The Influence of Treatment Methods on Bending Mechanical Properties of Bamboo Strips

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Treatment

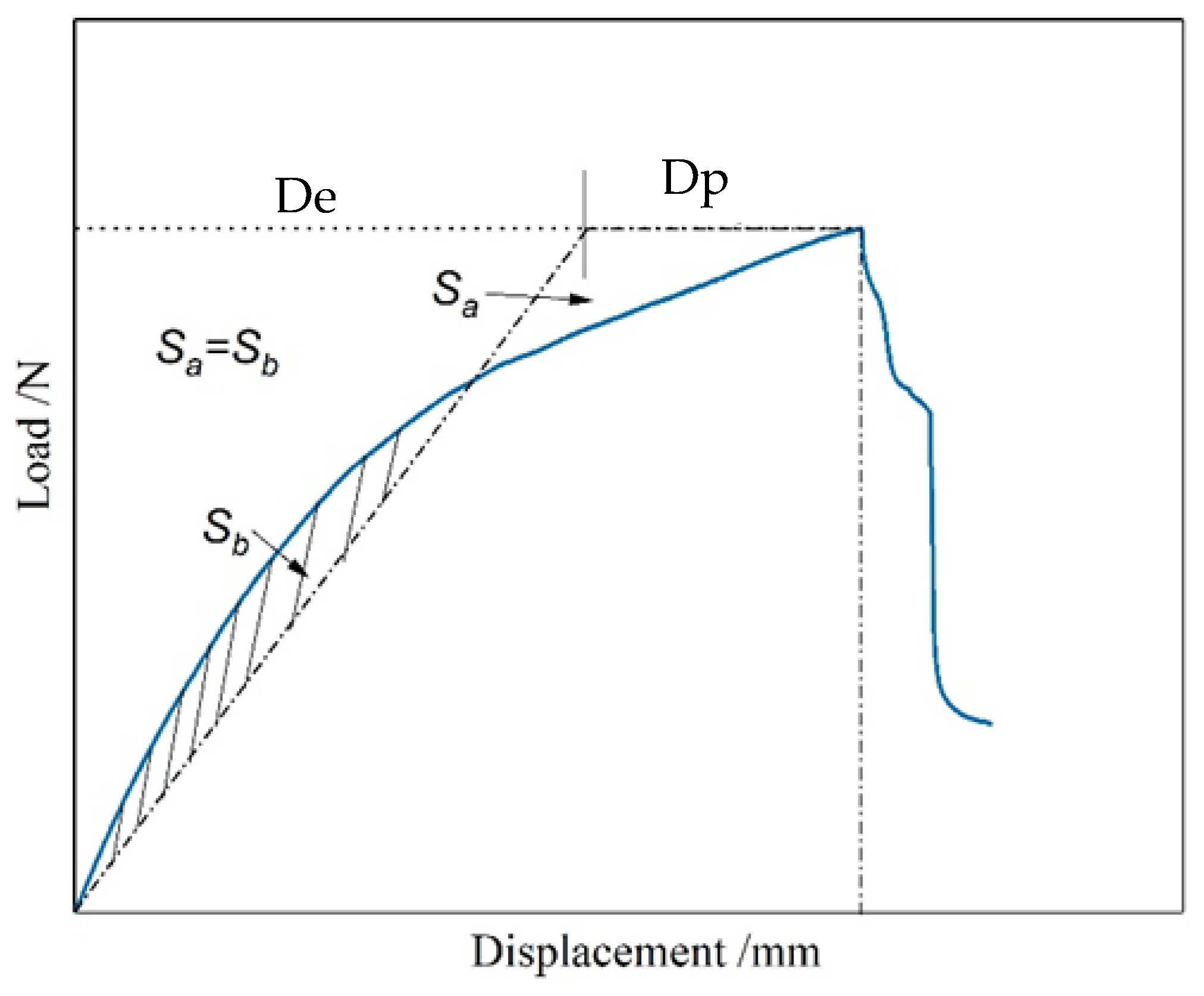

2.3. Testing Methods

3. Results

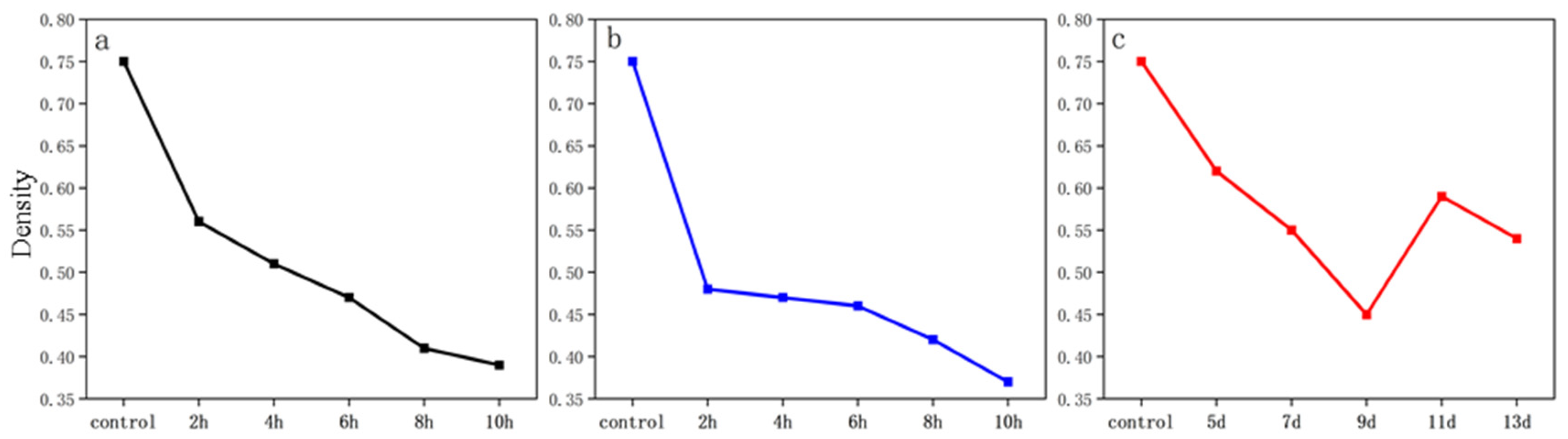

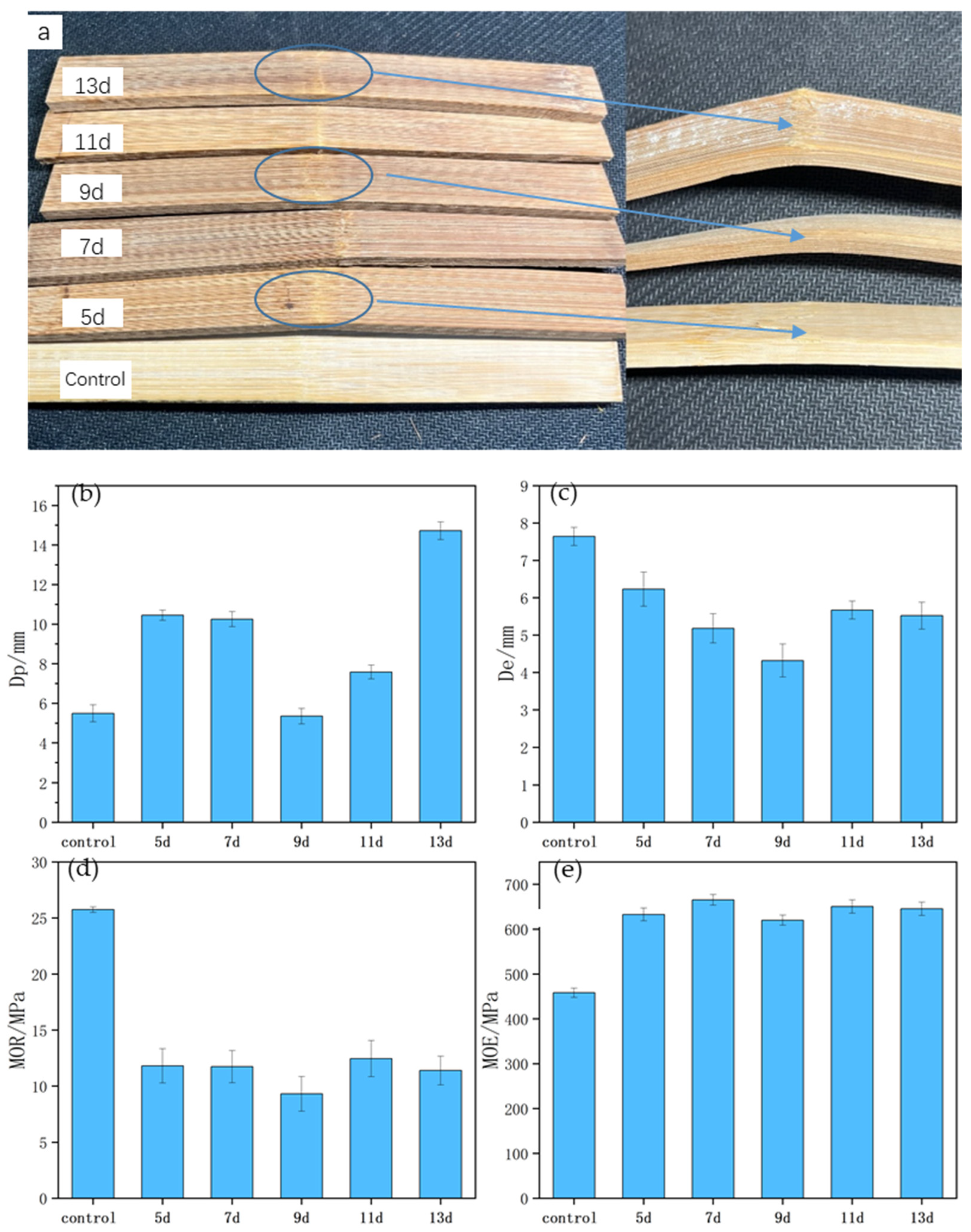

3.1. Physical and Mechanical Properties

3.2. X-ray Diffraction (XRD)

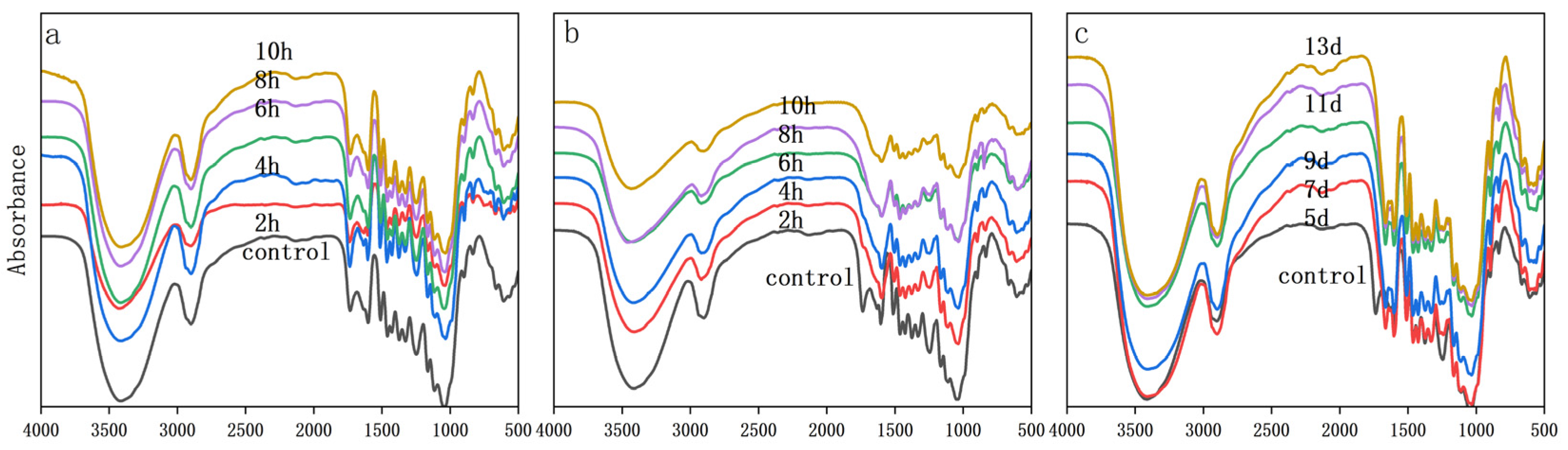

3.3. Infrared Spectroscopy

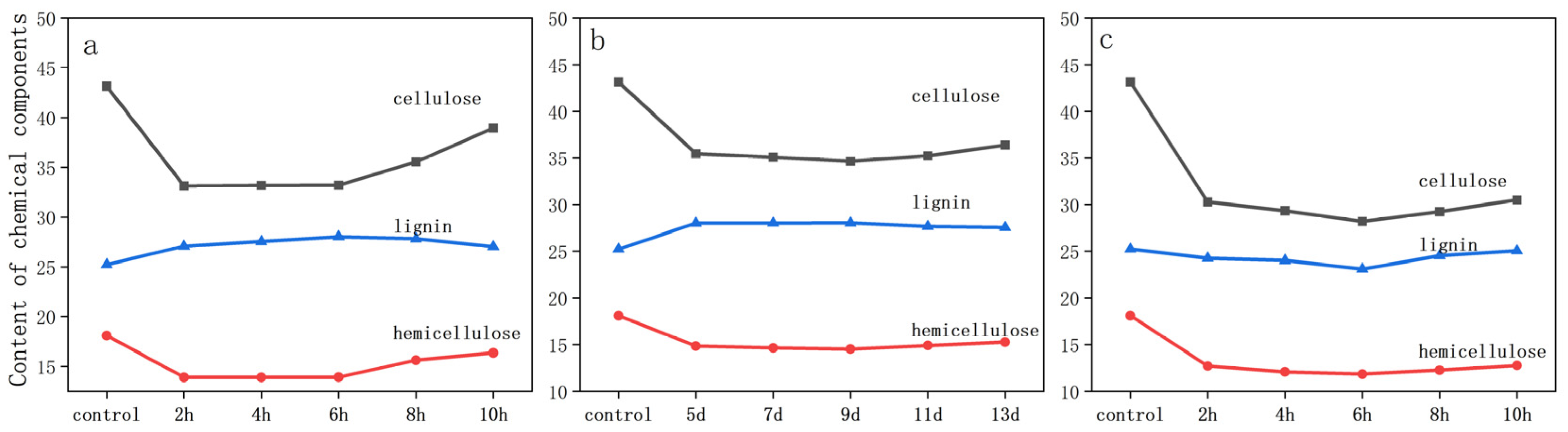

3.4. Chemical Composition

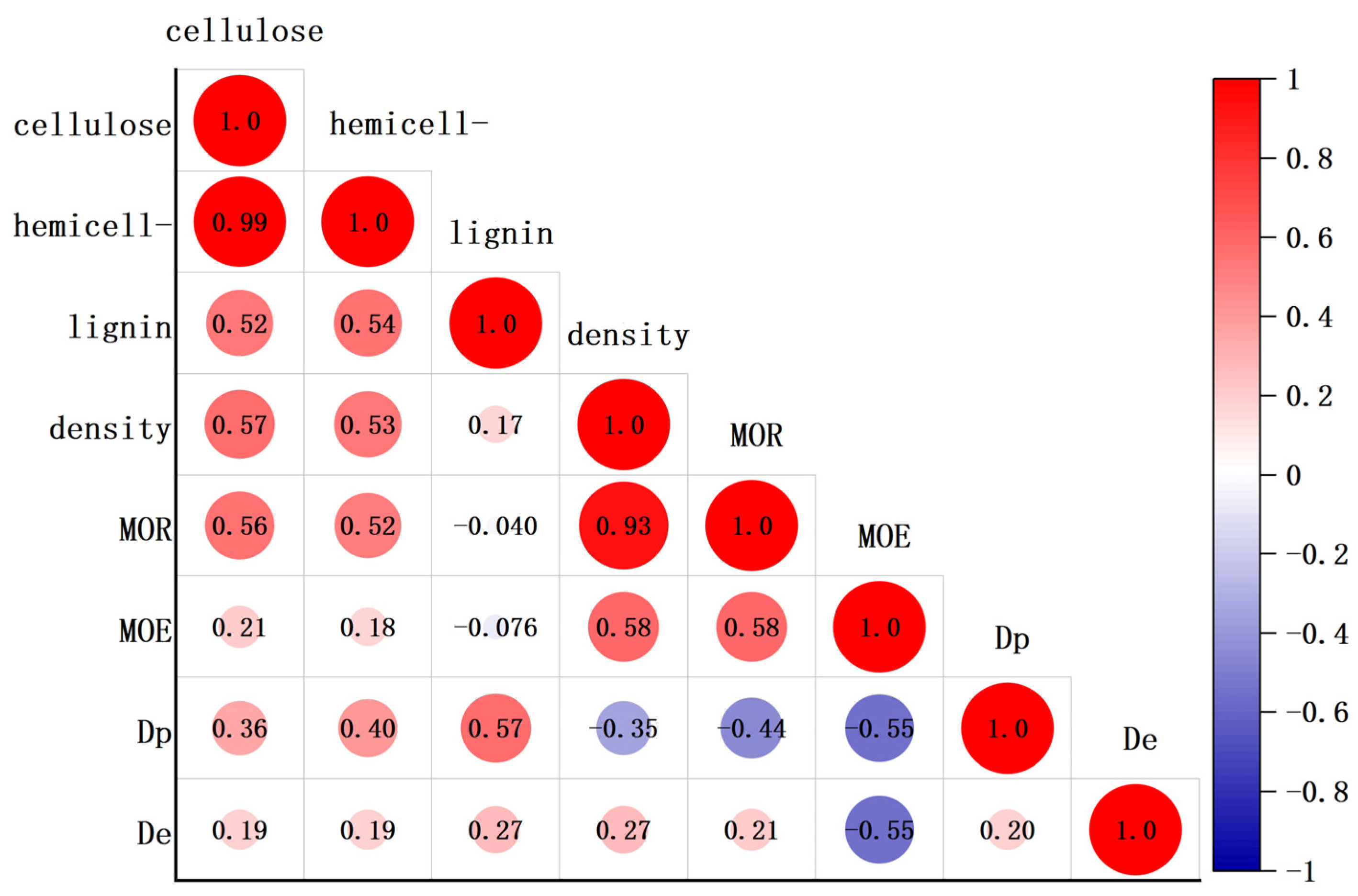

3.5. Correlation and Comprehensive Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tamang, M.; Nandy, S.; Srinet, R.; Das, A.K.; Padalia, H. Bamboo Mapping Using Earth Observation Data: A Systematic Review. J. Indian Soc. Remote Sens. 2022, 50, 2055–2072. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, S.; Huang, R. A Review of Researches on Wood Bending Techniques. World For. Res. 2010, 23, 40–44. [Google Scholar]

- Tang, Y.; Li, J.; Shen, Y.; Jin, Y.; Wang, Y.; Li, Y. Phyllostachys edulis with high temperature heat treatments. J. Zhejiang A F Univ. 2014, 31, 167–171. [Google Scholar]

- Fei, B.; Su, Q.; Liu, H.; Fang, C.; Ma, X.; Zhang, X.; Sun, F. Research progress of bamboo winding technology. J. For. Eng. 2022, 7, 25–33. [Google Scholar]

- Fang, W.; Niu, S.; Shen, D.; Cai, J.; Zhuang, R.; Li, Y. XRD and FTIR Analysis on Bamboo Culm Treated by High-temperature Hot Water Extraction. Zhejiang For. Sci. Technol. 2015, 35, 47–50. [Google Scholar]

- Chu, J.; Ma, L.; Zhang, J. The Chemical Composition of Bamboo after Heat Pretreatment with Fourier Infrared Spectrum Analysis. Spectrosc. Spectr. Anal. 2016, 36, 3557–3562. [Google Scholar]

- An, X.; Wang, H.; Li, W.; Yu, Y. Tensile mechanical properties of fiber sheaths microdissected from moso bamboo. J. Nanjing For. Univ. (Nat. Sci. Ed.) 2014, 38, 6–10. [Google Scholar]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose Nanocrystals vs. Cellulose Nanofibrils: A Comparative Study on Their Microstructures and Effects as Polymer Reinforcing Agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef]

- Zhang, Y.; Hosseinaei, O.; Wang, S.; Zhou, Z. Influence of hemicellulose extraction on water uptake behavior of wood strands. Wood Fiber Sci. J. Soc. Wood Sci. Technol. 2011, 43, 244–250. [Google Scholar]

- Xu, Y.; Liu, X.; Liu, X.; Tan, J.; Zhu, H. Influence of HNO3/H3PO4-NANO2 mediated oxidation on the structure and properties of cellulose fibers. Carbohydr. Polym. 2014, 111, 955–963. [Google Scholar] [CrossRef]

- Fang, X.; Xu, J.; Guo, H.; Liu, Y. The Effect of Alkali Treatment on the Crystallinity, Thermal Stability, and Surface Roughness of Bamboo Fibers. Fibers Polym. 2023, 24, 505–514. [Google Scholar] [CrossRef]

- GB/T 15780-1995; Testing Methods for Physical and Mechanical Properties of Bamboos. Institute of Chinese Academy of Forestry Timber Industry: Beijing, China, 1996.

- Furuta, Y.; Nakajima, M.; Nakatani, T.; Kojiro, K.; Ishimaru, Y. Effects of the Lignin on the Thermal-Softening Properties of the Water-Swollen Wood. J. Soc. Mater. Sci. Japan 2008, 57, 344–349. [Google Scholar] [CrossRef]

- Hao, J.; Liu, W.; Sun, D. Effect of heat treatment on color of bamboo strips. J. Bamboo Res. 2012, 31, 34–38. [Google Scholar]

- Li, Q.; Lin, J.; Chen, Z.; Wu, Q.; Li, X. Influences of Visual Properties of Phyllostachys heterocycla cv.pubescens Surface by Alkaline Hydrothermal Pretreatment. J. Northwest For. Univ. 2017, 32, 213–217. [Google Scholar]

- Pandey, K.K.; Pitman, A.J. FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int. Biodeterior. Biodegrad. 2003, 52, 151–160. [Google Scholar] [CrossRef]

- Meng, F.; Yu, Y.; Zhang, Y.; Yu, W.; Gao, J. Surface chemical composition analysis of heat-treated bamboo. Appl. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Yang, Z.; Jiang, Z.; Fei, B.; Liu, J. Application of Near Infrared(NIR) Spectroscopy to Wood Science. Sci. Silvae Sin. 2005, 41, 177–183. [Google Scholar]

- Qin, L. Effect of Thermo-Treatment on Physical, Mechanical Properties and Durability of Reconstituted Bamboo Lumber; Chinese Academy of Forestry: Beijing, China, 2010. [Google Scholar]

- Sun, R.H.; Li, X.J.; Liu, Y.; Hou, R.G.; Qiao, J.Z. Effects of high temperature heat treatment on FTIR and XRD characteristics of bamboo bundles. J. Cent. South Univ. For. Technol. 2013, 33, 97–100. [Google Scholar]

- Hosseinaei, O.; Wang, S.; Rials, T.G.; Xing, C.; Taylor, A.M.; Kelley, S.S.; Hosseinaei, S.W.O.; He, C.; Yao, X.; Xue, J.; et al. Effect of Hemicellulose Extraction on Physical and Mechanical Properties and Mold Susceptibility of Flakeboard. Prod. J. 2001, 61, 31–37. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Rials, T.G.; Xing, C.; Zhang, Y. Effects of Decreasing Carbohydrate Content on Properties of Wood Strands. Cellulose 2011, 18, 841–850. [Google Scholar] [CrossRef]

- Overend, R.P.; Chornet, E. Fractionation of Lignocellulosics by Steam-aqueous Pretreatments. Phys. Eng. Sci. 1987, 321, 523–536. [Google Scholar]

- Yang, S.; Jiang, Z.; Ren, H. Determination of Crystallinity of Bamboo Fiber Using X-ray Diffraction. J. Northeast For. Univ. 2010, 38, 75–77. [Google Scholar]

- Li, X.; Liu, Y.; Gao, J. FTIR and XRD Analysis of Wood Treated at High Temperatures. J. Beijing For. Univ. 2009, 31, 104–107. [Google Scholar]

- Chen, F.; He, Y.; Wei, X.; Han, S.; Ji, J.; Wang, G. Advances in strength and toughness of hierarchical bamboo under humidity and heat. J. For. Eng. 2023, 8, 10–18. [Google Scholar]

- Huang, M.; Zhang, X.; Yu, W.; Li, W.; Liu, X.; Zhang, W. Mechanical Properties and Structural Characterization of Bamboo Softened by High-Temperature Steam. J. For. Eng. 2016, 1, 64–68. [Google Scholar]

- Zhu, J.; Yu, B.; Cao, M.; Wang, X. Effect of Microwave Treatment on Round Bamboo Softening. For. Ind. 2023, 60, 15–19. [Google Scholar]

- Zhao, R.; Fu, D.; Sun, T. Influence of Different Softening Treatments on Bamboo Quality. J. Jiamusi Univ. (Nat. Sci. Ed.) 2009, 27, 637–640. [Google Scholar]

- Mo, J.; Zhang, W. Physical and Mechanical Properties of Thermally Treated Bamboo Based on Near-Infrared Spectroscopy Technology. J. For. Eng. 2019, 4, 32–38. [Google Scholar]

- Li, W.; Lin, W.; Yang, W.; Tang, K. Preparation and Structure Characterization of Bamboo Fiber by Alkali-Boiling and NaClO Oxidation. For. Ind. 2021, 58, 6–10. [Google Scholar]

- Ju, K.; Kil, M.; Ri, S.; Kim, T.; Kim, J.; Shi, W.; Zhang, L.; Yan, M.; Zhang, J.; Liu, G. Impacts of dietary supplementation of bamboo vinegar and charcoal powder on growth performance, intestinal morphology, and gut microflora of large-scale loach Paramisgurnus dabryanus. J. Oceanol. Limnol. 2023, 41, 1187–1196. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Hu, J.; Jin, Y.; Zheng, A.; Zhuan, S.; Lin, J.; Guan, X. Prediction for Compressive Strength Parallel to Grain of Zenia insignis Plantation Based on Fourier Infrared Spectroscopy. J. Southwest For. Univ. (Nat. Sci.) 2022, 42, 178–183. [Google Scholar]

- Shi, Y.; Liu, J.; Lü, W.; Wang, J.; Ni, L. Preparation and Properties of Wood Modified with Acidic and Alkaline Silica Sols. Wood Ind. 2019, 33, 21–24+33. [Google Scholar]

- Smith, C.A.; Want, E.J.; O’Maille, G.; Abagyan, R.; Siuzdak, G. XCMS: Processing mass spectrometry data for metabolite profiling using nonlinear peak alignment, matching, and identification. Anal. Chem. 2006, 78, 779–787. [Google Scholar] [CrossRef] [PubMed]

- Xia, J.; Sinelnikov, I.; Han, B.; Wishart, D.S. MetaboAnalyst 3.0—Making metabolomics more meaningful. Nucleic Acids Res. 2015, 43, W251–W257. [Google Scholar] [CrossRef] [PubMed]

- Pluskal, T.; Castillo, S.; Villar-Briones, A.; Orešič, M. MZmine 2: Modular framework for processing, visualizing, and analyzing mass spectrometry-based molecular profile data. BMC Bioinform. 2010, 11, 395. [Google Scholar] [CrossRef] [PubMed]

- Lancaster, C.; Espinoza, E. Evaluating agarwood products for 2-(2-phenylethyl) chromones using direct analysis in real time time-of-flight mass spectrometry. Rapid Commun. Mass Spectrom. 2012, 26, 2649–2656. [Google Scholar] [CrossRef] [PubMed]

- Selvius, D.; Armitage, R. Direct identification of dyes in textiles by direct analysis in real time-time of flight mass spectrometry. Anal. Chem. 2011, 83, 6924–6928. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Y.; Zhao, C.; Xue, H.; Yuan, L. Chemical variation in cell wall of sugar beet pulp caused by aqueous ammonia pretreatment influence enzymatic digestibility of cellulose. Ind. Crops Prod. 2020, 155, 112786. [Google Scholar] [CrossRef]

- Cajka, T.; Riddellova, K.; Tomaniova, M.; Hajslova, J. Ambient mass spectrometry employing a DART ion source for metabolomic fingerprinting/profiling: A powerful tool for beer origin recognition. Metabolomics 2011, 7, 500–508. [Google Scholar] [CrossRef]

| Treatment Method | Treatment Duration | Other Information |

|---|---|---|

| Control | - | Room temperature |

| Water boiling | 2 h, 4 h, 6 h, 8 h, 10 h | 135 °C |

| 15% NaOH | 2 h, 4 h, 6 h, 8 h, 10 h | Room temperature |

| 25% NH3 | 5 days(d), 7 d, 9 d, 11 d, 13 d | Room temperature |

| Treatment Method | 2θ/° | RC/% | Treatment Method | 2θ/° | RC/% | Treatment Method | 2θ/° | RC/% | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | - | 21.65 | 51.45 | - | - | - | - | - | - | - | - |

| Water boiling | 2 h | 22.15 | 59.66 | 15% NaOH | 2 h | 22.02 | 61.32 | 25% NH3 | 5d | 21.85 | 53.32 |

| 4 h | 22.42 | 61.89 | 4 h | 21.96 | 59.45 | 7d | 21.86 | 52.45 | |||

| 6 h | 22.56 | 62.22 | 6 h | 21.65 | 58.62 | 9d | 22.02 | 52.43 | |||

| 8 h | 22.64 | 63.34 | 8 h | 21.45 | 57.78 | 11d | 22.04 | 52.23 | |||

| 10 h | 22.78 | 64.75 | 10 h | 21.19 | 54.45 | 13d | 22.03 | 51.89 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Ji, J.; Yin, H.; Wang, X. The Influence of Treatment Methods on Bending Mechanical Properties of Bamboo Strips. Forests 2024, 15, 406. https://doi.org/10.3390/f15030406

Cao S, Ji J, Yin H, Wang X. The Influence of Treatment Methods on Bending Mechanical Properties of Bamboo Strips. Forests. 2024; 15(3):406. https://doi.org/10.3390/f15030406

Chicago/Turabian StyleCao, Shiyu, Jiagui Ji, Haowei Yin, and Xuehua Wang. 2024. "The Influence of Treatment Methods on Bending Mechanical Properties of Bamboo Strips" Forests 15, no. 3: 406. https://doi.org/10.3390/f15030406

APA StyleCao, S., Ji, J., Yin, H., & Wang, X. (2024). The Influence of Treatment Methods on Bending Mechanical Properties of Bamboo Strips. Forests, 15(3), 406. https://doi.org/10.3390/f15030406