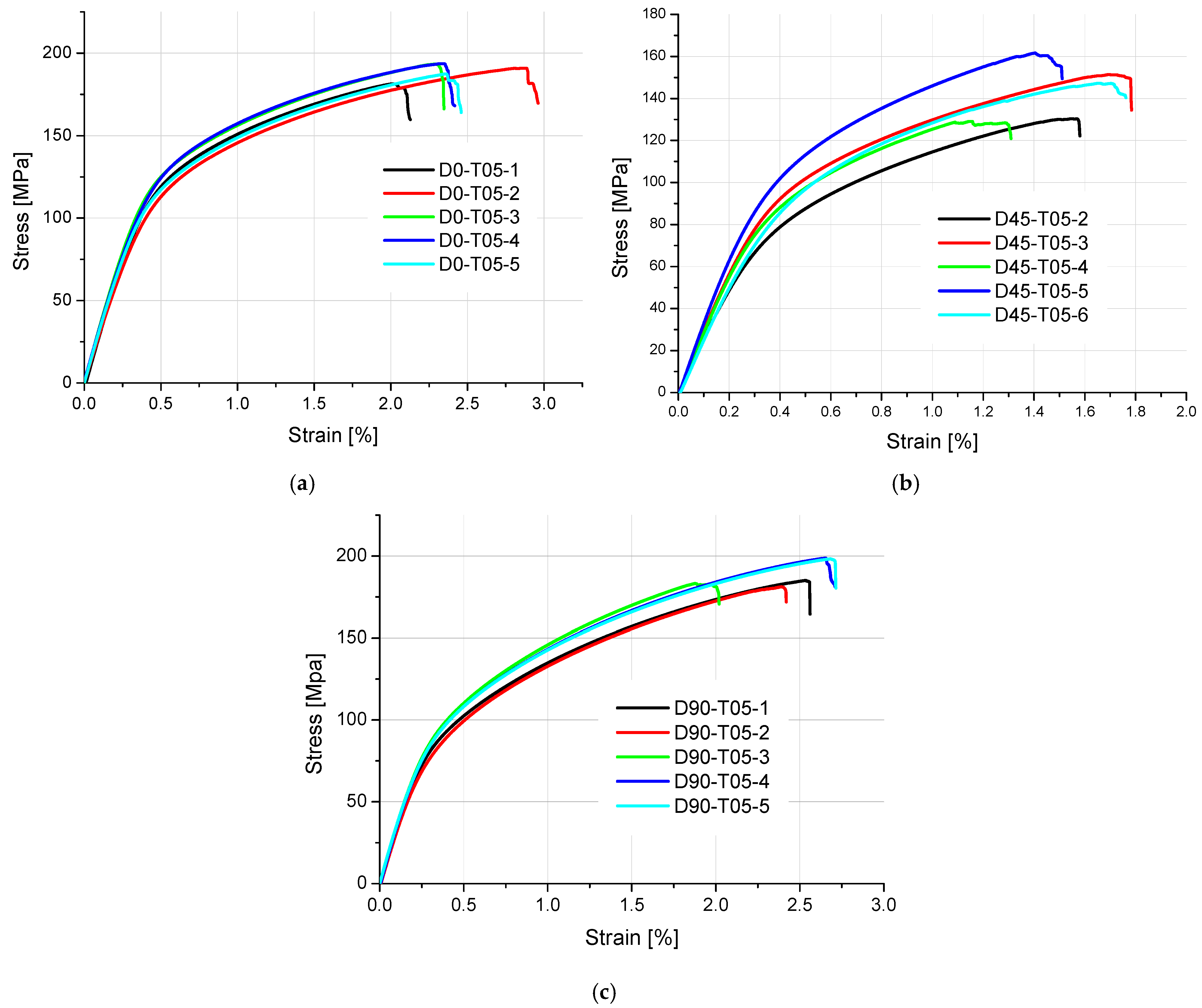

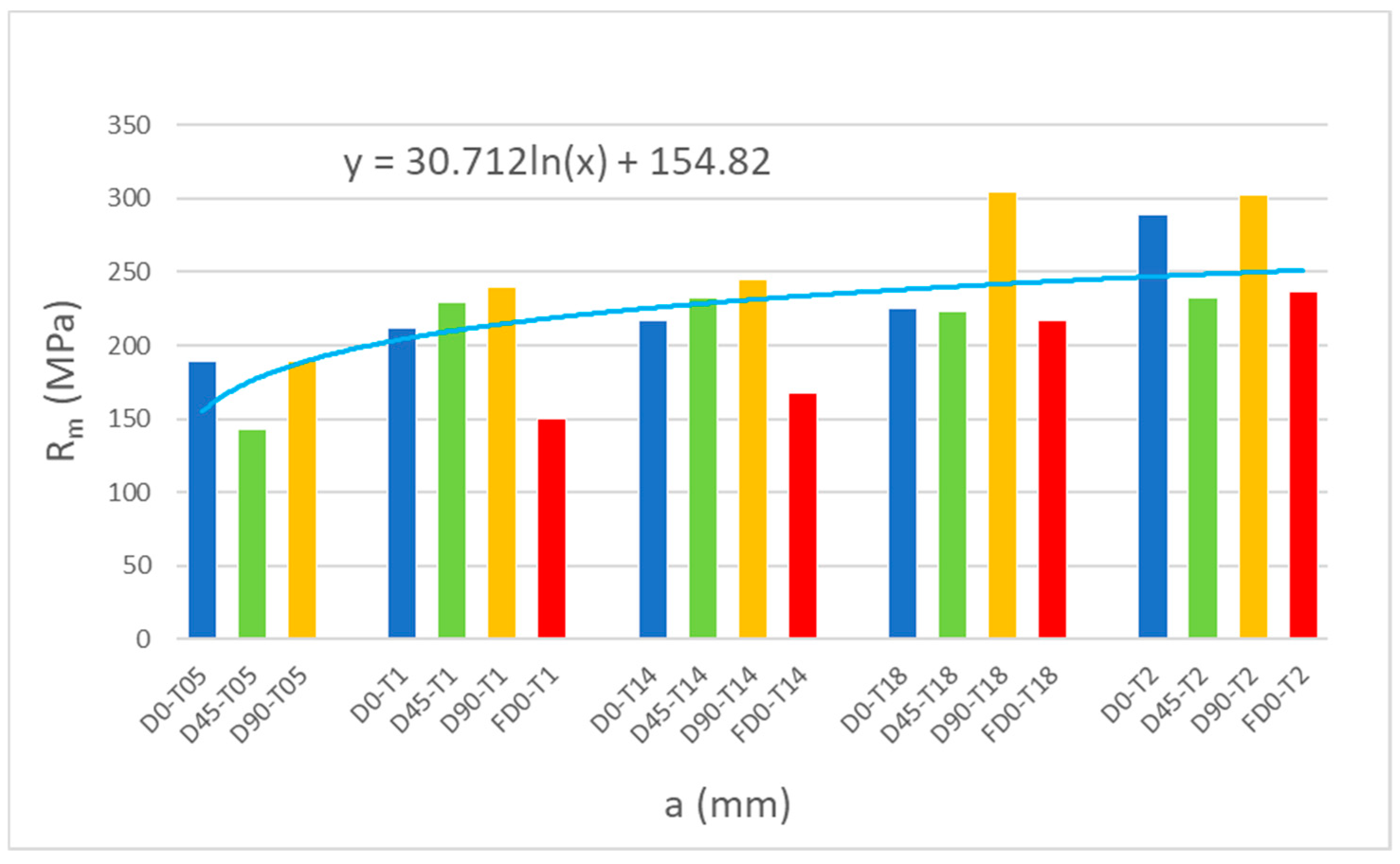

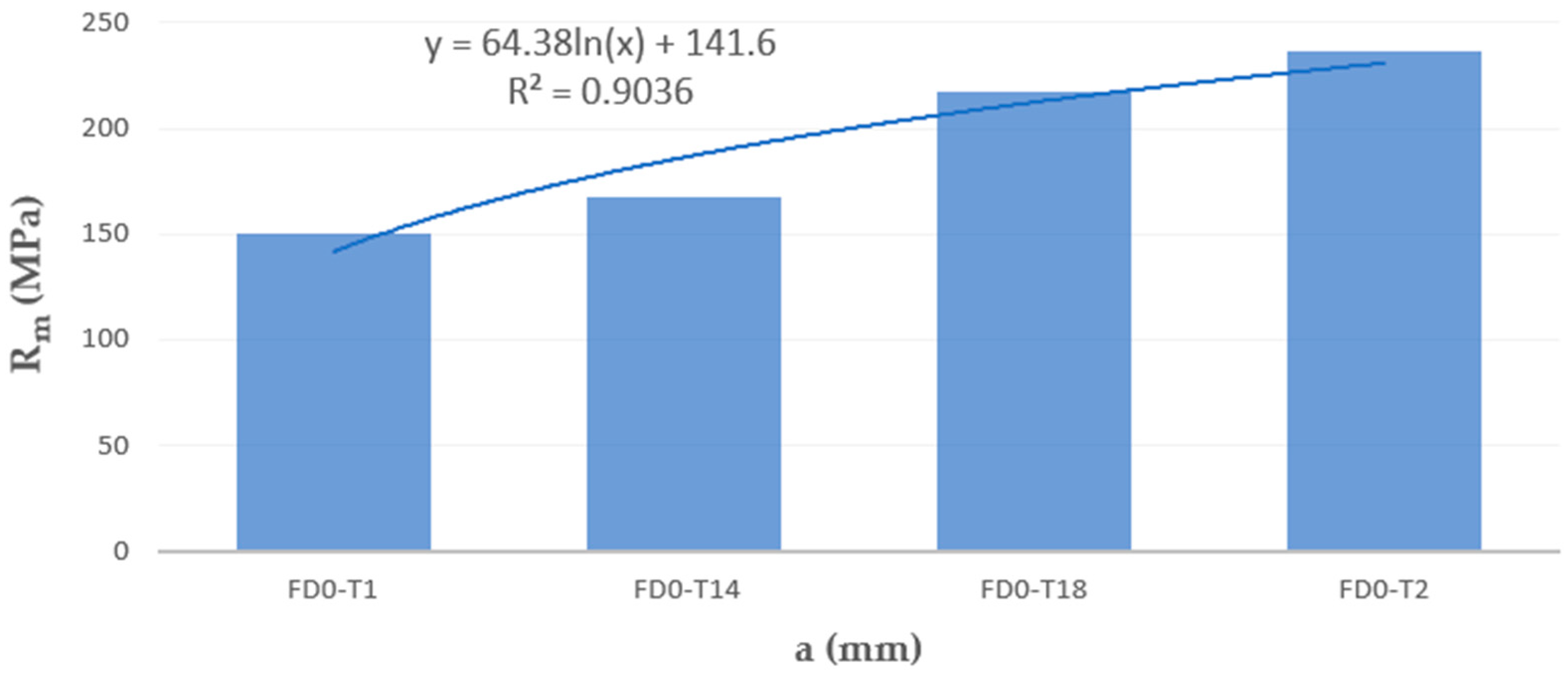

3.2. Tensile Test Results

3.3. Surface Analysis

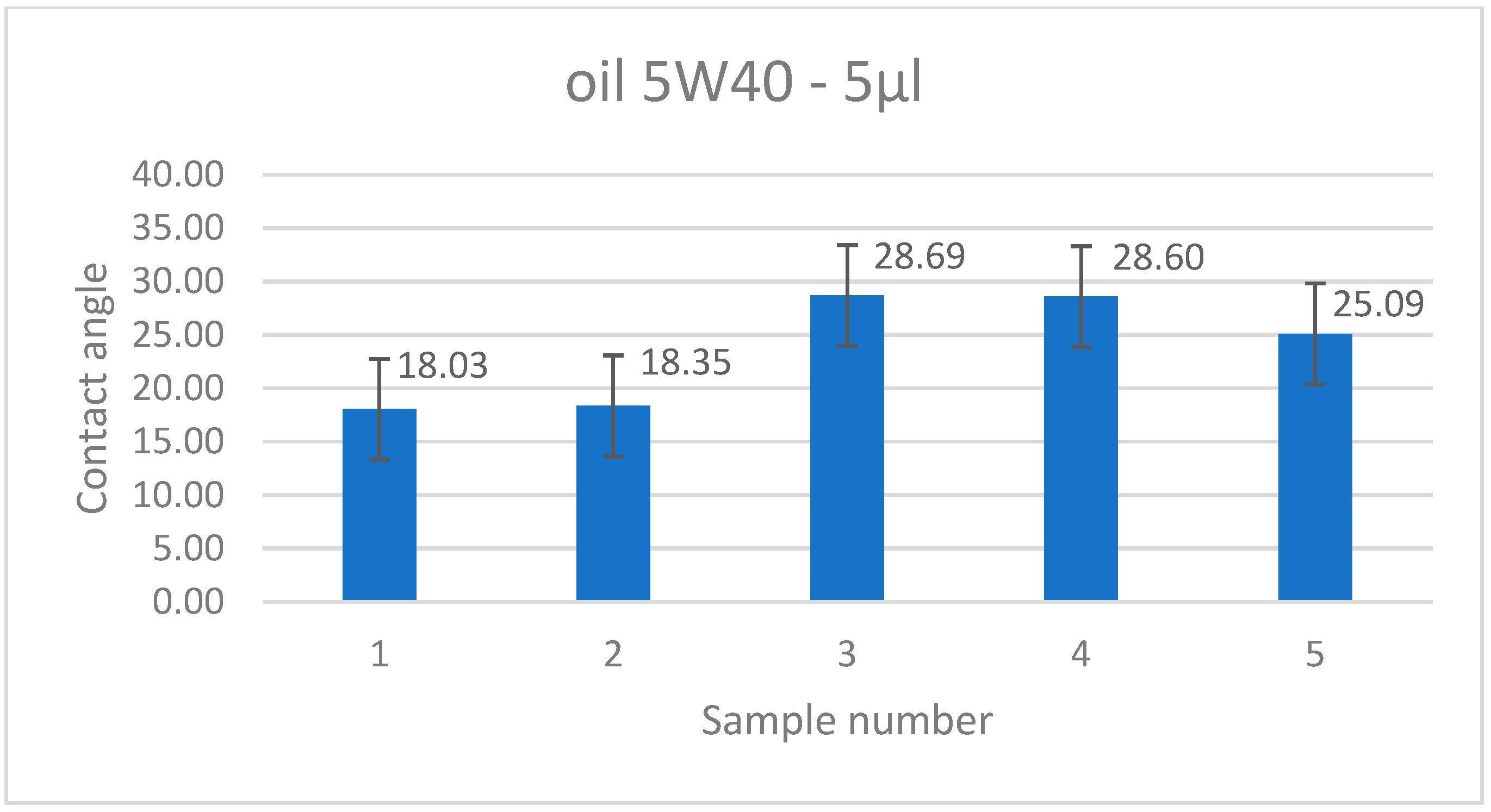

3.4. Contact Angle Measurement

3.5. Microscopy Analysis

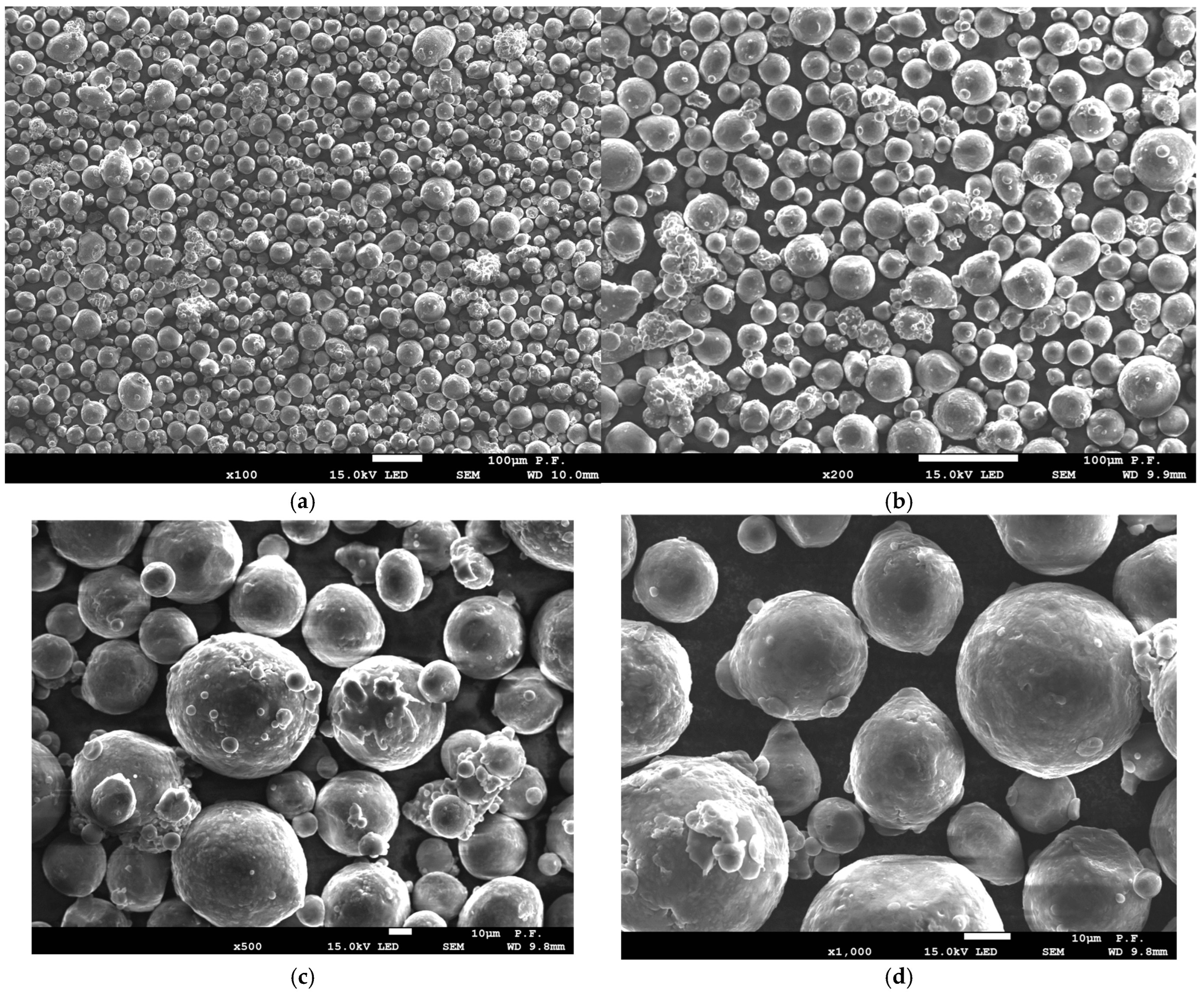

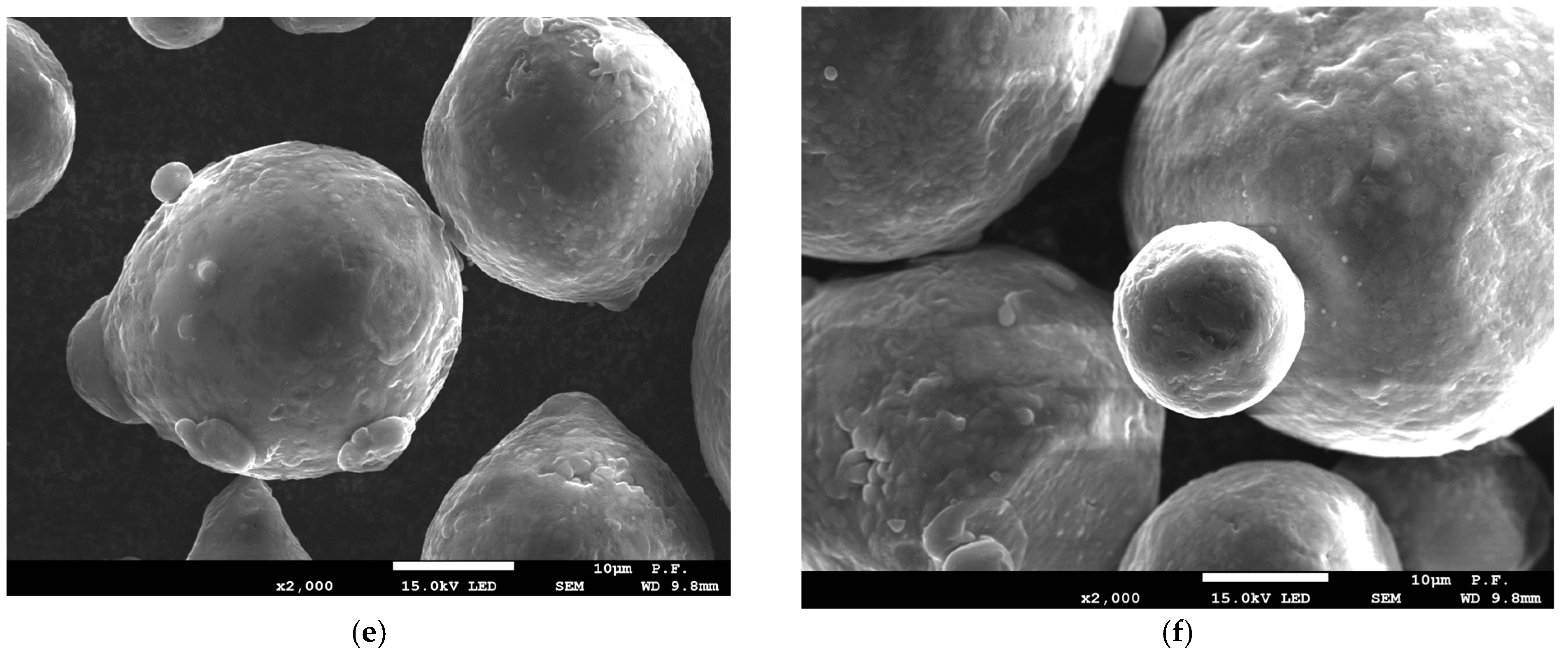

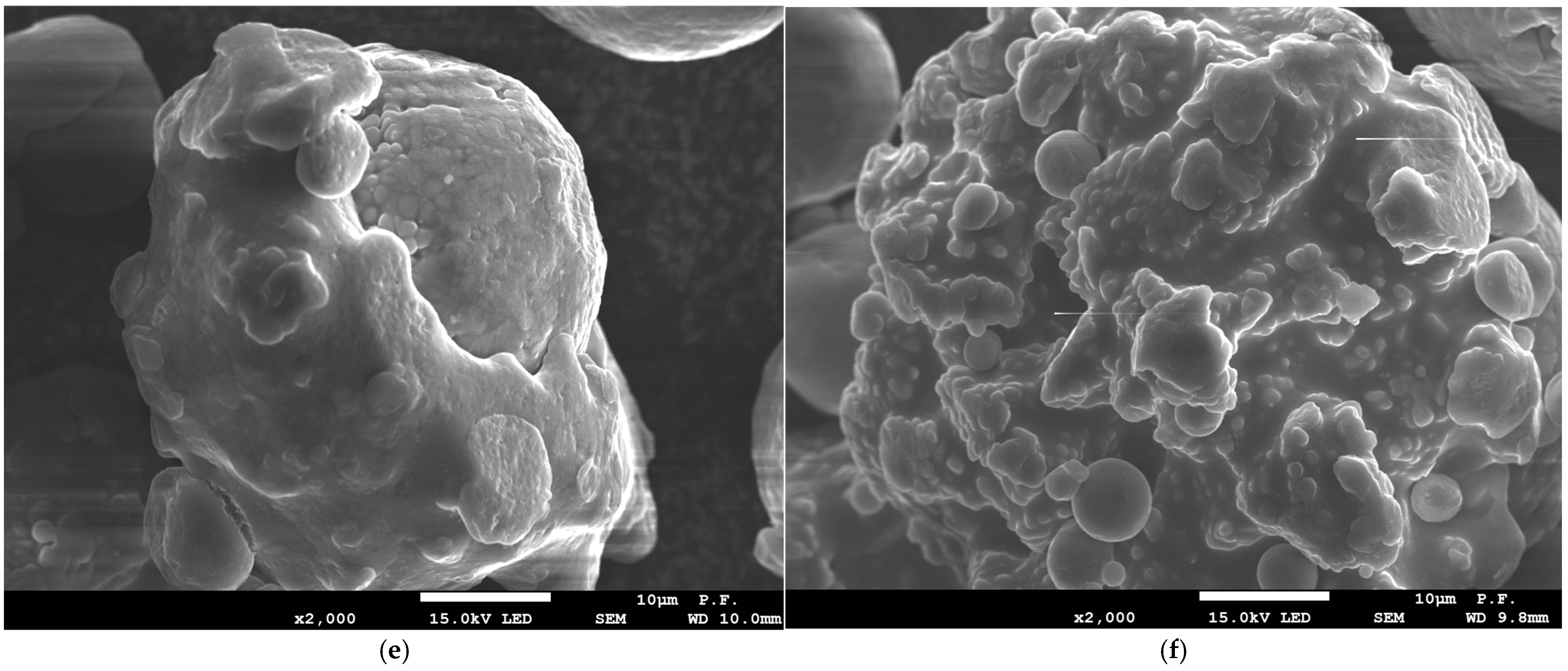

3.5.1. Powder

3.5.2. Sample Microstructure Analysis

4. Conclusions

- For thin-walled sample models, there are certain technological limitations regarding the minimum thickness in the manufacturing process, e.g., FD0-T1, for the 0° direction of flat samples (FD0) and a wall thickness of 0.5 mm; thus, it was not possible to produce these samples.

- The strength of thin-walled models in relation to solid-type samples depends on both the sample thickness and the printing direction, which is graphically shown in Figure 10.

- The tensile samples, which were manufactured in the 45° orientation, show greater dispersion of strength, which was also confirmed by the values of the standard deviation shown in Table 5, which reached the highest values in all series of samples with nominal thicknesses of 0.5, 1, 1.4, and 1.8 mm. The largest SD was 18.47 MPa, with an average strength (Rm) of 223.4 MPa for the D45-T18 sample series.

- During the measurements of the sample geometry before the static tensile test, differences in the thickness and width dimensions were found in relation to those designed in CAD models and set on the virtual construction platform. The largest differences in the obtained dimensions concern the measurement series with a thickness of 1 mm, where, in three cases, the dimensional difference for the “a” dimension, i.e., thickness, was as much as 57% in relation to the nominal CAD dimension. The dimensional differences in the “a” thickness for samples with a thickness of 0.5 mm ranged from 26% to 34%. In the remaining cases, the “a” thickness of the samples was characterized by a deviation between 10% and 24%. The most accurate samples were those made with a given thickness of 2 mm, where the deviations averaged 8.75% (from 7% to 12%).

- Anisotropy in the surface of samples was found. The average roughness values for samples made with the specified angles of 0°, 45°, and 90° were 11.33 µm, 10.81 µm, and 11.65 µm, respectively.

- Both the shape of the drop shown in Figure 14 and the measured values of the contact angle indicate the hydrophilic properties of the tested material.

- Based on microscopic observations, a few occurrences of material defects in the laser melting process were found, such as the residue of unmelted powder and the occurrence of gassing, craters, and inclusions, which can reduce the strength properties of thin-walled samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Etemadi, E.; Gholikord, M.; Zeeshan, M.; Hu, H. Improved Mechanical Characteristics of New Auxetic Structures Based on Stretch-Dominated-Mechanism Deformation under Compressive and Tensile Loadings. Thin-Walled Struct. 2023, 184, 110491. [Google Scholar] [CrossRef]

- Li, K.; Zhang, M.; Hou, Y.; Wu, Y.; Ji, C.; He, J.; Jin, P.; Wu, D.; Zhu, L. Multi-Scale Simulation of Residual Stress and Deformation of Large-Size Hollow Parts Fabricated by Laser-Based Powder Bed Fusion. Thin-Walled Struct. 2024, 198, 111743. [Google Scholar] [CrossRef]

- Bochnia, J.; Kozior, T.; Zyz, J. The Mechanical Properties of Direct Metal Laser Sintered Thin-Walled Maraging Steel (MS1) Elements. Materials 2023, 16, 4699. [Google Scholar] [CrossRef] [PubMed]

- Rudnik, M. Study of Cellular Structures Built from Self-Similar Models and Repeatable Structures Manufactured by FDM/FFF Technology. Polimery 2024, 69, 173–178. [Google Scholar] [CrossRef]

- Płatek, P.; Rajkowski, K.; Cieplak, K.; Sarzyński, M.; Małachowski, J.; Woźniak, R.; Janiszewski, J. Deformation Process of 3D Printed Structures Made from Flexible Material with Different Values of Relative Density. Polymers 2020, 12, 2120. [Google Scholar] [CrossRef] [PubMed]

- Grzelak, K.; Kluczyński, J.; Szachogłuchowicz, I.; Łuszczek, J.; Śnieżek, L.; Torzewski, J. Modification of Structural Properties Using Process Parameters and Surface Treatment of Monolithic and Thin-Walled Parts Obtained by Selective Laser Melting. Materials 2020, 13, 5662. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Kundera, C. Viscoelastic Properties of Cell Structures Manufactured Using a Photo-Curable Additive Technology—PJM. Polymers 2021, 13, 1895. [Google Scholar] [CrossRef] [PubMed]

- Szczygiel, P. Polymer Materials to Produce Wrist-Hand Orthoses Using the Additive Method. Polimery 2024, 69, 103–111. [Google Scholar] [CrossRef]

- Bochnia, J.; Kozior, T.; Musialek, M. Flexural Properties of Thin-Walled Specimens with Square Hollow Sections 3D Printed from ABS Reinforced with Aramid Fibers. Fibers 2023, 11, 77. [Google Scholar] [CrossRef]

- Budzik, G.; Przeszlowski, L.; Wieczorowski, M.; Rzucidlo, A.; Gapinski, B.; Krolczyk, G. Analysis of 3D Printing Parameters of Gears for Hybrid Manufacturing. AIP Conf. Proc. 2018, 1960, 140005. [Google Scholar] [CrossRef]

- Gunnar, M.; Daniel, M.; Marcel, R.; Katharina, S.; Johannes Henrich, S. Additive Manufacturing Processes In Fluid Power—Properties And Opportunities Demonstrated At A Flow-Optimized Fitting. In Proceedings of the 2018 International Conference on Hydraulics and Pneumatics–HERVEX, Baile Govora, Romania, 7–9 November 2018; pp. 12–23. [Google Scholar]

- Cooper, D.E.; Stanford, M.; Kibble, K.A.; Gibbons, G.J. Additive Manufacturing for Product Improvement at Red Bull Technology. Mater. Des. 2012, 41, 226–230. [Google Scholar] [CrossRef]

- Matthiesen, G.; Merget, D.; Pietrzyk, T.; Ziegler, S.; Schleifenbaum, J.H.; Schmitz, K. Design and Experimental Investigation of an Additive Manufactured Compact Drive. In Proceedings of the 12th International Fluid Power Conference, Dresden, Germany, 12–14 October 2020. [Google Scholar]

- Anton, W.; Liselott, E.; Johan, A.P.; Johan, Ö. Additive Manufacturing in Fluid Power with Novel Application Tohydraulic Pump Design. Int. Des. Conf.—Des. 2024, 4, 1889–1898. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland; ASTM International: West Conshohocken, PA, USA, 2021.

- Madej, M.; Piotrowska, K. Characterisation of TiCN Coatings for Biomedical Applications. Coatings 2024, 14, 775. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Madej, M.; Piotrowska, K.; Radoń-Kobus, K. Influence of Surface Roughness on Selected Properties of the Tialn Coating. Metalurgija 2024, 63, 57–60. [Google Scholar]

- ISO 25178-2; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms. Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 21920-2; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Problem of Non-Measured Points in Surface Texture Measurements. Metrol. Meas. Syst. 2017, 24, 525–536. [Google Scholar] [CrossRef]

- Zmarzly, P.; Kozior, T.; Gogolewski, D. The Effect of Non-Measured Points on the Accuracy of the Surface Topography Assessment of Elements 3D Printed Using Selected Additive Technologies. Materials 2023, 16, 460. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Song, J.; Nai, M.L.S.; Wei, J. Experimental Analysis of Additively Manufactured Component and Design Guide-lines for Lightweight Structures: A Case Study Using Electron Beam Melting. Addit. Manuf. 2020, 33, 101088. [Google Scholar] [CrossRef]

- Bailey, C.M.; Morrow, J.A.; Stallbaumer-Cyr, E.M.; Weeks, C.; Derby, M.M.; Thompson, S.M. Effects of Build Angle on Additively Manufactured Aluminum Alloy Surface Roughness and Wettability. Proc. J. Manuf. Sci. Eng 2022, 144, 081010. [Google Scholar] [CrossRef]

| Elements | Wt (%) |

|---|---|

| Al | balance |

| Si | 9.0–11.0 |

| Fe | ≤0.55 |

| Cu | ≤0.05 |

| Mn | ≤0.45 |

| Mg | ≤0.2–0.45 |

| Ni | ≤0.05 |

| Zn | ≤0.10 |

| Pb | ≤0.05 |

| Sn | ≤0.05 |

| Ti | ≤0.15 |

| Yield Strength Rp0.2 [MPa] | Tensile Strength Rm [MPa] | Elongation at Break A [%] | |

|---|---|---|---|

| Vertical | 240 | 380 | 2 |

| Horizontal | 260 | 400 | 3 |

| Parameter | Value |

|---|---|

| Layer thickness | 90 μm |

| Platform temperature | 165 °C |

| Atmosphere | Nitrogen |

| Differential pressure | 2.8 mbar |

| Gas flow | 300 m3/h |

| Recoating speed | 250 mm/s |

| Laser power | 600 W |

| Wave type | Continuous |

| Infill/downskin hatch distance | 160 μm |

| Upskin hatch distance | 200 μm |

| Infill laser speed | 1935 mm/s |

| Downskin laser speed | 5000 mm/s |

| Upskin laser speed | 1100 mm/s |

| No. | a (mm) | b (mm) | No. | a (mm) | b (mm) | No. | a (mm) | b (mm) | No. | a (mm) | b (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D0-T2-1 | 2.12 | 6.41 | D45-T2-1 | 2.18 | 6.54 | D90-T2-1 | 2.17 | 6.06 | FD0-T2-1 | 2.33 | 6.02 |

| D0-T2-2 | 2.20 | 6.38 | D45-T2-2 | 2.17 | 6.62 | D90-T2-2 | 2.15 | 6.08 | FD0-T2-2 | 2.21 | 6.04 |

| D0-T2-3 | 2.12 | 6.37 | D45-T2-3 | 2.19 | 6.49 | D90-T2-3 | 2.17 | 6.08 | FD0-T2-3 | 2.20 | 6.06 |

| D0-T2-4 | 2.14 | 6.43 | D45-T2-4 | 2.15 | 6.52 | D90-T2-4 | 2.15 | 6.11 | FD0-T2-4 | 2.23 | 6.09 |

| D0-T2-5 | 2.14 | 6.59 | D45-T2-5 | 2.15 | 6.60 | D90-T2-5 | 2.16 | 6.09 | FD0-T2-5 | 2.22 | 6.01 |

| 2.14 | 6.44 | 2.17 | 6.55 | 2.16 | 6.08 | 2.24 | 6.04 | ||||

| SD | 0.03 | 0.09 | SD | 0.02 | 0.05 | SD | 0.01 | 0.02 | SD | 0.05 | 0.03 |

| D0-T18-1 | 2.03 | 6.32 | D45-T18-1 | 1.97 | 6.53 | D90-T18-1 | 2.01 | 6.12 | FD0-T18-1 | 2.11 | 6.02 |

| D0-T18-2 | 1.96 | 6.43 | D45-T18-2 | 1.98 | 6.57 | D90-T18-2 | 2.00 | 6.05 | FD0-T18-2 | 2.09 | 6.03 |

| D0-T18-3 | 1.95 | 6.41 | D45-T18-3 | 1.93 | 6.53 | D90-T18-3 | 1.99 | 6.11 | FD0-T18-3 | 2.15 | 6.04 |

| D0-T18-4 | 1.96 | 6.44 | D45-T18-4 | 1.95 | 6.42 | D90-T18-4 | 1.98 | 6.12 | FD0-T18-4 | 2.09 | 6.07 |

| D0-T18-5 | 1.94 | 6.39 | D45-T18-5 | 1.97 | 6.52 | D90-T18-5 | 2.00 | 6.15 | FD0-T18-5 | 2.06 | 6.08 |

| 1.97 | 6.40 | 1.96 | 6.51 | 2.00 | 6.11 | 2.10 | 6.05 | ||||

| SD | 0.04 | 0.05 | SD | 0.02 | 0.06 | SD | 0.01 | 0.04 | SD | 0.03 | 0.03 |

| D0-T14-1 | 1.53 | 6.39 | D45-T14-1 | 1.56 | 6.50 | D90-T14-1 | 1.57 | 6.09 | FD0-T14-1 | 1.71 | 6.10 |

| D0-T14-2 | 1.58 | 6.35 | D45-T14-2 | 1.55 | 6.49 | D90-T14-2 | 1.55 | 6.14 | FD0-T14-2 | 1.72 | 6.03 |

| D0-T14-3 | 1.59 | 6.48 | D45-T14-3 | 1.53 | 6.32 | D90-T14-3 | 1.53 | 6.04 | FD0-T14-3 | 1.71 | 6.05 |

| D0-T14-4 | 1.58 | 6.48 | D45-T14-4 | 1.51 | 6.39 | D90-T14-4 | 1.56 | 6.10 | FD0-T14-4 | 1.75 | 6.01 |

| D0-T14-5 | 1.57 | 6.43 | D45-T14-5 | 1.55 | 6.35 | D90-T14-5 | 1.56 | 6.03 | FD0-T14-5 | 1.78 | 6.08 |

| 1.57 | 6.43 | 1.54 | 6.41 | 1.55 | 6.08 | 1.73 | 6.05 | ||||

| SD | 0.02 | 0.06 | SD | 0.02 | 0.08 | SD | 0.02 | 0.05 | SD | 0.03 | 0.04 |

| D0-T1-1 | 1.54 | 6.52 | D45-T1-1 | 1.60 | 6.58 | D90-T1-1 | 1.59 | 6.14 | FD0-T1-1 | 1.31 | 6.03 |

| D0-T1-2 | 1.56 | 6.49 | D45-T1-2 | 1.61 | 6.50 | D90-T1-2 | 1.56 | 6.09 | FD0-T1-2 | 1.25 | 6.05 |

| D0-T1-3 | 1.61 | 6.48 | D45-T1-3 | 1.54 | 6.43 | D90-T1-3 | 1.57 | 6.11 | FD0-T1-3 | 1.31 | 6.09 |

| D0-T1-4 | 1.57 | 6.47 | D45-T1-4 | 1.53 | 6.52 | D90-T1-4 | 1.55 | 6.06 | FD0-T1-4 | 1.28 | 6.05 |

| D0-T1-5 | 1.58 | 6.49 | D45-T1-5 | 1.55 | 6.57 | D90-T1-5 | 1.59 | 6.11 | FD0-T1-5 | 1.31 | 6.04 |

| 1.57 | 6.49 | 1.57 | 6.52 | 1.57 | 6.10 | 1.29 | 6.05 | ||||

| SD | 0.03 | 0.02 | SD | 0.04 | 0.06 | SD | 0.02 | 0.03 | SD | 0.03 | 0.02 |

| D0-T05-1 | 0.64 | 6.53 | D45-T05-2 | 0.71 | 6.77 | D90-T05-1 | 0.65 | 6.09 | |||

| D0-T05-2 | 0.64 | 6.54 | D45-T05-3 | 0.67 | 6.75 | D90-T05-2 | 0.65 | 6.08 | |||

| D0-T05-3 | 0.62 | 6.43 | D45-T05-4 | 0.68 | 6.63 | D90-T05-3 | 0.61 | 6.07 | |||

| D0-T05-4 | 0.62 | 6.46 | D45-T05-5 | 0.61 | 6.59 | D90-T05-4 | 0.62 | 6.05 | |||

| D0-T05-5 | 0.62 | 6.63 | D45-T05-6 | 0.68 | 6.44 | D90-T05-5 | 0.62 | 6.07 | |||

| 0.63 | 6.52 | 0.67 | 6.64 | 0.63 | 6.07 | ||||||

| SD | 0.01 | 0.08 | SD | 0.04 | 0.13 | SD | 0.02 | 0.01 |

| No. | Rm (MPa) | ε (mm) | No. | Rm (MPa) | ε (mm) | No. | Rm (MPa) | ε (mm) | No. | Rm (MPa) | ε (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| D0-T2-1 | 293 | 4.01 | D45-T2-1 | 225 | 6.05 | D90-T2-1 | 313 | 4.12 | FD0-T2-1 | 212 | 2.55 |

| D0-T2-2 | 277 | 3.62 | D45-T2-2 | 234 | 4.74 | D90-T2-2 | 291 | 3.31 | FD0-T2-2 | 244 | 3.66 |

| D0-T2-3 | 298 | 4.02 | D45-T2-3 | 230 | 4.06 | D90-T2-3 | 297 | 3.74 | FD0-T2-3 | 238 | 3.61 |

| D0-T2-4 | 280 | 3.49 | D45-T2-4 | 238 | 4.28 | D90-T2-4 | 304 | 3.78 | FD0-T2-4 | 240 | 3.60 |

| D0-T2-5 | 295 | 4.60 | D45-T2-5 | 235 | 4.37 | D90-T2-5 | 306 | 3.79 | FD0-T2-5 | 248 | 3.59 |

| 288.60 | 3.95 | 232.40 | 4.70 | 302.20 | 3.75 | 236.40 | 3.40 | ||||

| SD | 9.45 | 0.43 | SD | 5.03 | 0.79 | SD | 8.47 | 0.29 | SD | 14.17 | 0.48 |

| D0-T18-1 | 222 | 3.57 | D45-T18-1 | 232 | 4.23 | D90-T18-1 | 307 | 4.79 | FD0-T18-1 | 221 | 2.89 |

| D0-T18-2 | 228 | 3.79 | D45-T18-2 | 191 | 3.45 | D90-T18-2 | 305 | 4.14 | FD0-T18-2 | 191 | 2.11 |

| D0-T18-3 | 225 | 3.29 | D45-T18-3 | 230 | 4.35 | D90-T18-3 | 302 | 4.44 | FD0-T18-3 | 209 | 2.53 |

| D0-T18-4 | 227 | 3.72 | D45-T18-4 | 227 | 3.34 | D90-T18-4 | 311 | 4.43 | FD0-T18-4 | 238 | 3.97 |

| D0-T18-5 | 226 | 3.25 | D45-T18-5 | 237 | 4.52 | D90-T18-5 | 295 | 3.87 | FD0-T18-5 | 227 | 2.96 |

| 225.60 | 3.52 | 223.40 | 3.98 | 304.00 | 4.33 | 217.20 | 2.89 | ||||

| SD | 2.30 | 0.25 | SD | 18.47 | 0.54 | SD | 6.00 | 0.35 | SD | 18.01 | 0.69 |

| D0-T14-1 | 226 | 2.98 | D45-T14-1 | 226 | 3.98 | D90-T14-1 | 241 | 3.15 | FD0-T14-1 | 169 | 2.62 |

| D0-T14-2 | 217 | 2.76 | D45-T14-2 | 230 | 4.37 | D90-T14-2 | 242 | 2.92 | FD0-T14-2 | 166 | 2.31 |

| D0-T14-3 | 212 | 2.89 | D45-T14-3 | 245 | 4.38 | D90-T14-3 | 252 | 3.17 | FD0-T14-3 | 169 | 2.33 |

| D0-T14-4 | 217 | 3.08 | D45-T14-4 | 239 | 2.75 | D90-T14-4 | 246 | 3.01 | FD0-T14-4 | 165 | 2.38 |

| D0-T14-5 | 212 | 2.49 | D45-T14-5 | 223 | 3.08 | D90-T14-5 | 244 | 2.74 | FD0-T14-5 | 168 | 3.15 |

| 216.80 | 2.84 | 232.60 | 3.71 | 245.00 | 3.00 | 167.40 | 2.56 | ||||

| SD | 5.72 | 0.23 | SD | 9.18 | 1.12 | SD | 4.36 | 0.18 | SD | 1.82 | 0.35 |

| D0-T1-1 | 213 | 3.40 | D45-T1-1 | 237 | 4.78 | D90-T1-1 | 235 | 4.73 | FD0-T1-1 | 144 | 2.04 |

| D0-T1-2 | 212 | 4.01 | D45-T1-2 | 220 | 3.83 | D90-T1-2 | 245 | 4.88 | FD0-T1-2 | 157 | 2.13 |

| D0-T1-3 | 211 | 4.11 | D45-T1-3 | 235 | 4.56 | D90-T1-3 | 244 | 4.17 | FD0-T1-3 | 145 | 2.20 |

| D0-T1-4 | 211 | 3.49 | D45-T1-4 | 233 | 4.74 | D90-T1-4 | 236 | 4.49 | FD0-T1-4 | 152 | 2.39 |

| D0-T1-5 | 212 | 4.13 | D45-T1-5 | 224 | 4.32 | D90-T1-5 | 240 | 4.96 | FD0-T1-5 | 152 | 239 |

| 211.80 | 3.83 | 229.80 | 4.45 | 240.00 | 4.65 | 150.00 | 49.55 | ||||

| SD | 0.84 | 0.35 | SD | 7.40 | 0.39 | SD | 4.53 | 0.32 | SD | 5.43 | 105.90 |

| D0-T05-1 | 181 | 2.02 | D45-T05-2 | 130 | 1.55 | D90-T05-1 | 185 | 2.53 | |||

| D0-T05-2 | 191 | 2.86 | D45-T05-3 | 151 | 1.69 | D90-T05-2 | 181 | 2.39 | |||

| D0-T05-3 | 193 | 2.29 | D45-T05-4 | 128 | 1.27 | D90-T05-3 | 183 | 1.87 | |||

| D0-T05-4 | 194 | 2.34 | D45-T05-5 | 161 | 1.40 | D90-T05-4 | 199 | 2.65 | |||

| D0-T05-5 | 187 | 2.36 | D45-T05-6 | 147 | 1.70 | D90-T05-5 | 198 | 2.68 | |||

| 189.20 | 2.37 | 143.40 | 1.52 | 189.20 | 2.42 | ||||||

| SD | 5.31 | 0.30 | SD | 14.12 | 0.19 | SD | 8.61 | 0.33 |

| Sample Thickness (mm) | Printing Direction (°) | Sample Number | Ra | Rz | Rsk | Wa | Sa | Sz | NMP (%) |

|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 0 | D0-T05 | 9.659 | 52.808 | 0.437 | 13.358 | 14.512 | 488.217 | 0.061 |

| 45 | D45-T05 | 8.895 | 47.999 | 0.662 | 13.174 | 12.482 | 329.670 | 0.051 | |

| 90 | D90-T05 | 11.034 | 64.882 | 0.947 | 11.423 | 13.593 | 597.599 | 0.050 | |

| 1 | 0 | D0-T1 | 11.988 | 62.436 | 0.372 | 14.252 | 16.612 | 505.483 | 0.061 |

| 45 | D45-T1 | 10.562 | 58.557 | 0.217 | 11.395 | 14.397 | 465.435 | 0.034 | |

| 90 | D90-T1 | 12.914 | 70.434 | 0.524 | 15.503 | 15.837 | 404.276 | 0.742 | |

| parallel | FD0-T1 | 20.311 | 101.057 | −0160 | 29.693 | 27.532 | 400.634 | 0.387 | |

| 1.4 | 0 | D0-T14 | 13.597 | 70.759 | 0.441 | 17.228 | 18.839 | 496.055 | 0.136 |

| 45 | D45-T14 | 11.814 | 65.634 | 0.667 | 14.569 | 15.546 | 469.282 | 0.196 | |

| 90 | D90-T14 | 11.020 | 56.303 | 0.149 | 12.209 | 13.754 | 398.701 | 0.048 | |

| parallel | FD0-T14 | 3.567 | 21.596 | 0.270 | 6.596 | 5.641 | 427.922 | 0.072 | |

| 1.8 | 0 | D0-T18 | 10.108 | 51.077 | 0.211 | 11.649 | 13.909 | 371.121 | 0.090 |

| 45 | D45-T18 | 11.102 | 56.607 | −0.082 | 12.700 | 14.352 | 359.773 | 0.068 | |

| 90 | D90-T18 | 11.000 | 55.500 | 0.043 | 10.900 | 19.100 | 213.000 | 0.522 | |

| parallel | FD0-T18 | 4.970 | 30.900 | 0.184 | 8.120 | 10.800 | 267.000 | 0.001 | |

| 2.0 | 0 | D0-T2 | 10.500 | 58.600 | −0.021 | 10.700 | 18.800 | 307.000 | 0.180 |

| 45 | D45-T2 | 11.701 | 60.632 | 0.415 | 11.378 | 14.975 | 461.854 | 0.092 | |

| 90 | D90-T2 | 13.900 | 77.300 | 0.0695 | 13.500 | 22.500 | 429.000 | 0.542 | |

| parallel | FD0-T2 | 3.910 | 22.800 | 0.0716 | 4.410 | 9.210 | 243.000 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozior, T.; Bochnia, J.; Jurago, A.; Jędrzejewski, P.; Adamczyk, M. Evaluation of Selected Quality Characteristics of Thin-Walled Models Manufactured Using Powder Bed Fusion Technology. Materials 2025, 18, 1134. https://doi.org/10.3390/ma18051134

Kozior T, Bochnia J, Jurago A, Jędrzejewski P, Adamczyk M. Evaluation of Selected Quality Characteristics of Thin-Walled Models Manufactured Using Powder Bed Fusion Technology. Materials. 2025; 18(5):1134. https://doi.org/10.3390/ma18051134

Chicago/Turabian StyleKozior, Tomasz, Jerzy Bochnia, Alicja Jurago, Piotr Jędrzejewski, and Michał Adamczyk. 2025. "Evaluation of Selected Quality Characteristics of Thin-Walled Models Manufactured Using Powder Bed Fusion Technology" Materials 18, no. 5: 1134. https://doi.org/10.3390/ma18051134

APA StyleKozior, T., Bochnia, J., Jurago, A., Jędrzejewski, P., & Adamczyk, M. (2025). Evaluation of Selected Quality Characteristics of Thin-Walled Models Manufactured Using Powder Bed Fusion Technology. Materials, 18(5), 1134. https://doi.org/10.3390/ma18051134