Wood from Field Tests as a Model for Assessing the Suitability of Post-Consumer Wood

Abstract

:1. Introduction

2. Materials and Methods

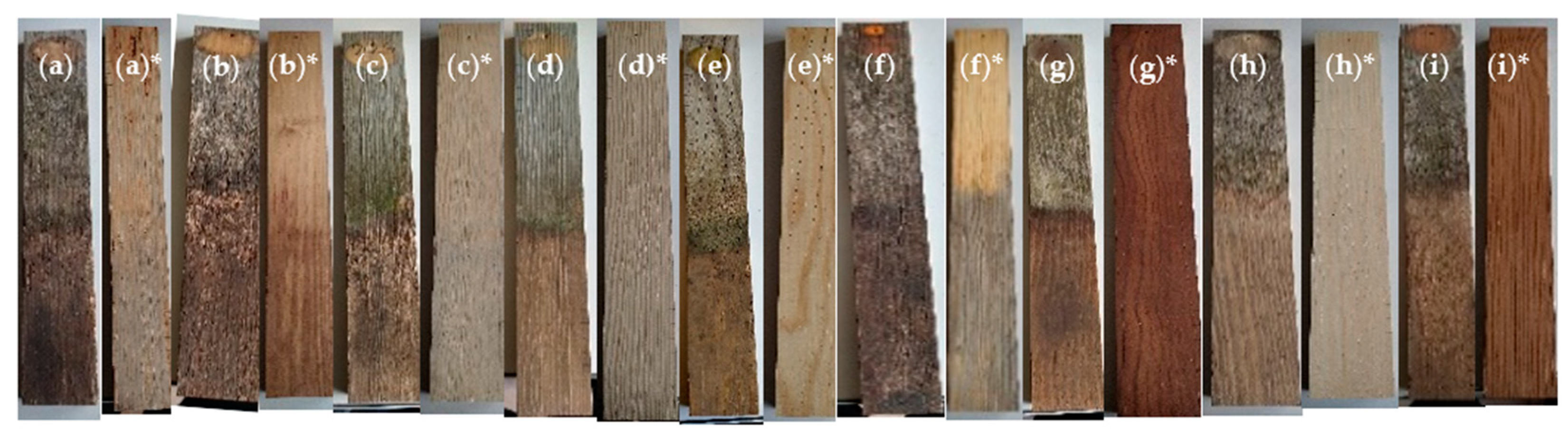

2.1. Materials

2.2. Field Exposure

2.3. Brown Rot Degradation

- -

- Nine replicates from the “double-layer test”;

- -

- Nine replicates from the “field-ground test” (above-ground part of samples);

- -

- Nine replicates from the “field-ground test” (in-ground part of samples).

2.4. Fire Properties

2.5. Colour Changes

3. Results and Discussion

3.1. Durability of Wood against C. puteana

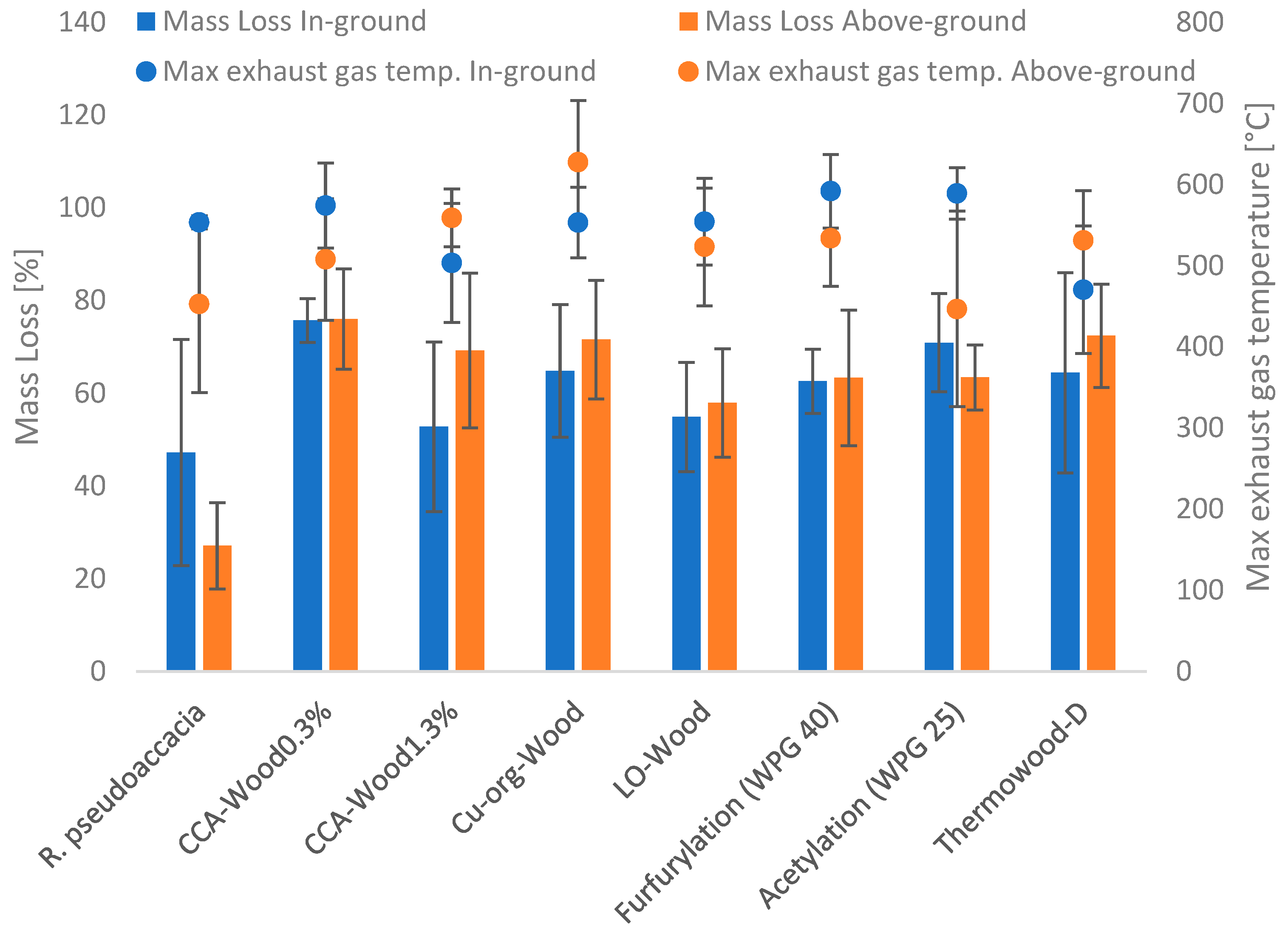

3.2. Durability of Wood against Fire

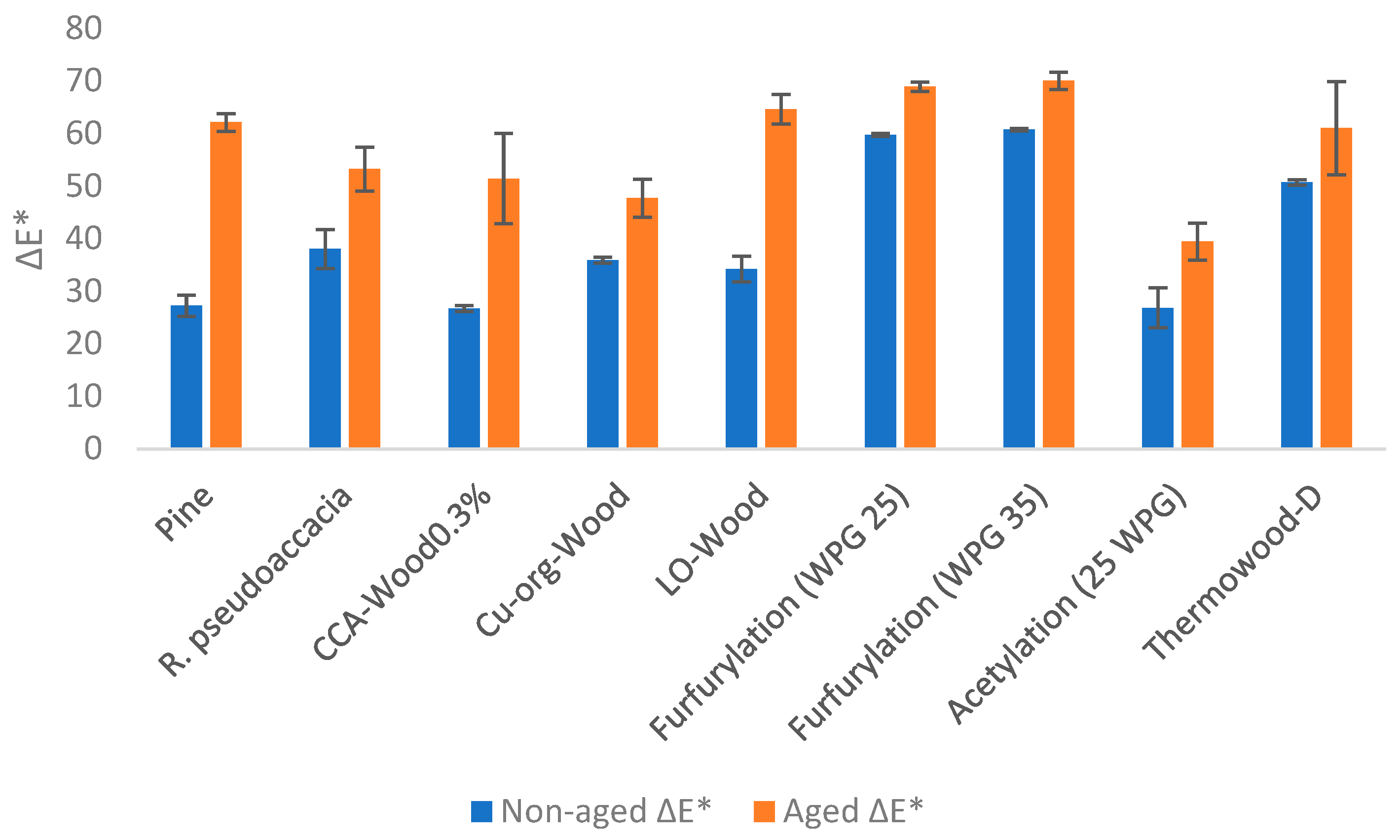

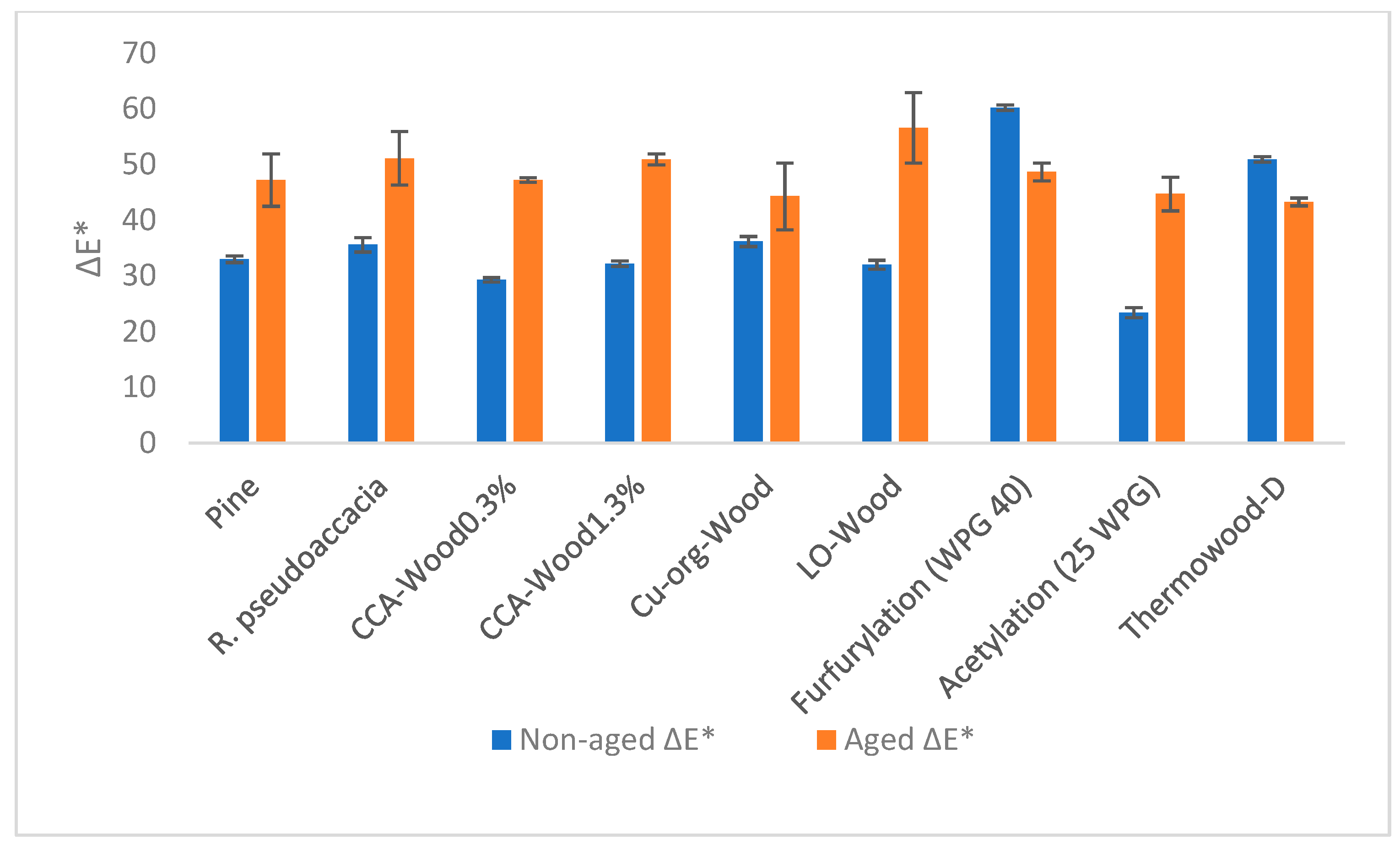

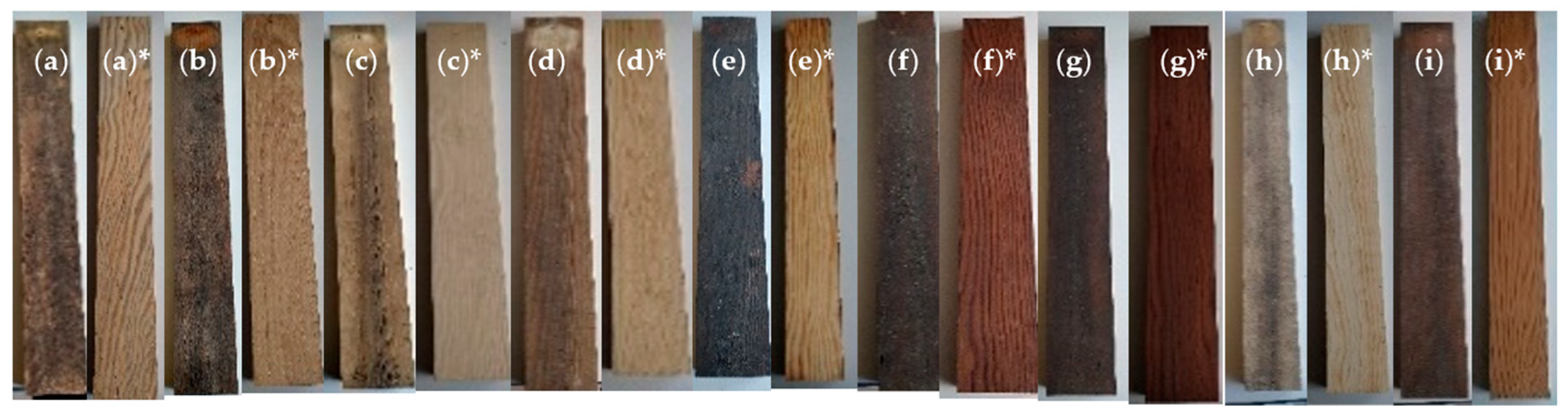

3.3. Colour Stabilities of Aging Wood

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kirker, G.; Winandy, J. Above Ground Deterioration of Wood and Wood-Based Materials. In Deterioration and Protection of Sustainable Biomaterials; ACS Publications: Washington, DC, USA, 2014; pp. 113–129. ISBN 1947-5918. [Google Scholar]

- Kutnik, M.; Suttie, E.; Brischke, C. European Standards on Durability and Performance of Wood and Wood-Based Products—Trends and Challenges. Wood Mater. Sci. Eng. 2014, 9, 122–133. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C.; Preston, A. Testing the Durability of Timber above Ground: A Review on Methodology. Wood Mater. Sci. Eng. 2016, 11, 283–304. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer, L.; Olberding, S. Durability of Wood Exposed in Ground–Comparative Field Trials with Different Soil Substrates. Int. Biodeterior. Biodegrad. 2014, 86, 108–114. [Google Scholar] [CrossRef]

- Brischke, C.; Rapp, A.O. Dose–Response Relationships between Wood Moisture Content, Wood Temperature and Fungal Decay Determined for 23 European Field Test Sites. Wood Sci. Technol. 2008, 42, 507–518. [Google Scholar] [CrossRef]

- EN 335:2013; Durability of Wood and Wood-Based Products-Use Classes: Definitions, Application to Solid Wood and Wood-Based Products. iTeh, Inc.: Newark, DE, USA, 2013.

- Singh, T.; Page, D. Evaluation of Selected Accelerated Above-Ground Durability Testing Methods for Wood after Ten Years Exposure. Forests 2020, 11, 559. [Google Scholar] [CrossRef]

- Alfredsen, G.; Westin, M. Durability of Modified Wood–Laboratory vs. Field Performance. In Proceedings of the 4th European Conference on Wood Modification, Stockholm, Sweden, 27–29 April 2009; Volume 4, pp. 515–522. [Google Scholar]

- Brischke, C.; Alfredsen, G.; Humar, M.; Conti, E.; Cookson, L.; Emmerich, L.; Flæte, P.O.; Fortino, S.; Francis, L.; Hundhausen, U. Modelling the Material Resistance of Wood—Part 3: Relative Resistance in above-and in-Ground Situations—Results of a Global Survey. Forests 2021, 12, 590. [Google Scholar] [CrossRef]

- Sirkin, T.; ten Houten, M. The Cascade Chain: A Theory and Tool for Achieving Resource Sustainability with Applications for Product Design. Resour. Conserv. Recycl. 1994, 10, 213–276. [Google Scholar] [CrossRef]

- Kharazipour, A.; Kües, U. 20. Recycling of Wood Composites and Solid Wood Products. In Wood Production, Wood Technology, and Biotechnological Impacts; Universitätsverlag Göttingen: Göttingen, Germany, 2007. [Google Scholar]

- Kuru, A. Biomimetic Adaptive Building Skins: An Approach towards Multifunctionality; UNSW Sydney: Sydney, Australia, 2020. [Google Scholar]

- Vimpolšek, B.; Androjna, A.; Lisec, A. Modelling of Post-Consumer Wood Sorting and Manipulation: Computational Conception and Case Study. Wood Res. 2022, 67, 472–487. [Google Scholar] [CrossRef]

- Vis, M.; Mantau, U.; Allen, B. CASCADES: Study on the Optimised Cascading Use of Wood; European Union Publications Office: Luxembourg, 2016; ISBN 92-79-57725-5. [Google Scholar]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

- Mantau, U.; Saal, U.; Prins, K.; Steierer, F.; Lindner, M.; Verkerk, H.; Eggers, J.; Leek, N.; Oldenburger, J.; Asikainen, A. Real Potential for Changes in Growth and Use of EU Forests; Methodology Report; EUwood: Hamburg, Germany, 2010. [Google Scholar]

- Faraca, G.; Boldrin, A.; Astrup, T. Resource Quality of Wood Waste: The Importance of Physical and Chemical Impurities in Wood Waste for Recycling. Waste Manag. 2019, 87, 135–147. [Google Scholar] [CrossRef] [PubMed]

- Mahnert, K.C.; Ragnhildstveit, I.; Modaresi, R. Initial Study on Sorting of Reclaimed Timber with Industrial State-of-the-Art Technology. In Proceedings of the World Conference on Timber Engineering 2023 (WCTE2023), Oslo, Norway, 12 October 2023. [Google Scholar]

- Irle, M.; Belloncle, C.; Buchner, J.; Herndon, A.; Marcadet, J.; Lebreton, F. A Study of End-of-Life Fibreboards: Their Characteristics and Availability in Europe. In Proceedings of the 11èmes Journées du GDR 3544 Sciences du Bois Conference, Nice, France, 16–18 November 2022. [Google Scholar]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status Quo and Future Directions of Construction and Demolition Waste Research: A Critical Review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Taylor, J.; Warnken, M. Wood Recovery and Recycling: A Source Book for Australia; Forest and Wood Products Australia: Melbourne, Australia, 2008. [Google Scholar]

- Bolin, C.A.; Smith, S.T. Life Cycle Assessment of CCA-Treated Wood Highway Guard Rail Posts in the US with Comparisons to Galvanized Steel Guard Rail Posts; Scientific Research Publishing: Wuhan, China, 2013. [Google Scholar]

- Candelier, K.; Dibdiakova, J. A Review on Life Cycle Assessments of Thermally Modified Wood. Holzforschung 2021, 75, 199–224. [Google Scholar] [CrossRef]

- Westin, M.; Conti, E.; Creemers, J.; Flæte, P.-O.; Gellerich, A.; Irbe, I.; Klamer, M.; Mazela, B.; Melcher, E.; Möller, R. Report on COST E37 Round Robin Tests: Comparison of Results from Laboratory and Field Tests. In Proceedings of the 44th IRG Annual Meeting 2013 (IRG44), Stockholm, Sweden, 16–20 June 2013. p. IRG/WP 13-20535. [Google Scholar]

- Westin, M.; Rapp, A.; Nilsson, T. Field Test of Resistance of Modified Wood to Marine Borers. Wood Mater. Sci. Eng. 2006, 1, 34–38. [Google Scholar] [CrossRef]

- Epmeier, H.; Westin, M.; Rapp, A. Differently Modified Wood: Comparison of Some Selected Properties. Scand. J. For. Res. 2004, 19, 31–37. [Google Scholar] [CrossRef]

- EN 113-1:2020; Durability of Wood and Wood-Based Products—Test Method against Wood Destroying Basidiomycetes—Part 1: Assessment of Biocidal Efficacy of Wood Preservatives. iTeh, Inc.: Newark, DE, USA, 2020.

- ASTM E69-02; Standard Test Method for Combustible Properties of Treated Wood by the Fire-Tube Apparatus. ASTM International: West Conshohocken, PA, USA, 2022.

- Pollet, C.; Jourez, B.; Hebert, J. Natural Durability of Black Locust (Robinia pseudoacacia L.) Wood Grown in Wallonia, Belgium. Can. J. For. Res. 2008, 38, 1366–1372. [Google Scholar] [CrossRef]

- Pizzi, A. A New Approach to the Formulation and Application of CCA Preservatives. Wood Sci. Technol. 1983, 17, 303–319. [Google Scholar] [CrossRef]

- Sellers, T., Jr.; Miller, G.D., Jr. Evaluations of Three Adhesive Systems for CCA-Treated Lumber. For. Prod. J. 1997, 47, 73. [Google Scholar]

- De Vetter, L.; Pilgård, A.; Treu, A.; Westin, M.; Van Acker, J. Combined Evaluation of Durability and Ecotoxicity: A Case Study on Furfurylated Wood. Wood Mater. Sci. Eng. 2009, 4, 30–36. [Google Scholar] [CrossRef]

- Lande, S.; Eikenes, M.; Westin, M. Chemistry and Ecotoxicology of Furfurylated Wood. Scand. J. For. Res. 2004, 19, 14–21. [Google Scholar] [CrossRef]

- Esteves, B.; Nunes, L.; Pereira, H. Properties of Furfurylated Wood (Pinus pinaster). Eur. J. Wood Wood Prod. 2011, 69, 521–525. [Google Scholar] [CrossRef]

- Ayata, U.; Akcay, C.; Esteves, B. Determination of Decay Resistance against Pleurotus ostreatus and Coniophora puteana Fungus of Heat-Treated Scotch Pine, Oak and Beech Wood Species. Maderas. Cienc. Tecnol. 2017, 19, 309–316. [Google Scholar] [CrossRef]

- Hill, C.A.; Curling, S.F.; Kwon, J.H.; Marty, V. Decay Resistance of Acetylated and Hexanoylated Hardwood and Softwood Species Exposed to Coniophora puteana. Holzforschung 2009, 63, 619–625. [Google Scholar] [CrossRef]

- Hasburgh, L.E.; Zelinka, S.L.; Bishell, A.B.; Kirker, G.T. Durability and Fire Performance of Charred Wood Siding (Shou Sugi Ban). Forests 2021, 12, 1262. [Google Scholar] [CrossRef]

| Sample ID | Process | Treatment/Modified | Retention/WPG | Wood Specimen | Additional Information |

|---|---|---|---|---|---|

| CCA-Wood0.3% | treatment | chromate copper arsenate | 0.3% | Pinus sylvestris L. (sapwood) | [8,26,27] |

| CCA-Wood1.3% | 1.3% | ||||

| Cu-org-Wood | copper hydroxycarbonate 13%, boric acid 4%, bis-(N-cyclohexyl-odiazenio-dioxy)-copper 2.8% | 11 kg/m2 | |||

| LO-Wood | Reactive linseed oil derivative | 150 kg/m2 | [27,28] | ||

| Furfurylation (WPG25) | furfurylation | furfuryl alcohol | 25 [-] | ||

| “Furfurylation (WPG35) | 35 [-] | [26,27,28] | |||

| “Furfurylation (WPG40)” | 40 [-] | ||||

| Acetylation (WPG25) | Acetylation | acetic anhydride | 25 [-] | ||

| Thermwood-D | Temp. modification | Temp 220 °C Steam | - | [8,26] | |

| Pine | - | - | - | - | |

| R. pseudoaccacia | - | - | - | - | - |

| Type of Sample | Δa* | Δb* | ΔL* | |||

|---|---|---|---|---|---|---|

| Non- Aging | Aging | Non- Aging | Aging | Non- Aging | Aging | |

| Pine | 7.2 ± 1.6 | 3.1 ± 2.7 | 17.7 ± 2.6 | 5.9 ± 1.7 | −28.3 ± 1.8 | −61.6 ± 3.9 |

| R. pseudoaccacia | 9.9 ± 0.3 | 3.5 ± 0.5 | 21.7 ± 1.1 | 5.5 ± 1.1 | −30.7 ± 2.2 | −62.6 ± 1.7 |

| CCA-Wood0.3% | 6.5 ± 0.4 | 2.2 ± 1.7 | 17.7 ± 0.8 | 8.4 ± 4.6 | −19.5 ± 0.9 | −54.1 ± 4.0 |

| Cu-org-Wood | 6.6 ± 0.6 | 2.7 ± 2.7 | 22.6 ± 0.5 | 9.4 ± 4.5 | −24.1 ± 1.6 | −54.4 ± 1.6 |

| LO-Wood | 9.4 ± 0.3 | 0.4 ± 0.5 | 27.5 ± 0.6 | 2.9 ± 0.4 | −15.5 ± 1.4 | −63.3 ± 1.8 |

| Furfurylation (WPG 25) | 9.0 ± 1.6 | 2.4 ± 1.3 | 9.0 ± 2.8 | 0.9 ± 1.2 | −58.5 ± 1.6 | −68.3 ± 2.2 |

| Furfurylation (WPG 35) | 9.2 ± 0.6 | 3.8 ± 1.8 | 6.9 ± 3.2 | −0.1 ± 0.4 | −59.7 ± 0.9 | −70.1 ± 1.1 |

| Acetylation (25 WPG) | 6.8 ± 0.2 | 3.2 ± 3.2 | 21.2 ± 0.6 | 9.6 ± 4.1 | −14.1 ± 1.8 | −52.1 ± 3.3 |

| Thermowood-D | 13.3 ± 0.4 | 5.8 ± 0.9 | 21.9 ± 0.9 | 8.6 ± 0.9 | −43.5 ± 1.0 | −61.4 ± 0.2 |

| Type of Sample | Δa* | Δb* | ΔL* | |||

|---|---|---|---|---|---|---|

| Non-Aging | Aging | Non-Aging | Aging | Non-Aging | Aging | |

| Pine | 5.5 ± 0.7 | 5.1 ± 1.5 | 14.6 ± 2.3 | 8.5 ± 1.0 | −22.1 ± 3.6 | −61.2 ± 1.7 |

| R. pseudoaccacia | 9.6 ± 0.2 | 8.0 ± 4.2 | 22.1 ± 1.4 | 16.1 ± 6.7 | −29.2 ± 5.3 | −49.5 ± 6.6 |

| CCA-Wood0.3% | 6.0 ± 0.5 | 5.8 ± 1.1 | 17.3 ± 0.6 | 16.7 ± 4.8 | −19.3 ± 0.6 | −47.8 ± 5.7 |

| Cu-org-Wood | 6.5 ± 0.3 | 7.1 ± 1.3 | 23.5 ± 1.0 | 24.7 ± 0.4 | −26.3 ± 0.5 | −40.1 ± 3.9 |

| LO-Wood | 9.9 ± 0.7 | 7.4 ± 6.6 | 28.6 ± 2.5 | 7.9 ± 1.9 | −15.9 ± 1.2 | −62.8 ± 4.9 |

| Furfurylation (WPG 25) | 8.6 ± 0.5 | 7.1 ± 3.6 | 8.6 ± 0.8 | 2.9 ± 2.1 | −58.4 ± 0.4 | −68.4 ± 1.0 |

| Furfurylation (WPG 35) | 9.0 ± 0.7 | 7.6 ± 0.8 | 8.6 ± 1.0 | 1.8 ± 1.6 | −59.7 ± 1.1 | −69.5 ± 1.6 |

| Acetylation (25 WPG) | 7.4 ± 1.2 | 5.6 ± 0.2 | 21.4 ± 2.0 | 19.8 ± 3.1 | −14.2 ± 3.9 | −33.5 ± 2.3 |

| Thermowood-D | 13.4 ± 0.3 | 9.4 ± 1.3 | 22.2 ± 0.9 | 11.2 ± 1.2 | −43.5 ± 1.1 | −58.6 ± 1.1 |

| Type of Sample | Δa* | Δb* | ΔL* | |||

|---|---|---|---|---|---|---|

| Non-Aging | Aging | Non-Aging | Aging | Non-Aging | Aging | |

| Pine | 6.4 ± 069 | 4.6 ± 0.4 | 18.4 ± 7.2 | 8.4 ± 2.0 | −27.9 ± 1.8 | −57.8 ± 4.2 |

| R. pseudoaccacia | 9.7 ± 1.0 | 4.2 ± 0.3 | 15.9 ± 1.6 | 6.1 ± 0.5 | −42.9 ± 0.8 | −61.8 ± 0.4 |

| CCA-Wood0.3% | 5.3 ± 0.4 | 5.5 ± 0.1 | 15.2 ± 1.0 | 13.0 ± 0.4 | −21.4 ± 2.5 | −50.8 ± 2.2 |

| CCA-Wood1.3% | 4.6 ± 0.3 | 5.0 ± 0.2 | 15.0 ± 0.7 | 13.3 ± 0.4 | −26.7 ± 0.1 | −50.9 ± 0.6 |

| Cu-org-Wood | 6.1 ± 1.0 | 5.9 ± 0.5 | 22.0 ± 1.0 | 15.3 ± 0.9 | −25.5 ± 3.2 | −50.2 ± 1.6 |

| LO-Wood | 4.7 ± 0.9 | 3.9 ± 0.4 | 12.1 ± 1.7 | 6.7 ± 1.7 | −34.3 ± 2.6 | −60.2 ± 4.0 |

| Furfurylation (WPG 40) | 9.7 ± 0.3 | 5.7 ± 0.6 | 10.7 ± 0.2 | 9.7 ± 0.2 | −58.5 ± 0.4 | −59.0 ± 1.1 |

| Acetylation (WPG 25) | 6.3 ± 1.0 | 6.8 ± 1.1 | 18.8 ± 2.8 | 17.2 ± 2.5 | −16.1 ± 3.2 | −36.9 ± 2.5 |

| Thermowood-D | 13.6 ± 0.2 | 8.3 ± 0.9 | 22.1 ± 0.3 | 17.9 ± 1.6 | −44.3 ± 0.5 | −44.0 ± 1.5 |

| Type of Sample | Δa* | Δb* | ΔL* | |||

|---|---|---|---|---|---|---|

| Non-Aging | Aging | Non-Aging | Aging | Non-Aging | Aging | |

| Pine | 9.6 ± 0.4 | 1.4 ± 0.8 | 21.5 ± 0.3 | 8.5 ± 1.7 | −23.1 ± 0.4 | −46.4 ± 4.7 |

| R. pseudoaccacia | 9.65 ± 0.4 | 2.06 ± 0.6 | 21.9 ± 1.4 | 8.5 ± 0.9 | −264 ± 0.5 | −50.3 ± 4.8 |

| CCA-Wood0.3% | 6.3 ± 0.1 | 0.5 ± 0.1 | 17.9 ± 0.4 | 6.9 ± 0.6 | −22.2 ± 0.7 | −46.4 ± 0.5 |

| CCA-Wood1.3% | 5.0 ± 0.1 | 0.7 ± 0.1 | 16.2 ± 0.4 | 7.1 ± 1.7 | −27.3 ± 0.3 | −50.4 ± 1.4 |

| Cu-org-Wood | 7.3 ± 0.8 | 2.06 ± 0.2 | 23.1 ± 0.7 | 10.4 ± 0.6 | −26.9 ± 0.5 | −43.0 ± 0.6 |

| LO-Wood | 9.7 ± 0.4 | 1.8 ± 1.4 | 27.2 ± 0.9 | 7.5 ± 1.4 | −14.2 ± 0.4 | −56.0 ± 6.7 |

| Furfurylation (WPG 40) | 10.0 ± 0.5 | 1.1 ± 0.3 | 10.7 ± 1.1 | 8.0 ± 1.3 | −58.3 ± 0.8 | −47.3 ± 1.7 |

| Acetylation (WPG 25) | 3.6 ± 1.3 | 2.5 ± 0.1 | 14.3 ± 4.1 | 10.2 ± 1.7 | −17.6 ± 3.6 | −43.1 ± 2.2 |

| Thermowood-D | 13.1 ± 0.4 | 2.2 ± 0.2 | 21.0 ± 0.8 | 9.2 ± 0.5 | −44.4 ± 1.0 | −42.4 ± 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perdoch, W.; Benc, M.; Mazela, B. Wood from Field Tests as a Model for Assessing the Suitability of Post-Consumer Wood. Forests 2024, 15, 80. https://doi.org/10.3390/f15010080

Perdoch W, Benc M, Mazela B. Wood from Field Tests as a Model for Assessing the Suitability of Post-Consumer Wood. Forests. 2024; 15(1):80. https://doi.org/10.3390/f15010080

Chicago/Turabian StylePerdoch, Waldemar, Mateusz Benc, and Bartłomiej Mazela. 2024. "Wood from Field Tests as a Model for Assessing the Suitability of Post-Consumer Wood" Forests 15, no. 1: 80. https://doi.org/10.3390/f15010080