1. Introduction

Despite the unprecedented post-second world war growth of cities [

1], little attention has been paid to the issue of sustainability. In Italy, in particular, real-estate developments between the 1950s and the 1980s [

2] were characterized by some local conditions that favored the spread of buildings that are far from being earthquake-resistant, as they usually failed to take into account the geographical, geological and topological features of the territory. Italy is a highly seismic territory. Politicians however, have, for many years, ignored this hazard. The first map that classifies, using a scientific approach, the Italian territory into seismic areas was in fact only produced between 1981 and 1984 (Ministerial Decree March 7, 1981), after the 1976 earthquake in the region of Friuli. Until then, most buildings located in highly seismic areas had been built without taking into account horizontal seismic actions [

3]. Moreover, according to the Italian National Institute of Statistics (ISTAT) 2011 census [

2,

4] more than 60% of the existing buildings predate 1974, which is the year the first specific and extensive Italian code for earthquake-resistant buildings was issued (law 64/1974) [

3]. This means that a large part of the current building stock was realized without anti-seismic restrictions and norms: about 10 million homes are located in the areas most at risk of which 1.4 million homes are located in zone 1 (high seismicity: Peak Ground Acceleration PGA > 0.25) and about 9 million homes in zone 2 (middle seismicity: 0.15 < PGA ≤ 0.25); while 8.5 million homes are in zone 3 (low seismicity: 0.05 < PGA ≤ 0.15) and 9.4 million ones in zone 4 (very low seismicity: ag ≤ PGA) [

5].

Lack of careful planning and the urban speculation allowed Italian real estate developers after the second world war to build poor quality structures in terms of materials, construction details and in terms of architectural image as well [

6,

7,

8]. It is also worth noting that most Italian buildings erected in compliance with the seismic regulations implemented between the 1950s and the 1990s are incompatible with current regulations, which feature much higher standards of anti-seismic efficiency. Hence, as stated by La Greca and Margani, over 50% of the Italian residential constructions are earthquake-prone but we have to highlight that they are also undeniably inadequate in terms of architectural aesthetics and design if compared to the beautiful Italian historic districts (

Figure 1).

Therefore, a policy of renovation is urgent not only to meet the demands for higher standards of anti-seismic and energy efficiency, but globally. Nevertheless, there are a number of limits to a global renovation of the existing building stock: (i) technical limits due to the difficulties and often ineffectiveness of conventional solutions when it comes to renovating existing buildings; (ii) organizational limits related to providing accommodation to the building’s residents during renovation: in fact, the current seismic and energy interventions generally mean relocating people and furniture to temporary accommodation throughout the duration of the work, which may last up to a year or more; (iii) economic limits due to the high costs of renovation. In addition to these limits, one must also take into account the current economic crisis [

2].

Research should, therefore, explore both different solutions to the problems described above and the tools to be used to overcome such limits. Parametric design, the tool proposed and used for this work, makes it possible to overcome various building renovation limits. Indeed, this type of design tool can control many variables at once to obtain a set of solutions among which it is possible to choose the most effective and appropriate ones. This paper also aims to underline that the buildings’ aesthetics and design are critical elements that should be linked to the concept of sustainability, as they affect all aspects of human life and experience. Nature has thus become our criterion in this study because it works taking into consideration all variables at play in the realm of sustainability, and parametric design is a tool that works in ways comparable to natural processes. It is the first time that parametric design has been used to retrofit buildings to better withstand seismic events while to date, literature shows only cases in which parametric design has been adopted for energy efficiency or architectural solutions. However, the main purpose of this paper is to show how this method works considering different variables, such as geometry, weight, materials, energy efficiency and structures. The relationship between sustainability, nature and the pursuit of beauty will be discussed in

Section 2.

Section 3 introduces steel exoskeletons as an optimal combination of shape and structure in nature as well as in architecture.

Section 4 presents our approach to the use of exoskeletons, and, in particular, introduces our prototyping algorithm.

Section 5 shows the creation of exoskeletons.

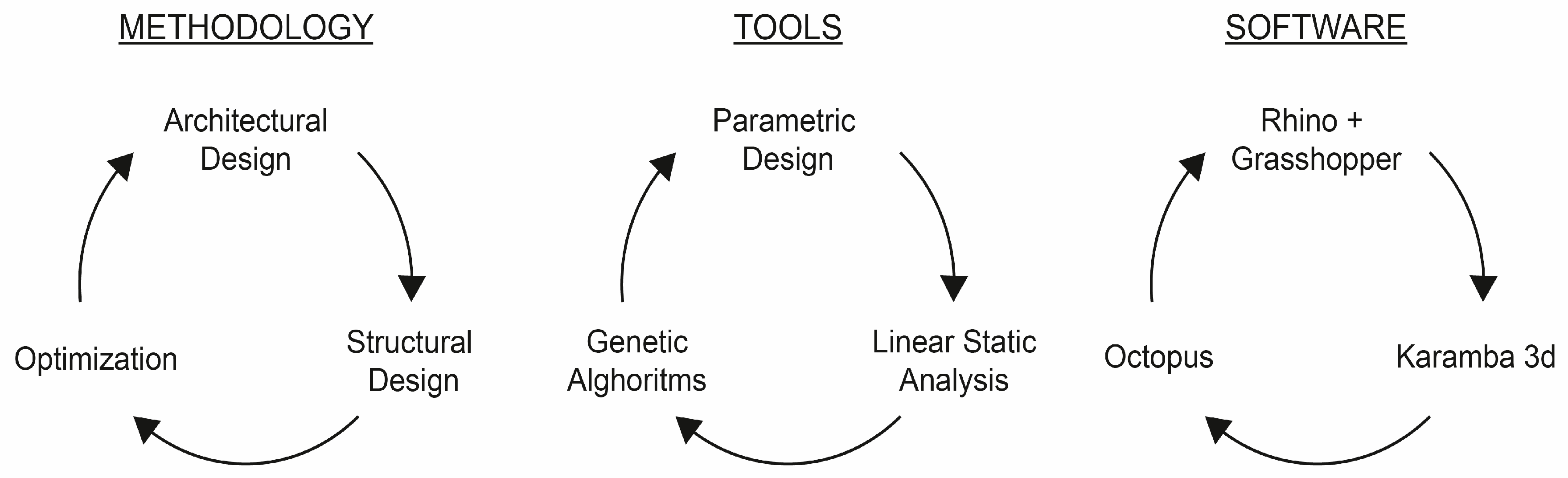

Section 6 illustrates the application of our methodology, tools and software (

Figure 2) to a case study. We chose a typical case study representative of the Italian residential stock. The same case study was analyzed in a previous research project and this work is a development of that research. Unlike the latter, here we focused on architectural shape, both in terms of seismic performance and the relationship with the urban context. Finally,

Section 7 presents our analysis and results.

2. Aesthetics and Nature as a Reference for Parametric Design

To highlight the unsustainability of unaesthetic architecture and its consequences on society, we should be aware of the beneficial effects that beauty can have on human beings, as proposed by Wohlwill [

9]. To do so we draw on the theories of James Hillman, who believes that the quest for beauty and aesthetics may give an answer to many of the problems of contemporary civilization [

10]. The search for sustainability should also be the pursuit of beauty. Sustainability, when working in a holistic way with a building, aims at recreating as much of a harmonious relationship as possible with the environment. Good architecture is always a complex activity that establishes a relationship with the environment. In fact, the more relationships with the environment architecture is capable of establishing, the more sustainable it is. Lack of aesthetics and unsustainability, on the other hand, derive from overlooking the critical relationship with the environment. Moreover, not considering environmental issues means neglecting the local seismicity and climate, ignoring the integration of cultural traditions, overlooking the local economy and its anthropological specifications as well as the sense of the living experience in one’s own context. Sustainability, like beauty [

11,

12,

13], depends on the level of complexity that can be achieved through design and it can be seen as the result of a truly holistic approach. Using the concept of sustainability as a measure of beauty does not presuppose a change of paradigm of aesthetics [

14,

15] but it is an important element of good design. Since design is an intrinsically complex and multidimensional activity, the designer normally tends to reduce complexity in smaller chunks that can be more easily managed. Through parametric design, that tends to imitate the generative algorithms of nature, it is possible to consider the multiple dimensions of design. The goal is to enhance the designing process and optimize results, aware that variables such as aesthetic value, given their intrinsic nature, lend themselves to subjective interpretations. However, through the concept of aesthetics as a value of sustainability, even when the results are not optimal because there is no formula that guarantees optimization, we can address the dilemma between performance and shape and between genotype and phenotype in architecture. The parametric architecture thus conceived is of great help in terms of optimization in relation to the technical parameters pertaining to the sustainability of structural stability [

16], energy efficiency, thermal and visual comfort, cost-effectiveness and architectural image.

In our case study and more generally in the context of structural optimization of buildings, we can proceed with three basic types of parametric designs that mimic the modus operandi of nature: the first intervenes on the dimensions of the structural elements, having fixed the shape of the building a priori; the second researches the formal configuration that best resists according to their relative shape; the third intervenes on the arrangement of the structural elements and on the connections between them.

The procedures nature implements, depending on each and every particular situation, develop one or more optimization solutions starting from their genotype. The genotypes nature offers as a reference are manifold. In our case study, exoskeletons seem to be the ones that promise more possibilities for effective solutions.

3. The Exoskeleton: Shape and Structure

The steel exoskeleton, when the characteristics of the building make it possible, is installed outside the building. This is the ideal choice in term of mechanical strength and quantity of materials, which are key features for the construction of new buildings and to retrofit existing ones to improve their anti-seismic performance.

As already stated, among the many limitations highlighted by conventional systems of anti-seismic solutions, emerges the difficulty of enhancing buildings also from an architectural point of view, reducing at the same time the inconveniences residents experience during renovation. For these reasons, the model of the exoskeleton, besides offering a more effective anti-seismic solution is also a support for energy-efficient devices and, we would emphasize, a way redesign the architectural image of the building [

17]. Furthermore, the external installation of an exoskeleton does not imply an interruption of the building’s operation during the construction works, avoiding temporary relocating costs [

18] and other inconveniences caused by large demolition activities, thus contributing to stimulating building owners to retrofit their buildings. As exoskeletons require less major structural intervention and reconstruction activities this is also in accordance with the principles of environmental sustainability and eco-efficiency. In fact, the use of new construction materials and the production of waste are minimized. However, some preliminary requirements are necessary to apply an exoskeleton to an existing building: the presence of free external spaces in front of the buildings’ façades is a mandatory requirement for the installation of exoskeletons and their foundations; moreover, the installation of the exoskeleton must be often preceded by local interventions to reinforce the existing beam-column joints, to which the new steel structure will be connected.

Nevertheless, even by using exoskeletons, if we do not proceed by considering the problem of renovation in a global way and we consider only one aspect, we could only produce structural prostheses that do not regard aesthetics in terms of sustainability (

Figure 3).

Even the example of the exoskeleton used for the seismic retrofit of the Magneti Marelli headquarters in Crevalcore is typical of a non-holistic approach [

19] (

Figure 4).

Here the adopted exoskeleton converts an office construction built in the 1970s into an earthquake-proof edifice, but this new structure does not integrate with the architecture it intends to strengthen and presents itself as a prosthesis that meets only its structural needs [

8]. Moreover, much of the building was demolished and then rebuilt. In fact, engineers spared only the existing reinforced concrete structure and repaired and adapted it to accommodate an external dissipative-type steel frame.

An interesting example in holistic terms is the one by European research project Pro-GET-onE (acronym of

Proactive Sinergy of integrate Efficient Technologies on Buildings’ Envelopes) [

8] (

Figure 5). The set of solutions tested in this case is part of a holistic view of the problem. The holistic vision promoted by Pro-GET-onE is based on the integration of different technologies with the aim of increasing building performance in terms of energy efficiency, seismic safety and social and economic sustainability. In this case too, the objective is to rely on such external envelopes, which not only make the building earthquake-proof, but also support technologies for renewable energy supplies, especially solar and wind energy. As a result, the architectural transformation, delivers, among the others, a renewed and harmonious image of the case study selected for the verification of the theoretical approach discussed here. In this case, the original reinforced concrete structure was not affected by repairs and betterments.

Among the most used exoskeletons, the diagrid system stands out: a two-dimensional structural system, made up of triangular modules capable of resisting both horizontal and vertical loads without the need for additional elements [

20].

From an architectural point of view, the ability of this system to adapt to any three-dimensional shape, even if not straight, offers the possibility to try an infinite number of configurations. On the external structure it is possible to obtain multiple solutions for the façade, from the simplest to the complex technological options available. Moreover, the geometry of the exoskeleton allows for a better management of the relationship between the full and empty spaces of the façade. The choice of materials plays a critical role in the diagrid solution. This choice often falls on steel because of the advantages it offers, but reinforced concrete diagrids are available too. In fact, steel exoskeletons provide the following advantages: high levels of prefabrication and dry assembly standards, which involve shorter construction times and, therefore, less disruption in urban areas; use of recyclable materials; and easy maintenance and replacement in case of seismic damage or breakage. Finally, a diagrid-type structure requires the use of a smaller amount of material, with significant economic advantages despite the initial higher financial costs. The advantages of using an exoskeleton system are relevant in the case of reinforced concrete constructions built after World War II, which have no historical and artistic constraints thus representing a viable solution, as it allows them to operate, as much as possible from the outside, through the application of a three-dimensional external structure that envelops the existing building, structurally linking itself to it as an exoskeleton. On the other hand, the application of exoskeletons on existing structures may have other disadvantages, for example the exoskeleton rods, if not properly designed, could become an obstacle to natural lighting and ventilation.

Among the advantages, using a diagrid system, or an exoskeleton in general, the only elements subject to demolition and reconstruction are the balconies. This could be, however, the input for the implementation of energy retrofit interventions [

8] with the consequent reduction of the thermal bridges, which would be limited only to the structural connections between the building and the exoskeleton. The exoskeleton could be the support for a second envelope which, if properly distanced from the façades of the existing building, can work as ventilated shading walls. The exoskeleton could also provide support for renewable energy production devices, increasingly used as elements for façade composition, as well as vertical gardens that contribute to passive cooling, and solar shadings of any kind for direct radiation control and natural lighting.

Finally, structural advantages are primarily linked to the ability to adapt to the shape of existing structures. The exoskeletons could also be combined with other structural seismic retrofit solutions, but even on their own they can solve the renovation issue. Furthermore, this type of structure ensures a better distribution of loads, thanks to the redundant character provided by the mesh, whose basic modules’ geometry is of fundamental importance.

The size of the modules making up the diagrid is usually calculated by dividing in equal parts the height of the building on which it is applied. The number of modules, and consequently the angle in relation to the horizontal plane of the diagonal elements, has a great influence on the general response of the system, and often represents one of the parameters of structural optimization. The basic form of a diagrid usually has a rhomboidal shape. However, in the composition of exoskeletons with diagrid geometry, triangular meshes are preferred for the various advantages they offer both in terms of design and construction phases. The triangle is in fact a non-deformable figure and this gives the structure an intrinsic stability. The designer can also think of the nodes as hinges, which result in less stress on the rods due to the absence of bending moments. A division into triangles, moreover, returns only flat faces, which are more compatible with a possible coating of the structure.

The theme of the renovation of apartment blocks has been addressed taking into account all of the above with an integrated parametric design approach, which is illustrated below. While some studies on parametric design aimed at energy rehabilitation are present in the scientific literature [

21], the use of this discipline in the field of seismic retrofit has remained unexplored until now.

4. The Prototyping Algorithm

The increasing diffusion of algorithms in design practice has led to the creation of user-friendly tools that can be exploited by all the professional figures involved in this field, regardless of the knowledge of complex programming languages. These tools are, in practice, software designed as graphic editors of algorithms.

The most widespread among the professionals in the field of architecture is Grasshopper [

22], capable of interfacing with the three-dimensional modeling software Rhinoceros, and equipped with a vast community that has led to the development of countless faces to increase power and versatility. Within this software it is possible to build your own script simply by connecting graphic elements (components), which represent the nodes of the parametric diagram and which are characterized by certain inputs and outputs, depending on the function that they perform [

23]. The connections are made through wires, graphically characterized according to the structure of the data transported.

In the present work, the Grasshopper software was used to create a procedural algorithm aimed at computation generation and optimization through genetic algorithms of structural steel exoskeletons. Applied externally to reinforced concrete buildings designed to withstand vertical actions alone, they aim to improve the seismic response of the latter, while at the same time characterizing them from an architectural point of view.

The structural treatment within Grasshopper was carried out thanks to the Karamba3d plug-in [

24], which uses finite element modeling to perform interactive static analyses on two-dimensional or three-dimensional systems, composed of both rods and shells. This plug-in does not present itself as a “full optional” structural calculation program for carrying out detailed engineering analyses but aims to be a support tool for architects and engineers, guiding the design choices from the initial stages of the process.

The procedural algorithm developed is presented as in

Figure 6. This was divided into modules, marked with different colors, each containing the components that perform a specific function. These modules are related to: the geometry of the existing structures (1), the geometry of the exoskeleton (2), the variables of the optimization, i.e., the variations of the exoskeleton geometry, obtained through the optimization process (3), the creation of the finite element model (FEM) (4), structural analysis (5), study of the results and definition of the fitness function for optimization (6), export to SAP2000 (7). The modules concerning the geometry of the exoskeleton and the variables of the optimization represent the “variable” part of the script and therefore are closely linked to the project idea. Their treatment is then referred to in paragraph 6. The remaining modules remain constant and compose the algorithm to develop the shapes of the exoskeleton that have not yet been optimized. Most relevant modules (4, 5, 6) are described in detail in

Figure 7.

First of all, the geometries of the structure are modeled. The inputs to be specified at this stage are the planimetric dimensions, the number of floors, the floor height and the span between columns in both directions. The definition of these parameters allows extending the use of the proposed algorithm to most buildings with reinforced concrete structure. The structure of the existing building (

Figure 8a) is not entirely modeled, but is approximated to a series of vertical lines, placed one on top of the other, in a number equal to that of the levels. Each of these lines represents the axis of a column with equivalent stiffness to that calculated on each storey. At the top of each of these lines lies a surface that represents the floor slab, surrounded by a system of linear elements, later made non-deformable, useful to avoid inconvenient deformation and torsional phenomena. Within this module it is also necessary to obtain the geometries related to the beam-pillar nodes of the existing structure, which represent the points of connection with the new steel exoskeleton.

The outputs of the geometric modeling flow into the module for the creation of the finite element model, visible in relation to the existing structure in

Figure 8b. This section is divided into three groups. The first has the task of converting the geometries into structural elements. In particular, we need linear elements as starting geometries for the creation of beams, of two-dimensional mesh elements for the creation of shells. In this phase, information relating to the materials is included: concrete is assigned to the existing structure, while steel is assigned to the exoskeleton. Here, also the cross sections assigned to the pillars of the existing structure are defined, which are useful to simulate the equivalent stiffness rate provided by the reinforced concrete building and drawn backwards from an FEM built in the SAP2000 environment.

The other two groups of the module in question are aimed at defining the supports, for creating the joints at the base and the carriages (useful to simulate a deformed beam attributable to a “shear-type” frame (

Figure 8c) placed at the top of the pillars with equivalent stiffness, and loads.

Although related to a seismic problem, the evaluations related to the stresses, in this phase, have been dealt with by adopting static simplifications. Despite this, the algorithm was not created to optimize an eternally static condition: the results of this process, in fact, will then be used in a dynamic treatment. The loads involved are, therefore, represented by equivalent seismic actions acting on each individual floor of the structure, obtained through a script created ad hoc, according to the project spectrum and to the fundamental period of the structure. These last two parameters must be inserted as inputs and vary according to the geographical location of the existing building and its structural characteristics.

Once the finite element model is assembled, it is subject to a linear static structural analysis, carried out within Grasshopper thanks to the Karamba3d plug-in. In this step, simultaneously with the structural analysis, a first process of optimization of the cross sections of the structural elements is carried out: on each beam of the exoskeleton, to which the minimum section, chosen in a range of user-defined profiles, is assigned according to a verification of resistance in the elastic field, combined, in the case of elements subjected to compression, on an instability test. Here, the solver is required to draw from a range of commercial tubular profiles with a diameter of approximately 30 cm. If none of the profiles contained in the chosen range are verified, the algorithm returns an error message.

The results of the linear static structural analysis, expressed in terms of nodal displacements and stresses on the rods, flow into the optimization module. The optimization process is carried out using genetic algorithms, that represent a tool that use Darwinian theories of evolution to solve problems related to parametric design [

25]. The optimization is based on a fitness function, built by the user, which returns a numerical value that defines the objectives of the process. In this case, the solver, the Octopus plug-in, starts a solution generation routine obtained by varying the intrinsic parameters of the model, located in the module related to variables definition. Among these solutions, only those that return a better fitness value than the previous ones survive.

The considered algorithm is aimed at minimizing the weight of steel used, keeping the totality of the structural elements of the exoskeleton under verification conditions and maintaining the relative drifts between the levels of the existing reinforced concrete building, below the limits, reduced to take into account the life safeguard limit [

26]. In order to pursue these objectives, the fitness function is obtained by increasing to the actual weight of the exoskeleton steel, of suitably calibrated coefficients, which are different from zero only in cases where there are drift values beyond the limits, or unverified beams. In this way, the configurations in which these conditions occur, tend to be discarded by the solver (the Octopus plug-in in this case), due to the higher fitness value that characterizes them.

The last of the modules that make up the algorithm is related to the export of the FEM model from Grasshopper to SAP2000, for the development of detailed dynamic analyses. For this operation to be possible, the GeometryGym plug-in [

27] is used. The dialogue between the software handled in this work, exploits the API interface integrated in SAP2000 [

28], able to provide complete and efficient access to all the tools of the structural software, allowing a bidirectional transfer of the models and control on the execution of the analysis and on the management of the data. A dialogue of this type between the software allows one to bypass the conventional user interface once again, and to speed up the export and import phases, especially in case of repeated modifications to the model.

5. The Creation of Structural Exoskeletons

Summing up, once you have modeled the geometry related to the structure equivalent to the existing building, you can move on to create the elements related to the exoskeleton and to the definition of the optimization variables. These are nothing but the possible morphological transformations that the model can undergo during the search for the solution capable of using the lowest amount of steel. It should, therefore, be noted that the geometry of the exoskeleton modeled in this phase does not yet represent the final shape of the latter, but a starting configuration that will be manipulated automatically during the optimization phase.

Together with the vectors inherent to the equivalent seismic actions, the totality of the geometries represents one of the inputs for the assembly of the finite element model, on which a linear static analysis is then carried out. The results of this become the parameters that make up the fitness function, built by the user to define the objectives of the process. In order to achieve a fitness value congruent with the objective, the solver will make changes to the geometry of the exoskeleton (allowed by the user via the upstream imposition of the variables), and then re-analyze the variant created. In this way a routine is generated will end only when the numerical value of the fitness function is suitable to the objectives of the optimization. The process of generating structural exoskeletons is summarized in

Figure 9.

It should be noted that the algorithm developed during the present work is not aimed at the seismic improvement of a specific building but, due to the parametric character that distinguishes it, its use can be extended to any existing multi-storey building with a framed structure in reinforced concrete. By varying the size of the sections assigned to the pillars that simulate the existing structure, it is possible to manage the stiffness equivalent to the real one, while the number and shape of the slabs, and the positioning of the beam-pillar nodes, can be adapted to the building by modifying the geometric values that represent the input for their creation. Likewise, the forces applied in assembling the FEM vary depending on the geographic location of the building and its natural oscillation period.

6. Application to a Case Study

As a case study, we adopted a prototype building consisting in an apartment block, already analyzed in a previous research project (

Figure 10) [

26,

29].

The structure of this prototype building has no real evidence but is obtained from a process called “simulated design”, based on the regulations in force before the introduction of the seismic and energy-efficiency legislation, on the construction uses of the time, and on the architectural peculiarities that distinguished the building boom between 1950 and 1980. This prototype is representative of a large share (almost 20%) [

6] of the existing residential stock in the city of Catania, located in the eastern coast of Sicily and classified as seismic-prone in 1981. From a morphological point of view this building type is characterized by medium height, between 5 and 12 floors, elongated rectangular plant, central stairs and strong regularity both in plan and in elevation. The structure, characterized by resistant elements placed in only one direction and frames symmetrically arranged, is able to withstand only vertical loads. To aggravate its behavior under horizontal loads there is the lack of masonry infill on the ground floor, which may cause a soft story collapse [

26,

29].

More in detail the considered case study is characterized by a reinforced concrete frame. It has 10 residential floors, and a commercial ground floor. The building is 35 m high and has a rectangular plan (31.80 × 13.80 m), symmetrical along the transversal axis. On each floor there are three apartments, each of which has an area of approximately 140 m2. The two external apartments are perfectly mirrored, with the central one interposed between them. Most windows are on the long sides and only two small windows per floor are on the short fronts.

The elevations reflect the symmetry of the plan, and are characterized by a strong repetitiveness in height, due to the identical configuration of the spaces between the various levels.

On each floor there are balconies, placed symmetrically along the two axes. Each apartment therefore has a portion of its balcony and can enjoy an outdoor space.

Using a prototype building as case study is beneficial to perform structural analysis. Results, considerations and possible retrofit solutions may be replicated, in fact, on most apartment blocks having the same structural and constructive characteristics. However, to set up relations with the specific urban landscape and seismic area, it was decided to place the case study inside the so-called “sea zone” of Catania, a prestigious neighborhood built between the 1960s and the 1970s, during the economic and construction boom. The building stock of this area was largely realized before the enforcement of regulations for energy-efficient and seismic-resistant buildings, and the construction practice strongly clashes with the “rules of art”, which up to some decades before, even in the absence of a theoretical awareness, allowed buildings to be respectful of the environment and often resistant to the earthquakes [

30].

The selection of the site took place considering the characteristics of the lot in which it is placed as the primary criterion. In particular, in view of the construction of an external structure, we need a free space, on all fronts, to be used for laying foundation works. The choice fell on a large green area near the urban waterfront (

Figure 11).

The advantages of the parametric approach to design include the possibility of easily creating multiple versions of the same project. Borrowing the term versioning from the jargon of software development, this indicates the opportunity offered by the management of files that are no longer static, but capable of evolving and generating variations when new forces and conditions come into play.

Two project ideas are proposed, each of which, due to the intrinsic nature of the parametric approach of generating multiple versions of the same concept, will return more than one final form in varying the parameters within the model and the definition of structural optimization. In a design of this type the design idea does not translate directly into the final shape of the exoskeleton, but in a starting geometric shape and in a series of variables that represent “what will happen to the model” during the optimization process.

The first project idea stems from the desire to clash, in order to cancel them, with the symmetry and regularity that characterize the considered building. Therefore, this leads to the creation of a strongly irregular structure-envelope, which, like a beneficial parasite, enters into symbiosis with the original structure, attacking it only where necessary and allowing the emergence of glimpses, through which to continue observing the existing building.

The first step is the one related to the creation of the starting form of the exoskeleton, which, once subjected to an optimization process according to rules imposed upstream, will return the final geometry of the structure. The starting structure is represented by a diagrid, of regular shape, that wraps the building parallel to its façades. The basic module of this structure, quadrangular with height equal to the floor (3.3m), is divided into four triangles deriving from the connection of the opposite nodes. The division into triangular modules enables the creation of a structure whose nodes are of the hinge type. Although more difficult to achieve in practice, these allow us to reduce the stresses on the rods to only axial stress, eliminating the bending momentum rates. In order to obtain a perfect closure of the mesh, at the corners of the building, the reticular system has been moved away from the façades of a distance equal to half the light of the span (2.25m). This is also convenient to avoid a “cage” effect, which risks generating feelings of oppression in the inhabitants of the building itself.

The starting diagrid system is modeled from four surfaces, each of which is parallel to a façade and divided into rectangular sub-areas measuring 3.3 × 2.25 m. Each of these has been divided into the four triangular surfaces whose sides represent the linear elements to be converted into rods (

Figure 12).

As for the optimization variables, the model just described is allowed to “curl up” thanks to the movement, with respect to the initial position, in the range from one meter to the outside, one meter inwards, orthogonally at the respective façade, of the diagrid nodes. This transformation granted to the model is aimed at finding a configuration that returns the best resistance, exploiting the shape, to seismic actions. The movement of the nodes is accompanied by a process of removing the rods that do not contribute to the response to horizontal loads, in order to pursue the objective of minimizing the steel used. The strategy adopted for the removal of the rods is as follows: thinking of the building as a box inside which they have freedom to move points, in a number chosen by the user. Each of these represents the center of a sphere (

Figure 13) capable of removing the triangular modules of which it incorporates the barycenters. The position of the spheres and their radius, as well as the value relative to the displacement of the nodes, fall within the optimization variables, and are therefore parameters that are automatically controlled by the solver of genetic algorithms, and in any case set manually by the ’user. The module for the geometric modeling of the exoskeleton also generates, automatically, and depending on the portions of the exoskeleton that are not removed, the connecting elements between the nodes of the new structure and those of the existing one. It was decided to operate with 20 spheres, each with a variable radius of 1 to 5 m.

The second project idea involves the creation of an exoskeleton which, while remaining regular in shape, aims at eliminating the symmetry that characterizes the existing building. While in the previously described solution, the solver of genetic algorithms is called to carry out a rod removal process, this time it aims to implement an additive strategy. The optimization, in fact, involves the insertion of structural elements in the areas of the exoskeleton that require greater rigidity.

Even in the case of the second design idea, the starting structure is a diagrid system, this time with quadrangular base module (

Figure 14) and therefore formed by rods stuck to the ends. Also in this case, the structure is moved, on each front, at a distance equal to half of the light of the span (2.25 m) to allow for an optimal closure of the angular modules. Similarly to the first design idea, the geometric modeling involves the creation of four surfaces parallel to the façades, each of which is divided into rhomboid portions of height equal to the storey height (3.3 m) and width equal to the light of the span (4.5 m). The sides of these diamonds represent the linear elements to be converted into rods in the phase of creating the finite element model.

The only transformation granted to the shape of this model consists in the possibility of each single rhomboidal module, to subdivide, in the optimization phase, into an additional four or 16 sub-modules, in order to obtain an increase in stiffness in the exoskeleton areas, under more stress caused by horizontal actions. Also in this case, the number of subdivisions represents one of the parameters of the optimization, and is automatically modified by the solver of genetic algorithms. As in the development of the first design idea, the portion of the algorithm relating to the modeling allows for the automatic generation of the connecting elements between the exoskeleton and the existing structure in reinforced concrete.

7. Analysis and Results

The results are now illustrated and compared, in numerical and geometrical terms, returned by the optimization processes carried out. As already mentioned above, the configuration of the exoskeleton obtained is not unique. The approach used, in fact, provides the possibility to choose among several variants, deriving from the modification of the model parameters and the objectives defined in the fitness function.

In the present work, the first distinction is feasible since two different design ideas are taken into consideration. For both, an optimization process was carried out aimed at minimizing the weight of steel used and maintaining relative drift below the limits reported in

Table 1. These are calculated by considering two thirds of the last minimum rotation of each storey of the concrete structure to obtain the value at the life-saving limit state.

It was also required to verify all the rods by following the assignment of a cross-section included in a pre-established range. The solution obtained by imposing these conditions on the first design idea (variant 1), shown in

Figure 15a, is not satisfactory since the removal of the rods is minimal. This is maybe caused by an incorrect interpretation of the problem by the genetic algorithm solver, and returns a design variant that is capable of maintaining the relative displacements below the limits. The result is a naked structural cage without any relationship with the context. In fact, the cage is neutral with respect to the surrounding environment: an indifferent isotropic metal structure that does not favor any relation. The minimization of steel weight resulting from this optimization process is also minimal, and for this reason this solution cannot be considered optimal. For this reason, this solution was compared with an equivalent that provided for a modification of the fitness function. Therefore, it is necessary for the optimization to point to the minimization, not more than the weight, but of the number of rods used. The exoskeleton obtained (variant 2), visible in

Figure 15b, despite keeping the displacements below the imposed limits, most likely presents problems related to the earthquake response and it is therefore not adequate from a structural point of view. The elimination of rods in the angular zones of the building induces, in fact, an accentuation of the torsional response of the building-exoskeleton complex subjected to the earthquake. In order to avoid excessive irregular configurations, the movement of the 20 spheres capable of removing the diagrid modules has been limited. First extended to the whole building, it now takes place exclusively in the central area, ensuring the integrity of the angular zones of the exoskeleton. This solution (variant 3) is illustrated in

Figure 15c. This optimization process led, in this case, to a considerable reduction of the weight of steel compared to the initial configuration, while maintaining relative displacements below the limits and a regular configuration in the corner areas of the building. Variant 3 is therefore characterized by a good balance between structural behavior and use of materials. It is interesting to analyze the solution (variant 4) obtained without imposing symmetry (

Figure 15d), considering limit displacement values, greater than previous solutions. Given the fewer restrictions, the solver is given more freedom in removing the rods. This variant is purely aimed at experimentation and, given the exceeding of the values allowed in terms of displacements, certainly does not return an adequate structural behavior.

Numerical data about each variant, in terms of steel weight, rods number and relative displacements, are compared in

Table 2.

Two distinct optimizations were carried out also for the option with embedded quadrangular modules, with the objective of minimizing the weight (variant 5) and the number of rods (variant 6). Because of the initial configuration, the resulting geometries, shown in

Figure 15e,f, do not present substantial differences in terms of the overall image of the system, and they both harmoniously relate to the existing building. In contrast to the previous design idea, in this case the definition of the fitness function that aims at minimizing the weight, shows better results.

Among all the obtained variants, numbers 3 and 5 are considered the best because of their structural responses in terms of displacements, obtained using a limited number of structural elements and a lower weight of steel compared to the other solutions.

The models of these variants were then exported within the SAP2000 finite element software to perform dynamic structural analyses of the existing building-exoskeleton assembly, confronting them with the bare building model. It should be noted that all data relating to materials, cross-sections of structural elements, nodal constraints and degrees of freedom of the rods are transferred automatically using the GeometryGym plug-in. In the SAP2000 environment we proceed exclusively to the introduction of the inputs for modal analysis and linear dynamic analysis.

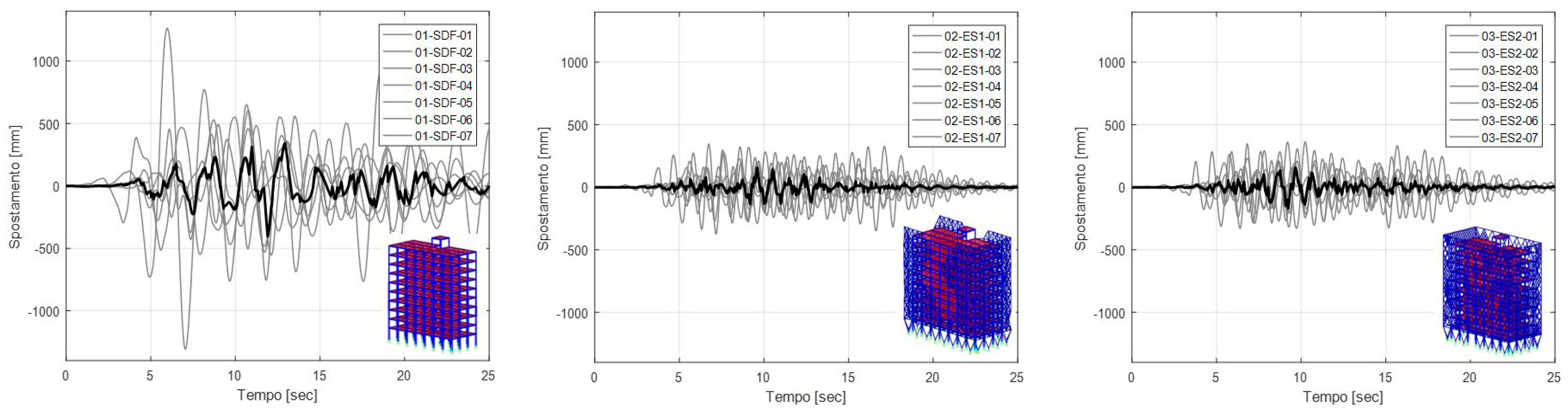

The two variants, topologically different, but deriving from the same optimization process, respond in a similar way to the dynamic loads. From the modal analysis, a substantial increase in stiffness is denoted, as expected, which causes a reduction of the fundamental periods of oscillation (

Figure 16). At the same time, from the examination of the results of the linear dynamic analyses, what emerged was that neither of the two geometric solutions obtained from the exoskeleton is able to maintain the displacements of the existing building within the fixed limits, even if, analyzing the overlap of the displacements over time, of the same point, for all the seven accelerograms chosen [

26], a notable reduction of the maximum mean value can be seen. From the 400mm of the actual state, it goes to about 160mm in the project states (

Figure 17). Although these are to be considered rough results, as deduced from a linear analysis applied to a problem that, with reference to the existing structure, is markedly non-linear, the results obtained glimpses of a positive response of the generated system.

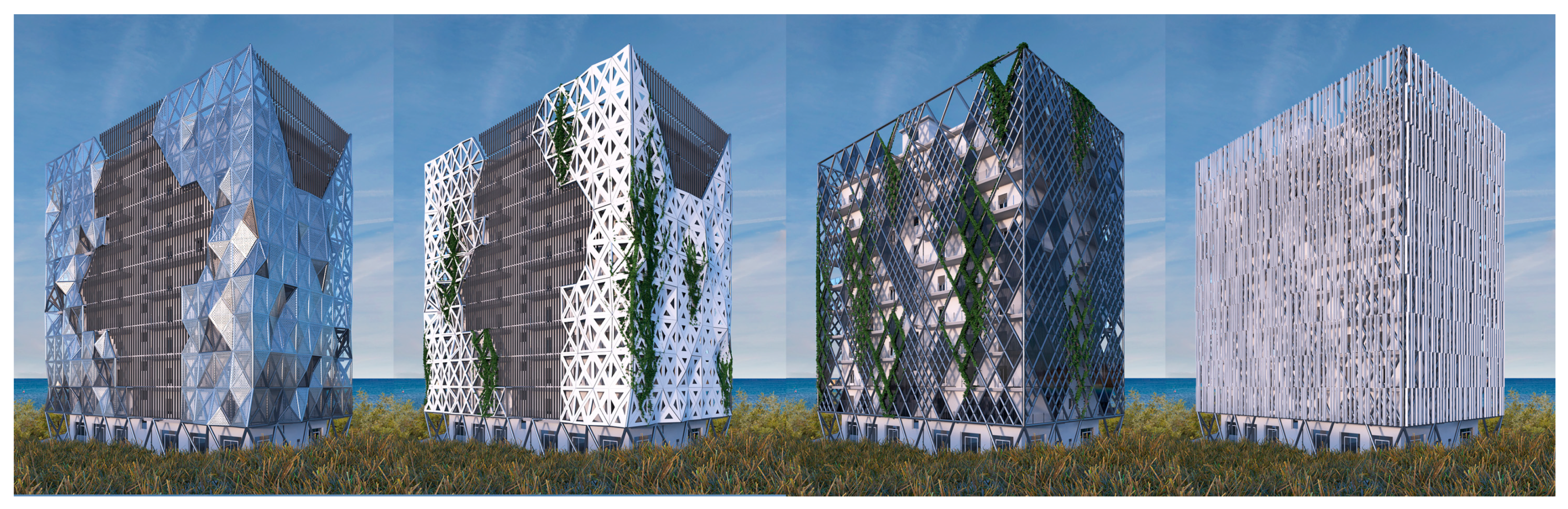

Among these are renderings (

Figure 18) that show how further variations can be obtained by completing the exoskeleton with non-structural elements, such as shielding and panels of all kinds, vegetation and solar modules.

8. Conclusions

The urgency of improving the existing building stock in terms of seismic vulnerability offered us the opportunity to reflect both on the structural aspects and on the architectural image. Thus, the present work has tried to highlight the need to consider aesthetic issue as an important—albeit often neglected—dimension of the search for sustainability. Even if the concept of beauty is hard to tackle, almost impossible to objectify and impossible to be fully reached, it can be considered as a research horizon. And the issue of sustainability offers the opportunity to approach aesthetic research: an opportunity that should be seized since beauty affects all aspects of human life and experience.

The proposed solutions are just proof of the concept of a holistic renovation strategy. In fact, these do not represent the best solutions from an aesthetic point of view. They just demonstrate how, with parametric design, it is possible to produce many complex solutions easily and to choose that which better interprets the aesthetic canons selected by the designer.

In more detail, we have proposed the use of exoskeletons for the seismic retrofit of apartment blocks with reinforced concrete frames. Since the exoskeleton is applied from the outside, it has the advantage of not interfering with the regular operation of the building during the renovation works.

The adopted parametric approach allowed us to consider many variables (geometry and shape, weight, materials, structural elements, forces), leading to a set of solutions that contemplate a multiplicity of aspects of sustainable renovation. In fact, since the early architectural design stages, the creative process has integrated both form and structural functions, as well as information relating on materials and stress response.

This approach is a single tool that offers the possibility to generate multiple retrofitting alternatives based on variables drawn from multiple disciplines, opening the door to a great variety of integrated solutions. In the case presented, we verified the adaptability potential of different types of exoskeleton, which change their shape according to the variability of the external conditions: as occurs in the evolutionary process, reproduction and mutation operate on the genotype, while competition and selection occur at the level of the phenotype. In fact, the use of exoskeleton genotype in this work starts from the simple structural cage to achieve an elaborate structural texture on the façade: an exoskeleton with asymmetrical balance between empty and full spaces. Furthermore, the structure opens (with empty spaces) towards the most interesting landscape points of view and closes (with full ones) to protect itself from unfavorable climatic conditions. In this way we try to establish further relations with the environment.

Such a tool has taken the form of a genetic algorithm, within the Grasshopper graphic editor, aimed at generating and optimizing the form of the steel frames, based on their structural response to equivalent static seismic stresses. The generated geometries are optimized to keep the relative drifts below the limits, to verify all rods, and to minimize the steel weight and the number of rods. Both these parameters were decisive for choosing the best options among the multiple solutions obtained according to different design concepts, geometric inputs and variables of the objective function. These variables have been subjected to linear dynamic analysis that has shown a considerable reduction of the structure displacements in comparison to the actual state. Due to the non-linear nature of the problem, the presented linear, static and dynamic analyses are to be considered preliminary. More detailed results could be expected from a non-linear analysis, thanks to the resistance contribution of steel in the plastic field.

Finally, the proposed solution, although limited to buildings whose footprint can be slightly enlarged, overcomes many of the limitations usually associated with seismic renovation actions including: (i) technical limits, because exoskeletons effectively minimize the renovation activities on the existing building and allow combining multiple interventions in a single stage (structural, energy efficiency, and architectural retrofitting); (ii) organizational limits, since occupants do not need to leave their apartments during renovation works, avoiding transfer disruption and costs, and facilitating condominium consensus; (iii) economic limits, since exoskeletons may reduce time and cost for renovation in comparison with other combined interventions.

The next development of this study will pursue the extension of the algorithm functionalities, introducing parameters related to thermal comfort and energy efficiency among the factors that influence the selection of the optimal exoskeleton shape. The introduction of new variables may further improve the holistic dimension of the proposed methodology, as well as its complexity and completeness.