Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Partial Delignification of the Wood Samples

2.3. Wood Mineralization

2.4. Mineralized Wood Compression

2.5. Characterization

3. Result Analysis

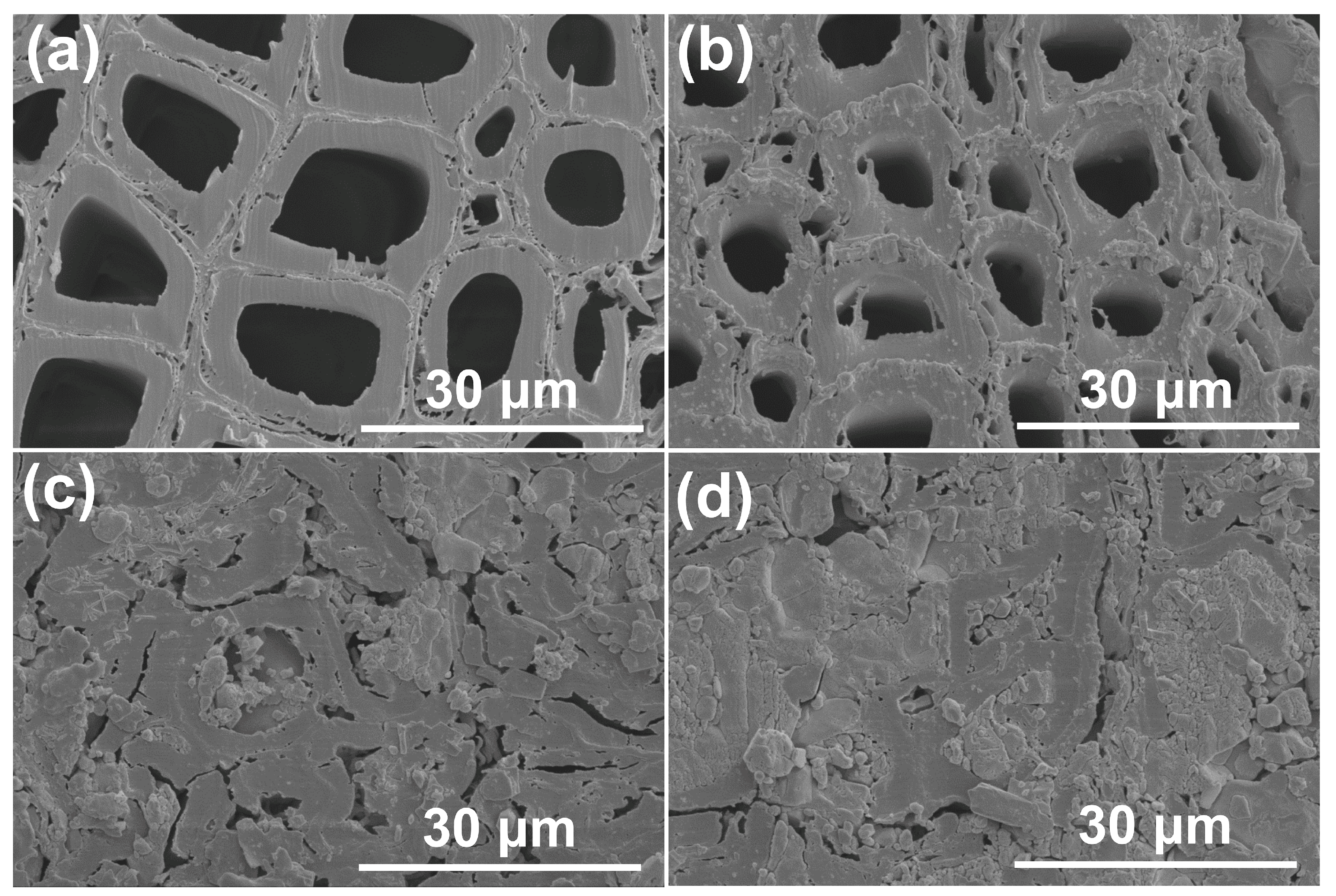

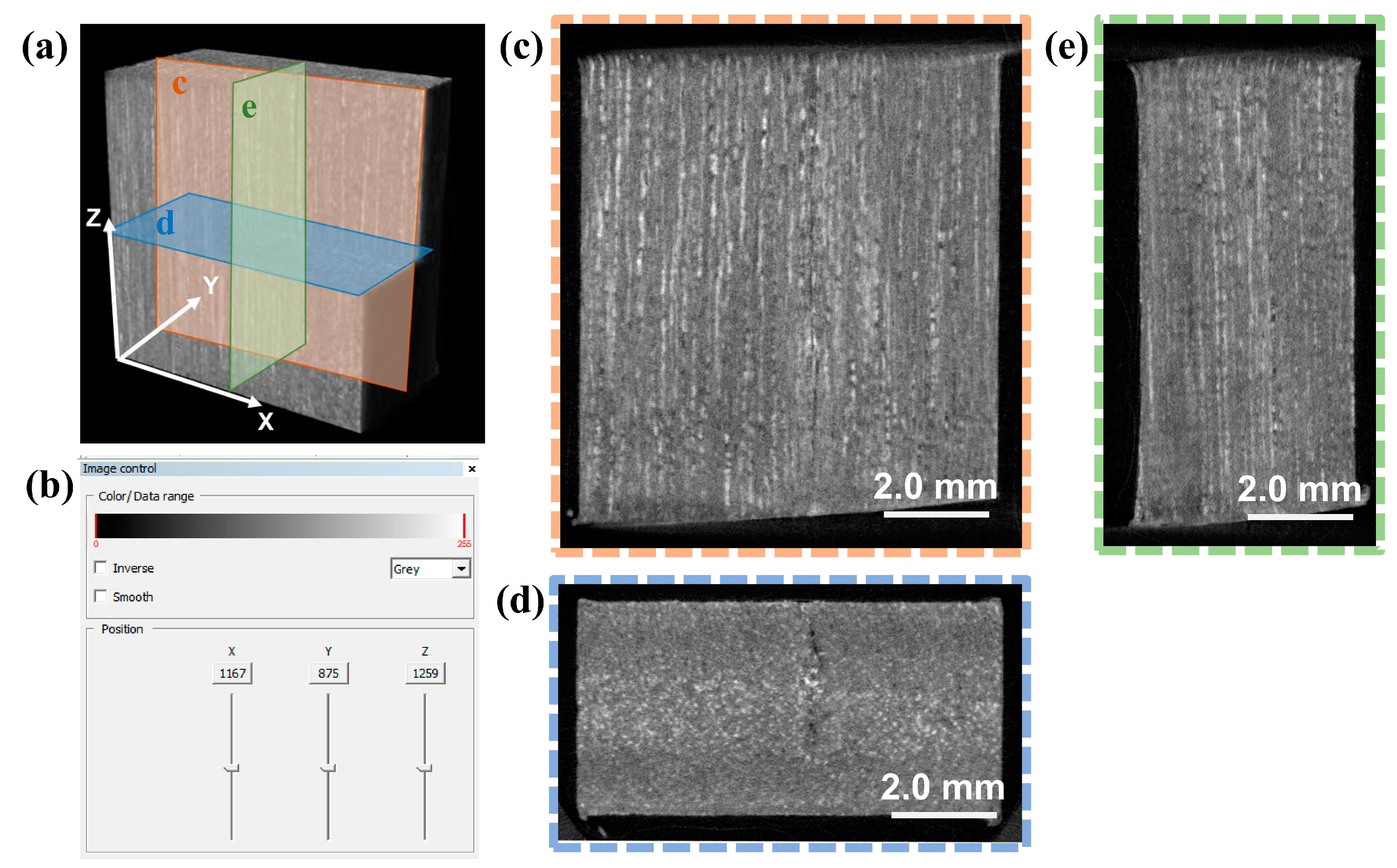

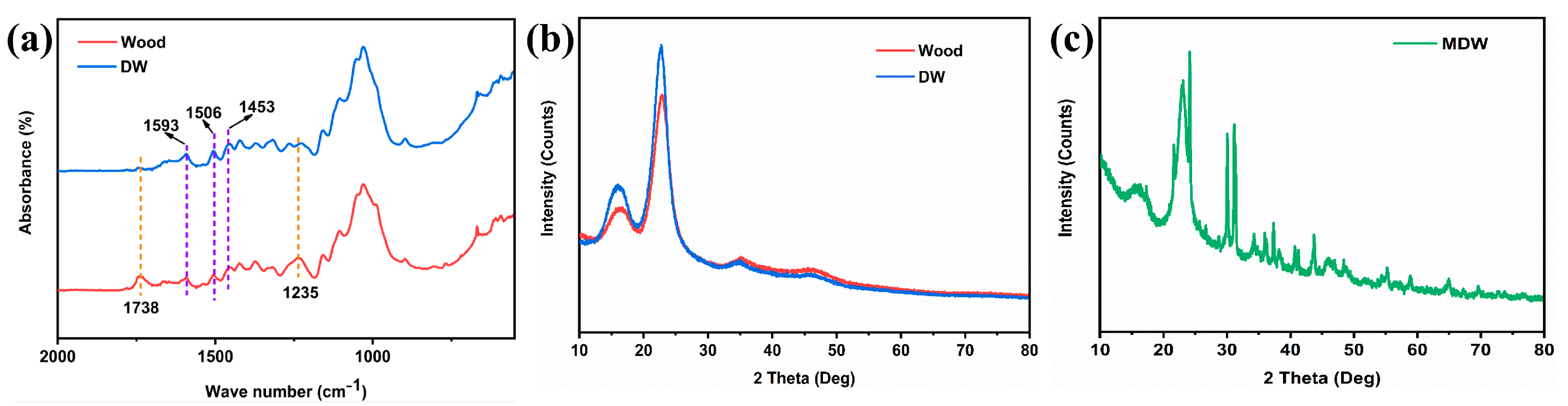

3.1. Microstructures and Chemical Components

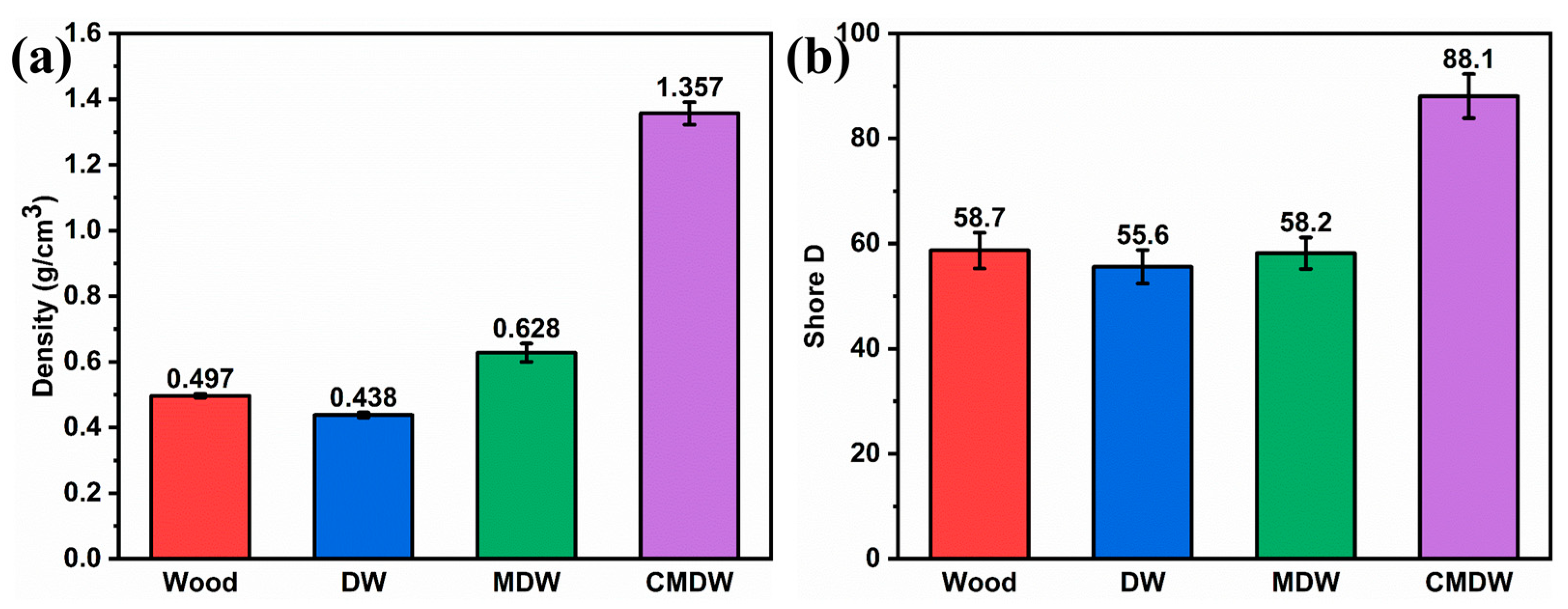

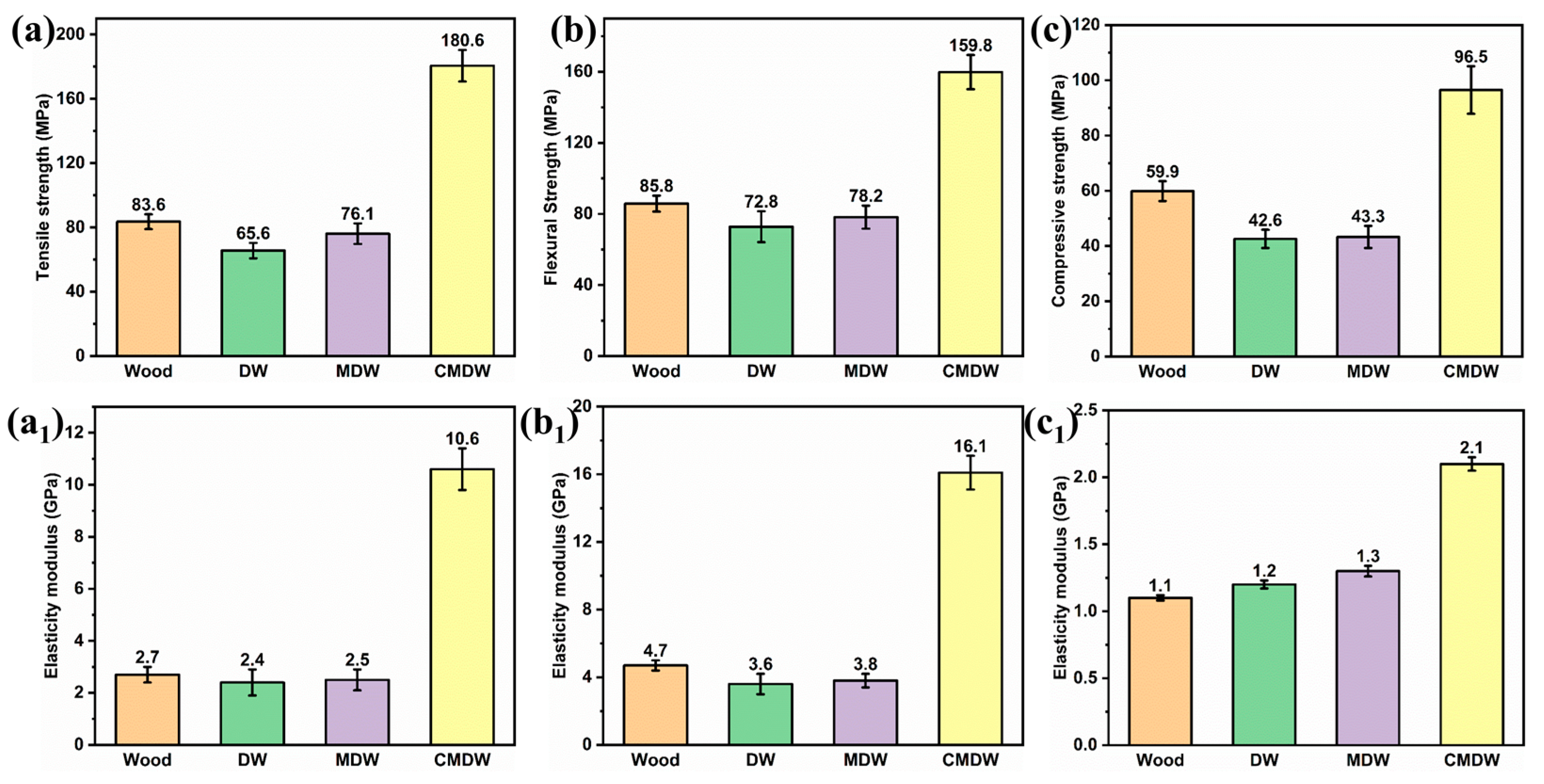

3.2. Mechanical Performance

3.3. Thermal Degradation Properties

3.4. Fire Retardance Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–Property–Function Relationships of Natural and Engineered Wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Mendez, D.F.; Olaniran, S.O.; Rüggeberg, M.; Burgert, I.; Herrmann, H.J.; Wittel, F.K. Mechanical behavior of chemically modified Norway spruce: A generic hierarchical model for wood modifications. Wood Sci. Technol. 2019, 53, 447–467. [Google Scholar] [CrossRef]

- Bi, W.; Li, H.; Hui, D.; Gaff, M.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Effects of Chemical Modification and Nanotechnology on Wood Properties. Nanotechnol. Rev. 2021, 10, 978–1008. [Google Scholar] [CrossRef]

- Panzarasa, G.; Burgert, I. Designing Functional Wood Materials for Novel Engineering Applications. Holzforschung 2022, 76, 211–222. [Google Scholar] [CrossRef]

- Wang, H.; He, M.; Ran, N.; Xie, D.; Wang, Q.; Teng, M.; Wang, P. China’s Key Forestry Ecological Development Programs: Implementation, Environmental Impact and Challenges. Forests 2021, 12, 101. [Google Scholar] [CrossRef]

- Báder, M.; Németh, R.; Vörös, Á.; Tóth, Z.; Novotni, A. The Effect of Agroforestry Farming on Wood Quality and Timber Industry and Its Supportation by Horizon 2020. Agrofor. Syst. 2023, 97, 587–603. [Google Scholar] [CrossRef]

- Acosta, A.P.; De Avila Delucis, R.; Amico, S.C.; Gatto, D.A. Fast-Growing Pine Wood Modified by a Two-Step Treatment Based on Heating and in Situ Polymerization of Polystyrene. Constr. Build. Mater. 2021, 302, 124422. [Google Scholar] [CrossRef]

- Dong, Y.; Qin, Y.; Wang, K.; Yan, Y.; Zhang, S.; Li, J.; Zhang, S. Assessment of the Performance of Furfurylated Wood and Acetylated Wood: Comparison among Four Fast-Growing Wood Species. BioResources 2016, 11, 3679–3690. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood Modification Technologies—A Review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Yue, K.; Li, X.; Jiao, X.; Wu, P.; Song, X. Strength grading of Chinese poplar wood for structural use following thermal modification. Polym. Test. 2023, 123, 708032. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood Modification by Heat Treatment: A Review. BioRes 2008, 4, 370–404. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Ren, D.; Yu, Y.; Yu, Y. Wood Modification with Furfuryl Alcohol Catalysed by a New Composite Acidic Catalyst. Wood Sci. Technol. 2015, 49, 845–856. [Google Scholar] [CrossRef]

- Pondelak, A.; Škapin, A.S.; Knez, N.; Knez, F.; Pazlar, T. Improving the Flame Retardancy of Wood Using an Eco-Friendly Mineralisation Process. Green Chem. 2021, 23, 1130–1135. [Google Scholar] [CrossRef]

- Luan, Y.; Fang, C.-H.; Ma, Y.-F.; Fei, B.-H. Wood Mechanical Densification: A Review on Processing. Mater. Manuf. Process. 2022, 37, 359–371. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Gaan, S.; Burgert, I. Mineralization of Wood by Calcium Carbonate Insertion for Improved Flame Retardancy. Holzforschung 2016, 70, 867–876. [Google Scholar] [CrossRef]

- Fei, T.; Yi, H.-J.; Zboray, R.; Yan, X.-Q.; Song, S.-S.; Ren, L.; Guo, H.; Jiang, Y. Bioinspired Enzymatic Mineralization Incorporates CaCO3 Mesocrystals in Wood for Surface Reinforcement and Flame-Retardancy. ACS Sustain. Chem. Eng. 2022, 10, 16118–16124. [Google Scholar] [CrossRef]

- Merk, V.; Chanana, M.; Keplinger, T.; Gaan, S.; Burgert, I. Hybrid Wood Materials with Improved Fire Retardance by Bio-Inspired Mineralisation on the Nano- and Submicron Level. Green Chem. 2015, 17, 1423–1428. [Google Scholar] [CrossRef]

- Cabral, J.P.; Kafle, B.; Subhani, M.; Reiner, J.; Ashraf, M. Densification of Timber: A Review on the Process, Material Properties, and Application. J. Wood Sci. 2022, 68, 20. [Google Scholar] [CrossRef]

- Gindl, W. Comparing Mechanical Properties of Normal and Compression Wood in Norway Spruce: The Role of Lignin in Compression Parallel to the Grain. Holzforschung 2002, 56, 395–401. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, Z.; Iida, I.; Guo, J. Studies on Pre-Treatment by Compression for Wood Impregnation I: Effects of Compression Ratio, Compression Direction, Compression Speed and Compression-Unloading Place on the Liquid Impregnation of Wood. J. Wood Sci. 2018, 64, 551–556. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing Bulk Natural Wood into a High-Performance Structural Material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Fu, Q.; Ansari, F.; Zhou, Q.; Berglund, L.A. Wood Nanotechnology for Strong, Mesoporous, and Hydrophobic Biocomposites for Selective Separation of Oil/Water Mixtures. ACS Nano 2018, 12, 2222–2230. [Google Scholar] [CrossRef]

- Wang, K.; Liu, X.; Tan, Y.; Zhang, W.; Zhang, S.; Li, J. Two-Dimensional Membrane and Three-Dimensional Bulk Aerogel Materials via Top-down Wood Nanotechnology for Multibehavioral and Reusable Oil/Water Separation. Chem. Eng. J. 2019, 371, 769–780. [Google Scholar] [CrossRef]

- Guan, H.; Cheng, Z.; Wang, X. Highly Compressible Wood Sponges with a Spring-like Lamellar Structure as Effective and Reusable Oil Absorbents. ACS Nano 2018, 12, 10365–10373. [Google Scholar] [CrossRef]

- Wang, K.; Peng, H.; Gu, Q.; Zhang, X.; Liu, X.; Dong, Y.; Cai, Y.; Li, Y.; Li, J. Scalable, Large-Size, and Flexible Transparent Bamboo. Chem. Eng. J. 2023, 451, 138349. [Google Scholar] [CrossRef]

- Garvey, C.J.; Parker, I.H.; Simon, G.P. On the Interpretation of X-Ray Diffraction Powder Patterns in Terms of the Nanostructure of Cellulose I Fibres. Macromol. Chem. Phys. 2005, 206, 1568–1575. [Google Scholar] [CrossRef]

- Tanaka, F.; Koshijima, T. Orientation Distributions of Cellulose Crystallites in Pinus Densiflora Woods. Wood Sci. Technol. 1984, 18, 177–186. [Google Scholar] [CrossRef]

- Guo, H.; Luković, M.; Mendoza, M.; Schlepütz, C.M.; Griffa, M.; Xu, B.; Gaan, S.; Herrmann, H.; Burgert, I. Bioinspired Struvite Mineralization for Fire-Resistant Wood. ACS Appl. Mater. Interfaces 2019, 11, 5427–5434. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.-P. The Effect of the Biomass Components Lignin, Cellulose and Hemicellulose on TGA and Fixed Bed Pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Grønli, M.G.; Várhegyi, G.; Blasi, C.D. Thermogravimetric Analysis and Devolatilization Kinetics of Wood. Ind. Eng. Chem. Res. 2002, 41, 4201–4208. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of Hemicellulose, Cellulose and Lignin Pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Guo, H.; Özparpucu, M.; Windeisen-Holzhauser, E.; Schlepütz, C.M.; Quadranti, E.; Gaan, S.; Dreimol, C.; Burgert, I. Struvite Mineralized Wood as Sustainable Building Material: Mechanical and Combustion Behavior. ACS Sustain. Chem. Eng. 2020, 8, 10402–10412. [Google Scholar] [CrossRef]

- Fleurotte, M.; Debenest, G.; Authier, O.; Fontaine, G.; Bourbigot, S.; Amokrane, A. Modelling of the swelling behaviour of a fire retarded material under a cone calorimeter. J. Fire Sci. 2023, 41, 136–166. [Google Scholar] [CrossRef]

- Zhou, H.; Wen, D.; Hao, X.; Chen, C.; Zhao, N.; Ou, R.; Wang, Q. Nanostructured Multifunctional Wood Hybrids Fabricated via in Situ Mineralization of Zinc Borate in Hierarchical Wood Structures. Chem. Eng. J. 2023, 451, 138308. [Google Scholar] [CrossRef]

- Park, W.C.; Atreya, A.; Baum, H.R. Determination of Pyrolysis Temperature for Charring Materials. Proc. Combust. Inst. 2009, 32, 2471–2479. [Google Scholar] [CrossRef]

- Liu, L.; Hu, J.; Zhuo, J.; Jiao, C.; Chen, X.; Li, S. Synergistic Flame Retardant Effects between Hollow Glass Microspheres and Magnesium Hydroxide in Ethylene-Vinyl Acetate Composites. Polym. Degrad. Stab. 2014, 104, 87–94. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Fang, X.; Sun, C.; Zhang, T.; Wang, K.; Dong, Y. Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy. Forests 2023, 14, 1567. https://doi.org/10.3390/f14081567

Liu X, Fang X, Sun C, Zhang T, Wang K, Dong Y. Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy. Forests. 2023; 14(8):1567. https://doi.org/10.3390/f14081567

Chicago/Turabian StyleLiu, Xiaorong, Xinyu Fang, Chen Sun, Tao Zhang, Kaili Wang, and Youming Dong. 2023. "Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy" Forests 14, no. 8: 1567. https://doi.org/10.3390/f14081567

APA StyleLiu, X., Fang, X., Sun, C., Zhang, T., Wang, K., & Dong, Y. (2023). Hybrid Wood Composites with Improved Mechanical Strength and Fire Retardance Due to a Delignification–Mineralization–Densification Strategy. Forests, 14(8), 1567. https://doi.org/10.3390/f14081567