Efficient Bio-Based Insulation Panels Produced from Eucalyptus Bark Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Eucalyptus globulus Fiber Production

2.2. Chemical Characterization of Eucalyptus globulus Bark

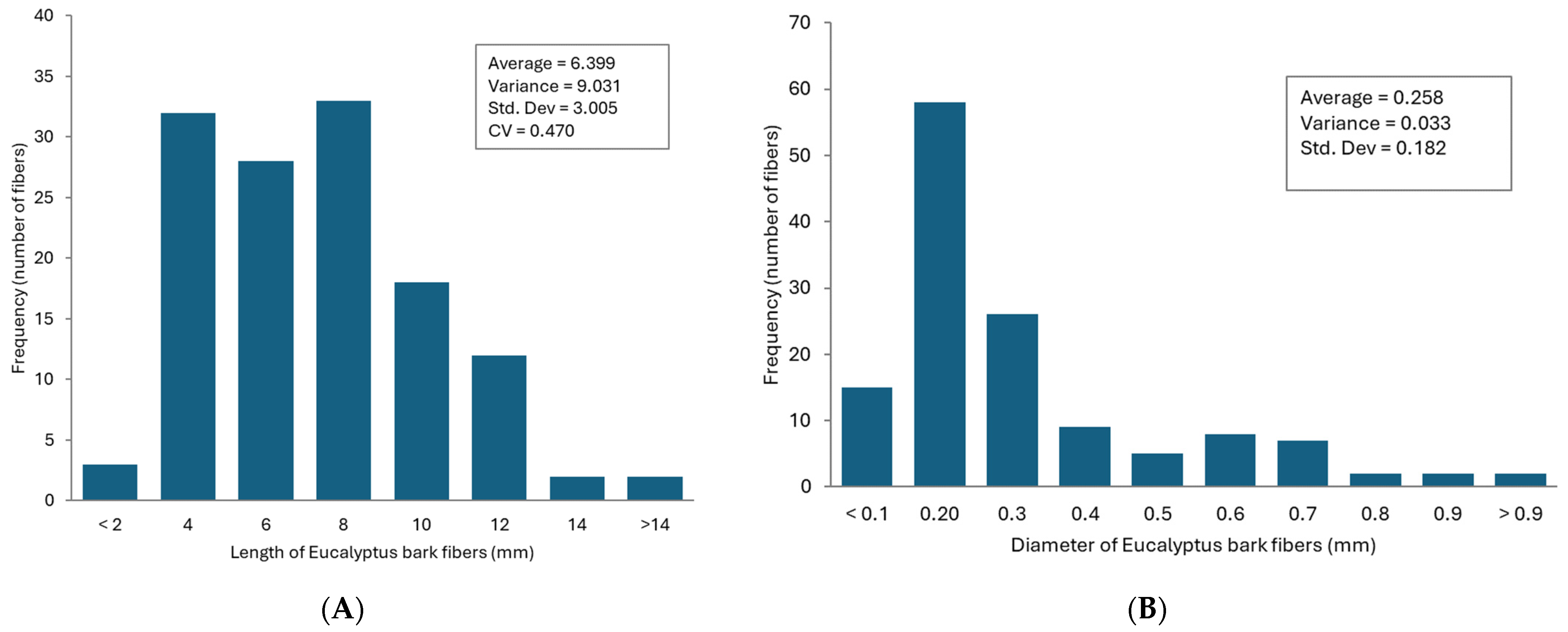

2.3. Morphological Characterization of E. globulus Bark’s Fibers

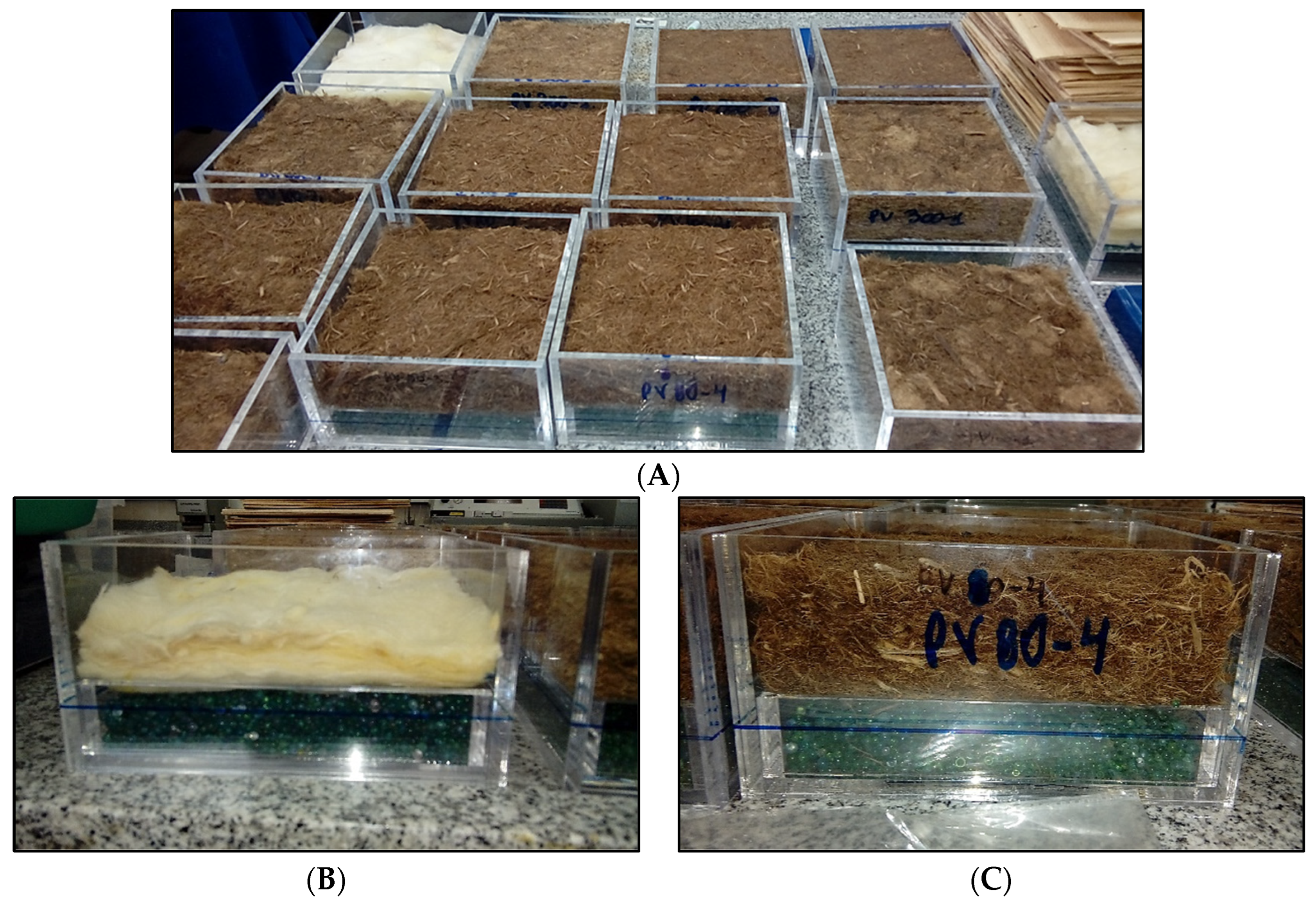

2.4. Production of Thermal Insulation Panel

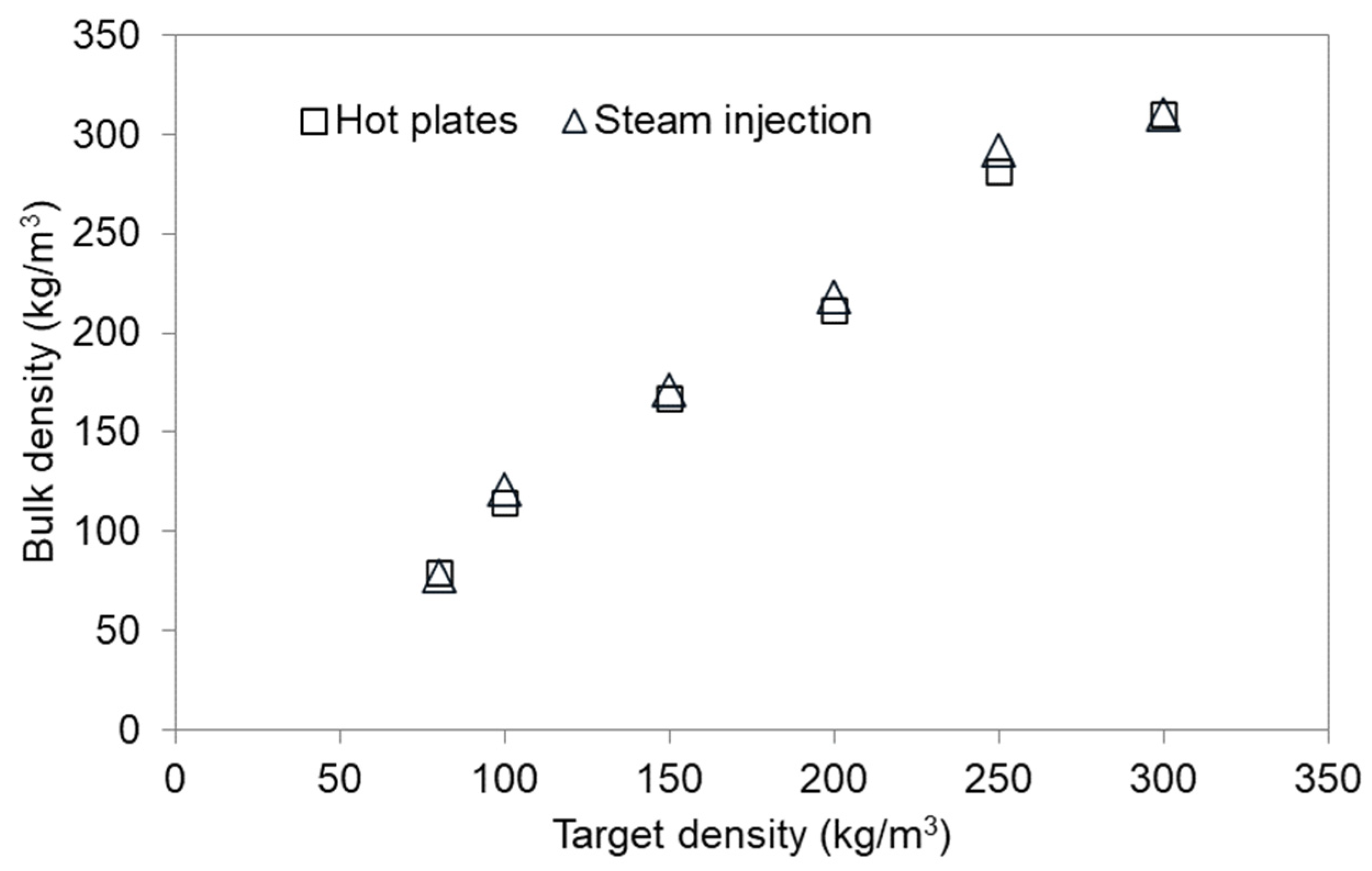

2.5. Determination of Apparent (Bulk) Density

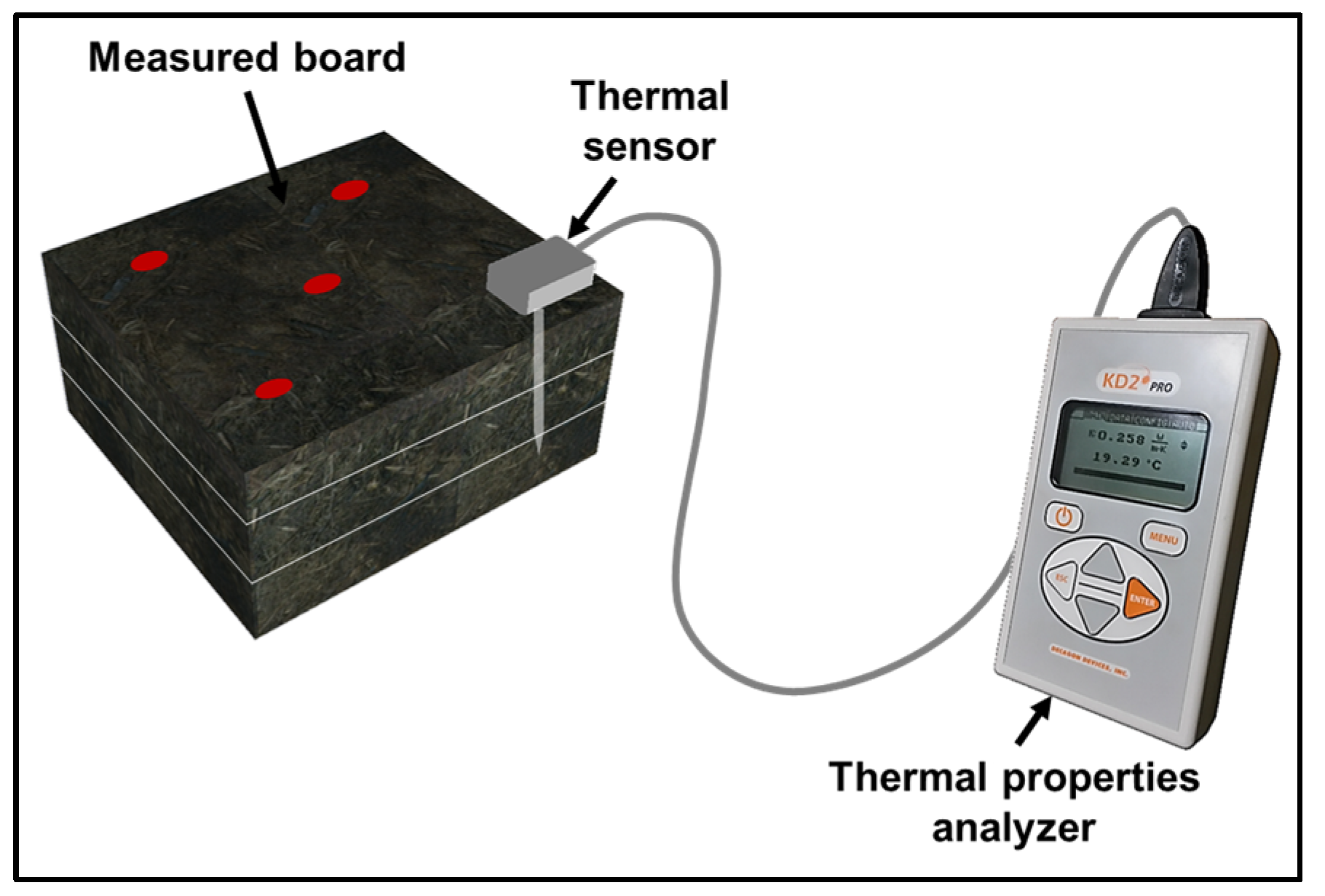

2.6. Determination of Thermal Conductivity

2.7. Thermal Diffusivity Determination

2.8. The Determination of the Water Vapor Transmission

2.9. Determination of Fire-Test Response

2.10. Determination of Mold Resistance

3. Results

3.1. Characterization of Eucalyptus Bark Fibers

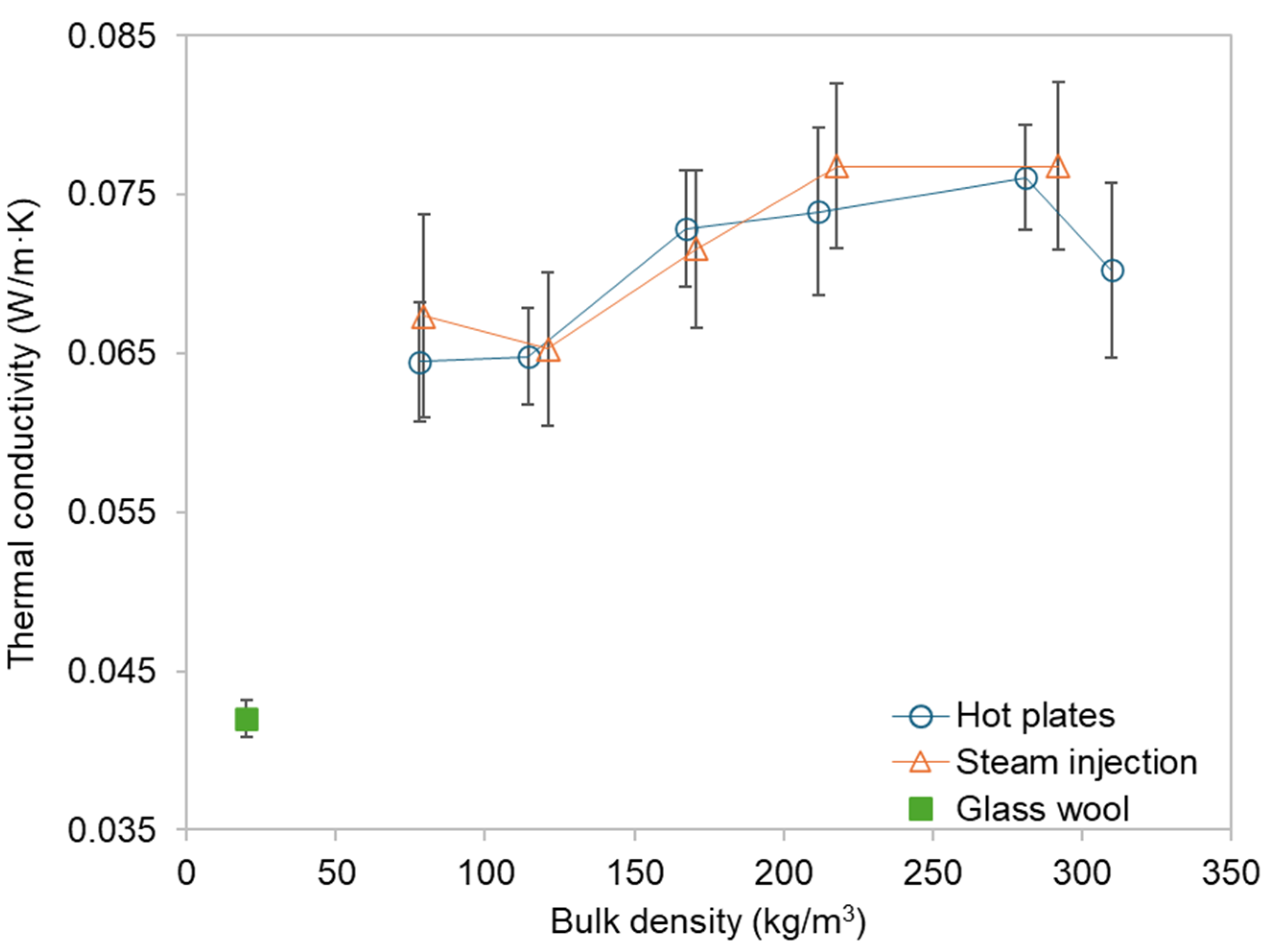

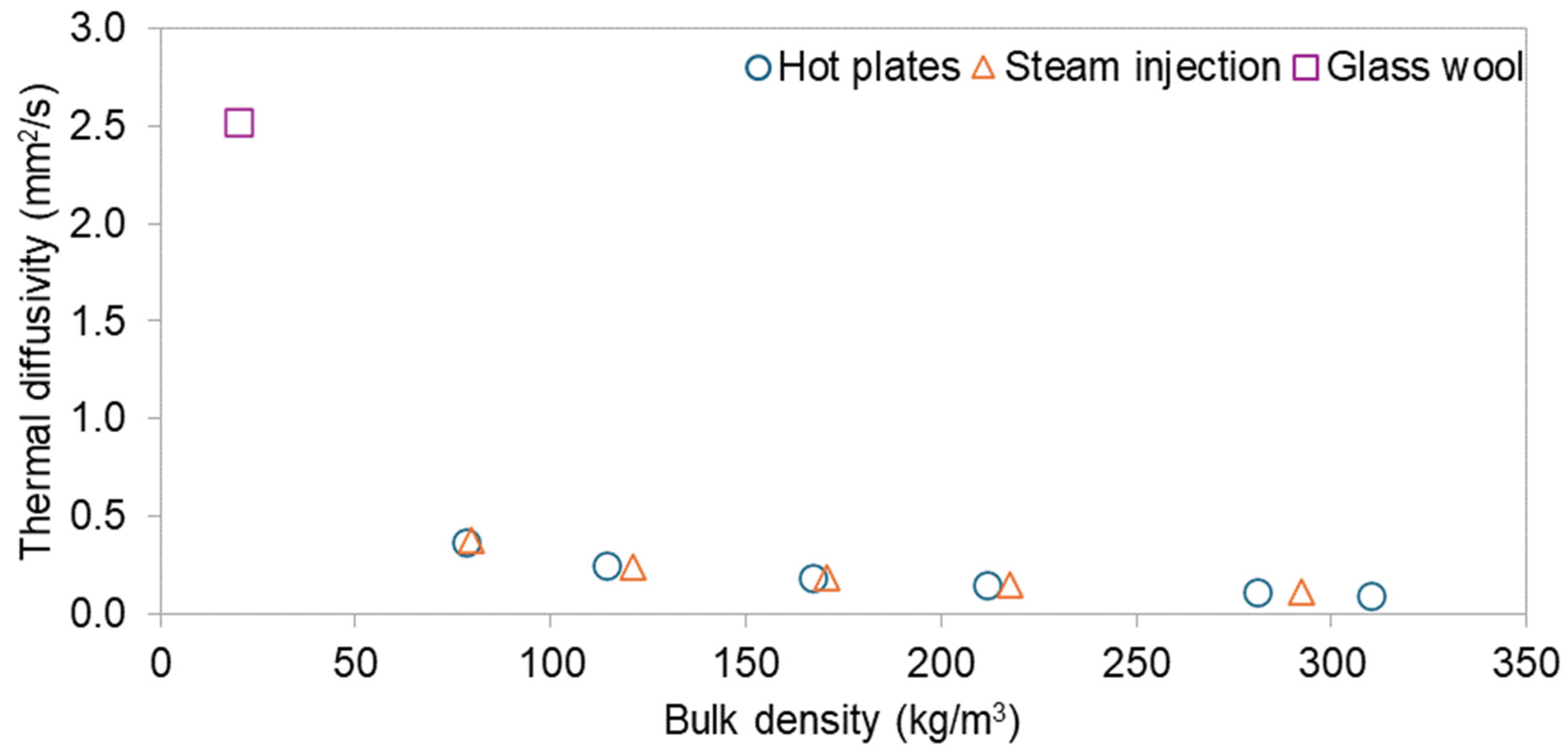

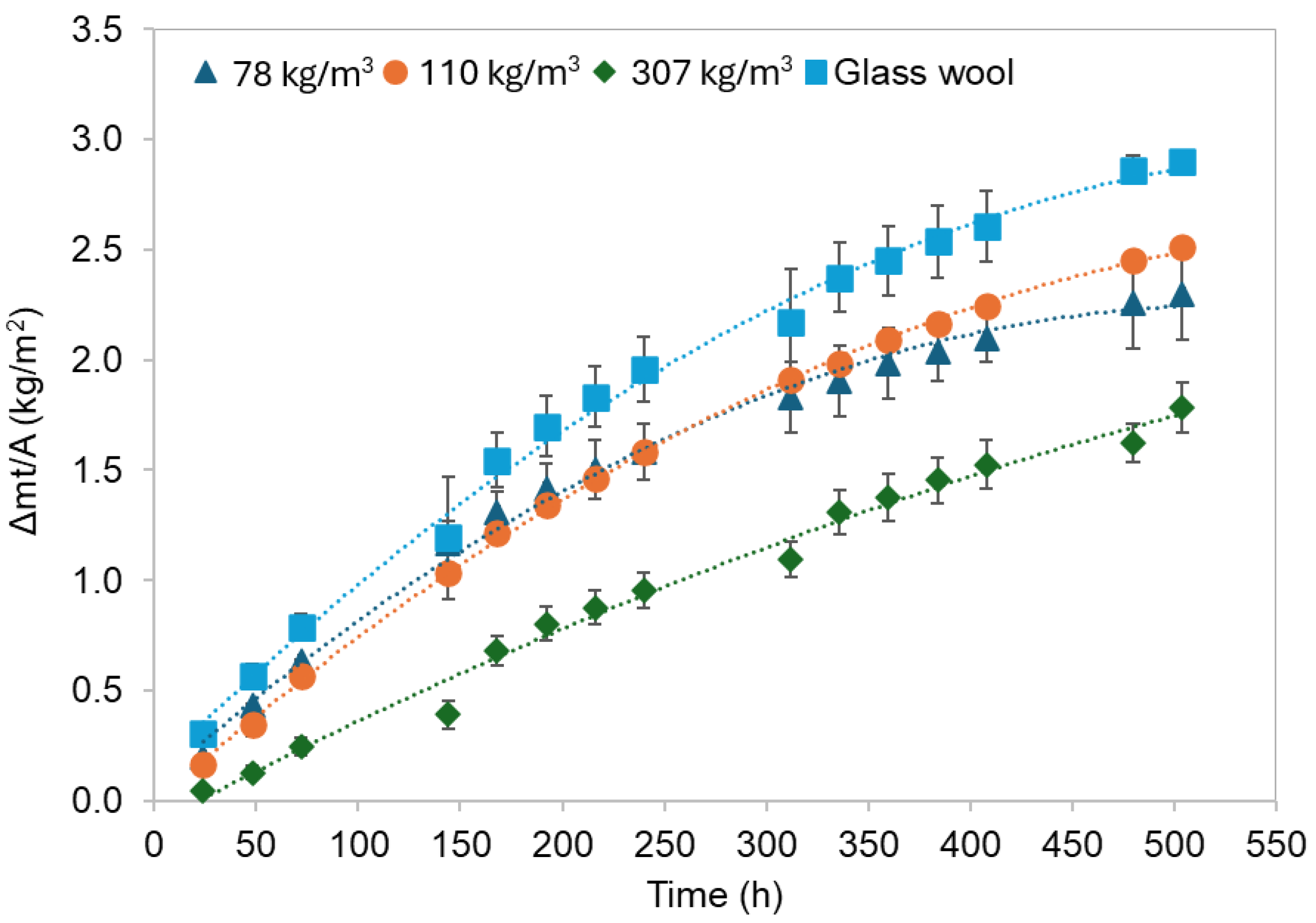

3.2. Characterization of EGFB-Based Panels

3.3. Fire-Test Response of Eucalyptus Bark Panel

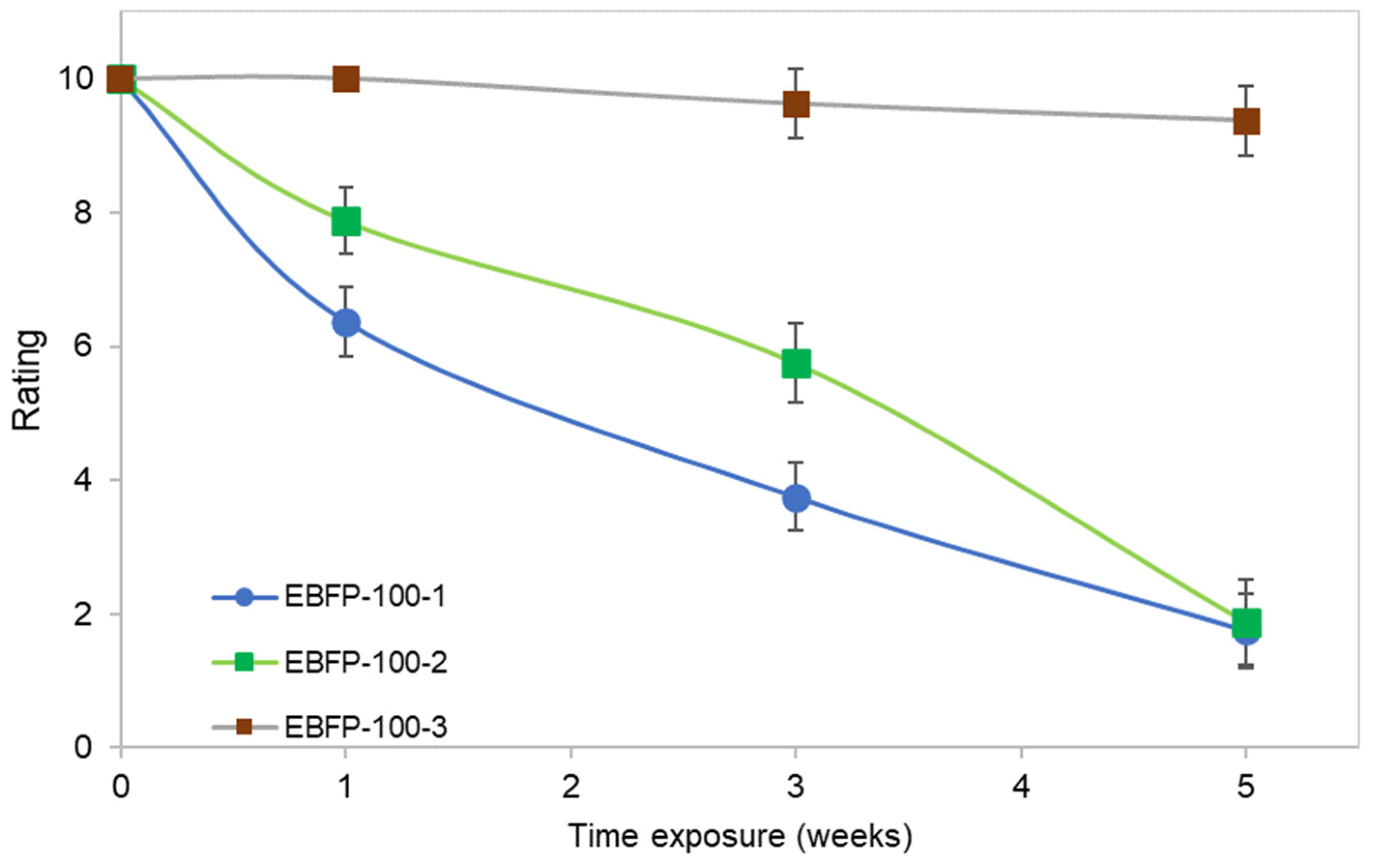

3.4. Mold Resistance

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Investigation of Material Characteristics and Hygrothermal Performances of Different Bio-Based Insulation Composites. Constr. Build. Mater. 2022, 346, 128440. [Google Scholar] [CrossRef]

- Güereca, L.P.; Jato-Espino, D.; Lizasoain-Arteaga, E. Life-Cycle Assessment of Construction Materials: Analysis of Environmental Impacts and Recommendations of Eco-Efficient Management Practices. In Handbook of Environmental Materials Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 2337–2372. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Biyada, S.; Merzouki, M.; Urbonavičius, J. New Resources for Sustainable Thermal Insulation Using Textile and Agricultural Waste in a New Circular Economy Approach: An Overview. Processes 2023, 11, 2683. [Google Scholar] [CrossRef]

- Siciliano, A.; Zhao, X.; Fedderwitz, R.; Ramakrishnan, K.; Dai, J.; Gong, A.; Zhu, J.; Kośny, J.; Hu, L. Sustainable Wood-Waste-Based Thermal Insulation Foam for Building Energy Efficiency. Buildings 2023, 13, 840. [Google Scholar] [CrossRef]

- Petcu, C.; Hegyi, A.; Stoian, V.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.-V.; Florean, C. Research on Thermal Insulation Performance and Impact on Indoor Air Quality of Cellulose-Based Thermal Insulation Materials. Materials 2023, 16, 5458. [Google Scholar] [CrossRef]

- Gamon, G.; Evon, P.; Rigal, L. Twin-Screw Extrusion Impact on Natural Fibre Morphology and Material Properties in Poly(Lactic Acid) Based Biocomposites. Ind. Crops Prod. 2013, 46, 173–185. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and Characterization of Thermal Insulation Materials from Renewable Resources. Constr. Build. Mater. 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Fei, M.; Qiu, R.; Yu, D.; Fu, T.; Qiu, J. Properties of Natural Fiber-Reinforced Biobased Thermoset Biocomposites: Effects of Fiber Type and Resin Composition. Compos. B Eng. 2019, 171, 87–95. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of Mechanical Properties of Flax Fibres for Composite Reinforcement. A Review. Ind. Crops Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and Sustainable Biobased Materials: An Assessment on Biofibers, Biofilms, Biopolymers and Biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Pratheep, V.G.; Priyanka, E.B.; Thangavel, S.; Jason Gousanal, J.; Bijoy Antony, P.T.; Kavin, E.D. Investigation and Analysis of Corn Cob, Coir Pith with Wood Plastic Composites. Mater. Today Proc. 2021, 45, 549–555. [Google Scholar] [CrossRef]

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial Hemp Fiber: A Sustainable and Economical Alternative to Cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Cosentino, L.; Fernandes, J.; Mateus, R. A Review of Natural Bio-Based Insulation Materials. Energies 2023, 16, 4676. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Lazzaretto, A.; Manente, G.; Tong, C.; Liu, Q.; Li, N. The Development History and Prospects of Biomass-Based Insulation Materials for Buildings. Renew. Sustain. Energy Rev. 2017, 69, 912–932. [Google Scholar] [CrossRef]

- Lanting, S. Biobased Materials in the Construction Industry: A Case Study into the Effects of Using Biobased Con-Struction Materials on Life Cycle Costs. Master’s Thesis, University of Twente, Twente, The Netherlands, 2023. [Google Scholar]

- Betts, D.; Sadeghian, P.; Fam, A. Post-Impact Residual Strength and Resilience of Sandwich Panels with Natural Fiber Composite Faces. J. Build. Eng. 2021, 38, 102184. [Google Scholar] [CrossRef]

- Martínez, B.; Bernat-Maso, E.; Gil, L. Applications and Properties of Hemp Stalk-Based Insulating Biomaterials for Buildings: Review. Materials 2023, 16, 3245. [Google Scholar] [CrossRef]

- Grenon, V.; Maref, W.; Ouellet-Plamondon, C.M. Comparison of Thermal Insulation Proprieties between Glass Wool, Hemp Wool and an Experimental Material Composed of Pleurotus Ostreatus Mycelium and Ash Wood Chips. Available online: https://dx.doi.org/10.2139/ssrn.4490479 (accessed on 23 May 2024).

- Shavyrkina, N.A.; Budaeva, V.V.; Skiba, E.A.; Gismatulina, Y.A.; Sakovich, G.V. Review of Current Prospects for Using Miscanthus-Based Polymers. Polymers 2023, 15, 3097. [Google Scholar] [CrossRef]

- Khalaf, Y.; El Hage, P.; Dimitrova Mihajlova, J.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of Agricultural Fibers Size on Mechanical and Insulating Properties of Innovative Chitosan-Based Insulators. Constr. Build. Mater. 2021, 287, 123071. [Google Scholar] [CrossRef]

- Masuda, T.; Takano, K.; Hiyama, K. Sound Absorption Performance Test of Grass Compression Board to Promote Resource Circulation. E3S Web Conf. 2023, 396, 01034. [Google Scholar] [CrossRef]

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of Mycelium-Miscanthus Composites as Building Insulation Material. Results Mater. 2021, 10, 100189. [Google Scholar] [CrossRef]

- Gößwald, J.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.-S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38–65. [Google Scholar] [CrossRef]

- Soto, M.; Rojas, C.; Cárdenas-Ramírez, J.P. Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability 2022, 15, 58. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative Life Cycle Assessment of Bio-based Insulation Materials: Environmental and Economic Performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Carabaño Rodríguez, R.; Bedoya Frutos, C.; Galván Martínez, J.; Ruiz Amador, D. La Utilización Del Corcho Como Material de Aislamiento Térmico Para Una Construcción Sostenible. In I Congreso Internacional Sobre Investigación en Construcción y Tecnología Arquitectónica; Universidad Politécnica de Madrid: Madrid, Spain, 2014. [Google Scholar]

- Cai, Z.; Song, X.; Wang, X.; Guo, T.; Takahashi, H.; Cai, C. Effect of Applied Pressure on the Performance of Biodegradable Fiber Insulation Board Manufactured from Camphor Branches (Cinnamomum camphora). Forests 2024, 15, 156. [Google Scholar] [CrossRef]

- Xu, J.; Sugawara, R.; Widyorini, R.; Han, G.; Kawai, S. Manufacture and Properties of Low-Density Binderless Particleboard from Kenaf Core. J. Wood Sci. 2004, 50, 62–67. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. Sugar Palm Tree: A Versatile Plant and Novel Source for Biofibres, Biomatrices, and Biocomposites. Polym. Renew. Resour. 2012, 3, 61–78. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.; Varum, H. Characterization of Corn Cob as a Possible Raw Building Material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Kain, G.; Tudor, E.M.; Barbu, M.-C. Bark Thermal Insulation Panels: An Explorative Study on the Effects of Bark Species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef]

- Urstöger, J.; Kain, G.; Prändl, F.; Barbu, M.C.; Kristak, L. Physical-Mechanical Properties of Light Bark Boards Bound with Casein Adhesives. Sustainability 2023, 15, 13530. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, Thermal and Acoustical Characterizations of an Insulating Bio-Based Composite Made from Sunflower Stalks Particles and Chitosan. Ind. Crops Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A Comprehensive Review of Techniques for Natural Fibers as Reinforcement in Composites: Preparation, Processing and Characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the Art in Thermal Insulation Materials and Aims for Future Developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Aly, N.M.; Seddeq, H.S.; Elnagar, K.; Hamouda, T. Acoustic and Thermal Performance of Sustainable Fiber Reinforced Thermoplastic Composite Panels for Insulation in Buildings. J. Build. Eng. 2021, 40, 102747. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic Characterization of Natural Fibers for Sound Absorption Applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Pennacchio, R.; Savio, L.; Bosia, D.; Thiebat, F.; Piccablotto, G.; Patrucco, A.; Fantucci, S. Fitness: Sheep-Wool and Hemp Sustainable Insulation Panels. Energy Procedia 2017, 111, 287–297. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers and Textile Waste Fibers: Elaboration and Performances Evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On Thermal Characteristics and Microstructure of a New Insulation Material Extracted from Date Palm Trees Surface Fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Ranefjärd, O.; Strandberg-de Bruijn, P.B.; Wadsö, L. Hygrothermal Properties and Performance of Bio-Based Insulation Materials Locally Sourced in Sweden. Materials 2024, 17, 2021. [Google Scholar] [CrossRef] [PubMed]

- Vural Gursel, I.; Elbersen, B.; Meesters, K.P.H.; van Leeuwen, M. Defining Circular Economy Principles for Biobased Products. Sustainability 2022, 14, 12780. [Google Scholar] [CrossRef]

- Brandão, A.S.; Gonçalves, A.; Santos, J.M.R.C.A. Circular Bioeconomy Strategies: From Scientific Research to Commercially Viable Products. J. Clean. Prod. 2021, 295, 126407. [Google Scholar] [CrossRef]

- Gregg, J.S.; Jürgens, J.; Happel, M.K.; Strøm-Andersen, N.; Tanner, A.N.; Bolwig, S.; Klitkou, A. Valorization of Bio-Residuals in the Food and Forestry Sectors in Support of a Circular Bioeconomy: A Review. J. Clean. Prod. 2020, 267, 122093. [Google Scholar] [CrossRef]

- Ferreira, V.; Boyero, L.; Calvo, C.; Correa, F.; Figueroa, R.; Gonçalves, J.F.; Goyenola, G.; Graça, M.A.S.; Hepp, L.U.; Kariuki, S.; et al. A Global Assessment of the Effects of Eucalyptus Plantations on Stream Ecosystem Functioning. Ecosystems 2019, 22, 629–642. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Antov, P.; Krišťák, Ľ.; Rahandi Lubis, M.A.; Fatriasari, W. (Eds.) Eucalyptus; Springer Nature: Singapore, 2024. [Google Scholar] [CrossRef]

- Quilhó, T.; Pereira, H. Within and between-tree variation of bark content and wood density of eucalyptus globulus in commercial plantations. IAWA J. 2001, 22, 255–265. [Google Scholar] [CrossRef]

- Ministerio de Agricultura. Anuario Forestal 2023. 2023. Available online: https://wef.infor.cl/index.php/publicaciones/boletines-estadisticos/anuario-forestal (accessed on 14 March 2024).

- Sartori, C.; da Silva Mota, G.; Ferreira, J.; Miranda, I.; Mori, F.A.; Pereira, H. Chemical Characterization of the Bark of Eucalyptus Urophylla Hybrids in View of Their Valorization in Biorefineries. Holzforschung 2016, 70, 819–828. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; de Carneiro, A.C.; Pereira, H. Potential of Eucalyptus globulus Industrial Bark as a Biorefinery Feedstock: Chemical and Fuel Characterization. Ind. Crops Prod. 2018, 123, 262–270. [Google Scholar] [CrossRef]

- Abdelkhalek, A.; Salem, M.Z.M.; Kordy, A.M.; Salem, A.Z.M.; Behiry, S.I. Antiviral, Antifungal, and Insecticidal Activities of Eucalyptus Bark Extract: HPLC Analysis of Polyphenolic Compounds. Microb. Pathog. 2020, 147, 104383. [Google Scholar] [CrossRef]

- Martini, S.; Afroze, S.; Ahmad Roni, K. Modified Eucalyptus Bark as a Sorbent for Simultaneous Removal of COD, Oil, and Cr(III) from Industrial Wastewater. Alex. Eng. J. 2020, 59, 1637–1648. [Google Scholar] [CrossRef]

- Ghodbane, I.; Hamdaoui, O. Removal of Mercury(II) from Aqueous Media Using Eucalyptus Bark: Kinetic and Equilibrium Studies. J. Hazard. Mater. 2008, 160, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Romaní, A.; Larramendi, A.; Yáñez, R.; Cancela, Á.; Sánchez, Á.; Teixeira, J.A.; Domingues, L. Valorization of Eucalyptus Nitens Bark by Organosolv Pretreatment for the Production of Advanced Biofuels. Ind. Crops Prod. 2019, 132, 327–335. [Google Scholar] [CrossRef]

- Wesolowski, A.; Adams, M.A.; Pfautsch, S. Insulation Capacity of Three Bark Types of Temperate Eucalyptus Species. Ecol. Manag. 2014, 313, 224–232. [Google Scholar] [CrossRef]

- Casas-Ledón, Y.; Daza Salgado, K.; Cea, J.; Arteaga-Pérez, L.E.; Fuentealba, C. Life Cycle Assessment of Innovative Insulation Panels Based on Eucalyptus Bark Fibers. J. Clean. Prod. 2020, 249, 119356. [Google Scholar] [CrossRef]

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass; Laboratory Analytical Procedure (LAP): Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure (LAP): Colorado, USA, 2012. [Google Scholar]

- ISO 18122:2022; Solid Biofuels—Determination of Ash Content. International Organization for Standardization (ISO): Geneva, Switzerland, 2022.

- UNE EN 323; Wood-Based Panels—Determination of Density. The Spanish Association for Standardization: Madrid, Spain, 1994.

- UNE EN 325; Wood-Based Panels—Determination of Dimensions of Test Pieces. The Spanish Association for Standardization: Madrid, Spain, 2012.

- ASTM D 5334; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2008.

- Morîntale, E.; Harabor, A.; Constantinescu, C.; Rotaru, P. Use of Heat Flows from DSC Curve for Calculation of Specific Heat of the Solid Materials. Phys. AUC 2013, 23, 89–94. [Google Scholar]

- ASTM E 95-96; Standard Test Methods for Water Vapor Transmission of Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 1995.

- BS 5250:2002; Incorporating Amendment No. 1: Code of Practice for Control of Condensation in Buildings ICS 91.120.99. British Standard (BS): London, UK, 2002.

- ASTM D 4986-03; Standard Test Method for Horizontal Burning Characteristics of Cellular Polymeric Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2003.

- ASTM D 3273; Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- Pereira, H. Variability in the Chemical Composition of Plantation Eucalypts (Eucalyptus globulus Labill). Wood Fiber Sci. 1988, 22, 82–90. [Google Scholar]

- DIN 4108-2; Thermal Protection and Energy Economy in Buildings—Part 2: Minimum Requirements to Thermal Insulation. DIN: Berlin, Germany, 2013.

- Ducoulombier, L.; Lafhaj, Z. Comparative Study of Hygrothermal Properties of Five Thermal Insulation Materials. Case Stud. Therm. Eng. 2017, 10, 628–640. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and Performance Evaluation of Natural Thermal-Insulation Materials Composed of Renewable Resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New Low-Cost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Actis. Wood Fibre Insulation Product Guide Sylvactis 55 FX; Actis: London, UK, 2015; Volume 297. [Google Scholar]

- Hauser, G.; Otto, F.; Ringeler, M. Verbesserung Des Sommerlichen Wärmeverhaltens von Wohngebäuden Durch Holzfaser-Dämmplatten. Ingenieurbüro Bauphys. 2005, 561, 1–21. [Google Scholar]

- Neroth, G.; Vollenschaar, D. Wendehorst Baustoffkunde; Neroth, G., Vollenschaar, D., Eds.; Vieweg+Teubner: Wiesbaden, Germany, 2011. [Google Scholar] [CrossRef]

- Fachgentur Nachwachsende Rohstoffe, e.V. Dämmstoffe Aus Nachwachseden Rohstoffen; Fachgentur Nachwachsende Rohstoffe e.V: Gülzow-Prüzen, Germany, 2016. [Google Scholar]

- Johra, H. Thermal Properties of Building Materials—Review and Database; Aalborg University: Aalborg, Denmark, 2021. [Google Scholar] [CrossRef]

- Shakir, M.A.; Ahmad, M.I.; Yusup, Y.; Wabaidur, S.M.; Siddiqui, M.R.; Alam, M.; Rafatullah, M. Sandwich Composite Panel from Spent Mushroom Substrate Fiber and Empty Fruit Bunch Fiber for Potential Green Thermal Insulation. Buildings 2023, 13, 224. [Google Scholar] [CrossRef]

- Božiková, M.; Kotoulek, P.; Bilčík, M.; Kubík, Ľ.; Hlaváčová, Z.; Hlaváč, P. Thermal Properties of Wood and Wood Composites Made from Wood Waste. Int. Agrophys. 2021, 35, 251–256. [Google Scholar] [CrossRef] [PubMed]

- Torres-Ramo, J.; González-Martínez, P.; Arriazu-Ramos, N.; Sánchez-Ostiz, A. Influence of the Water Vapour Permeability of Airtight Sheets on the Behaviour of Facade. Sustainability 2020, 12, 10480. [Google Scholar] [CrossRef]

- Charvátová, H.; Procházka, A.; Zálešák, M.; Drápela, J.; MAříK, V. Computational Analysis of Indoor Thermal Comfort in a Terraced Family House with Thermal Insulation. IEEE Access 2023, 11, 80822–80834. [Google Scholar] [CrossRef]

- Jerman, M.; Černý, R. Effect of Moisture Content on Heat and Moisture Transport and Storage Properties of Thermal Insulation Materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Kymäläinen, H.-R.; Sjöberg, A.-M. Flax and Hemp Fibres as Raw Materials for Thermal Insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Cámara Chilena de la Construcción. Informe MACh 60 Macroeconomía y Construcción; Cámara Chilena de la Construcción: Las Condes, Chile, 2022. [Google Scholar]

- Ministerio de Vivienda y Urbanismo (MINVU). Ordenanza General de Urbanismo y Construcciones; MINVU, Ed.; MINVU: Santiago, Chile, 2017. [Google Scholar]

| Parameter | Value |

|---|---|

| Moisture content fibers (%, dry basis) | 4 |

| Target density (kg/m3) | 80/100/150/200/250/300 |

| Thickness (mm) | 50 |

| Resin content (% w/w) | 10 |

| Press system—pressing time (min) | Hot plates—13 min Steam injection—3 min |

| Press (kgf/cm2) | 45 |

| Curing temperature (°C) | 110 |

| Target Density (kg/m3) | Panel Weight (g) | Fiber Quantity (g) | Resin Quantity (g) |

|---|---|---|---|

| 80 | 640 | 576 | 64 |

| 100 | 800 | 720 | 80 |

| 150 | 1200 | 1080 | 120 |

| 200 | 1600 | 1440 | 160 |

| 250 | 200 | 1800 | 200 |

| 300 | 2400 | 2160 | 240 |

| Sample | PF-Resin (% w/w) | Additive | Additive (% w/w) |

|---|---|---|---|

| EBFP-100-1 | 0 | - | 0 |

| EBFP-100-2 | 10 | - | 0 |

| EBFP-100-3 | 10 | Antifungal | 1 |

| Component | Content (%, Dry Solid Basis) | |||

|---|---|---|---|---|

| EGFB | Bark E. globulus | Wood E. globulus | Hemp Fibers | |

| Pereira, 1988 [72] | ||||

| Ethanol/water extractives | 7.43 ± 0.03 | 2.11 ± 0.52 | 2.8 ± 0.3 | 4.6 |

| Cellulose | 49.91 ± 2.56 | 51.5 ± 1.4 | 52.3 ± 0.9 | 79 |

| Hemicelluloses | 18.12 ± 4.16 | 14.6 ± 0.5 | 17.8 ± 1.0 | 9 |

| Klason lignin | 17.60 ± 0.49 | 18.3 ± 0.8 | 21.4 ± 0.6 | 6.5 |

| Ash | 7.62 ± 0.32 | 2.11 ± 0.52 | 0.76 ± 0.19 | n.d. |

| Material | Specific Heat (J/kg K) | |

|---|---|---|

| EGFB | 2290 | This study |

| Phenolic resin (cured state) | 1928 | This study |

| EGFB-based panel | 2254 | This study |

| Wood fiber a (commercial) | 1600–2100 J | a |

| Glass wool b (commercial) | 840 | b |

| Thermal Diffusivity (mm2/s) | ||

|---|---|---|

| EGFB-based panel 50–300 kg/m3, both press systems | 0.10–0.37 | This study |

| Bio-based insulation panel | 0.1–1 | Johra [81] |

| Mineral insulation | 0.1–5 | |

| Polymer insulation | 0.1–8 | |

| Wood | 0.08–0.13 | Božiková et al. [83] |

| Parameter | EBFP-80 | EBFP-100 | EBFP-300 | GW |

|---|---|---|---|---|

| Density (kg/m3) | 78 ± 1 | 110 ± 1 | 307 ± 7 | 20 ± 1 |

| δ (kg m/GN s) | 0.055 ± 0.008 | 0.047 ± 0.001 | 0.032 ± 0.001 | 0.054 ± 0.001 |

| W (kg/GN s) | 1.1 ± 0.1 | 0.946 ± 0.001 | 0.634 ± 0.002 | 1.08 ± 0.02 |

| Resistivity (GN s/kg m) | 18 ± 3 | 21.15 ± 0.03 | 31.54 ± 0.09 | 18.4 ± 0.4 |

| WVR (GN s/kg) | 0.92 ± 0.02 | 1.058 ± 0.001 | 1.577 ± 0.004 | 0.92 ± 0.01 |

| µ (adim.) | 3.6 ± 0.5 | 4.23 ± 0.01 | 6.31 ± 0.02 | 3.69 ± 0.07 |

| sd (m) | 0.18 ± 0.03 | 0.21 ± 0.001 | 0.32 ± 0.001 | 0.185 ± 0.004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuentealba, C.; Segovia, C.; Pradena-Miquel, M.; César, A.G. Efficient Bio-Based Insulation Panels Produced from Eucalyptus Bark Waste. Forests 2024, 15, 1628. https://doi.org/10.3390/f15091628

Fuentealba C, Segovia C, Pradena-Miquel M, César AG. Efficient Bio-Based Insulation Panels Produced from Eucalyptus Bark Waste. Forests. 2024; 15(9):1628. https://doi.org/10.3390/f15091628

Chicago/Turabian StyleFuentealba, Cecilia, César Segovia, Mauricio Pradena-Miquel, and Andrés G. César. 2024. "Efficient Bio-Based Insulation Panels Produced from Eucalyptus Bark Waste" Forests 15, no. 9: 1628. https://doi.org/10.3390/f15091628

APA StyleFuentealba, C., Segovia, C., Pradena-Miquel, M., & César, A. G. (2024). Efficient Bio-Based Insulation Panels Produced from Eucalyptus Bark Waste. Forests, 15(9), 1628. https://doi.org/10.3390/f15091628