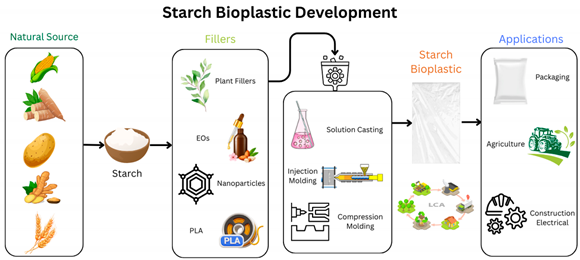

Starch-Derived Bioplastics: Pioneering Sustainable Solutions for Industrial Use

Abstract

1. Introduction

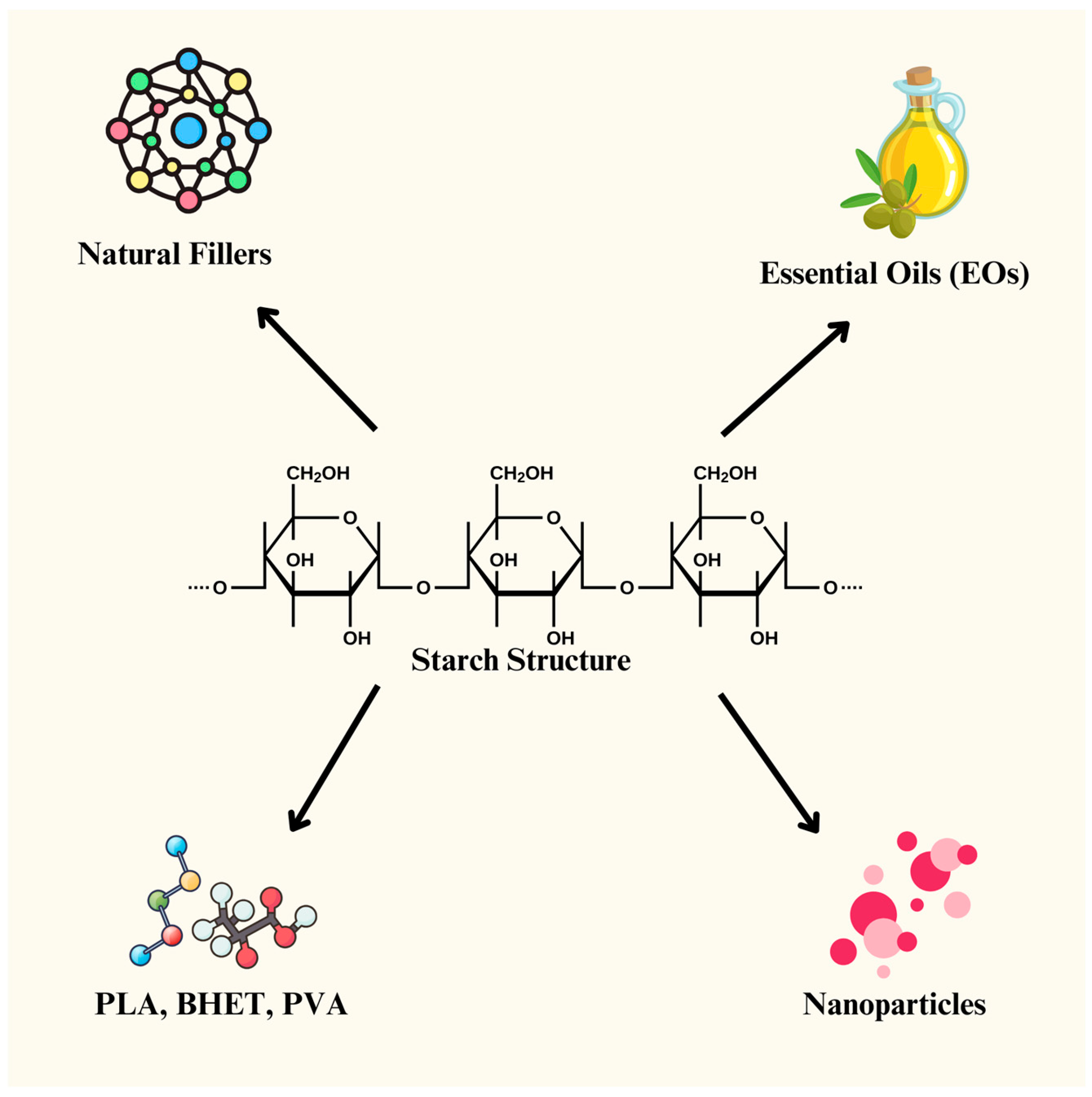

2. Starch-Based Bioplastics

2.1. Natural Fillers

2.1.1. Plant Fillers

2.1.2. Natural Mineral Fillers

| Starch | Fillers | Properties | Ref. |

|---|---|---|---|

| Corn | Pineapple Leaf Microfiber (3, 6, and 9%) | TS increased (48 to 51 MPa) Biodegradation after 28 days showed 82% weight loss for 9% | [46] |

| Cassava | Pineapple Leaf Microfiber (10, 20, 30, and 40% w/w) | TS increased (12.94 to 18.37 MPa) EAB decreased (9.23 to 5.73%) Optimal fiber composition, 30% | [47] |

| Cassava | Bamboo (10% w/w, untreated, alkali-treated and permanganate-treated) | Optimal TS (3.96 MPa) for alkali Biodegradability after 15 days (5.44% loss untreated, 5.97% loss alkali, and 6.15% permanganate) | [48] |

| Cassava | Coconut Fiber (5–30%) | Increased TS (3.24 to 11.2 MPa) Decreased EAB (112 to 20%) Decreased water absorption | [49] |

| Corn | Sugarcane Bagasse (12%) | Increased TS (5.6 MPa) and EAB (37%) Biodegradability weight loss of 30–66% after 35 days | [50] |

| Corn | Coffee and Risk Husk (1, 5, and 10% w/w) | Increased TS (7 to 8.7 MPa coffee husk) (7 to 8.1 MPa rice husk) Decreased EAB (12 to 3% coffee husk) (12 to 3% rice husk) Decreased moisture content and high thermal stability | [51] |

| Sago | Bentonite (1, 2, and 3% w/w) | TS increased (0.2936 to 0.449 Pa) EAB decreased (149.72 to 73.93%) Biodegradability rate increased with higher bentonite content | [52] |

| Cassava | Silica Bamboo Leaves (0–5% w/w) | TS increased (0.53 to 0.75 MPa) EAB increased (0.16 to 0.28%) | [53] |

| Arrowroot | Arrowroot Fiber (2, 4, 6, 8, and 10% w/w) | Increased thermal stability (315 to 323 °C) Biodegradability after 12 days, 10 wt% composted 100% | [54] |

| Cassava | Oil Palm Mesocarp Fiber (3.5, 7, and 14% w/w) | Increased TS (0.3 to 0.8 MPa) Decreased EAB (79 to 45%) Thermal stability | [55] |

| Corn | Nile Rose Residues (0, 20, 40, 60, and 80 wt%) | Increased TS (11.7 MPa 40 wt% and 18 MPa 60 wt%) Decreased EAB | [56] |

| Sugar Palm | Sugar Palm Fiber (0.1, 0.2, 0.3, 0.4, 0.5, and 1.0 wt%) | Increased TS (4.8 to 10.68 MPa) Decreased EAB (38.1 to 25.38%) | [57] |

| Corn | Walnut Shell Flour (0, 30, 40, and 50 wt%) | Increased TS (9.75 to 16.75 MPa) Decreased water absorption and increased biodegradability (25% weight loss) | [58] |

| Corn | Corn Husks (5, 10, 15, and 20% w/w) | Increased TS at 10 wt%. (3.8 to 10.12 MPa), decreased 20 wt% (5.15 MPa) Increased EAB (72.35 to 239.76%) | [59] |

| Potato | Pine Rosin (0–30%) | Increased TS at 15% (6.28 to 10.19 MPa), decreased to 5.9 MPa at 30% Lowest water absorption 15% (53.5%) and thermal stability | [60] |

| Corn | Wood (0, 0.27, 0.54, and 0.81 g/g) | Increased TS (6.52 to 12.51 MPa) and EAB (2.60 to 9.43%) | [61] |

| Corn | Okra Stalk (0–25%) | Increased TS (11.26 to 19.04) and EAB (0.13–5.14%) | [62] |

2.2. Essential Oils (EOs)

| Starch | EO (%) | Antimicrobial Activity | Properties | Ref. |

|---|---|---|---|---|

| Amphiphilic | Cinnamon (0.25, 0.5, and 1%) | E. coli (43.8–61%) S. aureus (65.9–80.9%) | Increased TS (11.21 to 22.09 MPa) and EAB (16.4 to 26.79%), 70% biodegradable after 28 days | [77] |

| Corn/Wheat | Lemon (0.5, 1%, and 2%) | E. coli (45.46%) S. aureus (47.72%) | TS decreased by 28.41%, EAB increased by 19.82% | [78] |

| Millet | Clove (0–3% w/w) | E. coli (23 mm), S. aureus (18 mm), P. aeruginosa (24 mm), Enterobacter sp. (27 mm), B. cereus (20 mm) and Trichoderma (14 mm) | Increased thickness and EAB (9.3 to 5.67%), decreased TS (10.52 to 6.25 MPa) | [79] |

| Corn | Orange (0, 0.3, 0.5, and 0.7 µL/g) | S. aureus (68%) L. monocytogenes (80%) growth reduction | Increased MC and water solubility, decreased TS (5.11 to 2.4 MPa) and EAB (64.58 to 15.25%) | [80] |

| Potato | Lavender (2, 4, and 6%) | S. aureus (24.5 mm) E. coli (15.1 mm) | Increased thickness; decreased water solubility, absorption, and TS (70.2 to 24.89 MPa) | [81] |

| Chitosan | Rosemary (0.5%) | B. subtilis, E. Coli, and L monocytogenes | Improved water barrier properties, TS (25.95 MPa), and EAB (14.87%) | [82] |

| Cassava | Tea Tree (0.08, 0.8, and 1.5% v/v) | S. aureus (68%) C. albicans (64%) | TS increased (3.73 to 8.34 MPa) and decreased by 1.5% (3.03 MPa) EAB decreased | [83] |

| Tapioca | Caraway (0.5, 1, 2, and 3% w/w) | B. cereus (29.83 mm), E. coli (10.33 mm), P. aeruginosa (12.63 mm), S. aureus (26.3 mm) | TS decreased (15.23 to 12.62 MPa), EAB decreased (27.84 to 20.94%) | [84] |

2.3. Nanoparticles

| Nanoparticles | Starch | Properties | Ref. |

|---|---|---|---|

| ZnO | Cassava (1, 2, 3, 4, and 5% w/w) | MC decreased, TS increased to 10.29 MPa, and EAB decreased to 5.69%; biodegradation occurred at 7 days | [90] |

| Banana (1, 3, and 5% w/w) | TS increased from 2.5 to 36 MPa, and EAB decreased from 28 to 8%; degradation time was 90 min | [91] | |

| SiO2 | Potato (0–1.5%) | Increased EAB (from 52 to 70%) and decreased tensile strength (from 1.1 to 0.2 MPa); biodegradation occurred at 5 days | [92] |

| Corn (0–1.5%) | Increased EAB (from 59.2 to 78.9%) and decreased TS (from 1.05 to 0.6 MPa); biodegradation occurred at 40 days | ||

| TiO2 | Corn | Increased TS (from 3.55 to 3.95 MPa) and decreased EAB (from 88.1 to 62.5%); biodegradation with 64% weight loss occurred at 30 days | [93] |

| CaCO3 | Potato (10, 20, 30, 40, and 50% w/w) | Increased TS (from 30 to 45 MPa) and decreased EAB (from 20 to 15%) Decreased water absorption | [94] |

| Cassava (2, 4, 6, 8, and 10% w/w) | Increased TS by up to 4% (3.25 MPa) and decreased EAB (from 53.14 to 26.5%) Decreased MC, thermally stable | [21] | |

| GO | Potato | Optimal ratio of starch:chitosan (75:25) Enhanced mechanical properties (TS 26 MPa), water resistance (<10% weight loss), and electrical conductivity (3.8 10−3 S/m) | [95] |

| Copper | Corn (0.25, 0.5, 0.75, 1, and 5% w/w) | Increased TS (from 1.6 to 1.75 MPa) Decreased EAB (from 26 to 8%) Antimicrobial against S. aureus and E. coli | [96] |

2.4. Polymer Blends

| Starch | Compatibilizer | Properties | Ref. |

|---|---|---|---|

| Cassava | Oligo (lactic acid) (1, 2, 3, and 5 wt%) | Decreased TS (from 45 to 21 MPa) Increased EAB (from 5 to 35%) Improved extensibility, water and oxygen vaper barrier properties, and thermal stability | [104] |

| Yam | Epoxidized sesame oil (1.5 and 3 wt%) | Increased deformation and decreased TS Thermal stability | [105] |

| Cassava | Glycidyl methacrylate (1 wt%) | Decreased TS (from 37.4 to 23.3 MPa) Increased EAB (from 3.6 to 8.6%) | [106] |

3. Current Industrial Applications

3.1. Packaging Industry

3.2. Agricultural Applications

3.3. Textile Industry

3.4. Automotive Industry

3.5. Biomedical Applications

3.6. Electronic Industry

3.7. Consumer Goods

3.8. Construction

4. Environmental and Economic Impacts

4.1. Sustainability: Life Cycle Assessments of Bioplastics

4.2. Degradation and Recycling

4.3. Circular Economy and Bioplastics

4.4. Economic Impacts

5. Challenges and Future Prospects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AESO | Acrylated epoxidized soybean oil |

| APTES | 3-aminopropyl trimethoxy silane |

| BHET | Bis(2-hydroxyethyl) Terephthalate |

| BU | Betaine:urea |

| CCNC | Cellulose nanocrystals from corn husk |

| CCU | Choline chloride:urea |

| EAB | Elongation at break |

| EO | Essential oil |

| LBMD | Locust bean milling dust |

| LCA | Life cycle assessment |

| LDPE | Low density polyethylene |

| ODI | n-octadecyl isocyanate |

| OPP | Olive pit powder |

| PCL | Poly(ε-caprolactone) |

| PEO | Peppermint essential oil |

| PLA | Polylactic acid |

| PVA | Polyvinyl alcohol |

| ROEO | Rosmarinus officinalis essential oil |

| TS | Tensile strength |

| ZBO | Zanthoxylum bungeanum essential oil |

References

- Geyer, R. A Brief History of Plastics. In Mare Plasticum—The Plastic Sea: Combatting Plastic Pollution Through Science and Art; Springer: Cham, Switzerland, 2020; pp. 31–47. [Google Scholar] [CrossRef]

- Agamuthu, P.; Mehran, S.B.; Norkhairah, A.; Norkhairiyah, A. Marine Debris: A Review of Impacts and Global Initiatives. Waste Manag. Res. J. Sustain. Circ. Econ. 2019, 37, 987–1002. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.; Collard, F.; Fabres, J.; Gabrielsen, G.W.; Provencher, J.F.; Rochman, C.M.; van Sebille, E.; Tekman, M.B. Plastic Pollution in the Arctic. Nat. Rev. Earth Environ. 2022, 3, 323–337. [Google Scholar] [CrossRef]

- Dokl, M.; Copot, A.; Krajnc, D.; Van Fan, Y.; Vujanović, A.; Aviso, K.B.; Tan, R.R.; Kravanja, Z.; Čuček, L. Global Projections of Plastic Use, End-of-Life Fate and Potential Changes in Consumption, Reduction, Recycling and Replacement with Bioplastics to 2050. Sustain. Prod. Consum. 2024, 51, 498–518. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental Exposure to Microplastics: An Overview on Possible Human Health Effects. Sci. Total Environ. 2020, 702, 134455. [Google Scholar] [CrossRef]

- Shen, M.; Huang, W.; Chen, M.; Song, B.; Zeng, G.; Zhang, Y. (Micro)Plastic Crisis: Un-Ignorable Contribution to Global Greenhouse Gas Emissions and Climate Change. J. Clean. Prod. 2020, 254, 120138. [Google Scholar] [CrossRef]

- Alobi, N.; Sunday, E.; Magu, T.; Oloko, G.; Nyong, B. Analysis of Starch from Non- Edible Root and Tubers as Sources of Raw Materials for the Synthesis of Biodegradable Starch Plastics. J. Basic. Appl. Res. Biomed. 2017, 3, 27–32. [Google Scholar]

- Brockhaus, S.; Petersen, M.; Kersten, W. A Crossroads for Bioplastics: Exploring Product Developers’ Challenges to Move beyond Petroleum-Based Plastics. J. Clean. Prod. 2016, 127, 84–95. [Google Scholar] [CrossRef]

- Xie, D.; Zhang, R.; Zhang, C.; Yang, S.; Xu, Z.; Song, Y. A Novel, Robust Mechanical Strength, and Naturally Degradable Double Crosslinking Starch-Based Bioplastics for Practical Applications. Int. J. Biol. Macromol. 2023, 253, 126959. [Google Scholar] [CrossRef]

- Otache, M.A.; Duru, R.U.; Achugasim, O.; Abayeh, O.J. Advances in the Modification of Starch via Esterification for Enhanced Properties. J. Polym. Environ. 2021, 29, 1365–1379. [Google Scholar] [CrossRef]

- Tan, S.X.; Andriyana, A.; Ong, H.C.; Lim, S.; Pang, Y.L.; Ngoh, G.C. A Comprehensive Review on the Emerging Roles of Nanofillers and Plasticizers towards Sustainable Starch-Based Bioplastic Fabrication. Polymers 2022, 14, 664. [Google Scholar] [CrossRef]

- Jayarathna, S.; Andersson, M.; Andersson, R. Recent Advances in Starch-Based Blends and Composites for Bioplastics Applications. Polymers 2022, 14, 4557. [Google Scholar] [CrossRef] [PubMed]

- Rahardiyan, D.; Moko, E.M.; Tan, J.S.; Lee, C.K. Thermoplastic Starch (TPS) Bioplastic, the Green Solution for Single-Use Petroleum Plastic Food Packaging—A Review. Enzym. Microb. Technol. 2023, 168, 110260. [Google Scholar] [CrossRef] [PubMed]

- Pérez, S.; Bertoft, E. The Molecular Structures of Starch Components and Their Contribution to the Architecture of Starch Granules: A Comprehensive Review. Starch Stärke 2010, 62, 389–420. [Google Scholar] [CrossRef]

- Nafchi, A.M.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic Starches: Properties, Challenges, and Prospects. Starch Stärke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- Cristofoli, N.L.; Lima, A.R.; Tchonkouang, R.D.N.; Quintino, A.C.; Vieira, M.C. Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 2023, 15, 6153. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Jawaid, M.; Asim, M. Corn and Rice Starch-Based Bio-Plastics as Alternative Packaging Materials. Fibers 2019, 7, 32. [Google Scholar] [CrossRef]

- Sultan, N.F.K.; Johari, W.L.W. The Development of Banana Peel/Corn Starch Bioplastic Film: A Preliminary Study. In Bioremediation Science and Technology Research; Public Knowledge Project: Drive Burnaby, BC, Canada, 2017; Volume 5, pp. 12–17. ISSN 2289-5892. [Google Scholar] [CrossRef]

- Lenz, D.M.; Tedesco, D.M.; Camani, P.H.; dos Santos Rosa, D. Multiple Reprocessing Cycles of Corn Starch-Based Biocomposites Reinforced with Curauá Fiber. J. Polym. Environ. 2018, 26, 3005–3016. [Google Scholar] [CrossRef]

- Romani, V.P.; Prentice-Hernández, C.; Martins, V.G. Active and Sustainable Materials from Rice Starch, Fish Protein and Oregano Essential Oil for Food Packaging. Ind. Crops Prod. 2017, 97, 268–274. [Google Scholar] [CrossRef]

- Syafri, E.; Kasim, A.; Abral, H.; Asben, A. Effect of Precipitated Calcium Carbonate on Physical, Mechanical and Thermal Properties of Cassava Starch Bioplastic Composites. Int. J. Adv. Sci. Eng. Inf. Technol. 2017, 7, 1950. [Google Scholar] [CrossRef]

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.W.; Kim, H.J. Characterization of Tapioca Starch Biopolymer Composites Reinforced with Micro Scale Water Hyacinth Fibers. Starch Stärke 2018, 70, 1700287. [Google Scholar] [CrossRef]

- Zuraida, A.; Nur Humairah, A.R.; Nur Izwah, A.W.; Siti Naqiah, Z. The Study of Glycerol Plasticized Thermoplastic Sago Starch. In Proceedings of the Advanced Materials Research; AMR: Greenwood Village, CO, USA, 2012; Volume 576, pp. 289–292. [Google Scholar]

- Podshivalov, A.; Zakharova, M.; Glazacheva, E.; Uspenskaya, M. Gelatin/Potato Starch Edible Biocomposite Films: Correlation between Morphology and Physical Properties. Carbohydr. Polym. 2017, 157, 1162–1172. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef] [PubMed]

- Lopes, J.; Pettersen, M.K.; Grøvlen, M.S.; Sharmin, N.; Li, K.D.; Wetterhus, E.; Ferreira, P.; Coimbra, M.A.; Gonçalves, I. Heat-Sealable Bioplastic Films of Blended Locust Bean and Potato Byproducts for Active Packaging of Fatty Foods: Cheese and Oat Cookies as Case Studies. Food Hydrocoll. 2024, 147, 109322. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Zainudin, E.S.; Wahab, N.I.A.; Ilyas, R.A. Effect of Kenaf Fibre as Reinforcing Fillers in Corn Starch-Based Biocomposite Film. Polymers 2022, 14, 1590. [Google Scholar] [CrossRef]

- Majamo, S.L.; Amibo, T.A. Study on Extraction and Characterization of Anchote (Coccinia abyssinica) Starch and Reinforced Enset (Ensete ventricosum) Fiber for the Production of Reinforced Bioplastic Film. Heliyon 2024, 10, e23098. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Chaffa, T.Y.; Meshesha, B.T.; Mohammed, S.A.; Jabasingh, S.A. Production, Characterization, and Optimization of Starch-Based Biodegradable Bioplastic from Waste Potato (Solanum tuberosum) Peel with the Reinforcement of False Banana (Ensete ventricosum) Fiber. Biomass Convers. Biorefinery 2022, 14, 27365–27377. [Google Scholar] [CrossRef]

- Santana, I.; Felix, M.; Bengoechea, C. Sustainable Biocomposites Based on Invasive Rugulopteryx Okamurae Seaweed and Cassava Starch. Sustainability 2024, 16, 76. [Google Scholar] [CrossRef]

- Ekielski, A.; Żelaziński, T.; Kulig, R.; Kupczyk, A. Properties of Biocomposites Made of Extruded Apple Pomace and Potato Starch: Mechanical and Physicochemical Properties. Materials 2024, 17, 2681. [Google Scholar] [CrossRef]

- Zdanowicz, M.; Rokosa, M.; Pieczykolan, M.; Antosik, A.K.; Chudecka, J.; Mikiciuk, M. Study on Physicochemical Properties of Biocomposite Films with Spent Coffee Grounds as a Filler and Their Influence on Physiological State of Growing Plants. Int. J. Mol. Sci. 2023, 24, 7864. [Google Scholar] [CrossRef]

- Dilkushi, H.A.S.; Jayarathna, S.; Manipura, A.; Chamara, H.K.B.S.; Edirisinghe, D.; Vidanarachchi, J.K.; Priyashantha, H. Development and Characterization of Biocomposite Films Using Banana Pseudostem, Cassava Starch and Poly (Vinyl Alcohol): A Sustainable Packaging Alternative. Carbohydr. Polym. Technol. Appl. 2024, 7, 100472. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Vijayakumar, A.; Krina, P.; Navaf, M.; Parambil Akhila, P.; Raviteja, P.; Mounir, S.; Lackner, M.; George, J.; et al. Fabrication and Characterization of Talipot Starch-Based Biocomposite Film Using Mucilages from Different Plant Sources: A Comparative Study. Food Chem. 2024, 438, 138011. [Google Scholar] [CrossRef] [PubMed]

- Oluba, O.M.; Owoso, T.O.; Bayo-Olorunmeke, A.O.; Erifeta, G.O.; Josiah, S.J.; Ojeaburu, S.I.; Subbiah, N.; Palanisamy, T. Probing the Role of Ginger Starch on Physicochemical and Thermal Properties of Gum Arabic Hybrid Biocomposite for Food Packaging Applications. Carbohydr. Polym. Technol. Appl. 2025, 9, 100650. [Google Scholar] [CrossRef]

- Lounis, F.M.; Benhacine, F.; Hadj-Hamou, A.S. Improving Water Barrier Properties of Starch Based Bioplastics by Lignocellulosic Biomass Addition: Synthesis, Characterization and Antibacterial Properties. Int. J. Biol. Macromol. 2024, 283, 137823. [Google Scholar] [CrossRef]

- Torres-Vargas, O.; Campos Paéz, M.; Lema González, M. Corn Starch Based Biocomposite Films Reinforced with Cellulosic Nanocrystals Extracted from Corn Husks (Zea mays L.): Characterization and Application in Cherry Tomato Packaging. Ind. Crops Prod. 2025, 225, 120486. [Google Scholar] [CrossRef]

- Charles, A.L.; Nero, Z.; Sulmartiwi, L.; Triningtyas, P.H.; Putra, N.R.; Abdillah, A.A.; Alamsjah, M.A. Characterization of a Biocomposite Film Using Coconut Jelly Powder to Improve Arrowroot Starch and Sodium Alginate Film Forming Properties. Int. J. Biol. Macromol. 2025, 292, 139161. [Google Scholar] [CrossRef]

- Guno, F.J.R.; Mopera, L.; Santiago, D.M.; Elegado, F.; Galeon, P.L. Optimization of Biocomposite Taro (Colocasia esculenta (L.) Schott) Starch and Aloe Vera (Aloe barbadensis (L.) Burm.f.) Gel Based Film-Using Response Surface Methodology. Int. J. Biol. Macromol. 2025, 305, 140960. [Google Scholar] [CrossRef]

- Kedir, W.M.; Geletu, A.K.; Weldegirum, G.S. Spider Web-Reinforced Chitosan/Starch Biopolymer for Active Biodegradable Food Packaging. Appl. Food Res. 2024, 4, 100526. [Google Scholar] [CrossRef]

- Behera, L.; Mohanta, M.; Thirugnanam, A. Intensification of Yam-Starch Based Biodegradable Bioplastic Film with Bentonite for Food Packaging Application. Environ. Technol. Innov. 2022, 25, 102180. [Google Scholar] [CrossRef]

- Singh, P.; Kaur, G.; Singh, A.; Kaur, P. Starch Based Bio-Nanocomposite Films Reinforced with Montmorillonite and Lemongrass Oil Nanoemulsion: Development, Characterization and Biodegradability. J. Food Meas. Charact. 2023, 17, 527–545. [Google Scholar] [CrossRef]

- Ren, J.; Dang, K.M.; Pollet, E.; Avérous, L. Preparation and Characterization of Thermoplastic Potato Starch/Halloysite Nano-Biocomposites: Effect of Plasticizer Nature and Nanoclay Content. Polymers 2018, 10, 808. [Google Scholar] [CrossRef] [PubMed]

- Mutmainna, I.; Tahir, D.; Gareso, P.L.; Ilyas, S.; Saludung, A. Improving Degradation Ability of Composite Starch/Chitosan by Additional Pineapple Leaf Microfibers for Food Packaging Applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 593, 012024. [Google Scholar] [CrossRef]

- Jaafar, J.; Siregar, J.P.; Oumer, A.N.; Hamdan, M.H.M.; Tezara, C.; Salit, M.S. Experimental Investigation on Performance of Short Pineapple Leaf Fiber Reinforced Tapioca Biopolymer Composites. Bioresources 2019, 13, 6341–6355. [Google Scholar] [CrossRef]

- Yusof, F.M.; Wahab, N.’A.; Abdul Rahman, N.L.; Kalam, A.; Jumahat, A.; Mat Taib, C.F. Properties of Treated Bamboo Fiber Reinforced Tapioca Starch Biodegradable Composite. Mater. Today Proc. 2019, 16, 2367–2373. [Google Scholar] [CrossRef]

- Lomelí Ramírez, M.G.; Satyanarayana, K.G.; Iwakiri, S.; De Muniz, G.B.; Tanobe, V.; Flores-Sahagun, T.S. Study of the Properties of Biocomposites. Part I. Cassava Starch-Green Coir Fibers from Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef]

- Fitch-Vargas, P.R.; Camacho-Hernández, I.L.; Rodríguez-González, F.J.; Martínez-Bustos, F.; Calderón-Castro, A.; Zazueta-Morales, J.d.J.; Aguilar-Palazuelos, E. Effect of Compounding and Plastic Processing Methods on the Development of Bioplastics Based on Acetylated Starch Reinforced with Sugarcane Bagasse Cellulose Fibers. Ind. Crops Prod. 2023, 192, 116084. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Boix, A.C. Reinforcement of Thermoplastic Starch Films with Cellulose Fibres Obtained from Rice and Coffee Husks. J. Renew. Mater. 2018, 6, 599–610. [Google Scholar] [CrossRef]

- Zamrud, Z.; Ng, W.M.; Salleh, H.M. Effect of Bentonite Nanoclay Filler on the Properties of Bioplastic Based on Sago Starch. IOP Conf. Ser. Earth Environ. Sci. 2021, 765, 012009. [Google Scholar] [CrossRef]

- Oluwasina, O.O.; Akinyele, B.P.; Olusegun, S.J.; Oluwasina, O.O.; Mohallem, N.D.S. Evaluation of the Effects of Additives on the Properties of Starch-Based Bioplastic Film. SN Appl. Sci. 2021, 3, 421. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Khalina, A.; Ilyas, R.A.; Zainudin, E.S. Thermal, Flammability, and Antimicrobial Properties of Arrowroot (Maranta arundinacea) Fiber Reinforced Arrowroot Starch Biopolymer Composites for Food Packaging Applications. Int. J. Biol. Macromol. 2022, 213, 1–10. [Google Scholar] [CrossRef]

- Campos, A.; Sena Neto, A.R.; Rodrigues, V.B.; Luchesi, B.R.; Mattoso, L.H.C.; Marconcini, J.M. Effect of Raw and Chemically Treated Oil Palm Mesocarp Fibers on Thermoplastic Cassava Starch Properties. Ind. Crops Prod. 2018, 124, 149–154. [Google Scholar] [CrossRef]

- Ibrahim, M.M.; Moustafa, H.; El Rahman, E.N.A.; Mehanny, S.; Hemida, M.H.; El-Kashif, E. Reinforcement of Starch Based Biodegradable Composite Using Nile Rose Residues. J. Mater. Res. Technol. 2020, 9, 6160–6171. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N.; Mohd Nurazzi, N.; Atiqah, A.; Ansari, M.N.M.; et al. Effect of Sugar Palm Nanofibrillated Cellulose Concentrations on Morphological, Mechanical and Physical Properties of Biodegradable Films Based on Agro-Waste Sugar Palm (Arenga pinnata (Wurmb.) Merr) Starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Sarsari, N.A.; Pourmousa, S.; Tajdini, A. Physical and Mechanical Properties of Walnut Shell Flour-Filled Thermoplastic Starch Composites. Bioresources 2016, 11, 6968–6983. [Google Scholar] [CrossRef]

- Lenhani, G.C.; dos Santos, D.F.; Koester, D.L.; Biduski, B.; Deon, V.G.; Machado Junior, M.; Pinto, V.Z. Application of Corn Fibers from Harvest Residues in Biocomposite Films. J. Polym. Environ. 2021, 29, 2813–2824. [Google Scholar] [CrossRef]

- Sakhare, K.M.; Borkar, S.P.; Kale, R.D. Fabrication and Characterization of Bio Composite Based on Jute Fiber and Pine Rosin Modified Potato Starch. J. Chem. Health Risks 2023, 13, 258–271. [Google Scholar]

- Cheng, W. Preparation and Properties of Lignocellulosic Fiber/CaCO3/Thermoplastic Starch Composites. Carbohydr. Polym. 2019, 211, 204–208. [Google Scholar] [CrossRef]

- Guleria, A.; Singha, A.S.; Rana, R.K. Mechanical, Thermal, Morphological, and Biodegradable Studies of Okra Cellulosic Fiber Reinforced Starch-Based Biocomposites. Adv. Polym. Technol. 2018, 37, 104–112. [Google Scholar] [CrossRef]

- Zubair, M.; Shahzad, S.; Hussain, A.; Pradhan, R.A.; Arshad, M.; Ullah, A. Current Trends in the Utilization of Essential Oils for Polysaccharide-and Protein-Derived Food Packaging Materials. Polymers 2022, 14, 1146. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef]

- Souza, A.G.; Ferreira, R.R.; Paula, L.C.; Mitra, S.K.; Rosa, D.S. Starch-Based Films Enriched with Nanocellulose-Stabilized Pickering Emulsions Containing Different Essential Oils for Possible Applications in Food Packaging. Food Packag. Shelf Life 2021, 27, 100615. [Google Scholar] [CrossRef]

- Hernando, H.; Marpongahtun; Julianti, E.; Nuryawan, A.; Amaturrahim, S.A.; Piliang, A.F.R.; Yanhar, M.R.; Goei, R.; Soykeabkaew, N.; Saputra, A.M.A.; et al. Impact of Glycerol on Oil Palm Trunk Starch Bioplastics Enhanced with Citric-Acid Epoxidized Palm Oil Oligomers. Case Stud. Chem. Environ. Eng. 2024, 10, 100839. [Google Scholar] [CrossRef]

- Enidiok, E.S.; Enidiok, S.E.; Anakor, D.O.; Erifeta, G.O.; Thanikaivelan, P.; Oluba, O.M. Development and Characterization of Chia Oil-Activated Ginger Starch-Feather Keratin Biocomposite for Prolonged Post-Harvest Preservation of Tomato Fruits. Carbohydr. Polym. Technol. Appl. 2024, 7, 100464. [Google Scholar] [CrossRef]

- Criollo-Feijoo, J.; Salas-Gomez, V.; Cornejo, F.; Auras, R.; Salazar, R. Cassava Bagasse Starch and Oregano Essential Oil as a Potential Active Food Packaging Material: A Physicochemical, Thermal, Mechanical, Antioxidant, and Antimicrobial Study. Heliyon 2024, 10, e36150. [Google Scholar] [CrossRef]

- Mao, S.; Li, F.; Zhou, X.; Lu, C.; Zhang, T. Characterization and Sustained Release Study of Starch-Based Films Loaded with Carvacrol: A Promising UV-Shielding and Bioactive Nanocomposite Film. Lebensm. Wiss. Technol. 2023, 180, 114719. [Google Scholar] [CrossRef]

- Srivastava, V.; Singh, S.; Das, D. Development and Characterization of Peppermint Essential Oil/Rice Husk Fibre/ Corn Starch Active Biocomposite Film and Its Performance on Bread Preservation. Ind. Crops Prod. 2024, 208, 117765. [Google Scholar] [CrossRef]

- Yang, Q.; Zheng, F.; Chai, Q.; Li, Z.; Zhao, H.; Zhang, J.; Nishinari, K.; Zhao, M.; Cui, B. Effect of Emulsifiers on the Properties of Corn Starch Films Incorporated with Zanthoxylum Bungeanum Essential Oil. Int. J. Biol. Macromol. 2024, 256, 128382. [Google Scholar] [CrossRef]

- Parada-Quinayá, C.; Garces-Porras, K.; Flores, E. Development of Biobased Films Incorporated with an Antimicrobial Agent and Reinforced with Stipa Obtusa Cellulose Microfibers, via Tape Casting. Results Mater. 2024, 24, 100637. [Google Scholar] [CrossRef]

- Castro, D.; Podshivalov, A.; Ponomareva, A.; Zhilenkov, A. Study of the Reinforcing Effect and Antibacterial Activity of Edible Films Based on a Mixture of Chitosan/Cassava Starch Filled with Bentonite Particles with Intercalated Ginger Essential Oil. Polymers 2024, 16, 2531. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Li, C.; Ching, Y.C.; Wang, R.; Wei, Y.; Liang, G.; Xu, S. Synthesis and Characterization of Bioplastics Based on Silyated Starch and Acrylated Epoxidized Soybean Oil. Ind. Crops Prod. 2024, 222, 119670. [Google Scholar] [CrossRef]

- Yang, J.; Xu, S.; Ching, Y.C.; Chuah, C.H.; Wang, R.; Li, C.; Wei, Y.; Liang, G. Effects of Silane Hydrolysis Time on the Physicochemical Properties of Bioplastics Based on Starch and Epoxidized Soybean Oil. Food Chem. 2024, 460, 140601. [Google Scholar] [CrossRef] [PubMed]

- Enwere, C.F.; Okafor, I.S.; Adeleke, A.A.; Petrus, N.; Jakada, K.; Olosho, A.I.; Ikubanni, P.P.; Paramasivam, P.; Ayuba, S. Production of Bioplastic Films from Wild Cocoyam (Caladium bicolor) Starch. Results Eng. 2024, 24, 103132. [Google Scholar] [CrossRef]

- He, X.; Li, M.; Gong, X.; Niu, B.; Li, W. Biodegradable and Antimicrobial CSC Films Containing Cinnamon Essential Oil for Preservation Applications. Food Packag. Shelf Life 2021, 29, 100697. [Google Scholar] [CrossRef]

- Song, X.; Zuo, G.; Chen, F. Effect of Essential Oil and Surfactant on the Physical and Antimicrobial Properties of Corn and Wheat Starch Films. Int. J. Biol. Macromol. 2018, 107, 1302–1309. [Google Scholar] [CrossRef]

- Al-Hashimi, A.G.; Ammar, A.B.; Lakshmanan, G.; Cacciola, F.; Lakhssassi, N. Development of a Millet Starch Edible Film Containing Clove Essential Oil. Foods 2020, 9, 184. [Google Scholar] [CrossRef]

- do Evangelho, J.A.; da Silva Dannenberg, G.; Biduski, B.; el Halal, S.L.M.; Kringel, D.H.; Gularte, M.A.; Fiorentini, A.M.; da Rosa Zavareze, E. Antibacterial Activity, Optical, Mechanical, and Barrier Properties of Corn Starch Films Containing Orange Essential Oil. Carbohydr. Polym. 2019, 222, 114981. [Google Scholar] [CrossRef]

- Jamróz, E.; Juszczak, L.; Kucharek, M. Investigation of the Physical Properties, Antioxidant and Antimicrobial Activity of Ternary Potato Starch-Furcellaran-Gelatin Films Incorporated with Lavender Essential Oil. Int. J. Biol. Macromol. 2018, 114, 1094–1101. [Google Scholar] [CrossRef]

- Akhter, R.; Masoodi, F.A.; Wani, T.A.; Rather, S.A. Functional Characterization of Biopolymer Based Composite Film: Incorporation of Natural Essential Oils and Antimicrobial Agents. Int. J. Biol. Macromol. 2019, 137, 1245–1255. [Google Scholar] [CrossRef]

- Silveira, M.P.; Silva, H.C.; Pimentel, I.C.; Poitevin, C.G.; da Costa Stuart, A.K.; Carpiné, D.; de Matos Jorge, L.M.; Jorge, R.M.M. Development of Active Cassava Starch Cellulose Nanofiber-Based Films Incorporated with Natural Antimicrobial Tea Tree Essential Oil. J. Appl. Polym. Sci. 2020, 137, 48726. [Google Scholar] [CrossRef]

- Bharti, S.K.; Pathak, V.; Alam, T.; Arya, A.; Singh, V.K.; Verma, A.K.; Rajkumar, V. Starch Bio-Based Composite Active Edible Film Functionalized with Carum carvi L. Essential Oil: Antimicrobial, Rheological, Physic-Mechanical and Optical Attributes. J. Food Sci. Technol. 2022, 59, 456–466. [Google Scholar] [CrossRef]

- Anugrahwidya, R.; Armynah, B.; Tahir, D. Bioplastics Starch-Based with Additional Fiber and Nanoparticle: Characteristics and Biodegradation Performance: A Review. J. Polym. Environ. 2021, 29, 3459–3476. [Google Scholar] [CrossRef]

- Iacovone, C.; Yulita, F.; Cerini, D.; Peña, D.; Candal, R.; Goyanes, S.; Pietrasanta, L.I.; Guz, L.; Famá, L. Effect of TiO2 Nanoparticles and Extrusion Process on the Physicochemical Properties of Biodegradable and Active Cassava Starch Nanocomposites. Polymers 2023, 15, 535. [Google Scholar] [CrossRef] [PubMed]

- Santos, J.D.C.; Brites, P.; Martins, C.; Nunes, C.; Coimbra, M.A.; Ferreira, P.; Gonçalves, I. Starch Consolidation of Calcium Carbonate as a Tool to Develop Lightweight Fillers for LDPE-Based Plastics. Int. J. Biol. Macromol. 2023, 226, 1021–1030. [Google Scholar] [CrossRef] [PubMed]

- Oluwasina, O.; Aderibigbe, A.; Ikupoluyi, S.; Oluwasina, O.; Ewetumo, T. Physico-Electrical Properties of Starch-Based Bioplastic Enhanced with Acid-Treated Cellulose and Graphene Oxide Fillers. Sustain. Chem. Environ. 2024, 6, 100093. [Google Scholar] [CrossRef]

- Arezoo, E.; Mohammadreza, E.; Maryam, M.; Abdorreza, M.N. The Synergistic Effects of Cinnamon Essential Oil and Nano TiO2 on Antimicrobial and Functional Properties of Sago Starch Films. Int. J. Biol. Macromol. 2020, 157, 743–751. [Google Scholar] [CrossRef]

- Abdullah, A.H.D.; Putri, O.D.; Fikriyyah, A.K.; Nissa, R.C.; Hidayat, S.; Septiyanto, R.F.; Karina, M.; Satoto, R. Harnessing the Excellent Mechanical, Barrier and Antimicrobial Properties of Zinc Oxide (ZnO) to Improve the Performance of Starch-Based Bioplastic. Polym. Plast. Technol. Mater. 2020, 59, 1259–1267. [Google Scholar] [CrossRef]

- Sapei, L.; Padmawijaya, K.S.; Sijayanti, O.; Wardhana, P.J. Study of the Influence of ZnO Addition on the Properties of Chitosan-Banana Starch Bioplastics. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2017; Volume 223. [Google Scholar]

- de Azêvedo, L.C.; Rovani, S.; Santos, J.J.; Dias, D.B.; Nascimento, S.S.; Oliveira, F.F.; Silva, L.G.A.; Fungaro, D.A. Study of Renewable Silica Powder Influence in the Preparation of Bioplastics from Corn and Potato Starch. J. Polym. Environ. 2021, 29, 707–720. [Google Scholar] [CrossRef]

- Amin, M.R.; Chowdhury, M.A.; Kowser, M.A. Characterization and Performance Analysis of Composite Bioplastics Synthesized Using Titanium Dioxide Nanoparticles with Corn Starch. Heliyon 2019, 5, e02009. [Google Scholar] [CrossRef]

- Dawale, S.A.; Bhagat, M.M.; Scholar, R. Preparation and Characterization of Potato Starch Based Film Blended with CaCO3 Nanoparticles. Int. J. Eng. Sci. Comput. 2018, 8, 16013. [Google Scholar]

- Alves, Z.; Ferreira, N.M.; Ferreira, P.; Nunes, C. Design of Heat Sealable Starch-Chitosan Bioplastics Reinforced with Reduced Graphene Oxide for Active Food Packaging. Carbohydr. Polym. 2022, 291, 119517. [Google Scholar] [CrossRef]

- López, O.V.; Villanueva, M.E.; Copello, G.J.; Villar, M.A. Flexible Thermoplastic Starch Films Functionalized with Copper Particles for Packaging of Food Products. Funct. Compos. Mater. 2020, 1, 6. [Google Scholar] [CrossRef]

- Collazo-Bigliardi, S.; Ortega-Toro, R.; Chiralt, A. Using Grafted Poly(ε-Caprolactone) for the Compatibilization of Thermoplastic Starch-Polylactic Acid Blends. React. Funct. Polym. 2019, 142, 25–35. [Google Scholar] [CrossRef]

- Estrada-Girón, Y.; Fernández-Escamilla, V.V.A.; Martín-del-Campo, A.; González-Nuñez, R.; Canché-Escamilla, G.; Uribe-Calderón, J.; Tepale, N.; Aguilar, J.; Moscoso-Sánchez, F.J. Characterization of Polylactic Acid Biocomposites Filled with Native Starch Granules from Dioscorea Remotiflora Tubers. Polymers 2024, 16, 899. [Google Scholar] [CrossRef]

- Baniasadi, H.; Äkräs, L.; Madani, Z.; Silvenius, F.; Fazeli, M.; Lipponen, S.; Vapaavuori, J.; Seppälä, J. Development and Characterization of Polylactic Acid/Starch Biocomposites—From Melt Blending to Preliminary Life Cycle Assessment. Int. J. Biol. Macromol. 2024, 279, 135173. [Google Scholar] [CrossRef]

- Abdollahi Moghaddam, M.R.; Hesarinejad, M.A.; Javidi, F. Characterization and Optimization of Polylactic Acid and Polybutylene Succinate Blend/Starch/Wheat Straw Biocomposite by Optimal Custom Mixture Design. Polym. Test. 2023, 121, 108000. [Google Scholar] [CrossRef]

- Kurup, G.; Fadzillah, M.F.F.B.M.; Royan, N.R.R.; Radzuan, N.A.M.; Sulong, A.B. Impact of Processing Parameters on the Compatibility and Performance of PLA/Tapioca Starch Biocomposites for Short-Term Food Packaging Applications. Mater. Today Commun. 2025, 43, 111651. [Google Scholar] [CrossRef]

- Oluwasina, O.O.; Adebayo, M.A.; Akinsola, M.O.; Olorunfemi, T.E.; Olajide, J.D. Influence of 2-Hydroxyethyl Terephthalate from Waste Polyethylene Plastic on the Properties of Starch-BHET Bioplastics. Waste Manag. Bull. 2024, 2, 203–213. [Google Scholar] [CrossRef]

- Mohammed, A.A.B.A.; Hasan, Z.; Borhana Omran, A.A.; Elfaghi, A.M.; Ali, Y.H.; Akeel, N.A.A.; Ilyas, R.A.; Sapuan, S.M. Effect of Sugar Palm Fibers on the Properties of Blended Wheat Starch/Polyvinyl Alcohol (PVA)-Based Biocomposite Films. J. Mater. Res. Technol. 2023, 24, 1043–1055. [Google Scholar] [CrossRef]

- Noivoil, N.; Yoksan, R. Oligo (Lactic Acid)-Grafted Starch: A Compatibilizer for Poly (Lactic Acid)/Thermoplastic Starch Blend. Int. J. Biol. Macromol. 2020, 160, 506–517. [Google Scholar] [CrossRef]

- Ortega-Toro, R.; López-Córdoba, A.; Avalos-Belmontes, F. Epoxidised Sesame Oil as a Biobased Coupling Agent and Plasticiser in Polylactic Acid/Thermoplastic Yam Starch Blends. Heliyon 2021, 7, e06176. [Google Scholar] [CrossRef]

- Palai, B.; Biswal, M.; Mohanty, S.; Nayak, S.K. In Situ Reactive Compatibilization of Polylactic Acid (PLA) and Thermoplastic Starch (TPS) Blends; Synthesis and Evaluation of Extrusion Blown Films Thereof. Ind. Crops Prod. 2019, 141, 111748. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on Durability of Sustainable Biobased Composites: A Review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Formela, K.; Zedler; Hejna, A.; Tercjak, A. Reactive Extrusion of Bio-Based Polymer Blends and Composites–Current Trends and Future Developments. Express Polym. Lett. 2018, 12, 24–57. [Google Scholar] [CrossRef]

- Gamage, A.; Thiviya, P.; Mani, S.; Ponnusamy, P.G.; Manamperi, A.; Evon, P.; Merah, O.; Madhujith, T. Environmental Properties and Applications of Biodegradable Starch-Based Nanocomposites. Polymers 2022, 14, 4578. [Google Scholar] [CrossRef]

- Tang, K.H.D.; Zhou, J. Ecotoxicity of Biodegradable Microplastics and Bio-Based Microplastics: A Review of in Vitro and in Vivo Studies. Environ. Manag. 2024, 75, 663–679. [Google Scholar] [CrossRef]

- Martins, P.; Brito-Pereira, R.; Ribeiro, S.; Lanceros-Mendez, S.; Ribeiro, C. Magnetoelectrics for Biomedical Applications: 130 Years Later, Bridging Materials, Energy, and Life. Nano Energy 2024, 126, 109569. [Google Scholar] [CrossRef]

- Khoo, P.S.; Ilyas, R.A.; Uda, M.N.A.; Hassan, S.A.; Nordin, A.H.; Norfarhana, A.S.; Ab Hamid, N.H.; Rani, M.S.A.; Abral, H.; Norrrahim, M.N.F. Starch-Based Polymer Materials as Advanced Adsorbents for Sustainable Water Treatment: Current Status, Challenges, and Future Perspectives. Polymers 2023, 15, 3114. [Google Scholar] [CrossRef]

- Ebrahimzade, I.; Ebrahimi-Nik, M.; Rohani, A.; Tedesco, S. Towards Monitoring Biodegradation of Starch-Based Bioplastic in Anaerobic Condition: Finding a Proper Kinetic Model. Bioresour. Technol. 2022, 347, 126661. [Google Scholar] [CrossRef]

- Dutta, D.; Sit, N. A Comprehensive Review on Types and Properties of Biopolymers as Sustainable Bio-based Alternatives for Packaging. Food Biomacromolecules 2024, 1, 58–87. [Google Scholar] [CrossRef]

- Wang, X.; Tarahomi, M.; Sheibani, R.; Xia, C.; Wang, W. Progresses in Lignin, Cellulose, Starch, Chitosan, Chitin, Alginate, and Gum/Carbon Nanotube (Nano) Composites for Environmental Applications: A Review. Int. J. Biol. Macromol. 2023, 241, 124472. [Google Scholar] [CrossRef]

- El-Beltagi, H.S.; Basit, A.; Mohamed, H.I.; Ali, I.; Ullah, S.; Kamel, E.A.R.; Shalaby, T.A.; Ramadan, K.M.A.; Alkhateeb, A.A.; Ghazzawy, H.S. Mulching as a Sustainable Water and Soil Saving Practice in Agriculture: A Review. Agronomy 2022, 12, 1881. [Google Scholar] [CrossRef]

- Salama, K.; Geyer, M. Plastic Mulch Films in Agriculture: Their Use, Environmental Problems, Recycling and Alternatives. Environments 2023, 10, 179. [Google Scholar] [CrossRef]

- Shelar, A.; Nile, S.H.; Singh, A.V.; Rothenstein, D.; Bill, J.; Xiao, J.; Chaskar, M.; Kai, G.; Patil, R. Recent Advances in Nano-Enabled Seed Treatment Strategies for Sustainable Agriculture: Challenges, Risk Assessment, and Future Perspectives. Nanomicro Lett. 2023, 15, 54. [Google Scholar] [CrossRef]

- Quilez-Molina, A.I.; Chandra Paul, U.; Merino, D.; Athanassiou, A. Composites of Thermoplastic Starch and Lignin-Rich Agricultural Waste for the Packaging of Fatty Foods. ACS Sustain. Chem. Eng. 2022, 10, 15402–15413. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Jerković, I.; Tarbuk, A. Bioplastics in Textiles. Polim. Časopis Plast. Gumu 2013, 34, 9–14. [Google Scholar]

- Drzal, L.T.; Mohanty, A.K.; Misra, M. Bio-Composite Materials as Alternatives to Petroleum-Based Composites for Automotive Applications. Magnesium 2001, 40, 1–3. [Google Scholar]

- Rungruangkitkrai, N.; Phromphen, P.; Chartvivatpornchai, N.; Srisa, A.; Laorenza, Y.; Wongphan, P.; Harnkarnsujarit, N. Water Repellent Coating in Textile, Paper and Bioplastic Polymers: A Comprehensive Review. Polymers 2024, 16, 2790. [Google Scholar] [CrossRef]

- Zhara, H.; Adeel, S.; Özomay, Z.; Mia, R. Properties and Performance Relationship of Biopolymers in Textile Industry. In Biopolymers in the Textile Industry: Opportunities and Limitations; Springer: Berlin/Heidelberg, Germany, 2024; pp. 87–121. [Google Scholar]

- Biehl, P.; Zhang, K. Introduction to Advances in Bio-Based Polymers: Chemical Structures and Functional Properties at the Interface. In Green by Design: Harnessing the Power of Bio-Based Polymers at Interfaces; IOP Publishing: Bristol, UK, 2024; pp. 1–69. [Google Scholar]

- Schutz, G.F.; de Ávila Gonçalves, S.; Alves, R.M.V.; Vieira, R.P. A Review of Starch-Based Biocomposites Reinforced with Plant Fibers. Int. J. Biol. Macromol. 2024, 261, 129916. [Google Scholar] [CrossRef]

- Oh, E.; Godoy Zúniga, M.M.; Nguyen, T.B.; Kim, B.-H.; Trung Tien, T.; Suhr, J. Sustainable Green Composite Materials in the Next-Generation Mobility Industry: Review and Prospective. Adv. Compos. Mater. 2024, 33, 1368–1419. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Akter, S.; Ferdous, J.; Afroz, K.; Refat, K.R.I.; Faruk, O.; Jamal, M.S.I.; Uddin, M.N.; Samad, M.A. Bin Cellulose and Starch-Based Bioplastics: A Review of Advances and Challenges for Sustainability. Polym. Plast. Technol. Mater. 2024, 63, 1329–1349. [Google Scholar]

- Aslam, J.; Parray, H.A. Biomimetic Coatings for Bone Regeneration. Smart Biomimetic Coatings: Design, Properties, and Biomedical Applications; Woodhead Publishing: Sawston, UK, 2024; pp. 147–171. [Google Scholar] [CrossRef]

- Rai, M.; Dos Santos, C.A. Biopolymer-Based Nano Films: Applications in Food Packaging and Wound Healing; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 0128233826. [Google Scholar]

- Megha, M.; Kamaraj, M.; Nithya, T.G.; GokilaLakshmi, S.; Santhosh, P.; Balavaishnavi, B. Biodegradable Polymers Research and Applications. Phys. Sci. Rev. 2024, 9, 949–972. [Google Scholar] [CrossRef]

- Bozó, É.; Ervasti, H.; Halonen, N.; Shokouh, S.H.H.; Tolvanen, J.; Pitkanen, O.; Jarvinen, T.; Palvolgyi, P.S.; Szamosvolgyi, A.; Sápi, A. Bioplastics and Carbon-Based Sustainable Materials, Components, and Devices: Toward Green Electronics. ACS Appl. Mater. Interfaces 2021, 13, 49301–49312. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Zhang, R.; Song, S.; Yang, S.; Yang, A.; Zhang, C.; Song, Y. Nacre-Inspired Starch-Based Bioplastic with Excellent Mechanical Strength and Electromagnetic Interference Shielding. Carbohydr. Polym. 2024, 331, 121888. [Google Scholar] [CrossRef]

- Si, W.; Zhang, S. The Green Manufacturing of Thermoplastic Starch for Low-Carbon and Sustainable Energy Applications: A Review on Its Progress. Green. Chem. 2024, 26, 1194–1222. [Google Scholar] [CrossRef]

- Muñoz-Gimena, P.F.; Oliver-Cuenca, V.; Peponi, L.; López, D. A Review on Reinforcements and Additives in Starch-Based Composites for Food Packaging. Polymers 2023, 15, 2972. [Google Scholar] [CrossRef]

- Lepak-Kuc, S.; Kądziela, A.; Staniszewska, M.; Janczak, D.; Jakubowska, M.; Bednarczyk, E.; Murawski, T.; Piłczyńska, K.; Żołek-Tryznowska, Z. Sustainable, Cytocompatible and Flexible Electronics on Potato Starch-Based Films. Sci. Rep. 2024, 14, 18838. [Google Scholar] [CrossRef]

- Gawande, G.; Khiratkar, T.; Urkude, Y.; Bombarde, S.; Sonwane, U.; Nikhade, S.; Sanap, J. Bioplastic Production from Corn and Potato Starch and Its Industrial Applications; Vishwakarma Institute of Technology: Maharashtra, India, 2024. [Google Scholar]

- Kong, U.; Mohammad Rawi, N.F.; Tay, G.S. The Potential Applications of Reinforced Bioplastics in Various Industries: A Review. Polymers 2023, 15, 2399. [Google Scholar] [CrossRef]

- Vitola, L.; Pundiene, I.; Pranckeviciene, J.; Bajare, D. Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol. Materials 2024, 17, 4911. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.J. Bio-Based Plastics—A Review of Environmental, Social and Economic Impact Assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Mastrolia, C.; Giaquinto, D.; Gatz, C.; Pervez, M.D.; Hasan, S.; Zarra, T.; Li, C.-W.; Belgiorno, V.; Naddeo, V. Plastic Pollution: Are Bioplastics the Right Solution? Water 2022, 14, 3596. [Google Scholar] [CrossRef]

- Lizundia, E.; Luzi, F.; Puglia, D. Organic Waste Valorisation towards Circular and Sustainable Biocomposites. Green. Chem. 2022, 24, 5429–5459. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Hussain, A.A.; Lin, C.; Nguyen, M.K.; Ahsan, W.A.; Hussain, A.; Lin, C.; Nguyen, M.K.; Program, P.D. Biodegradation of Different Types of Bioplastics through Composting—A Recent Trend in Green Recycling. Catalysts 2023, 13, 294. [Google Scholar] [CrossRef]

- Igliński, B. Valorization of Bioplastic Waste: A Review on Effective Recycling Routes for the Most Widely Used Biopolymers. Int. J. Mol. Sci. 2023, 24, 7696. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of Bioplastics in Natural Environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Figueiredo, F.; Nunes, J. Life Cycle Assessment of PLA Products: A Systematic Literature Review. Sustainability 2023, 15, 12470. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- PeerJ. Comprehensive Analysis of Bioplastics: Life Cycle Assessment. Waste Manag. Circ. Econ. 2024, 12, e18013. [Google Scholar]

- Boeve, M.; de Waal, I.M. Global Plastic Pollution and the Transition Towards a Circular Economy: Lessons from the EU’s Legal Framework on Plastics. Environ. Policy Law 2024, 53, 461–472. [Google Scholar] [CrossRef]

- Biopolymers Market Size, Share and Growth Report. 2030. Available online: https://www.grandviewresearch.com/industry-analysis/biopolymers-market-report (accessed on 18 February 2025).

- Pathak, S.; Sneha, C.; Mathew, B.B. Bioplastics: Its Timeline Based Scenario & Challenges. J. Polym. Biopolym. Phys. Chem. 2014, 2, 84–90. [Google Scholar] [CrossRef]

- Negrete-Bolagay, D.; Guerrero, V.H. Opportunities and Challenges in the Application of Bioplastics: Perspectives from Formulation, Processing, and Performance. Polymers 2024, 16, 2561. [Google Scholar] [CrossRef] [PubMed]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Sustainability of Biodegradable Plastics: New Problem or Solution to Solve the Global Plastic Pollution? Curr. Res. Green. Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Barrow, C.J.; Adhikari, B. The Future of Bioplastics in Food Packaging: An Industrial Perspective. Food Packag. Shelf Life 2024, 43, 101279. [Google Scholar] [CrossRef]

- Lenzi, L.; Degli Esposti, M.; Braccini, S.; Siracusa, C.; Quartinello, F.; Guebitz, G.M.; Puppi, D.; Morselli, D.; Fabbri, P. Further Step in the Transition from Conventional Plasticizers to Versatile Bioplasticizers Obtained by the Valorization of Levulinic Acid and Glycerol. ACS Sustain. Chem. Eng. 2023, 11, 9455–9469. [Google Scholar] [CrossRef]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable Polymers and Plastics: Performance beyond the Green. New Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Yang, X.; Deshmukh, R.K.; Gaikwad, K.K.; Bahmid, N.A.; Castro-Muñoz, R. Recent Advances in Reinforced Bioplastics for Food Packaging—A Critical Review. Int. J. Biol. Macromol. 2024, 263, 130399. [Google Scholar] [CrossRef]

- Bin Abu Sofian, A.D.A.; Lim, H.R.; Manickam, S.; Ang, W.L.; Show, P.L. Towards a Sustainable Circular Economy: Algae-Based Bioplastics and the Role of Internet-of-Things and Machine Learning. ChemBioEng Rev. 2024, 11, 39–59. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobeih, M.O.; Sawalha, S.; Hamed, R.; Ali, F.; Kim, M.P. Starch-Derived Bioplastics: Pioneering Sustainable Solutions for Industrial Use. Materials 2025, 18, 1762. https://doi.org/10.3390/ma18081762

Sobeih MO, Sawalha S, Hamed R, Ali F, Kim MP. Starch-Derived Bioplastics: Pioneering Sustainable Solutions for Industrial Use. Materials. 2025; 18(8):1762. https://doi.org/10.3390/ma18081762

Chicago/Turabian StyleSobeih, Mahmoud Omar, Shadi Sawalha, Rinad Hamed, Fathilah Ali, and Minsoo P. Kim. 2025. "Starch-Derived Bioplastics: Pioneering Sustainable Solutions for Industrial Use" Materials 18, no. 8: 1762. https://doi.org/10.3390/ma18081762

APA StyleSobeih, M. O., Sawalha, S., Hamed, R., Ali, F., & Kim, M. P. (2025). Starch-Derived Bioplastics: Pioneering Sustainable Solutions for Industrial Use. Materials, 18(8), 1762. https://doi.org/10.3390/ma18081762