Multiscale Analysis of Defect Structures in Single-Crystalline CMSX-4 Superalloys

Abstract

1. Introduction

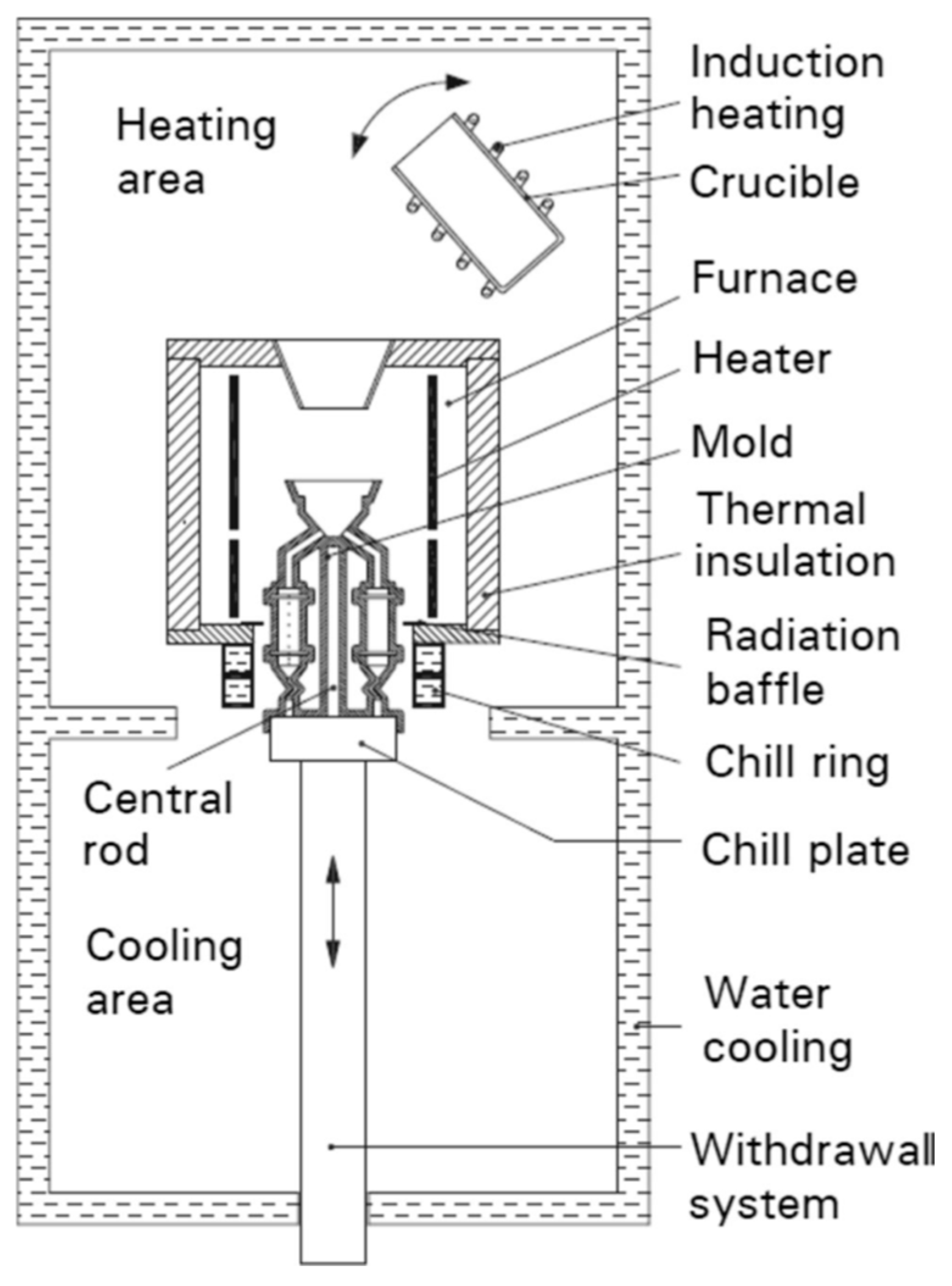

2. Materials and Methods

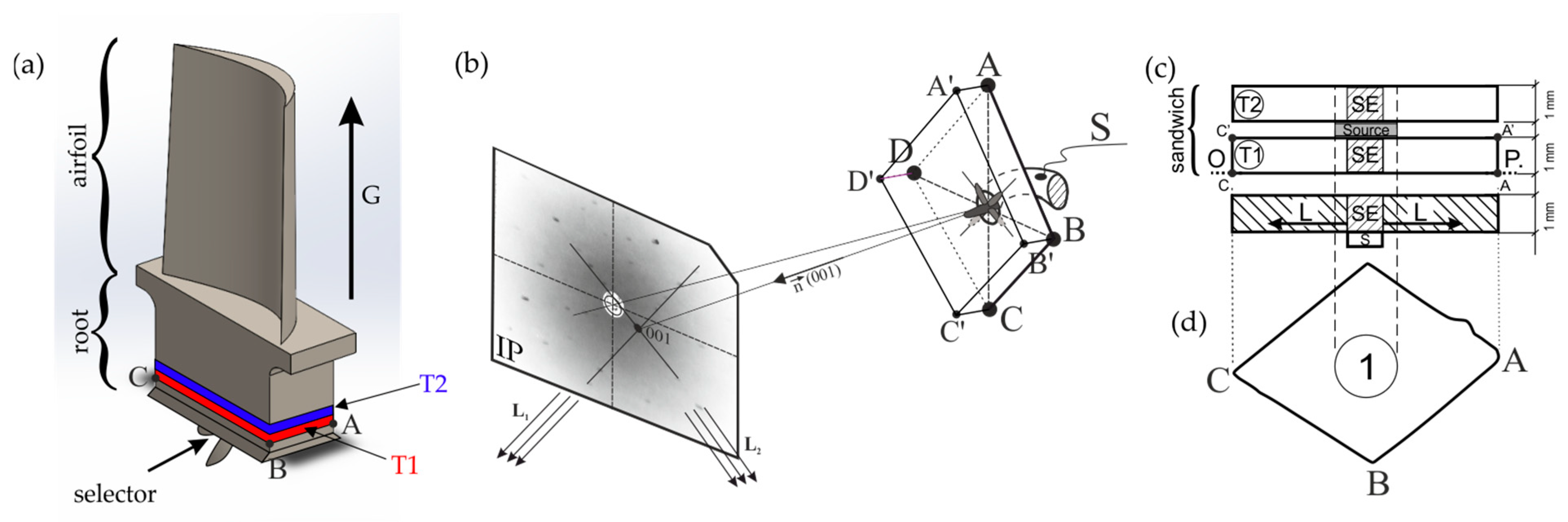

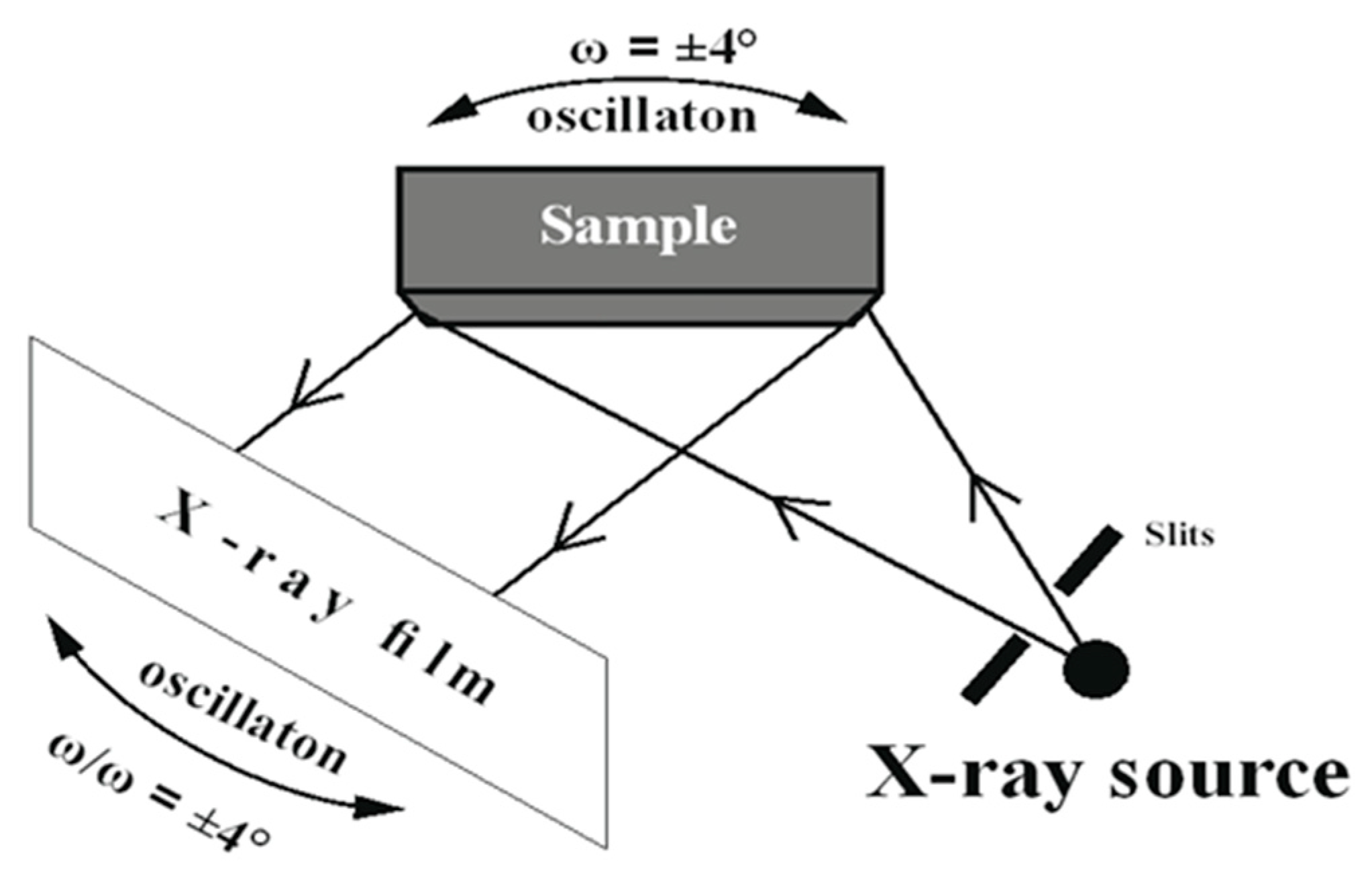

2.1. X-Ray Diffraction Topography

2.2. Positron Annihilation Lifetime Spectroscopy

2.3. Transmission Electron Microscopy

3. Results

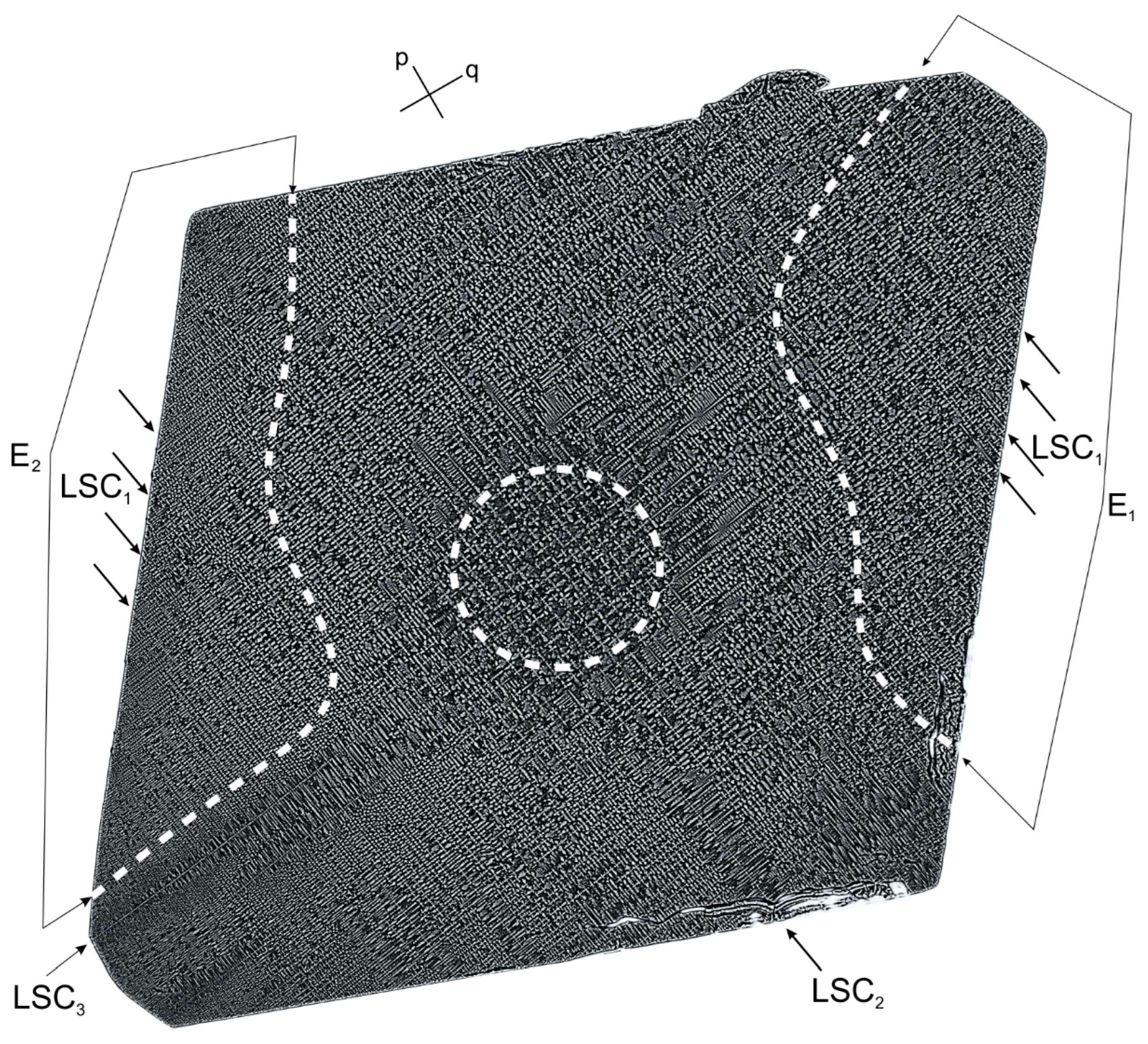

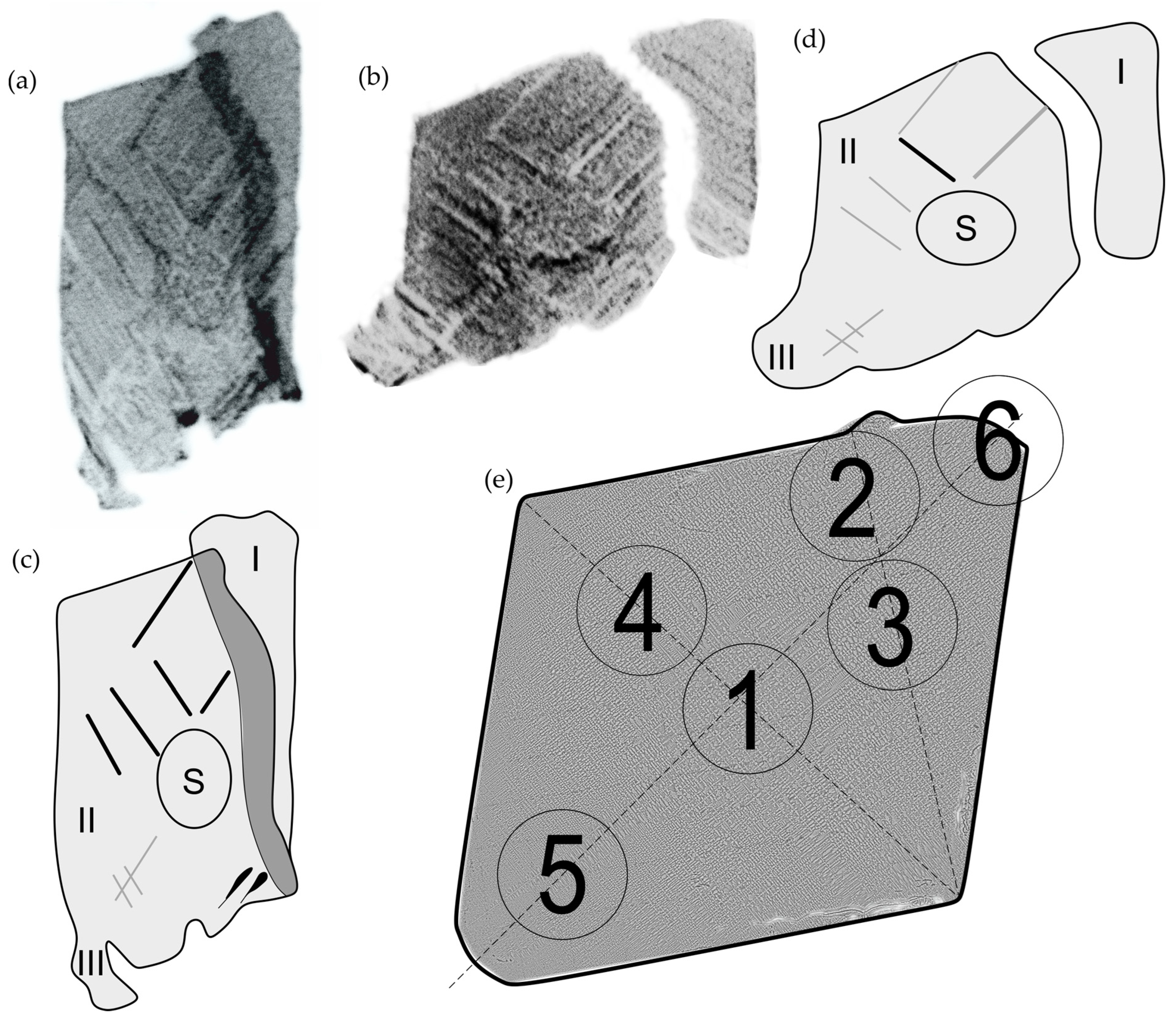

3.1. X-Ray Diffraction Topography

3.2. Positron Annihilation Lifetime Spectroscopy

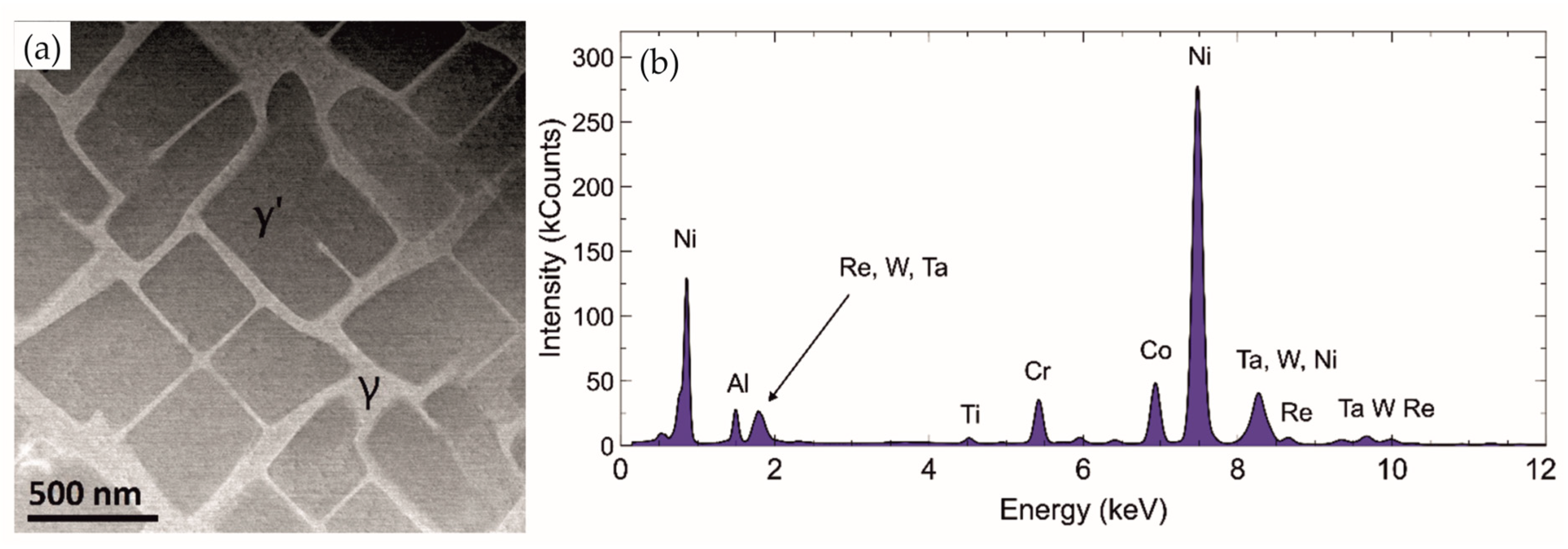

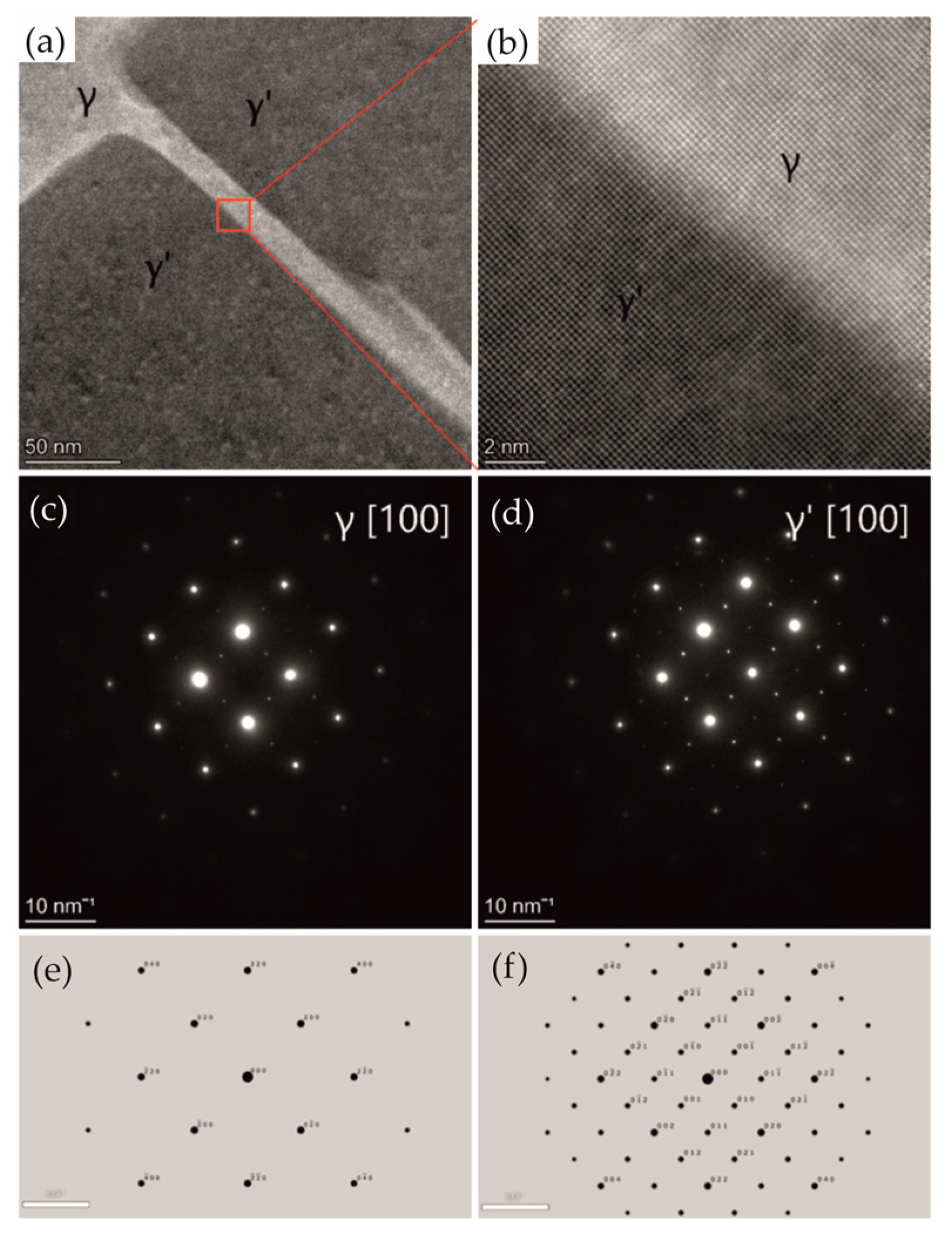

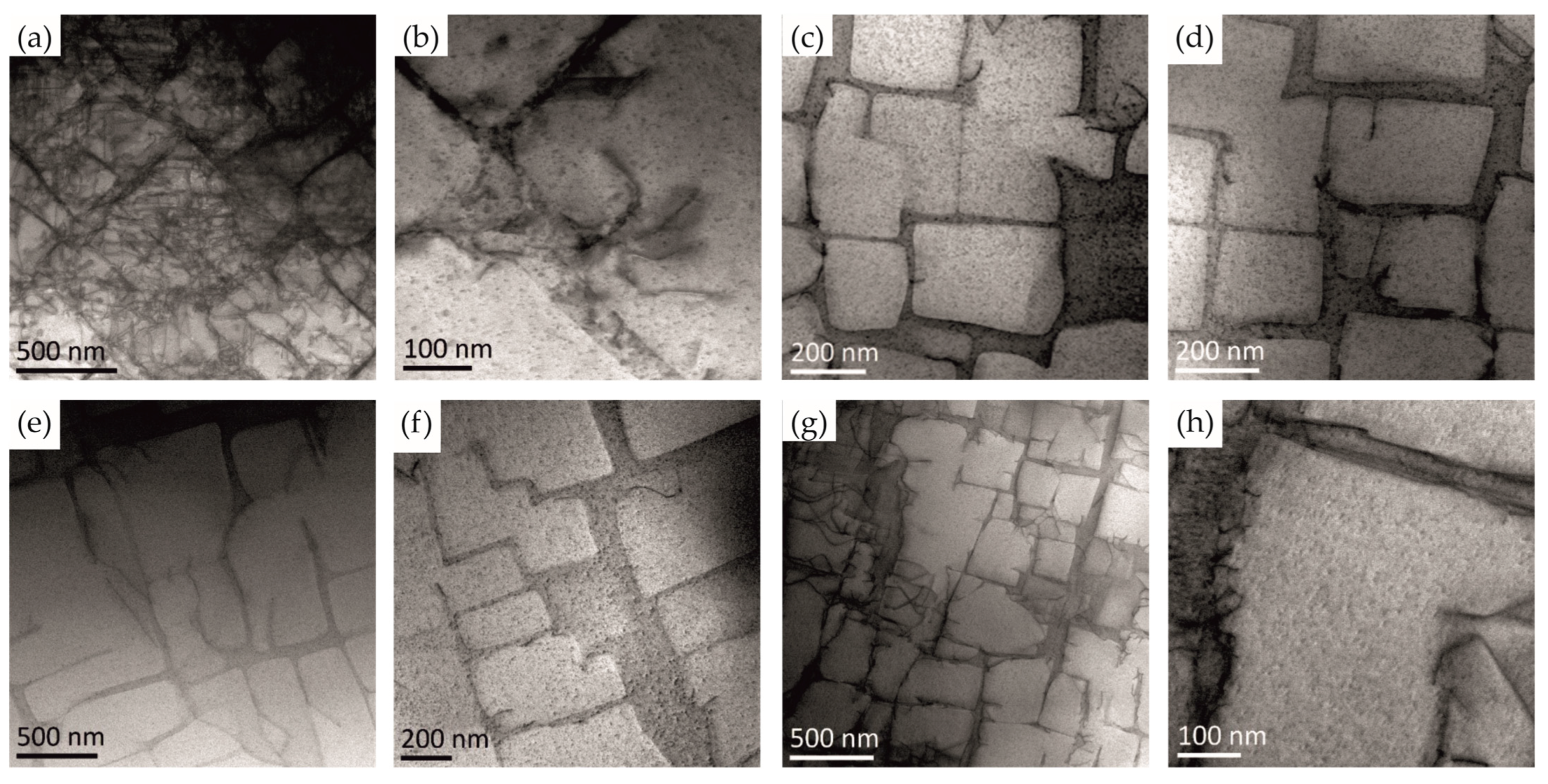

3.3. Transmission Electron Microscopy

4. Conclusions

- The lateral growth of dendrites starts from the selector extension area and proceeds along main paths, forming extended straight chains.

- X-ray topography studies on thin samples allowed the observation of contrast inversions and areas where internal stresses occur.

- The registered positron lifetimes ascribed to defects in the alloy under investigation, ranging from 522 ± 9 ps to 668 ± 23 ps, are outstandingly higher than those of typical defects found in metals and their alloys reported in the literature. These long lifetimes were ascribed to cationic vacancy clusters, which probably occur at the dendrite-matrix connection originating from the shrinking of liquid metal enclosed in inter-dendritic regions during solidification.

- Shorter lifetimes were registered in regions where low-angle grain boundaries were identified according to microscopic results and in the area where the selector, from which the crystal growth begins, was positioned. Thus, the lifetime will be affected by short-living components related to dislocations, which are structurally connected with low-angle grain boundaries, as well as at mono-vacancies and small vacancy complexes related to primary stages of crystal growth.

- Larger secondary dendrite arms facilitate void formation, extending the positron lifetime. Additionally, depending on the orientation of the dendrites, voids of varying sizes can be formed. The experimental results align with the theoretical model developed by Kundin et al. [47], which considers the critical role of crystallographic orientation in vacancy flow and its influence on the shape and distribution of voids in interdendritic regions. This model assumes that phenomena related to vacancy flow are strongly dependent on the dendritic structure, a conclusion that has been validated in the present study.

- It was found that lowering the withdrawal rate from 5 mm/min to 1 mm/min results in a reduction of positron lifetimes from 1.5 ns to ca. 0.5–0.7 ns, respectively. This is probably the result of shorter void defects in the slowlier withdrawn single crystal. However, unequivocal description of this phenomenon requires additional experimentation involving alternative analytical techniques such as impedance spectroscopy.

- TEM investigations complained with EDS analysis reviled [100] oriented γ and γ′ phases with well dispersed alloying components with low values of oxidation states. The bright field HAADF images revealed the presence of 2–5 nm structural defects in the investigated material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Ni | Co | Cr | Ta | W | Al | Re | Ti | Mo | Hf |

|---|---|---|---|---|---|---|---|---|---|

| 60.7 | 9.6 | 6.5 | 6.5 | 6.4 | 5.6 | 3.0 | 1.0 | 0.6 | 0.1 |

| Property | Unit | Value |

|---|---|---|

| Density | Kg/m3 | 8700 |

| Elastic modulus | GPa | 250 |

| Thermal conductivity | W/m·K | 11 |

| Melting temperature | °C | 1350–1420 |

| Coefficient of thermal expansion | μm/mK | 13 |

| 0.2% proof yield strength at 760 °C | MPa | 980 |

| Ultimate tensile strength | MPa | 1250 |

| Elongation | % | 10 |

| Reduction of area | % | 20 |

References

- Reed, R. The Superalloys, Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys—A Technical Guide, 2nd ed.; ASM International: Geauga, OH, USA, 2002. [Google Scholar]

- Konter, M.; Thumann, M. Materials and manufacturing of advanced industrial gas turbine components. J. Mater. Process. Technol. 2001, 117, 386–390. [Google Scholar] [CrossRef]

- Newell, M.; Devendra, K.; Jennings, P.A.; D’Souza, N. Role of dendrite branching and growth kinetics in the formation of low angle boundaries in Ni–base superalloys. Mater. Sci. Eng. A 2005, 412, 307–315. [Google Scholar] [CrossRef]

- Bogdanowicz, W.; Krawczyk, J.; Paszkowski, R.; Sieniawski, J. Variation of crystal orientation and dendrite array generated in the root of SX turbine blades. Materials 2019, 12, 4126. [Google Scholar] [CrossRef]

- Körner, C.; Ramsperger, M.; Meid, C.; Bürger, D.; Wollgramm, P.; Bartsch, M.; Eggeler, G. Microstructure and Mechanical Properties of CMSX-4 Single Crystals Prepared by Additive Manufacturing. Metall. Mater. Trans. A 2018, 49, 3781–3792. [Google Scholar] [CrossRef]

- D’Souza, N.; Kelleher, J.; Qiu, C.; Zhang, S.Y.; Gardner, S.; Jones, R.E.; Putman, D.; Panwisawas, C. The role of stress relaxation and creep during high temperature deformation in Ni-base single crystal superalloys—Implications to strain build-up during directional solidification. Acta Mater. 2016, 106, 322–332. [Google Scholar] [CrossRef]

- Krawczyk, J.; Paszkowski, R.; Bogdanowicz, W.; Hanc-Kuczkowska, A.; Sieniawski, J.; Terlecki, B. Defect creation in the root of single-crystalline turbine blades made of Ni-based superalloy. Materials 2019, 12, 870. [Google Scholar] [CrossRef]

- Krawczyk, J.; Bogdanowicz, W.; Hanc-Kuczkowska, A.; Tondos, A.; Sieniawski, J. Influence of heat treatment on defect structures in single-crystalline blade roots studied by X-ray topography and positron annihilation lifetime spectroscopy. Metall. Mater. Trans. A 2018, 49, 4353–4361. [Google Scholar] [CrossRef]

- Sims, C.T. Prediction of chase composition. In Superalloys II; Sims, C.T., Stalloff, N., Hagel, W.C., Eds.; John Wiley & Sons: New York, NY, USA, 1987; pp. 217–240. [Google Scholar]

- Caron, P.; Tasadduq, K. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp. Sci. Technol. 1999, 3, 513–523. [Google Scholar] [CrossRef]

- Schenk, T.; Trehorel, R.; Dirand, L.; Jacques, A. Dislocation Densities and Velocities within the γ Channels of an SX Superalloy during In Situ High-Temperature Creep Tests. Materials 2018, 11, 1527. [Google Scholar] [CrossRef]

- Paszkowski, R.; Krawczyk, J.; Bogdanowicz, W.; Szeliga, D.; Sieniawski, J. Heterogeneity of the Dendrite Array Created in the Root of Cored SX Turbine Blades during Initial Stage of Crystallization. Materials 2021, 14, 80. [Google Scholar] [CrossRef] [PubMed]

- Hautojärvi, P.; Dupasquier, A.; Manninen, M. Positrons in Solids; Springer: Berlin/Heidelberg, Germany, 1979. [Google Scholar]

- Eldrup, M. Positron Methods for the Study of Defects in Bulk Materials. J. Phys. IV 1995, 5, 93–109. [Google Scholar] [CrossRef][Green Version]

- Giebel, D.; Kansy, J. A New Version of LT Program for Positron Lifetime Spectra Analysis. Prog. Positron Annihil. 2011, 666, 138–141. [Google Scholar] [CrossRef]

- Kansy, J.; Giebel, D. Study of defect structure with new software for numerical analysis of PAL spectra. J. Phys. Conf. Ser. 2011, 265, 012030. [Google Scholar] [CrossRef]

- Wang, T.M.; Shimotomai, M.; Doyama, M. Study of vacancies in the intermetallic compound Ni3Al by positron annihilation. J. Phys. F Met. Phys. 1984, 14, 37–45. [Google Scholar] [CrossRef]

- Perminov, D.A.; Druzhkov, A.P.; Arbuzov, V.L. Positron-annihilation studies of the influence of nanodimensional intermetallic precipitates on the evolution of radiation defects in the Fe–Ni–Al alloy. Phys. Met. Metallogr. 2015, 116, 1151–1158. [Google Scholar] [CrossRef]

- Melikhova, O.; Kuriplach, J.; Prochazka, I.; Cizek, J.; Hou, M.; Zhurkin, E.; Pisov, S. Simulation of positron annihilation response to mechanical deformation of nanostructured Ni3Al. Appl. Surf. Sci. 2008, 255, 157–159. [Google Scholar] [CrossRef]

- Picassoa, A.; Somoza, A.; Tolley, A. Nucleation, growth and coarsening of γ0 -precipitates in a Ni–Cr–Al-based commercial superalloy during artificial aging. J. Alloy Compd. 2009, 479, 129–133. [Google Scholar] [CrossRef]

- Macchi, C.E.; Somoza, A.; Santos, G.; Petkov, M.; Lynn, K.G. On the precipitation sequence in a Ni-based superalloy: A Coincidence Doppler Broadening study. Phys. Stat. Sol. (C) 2007, 4, 3542–3545. [Google Scholar] [CrossRef]

- Anton, D.; Giamei, A. Porosity distribution and growth during homogenization in single crystals of a nickel-base superalloy. Mater. Sci. Eng. 1985, 76, 173–180. [Google Scholar] [CrossRef]

- Gancarczyk, K.; Albrecht, R.; Kawalec, M.; Koscielniak, B.; Gradzik, A.; Szeliga, D.; Kawalec, A.; Ziaja, W.; Motyka, M. The Effect of Re Content on Microstructure and Creep Resistance of Single Crystal Castings Made of Nickel-Based Superalloys. Adv. Sci. Technol.-Res. J. 2024, 18, 291–305. [Google Scholar] [CrossRef]

- Gancarczyk, K.; Albrecht, R.; Sulkowicz, P.; Szala, M.; Walczak, M. Evaluation of the Influence of Primary and Secondary Crystal Orientations and Selected Structural Characteristics on Creep Resistance in Single-Crystal Nickel-Based Turbine Blades. Materials 2025, 18, 919. [Google Scholar] [CrossRef] [PubMed]

- Onyszko, A.; Bogdanowicz, W.; Kubiak, K.; Sieniawski, J. X-ray topography and crystal orientation study of a nickel-based CMSX-4 superalloy single crystal. Cryst. Res. Technol. 2010, 12, 1326–1332. [Google Scholar] [CrossRef]

- Szeliga, D. Effect of Processing Parameters and Shape of Blade on the Solidification of Single-Crystal CMSX-4 Ni-Based Superalloy. Metall. Mater. Trans. B 2018, 49, 2550–2570. [Google Scholar] [CrossRef]

- Paszkowski, R.; Bogdanowicz, W.; Szeliga, D. The Low-Angle Boundaries Misorientation and Lattice Parameter Changes in the Root of Single-Crystalline CMSX-4 Superalloy Blades. Materials 2021, 14, 5194. [Google Scholar] [CrossRef]

- Harris, K.; Erickson, G.; Sikkenga, S.; Brentnall, W.; Aurrecoechea, J.; Kubarych, K. Development of the Rhenium Containing Superalloy CMSX-4 for Single Crystal Blade Applications in Advanced Turbine Engines. In Proceedings of the 7th International Symposium on Superalloys, Champion, PA, USA, 20–24 September 1992; pp. 20–24. [Google Scholar]

- Dryzek, J.; Singleton, D. Implantation profile and linear absorption coefficients for positrons injected in solids from radioactive sources Na-22 and Ge-68\Ga-68. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. At. 2006, 252, 197–204. [Google Scholar] [CrossRef]

- Krsjak, V.; Kuriplach, J.; Vieh, C.; Peng, L.; Dai, Y. On the empirical determination of positron trapping coefficient at nano-scale helium bubbles in steels irradiated in spallation target. J. Nucl. Mater. 2018, 504, 277–280. [Google Scholar] [CrossRef]

- Epishin, A.I.; Link, T.; Noltze, G.; Svetlov, I.L.; Bokshtein, B.S.; Rodin, A.O.; Salivan-Neumann, R.; Oder, G. Diffusion processes in multicomponent nickel-base superalloy-nickel system. Phys. Met. Metallogr. 2014, 115, 21–29. [Google Scholar] [CrossRef]

- Dryzek, E.; Romanowska, J.; Skowron, K. Positron Annihilation Studies of Modified Aluminide Coatings on Nickel and Nickel Superalloy. Russ. J. Non-Ferr. Met. 2020, 61, 608–614. [Google Scholar] [CrossRef]

- Djourelov, N.; Misheva, M. Source correction in positron annihilation lifetime spectroscopy. J. Phys.-Condens. Matter 1996, 8, 2081–2087. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K.; Zaleski, R.; Gorgol, M. Analysis of Surface Properties of Nickel Alloy Elements Exposed to Impulse Shot Peening with the Use of Positron Annihilation. Materials 2021, 14, 17. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Klobes, B.; Banhart, J. Positron lifetime study of the formation of vacancy clusters and dislocations in quenched Al, Al-Mg and Al-Si alloys. J. Mater. Sci. 2016, 51, 7754–7767. [Google Scholar] [CrossRef]

- Nieminen, R.M.; Laakkonen, J.; Hautojarvi, P.; Vehanen, A. Temperature-dependence of positron trapping at voids in metals. Phys. Rev. B 1997, 19, 1397–1402. [Google Scholar] [CrossRef]

- Eldrup, M.; Singh, B.N. Studies of defects and defect agglomerates by positron annihilation spectroscopy. J. Nucl. Mater. 1997, 251, 132–138. [Google Scholar] [CrossRef]

- Ohkubo, H.; Tang, Z.; Nagai, Y.; Hasegawa, M.; Tawara, T.; Kiritani, M. Positron annihilation study of vacancy-type defects in high-speed deformed Ni, Cu and Fe. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2003, 350, 95–101. [Google Scholar] [CrossRef]

- Cotterill, R.M.; Traff, J.; Trumpy, G.; Smedskjaer, L.; Mackenzie, I.K. Correlation of void size and positron-annihilation characteristics in neutron-irradiated molybdenum. Nature 1972, 239, 99. [Google Scholar] [CrossRef]

- Zaleski, R.; Gorgol, M.; Zaleski, K. Positron annihilation lifetime study of steel surface modification by shot peening. Positron Stud. Defects 2011, 35, 92–97. [Google Scholar] [CrossRef][Green Version]

- Madison, J.; Spowart, J.; Rowenhorst, D.; Pollock, T. The three-dimensional reconstruction of the dendritic structure at the solid-liquid interface of a Ni-based single crystal. JOM 2008, 60, 26–30. [Google Scholar] [CrossRef]

- Dreshfield, R.L. Defects in nickel-base superalloys. J. Met. 1987, 39, 16–21. [Google Scholar] [CrossRef]

- Liu, D.; Chen, X.; Wu, Y.; Wang, X.; Shang, C.; Zhang, L.; Zhao, C.; Zhang, H.; Shang, J.; Zhai, X. Microstructure regulation of WxV1-xO2(B) nanorods with improved electrochemical properties. J. Solid State Chem. 2025, 341, 125074. [Google Scholar] [CrossRef]

- Krbata, M.; Fabo, P.; Kohutiar, M.; Escherova, J.; Kuba, M.; Kianicova, M.; Eckert, M. Possibilities of Using Impedance Spectroscopy for Indirect Measurements of Thin Layers of Al & Cr-Al Coatings on Ni-based Superalloy Inconel 713LC Applied by the “Out-of-pack” Diffusion Method. Manuf. Technol. 2023, 23, 313–318. [Google Scholar]

- Kundin, J.; Riyahi khorasgani, A.; Schiedung, R.; Camin, B.; Steinbach, I. Modeling vacancy-induced porosity in compositionally-graded complex alloys. Acta Mater. 2024, 271, 119905. [Google Scholar] [CrossRef]

- Chyrkin, A.; Epishin, A.; Pillai, R.; Link, T.; Nolze, G.; Quadakkers, W. Modeling Interdiffusion Processes in CMSX-10/Ni Diffusion Couple. J. Phase Equilibria Diffus. 2016, 37, 201–211. [Google Scholar] [CrossRef]

- Riyahi khorasgani, A.; Steinbach, I.; Camin, B.; Kundin, J. A phase-field study to explore the nature of the morphological instability of Kirkendall voids in complex alloys. Sci. Rep. 2024, 14, 30489. [Google Scholar] [CrossRef]

- Sethurao, G.; Akula, R.; Srinivasa, R.N.; Kundan, K.S. Parametric evaluation of chip formation in peripheral milling of single crystal Ni based superalloy. Int. J. Adv. Manuf. Technol. 2024, 132, 2293–2313. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paszkowski, R.; Kołodziej, S.; Pawlyta, M.; Chrząszcz, B. Multiscale Analysis of Defect Structures in Single-Crystalline CMSX-4 Superalloys. Materials 2025, 18, 1819. https://doi.org/10.3390/ma18081819

Paszkowski R, Kołodziej S, Pawlyta M, Chrząszcz B. Multiscale Analysis of Defect Structures in Single-Crystalline CMSX-4 Superalloys. Materials. 2025; 18(8):1819. https://doi.org/10.3390/ma18081819

Chicago/Turabian StylePaszkowski, Robert, Sławomir Kołodziej, Mirosława Pawlyta, and Beata Chrząszcz. 2025. "Multiscale Analysis of Defect Structures in Single-Crystalline CMSX-4 Superalloys" Materials 18, no. 8: 1819. https://doi.org/10.3390/ma18081819

APA StylePaszkowski, R., Kołodziej, S., Pawlyta, M., & Chrząszcz, B. (2025). Multiscale Analysis of Defect Structures in Single-Crystalline CMSX-4 Superalloys. Materials, 18(8), 1819. https://doi.org/10.3390/ma18081819