A Potential Replacement to Phenol–Formaldehyde-Based Adhesives: A Study of Plywood Panels Manufactured with Bio-Based Wood Protein and Nanolignin Adhesives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

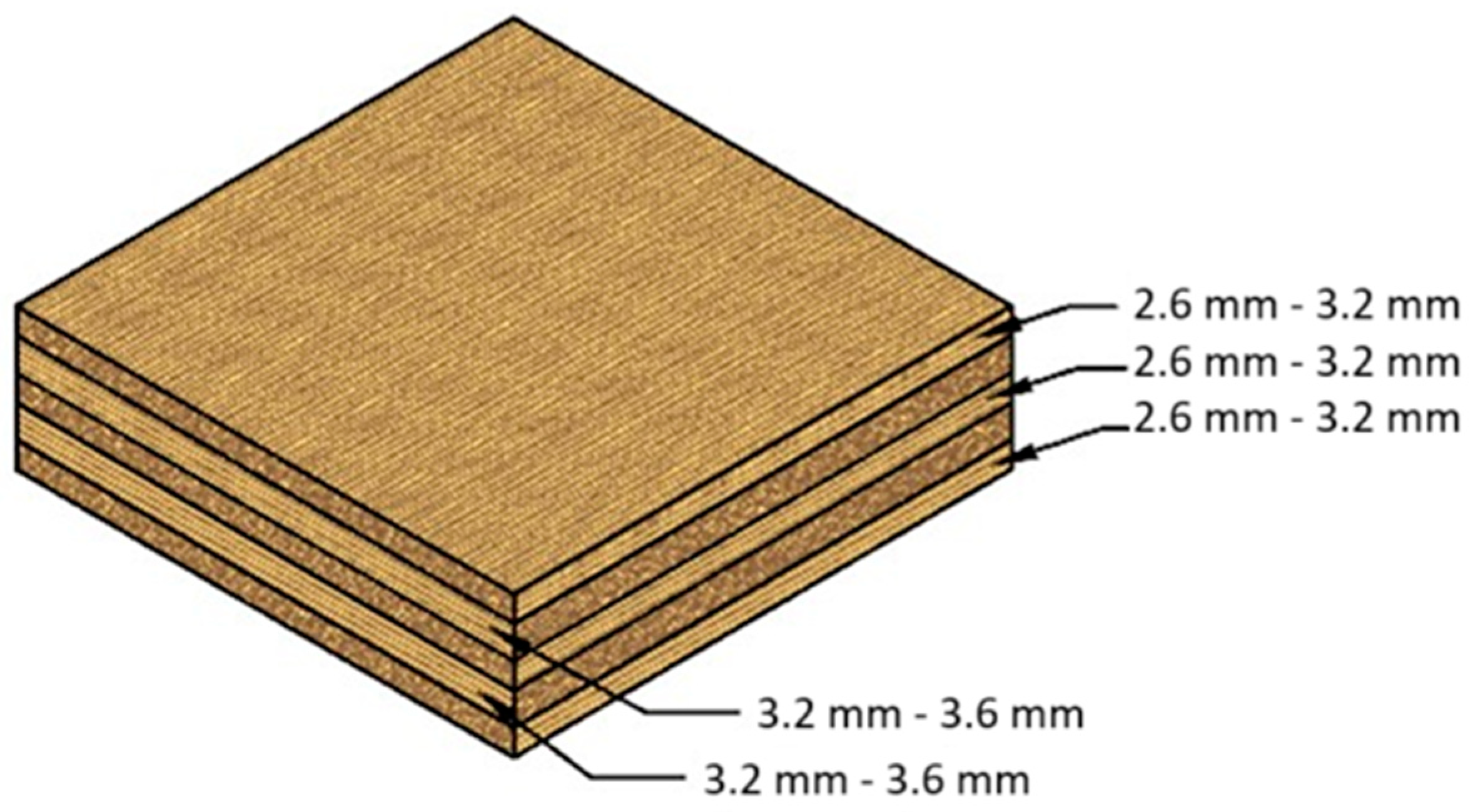

2.2. Manufacture of Plywood Panels Using Commercial Adhesive and Bio-Based Wood Adhesives

2.3. Physical–Chemical Properties of Wood Adhesives

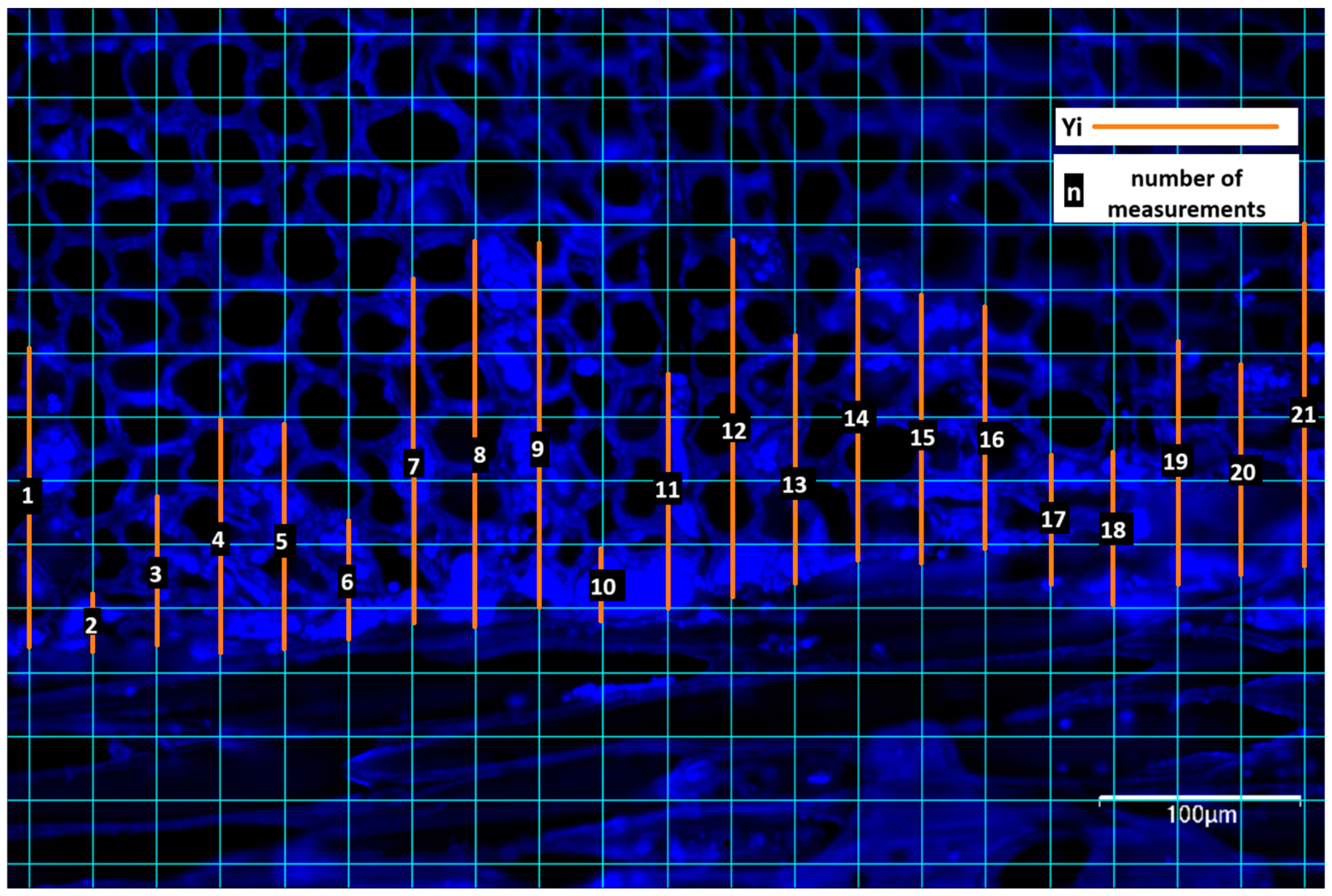

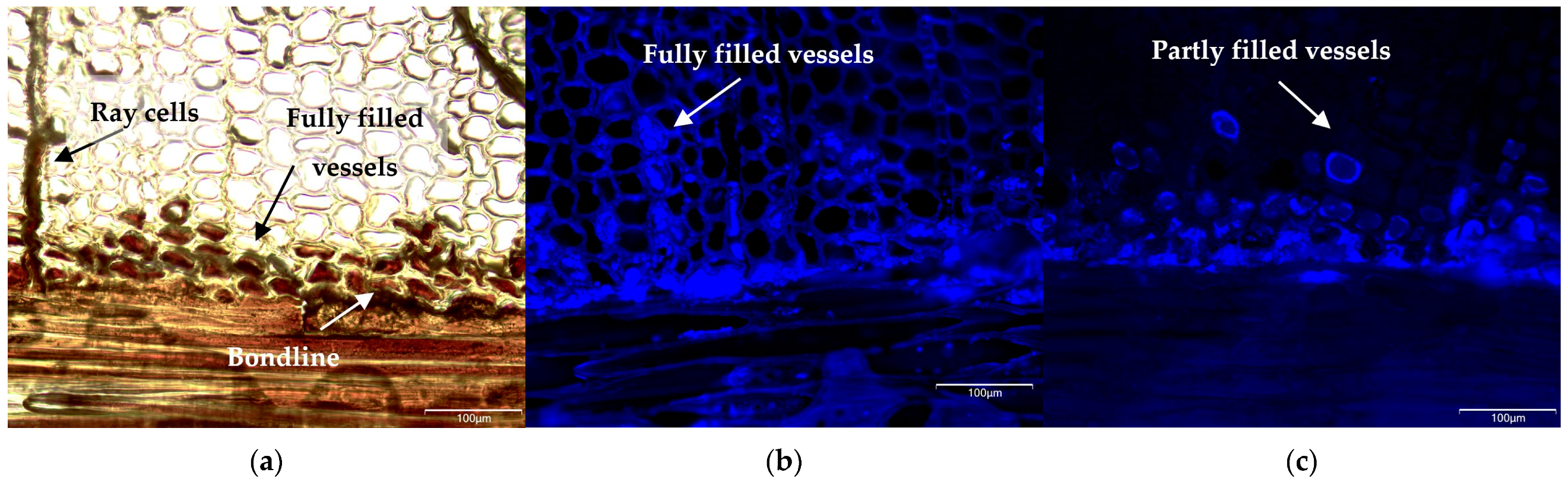

2.4. Evaluation of Adhesive Bonding Morphology

2.5. Physical Properties

2.6. Mechanical Properties

2.6.1. Static Bending Test

2.6.2. Bonding Quality Shear Test at Dry Condition

2.6.3. Tensile Strength

2.6.4. Hardness Test

2.7. Measurement of Formaldehyde Emissions

2.8. Effects of UVAccelerated Aging

2.9. Analysis of Data

3. Results and Discussion

3.1. Physical–Chemical Properties of Wood Adhesives

3.2. Evaluation of Adhesive Bonding Morphology

| Reference | Type of Adhesive | Type of Wood Composite/Joint | AP (µm) |

|---|---|---|---|

| [41] | Melamine Urea–Formaldehyde | Two-ply pine parallel Plywood | 186–283 |

| [42] | HDPE film | Plywood | 80–300 |

| [43] | Melamine-modified Urea–Formaldehyde | Laminated joint | 36–89 |

| [44] | Urea–Formaldehyde | Laminated joint | 150–274 |

| [23] | Urea–Formaldehyde | Laminated joint | 120–207 |

3.3. Physical Properties

3.4. Mechanical Properties

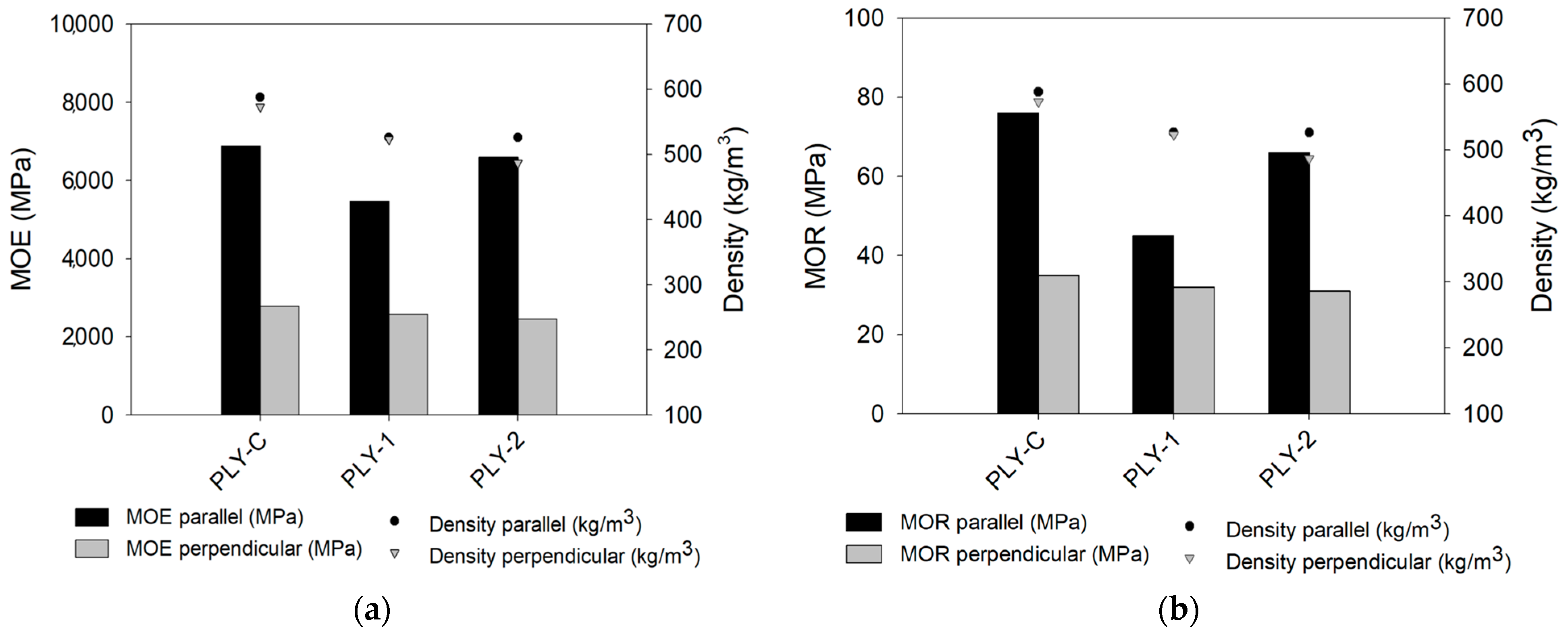

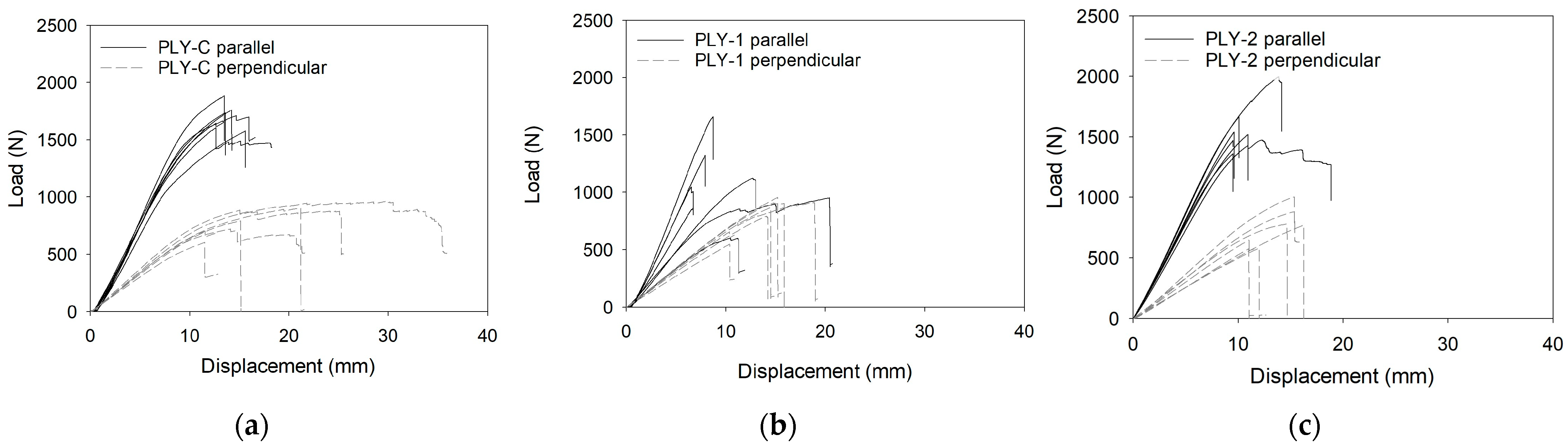

3.4.1. Three-Point Bending Test Properties

3.4.2. Shear Strength

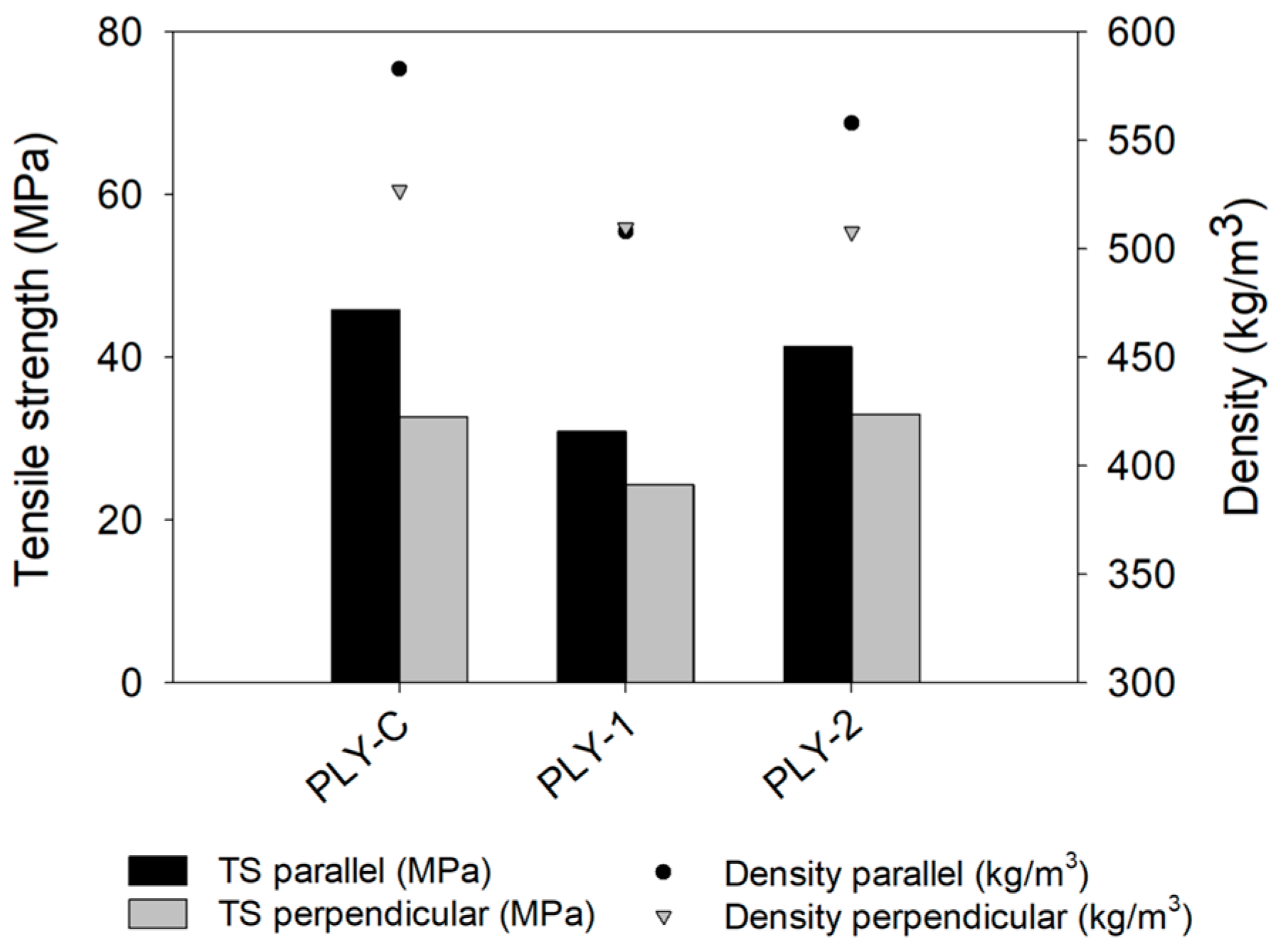

3.4.3. Tensile Strength

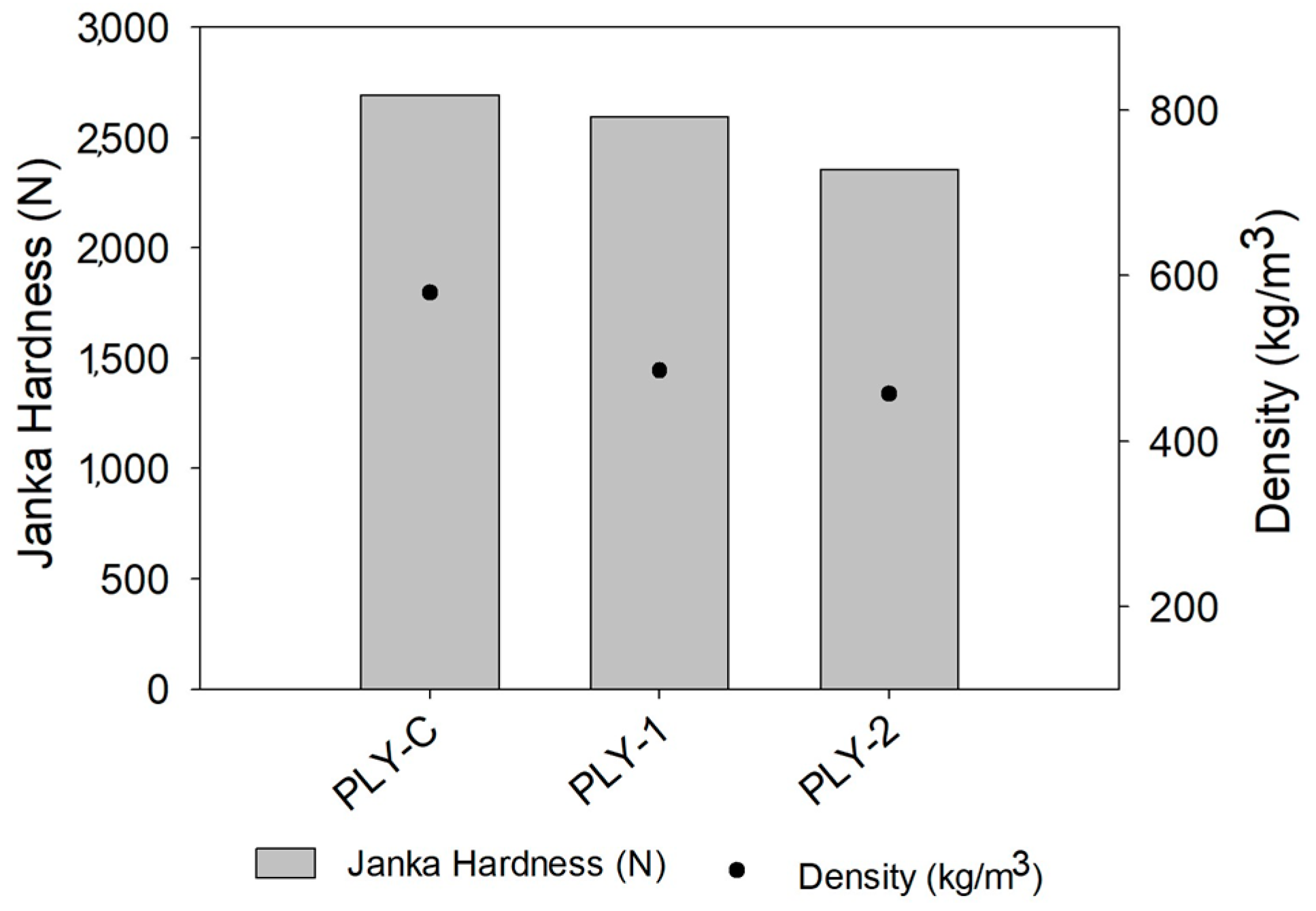

3.4.4. Janka Hardness

3.5. Measurement of Formaldehyde Emissions

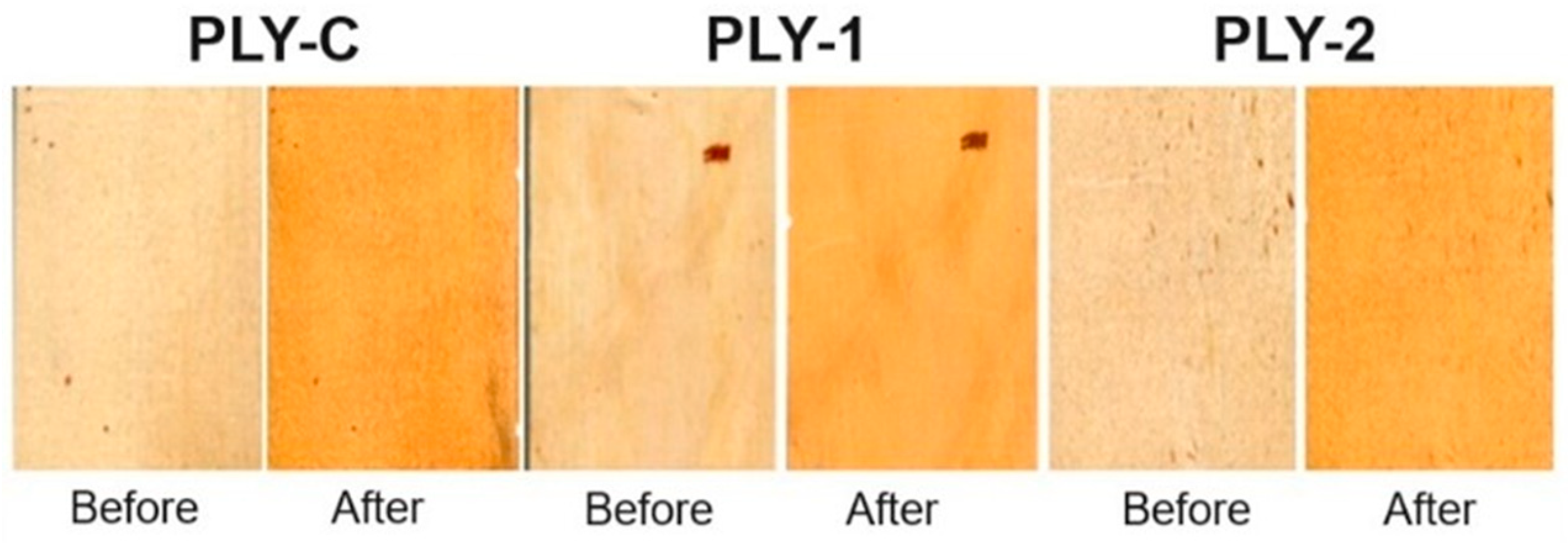

3.6. Effects of UVAccelerated Aging

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.N. Española. UNE-EN 636 Plywood. Specifications; Asociacion Espanola de Normalizacion: Madrid, Spain, 2004. [Google Scholar]

- Salazar Medina, M. Tableros a la Medida de lo Requerido: Una Revisión de las Opciones en MDF, MDP, OSB y Contrachapado. 30 October 2023. Available online: https://www.madera21.cl/blog/2020/10/16/tableros-a-la-medida-de-lo-requerido-una-revision-de-las-opciones-en-mdf-mdp-osb-y-contrachapado/ (accessed on 5 July 2024).

- Ross, R.J. Wood Handbook—Wood as an Engineering Material; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- United States Government. National Cancer Institute (NIH): Formaldehyde and Cancer Risk. 2011. Available online: https://www.cancer.gov/about-cancer/causes-prevention/risk/substances/formaldehyde/formaldehyde-fact-sheet (accessed on 5 July 2024).

- Días, F.M.; Rocco Lahr, F.A. Fabricación de madera contraplacada con adhesivo poliuretano alternativo a base de ricino. Maderas Cienc. Tecnol. 2003, 5, 163–175. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Canales-Constanzo, E.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. A Study of the Properties of UV-Aged and Low Formaldehyde Emissions Particleboards Manufactured with Bio-Based Wood Protein Adhesives. Forests 2023, 14, 1488. [Google Scholar] [CrossRef]

- Asafu-Adjaye, O.A.; Street, J.; Bansode, A.; Auad, M.L.; Peresin, M.S.; Adhikari, S.; Liles, T.; Via, B.K. Fast Pyrolysis Bio-Oil-Based Epoxy as an Adhesive in Oriented Strand Board Production. Polymers 2022, 14, 1244. [Google Scholar] [CrossRef]

- Nicolao, E.S.; Monteoliva, S.; Ciannamea, E.M.; Stefani, P. Plywoods of northeast Argentinian woods and soybean protein-based adhesives: Relationship between morphological aspects of veneers and shear strength values. Maderas-Cienc. Tecnol. 2021, 24. [Google Scholar] [CrossRef]

- Pradyawong, S.; Qi, G.; Sun, X.S.; Wang, D. Laccase/TEMPO-modified lignin improved soy-protein-based adhesives: Adhesion performance and properties. Int. J. Adhes. Adhes. 2019, 91, 116–122. [Google Scholar] [CrossRef]

- Bai, M.; Huang, Y.; Huang, S.; Wang, S.; Chen, W.; Hou, X.; Gao, Z. A novel wood adhesive based on yeast hydrolysate. BioResources 2019, 14, 6015–6024. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, X.; Yang, G.; Li, Q.; Zhou, N. Preparation and characterization of a nanolignin phenol formaldehyde resin by replacing phenol partially with lignin nanoparticles. RSC Adv. 2019, 9, 29255–29262. [Google Scholar] [CrossRef]

- Esfandiyari, M.R.T.; Pour, M.T.; Khademieslam, H.; Shokraei, S.A.M.; Bazyar, B. Investigating the possibility of making lignin-glyoxal resins as adhesives in the production of plywood. BioResources 2019, 14, 7122–7133. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Ballerini-Arroyo, A.; Alarcón-Enos, J. Sustainable particleboards with low formaldehyde emissions based on yeast protein extract adhesives Rhodotorula rubra. Eur. J. Wood Wood Prod. 2018, 76, 1279–1286. [Google Scholar] [CrossRef]

- Li, R.J.; Gutierrez, J.; Chung, Y.-L.; Frank, C.W.; Billington, S.L.; Sattely, E.S. A lignin-epoxy resin derived from biomass as an alternative to formaldehyde-based wood adhesives. Green Chem. 2018, 20, 1459–1466. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Y.; Yu, Y.; Song, J. Improve Performance of Soy Flour-Based Adhesive with a Lignin-Based Resin. Polymers 2017, 9, 261. [Google Scholar] [CrossRef] [PubMed]

- Pradyawong, S.; Qi, G.; Li, N.; Sun, X.S.; Wang, D. Adhesion properties of soy protein adhesives enhanced by biomass lignin. Int. J. Adhes. Adhes. 2017, 75, 66–73. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, D.; Li, N.; Sun, X.S. Bio-Based Wood Adhesive from Camelina Protein (a Biodiesel Residue) and Depolymerized Lignin with Improved Water Resistance. ACS Omega 2017, 2, 7996–8004. [Google Scholar] [CrossRef] [PubMed]

- Decap, M.N.; Arroyo, A.B.; Énos, J.A. Evaluation of single cell protein from yeast for the development of wood adhesives. Eur. J. Wood Wood Prod. 2016, 74, 821–828. [Google Scholar] [CrossRef]

- Luo, J.; Luo, J.; Yuan, C.; Zhang, W.; Li, J.; Gao, Q.; Chen, H. An eco-friendly wood adhesive from soy protein and lignin: Performance properties. RSC Adv. 2015, 5, 100849–100855. [Google Scholar] [CrossRef]

- ASTM D1084-16R21; Standard Test Methods for Viscosity of Adhesives. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E70-24; Standard Test Method for pH of Aqueous Solutions with the Glass Electrode. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D1490-01R18; Standard Test Method for Nonvolatile Content of Urea-Formaldehyde Resin Solutions. ASTM International: West Conshohocken, PA, USA, 2018.

- Gavrilović-Grmuša, I.; Miljković, J.; Ðiporović-Momčilović, M. Influence of the Degree of Condensation on the Radial Penetration of Urea-Formaldehyde Adhesives into Silver Fir (Abies alba, Mill.) Wood Tissue. J. Adhes. Sci. Technol. 2010, 24, 1437–1453. [Google Scholar] [CrossRef]

- Vidal-Vega, M.; Núñez-Decap, M.; Hernández-Durán, J.; Catricura-Muñoz, P.; Jara-Briones, C.; Moya-Rojas, B.; Opazo-Carlsson, C. Comparative Study of Carbon Nanotubes and Lignosulfonate as Polyvinyl Acetate (PVAc) Wood Adhesive-Reinforcing Agents. Appl. Sci. 2023, 14, 365. [Google Scholar] [CrossRef]

- UNE-EN 323; Wood-Based Panels—Determination of Density. U.N. Española: Madrid, Spain, 1994.

- UNE-EN 322; Wood-Based Panels. Determination of Moisture Content. U.N. Española: Madrid, Spain, 1994.

- UNE-EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water. U.N. Española: Madrid, Spain, 1994.

- UNE-EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. U.N. Española: Madrid, Spain, 1994.

- UNE-EN 636:2012+A1:2015; Plywood—Specifications. U.N. Española: Madrid, Spain, 2015.

- UNE-EN 314; Plywood. Bonding Quality. U.N. Española: Madrid, Spain, 2007.

- ASTM D3500-20; Standard Test Methods for Wood Structural Panels in Tension. ASTM International: West Conshohocken, PA, USA, 2020; p. 6.

- ASTM D1037-12; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D6007-22; Standard Test Method for Determining Formaldehyde Concentrations in Air from Wood Products Using a Samll-Scale Chamber. ASTM International: West Conshohocken, PA, USA, 2022.

- U.S. Environmental Protection Agency. Toxic Substances Control Act (TSCA) and Federal Facilities—Title VI- Formaldehyde Standards for Composite Wood Products. 2016. Available online: https://www.epa.gov/formaldehyde/formaldehyde-emission-standards-composite-wood-products (accessed on 5 July 2024).

- ASTM G154-23; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- De Melo, R.R.; Del Menezzi, C.H.S. Influence of Adhesive Type on the Properties of LVL Made from Paricá (Schizolobium amazonicum Huber ex. Ducke) Plantation Trees. Drv. Ind. 2015, 66, 205–212. [Google Scholar] [CrossRef]

- Islam, M.N.; Rahman, F.; Das, A.K.; Hiziroglu, S. An overview of different types and potential of bio-based adhesives used for wood products. Int. J. Adhes. Adhes. 2022, 112, 102992. [Google Scholar] [CrossRef]

- Bastani, A.; Adamopoulos, S.; Koddenberg, T.; Militz, H. Study of adhesive bondlines in modified wood with fluorescence microscopy and X-ray micro-computed tomography. Int. J. Adhes. Adhes. 2016, 68, 351–358. [Google Scholar] [CrossRef]

- Frihart, C.R. Adhesive Penetration of Wood and Its Effect on Bond Strength; U.S. Department of Agriculture, Ed.; Forest Products Laboratory: Madison, WI, USA, 2016.

- Kamke, F.A.; Lee, J.N. Adhesive Penetration in Wood—A Review. Wood Fiber Sci. 2007, 39, 205–220. [Google Scholar]

- Park, S.; Jeong, B.; Park, B.-D. A Comparison of Adhesion Behavior of Urea-Formaldehyde Resins with Melamine-Urea-Formaldehyde Resins in Bonding Wood. Forests 2021, 12, 1037. [Google Scholar] [CrossRef]

- Chang, L.; Guo, W.; Tang, Q. Assessing the Tensile Shear Strength and Interfacil Bonding Mechanism of Poplar Plywood with High-density Polyethylene Films as Adhesive. BioResources 2017, 12, 571–585. [Google Scholar] [CrossRef]

- Qin, L.; Lin, L.; Fu, F. Microstructural and Micromechanical Characterization of Modified Urea-Formaldehyde Resin Penetration into Wood. BioResources 2015, 11, 182–194. [Google Scholar] [CrossRef]

- Gavrilović-Grmuša, I.; Dunky, M.; Miljković, J.; Djiporović-Momčilović, M. Radial Penetration of Urea-Formaldehyde Adhesive Resins into Beech (Fagus Moesiaca). J. Adhes. Sci. Technol. 2010, 24, 1753–1768. [Google Scholar] [CrossRef]

- Bekhta, P.; Pipíška, T.; Gryc, V.; Sedliačik, J.; Král, P.; Ráheľ, J.; Vaněrek, J. Properties of Plywood Panels Composed of Thermally Densified and Non-Densified Alder and Birch Veneers. Forests 2023, 14, 96. [Google Scholar] [CrossRef]

- Umemura, K.; Sugihara, O.; Kawai, S. Investigation of a new natural adhesive composed of citric acid and sucrose for particleboard II: Effects of board density and pressing temperature. J. Wood Sci. 2014, 61, 40–44. [Google Scholar] [CrossRef]

- Mohebby, B.; Gorbani-Kokandeh, M.; Soltani, M. Springback in acetylated wood based composites. Constr. Build. Mater. 2009, 23, 3103–3106. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Talaei, A.; Ashori, A.; Heydari, V. A Comparative Study on the Mechanical and Physical Properties of Plywood Panels Prepared by Chitosan as Bio-Adhesive. J. Polym. Environ. 2022, 30, 4263–4270. [Google Scholar] [CrossRef]

- Frihart, C.R. Introduction to Special Issue: Wood Adhesives: Past, Present, and Future. For. Prod. J. 2015, 65, 4–8. [Google Scholar] [CrossRef]

- Núñez-Decap, M.; Barra-Rodríguez, Y.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M.; Opazo-Vega, A. Use of Carbon and Basalt Fibers with Adhesives to Improve Physical and Mechanical Properties of Plywood. Appl. Sci. 2022, 12, 5114. [Google Scholar] [CrossRef]

- Iliev, B.; Popovska, V.J. Impact of resin content on compressive strength and janka hardness of composite wood-based panels. Int. J. Wood Des. Technol. 2022, 11, 73–78. [Google Scholar]

- Büyüksarı, Ü. Surface characteristics and hardness of MDF panels laminated with thermally compressed veneer. Compos. Part B Eng. 2013, 44, 675–678. [Google Scholar] [CrossRef]

- Millaniyage, K.; Kotlarewski, N.; Wallis, L.; Taoum, A.; Nolan, G. Janka Hardness Evaluation of Plantation-Grown Eucalyptus nitens for Engineered Flooring Applications. Buildings 2022, 12, 1862. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Pánek, M. Volatile Organic Compounds (VOCs) from Wood and Wood-Based Panels: Methods for Evaluation, Potential Health Risks, and Mitigation. Polymers 2020, 12, 2289. [Google Scholar] [CrossRef]

- Evans, P.D. Development of Commercial Wood Preservatives; American Chemical Society: Washington, DC, USA, 2008; pp. 69–117. [Google Scholar]

- Herrera, R.; Sandak, J.; Robles, E.; Krystofiak, T.; Labidi, J. Weathering resistance of thermally modified wood finished with coatings of diverse formulations. Prog. Org. Coatings 2018, 119, 145–154. [Google Scholar] [CrossRef]

- Li, X.; Li, T.; Li, G.; Li, M.; Lu, Q.; Qin, S.; Li, J. Effects of UV light irradiation on color changes in thermally modified rubber wood based on FTIR. BioResources 2020, 15, 5179. [Google Scholar] [CrossRef]

| Thickness (mm) | Moisture Content (%) | Grade of Visual Classification | Defects | Veneers Quantity |

|---|---|---|---|---|

| 2.6 | 6.6 | Clear | Knots | 121 |

| 3.2 | 6.7 | Clear | knots | 77 |

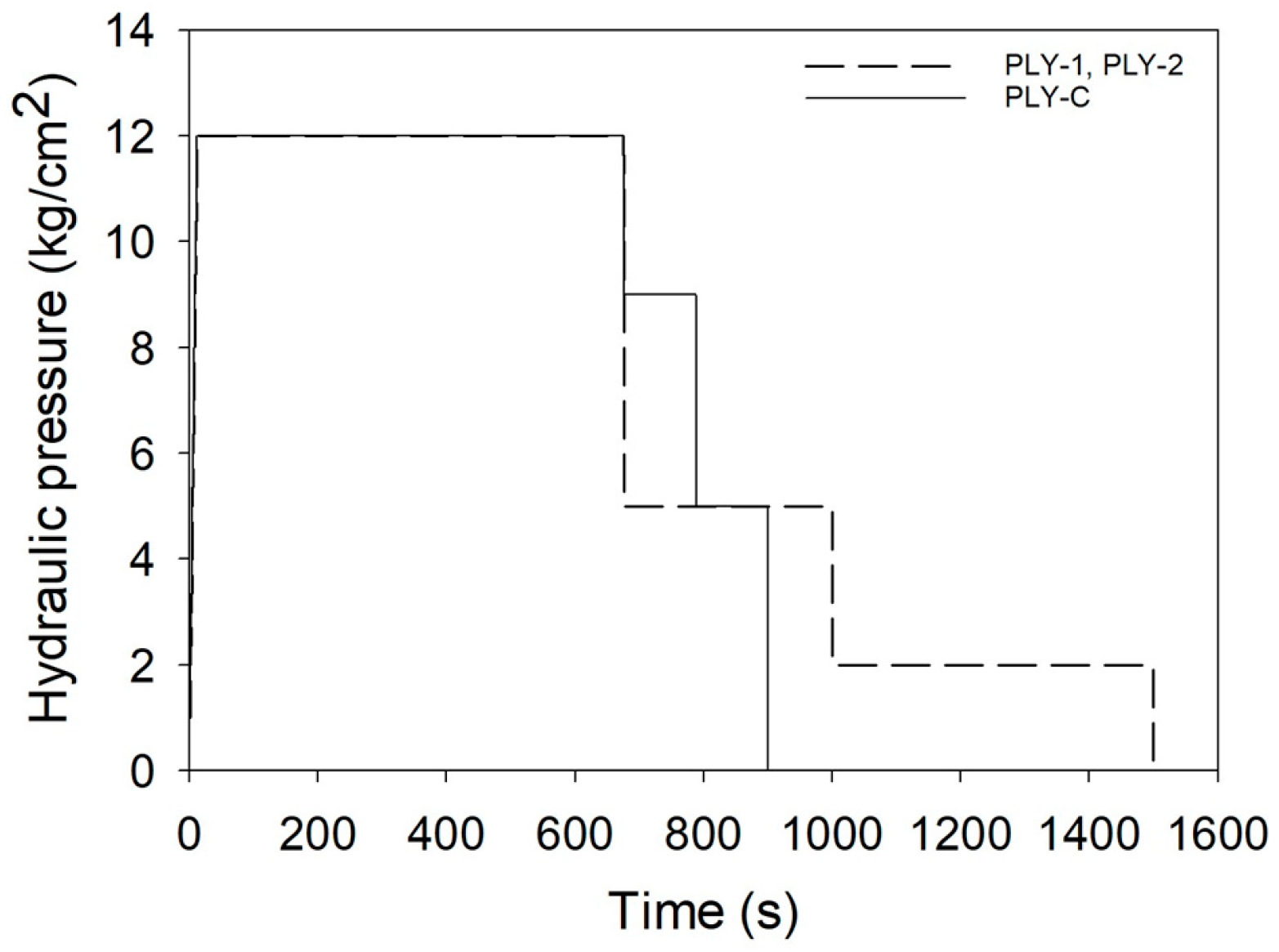

| Pressing Parameters | PLY-C | PLY-1 | PLY-2 |

|---|---|---|---|

| Grammage (g/m2) | 200 | 200 | 200 |

| Gluing time (min) | 5 | 5 | 5 |

| Hot press temperature (°C) | 130 | 150 | 150 |

| Press factor (mm/min) | 1 | 0.6 | 0.6 |

| Specific pressure stage 1 (bar) | 12 | 12 | 12 |

| Specific pressure stage 2 (bar) | 9 | 5 | 5 |

| Specific pressure stage 3 (bar) | 5 | 2 | 2 |

| Press time stage 1 (s) | 675 | 675 | 675 |

| Press time stage 2 (s) | 112.5 | 325 | 325 |

| Press time stage 3 (s) | 112.5 | 500 | 500 |

| ID | Viscosity (cP) | Ph 25 °C | Solid Content (%) |

|---|---|---|---|

| PLY-C | 4827 a ± 29.37 | 12.53 a ± 0.03 | 42.30 a ± 0.06 |

| PLY-1 | 2520 b ± 52.30 | 5.43 b ± 0.00 | 59.10 b ± 0.00 |

| PLY-2 | 582 c ± 6.08 | 5.90 c ± 0.00 | 57.60 c ± 0.00 |

| ID | AP (µm) |

|---|---|

| PLY-C | 73.14 a ± 19.72 |

| PLY-1 | 80.35 a ± 55.21 |

| PLY-2 | 105.60 b ± 38.81 |

| ID | Density (kg/m3) | Moisture Content (%) | Thickness Swelling (%) | |

|---|---|---|---|---|

| 24 h | 48 h | |||

| PLY-C | 597 a ± 24.64 | 12 a ± 0.30 | 5.43 a ± 0.42 | 5.88 a ± 1.01 |

| PLY-1 | 507 b ± 23.62 | 8 b ± 0.12 | 88.79 b ± 31.71 | 88.92 b ± 31.34 |

| PLY-2 | 493 b ± 44.27 | 7 c ± 0.46 | 6.29 c ± 0.65 | 7.27 c ± 0.93 |

| ID | Panel Fiber Direction | MOE (MPa) | MOR (MPa) | Density (kg/m3) | Moisture Content (%) |

|---|---|---|---|---|---|

| PLY-C | Parallel | 6878 a ± 635 | 75.54 a ± 5.45 | 588 ± 8 | 10.7 ± 0.35 |

| Perpendicular | 2786 c ± 276 | 35.28 cd ± 6.10 | 573 ± 20 | 10.4 ± 0.31 | |

| PLY-1 | Parallel | 5470 b ± 1837 | 44.77 c ± 13.44 | 526 ± 10 | 6.0 ± 0.34 |

| Perpendicular | 2580 c ± 193 | 32.19 d ± 5.54 | 523 ± 11 | 6.4 ± 0.62 | |

| PLY-2 | Parallel | 6591 a ± 583 | 65.66 b ± 10.85 | 526 ± 10 | 6.0 ± 0.54 |

| Perpendicular | 2454 c ± 147 | 31.28 d ± 4.66 | 487 ± 24 | 6.7 ± 0.47 |

| ID | Shear Strength (MPa) | Wood Failure (%) | Standard Requirement | ||

|---|---|---|---|---|---|

| Result | Requirement | Result | Requirement | Accept/Fail | |

| PLY-C | 2.5 a ± 0.43 | ≥1 | 87 a ± 13.75 | - | Accept |

| PLY-1 | 1.7 b ± 0.30 | ≥1 | 53 b ± 21.10 | - | Accept |

| PLY-2 | 2.0 b ± 0.50 | ≥1 | 40 b ± 23.34 | - | Accept |

| ID | Wood Fiber Direction | Tensile Strength (MPa) | Density (kg/m3) |

|---|---|---|---|

| PLY-C | Parallel | 45.87 d ± 3.6 | 583 ± 18.17 |

| Perpendicular | 32.73 abc ± 12.5 | 528 ± 52.61 | |

| PLY-1 | Parallel | 30.89 ab ± 4.0 | 508 ± 24.55 |

| Perpendicular | 24.36 a ± 6.0 | 510 ± 45.15 | |

| PLY-2 | Parallel | 41.31 cd ± 5.2 | 558 ± 24.34 |

| Perpendicular | 33.01 bc ± 8.5 | 508 ± 39.78 |

| ID | 2 h (ppm) | 7 Days (ppm) |

|---|---|---|

| PLY-C | 0.045 | 0.009 |

| PLY-1 | 0.005 | 0.001 |

| PLY-2 | 0.005 | 0.001 |

| ID | ΔΕ Average |

|---|---|

| PLY-C | 14.64 a ± 1.14 |

| PLY-1 | 12.70 b ± 2.24 |

| PLY-2 | 14.22 a ± 0.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Núñez-Decap, M.; Friz-Sánchez, C.; Opazo-Carlsson, C.; Moya-Rojas, B.; Vidal-Vega, M. A Potential Replacement to Phenol–Formaldehyde-Based Adhesives: A Study of Plywood Panels Manufactured with Bio-Based Wood Protein and Nanolignin Adhesives. Forests 2024, 15, 1345. https://doi.org/10.3390/f15081345

Núñez-Decap M, Friz-Sánchez C, Opazo-Carlsson C, Moya-Rojas B, Vidal-Vega M. A Potential Replacement to Phenol–Formaldehyde-Based Adhesives: A Study of Plywood Panels Manufactured with Bio-Based Wood Protein and Nanolignin Adhesives. Forests. 2024; 15(8):1345. https://doi.org/10.3390/f15081345

Chicago/Turabian StyleNúñez-Decap, Mario, Catherine Friz-Sánchez, Camila Opazo-Carlsson, Boris Moya-Rojas, and Marcela Vidal-Vega. 2024. "A Potential Replacement to Phenol–Formaldehyde-Based Adhesives: A Study of Plywood Panels Manufactured with Bio-Based Wood Protein and Nanolignin Adhesives" Forests 15, no. 8: 1345. https://doi.org/10.3390/f15081345