Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level

Abstract

1. Introduction

1.1. Contributions

- Geometry, mass, and capacity determination for energy density calculations at multiple levels.

- Quantification of the power unit’s efficiency in various state of charge (SOC) levels.

- Experimental quantification of the electric range of the vehicle in official and real driving test scenarios.

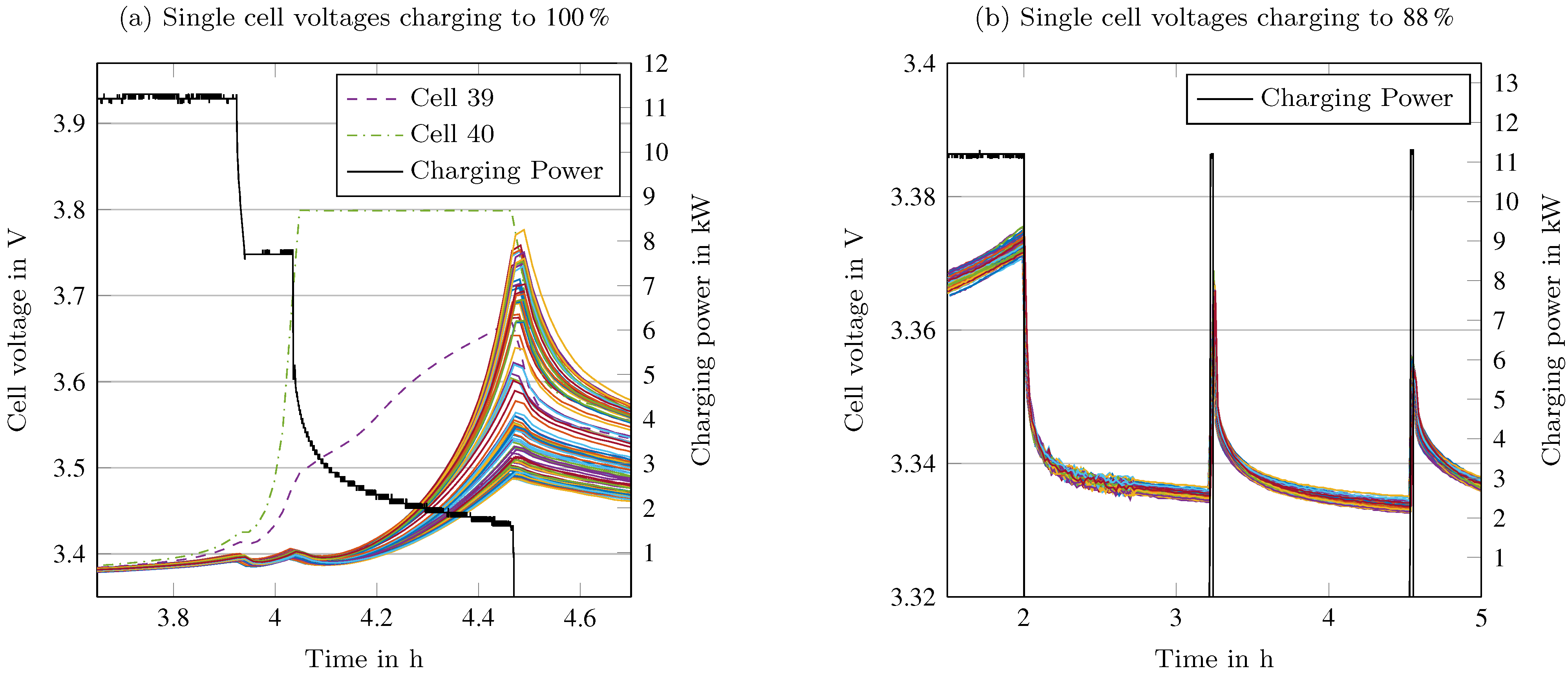

- Analysis of operation strategies on charging processes and cell balancing.

- Open access to extensive experimental data containing 1 GB of test data on the battery and vehicle levels and over 228 individual tracks (a total distance of 6207 km).

1.2. Layout

2. Material and Methods

2.1. Vehicle under Test and Data Acquisition

2.2. Experimental Techniques

2.2.1. Open-Circuit Voltage Determination and Differential Capacity Analysis

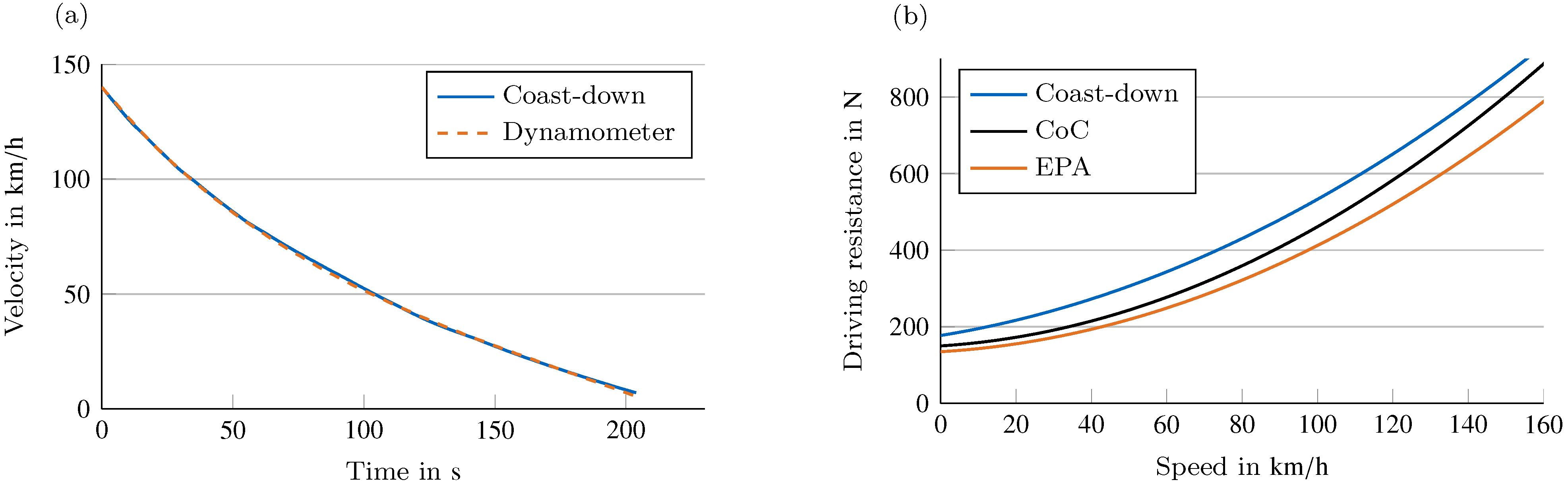

2.2.2. Vehicle Coast-Down Procedure and Driving Resistance Determination

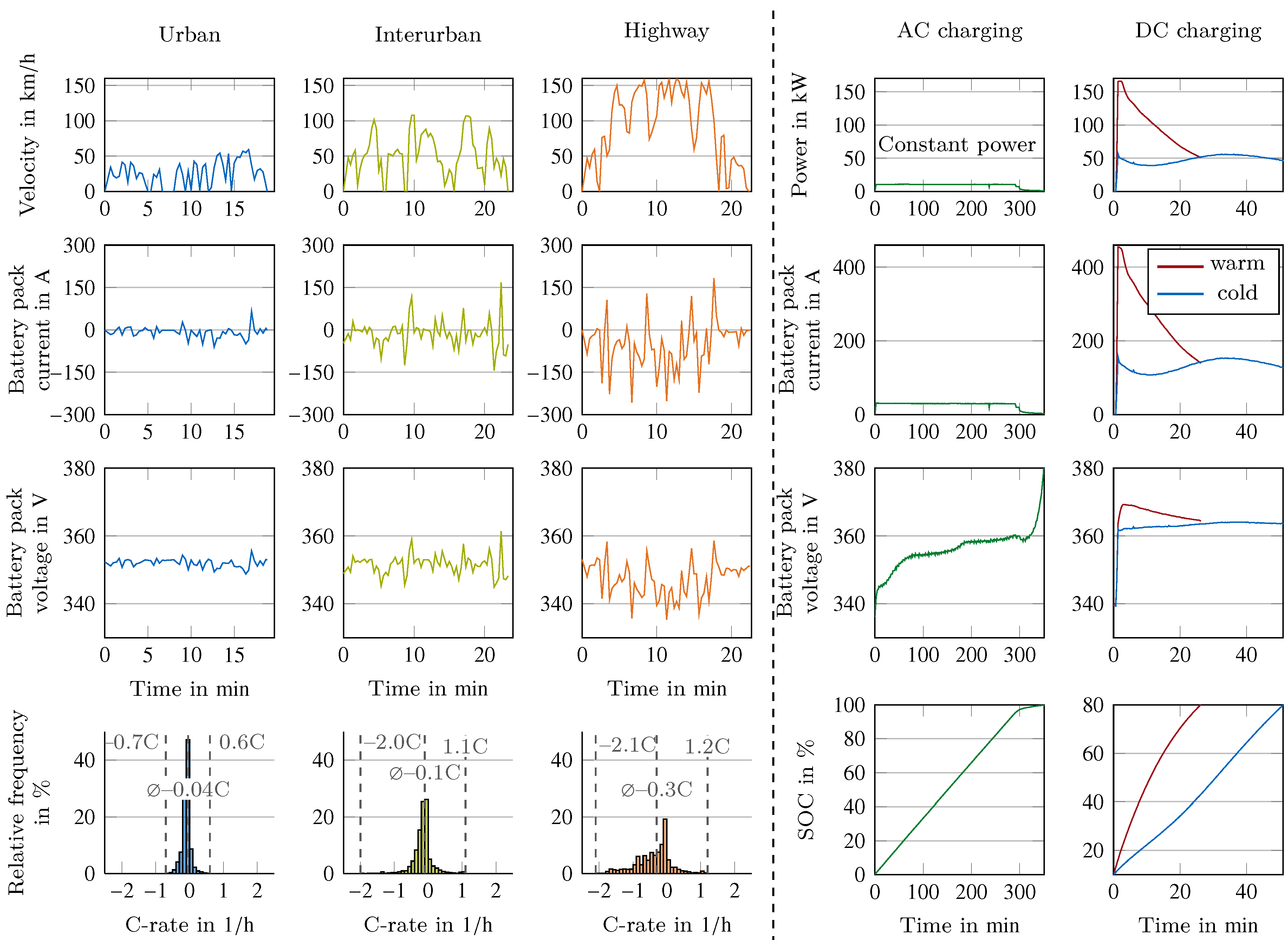

2.2.3. Vehicle Dynamometer and Charging Tests

3. Results and Discussion

3.1. Energy Storage Analysis

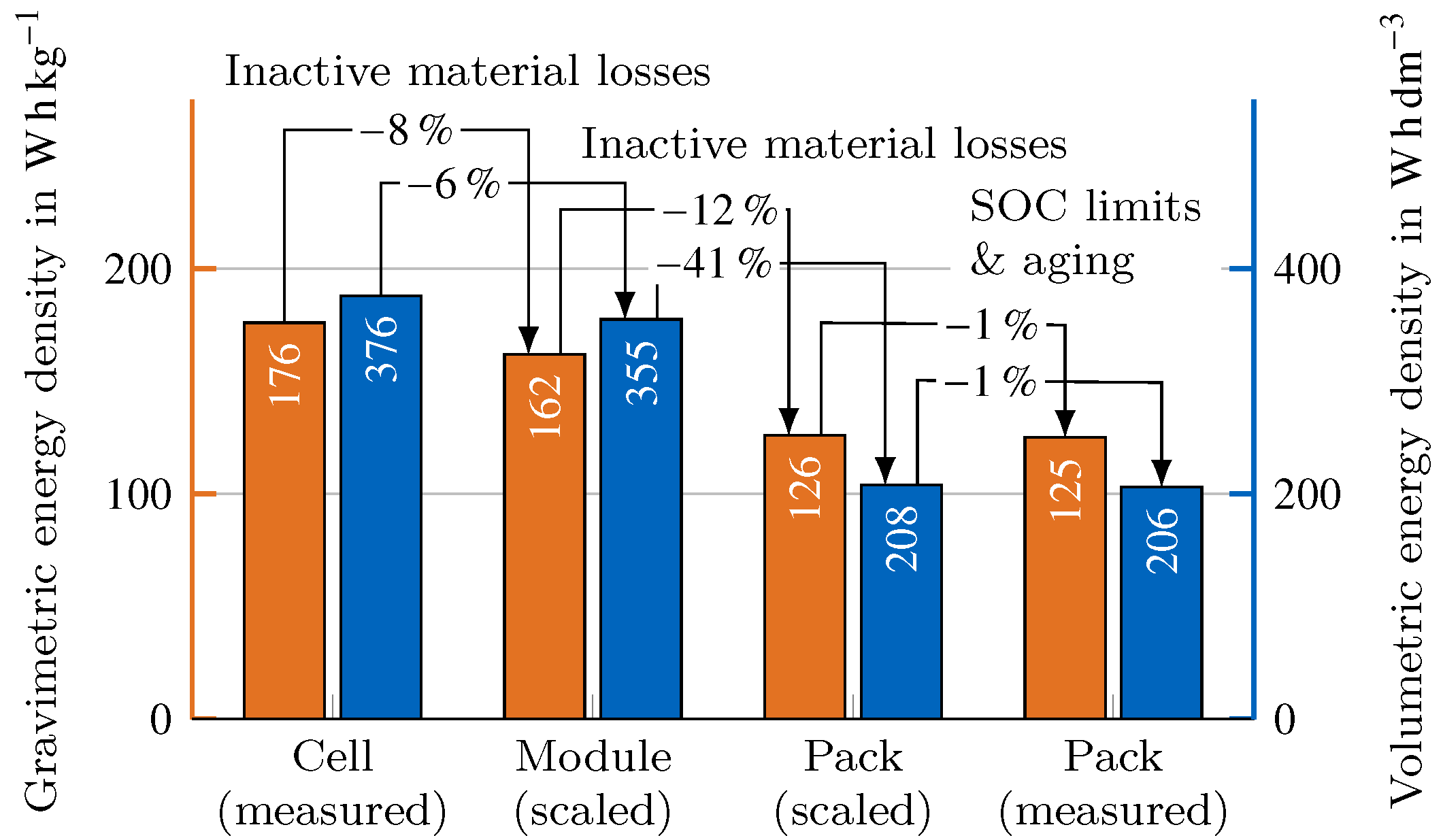

3.1.1. Energy Densities

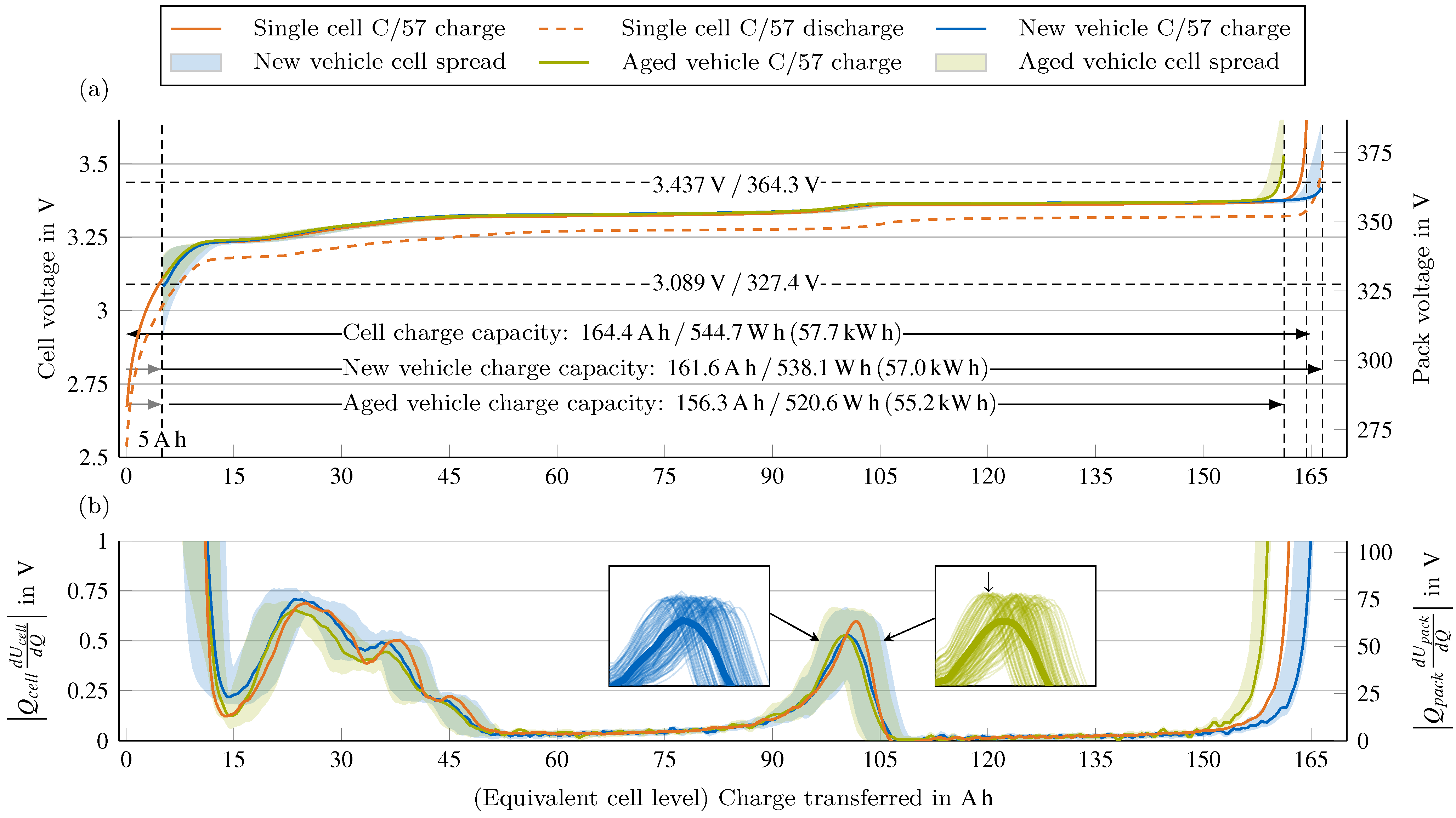

3.1.2. Comparison of the Cell and Pack pOCV and DVA

3.2. Power Unit Efficiency

3.2.1. Efficiency Map of the Power Unit

3.2.2. Efficiency Dependencies over SOC

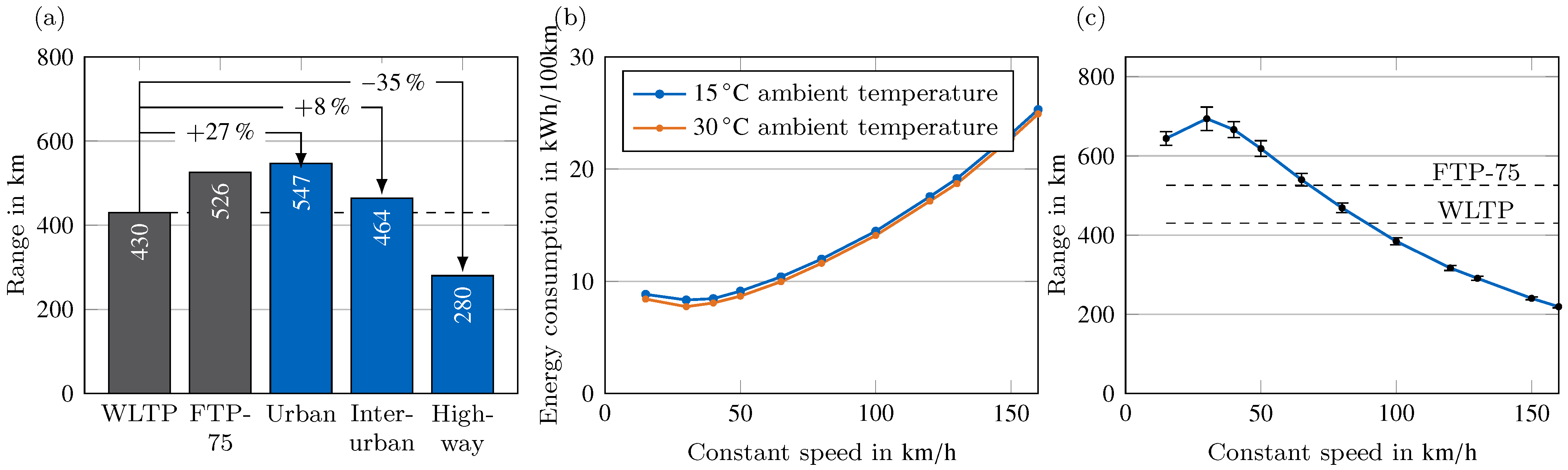

3.3. Range

3.3.1. Real-World Range and Influencing Factors

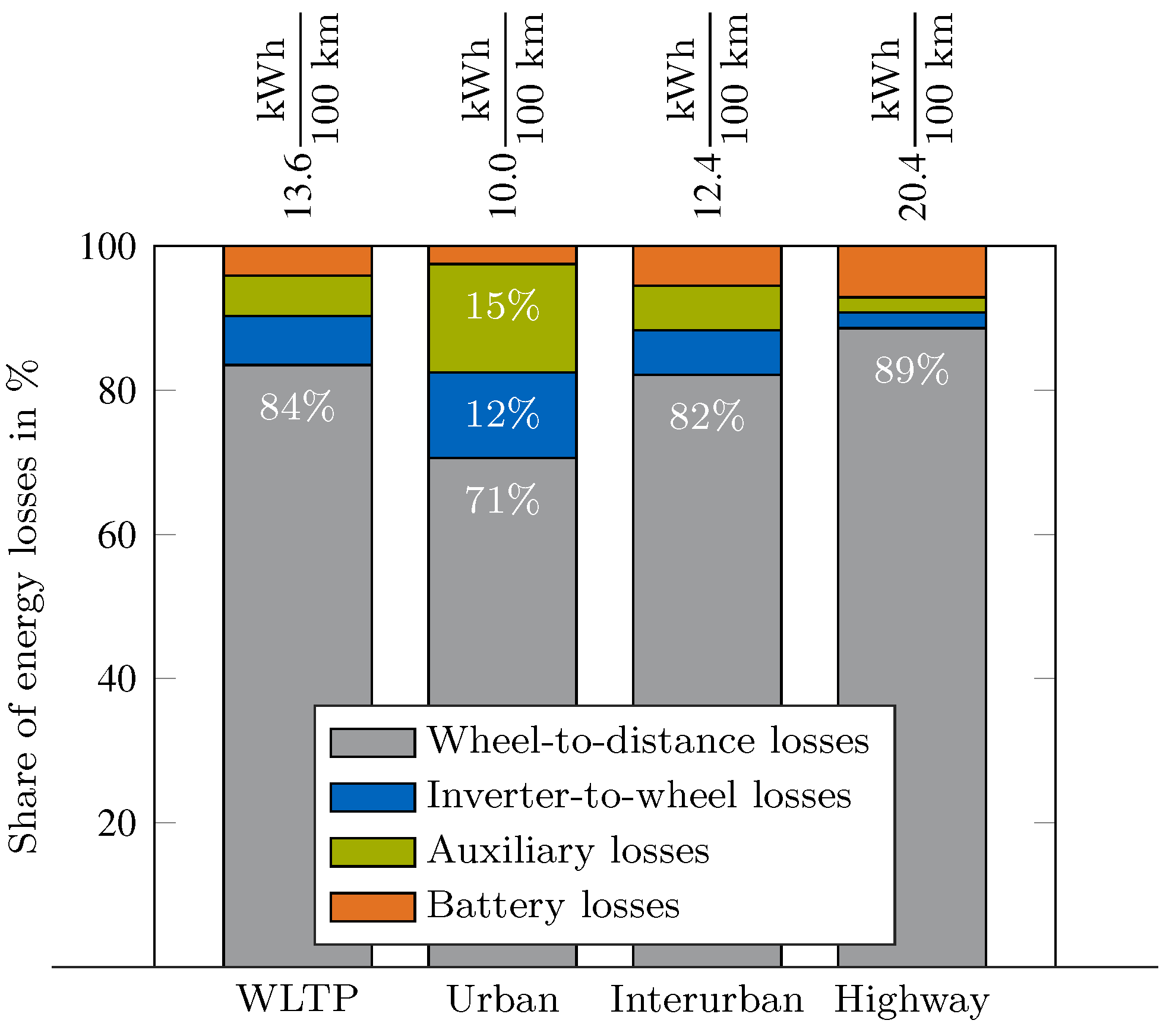

3.3.2. Quantification of Energy Loss Shares

3.4. Thermal and Electric Operation Strategies

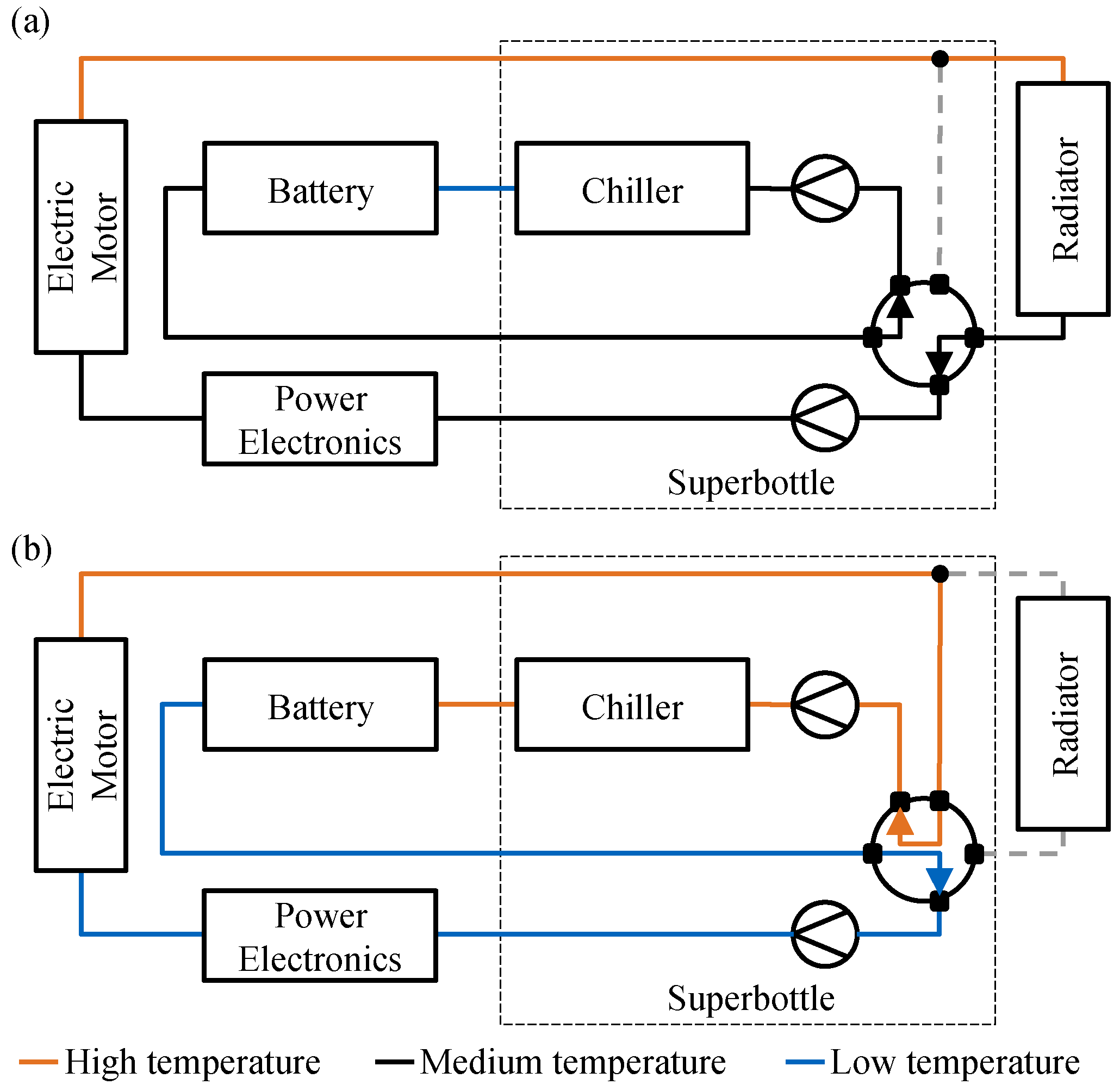

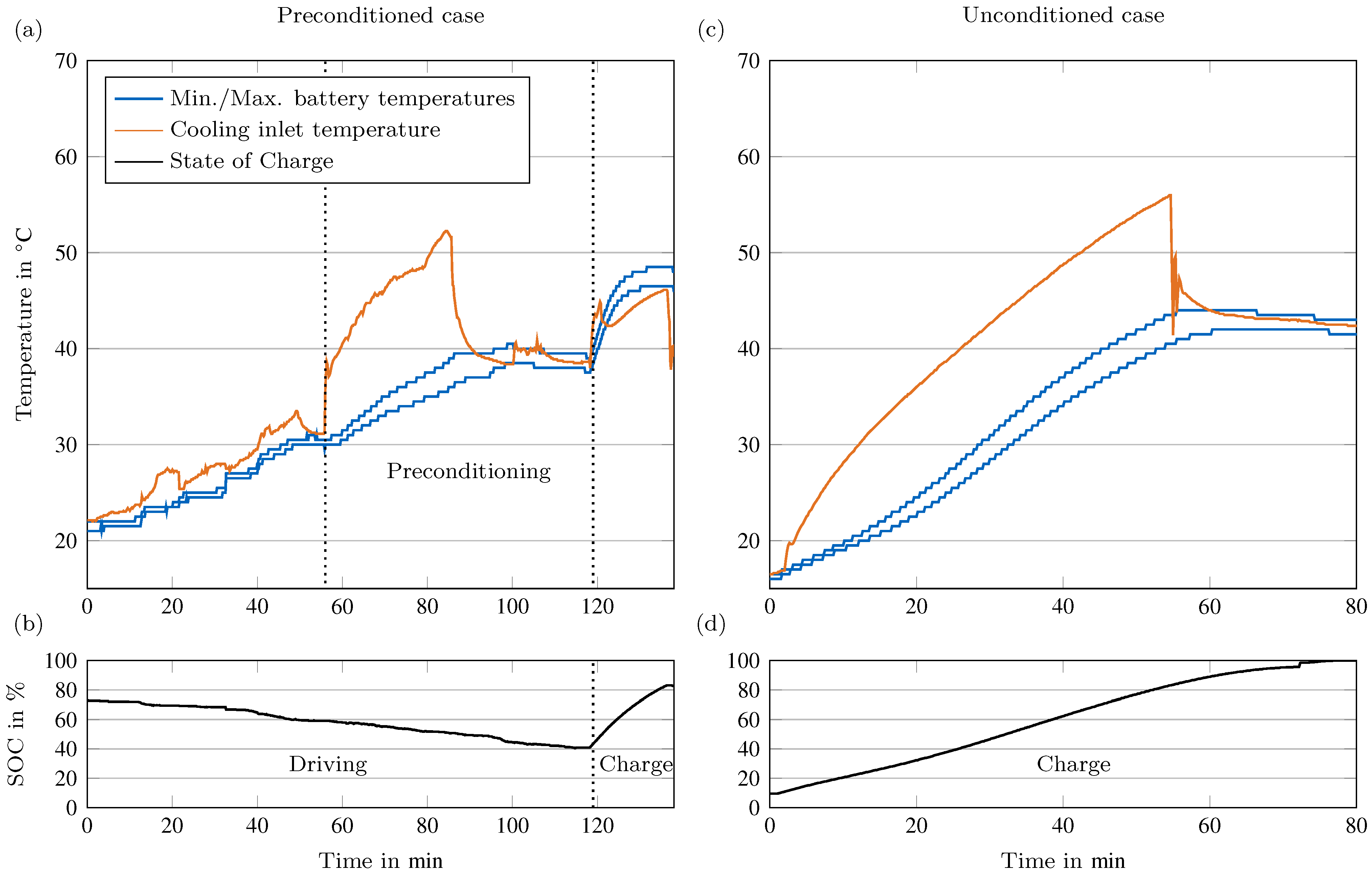

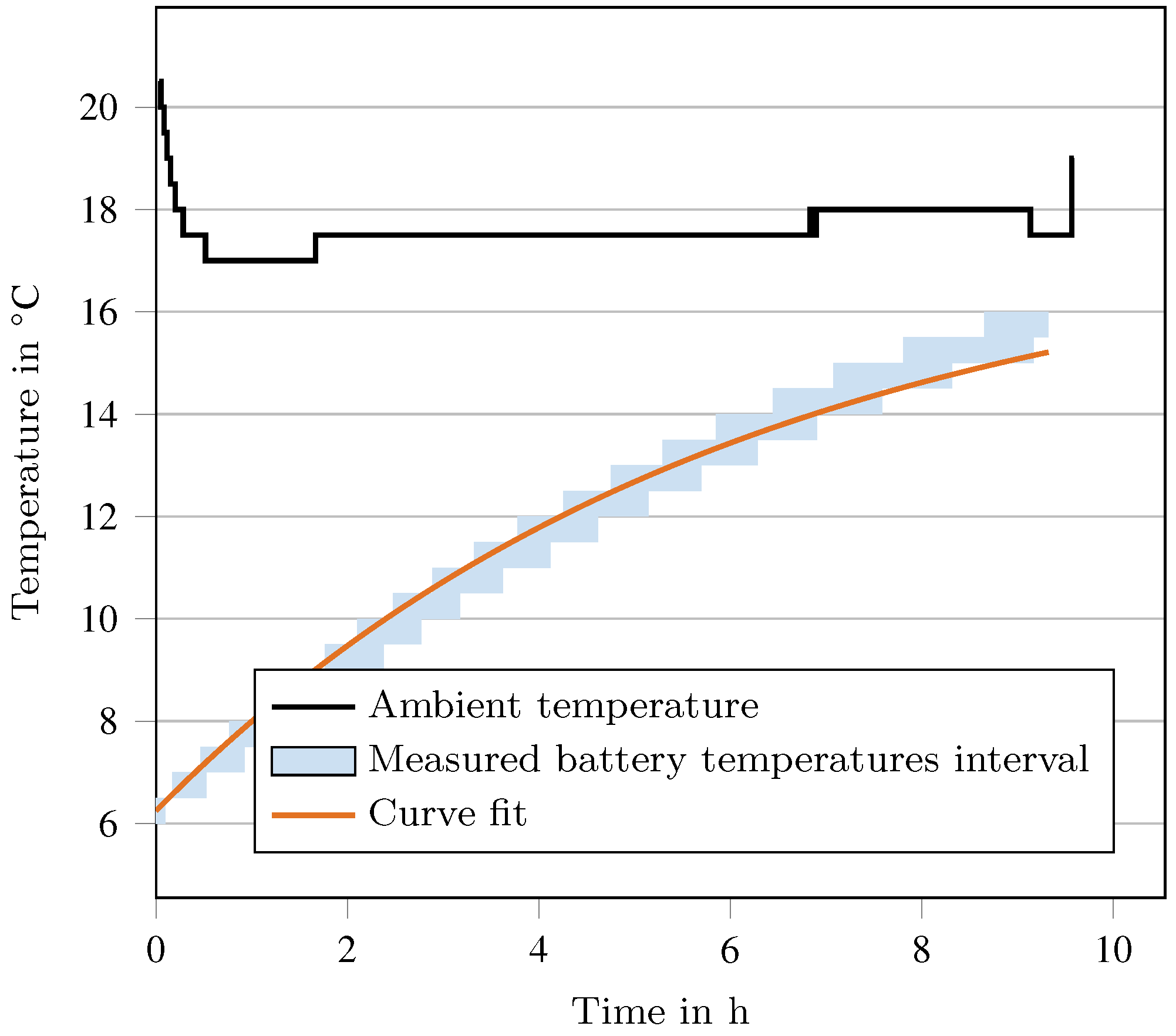

3.4.1. Thermal Management of the Battery Pack

3.4.2. Heat Transfer to Ambient

3.4.3. Balancing Strategies

4. Summary and Conclusions

- Component integration, energy density, and aging diagnosis.From 176 Wh/kg gravimetric and 376 Wh/L volumetric energy density on the cell level, the energy density drops down to 162 Wh/kg and 355 Wh/L on the module level and even further to 126 Wh/kg and 208 Wh/L on the battery pack level. If the voltage limit on the battery pack level is also considered, an additional 1% of energy density is lost. Transferring the DVA results from the cell level to the battery pack or vehicle level provides consistent results. This analysis enables aging observations in early states of calendric and cyclic aging.

- Power unit efficiency.All tests on the chassis dynamometer were recorded with the vehicle set to dyno mode, which limits its power capabilities. For the installed LFP cells, the SOC only negligibly affected the power unit’s efficiency, as shown by differences in the efficiency map of low, middle (reference), and high SOC levels. The maximum efficiency of 97% in both maps is reached at high speeds of 12,000–16,000 1/min and rather low torques.

- Range deviations from standard cycles.When comparing real-world driving scenarios to the official test procedures, the range of the urban (547 km) and interurban (464 km) drive cycles exceeds the range of the WLTP cycle (430 km), while only the urban cycle exceeds the Federal Test Procedure (FTP-75) cycle’s range (526 km). Due to aerodynamic losses, the highway cycle (280 km) reaches the lowest achievable electric range, even though the power unit reaches the highest possible efficiency at high speeds. Comparing the different shares of energy losses, the wheel-to-distance losses appear to reach the highest shares (between 71% and 89%), with other losses in similar shares in the respective drive cycles depending on the vehicle’s velocity. The electric range during real-world usage could be improved either by adjusting the areas of highest efficiency closer to those regions that are mainly driven, or by enhancing the current regenerative braking control logic, which might be set too conservatively regarding potential lithium plating of the LFP cells. This latter was observed during the braking test series, in which the brake pedal did not impact the share of regenerative braking. Although this is connected to more tuning effort, increasing the electric braking shares during brake pedal activation would increase the vehicle’s efficiency. Depending on the current vehicle state, a more advanced control strategy that distinguishes between different driving and charging modes might further improve the vehicle’s range.

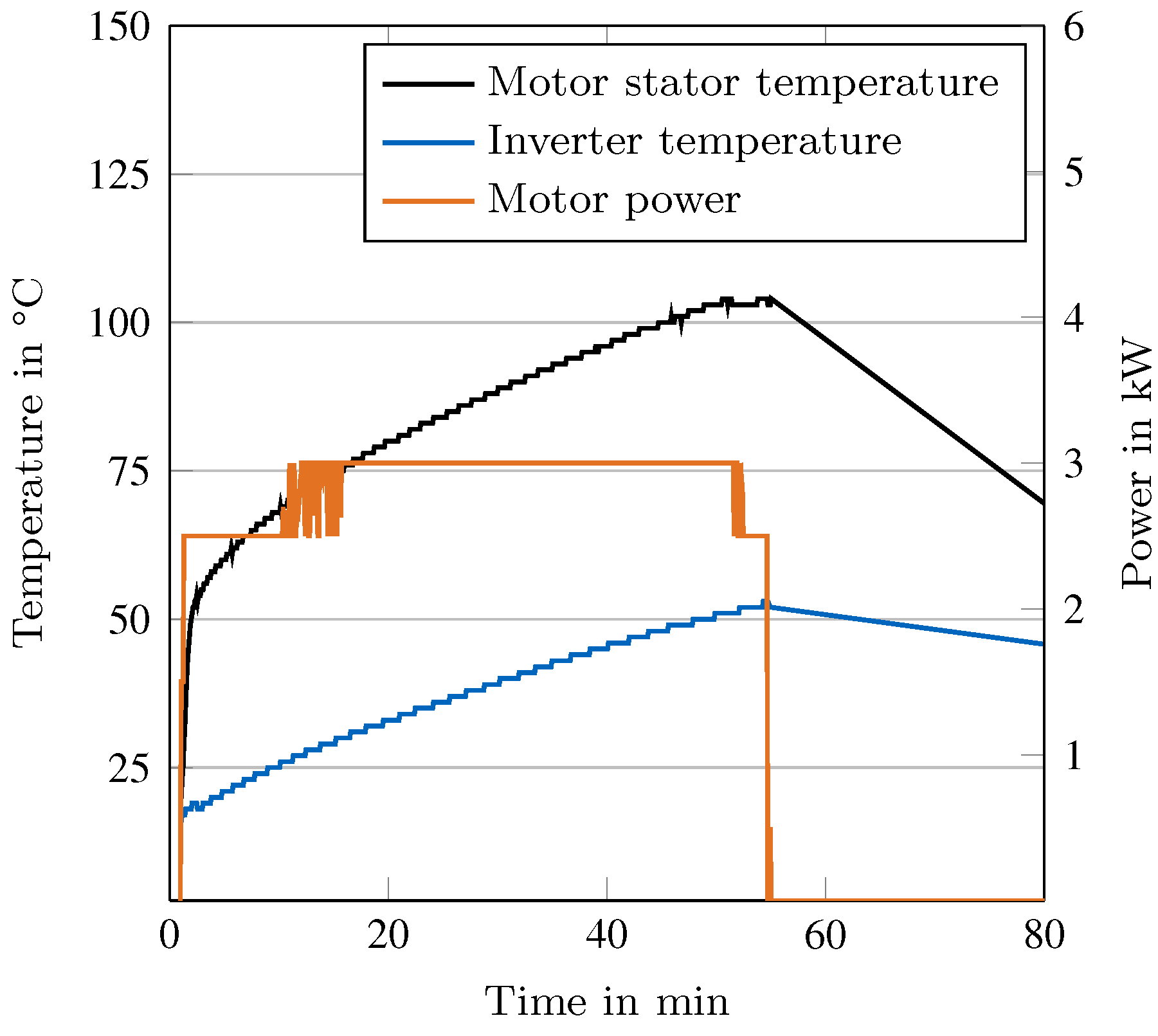

- Thermal management of the battery pack.A maximal thermal gradient between the battery modules of 2 K while driving within the highway scenario and 3.5 K during fast charging with an active chiller cooling was measured. During battery heating, a maximum spread of 3 K occurs. The threshold of 5 K from the literature was not exceeded in any of the investigated scenarios, underlining the importance of temperature homogeneity for the battery’s performance and lifetime. When parking at low ambient temperatures, fast cool-down of the battery pack can be observed. Therefore, active battery heating is required, which is realized by serial connection between the electric motor and the battery within the cooling circuit. The heating power is provided by the generation of up to 3 kW additional power losses in the electric motor. Our investigation of the charging protocols shows that fast charging is targeted at battery surface temperatures between 40 °C to 50 °C, which is also advised in literature, where a maximum of 60 °C is stated. The battery heating preconditioning starts one hour prior to reaching the targeted charging station. During the charging process, the battery is cooled to stay below 50 °C. The presented thermal management strategies could be optimized using intelligent automated self-learning strategies to reduce charging times and extend the battery’s lifetime.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Vehicle Specifications

| Domain | Attribute | Value | Unit |

|---|---|---|---|

| Vehicle | Range (WLTP) c | 440 | km |

| Max. speed c | 225 | km/h | |

| Mass c | 1825 | kg | |

| Actual mass c | 1861 | kg | |

| Tyres c | 235/45R18 98Y | - | |

| Tyre radius m | 346.8 | mm | |

| load coefficient—f0 c | 149.92 | N | |

| load coefficient—f1 c | 0.6299 | N/(km/h) | |

| load coefficient—f2 c | 0.02482 | N/(km/h)2 | |

| Power unit | Max. power c | 239 | kW |

| 30 min power c | 100 | kW | |

| Max. rotations a | 16,000 | 1/min | |

| Max. torque r | 420 | Nm | |

| Drive type a | Syn-RM | ||

| Inverter a | MOSFET | ||

| Gearing ratio c | 9.04:1 | - | |

| Battery unit | Pack energy r | 58 | kWh |

| Cell capacity l | 161.2 | Ah | |

| Cell format l | prismatic | - | |

| Chemistry l | LFP | - |

Appendix B. Coast-Down Procedure and Driving Resistance Regressions

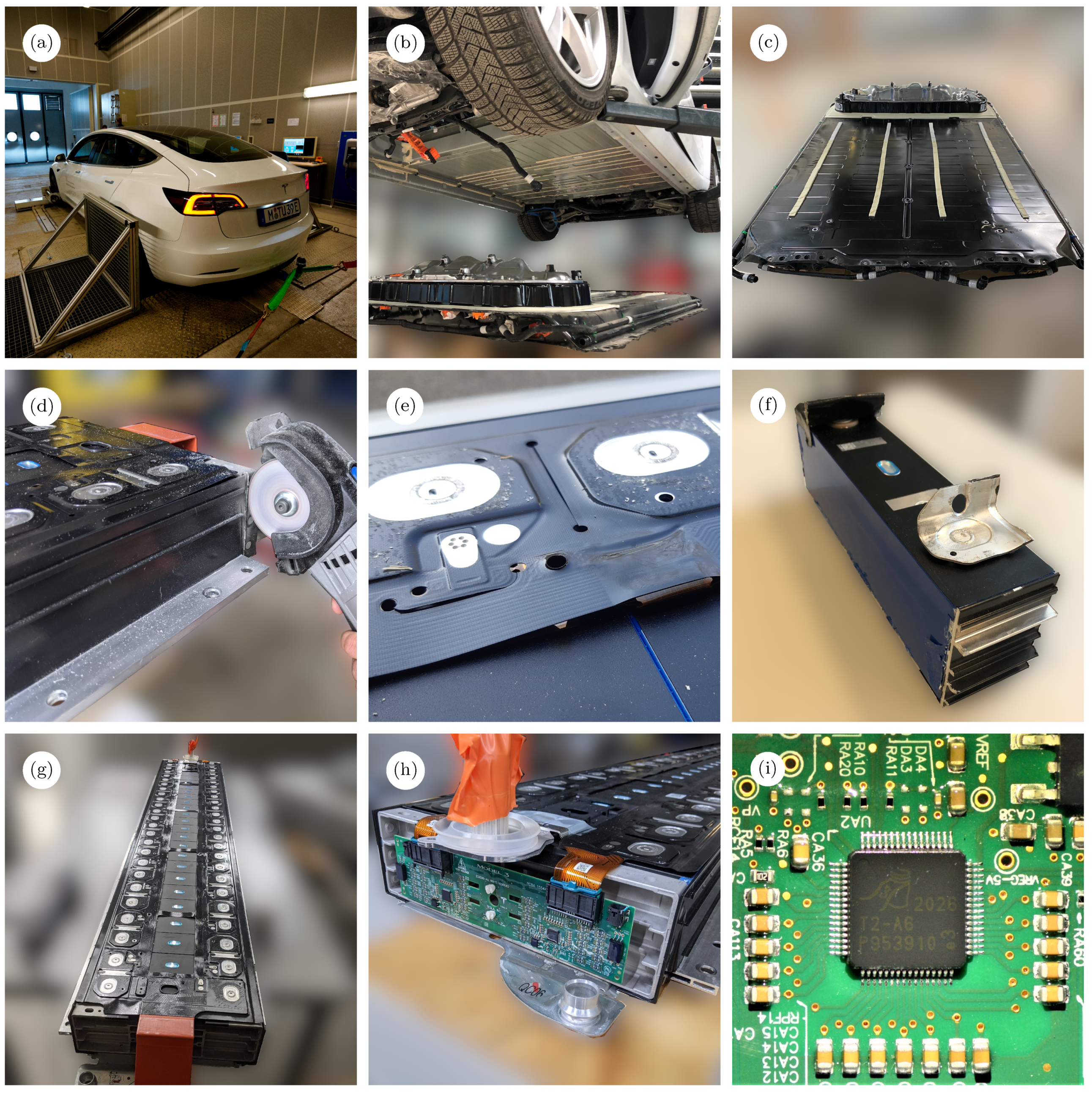

Appendix C. Battery Pack Teardown

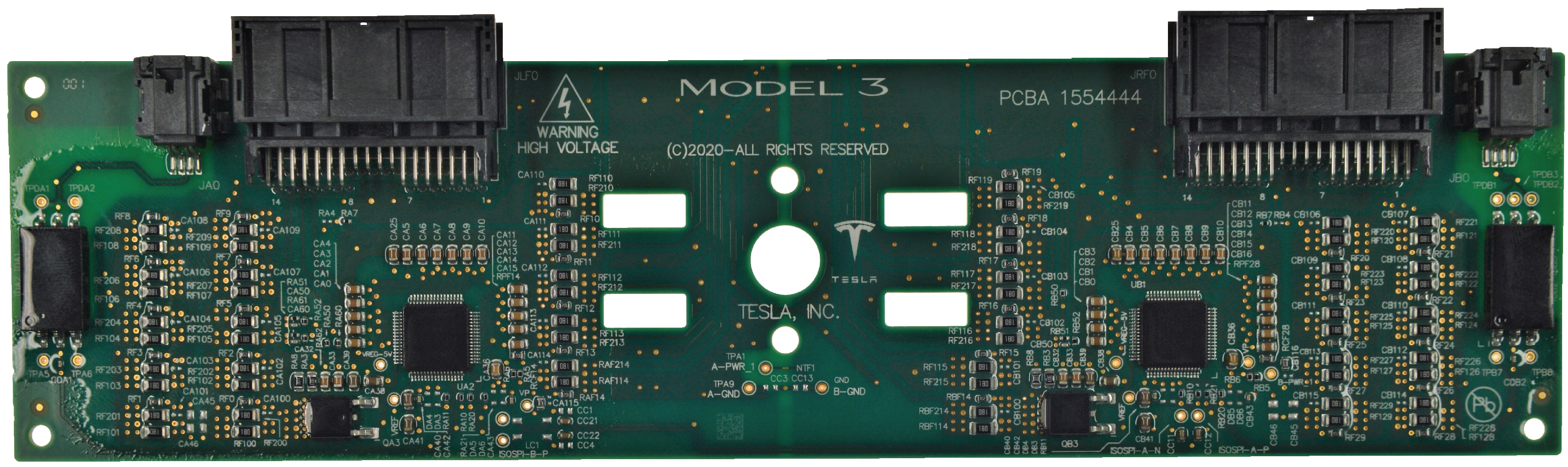

Appendix D. Printed Circuit Board of the Battery Management System of the Module Under Investigation

References

- International Energy Agency. Global EV Outlook 2023; International Energy Agency: Paris, France, 2023. [Google Scholar]

- European Union Council. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’); European Union Council: Brussels, Belgium, 2021. [Google Scholar]

- European Environment Agency. Transport and Environment Report 2021: Decarbonising Road Transport—The Role of Vehicles, Fuels and Transport Deman; European Environment Agency: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- European Commission. Delivering the European Green Deal; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Allinson, M. How have electric cars advanced in the past 10 years and what’s the future? In Robotics Automation News; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An Overview of Parameter and Cost for Battery Electric Vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- van Mierlo, J.; Berecibar, M.; El Baghdadi, M.; de Cauwer, C.; Messagie, M.; Coosemans, T.; Jacobs, V.A.; Hegazy, O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electr. Veh. J. 2021, 12, 20. [Google Scholar] [CrossRef]

- Blomgren, G.E. The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 2017, 164, A5019–A5025. [Google Scholar] [CrossRef]

- Momen, F.; Rahman, K.; Son, Y. Electrical propulsion system design of Chevrolet Bolt battery electric vehicle. IEEE Trans. Ind. Appl. 2018, 55, 376–384. [Google Scholar] [CrossRef]

- Sarlioglu, B.; Morris, C.T.; Han, D.; Li, S. Benchmarking of electric and hybrid vehicle electric machines, power electronics, and batteries. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Online, 2–4 September 2015; pp. 519–526. [Google Scholar] [CrossRef]

- Kovachev, G.; Schröttner, H.; Gstrein, G.; Aiello, L.; Hanzu, I.; Wilkening, H.; Foitzik, C.; Wellm, M.; Sinz, W.; Ellersdorfer, C. Analytical Dissection of an Automotive Li-Ion Pouch Cell. Batteries 2019, 5, 67. [Google Scholar] [CrossRef]

- Löbberding, H.; Wessel, S.; Offermanns, C.; Kehrer, M.; Rother, J.; Heimes, H.; Kampker, A. From Cell to Battery System in BEVs: Analysis of System Packing Efficiency and Cell Types. World Electr. Veh. J. 2020, 11, 77. [Google Scholar] [CrossRef]

- Oh, G.; Leblanc, D.J.; Peng, H. Vehicle Energy Dataset (VED), A Large-Scale Dataset for Vehicle Energy Consumption Research. IEEE Trans. Intell. Transp. Syst. 2020, 11, 23. [Google Scholar] [CrossRef]

- Diez, J. Advanced Vehicle Testing and Evaluation, Final Technical Report Encompassing Project Activities from 1 October 2011 to 30 April 2018; Technical Report; Intertek Testing Services, NA, Inc.: Arlington, IL, USA, 2018. [Google Scholar]

- Wassiliadis, N.; Steinsträter, M.; Schreiber, M.; Rosner, P.; Nicoletti, L.; Schmid, F.; Ank, M.; Teichert, O.; Wildfeuer, L.; Schneider, J.; et al. Quantifying the state of the art of electric powertrains in battery electric vehicles: Range, efficiency, and lifetime from component to system level of the Volkswagen ID.3. eTransportation 2022, 12, 100167. [Google Scholar] [CrossRef]

- Lancelot, J.; Rimal, B.P.; Dennis, E.M. Performance Evaluation of a Lane Correction Module Stress Test: A Field Test of Tesla Model 3. Future Internet 2023, 15, 138. [Google Scholar] [CrossRef]

- Xu, B.; Arjmandzadeh, Z. Parametric study on thermal management system for the range of full (Tesla Model S)/ compact-size (Tesla Model 3) electric vehicles. Energy Convers. Manag. 2023, 278, 116753. [Google Scholar] [CrossRef]

- Ank, M.; Sommer, A.; Gamra, K.A.; Schöberl, J.; Leeb, M.; Schachtl, J.; Streidel, N.; Stock, S.; Schreiber, M.; Bilfinger, P.; et al. Lithium-Ion Cells in Automotive Applications: Tesla 4680 Cylindrical Cell Teardown and Characterization. J. Electrochem. Soc. 2023, 170, 120536. [Google Scholar] [CrossRef]

- Statista.com. Best-Selling Plug-in Electric Vehicle Models Worldwide in 2022. 2023. Available online: https://www.statista.com (accessed on 14 February 2023).

- EV Specifications. 2017 Tesla Model 3 Long Range RWD—Specifications; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2018 Tesla Model 3 Mid Range RWD—Specifications; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2019 Tesla Model 3 Standard Range RWD—Specifications; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2019 Tesla Model 3 Standard Range Plus RWD—Specifications; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2023 Tesla Model 3 RWD—Specifications; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2021 Tesla Model 3 Long Range AWD—Specifications and Price; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- EV Specifications. 2021 Tesla Model 3 Performance AWD—Specifications and Price; Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- InsideEVs. Tesla Now Has Multiple Battery Options: Which One Should You Choose? Hearst Autos Inc.: Chamblee, GA, USA, 2022. [Google Scholar]

- ISO 1176:1990-07; Road Vehicles—Masses—Vocabulary and Codes. International Organization for Standardization: Geneva, Switzerland, 1990.

- European Parliament. Regulation (EU) 2018/858 of the European Parliament and of the Council of 30 May 2018 on the Approval and Market Surveillance of Motor Vehicles and Their Trailers, and of Systems, Components and Separate Technical Units Intended for such Vehicles, Amending Regulations (EC) No. 715/2007 and (EC) No. 595/2009 and Repealing Directive 2007/46/EC; European Parlament: Strasbourg, France, 2018. [Google Scholar]

- Wardell, J. Model3dbc. Available online: https://github.com/joshwardell/model3dbc (accessed on 14 February 2023).

- Barai, A.; Uddin, K.; Dubarry, M.; Somerville, L.; McGordon, A.; Jennings, P.; Bloom, I. A comparison of methodologies for the non-invasive characterisation of commercial Li-ion cells. Prog. Energy Combust. Sci. 2019, 72, 1–31. [Google Scholar] [CrossRef]

- Lewerenz, M.; Marongiu, A.; Warnecke, A.; Sauer, D.U. Differential voltage analysis as a tool for analyzing inhomogeneous aging: A case study for LiFePO4-Graphite cylindrical cells. J. Power Sources 2017, 368, 57–67. [Google Scholar] [CrossRef]

- Fath, J.P.; Dragicevic, D.; Bittel, L.; Nuhic, A.; Sieg, J.; Hahn, S.; Alsheimer, L.; Spier, B.; Wetzel, T. Quantification of aging mechanisms and inhomogeneity in cycled lithium-ion cells by differential voltage analysis. J. Energy Storag. 2019, 25, 100813. [Google Scholar] [CrossRef]

- Dubarry, M.; Devie, A.; Liaw, B.Y. The value of battery diagnostics and prognostics. Energy Power Sources 2014, 1, 242–249. [Google Scholar]

- Pütz, R.; Serne, T. Rennwagentechnik—Praxislehrgang Fahrdynamik, 1st ed.; Springer: Wiesbaden, Germany, 2017. [Google Scholar] [CrossRef]

- Liebl, J.; Lederer, M.; Rohde-Brandenburger, K.; Biermann, J.W.; Roth, M.; Schäfer, H. Energiemanagement im Kraftfahrzeug, 1st ed.; Springer Vieweg: Wiesbaden, Germany, 2014. [Google Scholar] [CrossRef]

- The European Comission. Comission Regulation (EU) 2018/1832; The European Comission: Geneva, Switzerland, 2018. [Google Scholar]

- Gyenes, B.; Stevens, D.A.; Chevrier, V.L.; Dahn, J.R. Understanding Anomalous Behavior in Coulombic Efficiency Measurements on Li-Ion Batteries. J. Electrochem. Soc. 2015, 162, A278–A283. [Google Scholar] [CrossRef]

- Petzl, M.; Danzer, M.A. Advancements in OCV Measurement and Analysis for Lithium-Ion Batteries. IEEE Trans. Energy Convers. 2013, 28, 675–681. [Google Scholar] [CrossRef]

- Simolka, M.; Heger, J.F.; Traub, N.; Kaess, H.; Friedrich, K.A. Influence of Cycling Profile, Depth of Discharge and Temperature on Commercial LFP/C Cell Ageing: Cell Level Analysis with ICA, DVA and OCV Measurements. J. Electrochem. Soc. 2020, 167, 110502. [Google Scholar] [CrossRef]

- Noel, M.; Santhanam, R. Electrochemistry of graphite intercalation compounds. J. Power Sources 1998, 72, 53–65. [Google Scholar] [CrossRef]

- Aurbach, D.; Markovsky, B.; Weissman, I.; Levi, E.; Ein-Eli, Y. On the correlation between surface chemistry and performance of graphite negative electrodes for Li ion batteries. Electrochim. Acta 1999, 45, 67–86. [Google Scholar] [CrossRef]

- Winter, M.; Besenhard, J.O.; Spahr, M.E.; Novák, P. Insertion Electrode Materials for Rechargeable Lithium Batteries. Adv. Mater. 1998, 10, 725–763. [Google Scholar] [CrossRef]

- Lerf, A. Storylines in intercalation chemistry. Dalton Trans. 2014, 43, 10276–10291. [Google Scholar] [CrossRef] [PubMed]

- Keil, P.; Jossen, A. Calendar Aging of NCA Lithium-Ion Batteries Investigated by Differential Voltage Analysis and Coulomb Tracking. J. Electrochem. Soc. 2017, 164, A6066–A6074. [Google Scholar] [CrossRef]

- Keil, P.; Schuster, S.F.; Wilhelm, J.; Travi, J.; Hauser, A.; Karl, R.C.; Jossen, A. Calendar Aging of Lithium-Ion Batteries. J. Electrochem. Soc. 2016, 163, A1872–A1880. [Google Scholar] [CrossRef]

- Sarasketa-Zabala, E.; Gandiaga, I.; Rodriguez-Martinez, L.M.; Villarreal, I. Calendar ageing analysis of a LiFePO4/graphite cell with dynamic model validations: Towards realistic lifetime predictions. J. Power Sources 2014, 272, 45–57. [Google Scholar] [CrossRef]

- Li, D.; Danilov, D.L.; Gao, L.; Yang, Y.; Notten, P.H.L. Degradation Mechanisms of the Graphite Electrode in C6/LiFePO4 Batteries Unraveled by a Non-Destructive Approach. J. Electrochem. Soc. 2016, 163, A3016–A3021. [Google Scholar] [CrossRef]

- Dubarry, M.; Anseán, D. Best practices for incremental capacity analysis. Front. Energy Res. 2022, 10, 555. [Google Scholar] [CrossRef]

- Schaltz, E.; Norregaard, K.; Christensen, A. Incremental Capacity Analysis Applied on Electric Vehicles for Battery State-of-Health Estimation. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar]

- Schaltz, E.; Stroe, D.I.; Norregaard, K.; Ingvardsen, L.S.; Christensen, A. Incremental Capacity Analysis Applied on Electric Vehicles for Battery State-of-Health Estimation. IEEE Trans. Ind. Appl. 2021, 57, 1810–1817. [Google Scholar] [CrossRef]

- Weng, C.; Feng, X.; Sun, J.; Peng, H. State-of-health monitoring of lithium-ion battery modules and packs via incremental capacity peak tracking. Appl. Energy 2016, 180, 360–368. [Google Scholar] [CrossRef]

- Nicoletti, L. Parametric Modeling of Battery Electric Vehicles in the Early Development Phase. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2022. [Google Scholar]

- EV Database. Tesla Model 3 Standard Plus; EV Database: Amsterdam, The Netherlands, 2020. [Google Scholar]

- MotorBiscuit. Tesla Driving Mode Was so Dangerous that Tesla Disabled It; Tesla Company: San Carlos, CA, USA, 2022. [Google Scholar]

- Binder, A. Elektrische Maschinen und Antriebe: Grundlagen, Betriebsverhalten; Springer: Berlin/Heidelberg, Germany, 2012; pp. 617–619. [Google Scholar]

- Doppelbauer, M. Grundlagen der Elektromobilität: Technik, Praxis, Energie und Umwelt; Springer: Berlin/Heidelberg, Germany, 2020; pp. 48–200. [Google Scholar]

- Krull, J.T.; Pinto, P.M. Heating and Cooling Reservoir for a Battery Powered Vehicle. U.S. Patent 1,066,590,8B2, 26 May 2020. [Google Scholar]

- Yang, B.; Martins, T.V.; Graves, S.M.; Swint, E.; Bellemare, E.; Fedoseyev, L.; Dellal, B.; Olsen, L.E.; Hain, A. Electric Motor Waste Heat Mode to Heat Battery. U.S. Patent 1,121,804,5B2, 4 January 2022. [Google Scholar]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Chung, Y.; Kim, M.S. Thermal analysis and pack level design of battery thermal management system with liquid cooling for electric vehicles. Energy Convers. Manag. 2019, 196, 105–116. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Wang, Y.; Li, C.; Wang, K. Effect analysis on thermal behavior enhancement of lithium–ion battery pack with different cooling structures. J. Energy Storage 2020, 32, 101800. [Google Scholar] [CrossRef]

- Yang, X.G.; Liu, T.; Gao, Y.; Ge, S.; Leng, Y.; Wang, D.; Wang, C.Y. Asymmetric Temperature Modulation for Extreme Fast Charging of Lithium-Ion Batteries. Joule 2019, 3, 3002–3019. [Google Scholar] [CrossRef]

- Yin, Y.; Choe, S.Y. Actively temperature controlled health-aware fast charging method for lithium-ion battery using nonlinear model predictive control. Appl. Energy 2020, 271, 115232. [Google Scholar] [CrossRef]

- Liu, T.; Ge, S.; Yang, X.G.; Wang, C.Y. Effect of thermal environments on fast charging Li-ion batteries. J. Power Sources 2021, 511, 230466. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Schneider, J.; Frank, A.; Wildfeuer, L.; Lin, X.; Jossen, A.; Lienkamp, M. Review of fast charging strategies for lithium-ion battery systems and their applicability for battery electric vehicles. J. Energy Storage 2021, 44, 103306. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Yang, X.G.; Liu, T.; Wang, C.Y. Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Yang, X.G.; Wang, C.Y. Understanding the trilemma of fast charging, energy density and cycle life of lithium-ion batteries. J. Power Sources 2018, 402, 489–498. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Abo Gamra, K.; Zähringer, M.; Schmid, F.; Lienkamp, M. Fast charging strategy comparison of battery electric vehicles and the benefit of advanced fast charging algorithms. In Proceedings of the Advanced Automotive Battery Conference, Detroit, MI, USA, 14–17 June 2022. [Google Scholar]

- Nobis, C.; Kuhnimhof, T. Mobilität in Deutschland- MiD: Ergebnisbericht; Bundesministerium für Verkehr und Digitale Infrastruktur: Bonn, Germany, 2018. [Google Scholar]

- Steinhardt, M.; Barreras, J.V.; Ruan, H.; Wu, B.; Offer, G.J.; Jossen, A. Meta-analysis of experimental results for heat capacity and thermal conductivity in lithium-ion batteries: A critical review. J. Power Sources 2022, 522, 230829. [Google Scholar] [CrossRef]

- Lienhard, I.V.J.H.; Lienhard, V.J.H. A Heat Transfer Textbook, 5th ed.; Dover Publications: Mineola, NY, USA, 2019. [Google Scholar]

- De Felice, M. Country Averages of Copernicus ERA5 Hourly Meteorological Variables; Zenodo: Geneva, Switzerland, 2018. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). Data on Cars Used for Testing Fuel Economy; EPA: New York, NY, USA, 2021.

- Contemporary Amperex Technology Ltd. Product Specifications—LFP6228082-161Ah; CATL: Ningde, China, 2023. [Google Scholar]

- Samaddar, N.; Kumar, N.S.; Jayapragash, R. Passive Cell Balancing of Li-Ion batteries used for Automotive Applications. J. Phys. Conf. Ser. 2020, 1716, 012005. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosenberger, N.; Rosner, P.; Bilfinger, P.; Schöberl, J.; Teichert, O.; Schneider, J.; Abo Gamra, K.; Allgäuer, C.; Dietermann, B.; Schreiber, M.; et al. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level. World Electr. Veh. J. 2024, 15, 268. https://doi.org/10.3390/wevj15060268

Rosenberger N, Rosner P, Bilfinger P, Schöberl J, Teichert O, Schneider J, Abo Gamra K, Allgäuer C, Dietermann B, Schreiber M, et al. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level. World Electric Vehicle Journal. 2024; 15(6):268. https://doi.org/10.3390/wevj15060268

Chicago/Turabian StyleRosenberger, Nico, Philipp Rosner, Philip Bilfinger, Jan Schöberl, Olaf Teichert, Jakob Schneider, Kareem Abo Gamra, Christian Allgäuer, Brian Dietermann, Markus Schreiber, and et al. 2024. "Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level" World Electric Vehicle Journal 15, no. 6: 268. https://doi.org/10.3390/wevj15060268

APA StyleRosenberger, N., Rosner, P., Bilfinger, P., Schöberl, J., Teichert, O., Schneider, J., Abo Gamra, K., Allgäuer, C., Dietermann, B., Schreiber, M., Ank, M., Kröger, T., Köhler, A., & Lienkamp, M. (2024). Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level. World Electric Vehicle Journal, 15(6), 268. https://doi.org/10.3390/wevj15060268