Abstract

In the Industry 4.0 era, integrating artificial intelligence (AI) with battery prognostics and health management (PHM) offers transformative solutions to the challenges posed by the complex nature of battery systems. These systems, known for their dynamic and nonl*-inear behavior, often exceed the capabilities of traditional PHM approaches, which struggle to account for the interplay of multiple physical domains and scales. By harnessing technologies such as big data analytics, cloud computing, the Internet of Things (IoT), and deep learning, AI provides robust, data-driven solutions for capturing and predicting battery degradation. These advancements address long-standing limitations in battery prognostics, enabling more accurate and reliable performance assessments. The convergence of AI with Industry 4.0 technologies not only resolves existing challenges but also introduces innovative approaches that enhance the adaptability and precision of battery health management. This perspective highlights recent progress in battery PHM and explores the shift from traditional methods to AI-powered, data-centric frameworks. By enabling more precise and scalable monitoring and prediction of battery health, this transition marks a significant step forward in advancing the field.

Keywords:

battery; AI; prognostics; battery health; machine learning; deep learning; big data; internet of things; digital twins 1. Introduction

The transition to vehicle electrification is a key strategy in the global effort to reduce carbon emissions in transportation [1]. This shift encompasses a broad spectrum of vehicles, from passenger cars [2] to commercial trucks [3]. Central to this transformation are rechargeable batteries, which have become increasingly critical due to their declining costs and expanding adoption in electric vehicles (EVs). These advancements position batteries as a cornerstone of sustainable transportation solutions [4,5]. Despite considerable progress, significant challenges hinder the broader adoption of EVs, including limited driving ranges, battery degradation, and safety issues [6,7]. In this context, prognostics and health management (PHM) emerges as an essential tool [8,9]. PHM provides critical insights into battery parameters, including charge, health, safety, and remaining life [10,11,12,13]. The academic community has extensively studied these aspects of battery behavior, providing detailed mechanisms and comprehensive analyses. However, accurately forecasting battery aging [14] and identifying potential failures [15] remain significant challenges in battery technology.

Battery behavior is characterized by inconsistencies that frequently exceed the capabilities of traditional analytical approaches, creating challenges in bridging the gap between academic findings and their practical application in industrial settings. This disconnect is compounded by the divergence between the controlled predictability of laboratory experiments and the unpredictable nature of real-world scenarios [16]. In this context, advancements in deep learning signify a pivotal shift [17], offering solutions to long-standing challenges by unraveling complex structures within high-dimensional datasets [18,19]. Probabilistic methods provide a robust framework for capturing essential insights, establishing a foundation for designing systems capable of learning from experiential data [20]. Machine learning techniques have proven instrumental in the battery domain, expediting the transition from academic research to industrial applications [21,22,23,24]. Recent innovations have highlighted their potential in multiple areas, including health-conscious management through deep reinforcement learning, which transforms complex electrochemical processes into data-driven models, enhancing energy storage performance [25,26]. Physics-informed machine learning combines fundamental physical laws with data-driven models, ensuring more reliable predictions by balancing theoretical constraints with observational insights [27,28,29,30]. Advanced models such as transformers, with their self-attention mechanisms, excel in handling sequential data and embedding temporal information, making them essential for sequence modeling and forecasting [31,32,33]. Furthermore, transfer learning addresses deep learning’s dependency on extensive datasets by leveraging minimal examples and existing knowledge, enabling more efficient learning and adaptability [34,35]. These advancements collectively enhance the reliability, safety, and efficiency of battery systems while accelerating the integration of cutting-edge machine learning techniques into practical applications.

For decades, creating pattern-recognition or machine-learning systems required meticulous engineering and substantial domain expertise. These systems included feature extractors that converted raw data, such as charging-discharging cycling data, into an appropriate internal representation or feature vector [36]. This vector served as input for the learning subsystem, typically a classifier or regressor, which assessed cell lifetime or identified patterns in the input [37,38]. With a substantial dataset encompassing the input spectrum of a learning task, machine learning has showcased remarkable prowess in achieving precise predictions of battery lifespan solely through time-resolved data [39].

When combined with the powerful capabilities of cloud computing [40], enhanced by the internet of things (IoT) [41], and fortified by state-of-the-art communication infrastructures, a superior platform for data-driven modeling emerges. This integration deepens our grasp of battery systems, revealing complex patterns within large datasets. Significantly, deep learning provides intricate interpretations of time-sequenced battery data [42,43,44,45]. Concurrently, the boundless capabilities of cloud platforms furnish users with flexible and scalable computational resources, further improving battery management systems [46,47,48,49].

More broadly, in an era where the industry 4.0 has evolved from boxed products to delivering continuous online services and applications for battery PHM, the dynamics of constructing and deploying these services have drastically changed. This shift emphasizes the significance of operational efficiency for such services. As the adoption of development and operations (DevOps) [50]—a strategy promoting seamless development and release of services—has become widespread, there arises a new set of challenges. The boom in cloud computing has resulted in an unparalleled increase in the scale and intricacy of services. Such an expansive scale and intricacy put forth numerous challenges for software and service engineers, especially in the context of implementing DevOps efficiently and effectively.

Originating around 2016, the term “AIOps” stands for Artificial Intelligence for IT Operations [51,52,53,54]. It was conceived with the primary intent of leveraging AI to amplify various dimensions of information technology (IT) operations, encompassing activities such as vigilant monitoring, accurate fault diagnosis, and proactive performance tuning [55], by leveraging advanced large-scale machine learning models. While there is not a universally accepted definition for AIOps yet, its essence lies in harnessing AI and machine learning techniques to empower software and service engineers. To streamline the construction and operation of services, ensuring they’re not only efficient but also easily supportable and maintainable. The implications of incorporating AIOps are profound. It does not just ensure top-tier service quality and heightened customer satisfaction but also propels engineering productivity and significantly curtails operational expenses.

Within the sphere of battery PHM, the potential of AIOps is groundbreaking. Batteries, with their intricate architecture and pivotal role in operations, stand to gain substantially from the application of AI-centric strategies. The integration of AIOps equips operational teams with an expansive toolkit and deeper insights, enabling them to adeptly manage these complex systems [56]. Central to AIOps in this field is its amalgamation of automation techniques and cutting-edge methodologies, enhancing predictability and fostering efficient oversight of battery health and longevity. However, the trajectory of this integration is ever-evolving. Addressing the nuanced challenges of PHM within tangible battery environments necessitates persistent innovation and flexible strategies.

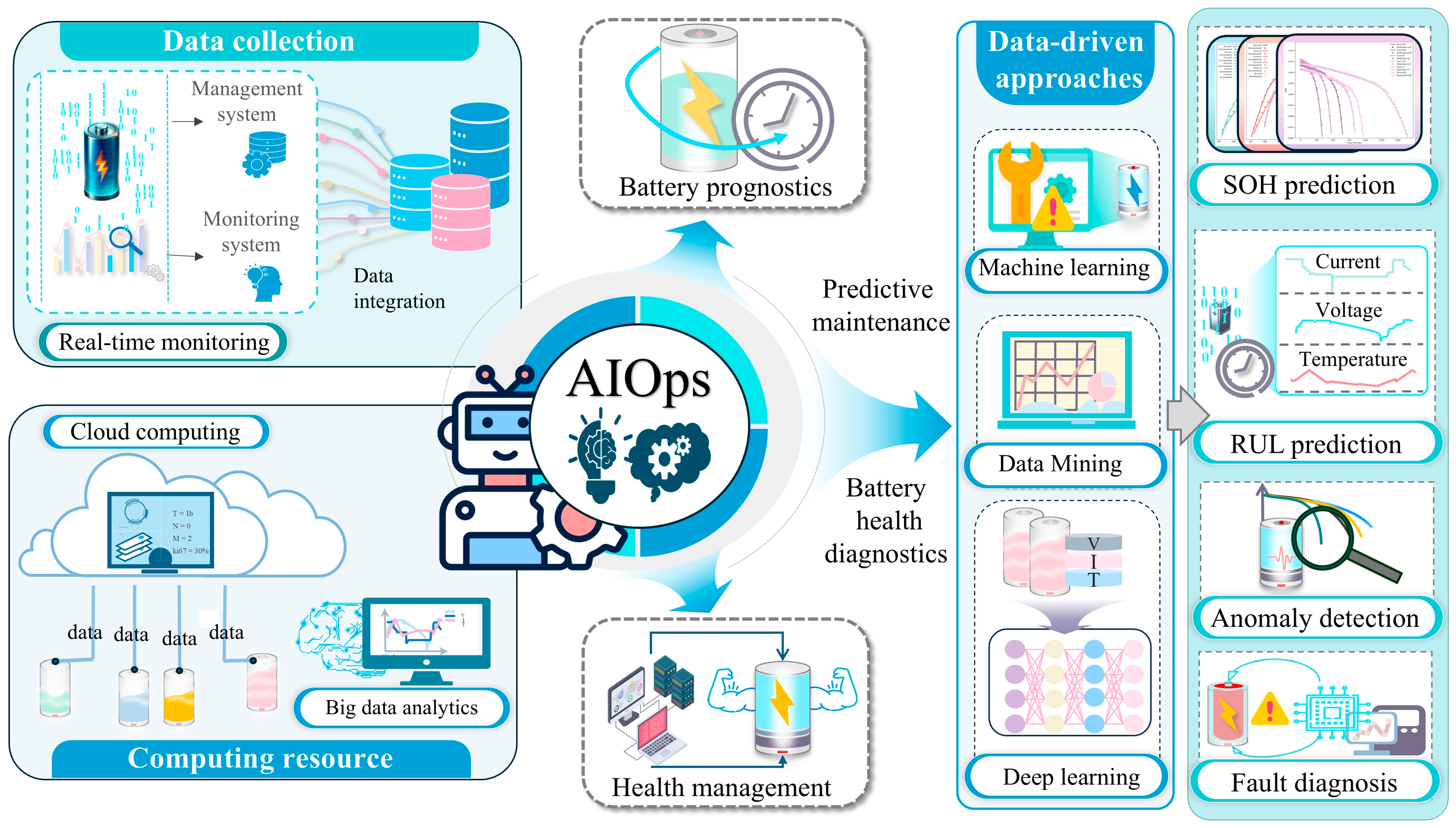

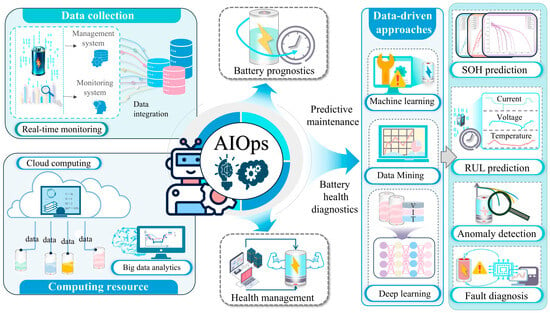

In this Perspective (Figure 1), we will dive into the practical challenges of developing AIOps solutions, informed by our hands-on experience from overseeing a vast fleet of EVs. We will also chart out a prospective research roadmap in the AIOps domain and share insights on successful AIOps deployments designed specifically for the EV battery suite in the context of PHM.

Figure 1.

AIOps for battery prognostics and health management: challenges and pathways.

2. Materials and Methods

2.1. Multiscale Modelling for Batteries

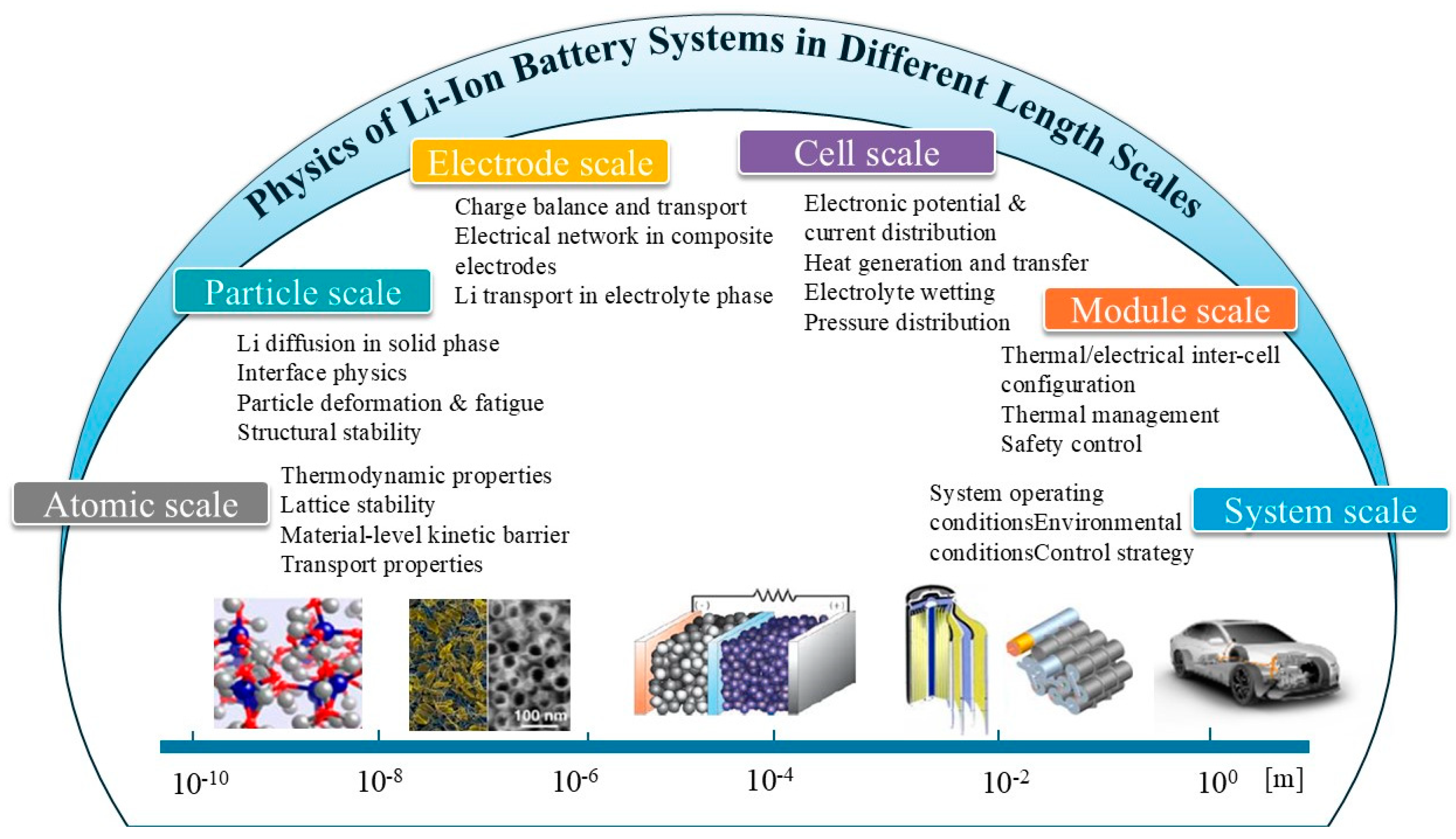

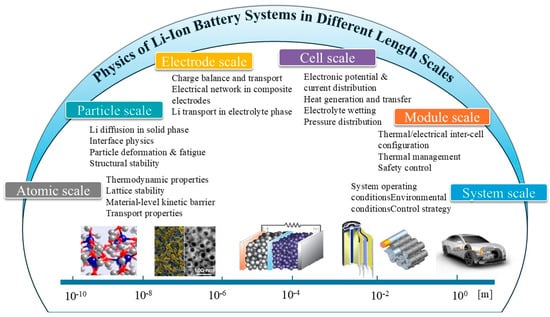

Rechargeable batteries operate through a sophisticated interplay of physical, chemical, and electrochemical reactions occurring across multiple scales, from molecular to cell-level to system-wide dynamics. These processes are fundamental to determining battery performance and efficiency. To address this complexity, researchers employ multiscale modeling (Table 1), which integrates phenomena across different scales into a cohesive framework [57]. This approach provides a deeper understanding of how microscopic interactions influence macroscopic properties and overall battery functionality (Figure 2). By bridging these scales, multiscale modeling enhances the study of battery behavior and performance, offering valuable insights to guide future advancements.

Table 1.

Summary of battery diagnostics and modeling at different scales.

Figure 2.

Multiscale battery modelling. Adapted with permission from ref. [57], copyright NREL with modifications.

- (1)

- Molecular Scale

At the atomic and molecular scale, modeling focuses on fundamental processes that govern battery behavior, such as ion transport, electron transfer, and interactions at material interfaces [58]. Advanced computational methods are applied to investigate these phenomena with exceptional precision. These techniques enable a detailed analysis of critical challenges, including the degradation of electrolyte components and the structural and chemical transformations in electrode materials. By uncovering the underlying mechanisms, this level of modeling provides essential insights to inform the design and optimization of more durable and efficient battery systems.

- (2)

- Electrode Scale

At this scale, the analysis focuses on ion transport within the porous electrode structure and the accompanying electrochemical reactions [59]. A primary objective is to investigate how these processes influence overall battery performance, with particular emphasis on understanding the factors that contribute to capacity degradation. By examining the interplay between ion movement and reaction dynamics, researchers aim to identify mechanisms that lead to performance loss and develop strategies to mitigate these effects, thereby improving battery longevity and efficiency.

- (3)

- Cell Scale

Cell modeling examines the battery as an integrated system, focusing on the interactions among key components such as the positive electrode, negative electrode, and separator, and their collective impact on performance and efficiency. Thermal management is a critical area, with research often addressing heat generation and dissipation within the cell. Advances in health monitoring leverage machine learning to enhance predictive accuracy. For instance, machine learning methods estimate the state of health (SOH) with high precision, incorporating uncertainty quantification [60]. Transfer learning further enables real-time monitoring under various usage profiles, providing accurate predictions of capacity and remaining useful life (RUL) [61]. Innovative deep learning models predict complete charging curves from partial data, offering detailed insights into degradation, while fusion models use transfer learning to reconstruct aging curves under diverse conditions [62]. These advancements highlight the transformative potential of scalable, data-driven approaches to improve battery management and performance [63,64].

- (4)

- Module/Pack Scale

At the module and pack scale, modeling focuses on the collective operation of interconnected cells, addressing charging and discharging management, thermal regulation, and system safety. One study proposed a machine learning-based method to estimate the SOH of cells within a battery pack, addressing aging inconsistencies and limited cell-level measurability [65]. A BiGRU-based estimator is developed to determine branch charging capacity, while key features, including aging, inconsistency, and operating conditions, are extracted. These features are input into a support vector regression model for precise SOH estimation. The approach is validated under various charging conditions, demonstrating its potential to enhance SOH monitoring accuracy and improve battery pack safety. In addition, experimental studies replicate real-world conditions using laboratory-designed modules, while advanced techniques such as dual Gaussian process regression improve health and performance evaluations. This method uses health indicators from partial charging curves to monitor capacity loss, resistance increases, and cell inconsistencies, enhancing prognostic precision for automotive applications [66]. These innovations improve prediction accuracy, reduce computation times, and strengthen reliability, advancing battery management for safer and more efficient EV systems.

- (5)

- System Integration of Scales

At the system level, modeling integrates insights from multiple scales, spanning material, cell, and pack levels, to forecast the holistic behavior of battery systems. Advances in machine learning have become instrumental in enhancing these predictive capabilities. Lifelong learning frameworks, which continuously refine models with field data, represent a significant innovation in adaptive modeling. These frameworks enable the incorporation of real-world performance data into predictive algorithms, thereby increasing the robustness and accuracy of the models. One application involves stacking ensemble methods to estimate the SOH for LFP cells [67]. These methods leverage real-world charging data, employing advanced noise reduction techniques and domain-specific feature engineering to address complexities such as environmental variability and operational uncertainties. As onboard computing capabilities advance, the implementation of these sophisticated analytical techniques is transitioning from offline computation to real-time deployment, enabling more responsive battery management systems. The integration of cloud-based platforms and digital twin technologies further enhances system-level capabilities. Digital twins—virtual replicas of physical systems—facilitate the simulation and monitoring of battery behavior under various scenarios. When coupled with cloud computing, these tools enable comprehensive safety prognostics, including early failure prediction and proactive management strategies. In addition, another study demonstrates a cloud-based, data-driven robust model predictive control algorithm managing a 150 kWh lithium-ion battery at an operational site with over 100 office staff [68]. The algorithm integrates forecasts of site consumption, generation, and electricity costs to minimize electricity expenses. Despite two of the four battery inverters being non-functional, the system achieved 5.5% cost savings, primarily by reducing the site’s capacity charge from 358 kVa to 317 kVa. The study also highlights real-world challenges, including data outages, equipment failures, and communication issues, offering valuable insights for practical battery control deployments.

2.2. Multiphysics Battery Modelling

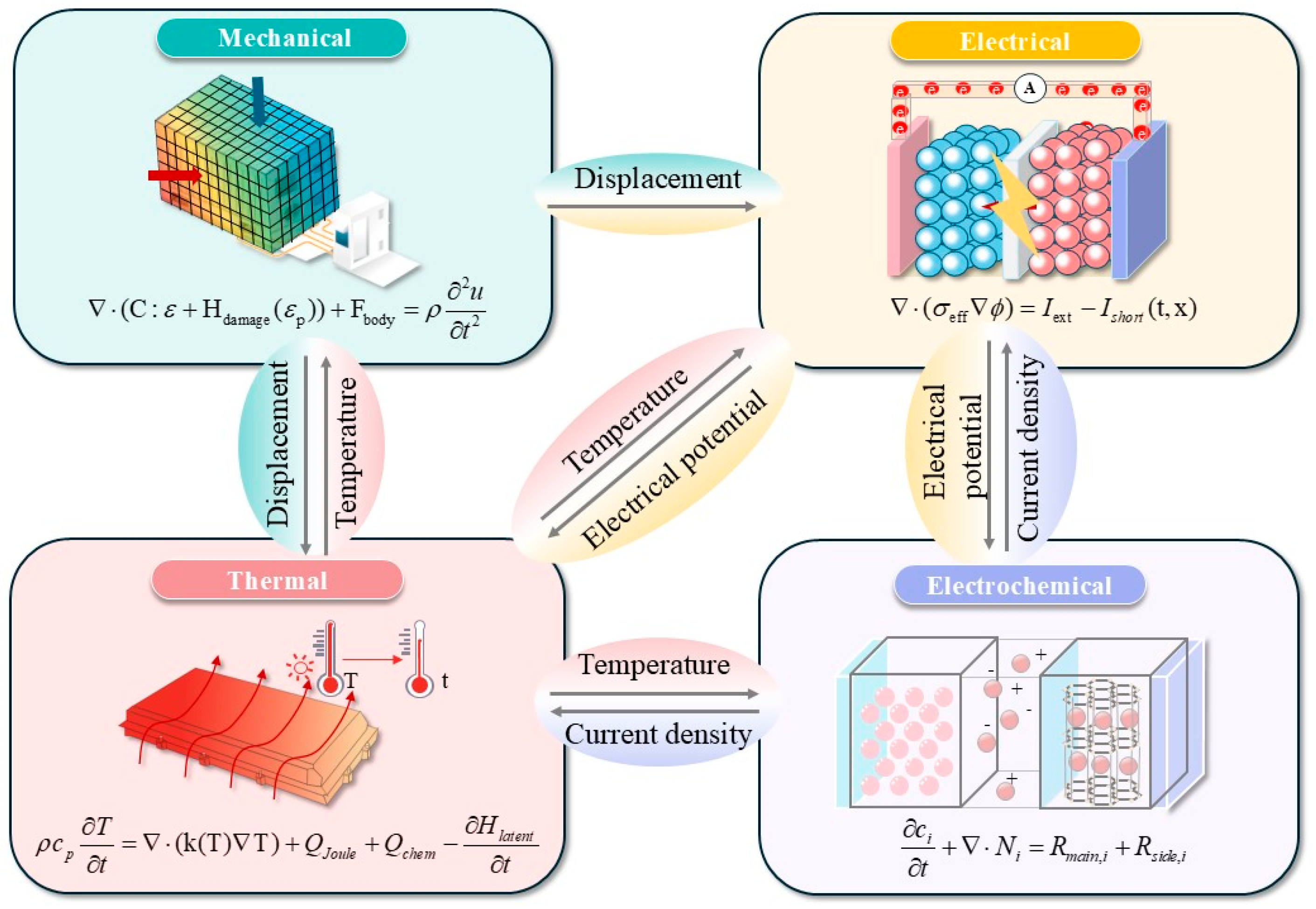

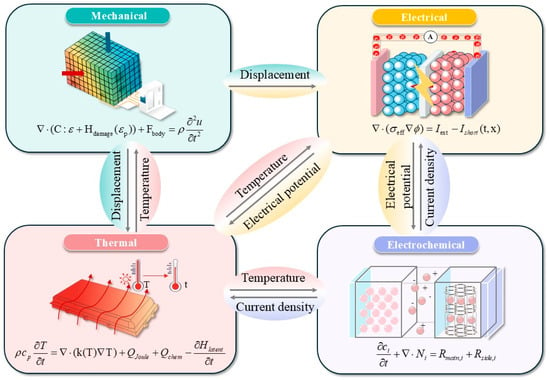

Understanding multiphysics processes is crucial for battery operations, as these involve intricate interactions among chemical, electrical, thermal, and mechanical phenomena, each influencing the others. Effective predictive modeling, performance evaluation, and design optimization rely on accurately capturing these simultaneous dynamics. Multiphysics battery modeling provides a framework to decode and quantify these complex interdependencies. This approach offers valuable insights into battery behavior, contributing to improved reliability and efficiency. The integration of these processes is detailed in the coupling scheme presented in Figure 3, highlighting the interconnected nature of battery systems and their operational challenges [69].

Figure 3.

Multiphysics battery modeling by coupling electrochemical, mechanical, electrical, and thermal phenomena (Mechanical Domain: Defined by parameters such as the displacement vector (m), the total strain tensor , the fourth-order nonlinear elasticity tensor incorporating plasticity, the damage evolution function dependent on plastic strain , and the body force vector (N/m3), which characterize material deformation and damage. Thermal Domain: Accounts for temperature-dependent thermal conductivity (W/m·K), Joule heating = E·i (W/m3), reaction heat generation , dependent on the reaction potential and temperature, and latent heat (J/m3) due to phase changes. Electrical Domain: Focuses on effective conductivity , reduced by the damage parameter , electrical potential (V), external current density (A/m2), and short-circuit current density , localized at and time , describing current and potential distribution. Electrochemical Domain: Involves the concentration of species (mol/m3), species flux , resulting from diffusion and migration, and the rates of main electrochemical reactions (mol/(m3·s)) and side reactions , such as SEI growth or gas generation).

- (1)

- Electrochemical Modelling

Electrochemical modeling serves as a vital tool to study and understand the key processes occurring at battery electrodes. It examines the transport of charged species, the movement of electrons, and transformations in electrode structures. These processes are crucial for evaluating essential battery characteristics such as electrical potential, charge levels, and storage efficiency. Recent advancements have refined these models to include intricate phenomena, such as the evolution of interfacial layers [70], metallic deposition [71], material degradation [72], and changes in resistance over time [73]. These developments contribute significantly to improving battery efficiency, extending lifespan, and guiding innovative designs for future energy storage technologies.

- (2)

- Thermal Modelling

Thermal modeling plays a critical role in understanding the complex thermal dynamics of batteries, including heat generation from electrochemical reactions and internal resistance, heat distribution within the cell, and dissipation to the environment [74]. Effective thermal modeling is essential for predicting temperature variations during charging and discharging cycles, identifying hotspots, and evaluating the impact of external conditions. These insights guide the design of advanced thermal management systems that maintain optimal operating temperatures, enhance efficiency, and mitigate safety risks such as overheating, thermal runaway, and cell degradation. By addressing these challenges, thermal modeling contributes significantly to the development of safer and more reliable energy storage solutions.

- (3)

- Mechanical Modelling

Mechanical modeling investigates stress and strain dynamics within batteries, particularly those caused by electrode volume changes during lithiation and delithiation. These mechanical stresses can result in electrode cracking, material degradation, or internal short circuits, directly impacting battery performance and safety. By pinpointing potential failure points and evaluating strain distributions, mechanical modeling provides crucial insights into structural integrity and durability. Advanced approaches integrate physics-based simulations with machine learning techniques to predict safety margins and develop data-driven frameworks for risk mitigation [75]. This integration enhances the ability to forecast mechanical failures, contributing to the design of safer, more reliable battery systems.

- (4)

- Electrical Modelling

The analysis of electrical dynamics, encompassing electron flow, internal resistance, and impedance, is fundamental to optimizing battery performance and ensuring reliability. Key factors such as electrode surface properties, separator integrity, and electrolyte conductivity directly affect operational efficiency and stability. Electrical stress, caused by conditions such as short circuits [76], overcharging [77], or over-discharging [78], can accelerate capacity loss, reduce lifespan, and compromise functionality. Advanced modeling and monitoring techniques are indispensable for predicting and mitigating these risks, thereby enhancing battery safety and overall performance.

- (5)

- Integrated Multiphysics Modeling

A multiphysics modeling approach integrates thermal, mechanical, electrical, and electrochemical processes to reflect their complex interactions and collective impact on battery performance. This comprehensive framework is critical for accurately simulating operational conditions in large-scale applications such as EVs [69]. Scaling these models from single cells to entire battery modules and packs enhances their applicability to real-world systems. Coupled with experimental validation, multiphysics modeling enables the development of effective strategies to improve battery safety, reliability, and overall efficiency.

3. Current Challenges of Battery PHM

3.1. Data Availability and Benchmarks

In the field of battery PHM, the importance of standardized benchmarks is critical. These benchmarks are vital for assessing the development of algorithms, ensuring reproducibility, and anticipating computational requirements. While existing datasets support data-driven approaches, there is potential to enhance them with benchmarks that also incorporate physical insights, provided these datasets are complemented by suitable parameterized physical models. Particularly, research has shown that integrating physics-driven knowledge into data-driven methods significantly improves the explainability and training of health and lifetime predictions, while reducing the dependence on extensive high-quality observations [79,80]. This fusion of physical and data-driven approaches has emerged as an exciting new direction in the field, showing great potential for applications in battery health management. It is important to recognize the unique challenges presented by specific physics and chemistry disciplines. Field data, though extremely valuable, are often scarce due to experimental constraints.

The creation of benchmarks that accurately evaluate the precision and efficiency of new algorithms is complex. Developing reliable benchmarks to evaluate the precision and efficiency of new algorithms is a challenging task. Refining these benchmarks is an ongoing effort, particularly in data-driven domains such as time series analysis. Effective benchmarking involves selecting suitable methods tailored to the characteristics of the data and the prediction time frame. For instance, some studies have introduced simple reference forecasting models, such as autoregressive models. This model, which operates without requiring training data, is used as a baseline for comparison with more sophisticated algorithms to assess their relative performance [81]. The task is further complicated by software discrepancies and hardware complexities. Predicting dynamics in physical systems, such as identifying specific transitions or understanding chaotic conditions, adds another layer of difficulty. A major challenge in battery PHM is managing prognostic uncertainty. Given the variability in operational modes, usage patterns, and degradation pathways of batteries, accurately predicting their health is especially challenging. Therefore, addressing the inherent uncertainty in battery health predictions is crucial, underscoring the need for robust and forward-looking strategies.

3.2. Real-Time Implementation

Battery assessment in EVs arises from several critical considerations. Safety and health are paramount, as batteries can pose significant risks if operated outside their optimal charge or health states. Early detection of anomalies is essential to prevent dangerous situations. From an operational standpoint, real-time insights into battery health facilitate optimal energy management, enhancing the driving range of the vehicle while safeguarding the longevity of the battery. Moreover, real-time monitoring is instrumental in facilitating predictive maintenance, which permits early interventions to avert failures and maintain uninterrupted vehicle usage, thereby extending the operational life of the battery. In the context of real-time battery health monitoring, recent developments in IoT-based systems for LiBs offer promising solutions. For example, a monitoring system utilizing Grafana for analytics and visualization enables real-time tracking of critical battery parameters, including state of charge, voltage, and temperature. Such systems, as described in study [82], are key for ensuring optimal performance in field applications and align with the needs for real-time monitoring in EVs. From an economic perspective, swift and accurate health evaluations contribute to cost reductions by identifying deteriorating cells early, potentially circumventing the necessity for comprehensive battery pack replacements. In addition, this type of monitoring enhances the driving experience by providing motorists with up-to-date information on driving strategies and charging practices, tailored to the current condition and capacity of their vehicle battery. However, implementing such immediate and accurate monitoring systems is complex. The challenges include the computational demands of the algorithms, the continuous influx of sensor data, and the need for instant data interpretation. Collaborative efforts among algorithm developers, hardware engineers, and industry experts are essential to overcoming these challenges. Such teamwork is crucial for ensuring that battery PHM systems are responsive, reliable, and capable of integrating seamlessly into the operational framework of EVs.

3.3. Integration with Operations

The integration of PHM systems within operational frameworks presents unique challenges, particularly in real-world, field settings where ensuring a seamless synergy between predictive health insights and on-ground operational and maintenance actions is crucial. This integration demands a multidisciplinary approach that bridges the gap between the technical prowess of battery technology experts and the practical expertise of operations professionals. Their collaborative efforts are essential to ensure that the insights generated by PHM systems are not only accurate but also actionable in a real-world context. Modern PHM systems, enhanced by AI, offer potential breakthroughs in predictive and preventive maintenance strategies. To address the challenges of integrating PHM systems within operational frameworks, several research efforts have proposed frameworks that facilitate seamless collaboration between stakeholders. One such framework is the PHM for digital twin framework, developed using model-based systems engineering principles. This approach highlights the importance of multidisciplinary collaboration to ensure effective integration and applicability of PHM systems [83]. However, leveraging these AI-powered insights effectively requires aligning the objectives and strategies of AI specialists with those of domain experts [84]. This alignment ensures that AI-driven recommendations are met with appropriate and timely operational responses, thereby maximizing the efficacy of maintenance interventions. Furthermore, for the continuous improvement of PHM systems, establishing robust feedback mechanisms is vital. Real-world operations provide invaluable data that can be used to refine and enhance PHM algorithms. This iterative process, fueled by real-world feedback, leads to improvements in both the accuracy and adaptability of the systems. Finally, as PHM systems become more ingrained in operational processes, it is pivotal to ensure that on-ground staff are well trained. Comprehensive training ensures that personnel not only understand the insights provided by PHM systems but are also well prepared to act on them effectively. This training component is crucial for maximizing the impact of insights on field operations, ultimately enhancing both safety and efficiency.

3.4. Privacy and Security

The integration of battery PHM, in particular, raises significant concerns related to data privacy and security. These systems, which rely on continuous data collection and analysis, must protect sensitive information while ensuring operational integrity and system functionality. Battery data, especially in contexts such as EVs, energy storage, and critical infrastructure, often contain sensitive information. This data may include insights into user behavior, operational patterns, and proprietary technical details. Unauthorized access could lead to privacy breaches and the exposure of intellectual property, making data protection a critical priority. To address these risks, secure data transmission and encryption are essential, particularly since many PHM systems operate wirelessly and require remote monitoring. Implementing robust encryption protocols and secure communication channels is necessary to prevent unauthorized access and cyber threats. Moreover, after data is collected, it must be stored securely. This involves encrypted storage, strict access controls, and regular audits to maintain confidentiality. In situations where detailed, identifiable information is unnecessary, anonymization or data masking can provide an additional layer of protection. By removing personally identifiable information and sensitive details, organizations can minimize the risk of unintended disclosures while still enabling useful data analysis.

As data privacy becomes an increasingly critical issue, one promising approach is federated learning. This decentralized machine learning method allows multiple entities to share sensitive data securely. In the context of battery PHM systems, federated learning enables different stakeholders, such as battery manufacturers, EV operators, and energy storage providers, to contribute to model development without exposing proprietary data. Instead of transmitting raw data, only model updates are shared between participants, ensuring that sensitive user and operational data remain private. This method greatly reduces the risk of data breaches while improving the robustness of predictive models by allowing the integration of diverse data sources. In a similar context, a privacy-preserving authentication protocol based on intelligent blockchain has been proposed for the internet of vehicles, which ensures both the security and reliability of data storage and transaction verification processes while maintaining privacy, such as user anonymity and untraceability [85]. Furthermore, addressing cybersecurity in battery management systems (BMSs) is critical, as highlighted by recent studies, which emphasize the importance of securing BMSs against potential cyber-attacks. The integration of blockchain technology into BMSs has been proposed as an effective defense strategy, enhancing the security of battery systems against cyber-physical threats and ensuring their safe operation in various applications [86].

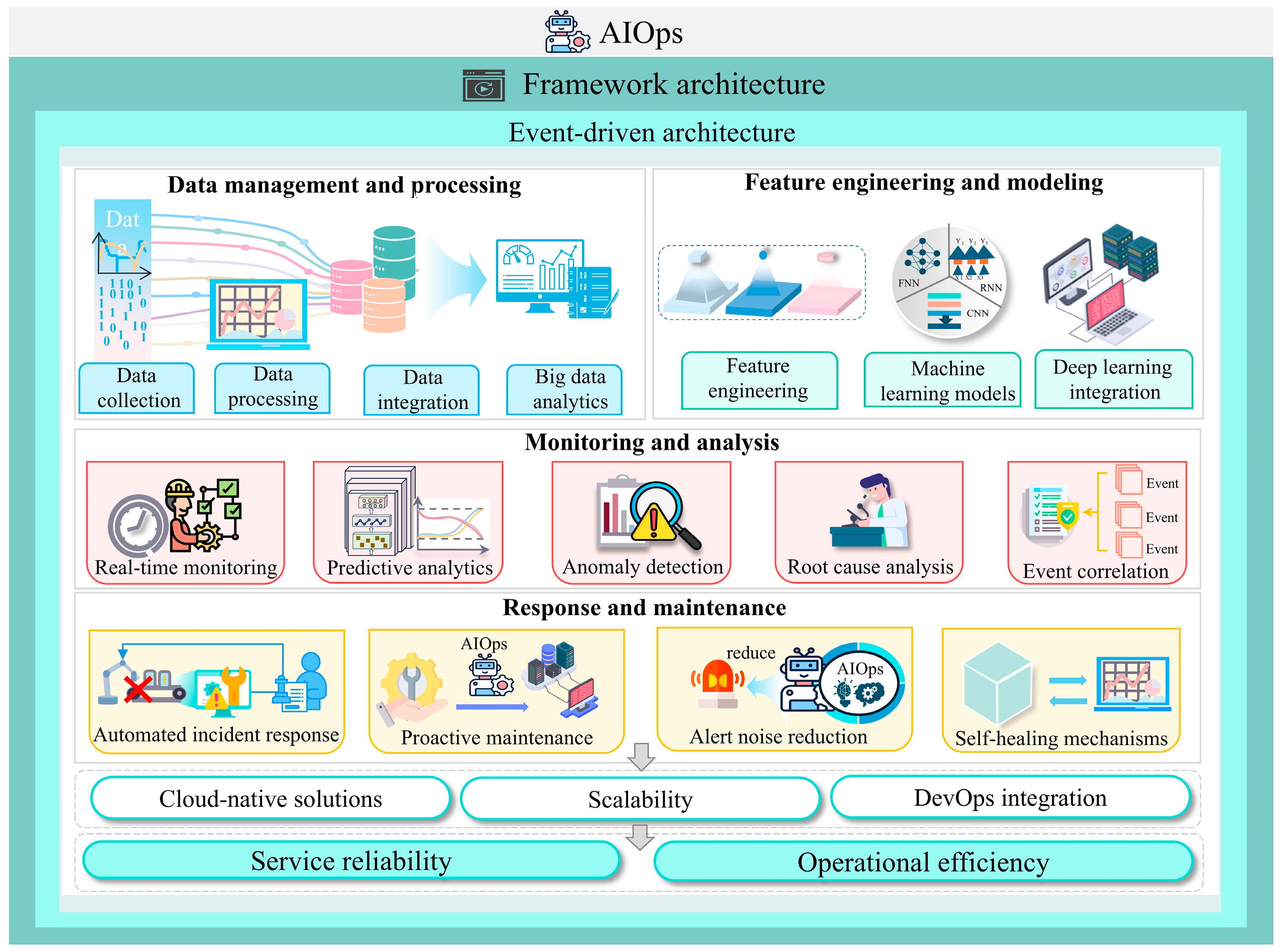

4. Key Components of AIOps

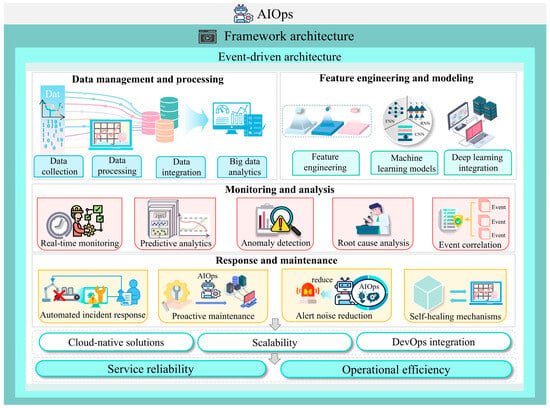

AIOps represents a sophisticated convergence of machine learning and advanced data analytics within the domain of information technology infrastructure (Figure 4). The methodology’s primary objectives encompass systematic task optimization, intelligent decision-making enhancement, and comprehensive system performance improvement. The foundational components of AIOps are characterized by the following critical elements:

Figure 4.

A general framework of AIOps.

- Data Collection and Aggregation: AIOps platforms retrieve data from a diverse array of IT sources, including servers, storage systems, networks, applications, and cloud resources. This capacity for data aggregation addresses challenges associated with data availability and the necessity for standardized benchmarks in PHM. Utilizing advanced data aggregation systems, organizations can secure the comprehensive, high-quality data essential for effective PHM, thus resolving issues related to scarce and inconsistent data sets. Moreover, in the context of battery diagnostics, where devices generate complex, time-sensitive data, AIOps platforms substantially enhance data collection rates. This enhancement depends significantly on the configuration of testing equipment and experimental design. For instance, systems such as MACCOR and Arbin can capture data at millisecond intervals, optimizing the balance between data resolution, storage efficiency, and processing demands. This refinement is vital for maintaining the integrity and applicability of data in critical settings.

- Big Data: Given the extensive data volumes managed by AIOps, a reliable big data platform such as Edge-to-Cloud is indispensable. This platform caters to substantial storage, processing, and analytical demands, playing a pivotal role in real-time data processing. The scalability of AIOps ensures that data from various sensors, such as those in EVs and energy storage systems, is processed promptly, offering immediate insights that enhance battery usage and prevent failures. This capability addresses the crucial requirement for a constant flow of data and immediate interpretation, integral to real-time battery health monitoring. Furthermore, efficient data processing of test data from these systems is crucial for expediting analyses and alleviating bottlenecks in testing pipelines. Python-based tools such as pandas, NumPy, and SciPy are extensively employed for data preprocessing and manipulation, aiding AIOps platforms in effectively managing large data challenges. By incorporating advanced machine learning algorithms for pattern recognition, anomaly detection, and forecasting, AIOps not only streamlines the management of vast datasets but also boosts predictive capacities, which are essential for proactive battery health management and enhancing operational reliability.

- Visualization: Post-data processing, the results should be rendered in a format comprehensible to IT teams. Visualization tools, such as charts and graphs, help operators in EVs or energy storage systems make informed decisions. Visualizing key metrics—like state-of-charge, temperature, and degradation levels—can significantly improve decision-making, supporting real-time monitoring needs in battery health management. This capability aligns with the need for effective, real-time decision-making tools, which have been emphasized in the context of battery performance and longevity.

- Automation Framework: AIOps employs this to enable automated actions based on data insights, which could be scripts, playbooks, or integrations with IT orchestration tools.

- Domain Knowledge: An evolving repository that accumulates insights, solutions, and patterns. This resource aids in refining machine learning models and can sometimes offer direct guidance to IT personnel. By automating maintenance alerts and interventions, AIOps enhances system reliability and battery longevity, addressing integration challenges and streamlining operational workflows. The automation capabilities of AIOps are instrumental in integrating predictive health management insights with operational processes, thereby improving overall system reliability.

- Integration Layer: Essential for interfacing AIOps with diverse IT monitoring and management tools. Features such as API connectors and plugins ensure smooth data integration and actions. This layer is crucial for overcoming the cross-disciplinary collaboration challenges identified in earlier sections, as it ensures that data from diverse sources (e.g., battery systems, EVs, and energy storage solutions) can be unified into one cohesive framework, enabling seamless PHM operations.

- Security and Compliance Mechanisms: By incorporating secure data transmission and storage protocols, AIOps effectively addresses privacy and security challenges, which are especially critical in battery PHM systems. This approach ensures that data from EVs and energy storage systems is safeguarded from unauthorized access and potential security threats, thereby alleviating privacy concerns and supporting safe and secure operations.

5. Prospects for Battery PHM Using AI-Driven Solutions

5.1. IoT-Enabled AI

As the digital landscape rapidly evolves with the expansion of the IoT, battery PHM is poised for a significant transformation. The increasing number of interconnected devices generates a continuous flow of battery data from sources as varied as smart vehicles, wearable devices, and large-scale grid storage systems. When consolidated, this vast data ecosystem offers valuable opportunities for in-depth analysis. The integration of AI-driven operations within this framework greatly amplifies its potential [87]. Real-time analysis, once a laborious process, becomes instantaneous, providing immediate insights into battery health and performance. Machine learning and AI-powered predictive maintenance enable a proactive approach, anticipating battery service needs, optimizing longevity, and reducing operational costs. As the interconnected network of devices grows, the combination of IoT and AI creates a comprehensive view of system operations. In smart environments, for instance, it allows for insights not only into individual device battery health but also into the overall efficiency and coordination of the entire network.

The expansion of IoT devices brings new concerns about data security. As more devices connect and share information, ensuring the safety of sensitive battery data becomes critical. AI technology plays a pivotal role in detecting potential security threats, safeguarding data, and helping organizations comply with privacy and security regulations. Another important aspect of integrating IoT with battery PHM is scalability. As IoT networks grow, PHM systems must keep pace with the increasing amount of data. AI enables these systems to handle large-scale data more efficiently, even when devices operate on different standards and protocols. By acting as the intermediary, AI ensures smooth communication and data sharing across diverse platforms. This fusion of IoT and AI is propelling battery health management forward, providing deeper operational insights and creating a future where battery-powered systems are more reliable, efficient, and capable of meeting evolving demands.

5.2. Physics-Informed AI

While data-driven machine learning models excel at fitting labeled datasets, they often struggle in scenarios involving extrapolation, observational biases, or insufficient training data. These challenges can result in predictions that, while numerically accurate, may be physically inconsistent or even implausible. To address this issue, a blend of empirical data science and fundamental physical principles is necessary. This is where PIML comes into play, as recent studies have shown [88]. Rather than relying solely on raw data, PIML incorporates established physical laws, ensuring that models adhere to these principles. PIML techniques provide robustness, particularly when handling imperfect data, such as gaps, noise, or anomalies. These methods are especially effective in analyzing complex phenomena that span multiple scientific domains. In the battery field, there is growing interest in advancing physics-informed neural networks (PINNs), which excel at capturing intricate spatial interactions across varying timescales.

The inclusion of meta-data in PINNs enhances their interpretability and capabilities. Meta-data refers to contextual information that provides context or constraints to the primary data [89], enabling the seamless integration of domain-specific knowledge into the neural network. Despite its importance, meta-data is often underrepresented in the literature, even though it plays a crucial role in improving PINNs, particularly for addressing complex physics-based challenges. Boundary and initial conditions, for instance, provide essential constraints, such as starting values and boundary behaviors, that ground the model in its physical context. Including this information ensures that the PINN adheres to governing equations throughout the domain. Similarly, details about domain geometry and properties, such as spatial dimensions, grid resolution, or material characteristics, offer structural insights that help the model address problems involving multi-scale or heterogeneous systems. Physical parameters and constants, such as diffusion coefficients or thermal conductivities, are another critical aspect of meta-data. These parameters help calibrate the model to align with real-world phenomena accurately. In addition, information about the characteristics of measurement data—such as noise levels, sensor precision, and sampling methods—enables the model to account for uncertainties and improves its robustness. Annotations and data-physics interactions further enhance the utility of meta-data by clarifying the regions governed by labeled data versus those governed by physical laws. This delineation allows for balanced training and improves the model’s ability to generalize across the domain. Furthermore, documenting hyperparameters, such as network architecture, learning rates, and regularization methods, supports reproducibility and ensures alignment between the model’s design and the problem’s requirements. Integrating meta-data into PINNs fosters a structured and informed approach to learning. By embedding this information, PINNs are better equipped to enforce physical laws while leveraging observed data, resulting in enhanced performance and interpretability. Meta-data also ensures consistency with real-world constraints, reducing the risk of overfitting and improving generalizability. Despite its significance, the systematic reporting and utilization of meta-data remain limited in PINN studies, hindering reproducibility and scalability. Future research should emphasize the comprehensive documentation and application of meta-data to establish best practices for integrating domain knowledge effectively. Such efforts would not only strengthen the theoretical foundations of PINNs but also broaden their applicability to more complex and interdisciplinary problems.

The continued refinement of PINNs and other PIML approaches is poised to transform forecasting in battery systems by integrating the strengths of data science with the reliability of physical laws. By adhering to these principles, PIML not only enhances the technical accuracy of AI models but also promotes transparency, accountability, and trust [90]. Explainable AI (XAI) is key in this regard, serving not only as a troubleshooting tool but also as a valuable partner in knowledge generation. As research expands, XAI is recognized for its potential to facilitate interdisciplinary understanding, support education, and accelerate innovation by building on previous discoveries [91].

5.3. Multimodal AI

The integration of multimodal AI into battery PHM enhances the accuracy, efficiency, and adaptability of health monitoring systems. As battery technologies evolve and find applications in areas such as EVs and grid storage, the complexity of managing battery health increases. Multimodal AI, which draws on data from various sources—including thermal, electrical, and mechanical sensors—provides a robust framework for synthesizing diverse data streams into meaningful insights. By incorporating multiple data types, multimodal AI offers a more comprehensive understanding of battery behavior under different conditions and over time. This approach enables more precise diagnostics, allowing for the early detection of degradation and failure modes that might be overlooked by traditional single-modality methods. Furthermore, multimodal AI enhances predictive maintenance capabilities, optimizing battery life and performance through more accurate health forecasts and operational planning.

A significant advantage of multimodal AI lies in its ability to adapt to real-world conditions, where batteries face a range of environmental and operational factors. By integrating data from various domains, these models capture the complex interactions between physical, chemical, and operational processes, leading to more reliable health assessments. This holistic approach also supports the scalability of PHM systems, equipping them to manage the large and complex datasets generated by modern battery applications. Despite its potential, the development and deployment of multimodal AI for battery PHM face challenges. These include the need for standardized datasets across different modalities, the computational demands of integrating large data volumes, and the requirement for real-time system responsiveness. Overcoming these challenges will necessitate ongoing collaboration between AI experts, battery researchers, and industry professionals.

5.4. End-to-End AI

The application of end-to-end AI in battery PHM holds considerable potential for transforming how battery health is monitored, managed, and optimized. Unlike traditional methods that rely on segmented models or manual feature extraction, end-to-end AI systems leverage deep learning techniques to automatically learn and predict battery health from raw data, streamlining the process and improving accuracy across multiple stages.

End-to-end AI systems enable seamless integration of data ingestion, processing, and output generation, significantly reducing the need for extensive human intervention. This approach supports real-time health monitoring by capturing intricate patterns in data that might be overlooked by conventional models. By utilizing large-scale datasets, these systems can identify complex relationships between operational parameters, such as temperature, voltage, and charge degradation. This results in a more comprehensive understanding of battery behavior, enhancing predictive capabilities for maintenance and performance optimization. Furthermore, the flexibility of end-to-end AI models allows their application across a wide range of cell types and use cases. This adaptability is particularly crucial as battery technologies diversify in fields such as electric vehicles, renewable energy storage, and consumer electronics. As battery systems become more complex, the ability of end-to-end AI to process and integrate various data sources becomes increasingly valuable for maintaining performance and ensuring safety.

Implementing end-to-end AI in battery PHM poses several challenges. Foremost among these is the need for extensive datasets that accurately represent various operational environments. These datasets are vital for the development of precise predictive models. As data from interconnected devices proliferates, maintaining the scalability of these systems is an increasingly daunting task. Moreover, the substantial computational requirements of real-time applications necessitate not only advanced hardware but also more streamlined algorithms to satisfy both performance and response time demands. Despite these hurdles, the prospects for end-to-end AI in battery PHM are optimistic. Ongoing enhancements in machine learning algorithms and computational hardware are improving the precision, efficiency, and scalability of these systems. The integration of such technologies is crucial for enhancing the durability, safety, and functionality of battery systems, marking a significant stride towards more resilient energy solutions.

5.5. Synergized Human-AI

As we navigate the complex landscape of battery PHM, it is clear that the merger of human intelligence with AI presents unprecedented opportunities. The role of AI, especially when integrated into the framework of Industry 4.0, promises a cloud-based [92], digital twins-enhanced [93] approach to battery PHM, reaching dimensions once considered unreachable. However, the real magic unfolds when humans and AI collaborate seamlessly. Central to this collaboration is understanding and harnessing the decision-making capabilities of AI. It is crucial to craft strategies ensuring the recommendations of AI regarding battery health are conveyed in an intelligible manner to human operators. This ensures that the insights AI provides are not just data points; they become actionable directives fostering effective decision-making.

The cross-disciplinary nature of the work beckons a fusion of minds from diverse fields. Battery scientists, with their nuanced understanding of the intricacies of energy storage and management, combined with AI experts, who understand the vast possibilities inherent within algorithms and data processing, can pioneer innovative solutions. Together, they can navigate the maze of observational data, which sprawls across a spectrum—from remote sensor readings and real-time in-situ observations to laboratory analyses, past records, and intricate patterns across both time and frequency domains.

Adding another layer of dynamism to this collaboration is the interaction between academia and industry. The former often brings theoretical depth and innovative thinking, while the latter adds practicality, understanding market needs, and real-world application. Such collaborations not only bridge the gap between fundamental and applied research but also between the potential of academic discoveries and tangible industrial applications. Our research underscores this point. As evidenced by findings [67], academic patents that transition to the corporate world face more scrutiny. This challenge is a testament to their relevance, indicating a higher probability of capturing innovations with significant market appeal.

Ultimately, fostering human-AI collaboration in battery PHM using AI promises a symbiotic future. It encourages the rapid transition of breakthroughs from research benches to the market, ensuring technologies not only evolve but also remain rooted in practicality and relevance. By bridging gaps between academia, industry, and the vast realm of AI, we chart a path toward more efficient, effective, and innovative battery management solutions.

5.6. Lifelong Learning AI

The capacity of the human brain for concept learning and lifelong learning is nothing short of astounding. Such capabilities enable us to grasp new ideas from minimal instances and to keep refining and building upon our knowledge base throughout our lives. When dissecting the various brain systems, from memory and perception to attention and reward, we find they synergize to create a robust mechanism for concept learning. This mechanism is versatile, adaptable to diverse categorizations, and intertwined with our motivational states [94]. But when it comes to machine learning, mimicking this continual learning prowess remains an elusive goal. Data encountered by artificial systems, especially in the real world, is continually shifting and embedded with temporal links [95]. This evolving landscape presents a challenge when models, inspired by the lifelong learning capabilities of the mammalian brain, confront the issue of catastrophic forgetting. They frequently struggle to integrate new knowledge without overwriting what was previously learned [96].

In the realm of battery PHM, this is where the potential of prediction-driven neural dynamics comes into play. Using this approach, we can usher in a new era of recurrent networks, which evolve and adapt by effectively piecing together input sequences over time. Although conventional machine learning techniques have shown prowess in discerning patterns from geospatial data, their performance can wane when spatial or temporal nuances heavily drive system behavior. The solution? Deep learning techniques tailored to auto-extract spatio-temporal features, thus enhancing our grasp on complex battery system science issues. By leveraging these techniques, we can amplify prediction precision for battery systems, ensuring better seasonal forecasting and modeling spatial ties across diverse time horizons. Such a multi-pronged approach stands to revolutionize the longevity and efficiency of pivotal energy storage systems.

6. Conclusions

Battery systems are defined by complex interactions that span various spatial and temporal scales. These interactions are shaped by numerous factors, including electrode materials, microstructures, binders, environmental conditions, and operational protocols. Collectively, these elements determine the functionality and performance of individual battery cells. Despite improvements in manufacturing processes, variability persists across production batches and among cells, illustrating the intricate nature of these systems. Such variability complicates accurate modeling and forecasting, making these tasks highly challenging. Nevertheless, the continued development of monitoring technologies offers a viable way forward. Optimizing battery safety and diagnosing potential issues hinges on effective monitoring strategies and the extraction of actionable insights. In this realm, AI, particularly when implemented via cloud-based frameworks, becomes indispensable. Integrating empirical data with comprehensive analyses of batteries’ physical and statistical properties, AI significantly enhances the precision and utility of predictive models. As we progress in the field of battery PHM, leveraging a combination of advanced battery analytics and AI provides a potent set of tools. This synergy not only addresses existing management challenges but also proactively anticipates potential problems, ensuring that energy storage systems remain effective and secure throughout their operational lifespan.

Author Contributions

Conceptualization, methodology, and writing—original draft preparation, J.Z.; supervision, project administration, and writing—review and editing, A.F.B.; original draft preparation and investigation, D.L.; formal analysis, resources, and funding, J.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Shenzhen Science and Technology Program, grant number No. 29853M-KCJ-2023-002-13, and Independent Innovation Projects of the Hubei Longzhong Laboratory, grant number 2022ZZ-24.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Energy Technology Perspectives 2023. Available online: https://www.iea.org/reports/energy-technology-perspectives-2023. (accessed on 25 October 2024).

- Burke, A.F.; Zhao, J.; Miller, M.R.; Fulton, L.M. Vehicle Choice Modeling for Emerging Zero-Emission Light-Duty Vehicle Markets in California. Heliyon 2024, 10, e32823. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Burke, A.F.; Miller, M.R.; Fulton, L.M. Vehicle choice modeling for emerging zero-emission medium-and heavy-duty vehicle markets in California. Transp. Res. Interdiscip. Perspect. 2024, 26, 101169. [Google Scholar] [CrossRef]

- Burke, A.F.; Zhao, J.; Fulton, L.M. Projections of the costs of light-duty battery-electric and fuel cell vehicles (2020–2040) and related economic issues. Res. Transp. Econ. 2024, 105, 101440. [Google Scholar] [CrossRef]

- Burke, A.F.; Zhao, J.; Miller, M.R.; Sinha, A.; Fulton, L.M. Projections of the costs of medium-and heavy-duty battery-electric and fuel cell vehicles (2020-2040) and related economic issues. Energy Sustain. Dev. 2023, 77, 101343. [Google Scholar] [CrossRef]

- Zeng, X.; Li, M.; Abd El-Hady, D.; Alshitari, W.; Al-Bogami, A.S.; Lu, J.; Amine, K.J. Commercialization of lithium battery technologies for electric vehicles. Adv. Energy Mater. 2019, 9, 1900161. [Google Scholar] [CrossRef]

- Zhao, J.; Lv, Z.; Li, D.; Feng, X.; Wang, Z.; Wu, Y.; Shi, D.; Fowler, M.; Burke, A.F. Battery Engineering Safety Technologies (BEST): Mechanisms, Modes, Metrics, Modelling and Mitigation. eTransportation 2024, 22, 100364. [Google Scholar] [CrossRef]

- Meng, H.; Li, Y.-F. A review on prognostics and health management (PHM) methods of lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 116, 109405. [Google Scholar] [CrossRef]

- Khaleghi, S.; Hosen, M.S.; Van Mierlo, J.; Berecibar, M. Towards machine-learning driven prognostics and health management of Li-ion batteries: A comprehensive review. Renew. Sustain. Energy Rev. 2024, 192, 114224. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M.J. Battery lifetime prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Pang, Q.; Fowler, M.; Lian, Y.; Ouyang, M.; Burke, A.F. Battery safety: Machine learning-based prognostics. Prog. Energy Combust. Sci. 2024, 102, 101142. [Google Scholar] [CrossRef]

- Finegan, D.P.; Zhu, J.; Feng, X.; Keyser, M.; Ulmefors, M.; Li, W.; Bazant, M.Z.; Cooper, S.J. The application of data-driven methods and physics-based learning for improving battery safety. Joule 2021, 5, 316–329. [Google Scholar] [CrossRef]

- Ng, M.-F.; Zhao, J.; Yan, Q.; Conduit, G.J.; Seh, Z.W.J. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2020, 2, 161–170. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M.J. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Palacín, M.R.; de Guibert, A.J. Why do batteries fail? Science 2016, 351, 1253292. [Google Scholar] [CrossRef] [PubMed]

- Sulzer, V.; Mohtat, P.; Aitio, A.; Lee, S.; Yeh, Y.T.; Steinbacher, F.; Khan, M.U.; Lee, J.W.; Siegel, J.B.; Stefanopoulou, A.G. The challenge and opportunity of battery lifetime prediction from field data. Joule 2021, 5, 1934–1955. [Google Scholar] [CrossRef]

- Zhao, J.; Qu, X.; Wu, Y.; Fowler, M.; Burke, A.F. Artificial intelligence-driven real-world battery diagnostics. Energy AI 2024, 18, 100419. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G.J. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Rusk, N. Deep learning. Nat. Methods 2016, 13, 35. [Google Scholar] [CrossRef]

- Ghahramani, Z.J. Probabilistic machine learning and artificial intelligence. Nature 2015, 521, 452–459. [Google Scholar] [CrossRef]

- Aykol, M.; Herring, P.; Anapolsky, A.J. Machine learning for continuous innovation in battery technologies. Nat. Rev. Mater. 2020, 5, 725–727. [Google Scholar] [CrossRef]

- Soo, Y.Y.; Wang, Y.; Xiang, H.; Chen, Z. Machine learning-based battery pack health prediction using real-world data. Energy 2024, 308, 132856. [Google Scholar] [CrossRef]

- Nozarijouybari, Z.; Fathy, H.K. Machine learning for battery systems applications: Progress, challenges, and opportunities. J. Power Sources 2024, 601, 234272. [Google Scholar] [CrossRef]

- Yang, H.; Hong, J.; Liang, F.; Xu, X. Machine learning-based state of health prediction for battery systems in real-world electric vehicles. J. Energy Storage 2023, 66, 107426. [Google Scholar] [CrossRef]

- Li, W.; Cui, H.; Nemeth, T.; Jansen, J.; Ünlübayir, C.; Wei, Z.; Feng, X.; Han, X.; Ouyang, M.; Dai, H. Cloud-based health-conscious energy management of hybrid battery systems in electric vehicles with deep reinforcement learning. Appl. Energy 2021, 293, 116977. [Google Scholar] [CrossRef]

- Park, S.; Pozzi, A.; Whitmeyer, M.; Perez, H.; Kandel, A.; Kim, G.; Choi, Y.; Joe, W.T.; Raimondo, D.M.; Moura, S. A deep reinforcement learning framework for fast charging of li-ion batteries. IEEE Trans. Transp. Electrif. 2022, 8, 2770–2784. [Google Scholar] [CrossRef]

- Kohtz, S.; Xu, Y.; Zheng, Z.; Wang, P. Physics-informed machine learning model for battery state of health prognostics using partial charging segments. Mech. Syst. Signal Process. 2022, 172, 109002. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Lu, J.; Chen, C.; Shen, W. Battery state-of-charge estimation amid dynamic usage with physics-informed deep learning. Energy Storage Mater. 2022, 50, 718–729. [Google Scholar] [CrossRef]

- Lin, Y.H.; Ruan, S.J.; Chen, Y.X.; Li, Y.F. Physics-informed deep learning for lithium-ion battery diagnostics using electrochemical impedance spectroscopy. Renew. Sustain. Energy Rev. 2023, 188, 113807. [Google Scholar] [CrossRef]

- Shi, J.; Rivera, A.; Wu, D. Battery health management using physics-informed machine learning: Online degradation modeling and remaining useful life prediction. Mech. Syst. Signal Process. 2022, 179, 109347. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z. Specialized convolutional transformer networks for estimating battery health via transfer learning. Energy Storage Mater. 2024, 71, 103668. [Google Scholar] [CrossRef]

- Lv, Z.; Zhao, J. Resource-Efficient Artificial Intelligence for Battery Capacity Estimation using Convolutional FlashAttention Fusion Networks. eTransportation 2024, 23, 100383. [Google Scholar] [CrossRef]

- Zhao, J.; Han, X.; Wu, Y.; Wang, Z.; Burke, A.F. Opportunities and Challenges in Transformer Neural Networks for Battery State Estimation: Charge, Health, Lifetime, and Safety. J. Energy Chem. 2024, 102, 463–496. [Google Scholar] [CrossRef]

- Deng, Z.; Lin, X.; Cai, J.; Hu, X. Battery health estimation with degradation pattern recognition and transfer learning. J. Power Sources 2022, 525, 231027. [Google Scholar] [CrossRef]

- Shen, S.; Sadoughi, M.; Li, M.; Wang, Z.; Hu, C. Deep convolutional neural networks with ensemble learning and transfer learning for capacity estimation of lithium-ion batteries. Appl. Energy 2020, 260, 114296. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.-H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 2020, 578, 397–402. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Shi, D.; Zhao, J.; Chu, Z.; Guo, D.; Eze, C.; Qu, X.; Lian, Y.; Burke, A.F. Battery health diagnostics: Bridging the gap between academia and industry. eTransportation 2023, 19, 100309. [Google Scholar] [CrossRef]

- Berecibar, M. Accurate predictions of lithium-ion battery life. Nature 2019, 568, 325–326. [Google Scholar] [CrossRef] [PubMed]

- Drake, N. Cloud computing beckons scientists. Nature 2014, 509, 543–544. [Google Scholar] [CrossRef] [PubMed]

- Perkel, J.M. The Internet of Things comes to the lab. Nature 2017, 542, 125–126. [Google Scholar] [CrossRef]

- Lu, J.; Xiong, R.; Tian, J.; Wang, C.; Hsu, C.W.; Tsou, N.T.; Li, J. Battery degradation prediction against uncertain future conditions with recurrent neural network enabled deep learning. Energy Storage Mater. 2022, 50, 139–151. [Google Scholar] [CrossRef]

- Liu, Y.; He, Y.; Bian, H.; Guo, W.; Zhang, X. A review of lithium-ion battery state of charge estimation based on deep learning: Directions for improvement and future trends. J. Energy Storage 2022, 52, 104664. [Google Scholar] [CrossRef]

- Su, S.; Li, W.; Mou, J.; Garg, A.; Gao, L.; Liu, J. A hybrid battery equivalent circuit model, deep learning, and transfer learning for battery state monitoring. IEEE Trans. Transp. Electrif. 2022, 9, 1113–1127. [Google Scholar] [CrossRef]

- Tian, J.; Chen, C.; Shen, W.; Sun, F.; Xiong, R. Deep learning framework for lithium-ion battery state of charge estimation: Recent advances and future perspectives. Energy Storage Mater. 2023, 61, 102883. [Google Scholar] [CrossRef]

- Naseri, F.; Kazemi, Z.; Larsen, P.G.; Arefi, M.M.; Schaltz, E. Cyber-physical cloud battery management systems: Review of security aspects. Batteries 2023, 9, 382. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, M. Cloud-based in-situ battery life prediction and classification using machine learning. Energy Storage Mater. 2023, 57, 346–359. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, L.; Zhang, Z.; Yu, H.; Wang, W.; Ouyang, M.; Liu, X. Battery state of health estimate strategies: From data analysis to end-cloud collaborative framework. Batteries 2023, 9, 351. [Google Scholar] [CrossRef]

- Davoudkhani, I.F.; Dejamkhooy, A.; Nowdeh, S.A. A novel cloud-based framework for optimal design of stand-alone hybrid renewable energy system considering uncertainty and battery aging. Appl. Energy 2023, 344, 121257. [Google Scholar] [CrossRef]

- DevOps Solutions. Available online: https://www.ibm.com/devops?utm_content=SRCWW&p1=Search&p4=43700074528918092&p5=e&gclid=CjwKCAjw29ymBhAKEiwAHJbJ8lGPcCxihE4G_URwY4yXnTayc0Qm0WUD80pUWfN_XHLhXDNFKldVoBoCuFIQAvD_BwE&gclsrc=aw.ds (accessed on 25 October 2024).

- Diaz-De-Arcaya, J.; Torre-Bastida, A.I.; Zárate, G.; Miñón, R.; Almeida, A. A joint study of the challenges, opportunities, and roadmap of MLOps and AIOps: A systematic survey. ACM Comput. Surv. 2023, 56, 1–30. [Google Scholar] [CrossRef]

- Notaro, P.; Cardoso, J.; Gerndt, M. A survey of AIOps methods for failure management. ACM Trans. Intell. Syst. Technol. (TIST) 2021, 12, 1–45. [Google Scholar] [CrossRef]

- Cheng, Q.; Sahoo, D.; Saha, A.; Yang, W.; Liu, C.; Woo, G.; Hoi, S.C. AI for IT operations (AIOps) on cloud platforms: Reviews, opportunities and challenges. arXiv 2023, arXiv:2304.04661. [Google Scholar]

- Li, Y.; Jiang, Z.M.; Li, H.; Hassan, A.E.; He, C.; Huang, R.; Chen, P. Predicting node failures in an ultra-large-scale cloud computing platform: An AIOps solution. ACM Trans. Softw. Eng. Methodol. (TOSEM) 2020, 29, 1–24. [Google Scholar] [CrossRef]

- Market Guide for AIOps Platforms. Available online: https://www.gartner.com/en/documents/4000217 (accessed on 25 October 2024).

- Dang, Y.; Lin, Q.; Huang, P. Aiops: Real-world challenges and research innovations. In Proceedings of the 2019 IEEE/ACM 41st International Conference on Software Engineering: Companion Proceedings (ICSE-Companion), Montreal, QC, Canada, 25–31 May 2019; IEEE: New York, NY, USA, 2019; pp. 4–5. [Google Scholar]

- Lee, K.-J.; Smith, K.; Kim, G.-H. Three-Dimensional Thermal-Electrochemical Coupled Model for Spirally Wound Large-Format Lithium-Ion Batteries (Presentation). In Proceedings of the Space Power Workshop, Los Angeles, CA, USA, 18 April 2011; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2011. [Google Scholar]

- Ariga, K.; Li, J.; Fei, J.; Ji, Q.; Hill, J.P. Nanoarchitectonics for dynamic functional materials from atomic-/molecular-level manipulation to macroscopic action. Adv. Mater. 2016, 28, 1251–1286. [Google Scholar] [CrossRef]

- Smith, R.B.; Bazant, M.Z. Multiphase porous electrode theory. J. Electrochem. Soc. 2017, 164, E3291. [Google Scholar] [CrossRef]

- Roman, D.; Saxena, S.; Robu, V.; Pecht, M.; Flynn, D. Machine learning pipeline for battery state-of-health estimation. Nat. Mach. Intell. 2021, 3, 447–456. [Google Scholar] [CrossRef]

- Ma, G.; Xu, S.; Jiang, B.; Cheng, C.; Yang, X.; Shen, Y.; Yang, T.; Huang, Y.; Ding, H.; Yuan, Y.; et al. Real-time personalized health status prediction of lithium-ion batteries using deep transfer learning. Energy Environ. Sci. 2022, 15, 4083–4094. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W.; Lu, J.; Yang, X.-G. Deep neural network battery charging curve prediction using 30 points collected in 10 min. Joule 2021, 5, 1521–1534. [Google Scholar] [CrossRef]

- Zhao, J.; Qu, X.; Han, X.; Wu, Y.; Burke, A.F. Cross-material battery capacity estimation using hybrid-model fusion transfer learning. J. Power Sources 2025, 625, 235674. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Wu, Y.; Burke, A.F. Predictive pretrained transformer (PPT) for real-time battery health diagnostics. Appl. Energy 2025, 377, 124746. [Google Scholar] [CrossRef]

- Yu, Q.; Nie, Y.; Guo, S.; Li, J.; Zhang, C. Machine learning enables rapid state of health estimation of each cell within battery pack. Appl. Energy 2024, 375, 124165. [Google Scholar] [CrossRef]

- Hu, X.; Che, Y.; Lin, X.; Deng, Z. Health prognosis for electric vehicle battery packs: A data-driven approach. IEEE/ASME Trans. Mechatron. 2020, 25, 2622–2632. [Google Scholar] [CrossRef]

- Zhao, J.; Ling, H.; Liu, J.; Wang, J.; Burke, A.F.; Lian, Y. Machine learning for predicting battery capacity for electric vehicles. eTransportation 2023, 15, 100214. [Google Scholar] [CrossRef]

- Goldsworthy, M.; Moore, T.; Peristy, M.; Grimeland, M. Cloud-based model-predictive-control of a battery storage system at a commercial site. Appl. Energy 2022, 327, 120038. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Marcicki, J.; Masias, A.; Miller, T. Safety modelling and testing of lithium-ion batteries in electrified vehicles. Nat. Energy 2018, 3, 261–266. [Google Scholar] [CrossRef]

- Louli, A.; Ellis, L.; Dahn, J. Operando pressure measurements reveal solid electrolyte interphase growth to rank Li-ion cell performance. Joule 2019, 3, 745–761. [Google Scholar] [CrossRef]

- Lin, X.; Khosravinia, K.; Hu, X.; Li, J.; Lu, W. Lithium plating mechanism, detection, and mitigation in lithium-ion batteries. Prog. Energy Combust. Sci. 2021, 87, 100953. [Google Scholar] [CrossRef]

- Ford, H.O.; Doyle, E.S.; He, P.; Boggess, W.C.; Oliver, A.G.; Wu, T.; Sterbinsky, G.E.; Schaefer, J.L. Self-discharge of magnesium–sulfur batteries leads to active material loss and poor shelf life. Energy Environ. Sci. 2021, 14, 890–899. [Google Scholar] [CrossRef]

- Zhu, J.; Darma, M.S.D.; Knapp, M.; Sørensen, D.R.; Heere, M.; Fang, Q.; Wang, X.; Dai, H.; Mereacre, L.; Senyshyn, A. Investigation of lithium-ion battery degradation mechanisms by combining differential voltage analysis and alternating current impedance. J. Power Sources 2020, 448, 227575. [Google Scholar] [CrossRef]

- Bibin, C.; Vijayaram, M.; Suriya, V.; Ganesh, R.S.; Soundarraj, S. A review on thermal issues in Li-ion battery and recent advancements in battery thermal management system. Mater. Today Proc. 2020, 33, 116–128. [Google Scholar] [CrossRef]

- Li, W.; Zhu, J.; Xia, Y.; Gorji, M.B.; Wierzbicki, T. Data-driven safety envelope of lithium-ion batteries for electric vehicles. Joule 2019, 3, 2703–2715. [Google Scholar] [CrossRef]

- Xiong, R.; Yang, R.; Chen, Z.; Shen, W.; Sun, F. Online fault diagnosis of external short circuit for lithium-ion battery pack. IEEE Trans. Ind. Electron. 2019, 67, 1081–1091. [Google Scholar] [CrossRef]

- Liu, J.; Duan, Q.; Ma, M.; Zhao, C.; Sun, J.; Wang, Q. Aging mechanisms and thermal stability of aged commercial 18650 lithium ion battery induced by slight overcharging cycling. J. Power Sources 2020, 445, 227263. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, P.; Wang, S.; Zhu, Y. Effects of over-discharging cycling on battery degradation at low temperatures. Energy 2004, 30, 2965. [Google Scholar]

- Li, H.; Zhang, Z.; Li, T.; Si, X. A review on physics-informed data-driven remaining useful life prediction: Challenges and opportunities. Mech. Syst. Signal Process. 2024, 209, 111120. [Google Scholar] [CrossRef]

- Tang, A.; Huang, Y.; Xu, Y.; Hu, Y.; Yan, F.; Tan, Y.; Jin, X.; Yu, Q. Data-physics-driven estimation of battery state of charge and capacity. Energy 2024, 294, 130776. [Google Scholar] [CrossRef]

- Voyant, C.; Notton, G.; Duchaud, J.L.; Gutiérrez LA, G.; Bright, J.M.; Yang, D. Benchmarks for solar radiation time series forecasting. Renew. Energy 2022, 191, 747–762. [Google Scholar] [CrossRef]

- Gonzalez, I.; Calderón, A.J.; Folgado, F.J. IoT real time system for monitoring lithium-ion battery long-term operation in microgrids. J. Energy Storage 2022, 51, 104596. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.F. Prognostics and health management of Lithium-ion battery using deep learning methods: A review. Renew. Sustain. Energy Rev. 2022, 161, 112282. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Liu, S.; Wu, C.; Huang, J.; Zhang, Y.; Ye, M.; Huang, Y. Blockchain-based interpretable electric vehicle battery life prediction in IoV. IEEE Internet Things J. 2024, 11, 1361–1373. [Google Scholar] [CrossRef]

- Kim, T.; Ochoa, J.; Faika, T.; Mantooth, H.A.; Di, J.; Li, Q.; Lee, Y. An overview of cyber-physical security of battery management systems and adoption of blockchain technology. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 10, 1270–1281. [Google Scholar] [CrossRef]

- Masood, A.; Hashmi, A.; Masood, A.; Hashmi, A. AIOps: Predictive analytics & machine learning in operations. In Cognitive Computing Recipes: Artificial Intelligence Solutions Using Microsoft Cognitive Services and TensorFlow; Apress: Berkeley, CA, USA, 2019; pp. 359–382. [Google Scholar]

- Karniadakis, G.E.; Kevrekidis, I.G.; Lu, L.; Perdikaris, P.; Wang, S.; Yang, L. Physics-informed machine learning. Nat. Rev. Phys. 2021, 3, 422–440. [Google Scholar] [CrossRef]

- Clark, S.; Bleken, F.L.; Stier, S.; Flores, E.; Andersen, C.W.; Marcinek, M.; Friis, J. Toward a unified description of battery data. Adv. Energy Mater. 2022, 12, 2102702. [Google Scholar] [CrossRef]

- Gunning, D.; Stefik, M.; Choi, J.; Miller, T.; Stumpf, S.; Yang, G.-Z. XAI—Explainable artificial intelligence. Sci. Robot. 2019, 4, eaay7120. [Google Scholar] [CrossRef] [PubMed]

- Rudin, C. Stop explaining black box machine learning models for high stakes decisions and use interpretable models instead. Nat. Mach. Intell. 2019, 1, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Gibney, E. European labs set sights on continent-wide computing cloud. Nature 2015, 523, 136–137. [Google Scholar] [CrossRef] [PubMed]

- Tao, F.; Qi, Q. Make more digital twins. Nature 2019, 573, 490–491. [Google Scholar] [CrossRef] [PubMed]

- Lake, B.M.; Salakhutdinov, R.; Tenenbaum, J.B. Human-level concept learning through probabilistic program induction. Science 2015, 350, 1332–1338. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Huang, T.; Wu, C.; Zhang, R.-X.; Sun, L. Adversarial feature alignment: Avoid catastrophic forgetting in incremental task lifelong learning. Neural Comput. 2019, 31, 2266–2291. [Google Scholar] [CrossRef] [PubMed]

- Kudithipudi, D.; Aguilar-Simon, M.; Babb, J.; Bazhenov, M.; Blackiston, D.; Bongard, J.; Brna, A.P.; Chakravarthi Raja, S.; Cheney, N.; Clune, J. Biological underpinnings for lifelong learning machines. Nat. Mach. Intell. 2022, 4, 196–210. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).