Evaluation of Moisture Performance of Tall Wood Building Envelope under Climate Change in Different Canadian Climatic Regions

Abstract

:1. Introduction

2. Methods

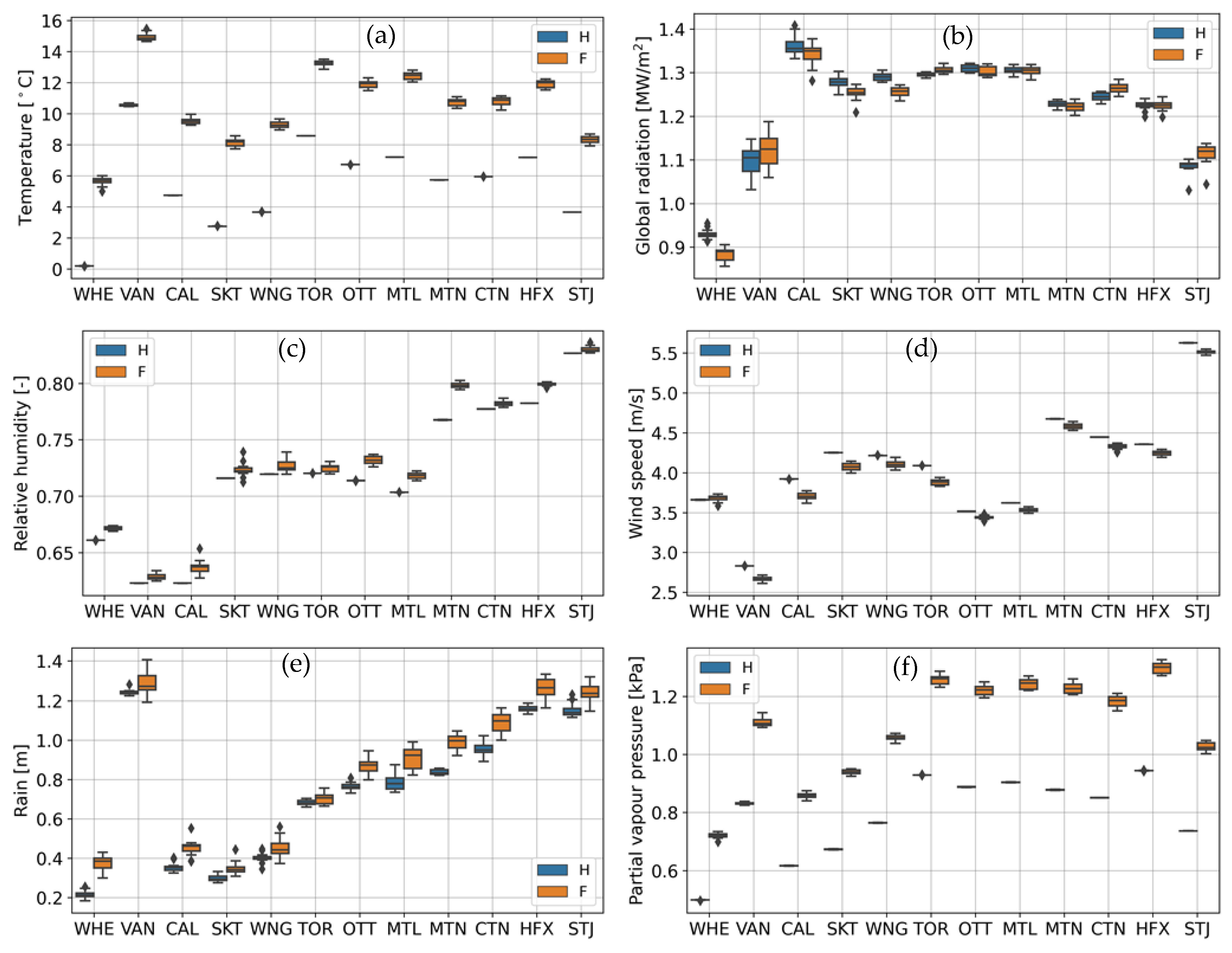

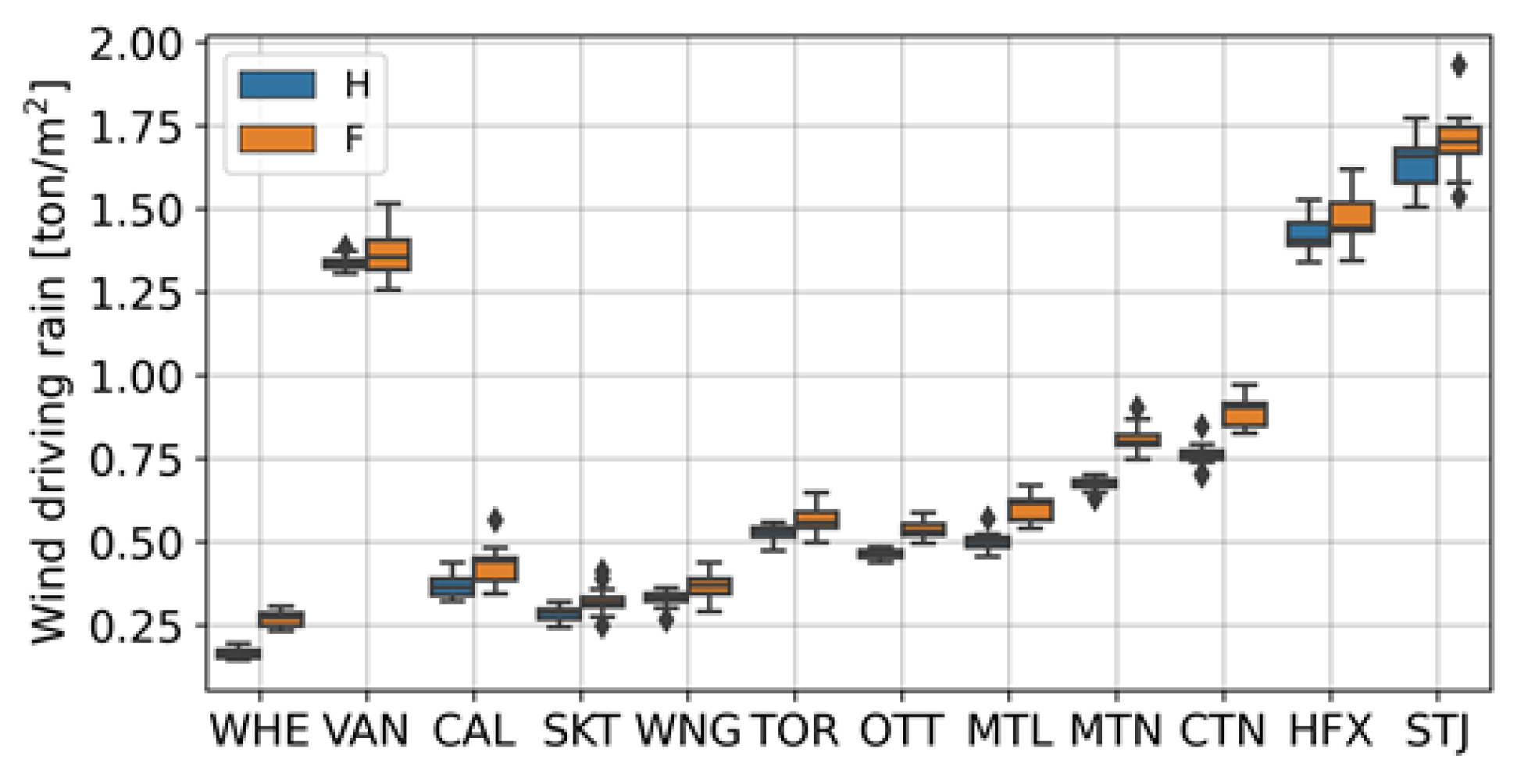

2.1. Regions and Cities Considered for the Study

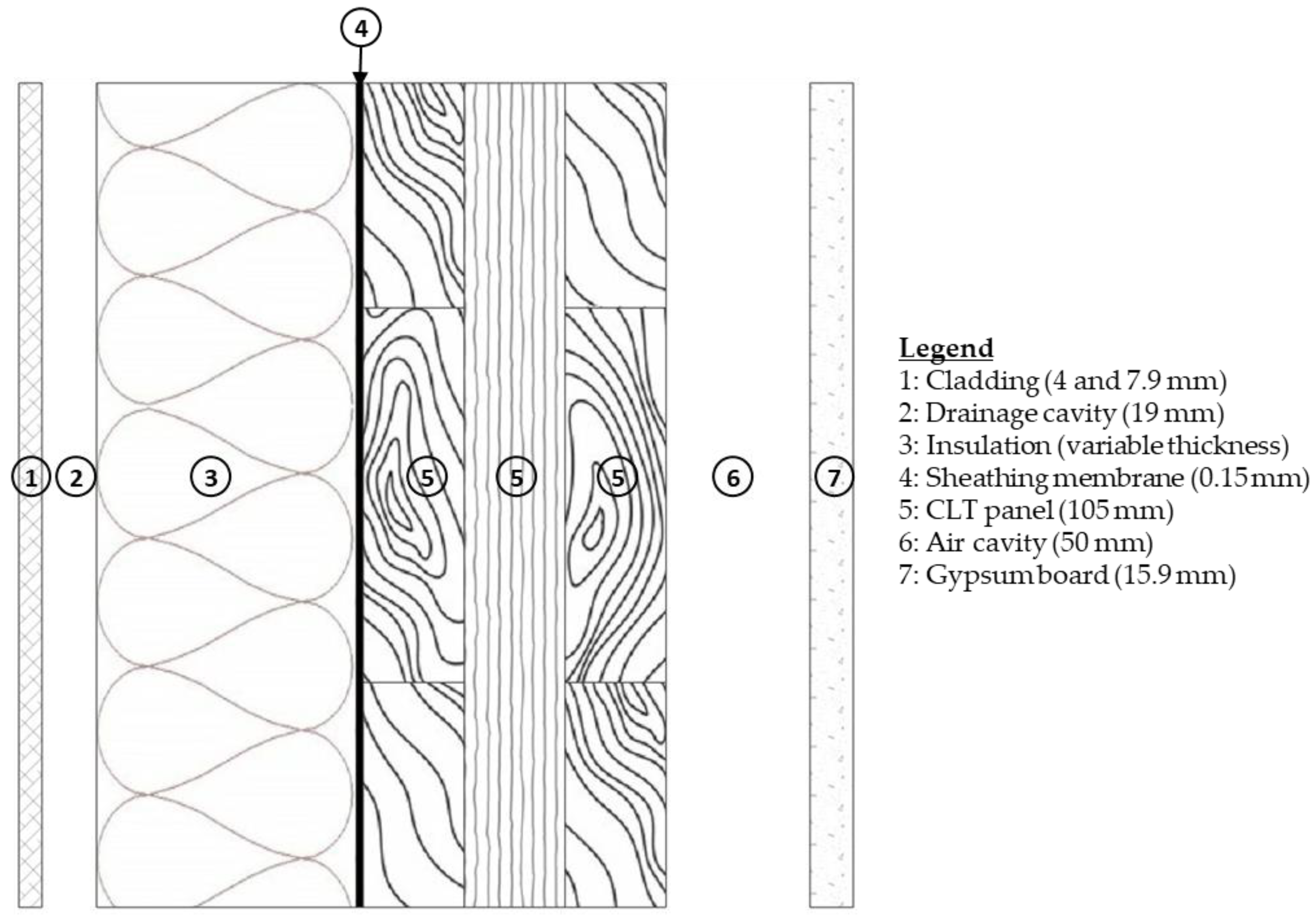

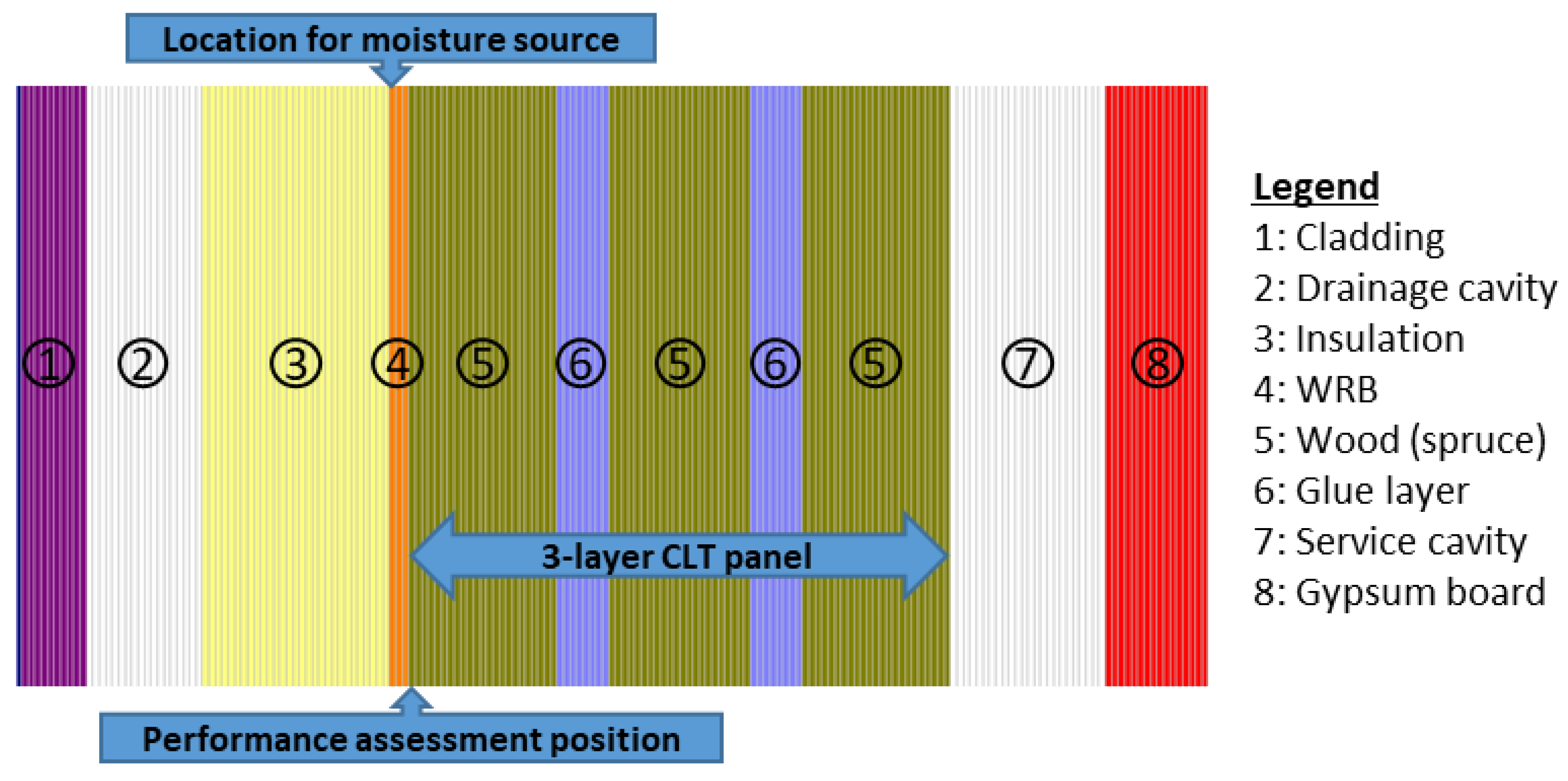

2.2. Building and Wall Configuration

2.3. Material Properties

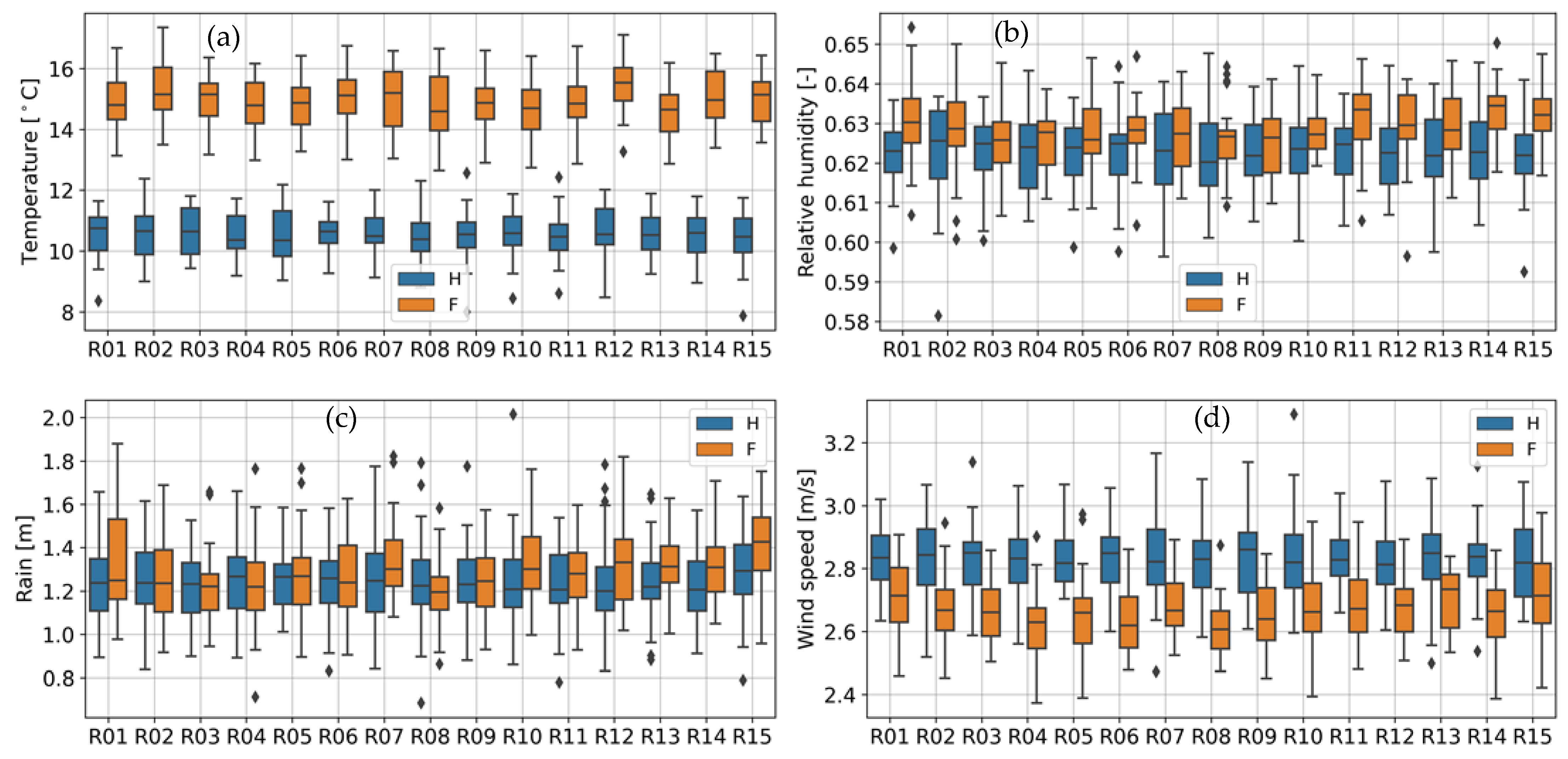

2.4. Climate Data

2.5. Hygrothermal Simulations Setting

2.5.1. Simulation Tool

2.5.2. Wall Geometry, Discretization, and Solver Parameters

2.5.3. Moisture Reference Years and Initial Conditions

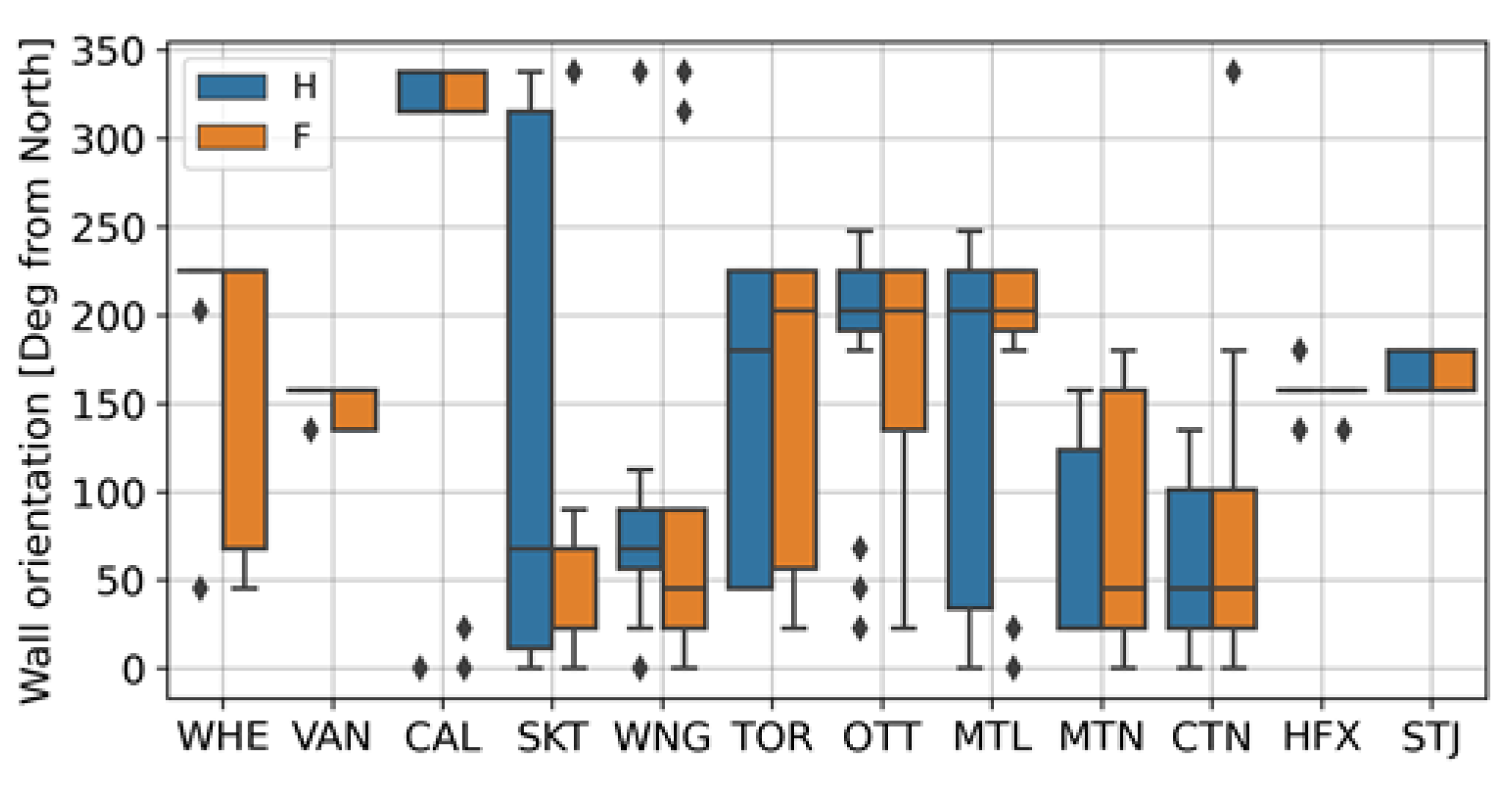

2.5.4. Wall Orientation

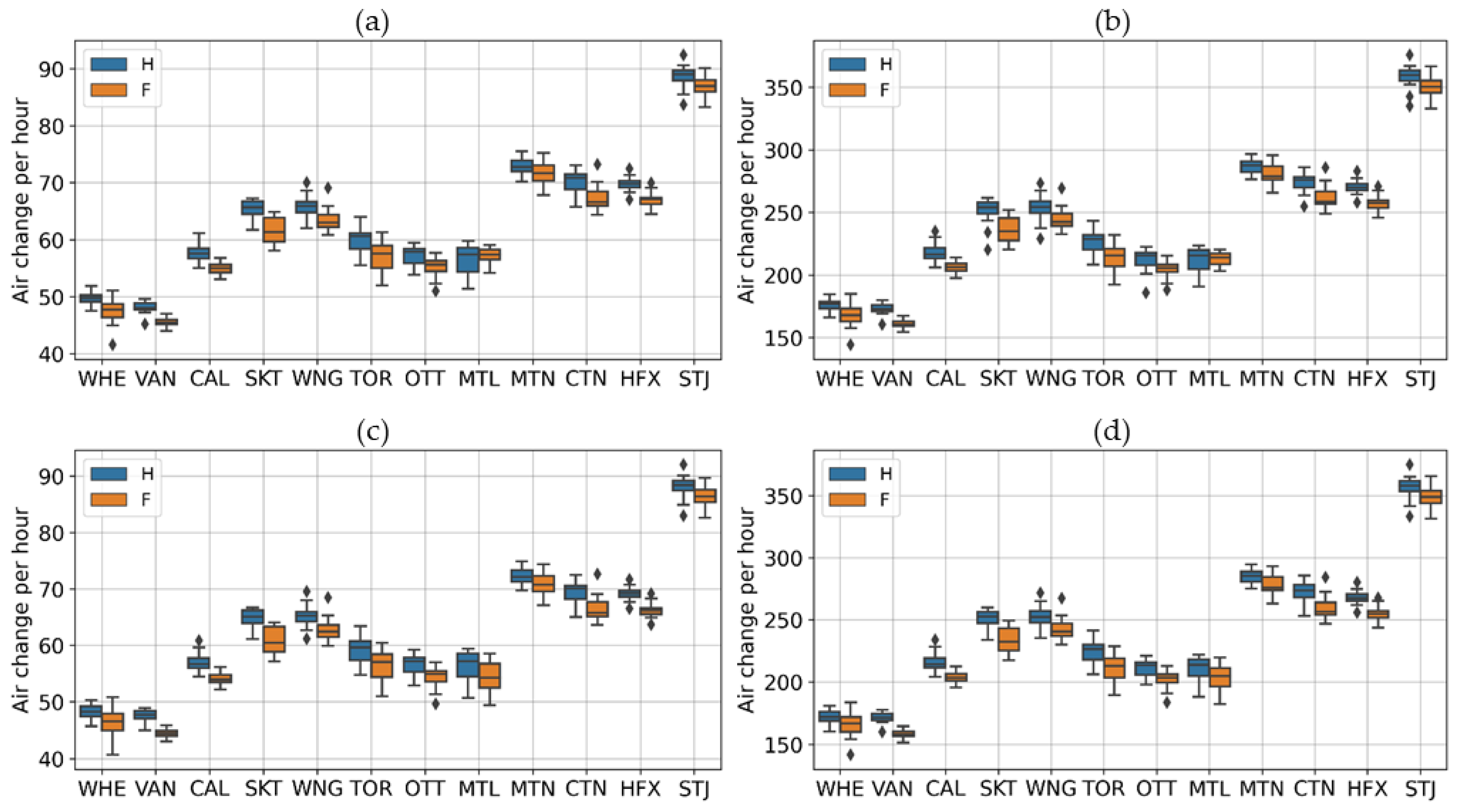

2.5.5. Air Change Rate

2.5.6. Moisture Source

2.5.7. Boundary Conditions

2.6. Performance Evaluation

3. Results and Discussion

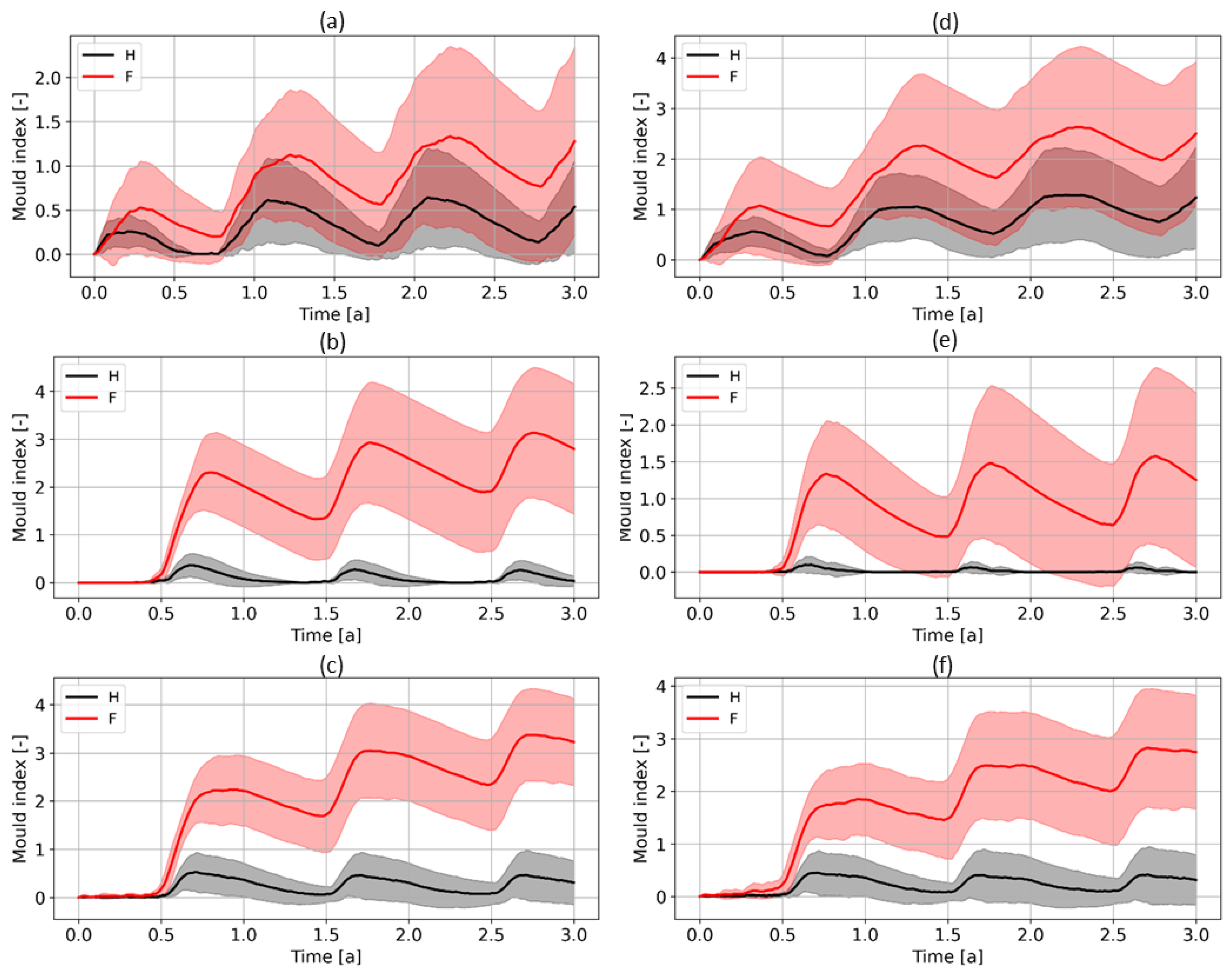

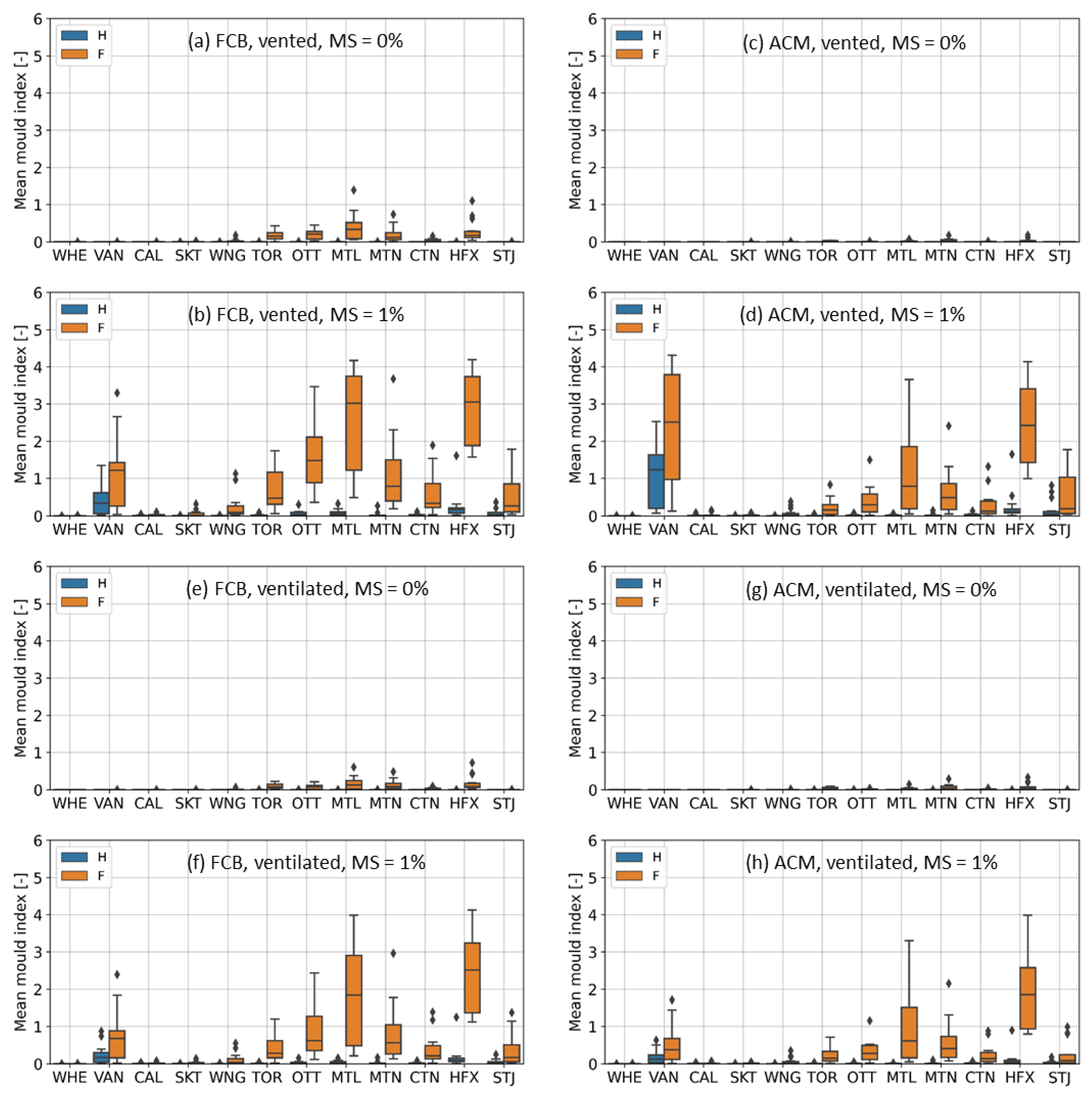

3.1. Mold Growth Index

3.2. Effects of Climate Change on Mold Growth Risk

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 1-D | One-dimensional |

| ACM | Aluminum composite material |

| ACH | Air change per hour |

| CAL | Calgary |

| CLT | Cross-Laminated Timber |

| CTN | Charlottetown |

| DRWP | Driving rain wind pressure |

| EMC | Equilibrium moisture content |

| F | Future |

| FCB | Fiber cement board |

| H | Historical |

| HDD | Heating-degree-days |

| HFX | Halifax |

| MI | Moisture index |

| MoI | Mold growth index |

| MS | Moisture source |

| MTL | Montreal |

| MTN | Moncton |

| OTT | Ottawa |

| R | Climate run or realization |

| RCP | Representative Concentration Pathway |

| RH | Relative humidity |

| SBPO | Spun bonded polyolefin |

| SKT | Saskatoon |

| STJ | St. John’s |

| TOR | Toronto |

| V | Wind speed |

| VAN | Vancouver |

| WDR | Wind-driven rain |

| WHE | Whitehorse |

| WNG | Winnipeg |

| WRB | Weather resistive barrier |

References

- IPCC Climate Change 2021: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; p. 2391.

- Bizikova, L.; Neale, T.; Burton, I. Canadian Communities’ Guidebook for Adaptation to Climate Change; Environment Canada: Ottawa, ON, Canada, 2009. [Google Scholar]

- Nijland, T.G.; Adan, O.C.; Van Hees, R.P.; van Etten, B.D. Evaluation of the effects of expected climate change on the durability of building materials with suggestions for adaptation. Heron 2009, 54, 37–48. [Google Scholar]

- Nick, V.; Mundt-Petersen, S.; Kalagasidis, A.; De Wilde, P. Future moisture loads for buildings facades in Sweden: Climate change and wind-driven rain. Build. Environ. 2015, 93, 362–375. [Google Scholar] [CrossRef]

- Sehizadeh, A.; Ge, H. Impacts of future climates on the durability of typical residential wall assemblies retroffited to the PassiveHaus for Eastern Canada region. Build. Environ. 2016, 97, 111–125. [Google Scholar] [CrossRef]

- Bylund Melin, C.; Hagentoft, C.E.; Holl, K.; Nik, V.M.; Kilian, R. Simulations of moisture gradients in wood subjected to changes in relative humidity and temperature due to climate change. Geosciences 2018, 8, 378. [Google Scholar] [CrossRef] [Green Version]

- Hayles, C.; Huddleston, M.; Chinoowsky, P.; Helman, J. Quantifying the effects of projected climate change on the durability and service life of housing in Wales, UK. Buildings 2022, 12, 184. [Google Scholar] [CrossRef]

- Vandemeulebroucke, I.; Kotova, L.; Caluwaerts, S.; Van Den Bossche, N. Degradation of brick masonry walls in Europe and the Mediterranean: Advantages of response-based analysis to study climate change. Build. Environ. 2023, 230, 109963. [Google Scholar] [CrossRef]

- Chang, S.; Wi, S.; Kang, Y.; Kim, S. Moisture risk assessment of cross-laminated timber walls: Perspectives on climate conditions and water vapor resistance performance of building materials. Build. Environ. 2020, 168, 106502. [Google Scholar] [CrossRef]

- Chang, S.J.; Yoo, J.; Wi, S.; Kim, S. Numerical analysis on the hygrothermal behavior of building envelope according to CLT wall assembly considering the hygrothermal-environmental zone in Korea. Environ. Res. 2020, 191, 110198. [Google Scholar] [CrossRef]

- Chang, S.; Kang, Y.; Yun, B.; Yang, S.; Kim, S. Assessment of effect of climate change on hygrothermal performance of cross-laminated timber building envelope with modular construction. Case Stud. Therm. Eng. 2021, 28, 101703. [Google Scholar]

- Defo, M.; Lacasse, M. Effects of Climate Change on the Moisture Performance of Tallwood Building Envelope. Buildings 2021, 11, 35. [Google Scholar] [CrossRef]

- NEBC National Energy Code of Canada for Buildings; National Research Council of Canada: Ottawa, ON, Canada, 2020.

- NBCC National Building Code of Canada; National Research Council of Canada: Ottawa, ON, Canada, 2020.

- Cornick, S.; Dalgliesh, W.A. A moisture index approach to characterizing climates for moisture management of building envelopes. In Proceedings of the 9th Canadian Conference on Building Science and Technology, Vancouver, BC, Canada, 27–28 February 2003. [Google Scholar]

- Glass, S.; Wang, J.; Easley, S.; Finch, G. Building enclosure design for cross-laminated timber construction. In CLT Handbook: Cross-Laminated Timber; U.S. Edition Special publication SP-529E; Karacabeyli, E., Douglas, B., Eds.; FPInnovations: Ponte-Claire, QC, Canada, 2013; pp. 393–441. [Google Scholar]

- Nordic Structures, Nordic Engineered Wood. In Non-Residential Design; Construction Guide, Nordic X-Lam; Nordic Structures: Montreal, QC, Canada, 2015.

- Finch, G.; Wang, J. Building enclosure design design of cross-laminated timber construction. In Canadian CLT Handbook; Special Publication SP-532E; Karacabeyli, E., Gagon, S., Eds.; FPInnovations: Pointe Claire, QC, Canada, 2019; pp. 517–581. [Google Scholar]

- 3A Composites USA Inc. Available online: https://d371dyuip757b1.cloudfront.net/downloads/ALUCOBOND%20PLUS%20-%20Tech%20Data%20sheet%20(12.21).pdf (accessed on 10 February 2022).

- Kumaran, M.K.; Lackey, J.C.; Normandin, N.; Tariku, F.; van Reenen, D. A thermal and moisture transport property database for common building and insulation materials. In Final Report from ASHRAE Research Project 1018-RP; ASHRAE: Atlanta, Georgia, 2002. [Google Scholar]

- AlSayegh, G. Hygrothermal Properties of Cross-Laminated Timber and Moisture Response of Wood at High Relative Humidity. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2012. [Google Scholar]

- IPCC Climate Change 2014: Synthesis Report; Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Team, C.W.; Pachauri, R.; Meyer, L. (Eds.) IPCC: Geneva, Switzerland, 2014; p. 151. [Google Scholar]

- Gaur, A.; Lacasse, M.; Armstrong, M. Climate data to undertake hygrothermal and whole building simulations under projected climate change influences for 11 Canadian cities. Data 2019, 4, 72. [Google Scholar] [CrossRef] [Green Version]

- ASHRAE ASHRAE Standard 160-2016; Criteria for Moisture-Control Design Analysis in Buildings. ASHRAE: Atlanta, Georgia, 2016.

- Nath, D. U.K. Field Measurements of Wind-Driven Rain on Mid- and High-Rise Buildings in Two Canadian Regions. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, 2015. [Google Scholar]

- Sontag, L.; Nicolai, A.; Vogelsang, S. Validierung der Solverimplementierung des Hygrothermischen Simulationsprogramms Delphin; Institute of Building Climatology (TU Dresden): Dresden, Germany, 2013. [Google Scholar]

- Langmans, J.; Nicolai, A.; Klein, R.; Roels, S. A quasi-steady state implementation of air convection in a transient heat and moisture building component model. Build. Environ. 2012, 58, 208–218. [Google Scholar] [CrossRef]

- Vogelsang, S.; Kehl, D.; Ruisinger, U.; Meissner, F. Three-dimensional HAM Transport in Timber Beam Ends–Measurements and Simulation. In Proceedings of the 5th German-Austrian Conference of the International Building Performance Simulation Association (IBPSA), Aachen, Germany, 22–24 September 2014. [Google Scholar]

- Hejazi, B.; Sakiyama, N.R.; Frick, J.; Garrecht, H. Hygrothermal Simulations Comparative Study: Assessment of Different Materials Using WUFI and DELPHIN Software. In Proceedings of the 16th IBPSA International Conference, Rome, Italy, 2–4 September 2019. [Google Scholar]

- Ruisinger, U.; Kautsch, P. Comparison of hygrothermal 2D- and 3D-simulation results with measurements from a test house. In E3S Web of Conferences; EDP Sciences, P.A. de Courtaboeuf, France: Les Ulis, France, 2020; Volume 172, p. 08004. [Google Scholar]

- Janssens, A. Reliability Control of Interstitial Condensation in Lightweight Roof Systems. Calculation and Assessment Methods. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 1998. [Google Scholar]

- Nicolai, A. Modeling and Numerical Simulation of Salt Transport and Phase Transitions in Unsaturated Porous Building Materials. Ph.D. Thesis, Syracuse University, New York, NY, USA, 2008. [Google Scholar]

- Langmans, L. Feasibility of Exterior Air Barriers in Timber Frame Construction. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2013. [Google Scholar]

- Nicolai, A.; Grunewald, J. DELPHIN 5 User Manual and Program Reference; Institute for Building Climatology/University of Technology Dresden (TUD): Dresden, Germany, 2014. [Google Scholar]

- Candenedo, L.; Derome, D.; Fazio, P.; Ge, H. Analysis of Montreal 30-year weather data to select loading conditions for large-scale tests on wall panels. In Proceedings of the 3th International Building Physics Conference, Montreal, QC, Canada, 27–31 August 2006. [Google Scholar]

- Salonvaara, M.; Sedlbauer, K.; Holm, A.; Pazera, M. Effect of selected weather year for hygrothermal analyses. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Buildings XI Conference, Clearwater Beach, FL, USA, 5–9 December 2010. [Google Scholar]

- Zhou, X.; Derome, D.; Carmeliet, J. Robust moisture reference year methodology for hygrothermal simulations. Build. Environ. 2016, 110, 23–35. [Google Scholar] [CrossRef]

- Barreira, E.; Simões, M.L.; Delgado, J.M.P.Q.; Sousa, I. Procedures in the construction of a test reference year for Porto-Portugal and implications for hygrothermal simulation. Sustain. Cities Soc. 2017, 32, 397–410. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Ge, H.; Hegel, M.; Jutras, R.; Laouadi, A.; Sturgeon, G.; Wells, J. Guideline on Design for Durability of Building Envelopes, CRBCPI-Y2-R19; National Research Council Canada: Ottawa, ON, Canada, 2018. [Google Scholar]

- Straube, J.; Burnett, E. Vents, Ventilation Drying, and Pressure Moderation; CMHC: Ottawa, ON, Canada, 1995. [Google Scholar]

- Straube, J.; Finch, G. Ventilated Wall Claddings: Review, Field Performance, and Hygrothermal Modelling Research Report-0907; Building Science Press: San Raphael, CA, USA, 2009. [Google Scholar]

- Defo, M.; Wang, L.; Lacasse, M. Evaluation of the Durability and Resilience of Wall Assemblies to Climate Change Using Hygrothermal Simulations RR NRCC-CONST-56534E; NRC: Ottawa, ON, Canada, 2021. [Google Scholar]

- Henninger, J.H. Solar Absorbance and Thermal Emittance of Some Common Space Craft Thermal-Control Coatings RP-1121; NASA: Washington, DC, USA, 1984. [Google Scholar]

- ISO 15927-3; Hygrothermal Performance of Buildings—Calculation and Presentation of Climatic Data. International Organization for Standardization. ISO: Geneva, Switzerland, 2009.

- Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer, 4th ed.; John Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Wang, J.Y.; Stirling, R.; Paul, I.; Morris, A.; Taylor, J.; Lloyd, G.; Kirker, S.; Lebow, M.; Mankowski, H.; Barnes, M.; et al. Durability of mass timber structures: A review of the biological risks. Wood Fiber. Sci. 2018, 50, 110–127. [Google Scholar] [CrossRef] [Green Version]

- Viitanen, H.A.; Ritschkoff, A. Mould Growth in Pine and Spruce Sapwood in Relation to Air Humidity and Temperature; The Swedish University of Agricultural Sciences, Dept. of Forest Products: Uppsala, Sweden, 1991. [Google Scholar]

- Viitanen, H.A. Modelling the time factor in the development of mould fungi—The effect of critical humidity and temperature conditions on pine and spruce sapwood. Holzforshung 1997, 51, 6–14. [Google Scholar] [CrossRef]

- Hukka, A.; Viitanen, H.A. A mathematical model of mould growth on wooden material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Ojanen, T.; Viitanen, H.; Peuhkuri, R.; Lâhdesmäki, K.; Vinha, J.; Salminen, K. Mold growth modeling of building structures using sensitivity classes of materials. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Building XI Conference, Clearwater Beach, FL, USA, 5–9 December 2010. [Google Scholar]

- Yeo, I.; Johnson, R. A new family of power transformations to improve normality or symmetry. Biometrika 2000, 87, 954–959. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009. [Google Scholar]

- Welch, B.L. The generalization of "Student’s" problem when several different population variances are involved. Biometrika 1947, 34, 28–35. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2000, 17, 261–272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| City (Province) | Lat. | Long. | Time | Climate | CZ 1 | KC 2 | HDD 3 | RSI 4 | MI 5 | Rain | DRWP 6 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (o) | (o) | Zone | Region | (m2 K/W) | (mm) | (Pa, 1/5) | |||||

| Whitehorse (YT) | 60.71 | −135.07 | −8.0 | Cordillera | 7B | Dfc | 6580 | 5.26 | 0.50 | 170 | 40 |

| Vancouver (BC) | 49.19 | −123.18 | −8.0 | Western maritime | 4 | Csb | 2800 | 3.45 | 1.20 | 1070 | 160 |

| Calgary (AB) | 51.11 | −114.02 | −7.0 | Prairie | 7A | Dfb | 5000 | 4.65 | 0.40 | 325 | 220 |

| Saskatoon (SK) | 52.17 | −106.70 | −6.0 | Prairie | 7A | Dfb | 5700 | 4.65 | 0.40 | 265 | 160 |

| Winnipeg (MB) | 49.91 | −97.24 | −6.0 | Prairie | 7A | Dfb | 5670 | 4.65 | 0.60 | 415 | 180 |

| Toronto (ON) 7 | 43.63 | −79.39 | −5.0 | Southeastern | 5 | Dfb | 3520 | 3.77 | 0.90 | 720 | 160 |

| Ottawa (ON) | 45.32 | −75.67 | −5.0 | Southeastern | 6 | Dfb | 4500 | 4.17 | 0.80 | 750 | 160 |

| Montreal (QC) 8 | 45.47 | −73.74 | −5.0 | Southeastern | 6 | Dfb | 4400 | 4.17 | 0.90 | 760 | 180 |

| Moncton (NB) | 46.11 | −64.68 | −4.0 | Eastern maritime | 6 | Dfb | 4680 | 4.17 | 1.00 | 850 | 220 |

| Charlottetown (PE) | 46.29 | −63.12 | −4.0 | Eastern maritime | 6 | Dfb | 4460 | 4.17 | 1.10 | 900 | 350 |

| Halifax (NS) | 44.88 | −63.51 | −4.0 | Eastern maritime | 6 | Dfb | 4000 | 4.17 | 1.50 | 1350 | 280 |

| St.-John’s (NL) | 47.62 | −52.75 | −4.0 | Eastern maritime | 6 | Dfb | 4800 | 4.17 | 1.40 | 1200 | 400 |

| Component | e | Density | l | Porosity | EMC (%) | Vapor Permeance (ng/m2sPa) | A | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | (mm) | (kg/m3) | (W/mK) | (m3/m3) | 50%RH | 80%RH | 95%RH | 10%RH | 50%RH | 90%RH | (kg/m2s0.5) |

| Cladding | |||||||||||

| Regular Portland stucco | 19 | 1960 | 0.407 | 0.24 | 3.55 | 5.27 | 7.63 | 30.6 | 94.7 | 160.5 | 0.01230 |

| ACM | 4 | 1900 | 0.440 | - | - | - | - | - | - | - | - |

| Fibre cement | 7.9 | 1380 | 0.250 | 0.48 | 5.30 | 12.00 | 24.00 | 26.6 | 206.3 | 1899 | 0.02500 |

| Rainscreen | |||||||||||

| Air | 19 | 1.204 | 0.026 | 1.00 | - | - | - | 10,000 | 10,000 | 10,000 | - |

| Insulation | |||||||||||

| Mineral wool | 64 | 37 | 0.032 | 0.92 | 0.003 | 0.007 | 0.008 | 2047 | 2047 | 2047 | - |

| 76 | 37 | 0.032 | 0.92 | 0.003 | 0.007 | 0.008 | 1724 | 1724 | 1724 | - | |

| 89 | 37 | 0.032 | 0.92 | 0.003 | 0.007 | 0.008 | 1472 | 1472 | 1472 | - | |

| 114 | 37 | 0.032 | 0.92 | 0.003 | 0.007 | 0.008 | 1149 | 1149 | 1149 | - | |

| WRB | |||||||||||

| SBPO | 0.15 | 464 | 0.248 | 0.01 | 0.01 | 0.05 | 0.1 | 4080 | 4080 | 4080 | 0.00031 |

| CLT | 105 | ||||||||||

| Spruce | 35 | 400 | 0.094 | 0.75 | 11.0 | 21.0 | 27.0 | 10.8 | 89.4 | 842.9 | 0.00220 |

| Glue line | 4 | 400 | 0.094 | 0.75 | 11.0 | 21.0 | 27.0 | 47.1 | 391.3 | 3688 | 0.00220 |

| Service cavity | |||||||||||

| Air | 50 | 1.204 | 0.278 | 1.00 | - | - | - | 10,000 | 3800 | 10,000 | - |

| Interior sheathing | |||||||||||

| Gypsum | 15.9 | 700 | 0.160 | 0.4 | 9.0 | 10.7 | 13.0 | 85.5 | 319.2 | 1302 | 0.00190 |

| Historical | Future | % Change | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Region | City | Min | Median | Max | Min | Median | Max | Min | Median | Max |

| Cordillera | WHE | 0.14 | 0.16 | 0.19 | 0.23 | 0.27 | 0.31 | 61.4 | 67.2 | 57.8 |

| Western maritime | VAN | 1.31 | 1.33 | 1.38 | 1.26 | 1.36 | 1.51 | −3.8 | 1.7 | 9.4 |

| Prairie | CAL | 0.32 | 0.36 | 0.44 | 0.34 | 0.44 | 0.56 | 7.2 | 21.6 | 29.4 |

| Prairie | SKT | 0.24 | 0.29 | 0.32 | 0.25 | 0.32 | 0.41 | 2.0 | 10.1 | 28.4 |

| Prairie | WNG | 0.27 | 0.33 | 0.36 | 0.29 | 0.37 | 0.44 | 8.6 | 11.6 | 21.0 |

| Southeastern | TOR | 0.47 | 0.53 | 0.56 | 0.50 | 0.56 | 0.65 | 5.0 | 5.3 | 16.1 |

| Southeastern | OTT | 0.44 | 0.46 | 0.48 | 0.50 | 0.53 | 0.59 | 13.3 | 15.8 | 20.9 |

| Southeastern | MTL | 0.45 | 0.50 | 0.57 | 0.54 | 0.62 | 0.67 | 18.7 | 23.0 | 17.5 |

| Eastern maritime | MTN | 0.63 | 0.67 | 0.70 | 0.75 | 0.80 | 0.90 | 19.1 | 18.9 | 28.6 |

| Eastern maritime | CTN | 0.70 | 0.76 | 0.85 | 0.83 | 0.90 | 0.97 | 18.1 | 19.2 | 15.0 |

| Eastern maritime | HFX | 1.34 | 1.41 | 1.53 | 1.34 | 1.44 | 1.62 | 0.4 | 2.6 | 6.0 |

| Eastern maritime | STJ | 1.50 | 1.66 | 1.77 | 1.54 | 1.70 | 1.93 | 2.1 | 2.6 | 9.0 |

| H: 1986–2016 | F: 2062–2092 | F–H 3 | t-Test | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Climate Region | City | Min | P50 1 | Max | Runs > 1 2 | Min | P50 | Max | Runs > 1 | Min | P50 | Max | Runs > 1 | t-Value | p-Value |

| Fibre cement cladding, vented, MS = 1% | |||||||||||||||

| Cordillera | WHE | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | −2.640 | 0.019 |

| Western maritime | VAN | 0.0 | 0.3 | 1.3 | 2 | 0.0 | 1.2 | 3.3 | 8 | 0.0 | 0.9 | 1.9 | 6 | −3.310 | 0.004 |

| Prairie | CAL | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.1 | 0 | −3.629 | 0.002 |

| Prairie | SKT | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.3 | 0 | 0.0 | 0.0 | 0.3 | 0 | −3.677 | 0.002 |

| Prairie | WNG | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.1 | 1.1 | 1 | 0.0 | 0.1 | 1.1 | 1 | −5.041 | 0.000 |

| Southeastern | TOR | 0.0 | 0.0 | 0.1 | 0 | 0.1 | 0.5 | 1.7 | 6 | 0.1 | 0.5 | 1.7 | 6 | −7.101 | 0.000 |

| Southeastern | OTT | 0.0 | 0.0 | 0.3 | 0 | 0.4 | 1.5 | 3.5 | 11 | 0.4 | 1.4 | 3.2 | 11 | −8.640 | 0.000 |

| Southeastern | MTL | 0.0 | 0.0 | 0.3 | 0 | 0.5 | 3.0 | 4.2 | 12 | 0.5 | 3.0 | 3.8 | 12 | −7.027 | 0.000 |

| Eastern maritime | MTN | 0.0 | 0.0 | 0.3 | 0 | 0.2 | 0.8 | 3.7 | 7 | 0.2 | 0.8 | 3.4 | 7 | −8.881 | 0.000 |

| Eastern maritime | CTN | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.3 | 1.9 | 3 | 0.0 | 0.3 | 1.8 | 3 | −7.093 | 0.000 |

| Eastern maritime | HFX | 0.0 | 0.2 | 1.6 | 1 | 1.6 | 3.0 | 4.2 | 15 | 1.6 | 2.9 | 2.6 | 14 | −13.109 | 0.000 |

| Eastern maritime | STJ | 0.0 | 0.0 | 0.4 | 0 | 0.0 | 0.3 | 1.8 | 3 | 0.0 | 0.2 | 1.4 | 3 | −4.541 | 0.000 |

| Fibre cement cladding, ventilated, MS = 1% | |||||||||||||||

| Cordillera | WHE | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | −2.528 | 0.023 |

| Western maritime | VAN | 0.0 | 0.2 | 0.9 | 0 | 0.0 | 0.7 | 2.4 | 3 | 0.0 | 0.5 | 1.5 | 3 | −3.444 | 0.003 |

| Prairie | CAL | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.0 | 0 | −2.567 | 0.018 |

| Prairie | WNG | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.1 | 0 | −3.596 | 0.003 |

| Prairie | SKT | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.5 | 0 | 0.0 | 0.0 | 0.5 | 0 | −3.947 | 0.001 |

| Southeastern | TOR | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.3 | 1.2 | 2 | 0.0 | 0.3 | 1.2 | 2 | −6.290 | 0.000 |

| Southeastern | OTT | 0.0 | 0.0 | 0.2 | 0 | 0.1 | 0.6 | 2.4 | 6 | 0.1 | 0.6 | 2.3 | 6 | −7.329 | 0.000 |

| Southeastern | MTL | 0.0 | 0.0 | 0.2 | 0 | 0.2 | 1.8 | 4.0 | 10 | 0.2 | 1.8 | 3.8 | 10 | −6.368 | 0.000 |

| Eastern maritime | MTN | 0.0 | 0.0 | 0.2 | 0 | 0.1 | 0.6 | 3.0 | 4 | 0.1 | 0.6 | 2.8 | 4 | −8.034 | 0.000 |

| Eastern maritime | CTN | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.2 | 1.4 | 2 | 0.0 | 0.2 | 1.3 | 2 | −6.428 | 0.000 |

| Eastern maritime | HFX | 0.0 | 0.1 | 1.2 | 1 | 1.1 | 2.5 | 4.1 | 15 | 1.1 | 2.4 | 2.9 | 14 | −13.836 | 0.000 |

| Eastern maritime | STJ | 0.0 | 0.0 | 0.2 | 0 | 0.0 | 0.2 | 1.4 | 3 | 0.0 | 0.1 | 1.1 | 3 | −4.134 | 0.001 |

| H: 1986–2016 | F: 2062–2092 | F–H 3 | t-Test | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Climate Region | City | Min | P50 1 | Max | Runs > 1 2 | Min | P50 | Max | Runs > 1 | Min | P50 | Max | Runs > 1 | t-Value | p-Value |

| Aluminum composite material cladding, vented, MS = 1% | |||||||||||||||

| Cordillera | WHE | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | −2.478 | 0.025 |

| Western maritime | VAN | 0.1 | 1.2 | 2.5 | 9 | 0.1 | 2.5 | 4.3 | 11 | 0.1 | 1.3 | 1.8 | 2 | −3.530 | 0.002 |

| Prairie | CAL | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.2 | 0 | 0.0 | 0.0 | 0.1 | 0 | −1.464 | 0.156 |

| Prairie | SKT | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.1 | 0 | −3.542 | 0.003 |

| Prairie | WNG | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.4 | 0 | 0.0 | 0.0 | 0.4 | 0 | −3.255 | 0.006 |

| Southeastern | TOR | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.2 | 0.8 | 0 | 0.0 | 0.2 | 0.8 | 0 | −4.968 | 0.000 |

| Southeastern | OTT | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.3 | 1.5 | 1 | 0.0 | 0.3 | 1.4 | 1 | −5.787 | 0.000 |

| Southeastern | MTL | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.8 | 3.7 | 6 | 0.0 | 0.8 | 3.6 | 6 | −5.683 | 0.000 |

| Eastern maritime | MTN | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.5 | 2.4 | 3 | 0.0 | 0.5 | 2.3 | 3 | −6.747 | 0.000 |

| Eastern maritime | CTN | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.1 | 1.3 | 1 | 0.0 | 0.1 | 1.2 | 1 | −4.644 | 0.000 |

| Eastern maritime | HFX | 0.0 | 0.1 | 1.6 | 1 | 1.0 | 2.4 | 4.1 | 14 | 1.0 | 2.3 | 2.5 | 13 | −12.414 | 0.000 |

| Eastern maritime | STJ | 0.0 | 0.0 | 0.8 | 0 | 0.0 | 0.2 | 1.8 | 5 | 0.0 | 0.1 | 1.0 | 5 | −3.563 | 0.003 |

| Aluminum composite material cladding, ventilated, MS = 1% | |||||||||||||||

| Cordillera | WHE | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | −2.384 | 0.030 |

| Western maritime | VAN | 0.0 | 0.1 | 0.6 | 0 | 0.0 | 0.4 | 1.7 | 2 | 0.0 | 0.3 | 1.1 | 2 | −3.177 | 0.005 |

| Prairie | CAL | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.0 | 0.0 | 0 | −1.643 | 0.113 |

| Prairie | WNG | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.0 | 0 | −3.478 | 0.003 |

| Prairie | SKT | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.0 | 0.4 | 0 | 0.0 | 0.0 | 0.3 | 0 | −3.264 | 0.006 |

| Southeastern | TOR | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.1 | 0.7 | 0 | 0.0 | 0.1 | 0.7 | 0 | −5.506 | 0.000 |

| Southeastern | OTT | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.3 | 1.1 | 1 | 0.0 | 0.3 | 1.1 | 1 | −5.812 | 0.000 |

| Southeastern | MTL | 0.0 | 0.0 | 0.0 | 0 | 0.0 | 0.6 | 3.3 | 5 | 0.0 | 0.6 | 3.3 | 5 | −5.698 | 0.000 |

| Eastern maritime | MTN | 0.0 | 0.0 | 0.1 | 0 | 0.1 | 0.4 | 2.1 | 3 | 0.1 | 0.4 | 2.1 | 3 | −7.051 | 0.000 |

| Eastern maritime | CTN | 0.0 | 0.0 | 0.1 | 0 | 0.0 | 0.1 | 0.9 | 0 | 0.0 | 0.1 | 0.8 | 0 | −5.121 | 0.000 |

| Eastern maritime | HFX | 0.0 | 0.0 | 0.9 | 0 | 0.8 | 1.8 | 4.0 | 10 | 0.8 | 1.8 | 3.1 | 10 | −14.104 | 0.000 |

| Eastern maritime | STJ | 0.0 | 0.0 | 0.2 | 0.0 | 0.0 | 0.1 | 1.0 | 0 | 0.0 | 0.1 | 0.8 | 0 | −3.708 | 0.002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Defo, M.; Wang, L.; Lacasse, M.A.; Moore, T.V. Evaluation of Moisture Performance of Tall Wood Building Envelope under Climate Change in Different Canadian Climatic Regions. Forests 2023, 14, 718. https://doi.org/10.3390/f14040718

Defo M, Wang L, Lacasse MA, Moore TV. Evaluation of Moisture Performance of Tall Wood Building Envelope under Climate Change in Different Canadian Climatic Regions. Forests. 2023; 14(4):718. https://doi.org/10.3390/f14040718

Chicago/Turabian StyleDefo, Maurice, Lin Wang, Michael A. Lacasse, and Travis V. Moore. 2023. "Evaluation of Moisture Performance of Tall Wood Building Envelope under Climate Change in Different Canadian Climatic Regions" Forests 14, no. 4: 718. https://doi.org/10.3390/f14040718