Enhanced Energy Storage Properties of the Relaxor and Antiferroelectric Crossover Ceramic Enabled by a High Entropy Design

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solid-State Synthesis

2.2. Characterization

3. Results and Discussion

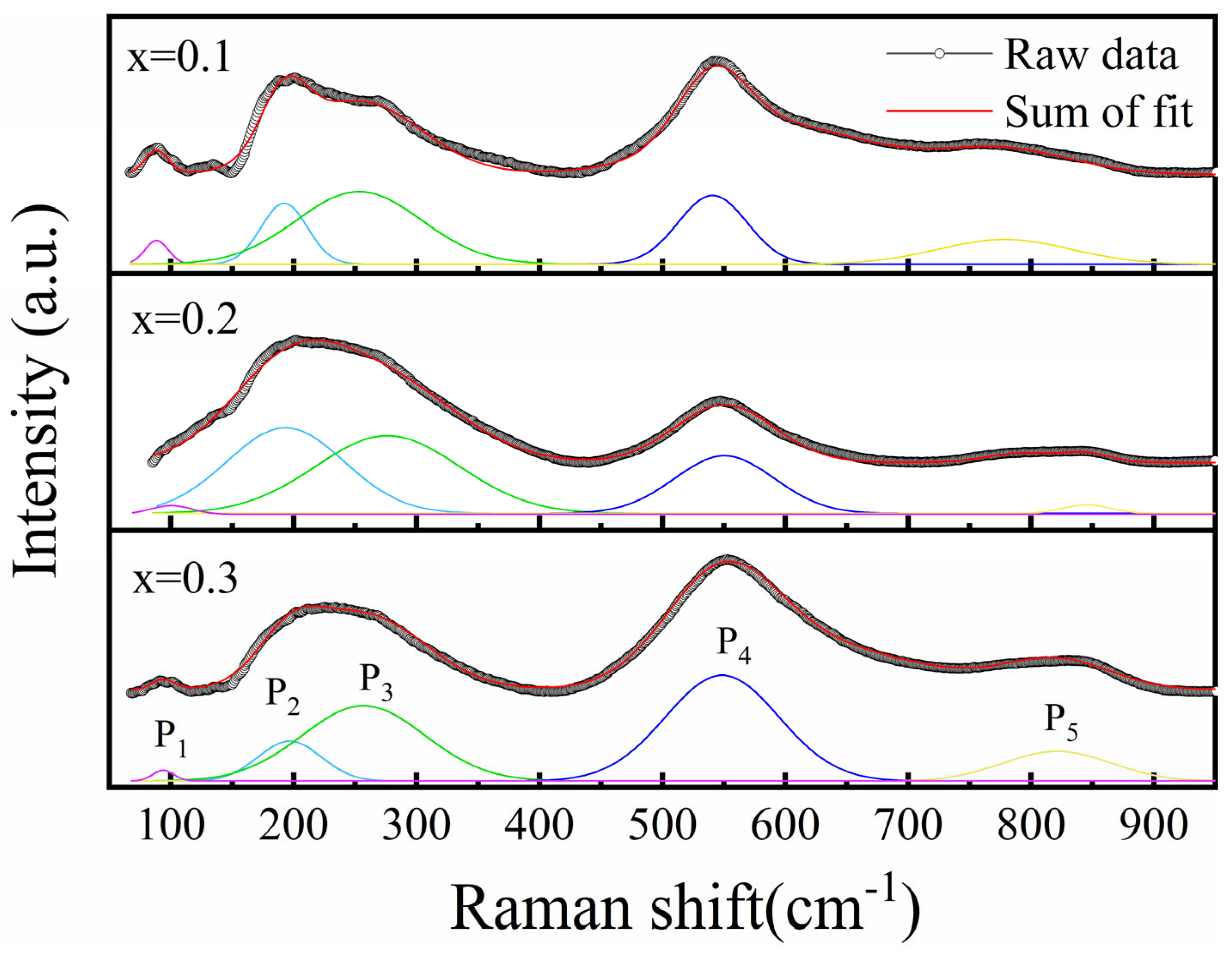

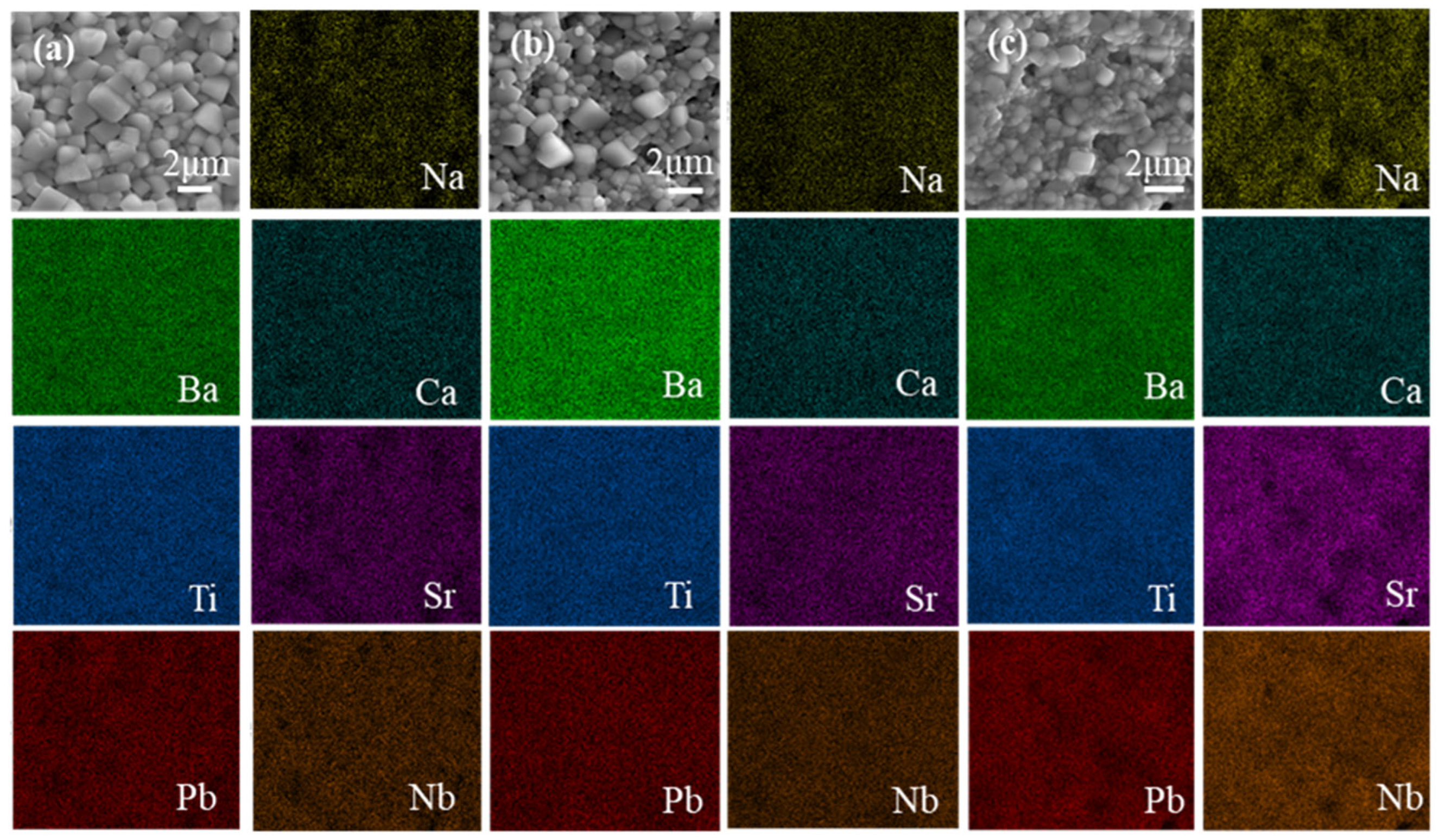

3.1. Phase Composition and Microstructure

3.2. Dielectric Properties

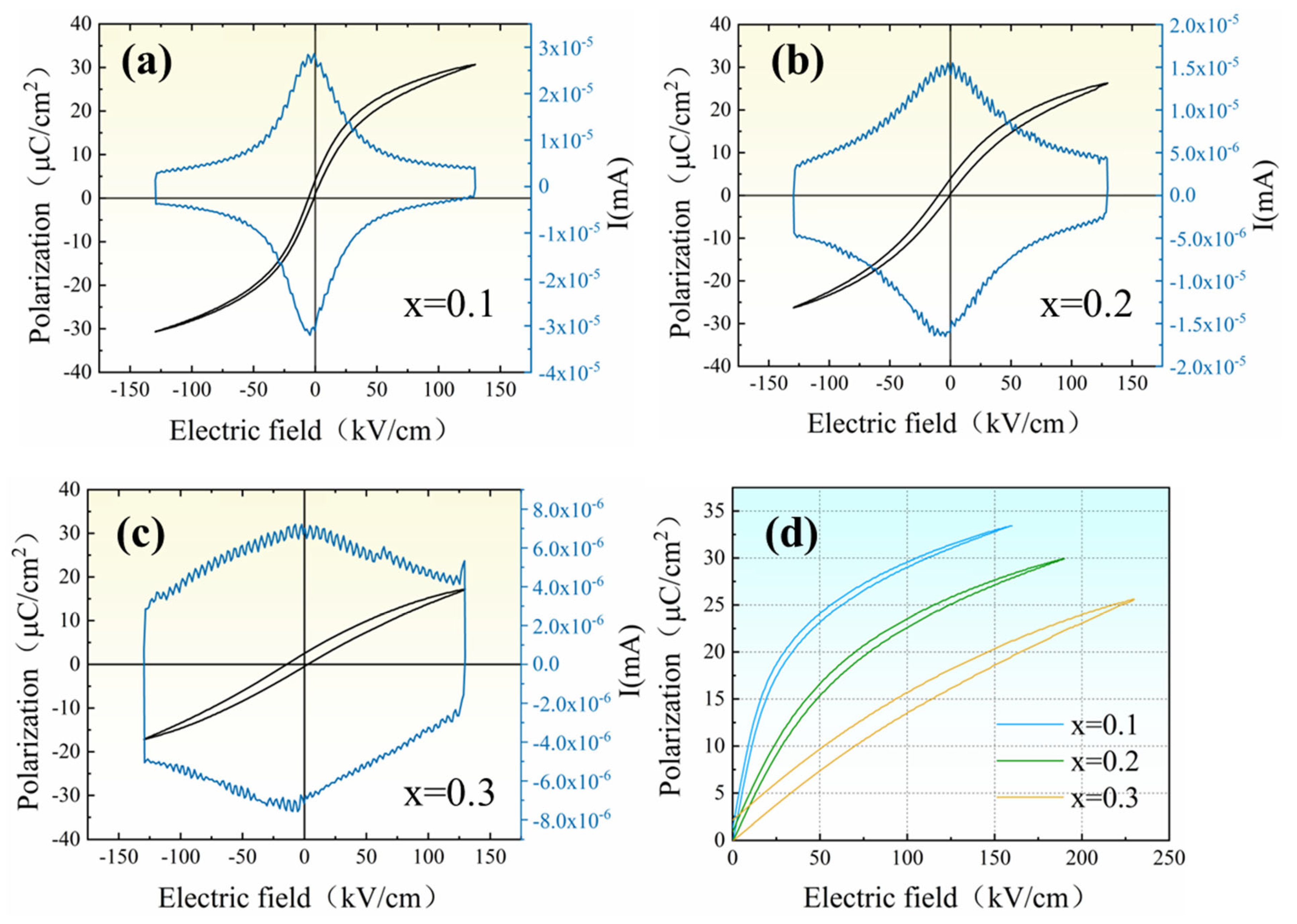

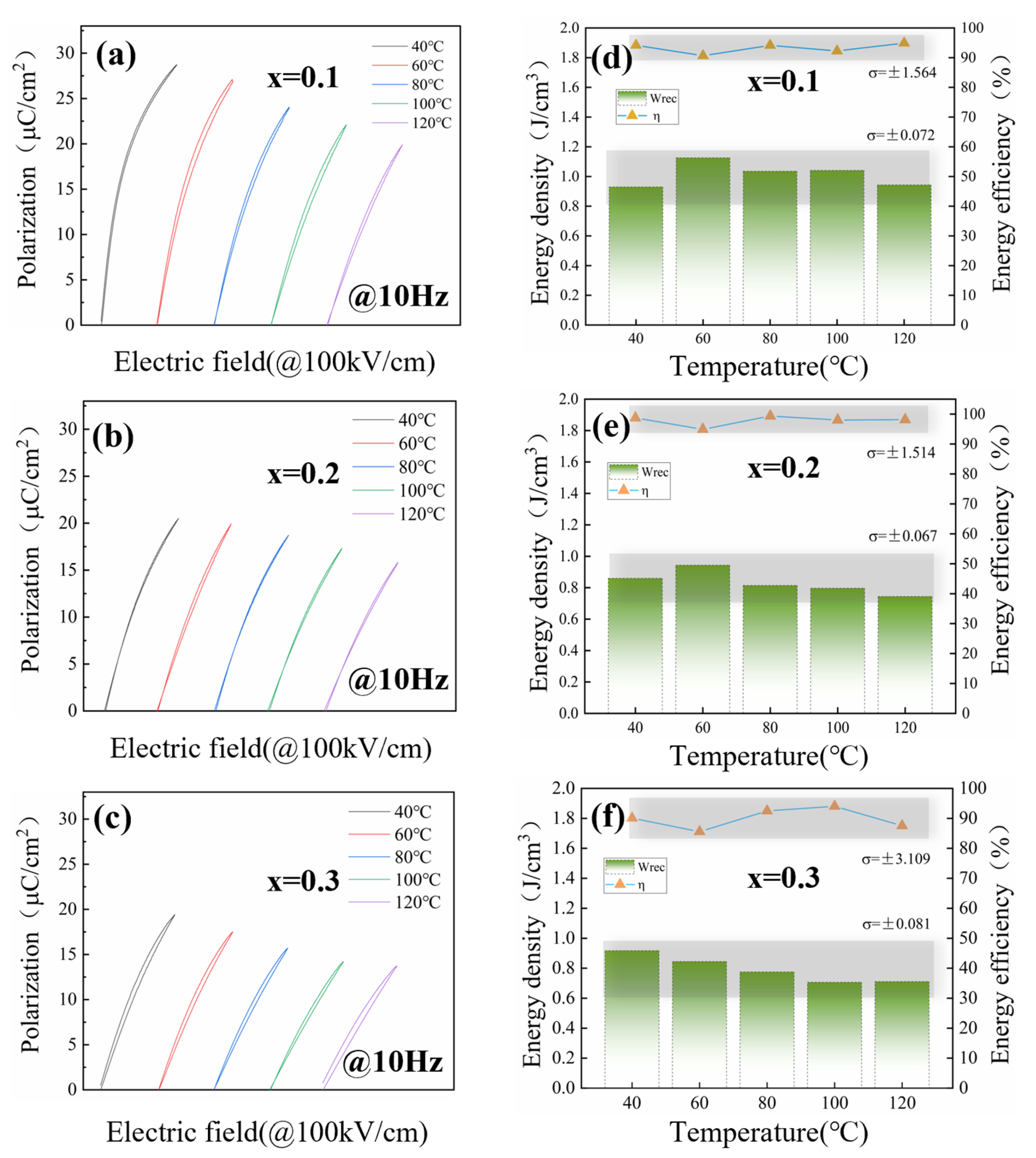

3.3. Ferroelectric Properties

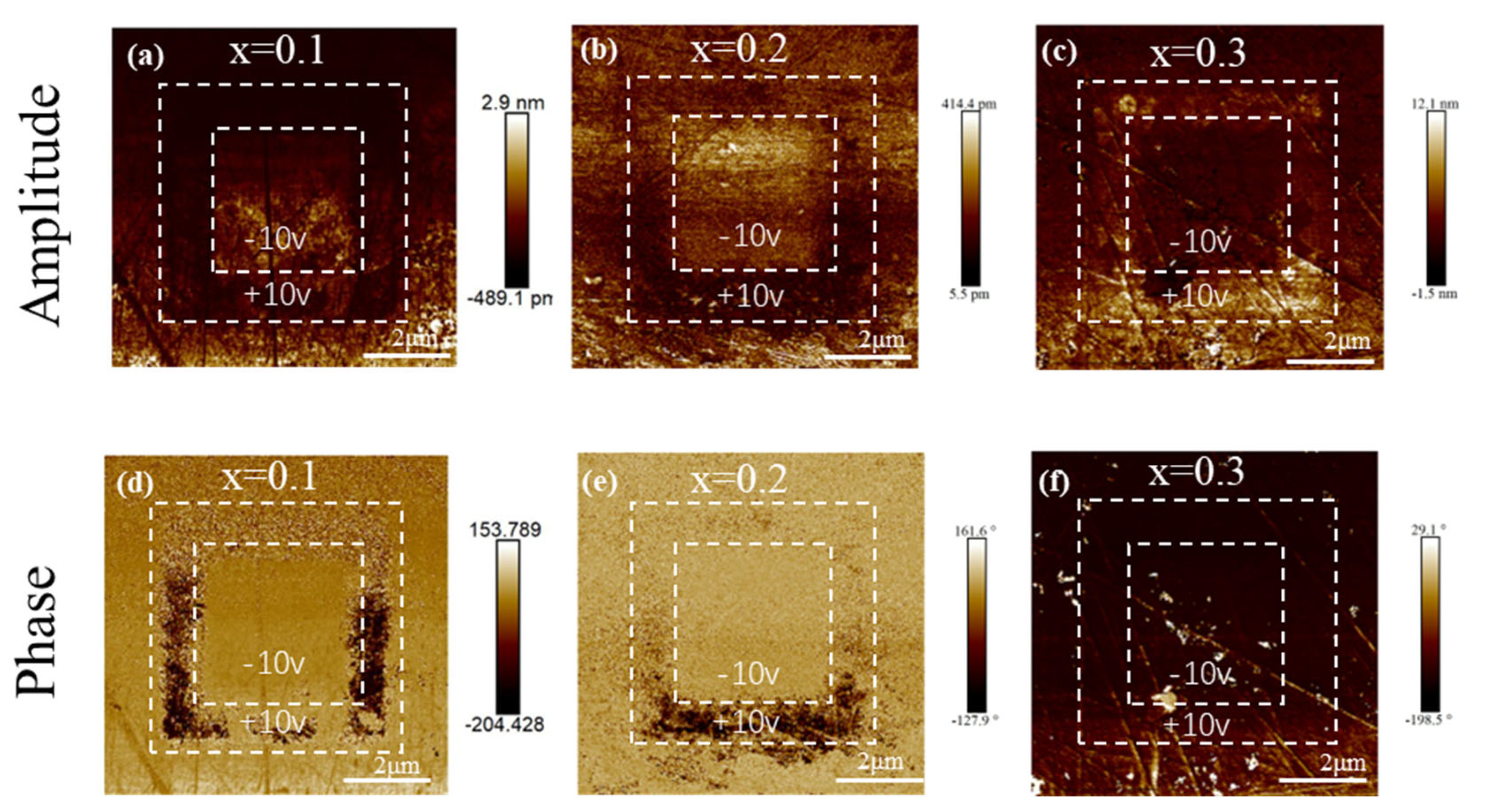

3.4. PFM

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, J.J.; Li, T.Y.; Chao, Q.Q.; Chen, Q.S.; Xie, A.W.; Jiang, X.W.; Rahman, A.; Zhang, Y.; Zuo, R.Z. High energy-storage properties of Sr0.7Bi0.2-xLaxTiO3 lead-free relaxor ferroelectric ceramics for pulsed power capacitors. Ceram. Int. 2024, 50, 38562–38568. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, Y.P.; Chen, M.; Peng, X.; Wang, B.; Shang, J. Design strategies of perovskite energy-storage dielectrics for next-generation capacitors. J. Eur. Ceram. Soc. 2023, 43, 5713–5747. [Google Scholar] [CrossRef]

- Guo, B.; Jin, F.; Li, L.; Pan, Z.Z.; Xu, X.W.; Wang, H. Design strategies of high-performance lead-free electroceramics for energy storage applications. Rare Met. 2024, 43, 853–878. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.-F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Zhang, J.; Pu, Y.; Hao, Y.; Zhang, L.; Wang, B.; Ning, Y.; Chen, M. Antiferroelectric-like BiFeO3-SrTiO3 based ceramics with high breakdown strength and energy-storage density. J. Alloys Compd. 2023, 968, 172147. [Google Scholar] [CrossRef]

- Kröll, E.; Dubey, A.; Shvartsman, V.V.; Lupascu, D.C. Enhanced energy storage and breakdown strength in barium titanate zirconate solid solutions with niobates and tantalates. J. Eur. Ceram. Soc. 2023, 43, 6864–6874. [Google Scholar] [CrossRef]

- Shi, X.H.; Li, K.; Shen, Z.Y.; Liu, J.Q.; Chen, C.Q.; Zeng, X.J.; Zhang, B.; Song, F.S.; Luo, W.Q.; Wang, Z.M.; et al. BS0.5BNT-based relaxor ferroelectric ceramic/glass-ceramic composites for energy storage. J. Adv. Ceram. 2023, 12, 695–710. [Google Scholar] [CrossRef]

- Zhou, S.; Pu, Y.; Zhang, X.; Shi, Y.; Gao, Z.; Feng, Y.; Shen, G.; Wang, X.; Wang, D. High energy density, temperature stable lead-free ceramics by introducing high entropy perovskite oxide. Chem. Eng. J. 2022, 427, 131684. [Google Scholar] [CrossRef]

- He, L.; Yang, Y.; Liu, C.; Ji, Y.; Lou, X.; Zhang, L.; Ren, X. Superior energy storage properties with thermal stability in lead-free ceramics by constructing an antiferroelectric/relaxor-antiferroelectric crossover. Acta Mater. 2023, 249, 118826. [Google Scholar] [CrossRef]

- Liao, Q.B.; Bao, Y.Z.; Yan, S.G.; Chen, X.F.; Lin, Y.Z.; Dong, X.L.; Wang, G.S. Tunable equivalent dielectric constant and superior energy storage stability in relaxor-like antiferroelectric PLZT ceramic. J. Eur. Ceram. Soc. 2022, 42, 3877–3885. [Google Scholar] [CrossRef]

- Jiang, J.; Meng, X.J.; Li, L.; Guo, S.; Huang, M.; Zhang, J.; Wang, J.; Hao, X.H.; Zhu, H.G.; Zhang, S.T. Ultrahigh energy storage density in lead-free relaxor antiferroelectric ceramics via domain engineering. Energy Storage Mater. 2021, 43, 383–390. [Google Scholar] [CrossRef]

- Qi, H.; Wang, G.; Zhang, Y.; Wang, D.; Liu, H.; Deng, S.; Zuo, R.; Chen, J. Tunable phase structure in NaNbO3 ceramics by grain-size effect, electric field and heat treatment. Acta Mater. 2023, 248, 118778. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, J.; Zhao, X.; Zhou, K.; He, L. Simultaneously realizing high energy density and high efficiency in NaNbO3–BaTiO3-based ceramic capacitors. J. Am. Ceram. Soc. 2024, 107, 6215–6223. [Google Scholar] [CrossRef]

- Li, C.L.; Wang, F.; Wang, H.; Wang, B.Y.; Sun, X.R.; Peng, X.C.; Li, W.K.; Diao, C.L.; Zheng, H.W. Optimized energy storage properties of Bi0.5Na0.5TiO3-based lead-free ceramics by composition regulation. Ceram. Int. 2024, 50, 18454–18461. [Google Scholar] [CrossRef]

- Zuo, J.; Xie, A.; Liu, J.; Zhang, Y.; Zuo, R. Significantly enhanced energy-storage properties in NaNbO3-based relaxor ferroelectric ceramics via introducing a wide band-gap linear dielectric. Ceram. Int. 2024, 50, 6332–6339. [Google Scholar] [CrossRef]

- Li, H.; Pan, Z.; Chen, X.; Zhao, J.; Tang, L.; Liu, J.; Li, P.; Zhai, J. Stable relaxor ferroelectric phase of NaNbO3-based ceramic with superb energy storage performances. Mater. Today Phys. 2023, 38, 101208. [Google Scholar] [CrossRef]

- Xie, S.; Chen, Y.; He, Q.; Chen, L.; Yang, J.; Deng, S.; Zhu, Y.; Qi, H. Relaxor antiferroelectric-relaxor ferroelectric crossover in NaNbO3-based lead-free ceramics for high-efficiency large-capacitive energy storage. Chin. Chem. Lett. 2024, 35, 108871. [Google Scholar] [CrossRef]

- Chen, L.; Long, F.X.; Qi, H.; Liu, H.; Deng, S.Q.; Chen, J. Outstanding Energy Storage Performance in High-Hardness (Bi0.5K0.5)TiO3-Based Lead-Free Relaxors via Multi-Scale Synergistic Design. Adv. Funct. Mater. 2022, 32, 2110478. [Google Scholar] [CrossRef]

- Joseph, J.; Cheng, Z.X.; Zhang, S.J. NaNbO3 modified BiScO3-BaTiO3 dielectrics for high-temperature energy storage applications. J. Mater. 2022, 8, 731–738. [Google Scholar] [CrossRef]

- Guo, H.T.; Zeng, F.F.; Xiao, W.R.; Jiang, S.L.; Chen, Y.X.; Wang, B.W.; Fan, G.F.; Lu, W.Z.; Tu, Z.K. Optimized energy storage performance in BF-BT-based lead-free ferroelectric ceramics with local compositional fluctuation. J. Eur. Ceram. Soc. 2023, 43, 4774–4781. [Google Scholar] [CrossRef]

- He, J.H.; Feng, Q.; Huang, H.X.; Sui, T.; Cen, Z.Y.; Chen, X.Y.; Fujita, T.; You, H.; Yuan, C.L.; Luo, N.N. The effect of A-site Mg substitution on energy-storage density and efficiency of Bi0.47Na0.47Ba0.06TiO3 ceramics by disordered induction. Ceram. Int. 2024, 50, 3334–3343. [Google Scholar] [CrossRef]

- Montecillo, R.; Chen, C.S.; Lee, Y.T.; Chen, P.Y.; Tu, C.S. Optimized electric-energy storage in BiFeO3-BaTiO3 ceramics via tailoring microstructure and nanocluster. J. Eur. Ceram. Soc. 2023, 43, 1941–1951. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Liu, H.; Zhai, J.; Yao, X. Dielectric nonlinear properties of BaTiO3–CaTiO3–SrTiO3 ceramics near the solubility limit. Mater. Chem. Phys. 2008, 112, 675–678. [Google Scholar] [CrossRef]

- Hao, H.; Liu, H.X.; Ouyang, S.X. Structure and ferroelectric property of Nb-doped SrBi4Ti4O15 ceramics. J. Electroceramics 2009, 22, 357–362. [Google Scholar] [CrossRef]

- Dube, T.C.; Zhang, J. Underpinning the relationship between synthesis and properties of high entropy ceramics: A comprehensive review on borides, carbides and oxides. J. Eur. Ceram. Soc. 2024, 44, 1335–1350. [Google Scholar] [CrossRef]

- Chen, D.Q.; Zhu, X.W.; Yang, X.R.; Yan, N.; Cui, Y.B.; Lei, X.Y.; Liu, L.J.; Khaliq, J.; Li, C.C. A review on structure-property relationships in dielectric ceramics using high-entropy compositional strategies. J. Am. Ceram. Soc. 2023, 106, 6602–6616. [Google Scholar] [CrossRef]

- Jiao, Y.T.; Dai, J.; Fan, Z.H.; Cheng, J.Y.; Zheng, G.P.; Grema, L.; Zhong, J.W.; Li, H.F.; Wang, D.W. Overview of high-entropy oxide ceramics. Mater. Today 2024, 77, 92–117. [Google Scholar] [CrossRef]

- Anand, G.; Wynn, A.P.; Handley, C.M.; Freeman, C.L. Phase stability and distortion in high-entropy oxides. Acta Mater. 2018, 146, 119–125. [Google Scholar] [CrossRef]

- Guo, J.; Yu, H.; Ren, Y.; Qi, H.; Yang, X.; Deng, Y.; Zhang, S.-T.; Chen, J. Multi-symmetry high-entropy relaxor ferroelectric with giant capacitive energy storage. Nano Energy 2023, 112, 108458. [Google Scholar] [CrossRef]

- Ning, Y.T.; Pu, Y.P.; Wu, C.H.; Chen, Z.M.; Zhang, X.Q.; Zhang, L.; Wang, B. Design strategy of high-entropy perovskite energy-storage ceramics: A review. J. Eur. Ceram. Soc. 2024, 44, 4831–4843. [Google Scholar] [CrossRef]

- Chen, L.; Yu, H.F.; Wu, J.; Deng, S.Q.; Liu, H.; Zhu, L.F.; Qi, H.; Chen, J. Large Energy Capacitive High-Entropy Lead-Free Ferroelectrics. Nano-Micro Lett. 2023, 15, 65. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Chen, L.; Liu, H.; Deng, S.Q.; Qi, H.; Chen, J. High-performance ferroelectric based materials via high-entropy strategy: Design, properties, and mechanism. InfoMat 2023, 5, e12488. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Zhao, X.; Ren, K.; Zhang, R.; Shang, F.; Du, H.; Wang, Y. Structure, dielectric, and relaxor properties of BaTiO3-modified high-entropy (Bi0.2Na0.2K0.2Ba0.2Ca0.2)TiO3 ceramics for energy storage applications. J. Alloys Compd. 2023, 947, 169626. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, T.; Zheng, B.; Ye, W.; Ma, J.; Chen, K. Enhanced energy storage performance of (Bi0·4Ba0·2K0·2Na0.2)TiO3–NaNbO3 high-entropy ceramics under moderate electric fields. Ceram. Int. 2024, 50, 21869–21877. [Google Scholar] [CrossRef]

- Wang, Y.H.; Liu, J.P.; Song, Y.F.; Yu, J.; Tian, Y.F.; Robson, M.J.; Wang, J.; Zhang, Z.Q.; Lin, X.D.; Zhou, G.D.; et al. High-Entropy Perovskites for Energy Conversion and Storage: Design, Synthesis, and Potential Applications. Small Methods 2023, 7, 2201138. [Google Scholar] [CrossRef]

- Xiong, W.; Zhang, H.; Cao, S.; Gao, F.; Svec, P.; Dusza, J.; Reece, M.J.; Yan, H. Low-loss high entropy relaxor-like ferroelectrics with A-site disorder. J. Eur. Ceram. Soc. 2021, 41, 2979–2985. [Google Scholar] [CrossRef]

- Chen, L.; Deng, S.Q.; Liu, H.; Wu, J.; Qi, H.; Chen, J. Giant energy-storage density with ultrahigh efficiency in lead-free relaxors via high-entropy design. Nat. Commun. 2022, 13, 3089. [Google Scholar] [CrossRef]

- Ning, Y.T.; Pu, Y.P.; Wu, C.H.; Zhang, J.B.; Zhang, X.; Shang, Y.C. Achieving high energy storage performance below 200 kV/cm in BaTiO3-based medium-entropy ceramics. Ceram. Int. 2023, 49, 20326–20333. [Google Scholar] [CrossRef]

- Li, S.; Hu, T.F.; Nie, H.C.; Fu, Z.Q.; Xu, C.H.; Xu, F.F.; Wang, G.S.; Dong, X.L. Giant energy density and high efficiency achieved in silver niobate-based lead-free antiferroelectric ceramic capacitors via domain engineering. Energy Storage Mater. 2021, 34, 417–426. [Google Scholar] [CrossRef]

- Kim, S.; Choi, H.; Han, S.; Park, J.S.; Lee, M.H.; Song, T.K.; Kim, M.-H.; Do, D.; Kim, W.-J. A correlation between piezoelectric response and crystallographic structural parameter observed in lead-free (1-x)(Bi0.5Na0.5)TiO3-xSr TiO3 piezoelectrics. J. Eur. Ceram. Soc. 2017, 37, 1379–1386. [Google Scholar] [CrossRef]

- Zuo, C.Y.; Yang, S.L.; Cao, Z.Q.; Jie, W.J.; Wei, X.H. Combustion synthesis of high-performance high-entropy dielectric ceramics for energy storage applications. Ceram. Int. 2023, 49, 25486–25494. [Google Scholar] [CrossRef]

- Li, C.Y.; Liu, J.K.; Bai, W.F.; Wu, S.T.; Zheng, P.; Zhang, J.J.; Pan, Z.B.; Zhai, J.W. Superior energy storage performance in (Bi0.5Na0.5)TiO3-based lead-free relaxor ferroelectrics for dielectric capacitor application via multiscale optimization design. J. Mater. Chem. A 2022, 10, 9535–9546. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, L.; Zhang, Z.A.; Zhang, X.; Jin, Q.; Cui, B. Boosting energy storage performance in Ba0.8Sr0.2Zr0.1Ti0.9O3–Na0.5Bi0.5TiO3 lead-free nanoceramics through polar nanoregions and grain refinement engineering. J. Mater. Sci. Mater. Electron. 2021, 32, 7259–7270. [Google Scholar] [CrossRef]

- Luo, N.N.; Han, K.; Cabral, M.J.; Liao, X.Z.; Zhang, S.J.; Liao, C.Z.; Zhang, G.Z.; Chen, X.Y.; Feng, Q.; Li, J.F.; et al. Constructing phase boundary in AgNbO3 antiferroelectrics: Pathway simultaneously achieving high energy density and efficiency. Nat. Commun. 2020, 11, 4824. [Google Scholar] [CrossRef]

- Liu, X.; Xue, S.D.; Ma, J.P.; Zhai, J.W.; Shen, B.; Wang, F.F.; Zhao, X.Y.; Yan, H.X. Electric-field-induced local distortion and large electrostrictive effects in lead-free NBT-based relaxor ferroelectrics. J. Eur. Ceram. Soc. 2018, 38, 4631–4639. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.; Deng, H.; Huang, T.; Li, X.; Zhao, X.; Hu, Z.; Wang, D.; Luo, H. Electric field and temperature-induced phase transition in Mn-doped Na0.5Bi0.5TiO3-5.0 at.%BaTiO3 single crystals investigated by micro-Raman scattering. Appl. Phys. Lett. 2014, 104, 142902. [Google Scholar] [CrossRef]

- Montecillo, R.; Chen, C.-S.; Feng, K.-C.; Chien, R.R.; Haw, S.-C.; Chen, P.-Y.; Tu, C.-S. Achieving superb electric energy storage in relaxor ferroelectric BiFeO3-BaTiO3-NaNbO3 ceramics via O2 atmosphere. J. Eur. Ceram. Soc. 2023, 43, 7446–7454. [Google Scholar] [CrossRef]

- Lu, Y.; Li, P.; Du, J.; Fu, P.; Hao, J.; Zeng, H.; Li, W. (1-x)Bi0.5Na0.47Li0.03TiO3-xNaNbO3 lead-free ceramics with superior energy storage performances and good temperature stability. Ceram. Int. 2022, 48, 24716–24724. [Google Scholar] [CrossRef]

- Ning, Y.; Pu, Y.; Zhang, Q.; Zhou, S.; Wu, C.; Zhang, L.; Shi, Y.; Sun, Z. Achieving high energy storage properties in perovskite oxide via high-entropy design. Ceram. Int. 2023, 49, 12214–12223. [Google Scholar] [CrossRef]

- Bao, C.; Chu, P.; Xu, C.X.; Yuan, J.P.; Si, L.J.; Bo, Z.; Ostrikov, K.; Yang, H.C. More disorder is better: Cutting-edge progress of high entropy materials in electrochemical energy storage applications. Energy Storage Mater. 2024, 69, 103408. [Google Scholar] [CrossRef]

- Kotsonis, G.N.; Almishal, S.S.I.; Vieira, F.M.D.; Crespi, V.H.; Dabo, I.; Rost, C.M.; Maria, J.P. High-entropy oxides: Harnessing crystalline disorder for emergent functionality. J. Am. Ceram. Soc. 2023, 106, 5587–5611. [Google Scholar] [CrossRef]

- Chen, M.; Pu, Y.; Zhang, L.; Wang, B.; Zhuo, F.; Gao, X.; Frömling, T. Reducing applied field in NBT-based high energy-storage ceramics via B-site entropy regulation. Chem. Eng. J. 2023, 474, 145386. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, F.; Du, H.; Jin, L.; Yan, L.; Hu, Q.; Yu, Y.; Qu, S.; Wei, X.; Xu, Z.; et al. Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties. Nano Energy 2019, 58, 768–777. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xiong, W.; Zhou, X.; Luo, H.; Guo, R.; Zhang, D. Enhanced Energy Storage Properties of the Relaxor and Antiferroelectric Crossover Ceramic Enabled by a High Entropy Design. Materials 2025, 18, 1937. https://doi.org/10.3390/ma18091937

Li Y, Xiong W, Zhou X, Luo H, Guo R, Zhang D. Enhanced Energy Storage Properties of the Relaxor and Antiferroelectric Crossover Ceramic Enabled by a High Entropy Design. Materials. 2025; 18(9):1937. https://doi.org/10.3390/ma18091937

Chicago/Turabian StyleLi, Yinghao, Wei Xiong, Xuefan Zhou, Hang Luo, Ru Guo, and Dou Zhang. 2025. "Enhanced Energy Storage Properties of the Relaxor and Antiferroelectric Crossover Ceramic Enabled by a High Entropy Design" Materials 18, no. 9: 1937. https://doi.org/10.3390/ma18091937

APA StyleLi, Y., Xiong, W., Zhou, X., Luo, H., Guo, R., & Zhang, D. (2025). Enhanced Energy Storage Properties of the Relaxor and Antiferroelectric Crossover Ceramic Enabled by a High Entropy Design. Materials, 18(9), 1937. https://doi.org/10.3390/ma18091937