Physical and Numerical Investigation of Hot Deformation Behavior in Medium-Mn Steel for Automotive Forgings

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

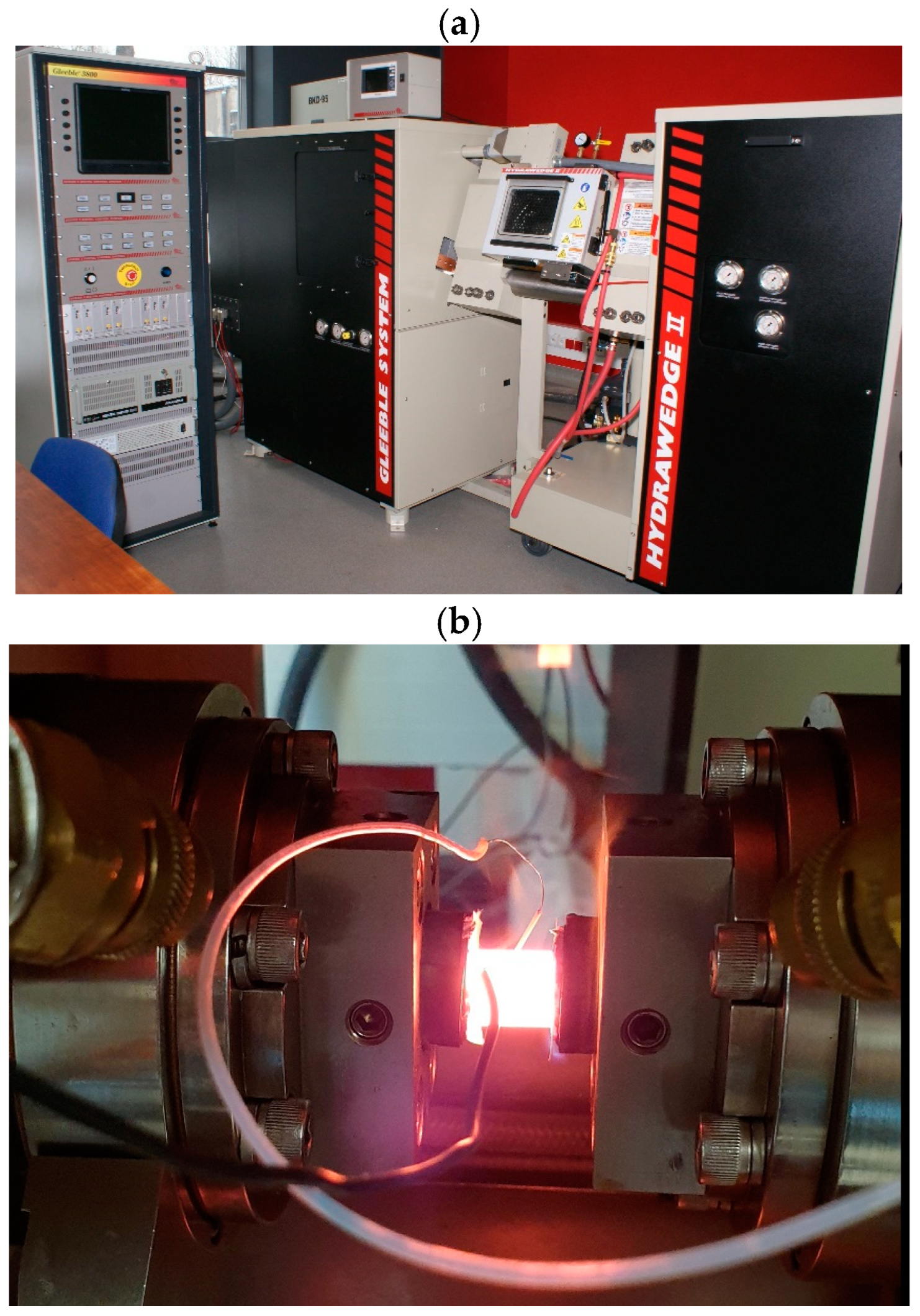

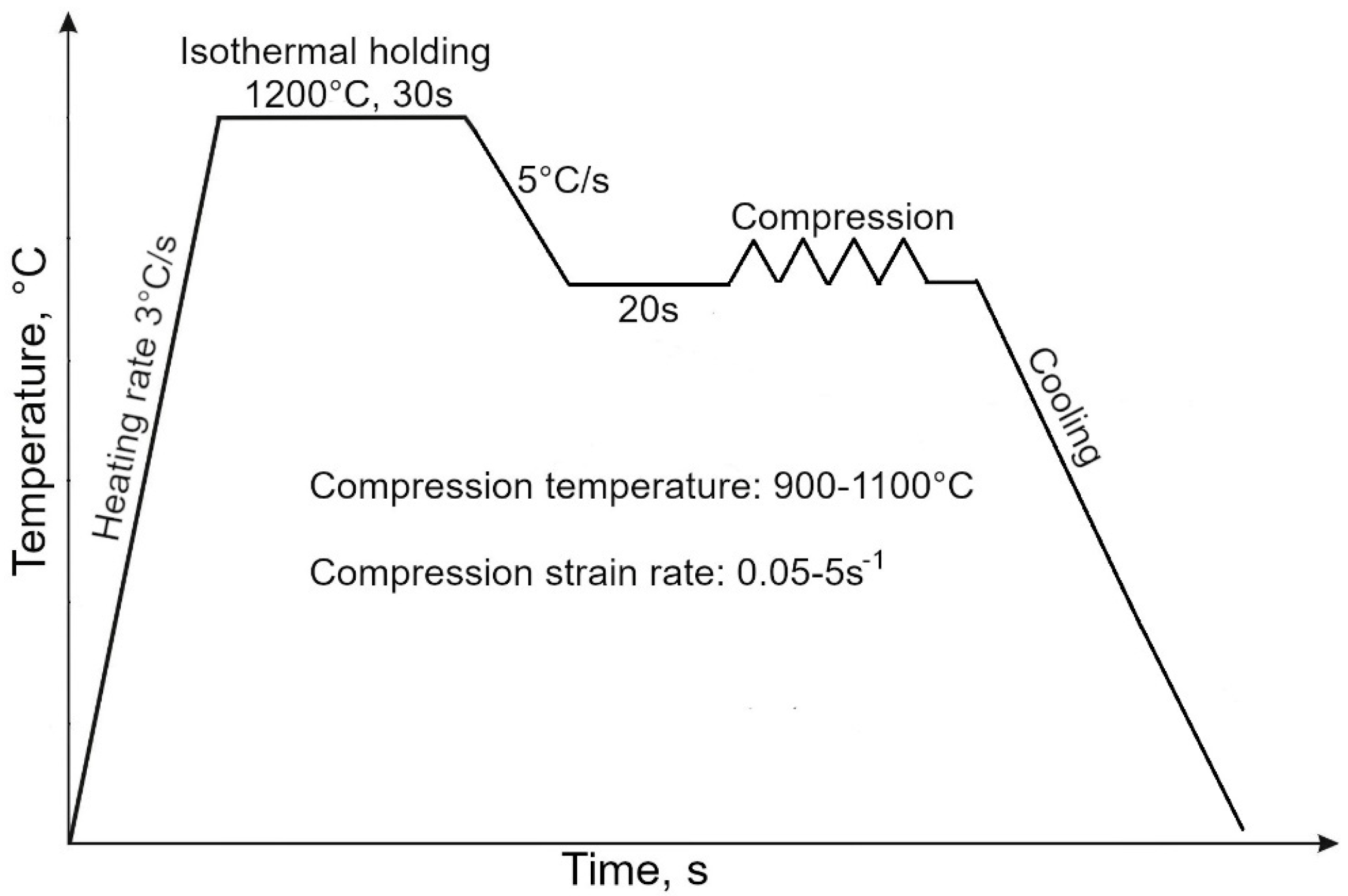

2.2. Gleeble Thermomechanical Simulations

2.3. Numerical Investigations

2.4. Hardness Measurements

2.5. Microstructure Observations

3. Results and Discussion

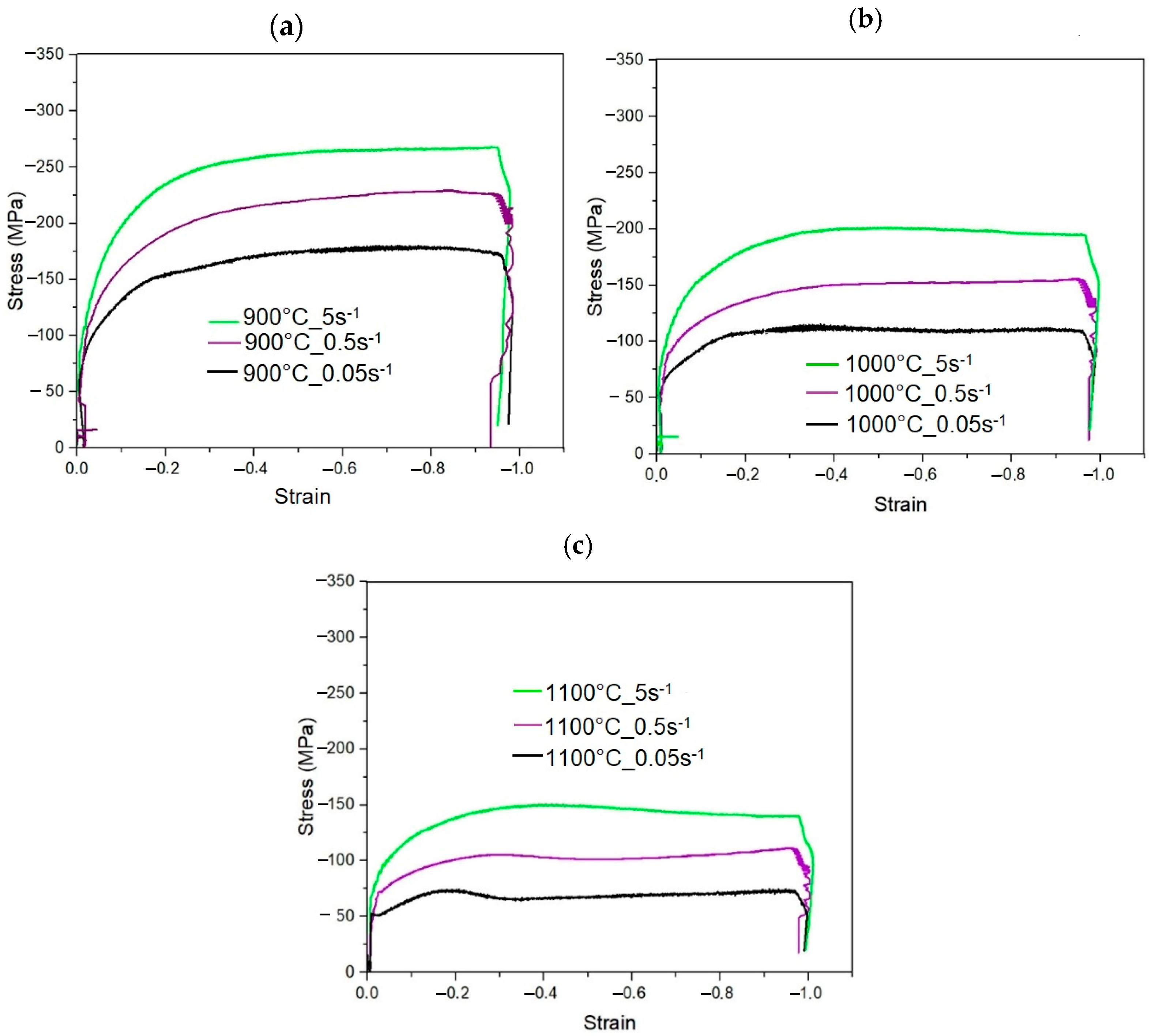

3.1. Flow Behavior Analysis

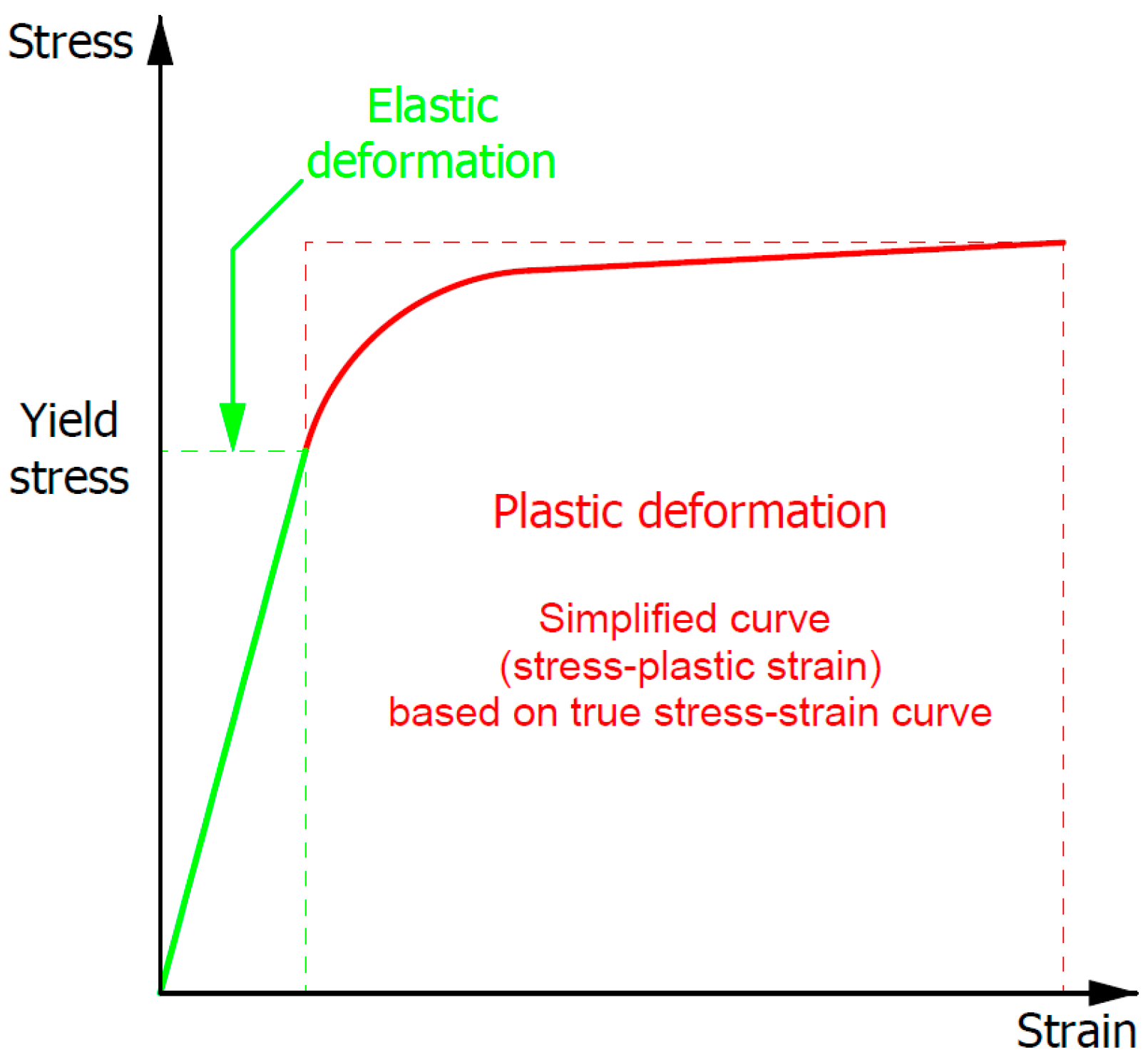

3.2. Identification of Material Model Parameters

3.3. FEM Numerical Analysis

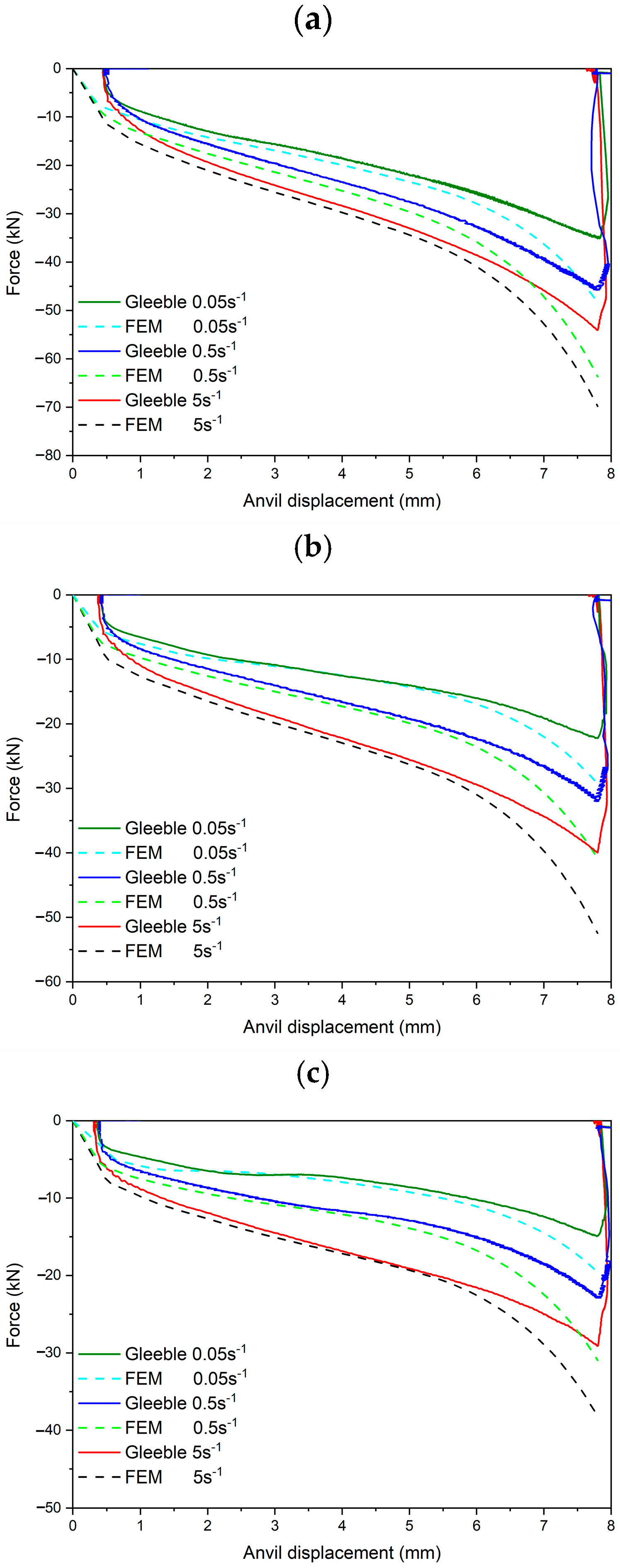

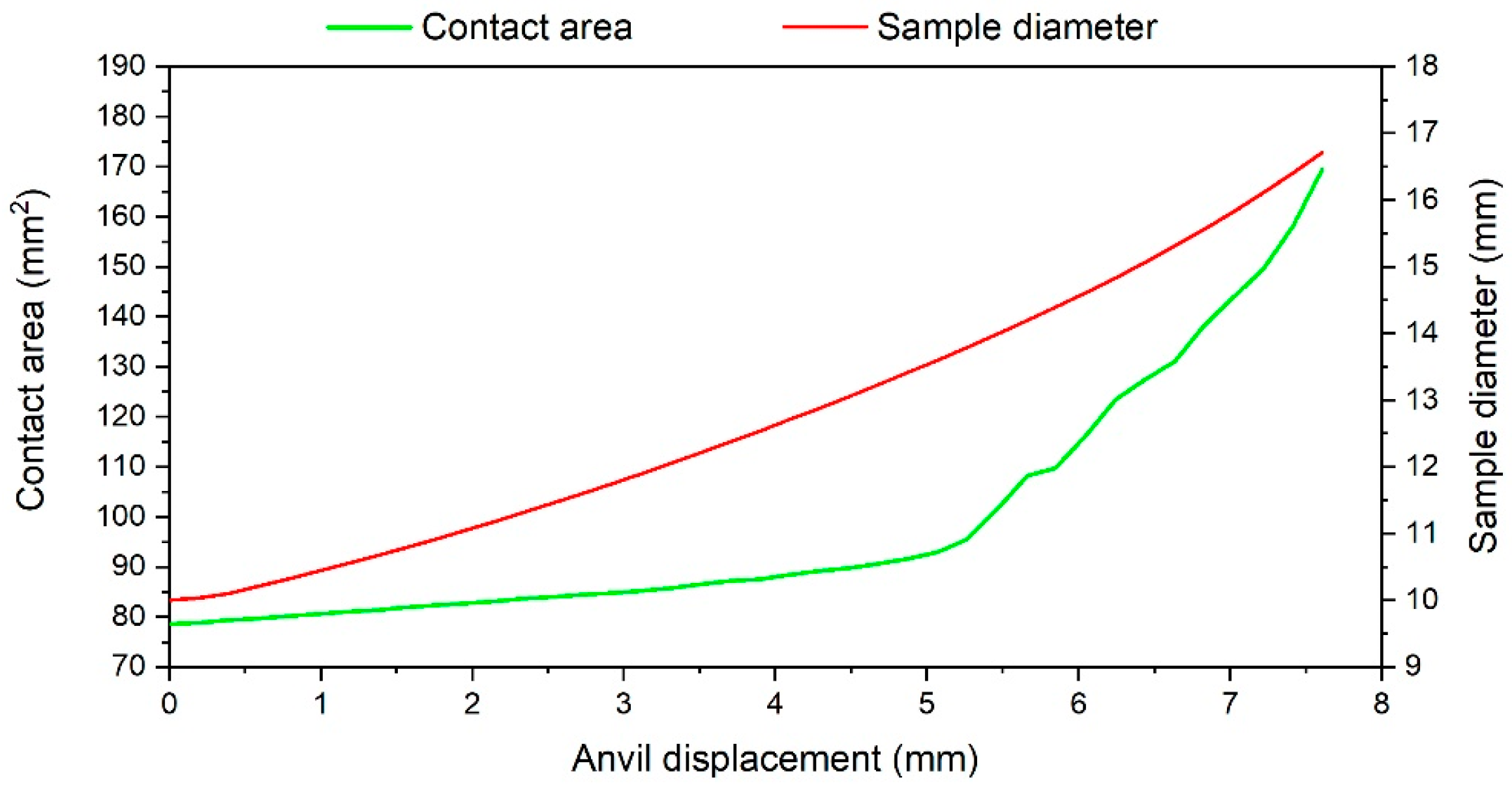

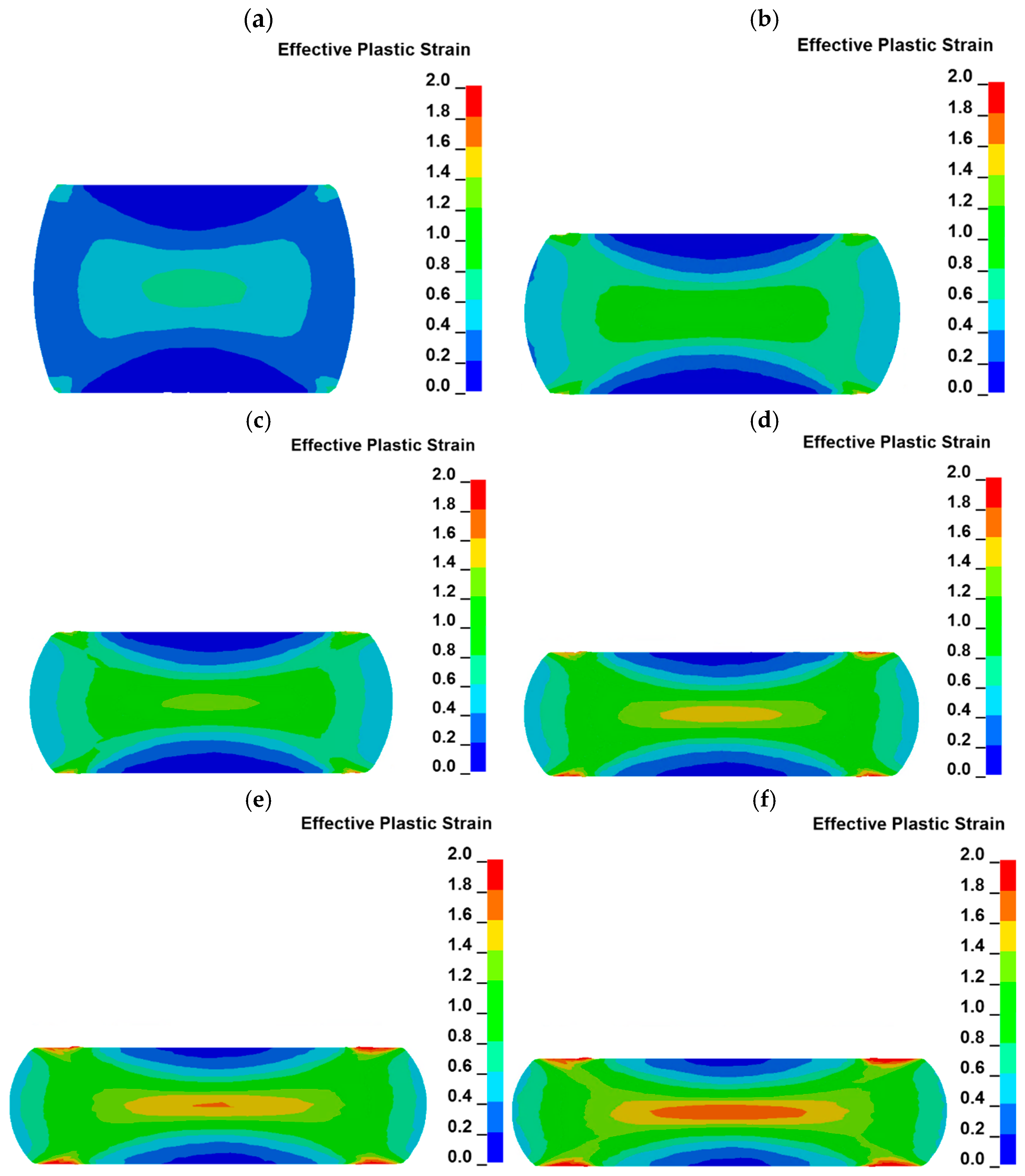

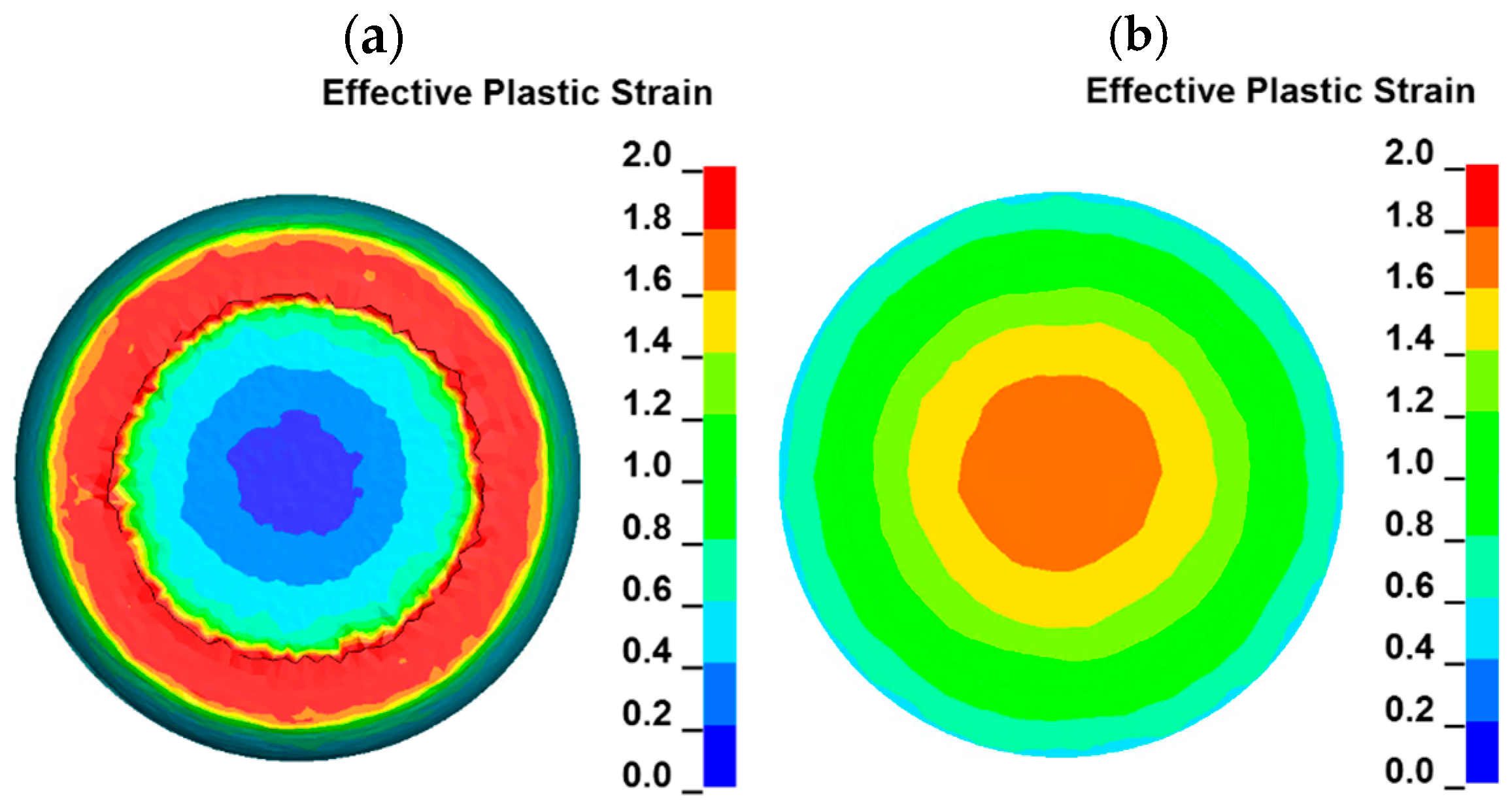

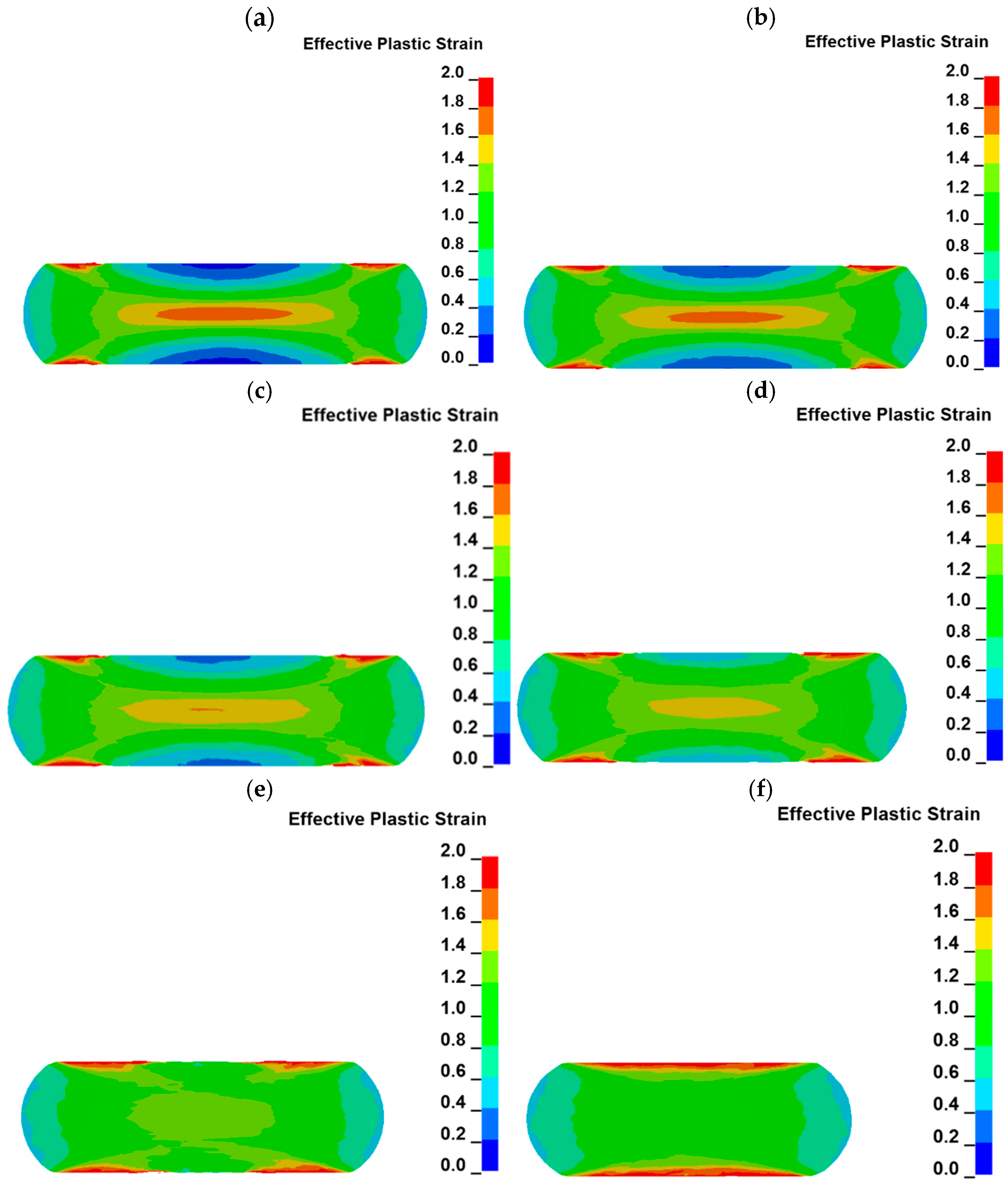

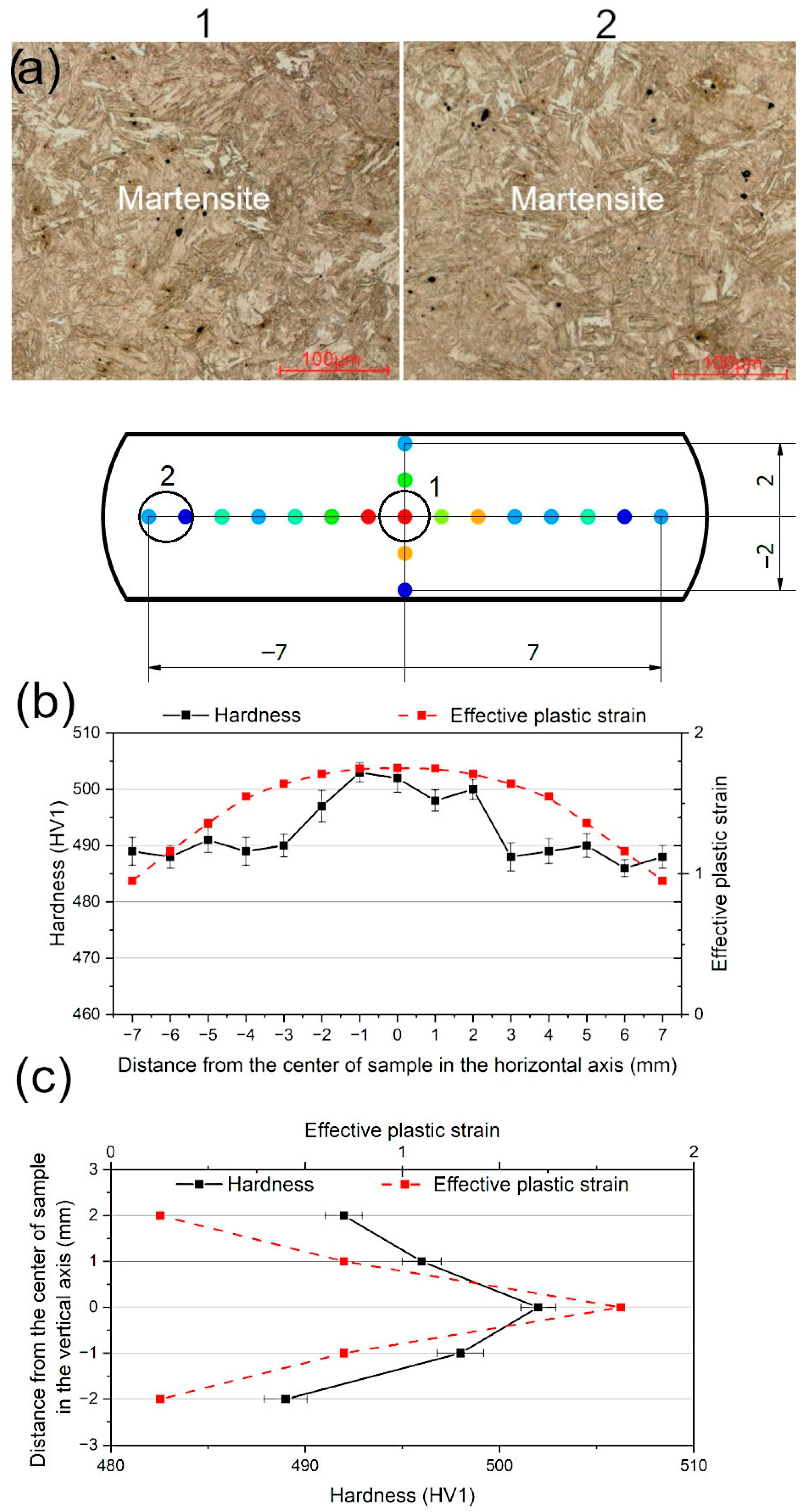

3.4. Hardness Measurements and Microstructure Observations

4. Conclusions

- The hot flow behavior of the investigated steel depends on the deformation temperature and strain rate. The stress values decrease with increasing deformation temperature and decreasing strain rate due to the enhanced intensity of dynamic recovery. The dynamic recrystallization controls the hot working behavior only at 1100 °C. The Young’s modulus and yield stress highly depend on the test temperature and strain rate. With the strain rate increase, the Young’s modulus and yield stress also increase. The opposite dependency occurs for temperature changes. At 1100 °C, the changes in the Young’s modulus depend on the strain rate to a greater extent than at lower temperatures. At the lowest analyzed temperature of 900 °C, the Young’s modulus increases about 13%, and at 1100 °C it increases about 96%, with an increasing strain rate from 0.05 to 5 s−1.

- Plastic strain distribution maps provide a lot of valuable information on the changes occurring in the sample volume during the uniaxial compression. The highest plastic strain (ca. 1.8–2.3) is observed in small areas located at the edges of the sample, which are under frictional contact with anvils. Another area of the sample volume characterized by high plastic strain (ca. 1.65–1.75) is located in the geometrical center of the sample. The lowest plastic strain in a range of ca. 0.1–0.2 can be observed in the areas which are located on the axis of the sample and have contact with the anvils. Thus, the plastic strain distribution in the sample cross section is similar to the letter “X”.

- Results of the FEM analysis show good compatibility with the experimental results. The rapid increase in hardness was measured at the distance of 3 mm from the sample axis, which corresponds to the highest strain ranges identified in the strain distribution maps. The highest hardness values in a range from 500 HV1 to 503 HV1 were noted in the zones experiencing the true strain in a range of 1.65–1.75. Regardless of the microstructure observation zone, the samples show fully martensitic microstructure due to high hardenability provided by the increased Mn addition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bilbao, O.; Loizaga, I.; Alonso, J.; Girot, F.; Torregaray, A. 42CrMo4 Steel Flow Behavior Characterization for High Temperature Closed Dies Hot Forging in Automotive Components Applications. Heliyon 2023, 9, e22256. [Google Scholar] [CrossRef]

- Shi, C.; Dietrich, S.; Schulze, V. Parameter Optimization and Mechanical Properties of 42CrMo4 Manufactured by Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2022, 121, 1899–1913. [Google Scholar] [CrossRef]

- Papuga, J.; Mzourek, M.; Matusu, M.; Mara, V.; Capek, J. Investigation of the Size Effect on 42CrMo4 + QT Steel in the High-cycle Fatigue Domain Part I: Experimental Campaign. Int. J. Fatigue 2023, 175, 107743. [Google Scholar] [CrossRef]

- Sugimoto, K.; Hojo, T.; Srivastava, A.K. Low and Medium Carbon Advanced High-Strength Forging Steels for Automotive Applications. Metals 2019, 9, 1263. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Hawryluk, M. The Main Aspects of Precision Forging. Arch. Civ. Mech. Eng. 2008, 7, 39–57. [Google Scholar] [CrossRef]

- Gramlich, A.; Emmrich, R.; Bleck, W. Austenite Reversion Tempering-Annealing of 4 wt.% Manganese Steels for Automotive Forging Application. Metals 2019, 9, 575. [Google Scholar] [CrossRef]

- Hawryluk, M.; Gronostajski, Z.; Zwierzchowski, M.; Jabłoński, P.; Barełkowski, A.; Krawczyk, J.; Jaśkiewicz, K.; Rychlik, M. Application of a Prototype Thermoplastic Treatment Line in Order to Design a Thermal Treatment Proces of Forgings With the Use of the Heat From the Forging Process. Materials 2020, 13, 2441. [Google Scholar] [CrossRef]

- Bleck, W.; Allam, T.; Gramlich, A. Alloying and Processing of Medium Manganese Steels for Forging Applications. BHM Berg Hüttenmännische Monatshefte 2022, 167, 534–537. [Google Scholar] [CrossRef]

- Tao, R.; Zeng, Q.; Chai, X.S.; Yuan, L.J.; Wen, P.C.; Li, D. The Relationship Between Austenite Morphology and Continuous TRIP Effects in Forged 4Mn Steel. Mater. Charact. 2022, 191, 112172. [Google Scholar] [CrossRef]

- Yadav, M.Y.; Kumar, D.; Kumar, N.; Bandyopadhyay, T.K. Hot-Rolled Al-added Medium Mn Steel (Fe-8Mn-2.85Al-1Si-0.2C): Microstructural Evolution and Tensile Behavior. Materialia 2023, 29, 101790. [Google Scholar] [CrossRef]

- Wu, H.; Guo, H.; Hu, B.; Enomoto, M.; Shang, C. Ultra-high Strength Attributed to Retardation of Recrystallization During Intercritical Annealing in Cold-rolled (V,Nb) Microalloyed 5Mn Steel. Mater. Sci. Eng. A 2020, 794, 139789. [Google Scholar] [CrossRef]

- Mishra, G.; Chandan, A.K.; Kundu, S. Hot Rolled and Cold Rolled Medium Manganese Steel: Mechanical Properties and Microstructure. Mater. Sci. Eng. A 2017, 701, 319–327. [Google Scholar] [CrossRef]

- Sugimoto, K.; Sato, S.; Arai, G. The Effects of Hot-forging on Mechanical Properties of Ultra High-strength TRIP-aided Steels. In Proceedings of the International Steel Technologies Symposium, Kaohsiung, Taiwan, 18–20 December 2008; pp. 1–9. [Google Scholar]

- Luo, P.; Hu, C.; Wang, Q.; Wang, B.; Zhang, J.; Zhong, L. Microstructure Simulation and Experiment Investigation of Dynamic Recrystallization for Ultra High Strength Steel During Hot Forging. J. Mater. Res. Technol. 2023, 26, 4310–4328. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhang, J. Modeling of Flow Stress of 42CrMo Steel Under Hot Compression. Mater. Sci. Eng. A 2009, 499, 88–92. [Google Scholar] [CrossRef]

- Ji, H.; Duan, H.; Li, Y.; Li, W.; Huang, X.; Pei, W.; Lu, Y. Optimization the Working Parameters of as-Forged 42CrMo Steel by Constitutive Equation-Dynamic Recrystallization Equation and Processing Maps. J. Mater. Res. Technol. 2020, 9, 7210–7224. [Google Scholar] [CrossRef]

- Grajcar, A.; Kuziak, R. Softening Kinetics in Nb-Microalloyed TRIP Steels with Increased Mn Content. Adv. Mat. Res. 2011, 314–316, 119–122. [Google Scholar] [CrossRef]

- Sun, X.; Wang, B.; Duan, Y.; Liu, Q.; Xu, X.; Wang, S.; Yang, X.; Feng, X. Kinetics and Microstructure Evolution of Dynamic Recrystallization of Medium-Mn Steel During Hot Working. J. Mater. Res. Technol. 2023, 23, 5631–5643. [Google Scholar] [CrossRef]

- Hawryluk, M.R.; Rychlik, M.; Polak, S.; Zwierzchowski, M.; Dudkiewicz, Ł.; Marzec, J.; Jabłoński, P. Analysis and Improvement of an Industrial Process of Hot Die Forging of an Elongated Forging Tipped with a Joggle with the Use of Numerical Simulation Results. Adv. Sci. Technol. Res. J. 2023, 17, 192–205. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhang, Y.; Zhuang, X.; Cao, Z.; Lu, Y.; Zhao, Z. Numerical Modeling and Anvil Design of High-Speed Forging Process for Railway Axles. Int. J. Mater. Form. 2021, 14, 813–832. [Google Scholar] [CrossRef]

- Baranowski, P.; Małachowski, J.; Mazurkiewicz, Ł. Local Blast Wave Interaction with Tire Structure. Def. Technol. 2020, 16, 520–529. [Google Scholar] [CrossRef]

- Fras, T.; Roth, C.C.; Mohr, D. Application of Two Fracture Models in Impact Simulations. Bull. Polish Acad. Sci. Tech. Sci. 2020, 68, 317–325. [Google Scholar] [CrossRef]

- Czapla, T.; Pawlak, M. Simulation of the Wheel-Surface Interaction Dynamics for all-Terrain Vehicles. Appl. Mech. 2022, 3, 360–374. [Google Scholar] [CrossRef]

- Zochowski, P.; Bajkowski, M.; Grygoruk, R.; Magier, M.; Burian, W.; Pyka, D.; Bocian, M.; Jamroziak, K. Finite Element Modeling of Ballistic Inserts Containing Aramid Fabrics Under Projectile Impact Conditions–Comparison of Methods. Compos. Struct. 2022, 294, 115752. [Google Scholar] [CrossRef]

- Kaczmarczyk, J. Modelling of the Guillotine Cutting Process by Means of a Symmetrical Blade with the Defined Geometry. Materials 2020, 13, 5404. [Google Scholar] [CrossRef]

- Kosiuczenko, K.; Simiński, P.; Gmitrzuk, M.; Nowakowski, M. Experimental and Numerical Validation of an Armor Plate Test Stand. Adv. Mil. Technol. 2024, 19, 55–69. [Google Scholar] [CrossRef]

- Sławski, S.; Kaczmarczyk, J.; Szymiczek, M.; Pakieła, W. Numerical Studies on the Influence of a Reinforcing Material on the Energy Absorption in a Multilayered Composite During Impacts. Mech. Compos. Mater. 2021, 57, 309–320. [Google Scholar] [CrossRef]

- Kaczmarczyk, J.; Kozłowska, A.; Grajcar, A.; Sławski, S. Modelling and Microstructural Aspects of Ultra-Thin Sheet Metal Bundle Cutting. Metals 2019, 9, 162. [Google Scholar] [CrossRef]

- Sheth, D.; Das, S.; Chatterjee, A.; Bhattacharya, A. Modeling of Closed-Die Forging for Estimating Forging Load. J. Inst. Eng. Ser. C 2017, 98, 53–61. [Google Scholar] [CrossRef]

- Kim, Y.B.; Kim, J. Numerical Study on Electromagnetic Hydraulic Forming Process to Overcome Limitations of Electromagnetic Forming Process. Materials 2024, 17, 1586. [Google Scholar] [CrossRef]

- Borkowski, L.; Anahid, M.; Staroselsky, A.; Hu, W. Microstructure-Sensitive Large-Deformation Model for Thermomechanical Processing Simulations. Int. J. Solids Struct. 2021, 230–231, 111161. [Google Scholar] [CrossRef]

- Kostić, N.; Ranđelović, S.; Stanković, S. FEM Analysis of the Stress Strain Rate During Hot Forging of Steel Non-rotational Form. Adv. Technol. Mater. 2022, 47, 27–31. [Google Scholar] [CrossRef]

- Opiela, M.; Grajcar, A. Hot Deformation Behavior and Softening Kinetics of Ti-V-B Microalloyed Steels. Arch. Civ. Mech. Eng. 2012, 12, 327–333. [Google Scholar] [CrossRef]

- Opiela, M.; Grajcar, A. Elaboration of Forging Conditions on the Basis of the Precipitation Analysis of MX-Type Phases in Microalloyed Steels. Arch. Civ. Mech. Eng. 2012, 12, 427–435. [Google Scholar] [CrossRef]

- Abid, N.H.; Abu Al-Ruba, R.K.; Palazotto, N.A. Micromechanical Finite Element Analysis of the Effects of Martensite Morphology on the Overall Mechanical Behavior of Dual Phase Steel. Int. J. Solids Struct. 2017, 104–105, 8–24. [Google Scholar] [CrossRef]

- Grajcar, A.; Skrzypczyk, P.; Kuziak, R.; Gołombek, K. Effect of finishing hot-working temperature on microstructure of thermomechanically processed Mn-Al multiphase steels. Steel Res. Int. 2014, 85, 1058–1069. [Google Scholar] [CrossRef]

- Tavaei, K.; Meysami, A. Effects of V-Ti on dynamic recrystallization behavior and hot deformation activation energy of 30MSV6 micro-alloyed steel. Arch. Metall. Mater. 2019, 64, 1195–1200. [Google Scholar] [CrossRef]

- Skolly, R.M.; Poliak, E.I. Aspects of Production Hot Rolling of Nb Microalloyed High Al High Strength Steels. Mater. Sci. Forum 2005, 500–501, 187–194. [Google Scholar] [CrossRef]

- Delannay, L.; Doghri, I.; Pierard, O. Prediction of Tension–Compression Cycles in Multiphase Steel Using a Modified Incremental Mean-Field Model. Int. J. Solids Struct. 2007, 44, 7291–7306. [Google Scholar] [CrossRef]

- Asuero, A.G.; Sayago, A.; González, A.G. The Correlation Coefficient: An Overview. Crit. Rev. Anal. Chem. 2006, 36, 41–59. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Hu, L.; Jiang, S.; Zhou, T.; Tu, J.; Shi, L.; Chen, Q.; Yang, M. Multiscale Modeling of Polycrystalline NiTi Shape Memory Alloy Under Various Plastic Deformation Conditions by Coupling Microstructure Evolution and Macroscopic Mechanical Response. Materials 2017, 10, 1172. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhao, Y.; Liu, J. A modified kinetics model and softening behavior for static recrystallization of 12Cr ultra-super-critical rotor steel. Mater. Res. Express 2020, 7, 056507. [Google Scholar] [CrossRef]

- Pop, M.F.; Neag, A.V.; Sas-Boca, I.M. Experimental and Numerical Study on the Influence of Lubrication Conditions on AA6068 Aluminum Alloy Cold Deformation Behavior. Materials 2023, 16, 2045. [Google Scholar] [CrossRef] [PubMed]

- Kozłowska, A.; Skowronek, A.; Grzegorczyk, B.; Grajcar, A. Thermodynamic approach for designing processing routes of 4 Mn Quenching and Partitioning steel. J. Therm. Anal. Calorim. 2024. [Google Scholar] [CrossRef]

| Temperature [°C] | 900 | 1000 | 1100 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Strain rate [s−1] | 0.05 | 0.5 | 5 | 0.05 | 0.5 | 5 | 0.05 | 0.5 | 5 |

| Young’s modulus [GPa] | 3.0 | 3.2 | 3.4 | 2.0 | 2.7 | 2.9 | 1.15 | 2.0 | 2.25 |

| Yield stress [MPa] | 82 | 115 | 140 | 67 | 91 | 122 | 63 | 72 | 97 |

| Temperature [°C] | 900 | 1000 | 1100 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Strain rate [s−1] | 0.05 | 0.5 | 5 | 0.05 | 0.5 | 5 | 0.05 | 0.5 | 5 |

| Pressing force error [%] | 7.4 | 8.5 | 5.2 | 1.8 | 5.3 | 4.0 | 5.7 | 6.2 | 8.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozłowska, A.; Sławski, S.; Borek, W.; Grajcar, A. Physical and Numerical Investigation of Hot Deformation Behavior in Medium-Mn Steel for Automotive Forgings. Materials 2025, 18, 1883. https://doi.org/10.3390/ma18081883

Kozłowska A, Sławski S, Borek W, Grajcar A. Physical and Numerical Investigation of Hot Deformation Behavior in Medium-Mn Steel for Automotive Forgings. Materials. 2025; 18(8):1883. https://doi.org/10.3390/ma18081883

Chicago/Turabian StyleKozłowska, Aleksandra, Sebastian Sławski, Wojciech Borek, and Adam Grajcar. 2025. "Physical and Numerical Investigation of Hot Deformation Behavior in Medium-Mn Steel for Automotive Forgings" Materials 18, no. 8: 1883. https://doi.org/10.3390/ma18081883

APA StyleKozłowska, A., Sławski, S., Borek, W., & Grajcar, A. (2025). Physical and Numerical Investigation of Hot Deformation Behavior in Medium-Mn Steel for Automotive Forgings. Materials, 18(8), 1883. https://doi.org/10.3390/ma18081883