Recent Advances in Carbon-Based Sensors for Food and Medical Packaging Under Transit: A Focus on Humidity, Temperature, Mechanical, and Multifunctional Sensing Technologies—A Systematic Review

Abstract

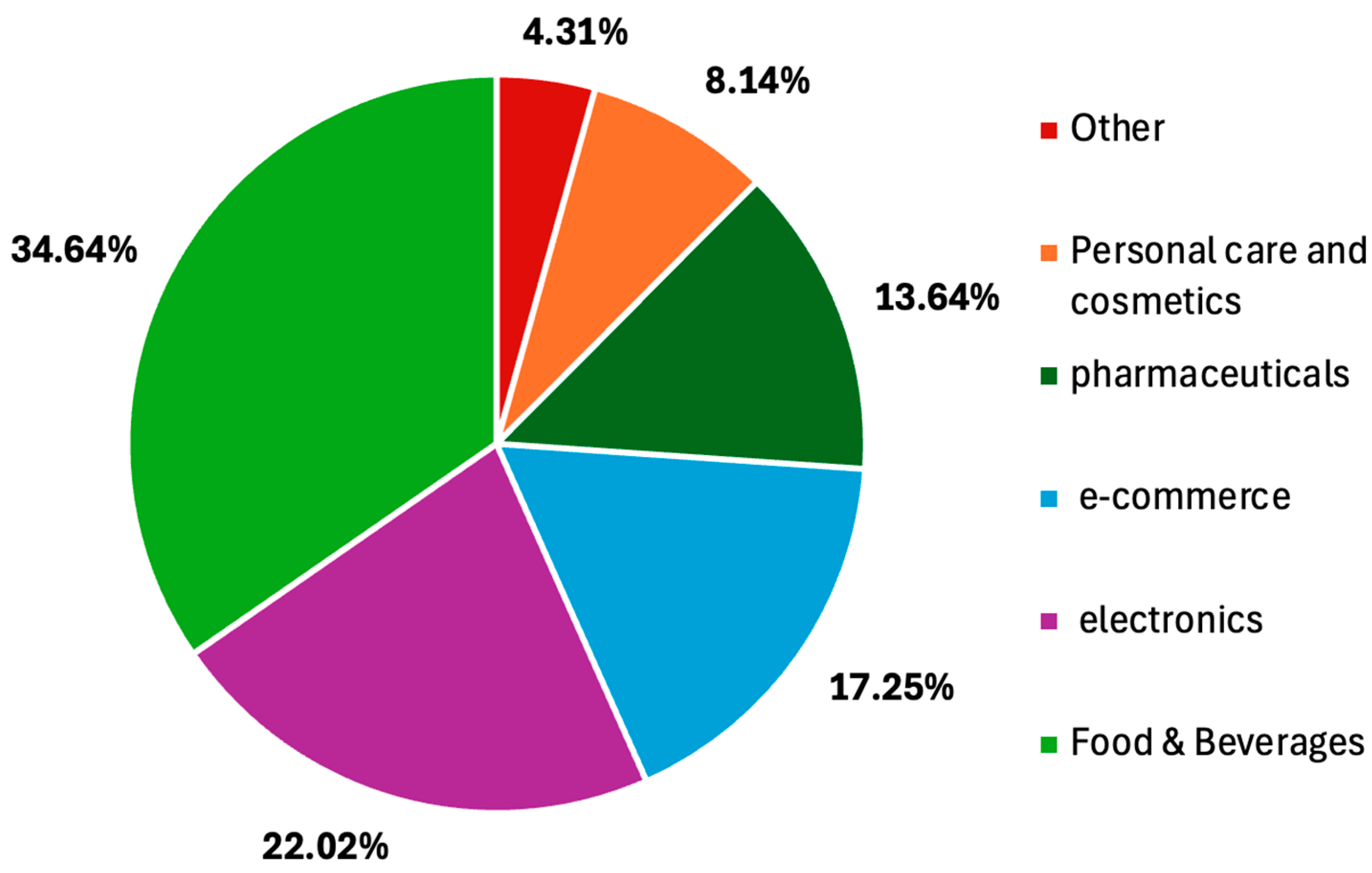

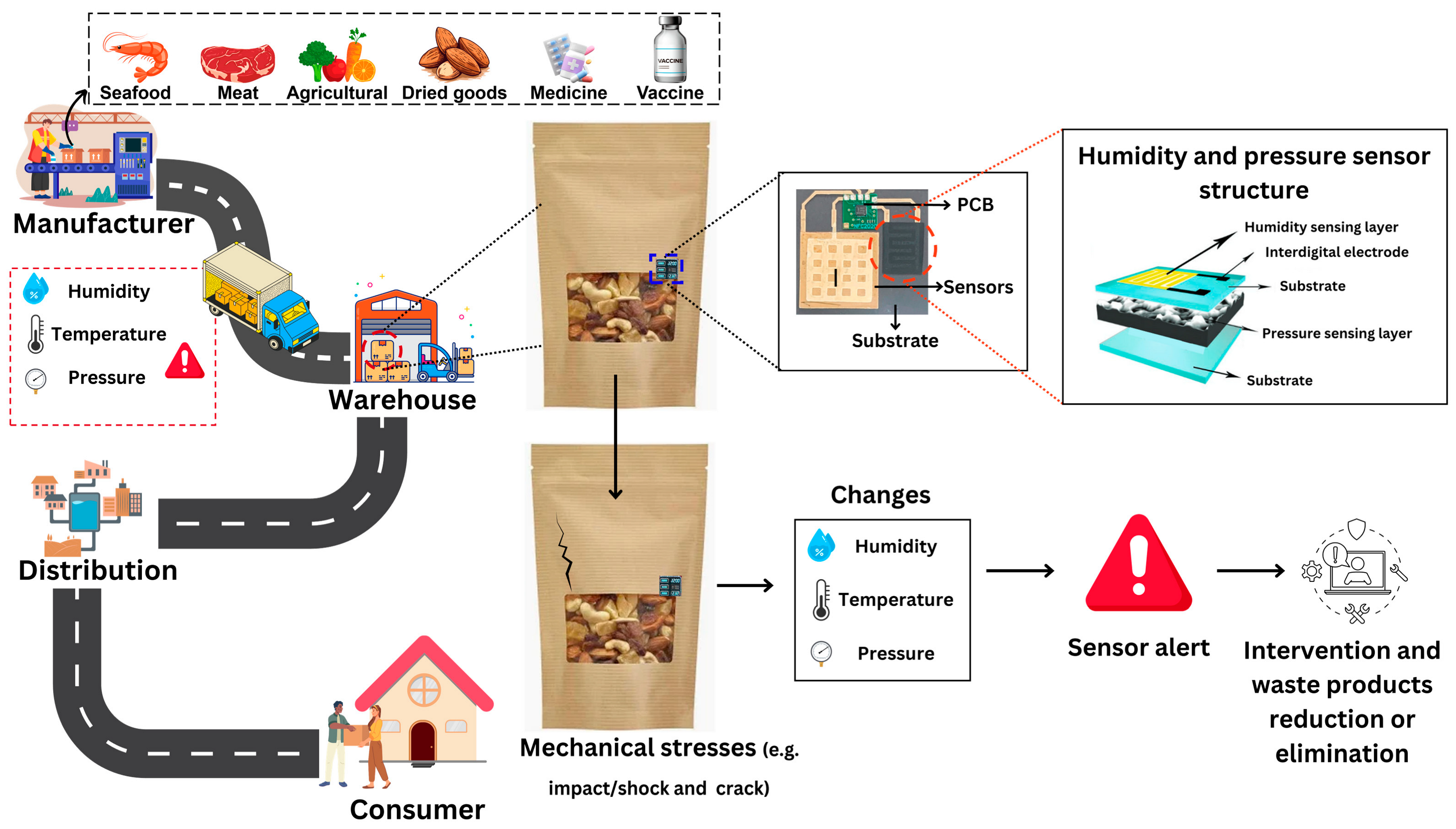

:1. Introduction

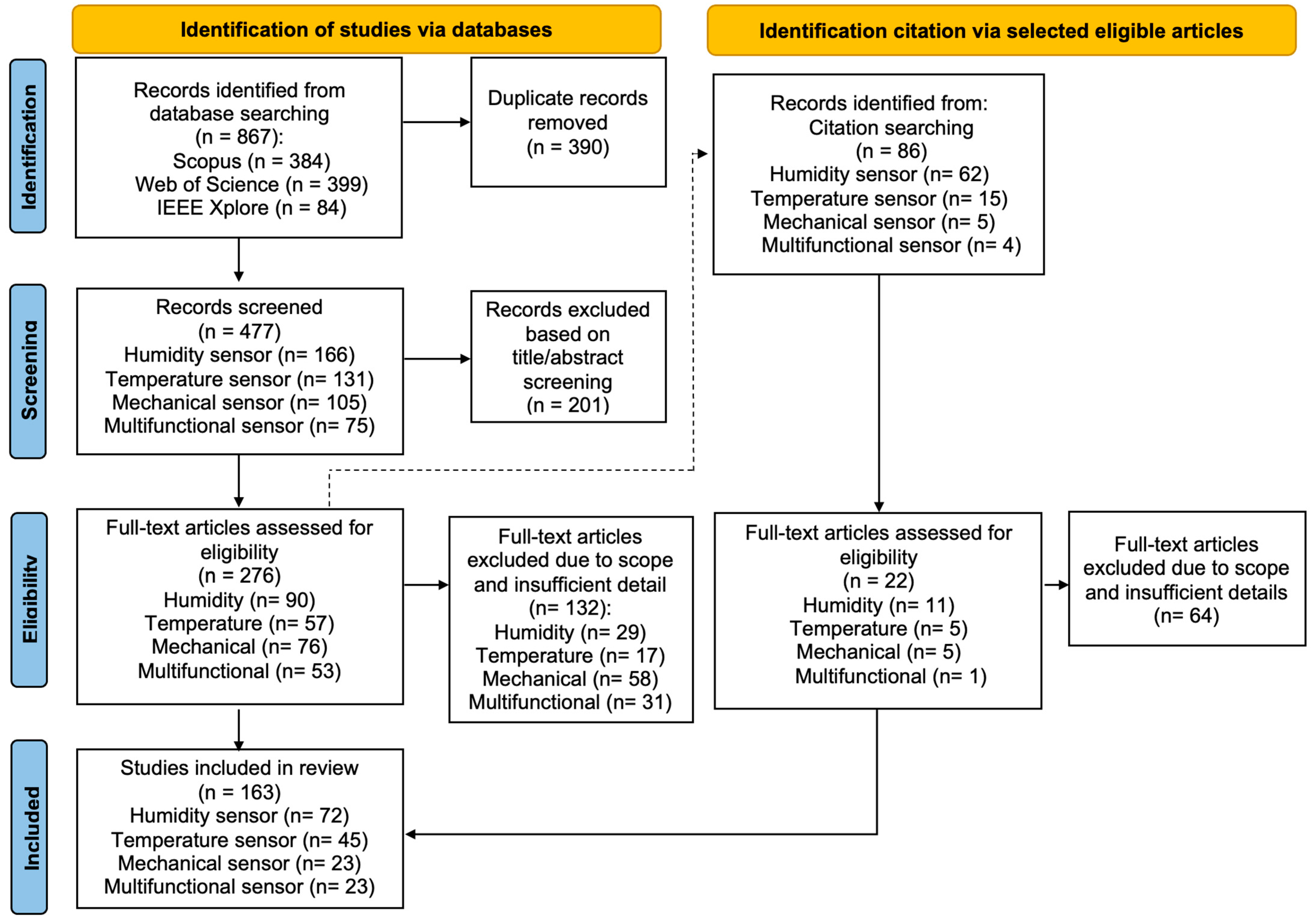

2. Materials and Methods

2.1. Database Selection and Search Strategy

2.2. Screening

2.3. Data Extraction

3. Results

3.1. Humidity Sensors

| Material | Fabrication Technique | Type | Sensing Range (%RH) | Sensitivity | Response/ Recovery Time (s) | Stability (Days) | Linearity | Remarks/Comments | Ref |

|---|---|---|---|---|---|---|---|---|---|

| Li-doped GO | Drop casting | Resistive | 11–97 | 17.13–3038.16% | 4/25 | Not reported (N) | Yes | Hysteresis is 0.83% and thermal stability is 850 °C. | [45] |

| GO functionalized with hydroxyl groups | 6–95 | ~38.5 | 8.5/13 | 390 | Yes | Hysteresis is 0.63%. High selectivity to humidity. Power consumption is 15 µW. | [46] | ||

| Oxidized CNH/GO/SnO2/PVP nanocomposite film | 0–100 | 0.9021 Ω/% RH | 42/164 | N | Yes | CNHox/GO/SnO2/PVP mass ratio is 1/1/1/1. Power consumption is <2 mW. | [47] | ||

| GO-oxidized CNH-PVP | 0–100 | 0.15–0.2 | 40–90/62–73 | N | Yes | Optimal GO:CNH:PVP is 1:1:1. Power consumption is <2 mW. | [48] | ||

| Ultra-thin, single-layer GO film | 10%–95 | 120.57%/%RH | 0.49/0.65 | 60 | No | Optimal sensor has 300 nm GO with 20 μm electrodes spacing. | [49] | ||

| Oxidized single-walled carbon nanohorns (SWCNHs) | 10–90 | ~2.1 × 107 Ω/RH (air) | 3/N (air) | N | Yes | Surface area is 1300–1400 m2/g. | [115] | ||

| ~9.1 × 106 Ω/RH (N2) | 8/N (N2) | ||||||||

| GO/PVA composite | Resistive Frequency | 20–80 | −12,000 Ω/%RH | N | N | N | It achieves ~1.8% RH resolution. | [50] | |

| 0.0001 kHz/%RH | |||||||||

| rGO/PVDF composite | Solution casting | Resistive | 11–97 | 98.99% | 21/26 | 90 | Yes | Optimal is 30 vol% rGO/PVDF. Hysteresis is 5.5% and decomposition from 434° C. | [95] |

| Endohedral lithium-doped SWCNT/sodium dodecylbenzenesulfonate (Li@SWCNT/SDBS) | Arc discharge and drop casting | 11–97 | 4%/%RH | N | N | No | Optimal sensor is five-layer thin film (~5 µm thickness). Hysteresis is 4.3%. | [104] | |

| GQDs/Ag nanoparticles (AgNPs) | Hydrothermal and drop casting | 25–95 | 98.14% | 15/15 | N | No | Optimal GQDs/AgNPs is 1:1. | [109] | |

| GO film | Drop casting | Capacitive | 15–95 | 37,800% | 10.5/41 | 30 | Yes | Hysteresis is ~5%. | [51] |

| GO/Ag composite | 11–97 | 25,809 pF/%RH | ~8/~12 | 30 | N | Optimal Ag content is 2 wt%. Good selectivity for H2O vapor. | [52] | ||

| GO | 0–97 | 1800 pF/% RH | 16/9 | N | Yes | Spiral LIG as electrodes. Optimal GO thickness is 50 nm. 3.03% hysteresis. | [53] | ||

| GO | 10–90 | 3862 pF/%RH | 58/15 | 42 | N | Hysteresis is 1.2%. Optimal sensor used 60 µL GO and 150 µm gap size for LIG interdigitated electrodes (IDE). | [54] | ||

| GO/MoTe2 composite nanosheets | 11.3–97.3 | 94.12 pF/%RH | 39/12 | 35 | N | Optimal GO to MoTe2 ratio is 1:2. High humidity selectivity. | [55] | ||

| ZnO/PVP-rGO nanocomposite | 15–95 | ~0.022 | ~12/~3 | 87 | Yes | [96] | |||

| GO-Mn-doped ZnO nanocomposite | Capacitive | 10–90 | N | 4.5/21 | 30 | Yes | 95.7 times higher sensitivity in capacitance and 97 times in resistance compared to conventional GO. | [56] | |

| Resistive | |||||||||

| GO-doped P(VDF-TrFE)/LiCl composite | Capacitive change | 25–95 | 1708.8 pF/%RH | 7.8/4.5 | N | Yes | Pores from 300 nm to 1.1 µm. Reduced hysteresis due to GO and LiCl modification. | [57] | |

| GO | Resonant frequency | 10–90 | 0.719 kHz/%RH | <78/54 | 30 | No | Resolution (0.4% RH), hysteresis (<4%), and minimal response to CO2. | [58] | |

| HGO/GO/Mg2+ composite membrane | 11–97 | 0.0343 kHz/%RH | 7/6 | 10 | Yes | Hysteresis is ~3.2% RH. High humidity selectivity. | [59] | ||

| GO | Voltage | 33–98 | 1.1–10.0 mV/%RH | 0.28/0.3 | 2.5 | Yes | GO thickness is 10 μm. | [61] | |

| 2D MoS2/graphene nanocomposite foam | Impedance | 0–100 | 50,000– 385,000 Ω/%RH | 4/2 | N | No | Sensor used LIG as electrodes. Hysteresis is 3.8%. | [78] | |

| Laser-reduced GO/MWCNT | Drop casting and direct laser scribing | Impedance | 11–97 | 350,000 Ω/%RH | 0.061/2.3 | 1095 | Yes | Sensor used rGO IDE. Hysteresis is 3.1%. | [97] |

| Capacitance | 798 pF/%RHc | ||||||||

| Thermally reduced GO | Spin-coating | Resistive | 32–65 | 5% | 35/N | N | Yes | Highly thermal-reduced GO has the optimal performance. | [98] |

| P(VDF-TrFE) with graphene flower composite | Capacitance Impedance | 8–98 | 0.0558 pF/% RH | 0.8/2.5 | 15 | Yes | N | [79] | |

| GO | Impedance | 6–97 | 182,068.791/%RH | 0.8/0.9 | 1 | Yes | Ti3C2Tx MXene-based sensor exhibited faster response than sensors using metallic electrodes. | [60] | |

| N-S co-doped GQDs | Hydrothermal and spin-coating | 40–90 | N | 15/55 | 90 | N | Optimal GQDs content is 10 mg with 2.2% hysteresis. | [110] | |

| GQDs/carbon nitride (g-C3N4) composite | 7–97 | 100,000 Ω/RH | 44 /10 | N | Yes | Low hysteresis (<1%) and high surface area (545 m2/g) | [111] | ||

| Bi-layered PVA/graphene flower composite film | Spin-coating and spray-coating | Capacitance | 40–90 | 29,000 pF/%RH | 2/3.5 | 15 | N | Uniform dispersion of PVA/GF layer with ~2.32 µm thickness. | [80] |

| Impedance | |||||||||

| Shellac-derived carbon (SDC) thin film | Spray coating and thermal annealing | Resistive | 0–90 | 0.54/% RH | 0.14/1.7 | 28 | Yes | Carbon IDE. High selective to humidity. Power consumption is ~1 mW. | [113] |

| rGO-sodium dodecyl sulfate (SDS) composite film | Drop-coating | Resistive | 25–95 | 11.4143 Ω/% RH (RT) | 9/10 | 10 | Yes | Hysteresis is 0.04852%. | [99] |

| GO | 11–97 | 1.113 Ω/Ω–%RH | 2/35 | N | Yes | Sensor used 300 nm wrinkled GO film on the LIG electrode. Hysteresis is 3%. High humidity selectivity. | [62] | ||

| GO | Quartz crystal microbalance (QCM) | 11.3–97.3 | 0.1605 kHz/%RH | 30/5 | N | Yes | The study used the finite element analysis software COMSOL Multiphysics. | [63] | |

| Polydopamine-coated cellulose nanocrystals/GO nanocomposite (PDA@CNC/GO) | Drop-coating | Resonance frequency | 11.3–97.3 | 0.05466 kHz/% RH | 37/5 | 21 | N | Optimal composition is 30 wt% PDA@CNC. Hysteresis is 4.3% RH. | [64] |

| Graphene flower/ZnO composite | Sol–gel and spray-coating | Resistive | 15–86 | 7.7 µA/%RH | 0.4/4 | N | N | High surface area to volume ratio and pore composite. | [81] |

| GO on tilted fiber grating (TFG) | Dip-coating | Resonance wavelength Intensity | 30–80 | 0.0185 nm/%RH | 0.042/0.115 | N | Yes | GO thickness is 54 nm. | [65] |

| GO/PVA composite film | Intensity | 20–99.9 | 0.529 RH (%) | 147/293 | N | Yes | N | [66] | |

| Graphene–carbon ink | Screen printing | Resistive | 25–91.7 | 12.4 Ω/%RH | ~31/~8 | 120 | N | Optimal configuration is single-layer sensor. | [82] |

| G/polypyrrole/carbon black (CB) composite | 23–92.7 | 12.2 Ω/%RH | 5/7 | 21 | N | Durability is 100 bending cycles Single-layer is the most effective configuration. | [83] | ||

| Graphite/WO3 nanocomposite | 11–97 | 12.7–60.8% | N | N | Yes | Optimal sensor using graphite/WO3 ratio is 1:3, with <1% hysteresis. 120° bending angles. | [116] | ||

| Multilayer GO | Resonance frequency Backscattered phase | 11–98 | 0.5°/%RH | N | N | N | 30 µm GO film and printed graphene antenna electrodes. | [67] | |

| Cellulose nanofiber (CNF) and graphene nanoplatelet (GNP) composite | Mixing and screen printing | Resistive | 30–90 | 240% | 17/22 | 240 | N | Composite with 200 mg GNP as electrode. | [84] |

| Graphene ink | Inkjet printing | Capacitive | 10–70 | 0.03 pF/%RH | 2.46/2.63 | 10 | N | Optimal sensor is six-layer graphene film with graphene IDEs. | [85] |

| GO/CNT−OH/Nafion nanocomposite | Resonance frequency | 30–95 | 547 kHz/%RH | 110/115 | 2.08 | Yes | Hysteresis is 3%. | [68] | |

| Functionalized MWCNTs and hydroxyethyl cellulose (HEC) composite | Gravure printing | Resistive | 20–80 | 0.0485/%RH | 20/35 | 0.4 | Yes | The optimal FMWCNT concentration is 2.5 wt%. | [105] |

| Carboxymethyl cellulose@graphene (CMC/G) composite | 3D printed groove mold | Impedance | 11–95 | 97% | 300/N | 16 | Yes | Optimal graphene content is 0.16 wt%. | [86] |

| Graphene film | Liquid phase exfoliation and LB assembly | Resistive | 8–95 | 5% | 0.028/0.03 | N | Yes | The thickness is ~3.4 nm (~ 10 layers). Flexibility is 10° bending. | [87] |

| GO | Self-assembly | Capacitive | 30–90 | 0.00565 pF/% RH | 180/N | 14 | N | Optimal sensor is 2 mg/mL GO with 2.85% hysteresis. | [69] |

| Pyranine modified-rGO composite | One-step supramolecular assembly | Impedance | 11–95 | IL/IH = 6000 | <2/~6 | N | Yes | Hysteresis is 8% RH. Stable for 100 cycles. | [100] |

| TEMPO-oxidized cellulose fibers (TOCFs)/CNTs | Electrostatic self-assembly | Current | 11–95 | 87% | 333/523 | 90 | Yes | Optimal TOCFs-to-CNTs ratio is 30:1 with a thickness of 48.2 µm and 7.3% hysteresis. | [106] |

| G with 3D flower-like ZnO composite | Hydrothermal | Impedance | 12–90 | 446 | 120/160 | 30 | N | Optimal G content is 70 wt% with 2.32% hysteresis. High humidity selectivity. | [88] |

| PVDF (polyvinylidene fluoride) with 0.5 wt% G | Electrospinning | Capacitive | 35–90 | 0.0463 pF/%RH | N | N | Yes | PVDF/G with Ag electrode, showed 21.3 times faster than DHT11. | [89] |

| SnO2/rGO nanocomposite | 11–95 | 37,491% | 80/4 | N | N | Optimal rGO doping content is 2 wt%. Durability is 1000 bending cycles. | [101] | ||

| BP/G hybrid | Electrospray | Resistive | 15–70 | 43.40% | 9/30 | 28 | Yes | [90] | |

| GO | Electrospray deposition | Resonant frequency | 11–97 | 1.74%/%RH | 54–68/12–22 | 30 | No | Low thermal noise. Optimal is 250 MHz sensor. | [70] |

| Holey-reduced graphene oxide (HRGO) | H2O2-etching-reaction-assisted hydrothermal | Impedance | 11–97 | −0.04317 log Z/%RH | <3/29 | 28 | Yes | Surface area is 274.5 m2/g. Hysteresis is 2.57%. | [102] |

| GO | Dripping and vacuum heating | Capacitive | 20–90 | 1.77–164.98 pF/% RH | 10/2 | N | N | Hysteresis is 1%. | [71] |

| GO | Dripping and coating | 10–90 | 16.7 pF/%RH | 0.0208/0.0199 | 80 | N | The optimal sensor used 1 mg/mL GO and CNTs as electrodes. Hysteresis (<0.44%). | [72] | |

| ZnO nanowires and GQDs composite | Dripping | Resonance frequency | 30–90 | 40.16 kHz/%RH | ~30/~35 | N | No | Optimal GQDs content is 2 mg/mL. 30° bending angle. | [112] |

| SWCNTs | Vacuum filtration | Resistive | 15–98 | 246.90% | 290/510 | N | Yes | Optimal sensor is suspended aligned. SWCNT beams, with 36 μm suspension lengths. | [107] |

| rGO/PANI composite | Filtration | 0–98 | 580% | ~70/~139 | N | Yes | Hysteresis is 3%. Optimal rGO to PANI ratio is 5%. | [103] | |

| Laser-induced graphene (LIG) | Laser Direct Writing (LDW) | Capacitive | 30–90 | N | 8/10 | N | No | The porous, hair-like LIG pattern was designed with 2-CAD. | [91] |

| Light-scribed GO | Laser scribe | Impedance | 7–97 | 1.67 × 106 Ω/%RH | N | 1 | Yes | Hysteresis is 0.3–7%. | [73] |

| G/ZrO2 nanocomposite | Sol–gel | 12–90 | 4011 | 5/20 | 6 | Yes | Hysteresis is <1.95%. Optimal is 40 wt% G/ZrO2 | [92] | |

| 3D graphene foam | Modified Hummers’ method | Resistive | 0–85.9 | N | 0.089/0.189 | N | N | Energy structure of 3DGF model analyzed via CASTEP in Materials Studio 8.0. | [93] |

| Nanocrystalline graphite | Plasma-enhanced CVD | Resistive | 15–85 | 0.0334%/%RH | 0.02/N | N | Yes | Hysteresis is 5%. It is meandered strip structure. | [114] |

| SWCNT | Immersion | 20–80 | 54.7% (s-CNT) | 40/100 | N | Yes | Hysteresis is 11.45% (semiconducting-CNT) and 0.31% (metallic-CNT). | [108] | |

| 2.9% (m-CNT) | |||||||||

| G/p-aminophenol/poly-2-hydroxyethyl acrylate (G/p-AP/PHEA) | In situ free-radical polymerization | 0–94 | 29% | N | N | N | N | [94] | |

| Etched GO film | Etching | Capacitive | 10–100 | 0.000106 pF/% RH | 1.011/N | N | N | The study using COMSOL Multiphysics. | [74] |

| Nanofibrillated cellulose (NFC)/GO/PDMS aerogel composite | Ultrasonic dispersion and freeze-drying | 11–97 | 6576.41 pF/% RH | 57/2 | N | No | Porosity is 99.6%. | [75] | |

| GO/MWCNTs hybrid on tilted Fiber Bragg Grating (TFBG) | Physical precipitation | Optical fiber Amplitude | 30–90 | 0.377 dB/%RH | 4/N | N | Yes | Hysteresis is 0.7%. | [76] |

| Paper cellulose fiber/GO matrix (PCFGOM) | N | Impedance | 10–90 | 9,750,000% (1 kHz) | 1.3 /0.8 | 1 | Yes | The sensor used 0.15 w/w% PCFGOM as active layer and 20 w/w% PCFGOM as electrode layers. | [77] |

| Capacitance | 1,442,500% (10 kHz) |

3.2. Temperature Sensors

| Material | Fabrication Technique | Sensing Range (◦C) | Sensitivity/TCR (%/°C) | Response/ Recovery Time (s) | Stability (Days) | Remarks/Comments | Ref |

|---|---|---|---|---|---|---|---|

| GO | Drop casting | 20–70 | 822 Ω/°C | 306/554 (uncovered) | N | Encapsulation: PDMS | [155] |

| Spray coating | 20–60 | N | 0.525/0.35 (uncovered) | ||||

| 5.18/9.68 (covered) | |||||||

| rGO | Spray coating | 30–100 | 0.6345%/°C | 1.2/N | N | Encapsulation: high-temperature transparent insulating tape. | [136] |

| Multilayer graphene ink film | 30–90 | 43.27 μV/K | 0.15 /15 | N | Optimal sensors have 108 nm thickness and provide 300 μV output voltage, and signal-to-noise ratio is 35. | [117] | |

| rGO | Spin coating | −196.15–299.85 | −0.801–−32.04%/°C | 52/285 | N | Optimal rGO concentration is 3wt%, with 0.1 °C resolution. | [137] |

| MWCNT doped in polyethylene glycol and PU (MWCNT-PEG-PU) nanocomposites | 25–50 | ~80% | N | 7 | Optimal MWCNT concentration is 8 wt% and stable 30 bending cycles. | [146] | |

| Graphene-coated microfiber (GCM) | Coating | 22–40 | 2.1 dB/°C | N | N | Minimum resolution is 0.0005 °C. | [118] |

| Polyaniline/graphene (GPANI) embedded in Polyvinyl Butyral (PVB) composite film | Coating using Mayer rod | 25–80 °C | −1.2%/°C | N | N | Sensor also responds to external pressures (0–30 kPa). Encapsulation: Bezel tape | [119] |

| Graphene and gelatin nanocomposite | Blade coating | −13–37 | −5.3–−23 mV/°C | 10.4/N | N | Stable for 20 cycles. | [120] |

| Graphene/gelatin nanocomposite | −13–37 | −19 mV/K | 41.8/N (pristine sensor) | 2 | Energy consumption is 8.1 μWh for pristine sensor. | [121] | |

| 28.9/N (aged sensor) | Energy consumption is 8.5 μWh for aged devices. | ||||||

| PU/G Nanocomposite | In situ polymerization and dip coating | 25–60 | 6 pm/°C | N | N | Thermal stability to 217 °C from 204 °C. | [122] |

| rGO | Air brush spray coating | 0–100 | 45.1% | 121/N | N | N | [123] |

| Graphene nanoplatelets (GNP) | 52% | 89/N | |||||

| Plasma-grown graphene (Gpl) | Plasma discharge | 20.5% | 125/N | ||||

| Graphene via CVD (Gcvd) | CVD | 27% | 68/N | ||||

| GO | Post-COMS MEMS Drop casting | −70–40 | 155.73–58,555.26 pF/°C | Not reported (N) | 30 | Capacitance sensor. | [156] |

| rGO/Ag nanocomposite | Ultrasonication and drop casting | −60–80 | 0.555 Ω/°C | 0.47/N (cold) | 730 | Encapsulation: Parylene. | [138] |

| 3.45/N (hot) | |||||||

| CNT/PEDOT:PSS composite | Drop casting | 25–45 | −1.97%/°C (initial) | N | 6 | Encapsulation: PDMS Optimal CNT/PEDOT ratios is 1:5. | [147] |

| −2.80%/°C (6 days aging) | |||||||

| CNT and methylcellulose (CNT/MC) composite | Solution casting | 20–70 | 0.2%/°C | 6.1/3.1 (hot) 5.2/7.2 (ice) | N | Stable over 480 cycles. | [148] |

| Graphene Nanoribbons (GNRs) | Mask spraying or direct handwriting | 30–80 | 172% TCR = 1.27%/°C | 0.5/0.5 | N | Using MWCNT ink electrodes and Scotch tape encapsulation. 0.2 °C resolution and stable 5000 bending cycles. | [124] |

| CNT | Gravure printing | −40–100 | −0.4%/°C | 0.3/4 | N | High accuracy (±0.5 °C). Encapsulation: organic and silver. | [149] |

| GO/PEDOT: PSS composite | Mask printing | 25–100 | −1.09%/°C | 18/32 | N | Encapsulation: Kapton tape. Stable 1000 bending cycles. | [157] |

| Functionalized and reduced graphene oxide via sulfonated aromatic diamine (f-rGO) | Inkjet printing | 30–82 | −0.0164/°C | 176.4/316.8 | N | [139] | |

| CNT/PEDOT-PSS composite | 25–50 | 0.31%/°C | ~39/~196 | N | Encapsulation: translucent polyurethane welding tape. Stable 1000 cycles bending. | [150] | |

| rGO with alkali lignin | 25–135 | 0.59%/°C | N | 180 | Sensor used meander-shaped rGO as electrode. | [140] | |

| rGO/Ag | Aerosol jet printing | 0–200 | 0.001162–0.001519/°C | N | N | Optimal four layers rGO/Ag. Stable 1000 bending cycles. | [141] |

| Porous LIG | CO2 laser-induced Direct laser writing | 1–8 | N | 16/58 | N | Encapsulation: PDMS. Stable 200 bending cycles. | [125] |

| LIG | Laser direct writing | 24–80 | −0.58%/°C | N | 14 | Sensors optimized by finite element analysis photothermal model. | [126] |

| Amorphous carbon films | DC Magnetron Sputtering | 20–150 | 1.62 mV/°C TCR = 0.00128/°C | N | N | DC magnetron sputtered sensors are more stable and practical than ion-beam-deposited sensor. | [161] |

| Micro-fabricated single-layer graphene | CVD | 10–30 | 1.25 Ω/°C (SiO2/Si substrate) | N | N | Sensor used graphene electrodes and PDMS gasket encapsulation. | [127] |

| 2.15 Ω/°C (SiN substrate) | |||||||

| 1.90 Ω/°C (suspended graphene substrate) | |||||||

| CNT forest-PDMS composite | 30–90 | 0.55 Ω/°C | N | N | Encapsulation: PDMS. | [151] | |

| Graphene and Lithium Niobate (LiNbO3) | 10–70 | −0.23 nm/°C | N | N | Encapsulation: PDMS. | [128] | |

| Multilayer graphene | −266.55–26.85 | −1 (THS < −243.15 °C) | ~0.030/N | N | Sensor made by seven layers of single-layer graphene. | [129] | |

| <0.1 (THS > −173.15 °C) | |||||||

| Vertically aligned CNT film | TCVD | 20–110 | 4.74 μA/°C (air) | N | 30 | Triple-electrode structure enables long-term sensor operation. | [152] |

| 22.72 μA/°C (N2) | |||||||

| MWCNT | CVD and wet transfer | 22–200 | 0.0033 V/°C TCR = 0.00103/°C | N | N | 2.7 μm MWCNT sensor had carrier mobility (−28.5574 cm2/Vs). | [153] |

| Single-layer graphene | 27–302 | 0.00207/°C (27–177 °C) | N | N | Resistance is almost unaffected by humidity. | [130] | |

| 0.00239/°C (177–302 °C) | |||||||

| Suspended few-layer and multilayer graphene | 25–120 | 1.07–3.5%/°C | N | N | N | [131] | |

| Graphene | CVD and AI sacrificial layer process | 25–200 | 2.134 Ω/◦C | N | N | Enhanced 41.93% consistency. Encapsulation: SiO2 layer. | [132] |

| GQDs embedded in a rGO/alumina composite film | Sol–gel | −196.15–26.85 26.85–99.85 | −1999%/°C −0.98%/°C | ~0.3/0.8 3.96/6.01 | N | Short-term stability is 50 cycles. | [142] |

| CNC-assisted carbon dots (CDs)-grafted SrAl2O4: Eu2+, Dy3+ (SAO) phosphors composite film | Sol–gel and vacuum filtration | −30–110 | 0.257 | N | N | Short-term stability is 3.5 cycles. | [160] |

| High-strength metallurgical graphene (HSMG) | Modified PMMA-based transfer | −253.15–21.85 | −0.007/°C | N | N | Encapsulation: transparent polymer. | [133] |

| Polyethyleneimine/reduced graphene oxide (PEI/rGO) | Spray dipping | 25–45 0–60 | 1.3%/°C | 0.33–0.443/N | 120 | Encapsulation: PDMS. 0.1 °C resolution and 500 bending cycle stability. | [143] |

| GO/PEDOT: PSS micro/nanowires | Soft lithography | 30–80 | −0.007599/°C | 3.5 /13.4 | 30 | Optimal GO doping ratio is 13:1. | [158] |

| LIG | CO2 laser irradiation | 30–60 | −0.04145%/°C | 30/N | N | High measurement accuracy (±0.15 °C). | [134] |

| PDA-rGO/sodium alginate/polyacrylamide composite organohydrogel | Solvent displacement and cross-linking | −20–60 | 97.6%/°C (−20–−5 °C) | 0.2/0.3 | N | Encapsulation: VHB tape. Stable over 3 h. | [144] |

| 10.57%/°C (−5–15 °C) | |||||||

| 1.45%/°C (15–60 °C) | |||||||

| Star-like rGO/SnO2/Co3O4 composite | Facile wet chemical precipitation | 25–125 | 0.561%/°C | N | N | [145] | |

| GNP/PDMS nanocomposite | Three-roll milling and molding | 30–80 | 0.052–11.7/°C | N | N | The optimal GNP concentration is 6 wt%. | [135] |

| Carboxyl-SWCNTs | N | 0–80 | −225 Ω/°C | N | N | Encapsulation: thermos-reversible polymer. Self-healing 30 bending cycles. | [154] |

| GQDs/hollow-core fiber | N | 10–80 | −0.01375/°C | N | N | N | [159] |

3.3. Mechanical Sensors

| Material | Fabrication Technique | Sensing Range (kPa) | Sensitivity/Gauge Factor (GF) | Response/ Recovery Time (s) | Durability (Cycles) | Remarks/Comments | Ref |

|---|---|---|---|---|---|---|---|

| Suspended monolayer graphene (G) | CVD | 0–80 | GF = 6.73 (circular membrane) | Not reported (N) | Not reported (N) | An improved theoretical model was developed to predict GF and confirm their independence of doping concentration and graphene crystallographic orientation. | [162] |

| GF = 3.91 (rectangular membrane) | |||||||

| Graphene | Plasma-enhanced CVD | 0–20,000 | 0.03313 mV/V/kPa | N | 35 days | Encapsulation: Si3N4 film. Error of hysteresis (2.0119%), nonlinear (3.3622%), and repeatability (4.0271%). | [163] |

| GF = ~1.35 | |||||||

| Graphene/PDMS sponge | Mixing and molding | 0.005–500 | 37.5–2200 kHz/kPa | ~0.007/0.06 | 5000 | LC technology used for long-distance wireless transmission. Optimal graphene concentration is 20%. | [164] |

| Porous PDMS | Sugar-cube mold | 0–1200 | 360–1120 kPa−1 | 1/<1 | 10,000 | Sensor used MWCNT/PEDOT composite electrode and low-pass filter. | [171] |

| Tannic acid (TA)-rGO/PVA hydrogel | Sonication, molding via freeze–thaw | 0–20 | 2.2695 kPa−1 | 0.67/0.84 | 100 | Optimal concentration is 2 mg/mL and tensile strength is 440.213 kPa. | [167] |

| Carbon ink-coated filter paper | Dip coating | 0.1–100 | 0.0259–0.627 kPa−1 | N | 4000 | N | [169] |

| PU/G foams | Solvent extraction | 0–500 | 0.05–7.62 kPa−1 | 0.81/0.81 | 1000 | Optimal graphene content is 30 wt%. | [165] |

| Nitrogen-doped GO, dopamine, and polyaniline composite aerogel | Self-assembly, freeze-drying, and thermal annealing | 0–25.48 | 0.10 kPa−1 | N | 150 | The optimal mass ratio of GO:DA:PANI is 5:2:2, with 1.46% nitrogen. | [166] |

| P(VDF-TrFE) matrix with MWCNTs | Electrospinning and mechanical drawing | 5–50 | ~540 mV/N | N | N | Self-powered sensor achieved piezoelectric coefficient of 50 pm/V with 98% linearity. | [168] |

| PDMS/CB/graphene nanosheets | Laser thermoforming | 0–100 | 109.4 kPa−1 | 0.079/0.055 | 5000 | CB as an endothermic agent and glucose as a porogen. | [170] |

| Material | Fabrication Technique | Sensing Range (%) | Sensitivity | Response/ Recovery Time (ms) | Durability (Cycles) | Remarks/Comments | Ref |

|---|---|---|---|---|---|---|---|

| Patterned MWCNT/PDMS | Microelectromechanical system-assisted EPD | 0–14 | 13–120 | N | N | Sensitivity tailored by MWCNT film thickness and entanglement. Sensor adapted to an arbitrarily curve surface. | [173] |

| Polymer-free CNTs | Hot-wall atmospheric CVD | 0–42.1 MPa | 1461 | N | N | Higher sensitivity in IDE devices than single-gap electrodes. | [174] |

| CNT/Agar composite | Solution casting | 0–118 | 0.28 | 160/250 | 10,000 | Increasing filler concentration improved strain from 0.8 to 1.1, and stress from 35.2 to 45.8 kPa. | [175] |

| PDMS-TDI (2,4′-Tolylene diisocyanate)-carboxyl-functionalized MWCNTs nanocomposite | One-pot synthesis, ultrasonication, and casting | 0–1000 | 0.65–2.43 | N | 1000 | Sensor had 98.1% self-healing efficiency at 60 °C over 9 h. | [176] |

| Fragmentized rGO sponge (FGS)/AgNPs/polystyrene-butadiene-styrene (SBS) composite | Multiple-step process | 0–120 | 20.5–1.25 × 107 | 20/N | 2000 | Microcrack contributed to sensitivity. Sensor had 1521 S/cm conductivity and 680% break elongation. | [177] |

| CNTs/PDMS | 0.007–100 | 87 | 65/N | 1500 | Optimal sensor had network cracks and 15 layers of CNT. | [178] | |

| rGO/MWCNTs composite | Direct writing printing | 10–40 | 18.55 | N | 900 | N | [179] |

| Carbon grease | Embedded 3D printing | 400 | 3.8 | N | 1000 | Up to 10% variation from its original value after large strains. | [184] |

| Few-layer graphene | Mechanical exfoliation and screen printing | 0–6 | 20.02 | N | 100,000 flexing cycles | Number of prepared graphene layers was 2–5 layers. | [181] |

| 1000 abrasion cycles | |||||||

| TA-rGO/PVA hydrogel | Sonication and molding via freeze–thaw cycles | 0–280 | 1.936 78 | 670/840 | 100 | Optimal concentration is 2 mg/mL and tensile strength is 440.213 kPa. | [167] |

| PEI-rGO nanocomposite | LBL self-assembly | 0–5 (~800 kPa) | N | N | 500 | Rapid self-healing (~10 s), and 98% efficiency at room temperature. | [180] |

| Ultrathin graphene film | Single-step Marangoni self-assembly | 2 | 1037 | N | N | Optimal thickness is 4.4 nm with 3.4% failure strain. | [182] |

| Chitosan-graphene | Bath sonication and vacuum filtration | 0–2 | 18.6 | N | N | Chitosan-G had better graphene electrical properties than pullulan and alginate. | [183] |

3.4. Multifunctional Sensor

| No. Modes | Carbon Materials | Modes | Fabrication | Mechanism | Working Range | Sensitivity | Response/ Recovery Time (s) | Durability (Cycles) | Ref |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Monolayer graphene | Humidity | CVD and oxygen plasma etching | Capacitive | 2–90%RH | 17–32%/%RH | ~8/~19 | 1000 | [185] |

| Resistive | |||||||||

| Temperature | Current | 10–90 °C | N | ~4/~10 | N | ||||

| Cracked paddy-shaped MoS2/graphene foam/Ecoflex | Strain | Thermal CVD, dipping, and annealing | Piezoresistive | 0–22% | GF = 24.1 | N | N | [186] | |

| Pressure | 0.6–25.4 kPa | 3.28–6.06/kPa | N | 4000 | |||||

| SWCNTs/PDMS | Pressure | Coating and molding | Capacitance | 0–25 kPa | 0.7/kPa | 0.05/N | 10,000 | [187] | |

| rGO | Temperature | Spray-coating | Resistive | 22–70 °C | 0.83%/°C | 0.1/N | N | ||

| PDMS/SWCNT composite | Pressure | Spray coating and leather mold | Piezoresistive | 0–400 kPa | 0.03–7.76/kPa | 0.132/0.12 | 10,000 | [188] | |

| PDMS/SWCNT composite with thermochromic material | Temperature | Resistive | 23–90 °C | N | N | N | |||

| Graphene–CNT–Silicone adhesive nanocomposite | Humidity | Doctor blade and drop casting | Impedance | 36–94% RH | −84.5 Ω/%RH | 26/74 | N | [189] | |

| Capacitance | 1336.7 pF/%RH | ||||||||

| Temperature | Impedance | 37–87 °C | −19.8 Ω/°C | 34/82 | N | ||||

| PU@CNT composite | Temperature | Hot pressing | Resistive | 30–110 °C | −2.84 × 10−3/°C | N | 5000 | [190] | |

| PU dielectric | Pressure | Capacitive | 0.1–50 kPa | 0.0549/kPa | 0.094/0.134 | 5000 | |||

| GO/SWCNTs/PDMS composite | Humidity | Screen and inkjet printing Blading and doctor blade | Resistive | 25–80%RH | 0.137–11.145%/%RH | 0.5/0.3 | N | [191] | |

| SWCNTs/PDMS composite | Pressure | Piezoresistive | 0.024–230 kPa | 27.91–77.78 /kPa | 0.03/0.03 | 6000 | |||

| Graphene/PEDOT:PSS hydrogel | Strain | One-pot method | Resistive | 1000% | 8.1 | 0.2/N | 10,000 | [192] | |

| Temperature | 7–60 °C | −7.16–−0.162%/°C | N | N | |||||

| 2 | CNTs sponge/PEDOT:PSS/PDMS | Pressure | Soaking and oven drying | Piezoresistive | 0–40 kPa | 26.8–902.2/kPa | 0.063/0.071 | 500 | [193] |

| Temperature | Resistive | 20–80 °C | 0.84%/°C | 1.1/1.5 | 5 days | ||||

| 3 | GO | Humidity | Spray coating | Capacitive | 20–90% | 0.0589 pF/%RH | N | N | [194] |

| rGO | Temperature | Resistive | 0–100 °C | −3.4 kΩ/°C | N | N | |||

| PDMS | Pressure | Lamination | Resistive | 0–450 kPa | 0.002/kPa | 0.2/N | 2000 | ||

| Capacitive | |||||||||

| rGO/CNCs | Compression Strain | Mixing, freezing, freeze-drying, and carbonization | Resistive | 0–99% | GF = 369.4 | N | 10,000 | [195] | |

| Pressure | 0.00075 kPa | N | N | N | |||||

| Bending | 0.052–180° | N | N | 10,000 | |||||

| Graphene-glycerol | Strain | Coating | Piezoresistive | 0–1000% | GF = 45.13 | 0.2/0.2 | 10,000 | [196] | |

| Pressure | Resistive | 0–50 kPa | 80% | N | N | ||||

| Twisting | 0–180° | 100% | N | N | |||||

| PDMS-coated microporous polypyrrole/graphene foam (PDMS/PPy/GF) | Pressure | CVD, electrochemical deposition, and dip-coating | Piezoresistive | 0–50 kPa | 2.01/kPa | 0.02/N | 10,000 | [197] | |

| Temperature | Thermoelectric | 25–70 °C | 49.8 µV/K | 1.5/8.3 | N | ||||

| Strain | Resistive | 0–50% | GF = −1.38 (<10%) | 1/2.5 | N | ||||

| GF = −0.09 (10–50%) | |||||||||

| Carbon fibers and MWCNTs (CFs-MWCNT) composite | Temperature | Resistive | 30–50 °C | 1.49–2.46%/°C | N | N | [198] | ||

| Pressure | Piezoresistive | 0–60 kPa | 0.91–42.5/kPa | 0.1/0.1 | 6000 | ||||

| Bending | 0–180° | 95.5%/rad | N | 1000 | |||||

| GO-doped-PU nanofiber membrane coated with PEDOT | Pressure | Electrospinning, in situ polymerization, low-temperature oxygen plasma | Piezoresistive | 0.001–20 kPa | 0.15–20.6/kPa | 0.012/N | 10,000 | [199] | |

| Strain | 0–550% | 10.1–193.2 | N | 10,000 | |||||

| Flexion | 1.0 cm−1 | N | N | 6000 | |||||

| CNT/PDMS composite | Pressure | Replica molding and ultraviolet-ozone exposure | Piezoresistive | 0–270 kPa | 6.67/kPa | 0.024/0.03 | 10,000 | [200] | |

| Bending | 1–6.5 mm | 17.7/mm | N | N | |||||

| Tensile strain | 0–50% | GF = 409 | N | N | |||||

| Nanopapillae-decorated carbon nanosheet (NP-CNS) | Humidity | Pyrolysis and screen printing | Resistive | 0–96%RH | 8.25 | 1.7/100.1 | N | [201] | |

| Strain | Piezoresistive | 0–500% | GF = 21.9–99.9 | 0.07/N | N | ||||

| Pressure | 0.005–0.6 kPa | N | 0.032/N | N | |||||

| 3 | rGO/polyorganosiloxane aerogels | Temperature | Copolycondensation | Resistive | 20–100 °C | 50.20% | N | 10,000 | [202] |

| Pressure | 0.01–110 kPa | 83.50% | N | ||||||

| Strain | 0.1–80% | 84% | N | ||||||

| CNC (10 mg)-CNT (30 mg) buckypaper | Strain | Mixed vacuum filtration and curing | Piezoresistive | 0–100% | GF = 352,085 | 0.033/0.016 | 10,000 | [203] | |

| Pre-stretched CNC (10 mg)-CNT (80 mg) buckypaper | Temperature | Mixed vacuum filtration, pre-stretch, and curing | Resistive | −266.15–126.85 °C | 1.88%/°C | N | 10 | ||

| CNC-CNT on cellulose filter paper (1:1) | Humidity | Dripping | Resistive | 10–80%RH | N | N | 10 | ||

| Graphene woven fabric (GWF)/PDMS composite | Pressure | Catalytic decomposition and dipping | Piezoresistive | 0–20 kPa | 0.0142/kPa | N | 1000 | [204] | |

| Strain | 0–140% | GF = 582 | N | N | |||||

| Temperature | Thermoresistive | 25–80 °C | 0.0238/°C | N | N | ||||

| 4 | CB/rGO composite | Strain | Spray coating | Resistive | N | GF = 14.6 (compression) | ~0.34/N | 1000 | [205] |

| GF = 1.8 (tension) | |||||||||

| Humidity | 16–95%RH | 2.04/%RH | ~300/~80 | N | |||||

| Temperature | 20–60 °C | 0.6%/°C | ~100/N | ||||||

| Pressure | 0–250 kPa | 0.09–0.59%/kPa | ~0.25/N | ||||||

| CB-PDMS | Strain | Spin coating | Resistive | 0–40% | GF = 81.2 (0–5%) | <0.05/N | 4000 | [206] | |

| GF = 28.5 (5–40%) | |||||||||

| Pressure | 0–20 kPa | 4 × 104% | 0.1/0.1 | N | |||||

| Flexion | 0–150° | N | N | ||||||

| Temperature | 25–150 °C | 0.515 ppm/°C | 8.4/N | ||||||

| Polyaniline-coated MWCNTs | Humidity | Two-step assembly | Conductive | 30–80% RH | 4.80% | 25/38 (Basal layer) | 2500 | [207] | |

| 56/55 (double layer) | |||||||||

| Pressure | Piezoresistive | 0.028–100 kPa | GF = 10 | 0.11/0.13 | 10,000 | ||||

| Bending strain | 0–2.7% | GF = 35.8 | |||||||

| Twisting strain | 0–90° | GF = 20.8 |

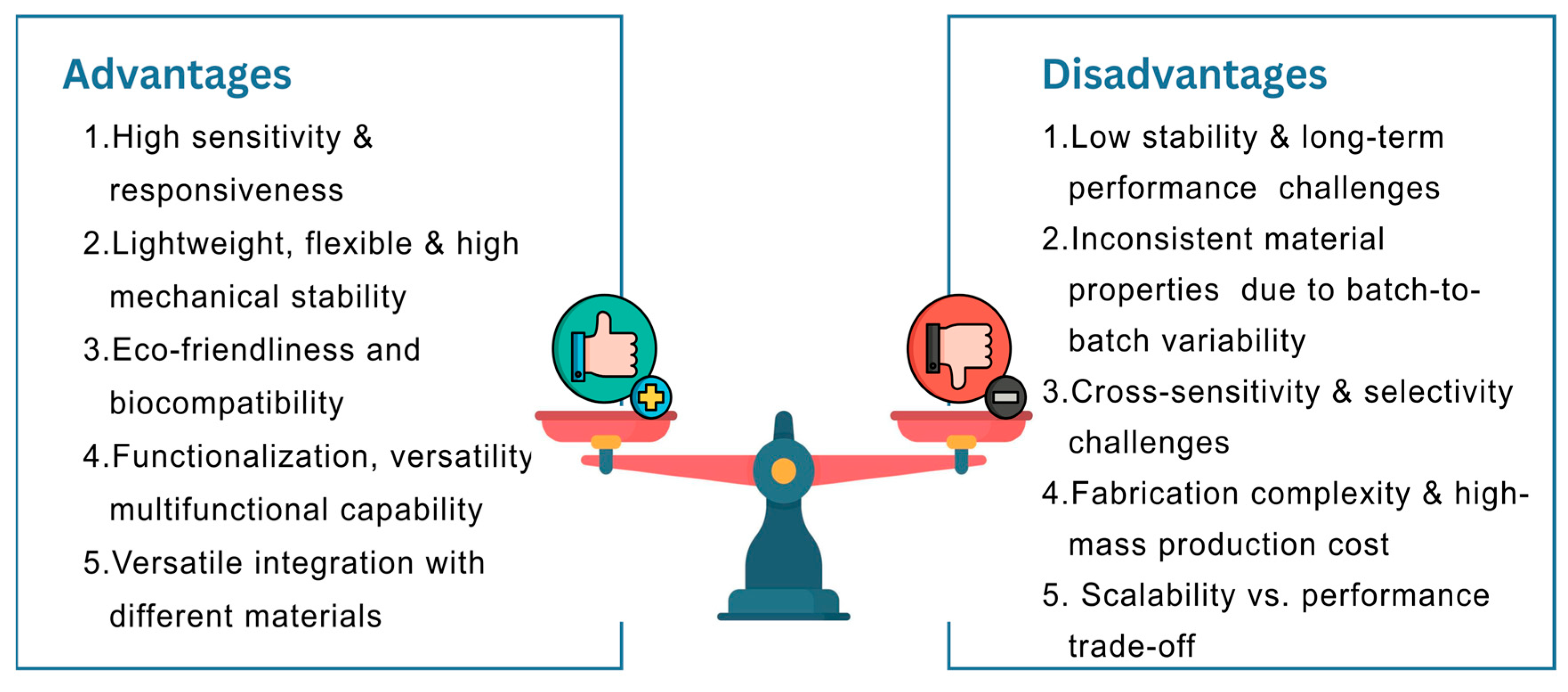

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| 3D | Three-Dimensional |

| ACBS | All Carbon-Based Sensor |

| Ag | Silver |

| BP | Black Phosphorus |

| CB | Carbon Black |

| CDs | Carbon Dots |

| CFs | Carbon Fibers |

| CMC | Carboxymethyl Cellulose |

| CNC | Cellulose Nanocrystals |

| CNCs | Carbon Nanocoils |

| CNF | Carbon Nanofiber |

| CNHs | Carbon Nanohorns |

| CNS | Carbon Nanosheet |

| CNT−OH | Hydroxyl-functionalized Carbon Nanotubes |

| CNTs | Carbon Nanotubes |

| Co3O4 | Cobalt (II,III) Oxide |

| CVD | Chemical Vapor Deposition |

| DA | Dopamine |

| DLS | Direct Laser-Scribed |

| EPD | Electrophoretic Deposition |

| f-rGO | Functionalized Reduced Graphene Oxide |

| FGS | Fragmentized rGO sponge |

| G | Graphene |

| g-C3N4 | Carbon nitride |

| GCM | Graphene-coated microfiber |

| Gcvd | Graphene via Chemical Vapor Deposition |

| GF | Gauge Factor |

| GF | Graphene Foam |

| GNP | Graphene Nanoplatelets |

| GNRs | Graphene Nanoribbons |

| GO | Graphene Oxide |

| GPANI | Polyaniline/Graphene |

| Gpl | Plasma-Grown Graphene |

| GQDs | Graphene Quantum Dots |

| GWF | Graphene Woven Fabrics |

| HEC | Hydroxyethyl Cellulose |

| HGO | Hummer’s Graphene Oxide |

| HRGO | Holey-Reduced Graphene Oxide |

| HSMG | High Strength Metallurgical Graphene |

| LB | Langmuir-Blodgett |

| LBL | Layer-by-Layer |

| LDW | Laser Direct Writing |

| Li | Lithium |

| LiCl | Lithium Chloride |

| LIG | Laser-Induced Graphene |

| LiNbO3 | Lithium Niobate |

| MC | Methyl Cellulose |

| Mg | Magnesium |

| Mn | Manganese |

| MoS2 | Molybdenum Disulfide |

| MoTe2 | Molybdenum Ditelluride |

| MWCNT | Multi-Walled Carbon Nanotubes |

| N | Nitrogen |

| NFC | Nanofibrillated Cellulose |

| NP | Nanopapillae |

| p-AP | p-aminophenol |

| P(VDF-TrFE) | Poly(Vinylidene Fluoride-Trifluoroethylene) |

| PAM | Polyacrylamide |

| PANI | Polyaniline |

| PCFGOM | Paper Cellulose Fiber/GO Matrix |

| PDA | Polydopamine |

| PDMS | Polydimethylsiloxane |

| PEDOT:PSS | Poly(3,4-ethylenedioxythiophene) Polystyrene Sulfonate |

| PEG | Polyethylene Glycol |

| PEI | Polyethyleneimine or Polyetherimide |

| PHEA | Poly-2-hydroxyethyl acrylate |

| POS | Polyorganosiloxane |

| PPy | Polypyrrole |

| PU | Polyurethane |

| PVA | Polyvinyl Alcohol |

| PVB | Polyvinyl Butyral |

| PVDF | Poly(vinylidene fluoride) |

| PVP | Poly(vinylpyrrolidone) |

| QCM | Quartz Crystal Microbalance |

| rGO | Reduced Graphene Oxide |

| S | Sulfur |

| SA | Sodium Alginate |

| SAO | SrAl2O4: Eu2+, Dy3+ |

| SBS | Styrene-Butadiene-Styrene |

| SDBS | Sodium Dodecylbenzenesulfonate |

| SDC | Shellac-derived Carbon |

| SDS | Sodium Dodecyl Sulfate |

| SnO2 | Tin(IV) Oxide |

| SWCNHs | Single-Walled Carbon Nanohorns |

| SWCNT | Single-Walled Carbon Nanotubes |

| TA | Tannic Acid |

| TDI | 2,4’-Tolylene Diisocyanate |

| TEMPO | 2,2,6,6-Tetramethylpiperidine 1-oxyl |

| TFBG | Tilted Fiber Bragg Grating |

| TFG | Tilted Fiber Grating |

| TOCFs | TEMPO-Oxidized Cellulose Fibers |

| VOCs | Volatile Organic Compounds |

| WO3 | Tungsten Trioxide |

| ZnO | Zinc Oxide |

| ZrO2 | Zirconium Dioxide |

References

- Janik-Karpinska, E.; Brancaleoni, R.; Niemcewicz, M.; Wojtas, W.; Foco, M.; Podogrocki, M.; Bijak, M. Healthcare Waste—A Serious Problem for Global Health. Healthcare 2023, 11, 242. [Google Scholar] [CrossRef] [PubMed]

- Lipinski, B. SDG TARGET 12.3 ON FOOD LOSS AND WASTE: 2023 PROGRESS REPORT|Champions 12.3; World Resources Institute: Washington, DC, USA, 2023; Available online: https://champions123.org/publication/sdg-target-123-2023-progress-report (accessed on 21 November 2024).

- NHS. NHS Clinical Waste Strategy; NHS England: London, UK, 2023; Available online: https://www.england.nhs.uk/long-read/nhs-clinical-waste-strategy/ (accessed on 21 November 2024).

- UKHSA. Vaccine Incident Guidance: Responding to Errors in Vaccine Storage, Handling and Administration; UK Health Security Agency: London, UK, 2022. Available online: https://assets.publishing.service.gov.uk/media/62c598188fa8f54e855dfe17/UKHSA-vaccine-incident-guidance-6-july-2022.pdf (accessed on 21 November 2024).

- WRAP. Returning to Normality After COVID-19: Food Waste Attitudes and Behaviours in 2021; WRAP: Banbury, UK, 2021; Available online: https://www.wrap.ngo/sites/default/files/2021-08/food-trends-report-august-2021.pdf (accessed on 21 November 2024).

- UNEP. United Nations Environment Programme Food Waste Index Report 2021; UNEP: Nairobi, Kenya, 2021; Available online: https://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 21 November 2024).

- Food Wastage Footprint: Impacts on Natural Resources: Summary Report; FAO: Rome, Italy, 2013; ISBN 978-92-5-107752-8.

- Fortune Business Insights. Smart Packaging Market Size, Share & Industry Analysis, By Technology Type (Modified Atmosphere Packaging (MAP), Active Packaging, and Intelligent Packaging), By Application (Food & Beverages, Personal Care & Cosmetics, Pharmaceuticals, Electronics, E-Commerce, and Others), and Regional Forecast, 2024–2032. 2024. Available online: https://www.fortunebusinessinsights.com/smart-packaging-market-109166 (accessed on 6 November 2024).

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Srinivasa Gopal, T.K. Smart Packaging Systems for Food Applications: A Review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef] [PubMed]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An Overview of the Intelligent Packaging Technologies in the Food Sector. Trends Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef]

- Yusufu, D.; Mills, A. A Colourimetric Vacuum Air-Pressure Indicator. Analyst 2019, 144, 5947–5952. [Google Scholar] [CrossRef]

- Sterr, J.; Fleckenstein, B.S.; Langowski, H.-C. The Effect of High-Pressure Processing on Tray Packages with Modified Atmosphere. Food Eng. Rev. 2015, 7, 209–221. [Google Scholar] [CrossRef]

- Li, X.; Koh, K.H.; Farhan, M.; Lai, K.W.C. An Ultraflexible Polyurethane Yarn-Based Wearable Strain Sensor with a Polydimethylsiloxane Infiltrated Multilayer Sheath for Smart Textiles. Nanoscale 2020, 12, 4110–4118. [Google Scholar] [CrossRef]

- Boz, Z.; Welt, B.A. Permeable Gas Cavity at Elevated Pressure Enhances Modified Atmosphere Packaging of Fresh Produce. J. Food Sci. 2018, 83, 1639–1649. [Google Scholar] [CrossRef]

- Seo, J.; Li, S.; Tsogbayar, D.; Hwang, T.; Park, J.; Ko, E.; Park, S.-J.; Yang, C.; Lee, H.S. Advanced Multiparallel-Connected Piezoresistive Physical Sensors: Elevating Performance Reliability of Flexible Strain and Pressure Sensors. ACS Appl. Mater. Interfaces 2024, 16, 22229–22237. [Google Scholar] [CrossRef]

- Bradford, K.J.; Dahal, P.; Van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The Dry Chain: Reducing Postharvest Losses and Improving Food Safety in Humid Climates. Trends Food Sci. Technol. 2018, 71, 84–93. [Google Scholar] [CrossRef]

- Kurmanov, N.; Tolysbayev, B.; Abilmazhinov, Y. The Limiting Storage Life of Perishables During Joint Transportation. CBUP 2015, 3, 499–505. [Google Scholar] [CrossRef]

- WHO. Good Storage and Distribution Practices; WHO: Geneva, Switzerland, 2019; Available online: https://www.who.int/publications/i/item/978-92-4-000182-4 (accessed on 13 October 2024).

- ISO 23412:2020; Indirect, Temperature-Controlled Refrigerated Delivery Services—Land Transport of Parcels with Intermediate Transfer. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/75468.html (accessed on 14 October 2024).

- ISO 23416:2023; General Specifications and Testing Methods for Temperature-Sensitive Medicinal Packages in Good Distribution Practice Principles. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/obp/ui/#iso:std:iso:23416:ed-1:v1:en (accessed on 14 October 2024).

- ISO 22982-1:2021; Packaging—Temperature-Controlled Transport Packaging for Parcels—Part 1: General Requirements and Testing Methods. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/standard/74273.html (accessed on 14 October 2024).

- ISO 12048:1994; Packaging—Complete, Filled Transport Packages—Compression and Stacking Tests. International Organization for Standardization: Geneva, Switzerland, 1994. Available online: https://www.iso.org/standard/21579.html (accessed on 14 October 2024).

- ISO 18602:2013; Packaging and the Environment—Optimization of the Packaging System. International Organization for Standardization: Geneva, Switzerland, 2013. Available online: https://www.iso.org/standard/55870.html (accessed on 14 October 2024).

- ISO 13355:2016; Packaging—Complete, Filled Transport Packages and Unit Loads—Vertical Random Vibration Test. International Organization for Standardization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/62098.html (accessed on 14 October 2024).

- Tarcan, R.; Todor-Boer, O.; Petrovai, I.; Leordean, C.; Astilean, S.; Botiz, I. Reduced Graphene Oxide Today. J. Mater. Chem. C 2020, 8, 1198–1224. [Google Scholar] [CrossRef]

- Guo, Y.; Wei, X.; Gao, S.; Yue, W.; Li, Y.; Shen, G. Recent Advances in Carbon Material-Based Multifunctional Sensors and Their Applications in Electronic Skin Systems. Adv. Funct. Mater. 2021, 31, 2104288. [Google Scholar] [CrossRef]

- Hou, P.-X.; Liu, C.; Cheng, H.-M. Purification of Carbon Nanotubes. Carbon 2008, 46, 2003–2025. [Google Scholar] [CrossRef]

- Eatemadi, A.; Daraee, H.; Karimkhanloo, H.; Kouhi, M.; Zarghami, N.; Akbarzadeh, A.; Abasi, M.; Hanifehpour, Y.; Joo, S.W. Carbon Nanotubes: Properties, Synthesis, Purification, and Medical Applications. Nanoscale Res. Lett. 2014, 9, 393. [Google Scholar] [CrossRef] [PubMed]

- Rao, N.; Singh, R.; Bashambu, L. Carbon-Based Nanomaterials: Synthesis and Prospective Applications. Mater. Today Proc. 2021, 44, 608–614. [Google Scholar] [CrossRef]

- Nasir, S.; Hussein, M.; Zainal, Z.; Yusof, N. Carbon-Based Nanomaterials/Allotropes: A Glimpse of Their Synthesis, Properties and Some Applications. Materials 2018, 11, 295. [Google Scholar] [CrossRef]

- Kirchner, E.-M.; Hirsch, T. Recent Developments in Carbon-Based Two-Dimensional Materials: Synthesis and Modification Aspects for Electrochemical Sensors. Microchim. Acta 2020, 187, 441. [Google Scholar] [CrossRef]

- Sevilla, M.; Fuertes, A.B. The Production of Carbon Materials by Hydrothermal Carbonization of Cellulose. Carbon 2009, 47, 2281–2289. [Google Scholar] [CrossRef]

- Simeonova, D.D.; Pollmann, K.; Bianco, A.; Lièvremont, D. Graphene Oxide and Bacteria Interactions: What Is Known and What Should We Expect? mSphere 2024, 9, e00715-23. [Google Scholar] [CrossRef]

- Lv, C.; Hu, C.; Luo, J.; Liu, S.; Qiao, Y.; Zhang, Z.; Song, J.; Shi, Y.; Cai, J.; Watanabe, A. Recent Advances in Graphene-Based Humidity Sensors. Nanomaterials 2019, 9, 422. [Google Scholar] [CrossRef]

- Zhu, S.; Kim, D.; Jeong, C. Recent Development of Mechanical Stimuli Detectable Sensors, Their Future, and Challenges: A Review. Sensors 2023, 23, 4300. [Google Scholar] [CrossRef] [PubMed]

- Mitura, K.; Kornacka, J.; Kopczyńska, E.; Kalisz, J.; Czerwińska, E.; Affeltowicz, M.; Kaczorowski, W.; Kolesińska, B.; Frączyk, J.; Bakalova, T.; et al. Active Carbon-Based Nanomaterials in Food Packaging. Coatings 2021, 11, 161. [Google Scholar] [CrossRef]

- Kamran, U.; Heo, Y.-J.; Lee, J.W.; Park, S.-J. Functionalized Carbon Materials for Electronic Devices: A Review. Micromachines 2019, 10, 234. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Adam, M.L.; Zhao, Y.; Zheng, W.; Gao, L.; Yin, Z.; Zhao, H. Machine Learning-Enhanced Flexible Mechanical Sensing. Nano-Micro Lett. 2023, 15, 55. [Google Scholar] [CrossRef]

- Yang, T.; Jiang, X.; Huang, Y.; Tian, Q.; Zhang, L.; Dai, Z.; Zhu, H. Mechanical Sensors Based on Two-Dimensional Materials: Sensing Mechanisms, Structural Designs and Wearable Applications. iScience 2022, 25, 103728. [Google Scholar] [CrossRef]

- Tang, C.; Wang, Y.; Li, Y.; Zeng, S.; Kong, L.; Li, L.; Sun, J.; Zhu, M.; Deng, T. A Review of Graphene-Based Temperature Sensors. Microelectron. Eng. 2023, 278, 112015. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC (Text with EEA Relevance). Available online: http://data.europa.eu/eli/reg/2025/40/oj (accessed on 1 March 2025).

- European Parliament; Council of the European Union. European Parliament and Council Directive 94/62/EC of 20 December 1994 on Packaging and Packaging Waste; Publications Office of the European Union: Luxembourg, 2018; Volume 31994L0062, Available online: http://data.europa.eu/eli/dir/1994/62/oj (accessed on 1 March 2025).

- Secretary of State for Environment, Food and Rural Affairs. 2024 No. 1332 The Producer Responsibility Obligations (Packaging and Packaging Waste) Regulations 2024; The Stationery Office: London, UK, 2024. Available online: https://www.legislation.gov.uk/uksi/2024/1332/made (accessed on 1 March 2025).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 89. [Google Scholar] [CrossRef]

- Rathi, K.; Pal, K. Impact of Doping on GO: Fast Response–Recovery Humidity Sensor. ACS Omega 2017, 2, 842–851. [Google Scholar] [CrossRef]

- Fatima, Q.; Haidry, A.A.; Yao, Z.; He, Y.; Li, Z.; Sun, L.; Xie, L. The Critical Role of Hydroxyl Groups in Water Vapor Sensing of Graphene Oxide. Nanoscale Adv. 2019, 1, 1319–1330. [Google Scholar] [CrossRef]

- Serban, B.-C.; Cobianu, C.; Buiu, O.; Bumbac, M.; Dumbravescu, N.; Avramescu, V.; Nicolescu, C.M.; Brezeanu, M.; Radulescu, C.; Craciun, G.; et al. Quaternary Oxidized Carbon Nanohorns—Based Nanohybrid as Sensing Coating for Room Temperature Resistive Humidity Monitoring. Coatings 2021, 11, 530. [Google Scholar] [CrossRef]

- Serban, B.-C.; Cobianu, C.; Buiu, O.; Bumbac, M.; Dumbravescu, N.; Avramescu, V.; Nicolescu, C.M.; Brezeanu, M.; Pachiu, C.; Craciun, G.; et al. Ternary Nanocomposites Based on Oxidized Carbon Nanohorns as Sensing Layers for Room Temperature Resistive Humidity Sensing. Materials 2021, 14, 2705. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Cao, Y.; Chen, H.; Fan, B.; Zou, X.; Cheng, J.; Zhang, C. Rapid-Response Humidity Sensors Based on Ultra-Thin Films Stacked with Single-Layer Graphene Oxide. Results Chem. 2024, 7, 101444. [Google Scholar] [CrossRef]

- Trigona, C.; Al-Hamry, A.; Kanoun, O.; Baglio, S. Analysis of a Hybrid Micro-Electro-Mechanical Sensor Based on Graphene Oxide/Polyvinyl Alcohol for Humidity Measurements. Sensors 2019, 19, 1720. [Google Scholar] [CrossRef] [PubMed]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.; Terrones, M.; Dresselhaus, M.S. Ultrahigh Humidity Sensitivity of Graphene Oxide. Sci. Rep. 2013, 3, 2714. [Google Scholar] [CrossRef]

- Li, N.; Chen, X.; Chen, X.; Ding, X.; Zhao, X. Ultrahigh Humidity Sensitivity of Graphene Oxide Combined with Ag Nanoparticles. RSC Adv. 2017, 7, 45988–45996. [Google Scholar] [CrossRef]

- Paterakis, G.; Vaughan, E.; Gawade, D.R.; Murray, R.; Gorgolis, G.; Matsalis, S.; Anagnostopoulos, G.; Buckley, J.L.; O’Flynn, B.; Quinn, A.J.; et al. Highly Sensitive and Ultra-Responsive Humidity Sensors Based on Graphene Oxide Active Layers and High Surface Area Laser-Induced Graphene Electrodes. Nanomaterials 2022, 12, 2684. [Google Scholar] [CrossRef]

- Fei, X.; Huang, J.; Shi, W. Humidity Sensor Composed of Laser-Induced Graphene Electrode and Graphene Oxide for Monitoring Respiration and Skin Moisture. Sensors 2023, 23, 6784. [Google Scholar] [CrossRef]

- Ni, L.; Li, X.; Cai, F.; Dong, Z.; Deng, Y.; Jiang, T.; Su, Z.; Chang, H.; Zhang, Z.; Luo, Y. Printable and Flexible Humidity Sensor Based on Graphene -Oxide-Supported MoTe2 Nanosheets for Multifunctional Applications. Nanomaterials 2023, 13, 1309. [Google Scholar] [CrossRef]

- Priyadharshini, B.; Valsalal, P. An Improved Humidity Sensor with GO-Mn-Doped ZnO Nanocomposite and Dimensional Orchestration of Comb Electrode for Effective Bulk Manufacturing. Nanomaterials 2022, 12, 1659. [Google Scholar] [CrossRef]

- Ganbold, E.; Sharma, P.K.; Kim, E.-S.; Lee, D.-N.; Kim, N.-Y. Capacitive Humidity Sensor with a Rapid Response Time on a GO-Doped P(VDF-TrFE)/LiCl Composite for Noncontact Sensing Applications. Chemosensors 2023, 11, 122. [Google Scholar] [CrossRef]

- Sun, C.; Shi, Q.; Yazici, M.S.; Lee, C.; Liu, Y. Development of a Highly Sensitive Humidity Sensor Based on a Piezoelectric Micromachined Ultrasonic Transducer Array Functionalized with Graphene Oxide Thin Film. Sensors 2018, 18, 4352. [Google Scholar] [CrossRef] [PubMed]

- Yi, R.; Peng, B.; Zhao, Y.; Nie, D.; Chen, L.; Zhang, L. Quartz Crystal Microbalance Humidity Sensors Based on Structured Graphene Oxide Membranes with Magnesium Ions: Design, Mechanism and Performance. Membranes 2022, 12, 125. [Google Scholar] [CrossRef] [PubMed]

- Waheed, W.; Anwer, S.; Khan, M.U.; Sajjad, M.; Alazzam, A. 2D Ti3C2Tx-MXene Nanosheets and Graphene Oxide Based Highly Sensitive Humidity Sensor for Wearable and Flexible Electronics. Chem. Eng. J. 2024, 480, 147981. [Google Scholar] [CrossRef]

- Zeng, S.; Pan, Q.; Huang, Z.; Gu, C.; Wang, T.; Xu, J.; Yan, Z.; Zhao, F.; Li, P.; Tu, Y.; et al. Ultrafast Response of Self-Powered Humidity Sensor of Flexible Graphene Oxide Film. Mater. Des. 2023, 226, 111683. [Google Scholar] [CrossRef]

- Yao, X.; Chen, L.; Luo, Z.; Ye, C.; Liang, F.; Yang, T.; Liu, X.; Tian, X.; Bi, H.; Wang, C.; et al. High-performance Flexible Humidity Sensors for Breath Detection and Non-touch Switches. Nano Sel. 2022, 3, 1168–1177. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, X.; Yao, Y.; Mao, K. Analysis of the Effect of Electrode Materials on the Sensitivity of Quartz Crystal Microbalance. Nanomaterials 2022, 12, 975. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, X.; Chen, Q.; Zhang, Z.; Ling, W. High Sensitivity and High Stability QCM Humidity Sensors Based on Polydopamine Coated Cellulose Nanocrystals/Graphene Oxide Nanocomposite. Nanomaterials 2020, 10, 2210. [Google Scholar] [CrossRef]

- Jiang, B.; Bi, Z.; Hao, Z.; Yuan, Q.; Feng, D.; Zhou, K.; Zhang, L.; Gan, X.; Zhao, J. Graphene Oxide-Deposited Tilted Fiber Grating for Ultrafast Humidity Sensing and Human Breath Monitoring. Sens. Actuators B Chem. 2019, 293, 336–341. [Google Scholar] [CrossRef]

- Syuhada, A.; Shamsudin, M.S.; Daud, S.; Krishnan, G.; Harun, S.W.; Aziz, M.S.A. Single-Mode Modified Tapered Fiber Structure Functionalized With GO-PVA Composite Layer for Relative Humidity Sensing. Photonic Sens. 2021, 11, 314–324. [Google Scholar] [CrossRef]

- Huang, X.; Leng, T.; Georgiou, T.; Abraham, J.; Raveendran Nair, R.; Novoselov, K.S.; Hu, Z. Graphene Oxide Dielectric Permittivity at GHz and Its Applications for Wireless Humidity Sensing. Sci. Rep. 2018, 8, 43. [Google Scholar] [CrossRef]

- Wang, C.; Jiao, C.; Wang, M.; Pan, J.; Wang, Q. GO/CNT−OH/Nafion Nanocomposite Humidity Sensor Based on the LC Wireless Method. Nanomaterials 2023, 13, 1925. [Google Scholar] [CrossRef] [PubMed]

- Alrammouz, R.; Podlecki, J.; Vena, A.; Garcia, R.; Abboud, P.; Habchi, R.; Sorli, B. Highly Porous and Flexible Capacitive Humidity Sensor Based on Self-Assembled Graphene Oxide Sheets on a Paper Substrate. Sens. Actuators B Chem. 2019, 298, 126892. [Google Scholar] [CrossRef]

- Jung, S.I.; Jang, I.R.; Ryu, C.; Park, J.; Padhan, A.M.; Kim, H.J. Graphene Oxide Decorated Multi-Frequency Surface Acoustic Wave Humidity Sensor for Hygienic Applications. Sci. Rep. 2023, 13, 6838. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Huang, J.; Chen, W.; Huang, Q. Fabrication and Characterization of Flexible Capacitive Humidity Sensors Based on Graphene Oxide on Porous PTFE Substrates. Sensors 2021, 21, 5118. [Google Scholar] [CrossRef]

- Wang, X.; Deng, Y.; Chen, X.; Jiang, P.; Cheung, Y.K.; Yu, H. An Ultrafast-Response and Flexible Humidity Sensor for Human Respiration Monitoring and Noncontact Safety Warning. Microsyst. Nanoeng. 2021, 7, 99. [Google Scholar] [CrossRef]

- Ouda, E.; Yousf, N.; Morsy, M.; Duraia, E.-S.M. Flexible Humidity Sensor Based on Light-Scribed Graphene Oxide. J. Mater. Sci. Mater. Electron. 2022, 33, 18241–18251. [Google Scholar] [CrossRef]

- Mohammedture, M.; Al Hashmi, S.; Lu, J.-Y.; Gutierrez, M.; Esawi, A.M.K.; Al Teneiji, M. Numerical Study of a Capacitive Graphene Oxide Humidity Sensor with Etched Configuration. ACS Omega 2021, 6, 29781–29787. [Google Scholar] [CrossRef]

- Yang, Y.; Su, G.; Li, Q.; Zhu, Z.; Liu, S.; Zhuo, B.; Li, X.; Ti, P.; Yuan, Q. Performance of the Highly Sensitive Humidity Sensor Constructed with Nanofibrillated Cellulose/Graphene Oxide/Polydimethylsiloxane Aerogel via Freeze Drying. RSC Adv. 2021, 11, 1543–1552. [Google Scholar] [CrossRef]

- Wang, F.; Wang, B.; Zhang, X.; Lu, M.; Zhang, Y.; Sun, C.; Peng, W. High Sensitivity Humidity Detection Based on Functional GO/MWCNTs Hybrid Nano-Materials Coated Titled Fiber Bragg Grating. Nanomaterials 2021, 11, 1134. [Google Scholar] [CrossRef]

- Khan, M.U.; Abbas, Y.; Abunahla, H.; Rezeq, M.; Alazzam, A.; Alamoodi, N.; Mohammad, B. Biocompatible Humidity Sensor Using Paper Cellulose Fiber/GO Matrix for Human Health and Environment Monitoring. Sens. Actuators B Chem. 2023, 393, 134188. [Google Scholar] [CrossRef]

- Khattak, Z.J.; Sajid, M.; Javed, M.; Zeeshan Rizvi, H.M.; Awan, F.S. Mass-Producible 2D Nanocomposite-Based Temperature-Independent All-Printed Relative Humidity Sensor. ACS Omega 2022, 7, 16605–16615. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Saqib, M.; Rehman, M.M.; Mutee Ur Rehman, H.M.; Rahman, S.A.; Yang, Y.; Kim, S.; Kim, W.-Y. A Full-Range Flexible and Printed Humidity Sensor Based on a Solution-Processed P(VDF-TrFE)/Graphene-Flower Composite. Nanomaterials 2021, 11, 1915. [Google Scholar] [CrossRef] [PubMed]

- Rahman, S.A.; Khan, S.A.; Rehman, M.M.; Kim, W.-Y. Highly Sensitive and Stable Humidity Sensor Based on the Bi-Layered PVA/Graphene Flower Composite Film. Nanomaterials 2022, 12, 1026. [Google Scholar] [CrossRef]

- Saqib, M.; Ali Khan, S.; Mutee Ur Rehman, H.M.; Yang, Y.; Kim, S.; Rehman, M.M.; Young Kim, W. High-Performance Humidity Sensor Based on the Graphene Flower/Zinc Oxide Composite. Nanomaterials 2021, 11, 242. [Google Scholar] [CrossRef]

- Beniwal, A.; Ganguly, P.; Aliyana, A.K.; Khandelwal, G.; Dahiya, R. Screen-Printed Graphene-Carbon Ink Based Disposable Humidity Sensor with Wireless Communication. Sens. Actuators B Chem. 2023, 374, 132731. [Google Scholar] [CrossRef]

- Parthasarathy, P. Graphene/Polypyrrole/Carbon Black Nanocomposite Material Ink-Based Screen-Printed Low-Cost, Flexible Humidity Sensor. Emergent Mater. 2023, 6, 2053–2060. [Google Scholar] [CrossRef]

- Yoshida, A.; Wang, Y.-F.; Tachibana, S.; Hasegawa, A.; Sekine, T.; Takeda, Y.; Hong, J.; Kumaki, D.; Shiba, T.; Tokito, S. Printed, All-Carbon-Based Flexible Humidity Sensor Using a Cellulose Nanofiber/Graphene Nanoplatelet Composite. Carbon Trends 2022, 7, 100166. [Google Scholar] [CrossRef]

- Lim, W.Y.; Goh, C.-H.; Yap, K.Z.; Ramakrishnan, N. One-Step Fabrication of Paper-Based Inkjet-Printed Graphene for Breath Monitor Sensors. Biosensors 2023, 13, 209. [Google Scholar] [CrossRef]

- Wang, H.; Tang, C.; Xu, J. A Highly Sensitive Flexible Humidity Sensor Based on Conductive Tape and a Carboxymethyl Cellulose@graphene Composite. RSC Adv. 2023, 13, 27746–27755. [Google Scholar] [CrossRef]

- Andrić, S.; Tomašević-Ilić, T.; Bošković, M.V.; Sarajlić, M.; Vasiljević-Radović, D.; Smiljanić, M.M.; Spasenović, M. Ultrafast Humidity Sensor Based on Liquid Phase Exfoliated Graphene. Nanotechnology 2021, 32, 025505. [Google Scholar] [CrossRef]

- Lin, W.-D.; Lin, Y.-C.; Wu, R.-J.; Chavali, M. Gr/3D–ZnO Nanocomposites as Humidity Sensors with Enhanced Sensing Response. Polymers 2021, 13, 1623. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Rivera, D.; Rodríguez-Roldán, G.; Mora-Martínez, R.; Suaste-Gómez, E. A Capacitive Humidity Sensor Based on an Electrospun PVDF/Graphene Membrane. Sensors 2017, 17, 1009. [Google Scholar] [CrossRef] [PubMed]

- Phan, D.-T.; Park, I.; Park, A.-R.; Park, C.-M.; Jeon, K.-J. Black P/Graphene Hybrid: A Fast Response Humidity Sensor with Good Reversibility and Stability. Sci. Rep. 2017, 7, 10561. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-U.; Ma, Y.-W.; Jeong, S.-Y.; Shin, B.-S. Direct Fabrication of Ultra-Sensitive Humidity Sensor Based on Hair-Like Laser-Induced Graphene Patterns. Micromachines 2020, 11, 476. [Google Scholar] [CrossRef]

- Lin, W.-D.; Chang, T.-C.; Wu, R.-J. Humidity Sensors Based on High Performance Graphene/Zirconium Dioxide Nanocomposite Material. Sens. Mater. 2018, 30, 1297. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, Y.; Jin, L.; Chen, Z.; Li, Y.; Li, Q.; Cao, M.; Che, Y.; Yang, J.; Yao, J. A Fast Response−Recovery 3D Graphene Foam Humidity Sensor for User Interaction. Sensors 2018, 18, 4337. [Google Scholar] [CrossRef]

- Muñoz, R.; León-Boigues, L.; López-Elvira, E.; Munuera, C.; Vázquez, L.; Mompeán, F.; Martín-Gago, J.Á.; Palacio, I.; García-Hernández, M. Acrylates Polymerization on Covalent Plasma-Assisted Functionalized Graphene: A Route to Synthesize Hybrid Functional Materials. ACS Appl. Mater. Interfaces 2023, 15, 46171–46180. [Google Scholar] [CrossRef]

- Shilpa, M.P.; Chethan, B.; Shetty, S.J.; Murari, M.S.; Waikar, M.R.; Sonkawade, R.G.; Gurumurthy, S.C. Highly Responsive Reduced Graphene Oxide Embedded PVDF Flexible Film-Based Room Temperature Operable Humidity Sensor. Sens. Actuators A Phys. 2024, 366, 115011. [Google Scholar] [CrossRef]

- Yang, H.; Ye, Q.; Zeng, R.; Zhang, J.; Yue, L.; Xu, M.; Qiu, Z.-J.; Wu, D. Stable and Fast-Response Capacitive Humidity Sensors Based on a ZnO Nanopowder/PVP-RGO Multilayer. Sensors 2017, 17, 2415. [Google Scholar] [CrossRef]

- Al-Hamry, A.; Lu, T.; Chen, H.; Adiraju, A.; Nasraoui, S.; Brahem, A.; Bajuk-Bogdanović, D.; Weheabby, S.; Pašti, I.A.; Kanoun, O. Ultra-Sensitive and Fast Humidity Sensors Based on Direct Laser-Scribed Graphene Oxide/Carbon Nanotubes Composites. Nanomaterials 2023, 13, 1473. [Google Scholar] [CrossRef]

- Papamatthaiou, S.; Argyropoulos, D.-P.; Farmakis, F.; Georgoulas, N. Investigation of the H 2 O Sensing Mechanism of DC-Operated Chemiresistors Based on Graphene Oxide and Thermally Reduced Graphene Oxide. IEEE Sens. J. 2019, 19, 7841–7848. [Google Scholar] [CrossRef]

- Lei, C.; Zhang, J.; Liang, T.; Liu, R.; Zhao, Z.; Xiong, J.; Yin, K. Humidity Sensor Based on rGO-SDS Composite Film. Micromachines 2022, 13, 504. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, Y.; Shang, Y.; Umar, A.; Xie, P.; Qi, Q.; Zhou, G. One-Step Fabrication of Pyranine Modified- Reduced Graphene Oxide with Ultrafast and Ultrahigh Humidity Response. Sci. Rep. 2017, 7, 2713. [Google Scholar] [CrossRef]

- Yan, H.; Chen, Z.; Zeng, L.; Wang, Z.; Zheng, G.; Zhou, R. The Effect of rGO-Doping on the Performance of SnO2/rGO Flexible Humidity Sensor. Nanomaterials 2021, 11, 3368. [Google Scholar] [CrossRef]

- Kim, S.J.; Park, H.J.; Yoon, E.S.; Choi, B.G. Preparation of Reduced Graphene Oxide Sheets with Large Surface Area and Porous Structure for High-Sensitivity Humidity Sensor. Chemosensors 2023, 11, 276. [Google Scholar] [CrossRef]

- Du, Y.; Li, X.; Zhao, X.; Wang, N.; Li, D. Fabrication and Humidity Sensing of Reduced Graphene Oxide/Polyaniline Composite Film on Flexible Paper Substrate. Sens. Mater. 2022, 34, 2065. [Google Scholar] [CrossRef]

- Müller, C.; Al-Hamry, A.; Kanoun, O.; Rahaman, M.; Zahn, D.R.T.; Matsubara, E.Y.; Rosolen, J.M. Humidity Sensing Behavior of Endohedral Li-Doped and Undoped SWCNT/SDBS Composite Films. Sensors 2019, 19, 171. [Google Scholar] [CrossRef]

- Turkani, V.S.; Maddipatla, D.; Narakathu, B.B.; Saeed, T.S.; Obare, S.O.; Bazuin, B.J.; Atashbar, M.Z. A Highly Sensitive Printed Humidity Sensor Based on a Functionalized MWCNT/HEC Composite for Flexible Electronics Application. Nanoscale Adv. 2019, 1, 2311–2322. [Google Scholar] [CrossRef]

- Zhu, P.; Kuang, Y.; Wei, Y.; Li, F.; Ou, H.; Jiang, F.; Chen, G. Electrostatic Self-Assembly Enabled Flexible Paper-Based Humidity Sensor with High Sensitivity and Superior Durability. Chem. Eng. J. 2021, 404, 127105. [Google Scholar] [CrossRef]

- Arunachalam, S.; Gupta, A.A.; Izquierdo, R.; Nabki, F. Suspended Carbon Nanotubes for Humidity Sensing. Sensors 2018, 18, 1655. [Google Scholar] [CrossRef]

- Lee, Y.; Yoon, J.; Kim, Y.; Kim, D.M.; Kim, D.H.; Choi, S.-J. Humidity Effects According to the Type of Carbon Nanotubes. IEEE Access 2021, 9, 6810–6816. [Google Scholar] [CrossRef]

- Chaloeipote, G.; Samarnwong, J.; Traiwatcharanon, P.; Kerdcharoen, T.; Wongchoosuk, C. High-Performance Resistive Humidity Sensor Based on Ag Nanoparticles Decorated with Graphene Quantum Dots. R. Soc. Open Sci. 2021, 8, 210407. [Google Scholar] [CrossRef]

- Jlassi, K.; Mallick, S.; Eribi, A.; Chehimi, M.M.; Ahmad, Z.; Touati, F.; Krupa, I. Facile Preparation of N-S Co-Doped Graphene Quantum Dots (GQDs) from Graphite Waste for Efficient Humidity Sensing. Sens. Actuators B Chem. 2021, 328, 129058. [Google Scholar] [CrossRef]

- Morsy, M.; Gomaa, I.; Mokhtar, M.M.; ElHaes, H.; Ibrahim, M. Design and Implementation of Humidity Sensor Based on Carbon Nitride Modified with Graphene Quantum Dots. Sci. Rep. 2023, 13, 2891. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Yin, C.; Zhou, J.; Li, H.; Liu, Y.; Shen, Y.; Garner, S.; Fu, Y.; Duan, H. Ultra-Thin Glass Based Flexible, Transparent and Ultra-Sensitive Surface Acoustic Wave Humidity Sensor with ZnO Nanowires and Graphene Quantum Dots. ACS Appl. Mater. Interfaces 2020, 12, 39817–39825. [Google Scholar] [CrossRef]

- Joshi, S.R.; Kim, B.; Kim, S.-K.; Kim, G.-H.; Song, W.; Park, K.; Shin, H. Low-Cost and Fast-Response Resistive Humidity Sensor Comprising Biopolymer-Derived Carbon Thin Film and Carbon Microelectrodes. J. Electrochem. Soc. 2020, 167, 147511. [Google Scholar] [CrossRef]

- Ling, T.Y.; Pu, S.H.; Fishlock, S.J.; Han, Y.; Reynolds, J.D.; McBride, J.W.; Chong, H.M.H. Sensing Performance of Nanocrystalline Graphite-Based Humidity Sensors. IEEE Sens. J. 2019, 19, 5421–5428. [Google Scholar] [CrossRef]

- Serban, B.C.; Buiu, O.; Dumbravescu, N.; Cobianu, C.; Avramescu, V.; Brezeanu, M.; Bumbac, M.; Nicolescu, C.M. Oxidized Carbon Nanohorns as Novel Sensing Layer for Resistive Humidity Sensor. ACSi 2020, 67, 469–475. [Google Scholar] [CrossRef]

- Saquib, M.; Shiraj, S.; Nayak, R.; Nirmale, A.; Selvakumar, M. Synthesis and Fabrication of Graphite/WO3 Nanocomposite-Based Screen-Printed Flexible Humidity Sensor. J. Electron. Mater. 2023, 52, 4226–4238. [Google Scholar] [CrossRef]

- Koskinen, T.; Juntunen, T.; Tittonen, I. Large-Area Thermal Distribution Sensor Based on Multilayer Graphene Ink. Sensors 2020, 20, 5188. [Google Scholar] [CrossRef]

- Wang, S.; Feng, M.; Wu, S.; Wang, Q.; Zhang, L. Highly Sensitive Temperature Sensor Based on Gain Competition Mechanism Using Graphene Coated Microfiber. IEEE Photonics J. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Pan, J.; Liu, S.; Zhang, H.; Lu, J. A Flexible Temperature Sensor Array with Polyaniline/Graphene–Polyvinyl Butyral Thin Film. Sensors 2019, 19, 4105. [Google Scholar] [CrossRef] [PubMed]

- Landi, G.; Granata, V.; Germano, R.; Pagano, S.; Barone, C. Low-Power and Eco-Friendly Temperature Sensor Based on Gelatin Nanocomposite. Nanomaterials 2022, 12, 2227. [Google Scholar] [CrossRef]

- Landi, G.; Pagano, S.; Granata, V.; Avallone, G.; La Notte, L.; Palma, A.L.; Sdringola, P.; Puglisi, G.; Barone, C. Regeneration and Long-Term Stability of a Low-Power Eco-Friendly Temperature Sensor Based on a Hydrogel Nanocomposite. Nanomaterials 2024, 14, 283. [Google Scholar] [CrossRef]

- Jasmi, F.; Azeman, N.H.; Bakar, A.A.A.; Zan, M.S.D.; Haji Badri, K.; Su’ait, M.S. Ionic Conductive Polyurethane-Graphene Nanocomposite for Performance Enhancement of Optical Fiber Bragg Grating Temperature Sensor. IEEE Access 2018, 6, 47355–47363. [Google Scholar] [CrossRef]

- Štulík, J.; Musil, O.; Josefík, F.; Kadlec, P. Graphene-Based Temperature Sensors–Comparison of the Temperature and Humidity Dependences. Nanomaterials 2022, 12, 1594. [Google Scholar] [CrossRef]

- Gong, X.; Zhang, L.; Huang, Y.; Wang, S.; Pan, G.; Li, L. Directly Writing Flexible Temperature Sensor with Graphene Nanoribbons for Disposable Healthcare Devices. RSC Adv. 2020, 10, 22222–22229. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, R.; Wan, Z.; Wu, Z.; Song, D.; Xiao, X. Laser-Induced Graphene Based Flexible Sensing and Heating for Food Monitoring. ACS Appl. Electron. Mater. 2024, 6, 3597–3609. [Google Scholar] [CrossRef]

- Li, Q.; Bai, R.; Guo, L.; Gao, Y. All Laser Direct Writing Process for Temperature Sensor Based on Graphene and Silver. Front. Optoelectron. 2024, 17, 5. [Google Scholar] [CrossRef]

- Davaji, B.; Cho, H.D.; Malakoutian, M.; Lee, J.-K.; Panin, G.; Kang, T.W.; Lee, C.H. A Patterned Single Layer Graphene Resistance Temperature Sensor. Sci. Rep. 2017, 7, 8811. [Google Scholar] [CrossRef]

- Irfan, M.; Khan, Y.; Rehman, A.U.; Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Plasmonic Refractive Index and Temperature Sensor Based on Graphene and LiNbO3. Sensors 2022, 22, 7790. [Google Scholar] [CrossRef] [PubMed]

- Viti, L.; Riccardi, E.; Beere, H.E.; Ritchie, D.A.; Vitiello, M.S. Real-Time Measure of the Lattice Temperature of a Semiconductor Heterostructure Laser via an On-Chip Integrated Graphene Thermometer. ACS Nano 2023, 17, 6103–6112. [Google Scholar] [CrossRef] [PubMed]

- Lei, S.; Su, N.; Li, M. Thermal-Resistance Effect of Graphene at High Temperatures in Nanoelectromechanical Temperature Sensors. Micromachines 2022, 13, 2078. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Zhou, S.; Mei, L.; Guo, M.; Zhang, H.; Li, Q.; Zhang, S.; Niu, Y.; Zhuang, Y.; Geng, W.; et al. Nanoelectromechanical Temperature Sensor Based on Piezoresistive Properties of Suspended Graphene Film. Nanomaterials 2023, 13, 1103. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Su, N.; Li, M. Improving Consistency and Performance of Graphene-Based Devices via Al Sacrificial Layer. Colloid Interface Sci. Commun. 2023, 56, 100743. [Google Scholar] [CrossRef]

- Pawlak, R.; Lebioda, M.; Rymaszewski, J.; Szymanski, W.; Kolodziejczyk, L.; Kula, P. A Fully Transparent Flexible Sensor for Cryogenic Temperatures Based on High Strength Metallurgical Graphene. Sensors 2016, 17, 51. [Google Scholar] [CrossRef]

- Kun, H.; Bin, L.; Orban, M.; Donghai, Q.; Hongbo, Y. Accurate Flexible Temperature Sensor Based on Laser-Induced Graphene Material. Shock Vib. 2021, 2021, 9938010. [Google Scholar] [CrossRef]

- Fernández Sánchez-Romate, X.X.; Del Bosque García, A.; Sánchez, M.; Ureña, A. Electrical Transport Mechanisms in Graphene Nanoplatelet Doped Polydimethylsiloxane and Application to Ultrasensitive Temperature Sensors. ACS Appl. Mater. Interfaces 2023, 15, 22377–22394. [Google Scholar] [CrossRef]

- Liu, G.; Tan, Q.; Kou, H.; Zhang, L.; Wang, J.; Lv, W.; Dong, H.; Xiong, J. A Flexible Temperature Sensor Based on Reduced Graphene Oxide for Robot Skin Used in Internet of Things. Sensors 2018, 18, 1400. [Google Scholar] [CrossRef]

- Sehrawat, P.; Abid; Islam, S.S.; Mishra, P. Reduced Graphene Oxide Based Temperature Sensor: Extraordinary Performance Governed by Lattice Dynamics Assisted Carrier Transport. Sens. Actuators B Chem. 2018, 258, 424–435. [Google Scholar] [CrossRef]

- Neella, N.; Gaddam, V.; Nayak, M.M.; Dinesh, N.S.; Rajanna, K. Scalable Fabrication of Highly Sensitive Flexible Temperature Sensors Based on Silver Nanoparticles Coated Reduced Graphene Oxide Nanocomposite Thin Films. Sens. Actuators A Phys. 2017, 268, 173–182. [Google Scholar] [CrossRef]

- Barmpakos, D.; Belessi, V.; Schelwald, R.; Kaltsas, G. Evaluation of Inkjet-Printed Reduced and Functionalized Water-Dispersible Graphene Oxide and Graphene on Polymer Substrate—Application to Printed Temperature Sensors. Nanomaterials 2021, 11, 2025. [Google Scholar] [CrossRef] [PubMed]

- Khan, J.; Mariatti, M.; Zubir, S.A.; Rusli, A.; Manaf, A.A.; Khirotdin, R.K. Eco-Friendly Alkali Lignin-Assisted Water-Based Graphene Oxide Ink and Its Application as a Resistive Temperature Sensor. Nanotechnology 2024, 35, 055301. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Han, Y.; Cheng, H.; Xiong, Z.; Luo, B.; Ma, T.; Li, L.; Liu, S.; Chen, X.; Yi, C. Synthesized Silver Nanoparticles Decorated Reduced Graphene Oxide/Silver Ink for Aerosol Jet Printed Conformal Temperature Sensor with a Wide Sensing Range and Excellent Stability. J. Mater. Res. Technol. 2023, 25, 873–886. [Google Scholar] [CrossRef]

- Sehrawat, P.; Abid, A.; Islam, S.S. An Ultrafast Quantum Thermometer from Graphene Quantum Dots. Nanoscale Adv. 2019, 1, 1772–1783. [Google Scholar] [CrossRef]

- Liu, Q.; Tai, H.; Yuan, Z.; Zhou, Y.; Su, Y.; Jiang, Y. A High-Performances Flexible Temperature Sensor Composed of Polyethyleneimine/Reduced Graphene Oxide Bilayer for Real-Time Monitoring. Adv. Mater. Technol. 2019, 4, 1800594. [Google Scholar] [CrossRef]

- Xie, Z.; Li, H.; Mi, H.-Y.; Feng, P.-Y.; Liu, Y.; Jing, X. Freezing-Tolerant, Widely Detectable and Ultra-Sensitive Composite Organohydrogel for Multiple Sensing Applications. J. Mater. Chem. C 2021, 9, 10127–10137. [Google Scholar] [CrossRef]

- Morsy, M.; Darwish, A.G.; Mokhtar, M.M.; Elbashar, Y.; Elzwawy, A. Preparation, Investigation, and Temperature Sensing Application of rGO/SnO2/Co3O4 Composite. J. Mater. Sci. Mater. Electron. 2022, 33, 25419–25433. [Google Scholar] [CrossRef]

- Kumar, A.; Hsieh, P.-Y.; Shaikh, M.O.; Kumar, R.K.R.; Chuang, C.-H. Flexible Temperature Sensor Utilizing MWCNT Doped PEG-PU Copolymer Nanocomposites. Micromachines 2022, 13, 197. [Google Scholar] [CrossRef]

- Tsai, T.-W.; Ni, I.-C.; Wu, C.-I.; Cheng, I.-C.; Chen, J.-Z. Effect of Solution Aging on Temperature Sensitivity of CNT/PEDOT:PSS. ECS J. Solid State Sci. Technol. 2023, 12, 027001. [Google Scholar] [CrossRef]

- Xiao, Y.; Lin, J.; Xiao, J.; Weng, M.; Zhang, W.; Zhou, P.; Luo, Z.; Chen, L. A Multi-Functional Light-Driven Actuator with an Integrated Temperature-Sensing Function Based on a Carbon Nanotube Composite. Nanoscale 2021, 13, 6259–6265. [Google Scholar] [CrossRef] [PubMed]

- Turkani, V.S.; Maddipatla, D.; Narakathu, B.B.; Bazuin, B.J.; Atashbar, M.Z. A Carbon Nanotube Based NTC Thermistor Using Additive Print Manufacturing Processes. Sens. Actuators A Phys. 2018, 279, 1–9. [Google Scholar] [CrossRef]

- Kuzubasoglu, B.A.; Sayar, E.; Bahadir, S.K. Inkjet-Printed CNT/PEDOT:PSS Temperature Sensor on a Textile Substrate for Wearable Intelligent Systems. IEEE Sens. J. 2021, 21, 13090–13097. [Google Scholar] [CrossRef]

- Ben-Shimon, Y.; Ya’akobovitz, A. Flexible and Bio-Compatible Temperature Sensors Based on Carbon Nanotube Composites. Measurement 2021, 172, 108889. [Google Scholar] [CrossRef]

- Song, H.; Zhang, Y.; Cao, J. Sensing Mechanism of an Ionization Gas Temperature Sensor Based on a Carbon Nanotube Film. RSC Adv. 2017, 7, 53265–53269. [Google Scholar] [CrossRef]

- Sarma, S.; Lee, J.H. Developing Efficient Thin Film Temperature Sensors Utilizing Layered Carbon Nanotube Films. Sensors 2018, 18, 3182. [Google Scholar] [CrossRef]

- Yang, H.; Qi, D.; Liu, Z.; Chandran, B.K.; Wang, T.; Yu, J.; Chen, X. Soft Thermal Sensor with Mechanical Adaptability. Adv. Mater. 2016, 28, 9175–9181. [Google Scholar] [CrossRef]

- Leng, X.; Li, W.; Luo, D.; Wang, F. Differential Structure With Graphene Oxide for Both Humidity and Temperature Sensing. IEEE Sens. J. 2017, 17, 4357–4364. [Google Scholar] [CrossRef]

- Cai, C.; Qin, M. High-performance Bulk Silicon Interdigital Capacitive Temperature Sensor Based on Graphene Oxide. Electron. lett. 2013, 49, 488–490. [Google Scholar] [CrossRef]

- Soni, M.; Bhattacharjee, M.; Ntagios, M.; Dahiya, R. Printed Temperature Sensor Based on PEDOT: PSS-Graphene Oxide Composite. IEEE Sens. J. 2020, 20, 7525–7531. [Google Scholar] [CrossRef]

- Zhou, C.; Tang, N.; Zhang, X.; Fang, Y.; Jiang, Y.; Zhang, H.; Duan, X. Simultaneously Optimize the Response Speed and Sensitivity of Low Dimension Conductive Polymers for Epidermal Temperature Sensing Applications. Front. Chem. 2020, 8, 194. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Tong, R.-J.; Chen, M.-Q.; Xia, F. Fluorescence Temperature Sensor Based on GQDs Solution Encapsulated in Hollow Core Fiber. IEEE Photon. Technol. Lett. 2017, 29, 1544–1547. [Google Scholar] [CrossRef]

- Zhang, L.; Lyu, S.; Zhang, Q.; Wu, Y.; Melcher, C.; Chmely, S.C.; Chen, Z.; Wang, S. Dual-Emitting Film with Cellulose Nanocrystal-Assisted Carbon Dots Grafted SrAl2O4, Eu2+, Dy3+ Phosphors for Temperature Sensing. Carbohydr. Polym. 2019, 206, 767–777. [Google Scholar] [CrossRef]

- Zhang, Q.; Liang, X.; Bi, W.; Pang, X.; Zhao, Y. Integrated Amorphous Carbon Film Temperature Sensor with Silicon Accelerometer into MEMS Sensor. Micromachines 2024, 15, 1144. [Google Scholar] [CrossRef]

- Smith, A.D.; Niklaus, F.; Paussa, A.; Schröder, S.; Fischer, A.C.; Sterner, M.; Wagner, S.; Vaziri, S.; Forsberg, F.; Esseni, D.; et al. Piezoresistive Properties of Suspended Graphene Membranes under Uniaxial and Biaxial Strain in Nanoelectromechanical Pressure Sensors. ACS Nano 2016, 10, 9879–9886. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, Z.; Qi, Y.; Li, M. A Novel Crossbeam Structure with Graphene Sensing Element for N/MEMS Mechanical Sensors. Nanomaterials 2022, 12, 2101. [Google Scholar] [CrossRef]

- Kou, H.; Zhang, L.; Tan, Q.; Liu, G.; Dong, H.; Zhang, W.; Xiong, J. Wireless Wide-Range Pressure Sensor Based on Graphene/PDMS Sponge for Tactile Monitoring. Sci. Rep. 2019, 9, 3916. [Google Scholar] [CrossRef]

- Feng, C.; Yi, Z.; Jin, X.; Seraji, S.M.; Dong, Y.; Kong, L.; Salim, N. Solvent Crystallization-Induced Porous Polyurethane/Graphene Composite Foams for Pressure Sensing. Compos. Part B Eng. 2020, 194, 108065. [Google Scholar] [CrossRef]

- Deng, Z.; Gao, C.; Feng, S.; Zhang, H.; Liu, Y.; Zhu, Y.; Wang, J.; Xiang, X.; Xie, H. Highly Compressible, Light-Weight and Robust Nitrogen-Doped Graphene Composite Aerogel for Sensitive Pressure Sensors. Chem. Eng. J. 2023, 471, 144790. [Google Scholar] [CrossRef]

- Du, B.; Chao, Y.; Yang, K.; Li, B.; Luo, R.; Zhou, S.; Li, H. Stretchable and Tough Tannic Acid-Modified Graphene Oxide/Polyvinyl Alcohol Conductive Hydrogels for Strain and Pressure Sensors. AIP Adv. 2022, 12, 095206. [Google Scholar] [CrossRef]

- Wang, A.; Hu, M.; Zhou, L.; Qiang, X. Self-Powered Wearable Pressure Sensors with Enhanced Piezoelectric Properties of Aligned P(VDF-TrFE)/MWCNT Composites for Monitoring Human Physiological and Muscle Motion Signs. Nanomaterials 2018, 8, 1021. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Ran, Y.; Li, X.; Xu, H.; Huang, Q.; Duan, Z.; Yuan, Z.; Jiang, Y.; Tai, H. Amorphous Carbon Derived from Daily Carbon Ink for Wide Detection Range, Low-Cost, Eco-Friendly and Flexible Pressure Sensor. Mater. Chem. Phys. 2024, 321, 129489. [Google Scholar] [CrossRef]

- Guo, D.; Lei, X.; Chen, H.; Yi, L.; Li, Y.; Zhao, Y.; Liu, F.; Cheng, G.J. Highly Flexible and Sensitive Pressure Sensor: Fabrication of Porous PDMS/Graphene Composite via Laser Thermoforming. Adv. Sens. Res. 2024, 3, 2300165. [Google Scholar] [CrossRef]

- Park, S.W.; Das, P.S.; Park, J.Y. Development of Wearable and Flexible Insole Type Capacitive Pressure Sensor for Continuous Gait Signal Analysis. Org. Electron. 2018, 53, 213–220. [Google Scholar] [CrossRef]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the Solubility and Stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Xu, W.; Allen, M.G. Deformable Strain Sensors Based on Patterned MWCNTs/Polydimethylsiloxane Composites. J. Polym. Sci. B Polym. Phys. 2013, 51, 1505–1512. [Google Scholar] [CrossRef]

- Chang, W.-T.; Yang, F.-S. Extended Width in Discontinuously Connected Polymer-Free Carbon Nanotubes Grown between Electrodes. Phys. B Condens. Matter 2015, 459, 24–28. [Google Scholar] [CrossRef]

- Tippo, P.; Maruthappan, M.; Ručman, S.; Jumrus, N.; Kantarak, E.; Sroila, W.; Thongsuwan, W.; Wiranwetchayan, O.; Thongpan, W.; Kumpika, T.; et al. Processing Improvement of Response and Stability of Strain Sensor Based on CNT-bioplastic Composite for Estimation of Elbow Angles. J. Appl. Polym. Sci. 2024, 141, e55892. [Google Scholar] [CrossRef]

- Jing, X.; Ma, Z.; Antwi-Afari, M.F.; Wang, L.; Li, H.; Mi, H.-Y.; Feng, P.-Y.; Liu, Y. Synthesis and Fabrication of Supramolecular Polydimethylsiloxane-Based Nanocomposite Elastomer for Versatile and Intelligent Sensing. Ind. Eng. Chem. Res. 2021, 60, 10419–10430. [Google Scholar] [CrossRef]

- Zhao, S.; Guo, L.; Li, J.; Li, N.; Zhang, G.; Gao, Y.; Li, J.; Cao, D.; Wang, W.; Jin, Y.; et al. Binary Synergistic Sensitivity Strengthening of Bioinspired Hierarchical Architectures Based on Fragmentized Reduced Graphene Oxide Sponge and Silver Nanoparticles for Strain Sensors and Beyond. Small 2017, 13, 1700944. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, P.; Liang, Y.; Zhang, J.; Huang, Y.; Wu, S.; Kuo, S.-W.; Chen, T. Network Cracks-Based Wearable Strain Sensors for Subtle and Large Strain Detection of Human Motions. J. Mater. Chem. C 2018, 6, 5140–5147. [Google Scholar] [CrossRef]

- Chen, C.; Chu, F.; Zhang, Y.; Ma, M.; Sun, R.; Jia, P.; Sun, J. Fabricating Flexible Strain Sensor with Direct Writing Graphene/Carbon Nanotube Aerogel. ACS Appl. Electron. Mater. 2023, 5, 1429–1436. [Google Scholar] [CrossRef]

- Yao, Y.; Tai, H.; Wang, D.; Jiang, Y.; Yuan, Z.; Zheng, Y. One-Pot Preparation and Applications of Self-Healing, Self-Adhesive PAA-PDMS Elastomers. J. Semicond. 2019, 40, 112602. [Google Scholar] [CrossRef]