Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing

Abstract

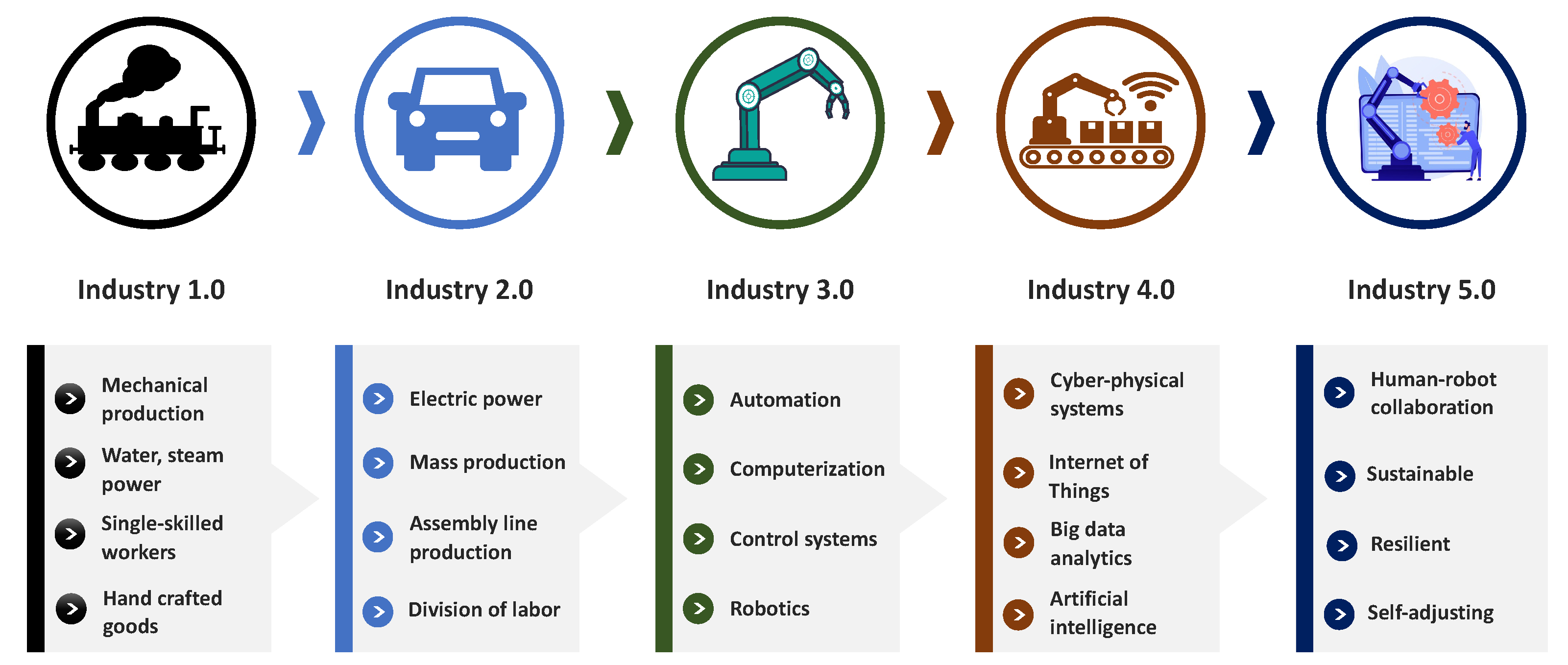

:1. Introduction

2. Industrial Communications with 5G

- Flexible numerology for radio resource allocation [20,21]: 3GPP outlines two main frequency ranges for 5G NR use, called frequency range 1 (FR1) and frequency range 2 (FR2). FR1 is also known as the sub-6 GHz band, while FR2 is referred to as the millimeter-wave (mmWave) band. The maximum channel bandwidth and the space between OFDM subcarriers can vary depending on the specific frequency range being used. The concept of flexible numerology allows for variations in both the value of subcarrier spacing and the duration of OFDM symbols, impacting the available data rate and transmission latency.These subcarrier spacings are obtained by scaling up the LTE-based subcarrier spacing by , leading to a range from 15 kHz up to 240 kHz, with a proportional change in cyclic prefix duration. This allows tailoring radio access parameters to suit the unique demands of industrial applications, like achieving low latency for real-time control or high throughput for data-intensive tasks. Furthermore, the adaptability of numerology allows for different applications with varying requirements to operate together within the same frequency band, resulting in optimal spectrum usage [22]. This can lead to enhanced efficiency and productivity in manufacturing processes, as well as improved automation and quality control beyond what other wireless technologies can offer.

- mmWave communication [21,23,24]: The allocated mmWave radio spectrum provides much more bandwidth than is available in the sub-6 GHz band, allowing for the accommodation of a wide range of novel applications for Industry 4.0 and beyond. Example applications include advanced smart industrial functions like vision-guided robots, ultra-high-definition video and imaging for remote visual monitoring and inspection, smart safety instrumented systems, intelligent logistics, and high-precision image-guided automated assembly, among others. The availability of ultra-reliable and low-latency communications (URLLC) in factory automation scenarios enables smart machines and robots to work alongside humans or cooperate toward a common goal, which is a key aspect of the future Industry 5.0 vision. Furthermore, utilizing mmWaves enables not only thorough communication but also sensing, which can support seamless and adaptive behavior in equipment and machines, allowing them to detect nearby individuals or objects and react appropriately by adjusting their movements or slowing their operating rate.

- Beamforming [25,26,27]: Antenna beamforming employs an array of multiple antenna elements to generate a directed beam. This has the significant advantage of reducing interference in sub-6 GHz bands, resulting in higher throughput due to directional transmission. At mmWave frequencies, beamforming is essential for reliable communication, as it enhances channel gain. Beamforming, for example, facilitates concurrent communication among collaborative robots in a smart industrial environment.

- Massive MIMO [28,29,30,31,32,33]: Massive MIMO utilizes a large number of antennas to exploit spatial degrees of freedom, enabling it to support communication with multiple devices simultaneously without requiring additional time or frequency resources [34]. As industrial environments tend to contain metallic surfaces from equipment, many such environments are challenging for wireless communication. Massive MIMO’s channel-hardening effect improves its immunity to fast fading and allows for more deterministic communications, which is important for many industrial applications with strict quality-of-service requirements.

- Network Slicing [35]: Next-generation factories will need to handle diverse traffic flows that may have conflicting needs for performance, reliability, and security. A single large system cannot meet the demands of these new industrial situations. Slicing permits the delivery of a variety of specific services with potentially incompatible requirements on a single physical 5G substrate [36].

- The 5G LAN-Type Service [37]: Most current automation systems in industry are based on a range of proprietary wired local area network (LAN) technologies. These systems allow devices to communicate directly with each other across the LAN, discover their services, and utilize multi-cast communication and other LAN features. This contrasts with 5G communication modes, which are more peer-to-peer oriented and rely on switching and routing in the 5G core network. The 5G LAN-type service [38] is designed to replicate LAN features and simplify communication between 5G-based devices, particularly in industrial automation environments [39].

3. WiFi 7 for Industrial Communications

- High Modulation Order: WiFi 7 utilizes Orthogonal Frequency-Division Multiplexing (OFDM) with a modulation order of up to 4096-QAM [44], allowing it to transmit at very high data rates within a given bandwidth, such as for vision-based applications. In the context of smart manufacturing, the significance of high data rates extends beyond the transmission of large volumes of data, as it also enables the ultra-low-latency transmission of small data packets within short timeframes, which is desirable in many industrial applications. Industrial processes that benefit from high data rate services include machine-to-machine communication, real-time monitoring, and production optimization, where the ability to swiftly transmit data is critical. It is worth noting that a signal-to-noise ratio (SNR) of approximately 40 dB is required at the receiver end to accurately decode a 4096-QAM signal, a threshold that may not always be attainable in many environments [43]. However, antenna beamforming can help alleviate this problem by increasing the channel gain.

- Multi-Link Operation: WiFi 7 has an additional characteristic called multi-link operation, which allows the access point and end devices to function concurrently over 2.4 GHz, 5 GHz, and 6 GHz frequency bands, thereby providing multiple channels for data transmission [45,46]. This feature aims to enhance network performance by increasing peak throughput, minimizing latency and jitter, and augmenting network reliability. It ensures that even if one connection fails, essential data will still be delivered, making WiFi 7 networks more dependable [47]. Additionally, link aggregation can be performed to significantly increase network throughput. In the industrial domain, these features are especially useful for processes such as machine-to-machine communication and real-time inventory control, where a dependable network is essential for proper and effective performance.

- Wider Bandwidth: A distinguishing characteristic of WiFi 7 is its expanded bandwidth. After the initial adoption of 802.11ax, the WiFi industry is increasingly utilizing the 6 GHz band to swiftly enhance the peak throughput of WiFi, which will have a significant impact on industrial use cases. Consequently, discussions have arisen about the most optimal methods for utilizing the available unlicensed spectrum, ranging up to 1.2 GHz between 5.925 and 7.125 GHz, which more than doubles the bandwidth compared to the 5 GHz band alone [18]. By providing a wider bandwidth, WiFi 7 has the potential to support a large number of industrial devices. Moreover, operating in a less congested frequency spectrum also reduces interference, which can be a challenge in industrial settings where many systems and devices operate in close proximity.

- Multi-AP Operation: WiFi 7’s multi-AP operation allows multiple access points to work together as a single, continuous network. This feature can facilitate seamless handovers between WiFi networks, simplify overall network configuration (e.g., selecting operating channels), and enhance the capacity of the WiFi network [48]. By synchronizing multiple access points, coverage can be extended across the entire factory floor, guaranteeing that all machines and mobile devices maintain a reliable and strong connection. Furthermore, cooperation among neighboring APs through the exchange of crucial scheduling information and channel state information (CSI) is a potential strategy to enhance the utilization of scarce radio resources [43], particularly in an industrial environment with a high density of sensors and actuators, where co-channel interference can reach intolerable levels.

- WiFi Sensing: Wireless radio sensing is a cutting-edge feature of WiFi that allows WiFi networks to sense and detect the presence of people, objects, and other devices, even when they are not actively transmitting data. In smart manufacturing, WiFi sensing has a range of important applications, including enabling location-based services, asset tracking, and improved safety and security. Location-based services allow for real-time tracking of machines, devices, and personnel across the factory floor. Asset tracking is another significant application of WiFi sensing, ensuring that costly machinery and equipment are not misplaced or stolen. By detecting the presence of these assets, manufacturers can monitor their usage, maintenance schedules, and movements, ensuring they are always in good working condition and ready for use. Furthermore, WiFi sensing can be key to improving the safety and security of the smart factory [49]. By detecting people and machines, WiFi sensing helps ensure a safe and secure work environment for all personnel by preventing accidents. For instance, WiFi sensing can alert workers to dangers in areas where machinery may pose a risk, allowing them to take appropriate measures.

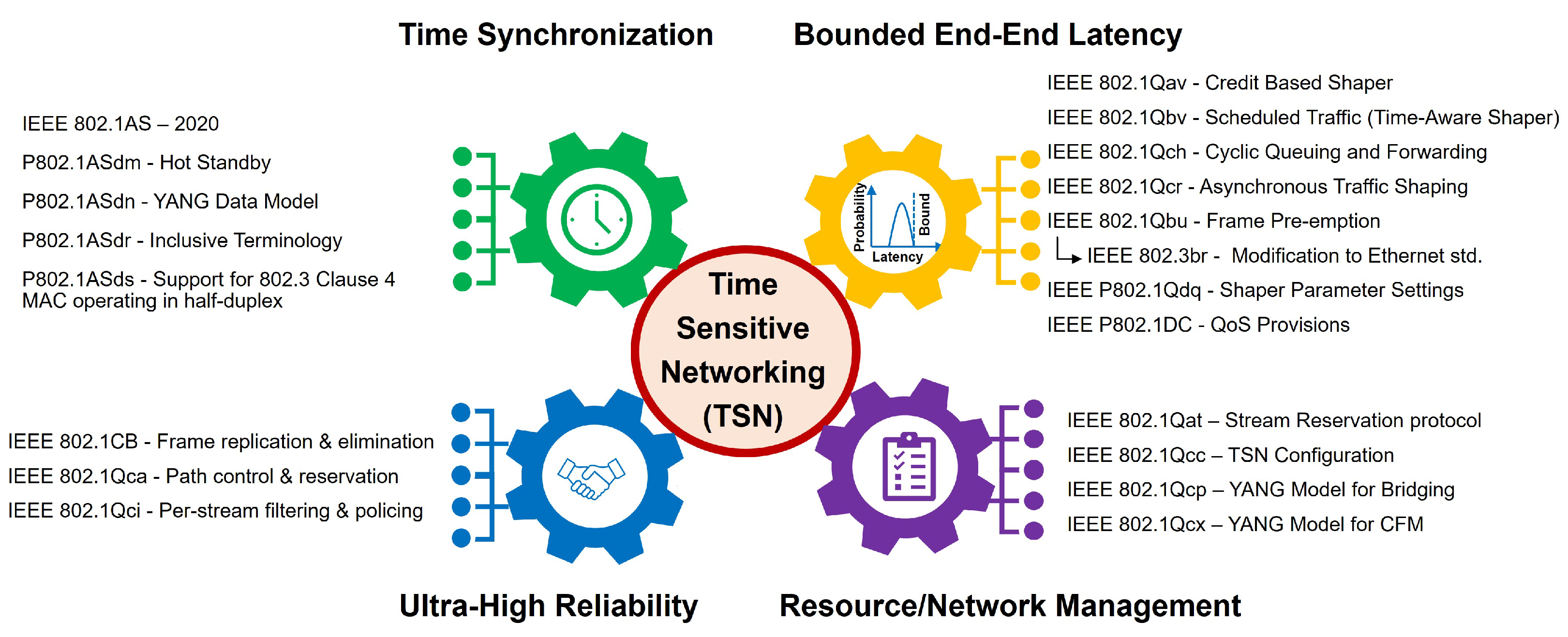

4. TSN for Industrial Communications

4.1. TSN over Wireless

4.1.1. TSN over WiFi

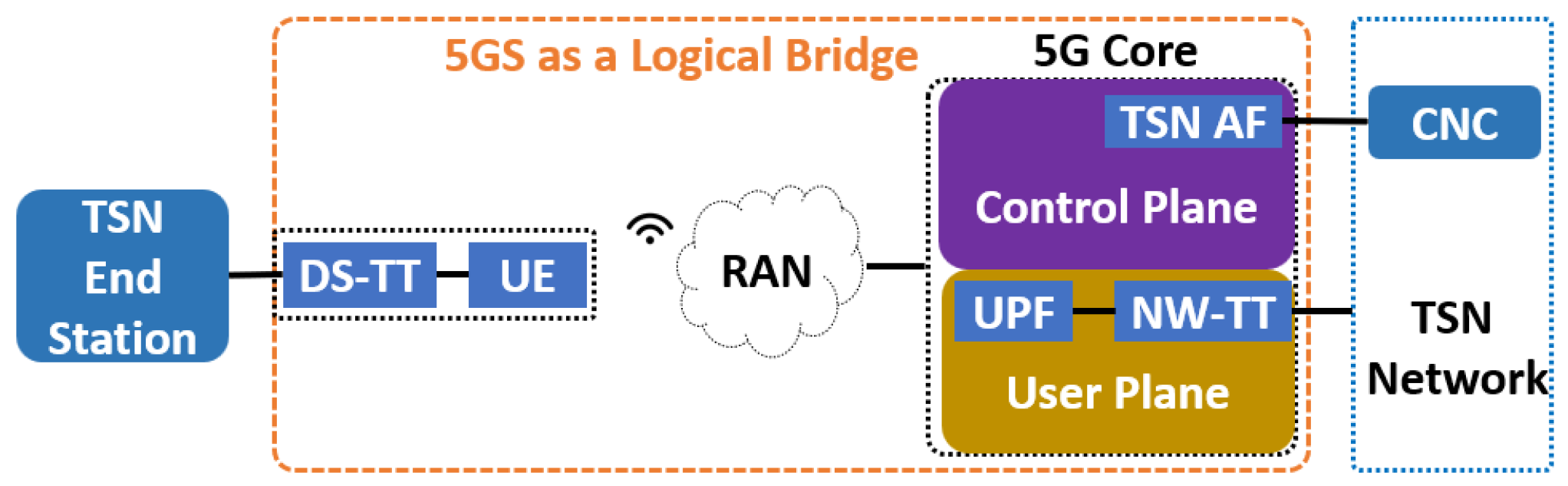

4.1.2. TSN over 5G

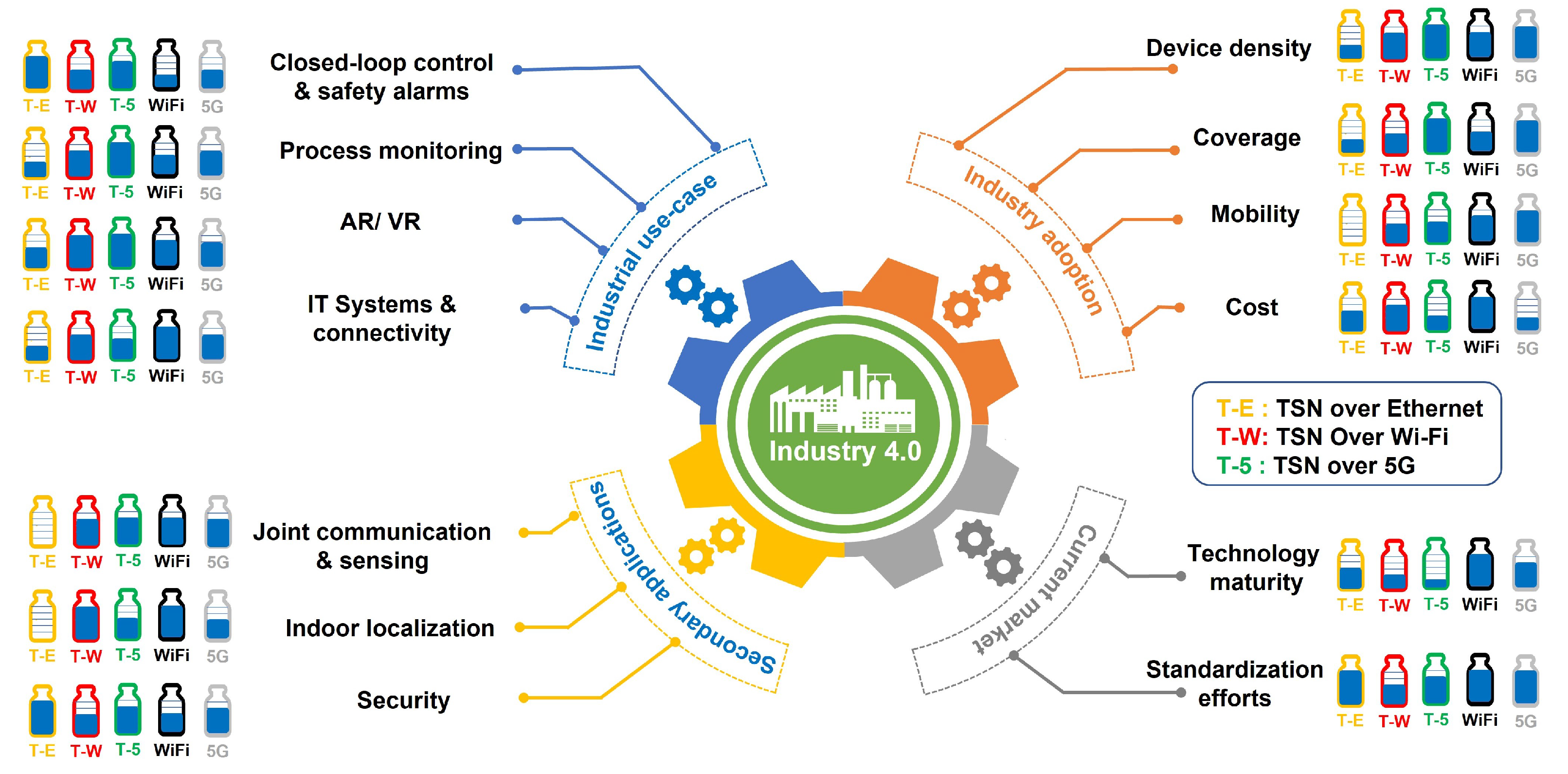

5. A Comparative Analysis

6. Challenges and Future Directions

6.1. Dynamic Network Management

6.2. Deployment Issues

6.3. TSN-Grade Wireless Performance

6.4. Implementation Challenges

6.5. AI in Industrial Wireless Communications

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Qiu, T.; Chi, J.; Zhou, X.; Ning, Z.; Atiquzzaman, M.; Wu, D.O. Edge Computing in Industrial Internet of Things: Architecture, Advances and Challenges. IEEE Commun. Surv. Tutor. 2020, 22, 2462–2488. [Google Scholar] [CrossRef]

- Vitturi, S.; Zunino, C.; Sauter, T. Industrial Communication Systems and Their Future Challenges: Next-Generation Ethernet, IIoT, and 5G. Proc. IEEE 2019, 107, 944–961. [Google Scholar] [CrossRef]

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial internet of things: Challenges, opportunities, and directions. IEEE Trans. Ind. Inform. 2018, 14, 4724–4734. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Piardi, L.; Leitão, P.; Queiroz, J.; Pontes, J. Role of digital technologies to enhance the human integration in industrial cyber–physical systems. Annu. Rev. Control 2024, 57, 100934. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. The reference architectural model industrie 4.0 (rami 4.0). Zvei 2015, 2, 4–9. [Google Scholar]

- Gamberini, L.; Pluchino, P. Industry 5.0: A comprehensive insight into the future of work, social sustainability, sustainable development, and career. Aust. J. Career Dev. 2024, 33, 5–14. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- van Erp, T.; Carvalho, N.G.P.; Gerolamo, M.C.; Gonçalves, R.; Rytter, N.G.M.; Gladysz, B. Industry 5.0: A new strategy framework for sustainability management and beyond. J. Clean. Prod. 2024, 461, 142271. [Google Scholar] [CrossRef]

- Rojek, I.; Jasiulewicz-Kaczmarek, M.; Piszcz, A.; Galas, K.; Mikołajewski, D. Review of the 6G-Based Supply Chain Management within Industry 4.0/5.0 Paradigm. Electronics 2024, 13, 2624. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards More Sustainable, Resilient and Human-Centric Industry; Research and innovation, European Commission: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- Noor-A-Rahim, M.; Firyaguna, F.; John, J.; Khyam, M.O.; Pesch, D.; Armstrong, E.; Claussen, H.; Poor, H.V. Toward Industry 5.0: Intelligent Reflecting Surface in Smart Manufacturing. IEEE Commun. Mag. 2022, 60, 72–78. [Google Scholar] [CrossRef]

- Antonaci, F.G.; Olivetti, E.C.; Marcolin, F.; Jimenez, I.A.C.; Eynard, B.; Vezzetti, E.; Moos, S. Workplace Well-Being in Industry 5.0: A Worker-Centered Systematic Review. Sensors 2024, 24, 5473. [Google Scholar] [CrossRef] [PubMed]

- Mladineo, M.; Celent, L.; Milković, V.; Veža, I. Current State Analysis of Croatian Manufacturing Industry with Regard to Industry 4.0/5.0. Machines 2024, 12, 87. [Google Scholar] [CrossRef]

- Chettri, L.; Bera, R. A Comprehensive Survey on Internet of Things (IoT) Toward 5G Wireless Systems. IEEE Internet Things J. 2020, 7, 16–32. [Google Scholar] [CrossRef]

- Lopez-Perez, D.; Garcia-Rodriguez, A.; Galati-Giordano, L.; Kasslin, M.; Doppler, K. IEEE 802.11be Extremely High Throughput: The Next Generation of Wi-Fi Technology Beyond 802.11ax. IEEE Commun. Mag. 2019, 57, 113–119. [Google Scholar] [CrossRef]

- Seol, Y.; Hyeon, D.; Min, J.; Kim, M.; Paek, J. Timely Survey of Time-Sensitive Networking: Past and Future Directions. IEEE Access 2021, 9, 142506–142527. [Google Scholar] [CrossRef]

- Raftopoulou, M.; Litjens, R. Optimisation of Numerology and Packet Scheduling in 5G Networks: To Slice or not to Slice? In Proceedings of the 2021 IEEE 93rd Vehicular Technology Conference (VTC2021-Spring), Virtual Event, 25–28 April 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Dahlman, E.; Parkvall, S.; Skold, J. 5G NR: The Next Generation Wireless Access Technology; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Flores de Valgas, J.; Monserrat, J.F.; Arslan, H. Flexible numerology in 5G NR: Interference quantification and proper selection depending on the scenario. Mob. Inf. Syst. 2021, 2021, 6651326. [Google Scholar] [CrossRef]

- Elkashlan, M.; Duong, T.Q.; Chen, H.H. Millimeter-wave communications for 5G: Fundamentals: Part I [Guest Editorial]. IEEE Commun. Mag. 2014, 52, 52–54. [Google Scholar] [CrossRef]

- Elkashlan, M.; Duong, T.Q.; Chen, H.h. Millimeter-wave communications for 5G–Part 2: Applications [Guest Editorial]. IEEE Commun. Mag. 2015, 53, 166–167. [Google Scholar] [CrossRef]

- Ahmed, I.; Khammari, H.; Shahid, A.; Musa, A.; Kim, K.S.; De Poorter, E.; Moerman, I. A Survey on Hybrid Beamforming Techniques in 5G: Architecture and System Model Perspectives. IEEE Commun. Surv. Tutor. 2018, 20, 3060–3097. [Google Scholar] [CrossRef]

- Molisch, A.F.; Ratnam, V.V.; Han, S.; Li, Z.; Nguyen, S.L.H.; Li, L.; Haneda, K. Hybrid beamforming for massive MIMO: A survey. IEEE Commun. Mag. 2017, 55, 134–141. [Google Scholar] [CrossRef]

- Shevada, L.; Raut, H.D.; Malekar, R.; Kumar, S. Comparative study of different beamforming techniques for 5G: A review. In Inventive Communication and Computational Technologies: Proceedings of ICICCT 2020; Lecture Notes in Networks and Systems; Springer: Singapore, 2021; Volume 145, pp. 589–595. [Google Scholar]

- Larsson, E.G.; Edfors, O.; Tufvesson, F.; Marzetta, T.L. Massive MIMO for next generation wireless systems. IEEE Commun. Mag. 2014, 52, 186–195. [Google Scholar] [CrossRef]

- Shafi, M.; Molisch, A.F.; Smith, P.J.; Haustein, T.; Zhu, P.; De Silva, P.; Tufvesson, F.; Benjebbour, A.; Wunder, G. 5G: A Tutorial Overview of Standards, Trials, Challenges, Deployment, and Practice. IEEE J. Sel. Areas Commun. 2017, 35, 1201–1221. [Google Scholar] [CrossRef]

- Agiwal, M.; Roy, A.; Saxena, N. Next Generation 5G Wireless Networks: A Comprehensive Survey. IEEE Commun. Surv. Tutor. 2016, 18, 1617–1655. [Google Scholar] [CrossRef]

- Marzetta, T.L.; Larsson, E.G.; Yang, H.; Ngo, H.Q. Fundamentals of Massive MIMO; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Lu, L.; Li, G.Y.; Swindlehurst, A.L.; Ashikhmin, A.; Zhang, R. An Overview of Massive MIMO: Benefits and Challenges. IEEE J. Sel. Top. Signal Process. 2014, 8, 742–758. [Google Scholar] [CrossRef]

- Chataut, R.; Akl, R. Massive MIMO Systems for 5G and beyond Networks—Overview, Recent Trends, Challenges, and Future Research Direction. Sensors 2020, 20, 2753. [Google Scholar] [CrossRef]

- Zhang, J.; Björnson, E.; Matthaiou, M.; Ng, D.W.K.; Yang, H.; Love, D.J. Prospective Multiple Antenna Technologies for Beyond 5G. IEEE J. Sel. Areas Commun. 2020, 38, 1637–1660. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Bouali, F.; Haas, O.C. Resource Management From Single-domain 5G to End-to-End 6G Network Slicing: A Survey. IEEE Commun. Surv. Tutor. 2024; E-pub ahead of print. [Google Scholar] [CrossRef]

- Ordonez-Lucena, J.; Ameigeiras, P.; Lopez, D.; Ramos-Munoz, J.J.; Lorca, J.; Folgueira, J. Network Slicing for 5G with SDN/NFV: Concepts, Architectures, and Challenges. IEEE Commun. Mag. 2017, 55, 80–87. [Google Scholar] [CrossRef]

- Parvez, I.; Rahmati, A.; Guvenc, I.; Sarwat, A.I.; Dai, H. A survey on low latency towards 5G: RAN, core network and caching solutions. IEEE Commun. Surv. Tutor. 2018, 20, 3098–3130. [Google Scholar] [CrossRef]

- Zhu, X.; Chi, Y. 5G Release 16 Key Technologies for Vertical Industries Application. In Proceedings of the 2021 International Wireless Communications and Mobile Computing (IWCMC), Harbin, China, 28 June–2 July 2021. [Google Scholar]

- Phan, L.A.; Pesch, D.; Roedig, U.; Sreenan, C.J. Demonstration of LAN-type Communication for an Industrial 5G Network. In Proceedings of the IEEE INFOCOM 2023—IEEE Conference on Computer Communications Workshops (INFOCOM WKSHPS), Hoboken, NJ, USA, 20 May 2023. [Google Scholar]

- Noor-A-Rahim, M.; John, J.; Firyaguna, F.; Sherazi, H.H.R.; Kushch, S.; Vijayan, A.; O’Connell, E.; Pesch, D.; O’Flynn, B.; O’Brien, W.; et al. Wireless Communications for Smart Manufacturing and Industrial IoT: Existing Technologies, 5G and Beyond. Sensors 2023, 23, 73. [Google Scholar] [CrossRef] [PubMed]

- Gundall, M.; Strufe, M.; Schotten, H.D.; Rost, P.; Markwart, C.; Blunk, R.; Neumann, A.; Grießbach, J.; Aleksy, M.; Wübben, D. Introduction of a 5G-Enabled Architecture for the Realization of Industry 4.0 Use Cases. IEEE Access 2021, 9, 25508–25521. [Google Scholar] [CrossRef]

- Sasiain, J.; Sanz, A.; Astorga, J.; Jacob, E. Towards Flexible Integration of 5G and IIoT Technologies in Industry 4.0: A Practical Use Case. Appl. Sci. 2020, 10, 7670. [Google Scholar] [CrossRef]

- Deng, C.; Fang, X.; Han, X.; Wang, X.; Yan, L.; He, R.; Long, Y.; Guo, Y. IEEE 802.11be Wi-Fi 7: New Challenges and Opportunities. IEEE Commun. Surv. Tutor. 2020, 22, 2136–2166. [Google Scholar] [CrossRef]

- Haxhibeqiri, J.; Jiao, X.; Shen, X.; Pan, C.; Jiang, X.; Hoebeke, J.; Moerman, I. Coordinated SR and Restricted TWT for Time Sensitive Applications in WiFi 7 Networks. IEEE Commun. Mag. 2024, 62, 118–124. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, Q.; Gao, Y.; Sun, X.; Zhan, W. WiFi 7 with Different Multi-Link Channel Access Schemes: Modeling, Fairness and Optimization. IEEE Trans. Commun. 2024. [Google Scholar] [CrossRef]

- Lopez-Raventos, A.; Bellalta, B. Dynamic Traffic Allocation in IEEE 802.11be Multi-Link WLANs. IEEE Wirel. Commun. Lett. 2022, 11, 1404–1408. [Google Scholar] [CrossRef]

- Adhikari, S.; Verma, S. Analysis of Multilink in IEEE 802.11be. IEEE Commun. Stand. Mag. 2022, 6, 52–58. [Google Scholar] [CrossRef]

- Jayasekara, B.G.; Balapuwaduge, I.A.; Li, F.Y. Dynamic Sensitivity Control for Mitigating Hidden and Exposed Terminals in WiFi 7 Networks. In Proceedings of the 2023 IEEE World Forum on Internet of Things: The Blue Planet: A Marriage of Sea and Space, WF-IoT 2023, Aveiro, Portugal, 12–27 October 2023. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.; Zhang, L.; Gao, Q.; Pan, M.; Wang, J. Practical Device-Free Gesture Recognition Using WiFi Signals Based on Metalearning. IEEE Trans. Ind. Inform. 2020, 16, 228–237. [Google Scholar] [CrossRef]

- Shi, B.; Tu, X.; Wu, B.; Peng, Y. Recent Advances in Time-Sensitive Network Configuration Management: A Literature Review. J. Sens. Actuator Netw. 2023, 12, 52. [Google Scholar] [CrossRef]

- Tian, S.; Hu, Y. The role of opc ua tsn in it and ot convergence. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 2272–2276. [Google Scholar]

- Arestova, A.; Martin, M.; Hielscher, K.S.J.; German, R. A service-oriented real-time communication scheme for AUTOSAR adaptive using OPC UA and time-sensitive networking. Sensors 2021, 21, 2337. [Google Scholar] [CrossRef] [PubMed]

- Kobzan, T.; Blöcher, I.; Hendel, M.; Althoff, S.; Gerhard, A.; Schriegel, S.; Jasperneite, J. Configuration Solution for TSN-based Industrial Networks utilizing SDN and OPC UA. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 1629–1636. [Google Scholar]

- Lo Bello, L.; Steiner, W. A Perspective on IEEE Time-Sensitive Networking for Industrial Communication and Automation Systems. Proc. IEEE 2019, 107, 1094–1120. [Google Scholar] [CrossRef]

- Finn, N. Introduction to Time-Sensitive Networking. IEEE Commun. Stand. Mag. 2022, 6, 8–13. [Google Scholar] [CrossRef]

- IEEE 802.1 Working Group. IEEE Time-Sensitive Networking (TSN) Task Group. Available online: https://1.ieee802.org/tsn/ (accessed on 17 September 2024).

- IEEE SA. IEEE Standard for Local and Metropolitan Area Networks–Timing and Synchronization for Time-Sensitive Applications. Available online: https://standards.ieee.org/ieee/802.1AS/7121/ (accessed on 17 September 2024).

- Atiq, M.K.; Muzaffar, R.; Seijo, Ó.; Val, I.; Bernhard, H.P. When IEEE 802.11 and 5G meet time-sensitive networking. IEEE Open J. Ind. Electron. Soc. 2021, 3, 14–36. [Google Scholar] [CrossRef]

- Seliem, M.; Zahran, A.; Pesch, D. Delay analysis of TSN based industrial networks with preemptive traffic using network calculus. In Proceedings of the 2023 IFIP Networking Conference (IFIP Networking), Barcelona, Spain, 12–15 June 2023. [Google Scholar]

- Fedullo, T.; Morato, A.; Tramarin, F.; Rovati, L.; Vitturi, S. A Comprehensive Review on Time Sensitive Networks with a Special Focus on Its Applicability to Industrial Smart and Distributed Measurement Systems. Sensors 2022, 22, 1638. [Google Scholar] [CrossRef]

- IEEE SA. IEEE Standard for Local and Metropolitan Area Networks Bridges and Bridged Networks. Available online: https://standards.ieee.org/ieee/802.1Q/10323/ (accessed on 28 June 2023).

- Cavalcanti, D.; Cordeiro, C.; Smith, M.; Regev, A. WiFi TSN: Enabling Deterministic Wireless Connectivity over 802.11. IEEE Commun. Stand. Mag. 2022, 6, 22–29. [Google Scholar] [CrossRef]

- Val, I.; Seijo, Ó.; Torrego, R.; Astarloa, A. IEEE 802.1AS Clock Synchronization Performance Evaluation of an Integrated Wired-Wireless TSN Architecture. IEEE Trans. Ind. Inform. 2022, 18, 2986–2999. [Google Scholar] [CrossRef]

- IEEE SA. IEEE Standard for Information Technology-Telecommunications and Information Exchange between Systems-Local and Metropolitan Area Networks-Specific Requirements Part 11: Wireless LAN Medium Access Control (MAC) and Physical Layer (PHY) Specifications. Available online: https://standards.ieee.org/ieee/802.11/5536/ (accessed on 17 September 2024).

- 5GACIA. Integration of 5G with Time-Sensitive Networking for Industrial Communications (White Paper). Available online: https://5g-acia.org/whitepapers/integration-of-5g-with-time-sensitive-networking-for-industrial-communications/ (accessed on 25 April 2023).

- Collotta, M.; Gentile, L.; Pau, G.; Scata, G. A dynamic algorithm to improve industrial Wireless Sensor Networks management. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 2802–2807. [Google Scholar] [CrossRef]

- Chen, J.J.; Tsai, M.H.; Zhao, L.; Chang, W.C.; Lin, Y.H.; Zhou, Q.; Lu, Y.Z.; Tsai, J.L.; Cai, Y.Z. Realizing Dynamic Network Slice Resource Management based on SDN networks. In Proceedings of the 2019 International Conference on Intelligent Computing and Its Emerging Applications, ICEA 2019, Tainan, Taiwan, 30 August–1 September 2019; pp. 120–125. [Google Scholar] [CrossRef]

- Ruoxi, W.; Beshley, H.; Lingyu, Y.; Urikova, O.; Beshley, M.; Kuzmin, O. Industrial 5G Private Network: Architectures, Resource Management, Challenges, and Future Directions. In Proceedings of the 16th International Conference on Advanced Trends in Radioelectronics, Telecommunications and Computer Engineering, TCSET 2022, Lviv-Slavske, Ukraine, 22–26 February 2022; pp. 780–784. [Google Scholar] [CrossRef]

- Du, J.; Xiong, W.; Wang, J.; Cao, X. A Heuristic AP Deployment Approach for Industrial Wireless Networks. In Proceedings of the 2021 China Automation Congress, CAC 2021, Beijing, China, 22–24 October 2021; pp. 8035–8040. [Google Scholar] [CrossRef]

- Bedhief, I.; Foschini, L.; Bellavista, P.; Kassar, M.; Aguili, T. Toward self-adaptive software defined fog networking architecture for IIoT and industry 4.0. In Proceedings of the 2019 IEEE 24th International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Limassol, Cyprus, 11–13 September 2019. [Google Scholar] [CrossRef]

- Cavalcanti, D.; Perez-Ramirez, J.; Rashid, M.M.; Fang, J.; Galeev, M.; Stanton, K.B. Extending accurate time distribution and timeliness capabilities over the air to enable future wireless industrial automation systems. Proc. IEEE 2019, 107, 1132–1152. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Zhang, W.; Qin, F.; Zhu, P.; Wang, C.X. Generative-adversarial-network-based wireless channel modeling: Challenges and opportunities. IEEE Commun. Mag. 2019, 57, 22–27. [Google Scholar] [CrossRef]

- Lin, M.; Zhao, Y. Artificial intelligence-empowered resource management for future wireless communications: A survey. China Commun. 2020, 17, 58–77. [Google Scholar] [CrossRef]

- Garg, S.; Guizani, M.; Guo, S.; Verikoukis, C. Guest editorial special section on AI-driven developments in 5G-envisioned industrial automation: Big data perspective. IEEE Trans. Ind. Inform. 2019, 16, 1291–1295. [Google Scholar] [CrossRef]

| Use Case | Reliability | Device Costs | Device Density | Low Latency | Band- Width | Flexibility | Ubiquity | Location- Awareness |

|---|---|---|---|---|---|---|---|---|

|

Advanced predictive Maintenance | ✓ | ✓ | ✓ | |||||

|

Precision Monitoring & Control | ✓ | ✓ | ||||||

| Augmented Reality & Remote expert | ✓ | ✓ | ||||||

| Remote Robot Control | ✓ | |||||||

| Manufacturing-as-a Service | ✓ | ✓ | ✓ | |||||

| Automated Guided Vehicle | ✓ | ✓ | ✓ | |||||

| Drone Inspections | ✓ | ✓ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

John, J.; Noor-A-Rahim, M.; Vijayan, A.; Poor, H.V.; Pesch, D. Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing. Future Internet 2024, 16, 345. https://doi.org/10.3390/fi16090345

John J, Noor-A-Rahim M, Vijayan A, Poor HV, Pesch D. Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing. Future Internet. 2024; 16(9):345. https://doi.org/10.3390/fi16090345

Chicago/Turabian StyleJohn, Jobish, Md. Noor-A-Rahim, Aswathi Vijayan, H. Vincent Poor, and Dirk Pesch. 2024. "Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing" Future Internet 16, no. 9: 345. https://doi.org/10.3390/fi16090345

APA StyleJohn, J., Noor-A-Rahim, M., Vijayan, A., Poor, H. V., & Pesch, D. (2024). Industry 4.0 and Beyond: The Role of 5G, WiFi 7, and Time-Sensitive Networking (TSN) in Enabling Smart Manufacturing. Future Internet, 16(9), 345. https://doi.org/10.3390/fi16090345