The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of the Study Area

2.2. Characteristics of the Study Site

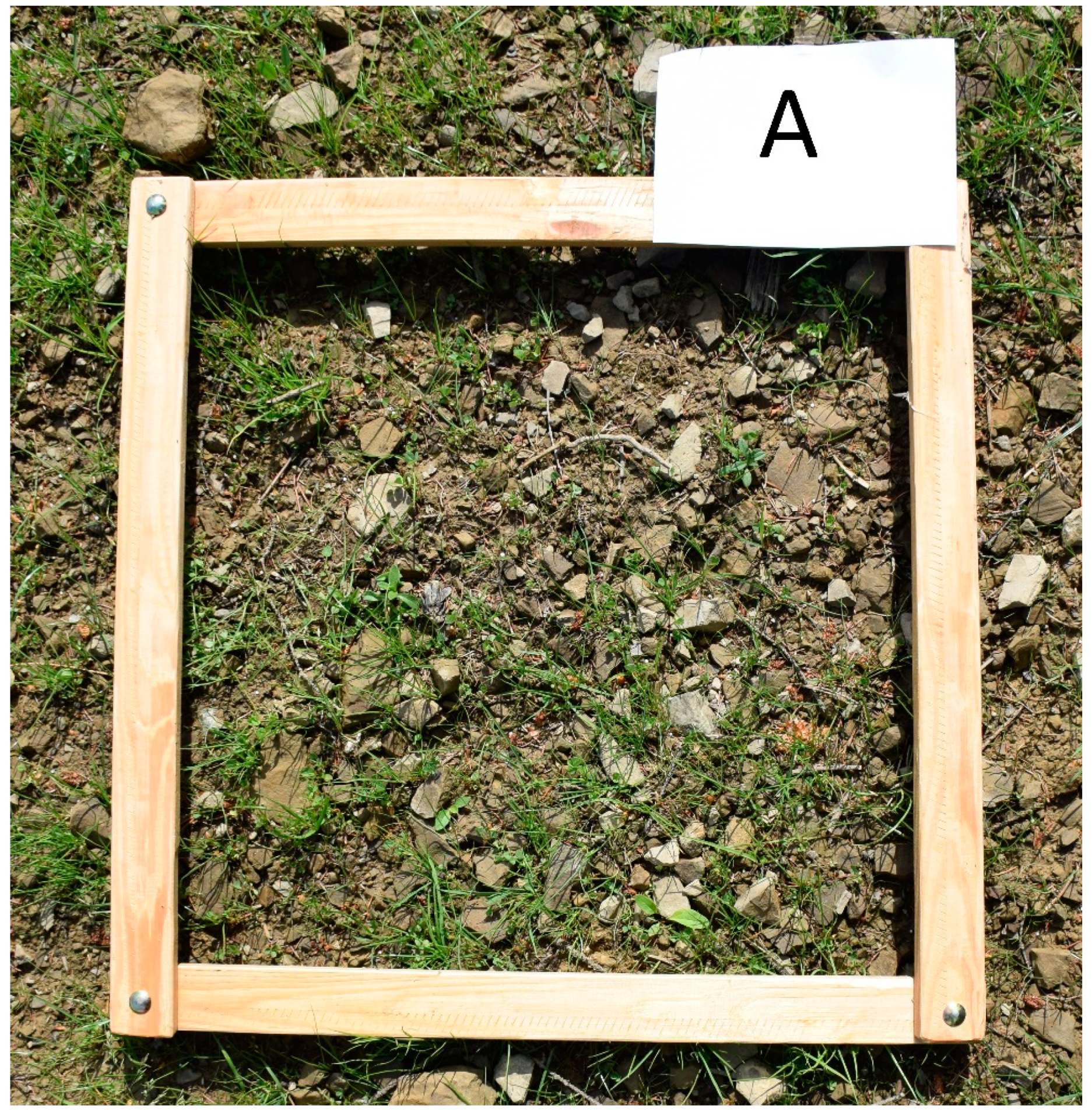

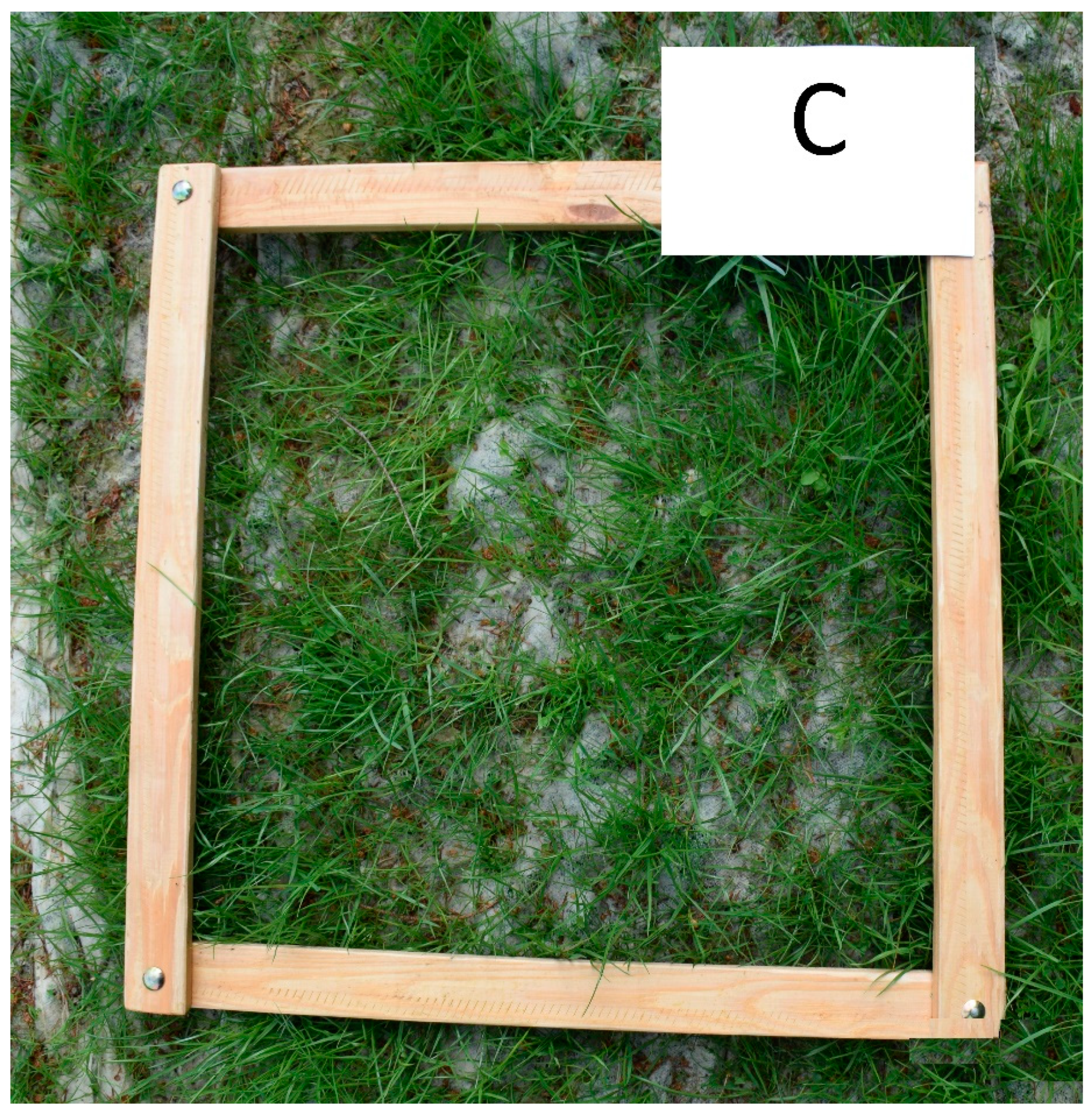

2.3. Characterization of the Experiment

2.4. Characterization of the Analytical Methods

3. Results

3.1. Solution Application Area

3.2. Water Capacity of the Geotextiles

3.3. Soil Moisture Content

3.4. Soil Sodding Assesment

4. Discussion

5. Conclusions

- Based on the study, it was determined that rapid and permanent sodding of difficult terrain is possible provided that agents assisting in the initial development of plants are applied.

- The main factor influencing the efficiency of sodding of difficult terrain is the application of fabrics that are capable of absorbing up to 45.0% of water from precipitation and from steam, which are then given to plants over a longer period of time, thus stabilizing the water regime.

- Considering fabrics used in the experiment, vegetation grew easiest through the geotextile made of sheep wool with the addition of bird feathers, despite it having the greatest basis weight. The ease with which plants grew through the geotextile made of wool and feathers resulted from its fluffy structure, which also affected the water capacity and absorption of water from steam.

- Using problematic waste (bird feathers from poultry slaughterhouse) for the manufacture of fabrics has a number of advantages: one can obtain a fluffy fabric with adequate parameters for the sodding of difficult terrain, fabrics are biodegraded at the site of application, and decomposing fabrics enrich the soil with nutrients for plants and are an alternative for synthetic fabrics.

- Fabrics manufactured from problematic waste materials (bird feathers) contribute to a measurable ecological effect as well as an economic effect, which is a result of not having to bear the costs of waste management as well as the income from selling the innovative product.

6. Patents

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Borys, M. Przepisy i Wymogi Oraz Aktualny Stan Obwałowań Przeciwpowodziowych w Polsce; Wyd. IMUZ: Falenty, Poland, 2007; pp. 25–44. [Google Scholar]

- Twardy, S. Racjonalne Wykorzystanie Potencjału Produkcyjnego Trwałych Użytków Zielonych w Polsce w Różnych Warunkach Glebowych i Systemach Gospodarowania. Rozprawy Naukowe i Monografie, 40; Wydawnictwo ITP: Falenty, Poland, 2015. [Google Scholar]

- Helešic, J. Trendy v rozvoji lyžařských středisek a jejich vliv na cestovní ruch. In Proceedings of the Conference Cestovní Ruch, Hotelnictví a Lázeňství ve Světle Vědeckého Výzkumu A Praxe, Karviná, Czech Republic, 14–15 April 2014. [Google Scholar]

- Bauman-Kaszubska, H.; Sikorski, M. Metodyczne podstawy dotyczące ocen oddziaływania na środowisko osadów ściekowych wykorzystanych w celach rolniczych bądź przyrodniczych. Inżynieria i Ochrona Środowiska 2014, 17, 199–210. [Google Scholar]

- Latosińska, J. Analiza mobilności metali ciężkich z osadów ściekowych z oczyszczalni ścieków w Olsztynie i Sitkówce-Nowiny. Inżynieria i Ochrona Środowiska 2014, 17, 243–253. [Google Scholar]

- Pohl, M.; Graf, F.; Buttler, A.; Rixen, C. The relationship between plant species richness and soil aggregate stability can depend on disturbance. Plant Soil 2012, 355, 87–102. [Google Scholar] [CrossRef] [Green Version]

- Wysocka, A.; Wysocki, M.; Pawłowska, M.; Wisniewska, M.; Stępiński, W. Zadania i budowa pokrywy rekultywacyjnej składowiska odpadów. In Monografie Komitetu Inżynierii Środowiska; Ochrona i inżynieria środowiska—zrównoważony rozwój; PAN: Lodz, Poland, 2004; Volume 25, pp. 225–231. [Google Scholar]

- Frey, L. Księga Polskich traw. Instytut Botaniki im. W.; Szafera, Polska Akademia Nauk: Kraków, Poland, 2002; pp. 46–47. [Google Scholar]

- Kacorzyk, P.; Kasperczyk, M.; Szkutnik, J. The share of roots, sward and stubble biomass in biological yield of selected grass species. Mod. Phytomorphol. 2013, 4, 79–82. [Google Scholar]

- Herbich, J. Flora of the planned nature reserve “Meadows at the Patulskie Lake” in the Kaszubskie Lake District. Acta Botanica Cassubica 2000, 1, 21–30. [Google Scholar]

- Zielewicz, W.; Kozłowski, S. Właściwości biologiczne Holcus lanatus a możliwości produkcji jej nasion dla rekultywacji i zadarniania trudnych stanowisk. Zesz. Nauk. UP Wroc. Rol. LXXXVIII 2006, 545, 331–340. [Google Scholar]

- Prończuk, M.; Laudański, Z.; Prończuk, S. Porównanie gatunków i odmian Festuca ssp. w wieloletnim użytkowaniu trawnikowym. Biul. IHAR 2003, 225, 239–257. [Google Scholar]

- Antonkiewicz, J.; Radkowski, A. Przydatność wybranych gatunków traw i roślin motylkowatych do biologicznej rekultywacji składowisk popiołów paleniskowych. Ann. UMCS Sec. E 2006, 61, 413–421. [Google Scholar]

- Jermołowicz, P. Geosyntetyki—podział i charakterystyka. Rynek Inwestycji 2016, 52–57. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiL98Sj6OTtAhVL6qQKHRgyCSEQFjAAegQIAxAC&url=https%3A%2F%2Fwww.inzynieriasrodowiska.com.pl%2Fimages%2Fpdf_encyklopedia%2Fgeosyntetyki-podzial_i_charakterystyka.pdf&usg=AOvVaw3uJjzHsxBxF-ZFaL-wiq4x (accessed on 12 November 2020).

- Bolt, A.F.; Duszyńska, A. Badania cech i trwałości geotekstyliów według przepisów. CEN 2001, 3, 125–137. [Google Scholar]

- Cholewa, M.; Zydroń, T.; Pelc, Ł. Badania wybranych parametrów wytrzymałości geowłóknin ułożonych na podłożu odkształcalnym i nieodkształcalnym. Infrastruktura i Ekologia Terenów Wiejskich 2013, 1/IV, 129–141. [Google Scholar]

- Siwek, P.; Kalisz, A.; Domagała-Świątkiewicz, I.; Libik, A. Efektywność zastosowania włóknin biodegradowalnych w uprawie wybranych gatunków warzyw. In Innowacyjne Metody Ochrony w Uprawach Ekologicznych; Małopolski Ośrodek Doradztwa Rolniczego z siedzibą w Karniowicach: Karniowice, Poland, 2017; pp. 21–24. [Google Scholar]

- Tosic, I.; Mirosavljevic, M.; Przulj, N.; Trkulja, V.; Pesevic, D.; Barbir, J. Effect of geotextile and agrotextile covering on productivity and nutritional values in lettuce. Chil. J. Agr. Res. 2019, 79, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Łaba, W.; Rodziewicz, A. Biodegradacja odpadów keratynowych z przemysłu drobiowego przy udziale bakterii z rodzajów Bacillus i Sarcina. Biotechnologia 2004, 3, 109–120. [Google Scholar]

- Staroń, P.; Banach, M.; Kowalski, Z. Keratyna—źródła, właściwości, zastosowanie. Chemik 2011, 65, 1019–1026. [Google Scholar]

- Riffel, A.; Brandelli, A. Keratinolytic bacteria isolated from feather waste. Braz. J. Microbiol. 2006, 37, 395–399. [Google Scholar] [CrossRef] [Green Version]

- Bohacz, J.; Korniłłowicz-Kowalska, T. Changes in enzymatic activity in composts containing chicken feathers. Bioresour. Technol. 2009, 100, 3604–3612. [Google Scholar] [CrossRef]

- Paul, T.; Halder, S.K.; Das, A.; Bera, S.; Maity, C.; Mandal, A.; Das, P.S.; Das Mohapatra, P.K.; Pati, B.R.; Mondal, K.C. Exploitation of chicken feather waste 49 as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatal. Agric. Biotechnol. 2013, 2, 50–57. [Google Scholar] [CrossRef]

- Brandelli, A. Bacterial Keratinases: Useful Enzymes for Bioprocessing Agroindustrial Wastes and Beyond. Food Bioproc. Tech. 2008, 1, 105–116. [Google Scholar] [CrossRef]

- Rodziewicz, A.; Łaba, W.; Sobolczyk, J.; Grzelak, A.; Drozd, J. Kompostowanie odpadów keratynowych przy udziale szczepionki bakteryjnej w bioreaktorze obrotowym. Inż. Ap. Chem. 2009, 48, 95–97. [Google Scholar]

- Margielewski, W. Rozwój form osuwiskowych w Barnowcu (Beskid Sądecki, Karpaty zewnętrzne), w świetle analizy strukturalnych uwarunkowań osuwisk w Karpatach fliszowych. Przegl. Geol. 1998, 46, 436–450. [Google Scholar]

- PTG. Klasyfikacja uziarnienia gleb i utworów mineralnych. Soil Sci. Ann. 2008, 60, 5–16. [Google Scholar]

- Kabała, C.; Karczewska, A. Metodyka analiz laboratoryjnych gleb i roślin. wyd. 8. Wrocław. 2019. Available online: http://www.up.wroc.pl/~kabala (accessed on 10 November 2019).

- Bache, D.H.; MacAskill, I.A. Vegetation in Civil and Landscape Engineering; Granada Publishing Ltd.: London, UK, 1984. [Google Scholar]

- Bochet, E.; Garcìa-Fayos, P. Factors controlling vegetation establishment and water erosion on motorway slopes in Valencia, Spain. Restor Ecol. 2004, 12, 166–174. [Google Scholar] [CrossRef]

- Petersen, S.L.; Roundy, B.A.; Bryant, R.M. Revegetation methods for high-elevation roadsides at Bryce Canyon National Park, Utah. Restor. Ecol. 2004, 12, 248–257. [Google Scholar] [CrossRef]

- Tormo, J.; Bochet, E.; García-Fayos, P. Is seed availability enough to ensure colonization success? An experimental study in road embankments. Ecol Eng. 2006, 26, 224–230. [Google Scholar] [CrossRef]

- Vallone, M.; Pipitone, F.; Alleri, M.; Febo, P.; Catania, P. Hydroseeding application on degraded slopes in the southern Mediter-ranean area (Sicily). Appl. Eng Agric. 2013, 29, 309–319. [Google Scholar]

- Faucette, L.B.; Risse, L.M.; Jordan, C.F.; Cabrera, M.L.; Coleman, D.C.; West, L.T. Vegetation and soil quality effects from hydroseed and compost blankets used for erosion control in construction activities. J. Soil Water Conserv. 2006, 61, 355–362. [Google Scholar]

- Matesanz, S.; Valladares, F.; Tena, D.; Costa-Tenorio, M.; Daniel Bote, D. Early Dynamics of Plant Communities on Revegetated Motorway Slopes from Southern Spain: Is Hydroseeding Always Needed? Restor. Ecol. 2006, 14, 297–307. [Google Scholar] [CrossRef]

- Muzzi, E.; Roffi, F.; Sirotti, M.; Bagnares, U. Revegetation techniques on clay soil slopes in northern Italy. Land Degrad. Dev. 1997, 8, 127–137. [Google Scholar] [CrossRef]

- Bradshaw, A.D.; Chadwick, M.J. The Restoration of Land; Blackwell: Oxford, UK, 1980. [Google Scholar]

- Koerner, R. Geotextiles: From Design to Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Park, J.B.; Park, H.S.; Kim, D. Geosynthetic Reinforcement of Sand-Mat Layer above Soft Ground. Materials 2013, 6, 5314–5334. [Google Scholar] [CrossRef] [Green Version]

- Yamanouchi, T. Historical Review of Geotextiles for Reinforcement of Earth Works in Asia, International Symposium Earth Reinforcement Practice; Earth Reinforcement. In Proceedings of the International Symposium on Earth Reinforcement, Fukuoka, Japan, 11–13 November 1992; pp. 1–15. [Google Scholar]

- Rawal, A.; Shah, T.; Anand, S. Geotextiles in civil engineering. In Handbook of Technical Textiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 111–133. [Google Scholar]

- Agrawal, B.J. Geotextile: It’s application to civil engineering–overview. In Proceedings of the National Conference on Recent Trends in Engineering & Technology, Anand, India, 13–14 May 2011; pp. 1–6. [Google Scholar]

- Koerner, G.R. Geotextiles used in separation. In Geotextiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 239–256. [Google Scholar]

- Li, Y.; Sun, Y.; Qiu, J.; Liu, T.; Yang, L.; She, H. Moisture absorption characteristics and thermal insulation performance of thermal insulation materials for cold region tunnels. Constr. Build. Mater. 2020, 237. [Google Scholar] [CrossRef]

- Liu, C.; Xing, L.; Liu, H.; Quan, Z.; Fu, G.; Wu, J.; Lv, Z.; Zhu, C. Numerical study of bond slip between section steel and recycled aggregate concrete with full replacement ratio. Appl. Sci. 2020, 10, 887. Available online: https://www.mdpi.com/2076-3417/10/3/887 (accessed on 5 January 2021). [CrossRef] [Green Version]

- Muthukumaran, A.; Ilamparuthi, K. Laboratory studies on geotextile filters as used in geotextile tube dewatering. Geotext. Geomembr. 2006, 24, 210–219. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, D.; Fang, Q.; Yu, L. Movements of ground and existing structures induced by slurry pressure-balance tunnel boring machine (SPB TBM) tunnelling in clay. Tunn. Undergr. Space Technol. 2020, 97. [Google Scholar] [CrossRef]

- Lin, C.; Zhang, X.; Han, J. Comprehensive Material Characterizations of Pavement Structure Installed with Wicking Fabrics. J. Mater. Civ. Eng. 2019, 31. [Google Scholar] [CrossRef]

- Wang, F.; Han, J.; Zhang, X.; Guo, J. Laboratory tests to evaluate efectiveness of wicking geotextile in soil moisture reduction. Geotext. Geomembr. 2017, 45, 8–13. [Google Scholar] [CrossRef]

- Wiewel, B.V.; Lamoree, M. Geotextile composition, application and ecotoxicology—A review. J. Hazard. Mater. 2016, 317, 640–655. [Google Scholar] [CrossRef]

- Rawal, A.; Shah, T.; Anand, S. Geotextiles: Production, properties and performance. Text. Prog. 2010, 42, 181–226. [Google Scholar] [CrossRef]

- Rankilor, P.R. Problems relating to light degradation and site testing of geotextiles—Interim results of an international weathering programme. In Durability of Geotextiles; Chapman and Hall Ltd.: London, UK, 2005; pp. 158–168. [Google Scholar]

- Stepanovic, J.M.; Trajkovic, D.; Stojiljkovic, D.; Djordjic, D. Predicting the behavior of nonwoven geotextile materials made of polyester and polypropylene fibers. Text. Res. J. 2016, 86, 1385–1397. [Google Scholar] [CrossRef]

- Pelyk, L.V.; Vasylechko, V.O.; Kyrychenko, O.V. Influence of Biodestructors on the Wear Resistance of Polyester Geotextile Materials. Colloids Interfaces 2019, 3, 21. [Google Scholar] [CrossRef] [Green Version]

- Touze-Foltza, N.; Bannourc, H.; Barralb, C.; Stoltz, G. A review of the performance of geosynthetics for environmental protection. Geotext Geomembr. 2016, 44, 656–672. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of Application and Innovation of Geotextiles in Geotechnical Engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef] [Green Version]

- Benjamim, C.V.; Bueno, B.; Zornberg, J.G. Field monitoring evaluation of geotextile-reinforced soil-retaining walls. Geosynth. Int. 2007, 14, 100–118. [Google Scholar] [CrossRef] [Green Version]

- Ma, E.; Lai, J.; Wang, L.; Wang, K.; Xu, S.; Li, C.; Guo, C. Review of cutting-edge sensing technologies for urban underground construction. Measurement 2021, 167. [Google Scholar] [CrossRef]

- Voet, M.R.-H.; Nancey, A.; Vlekken, J. Geodetect: A new step for the use of Fibre Bragg Grating technology in soil engineering. In Proceedings of the 17th International Conference on Optical Fibre Sensors, Bruges, Belgium, 23–27 May 2005; pp. 214–217. [Google Scholar]

- Jotisankasa, A.; Rurgchaisri, N. Shear strength of interfaces between unsaturated soils and composite geotextile with polyester yarn reinforcement. Geotext. Geomembr. 2018, 46, 338–353. [Google Scholar] [CrossRef]

- Prambauer, M.; Wendeler, C.; Weitzenböck, J.; Burgstaller, C. Biodegradable geotextiles—An overview of existing and potential materials. Geotext. Geomembr. 2019, 47, 48–59. [Google Scholar] [CrossRef]

- Piehl, S. Contamination of the Environment with Plastic Debris: “Development, Improvement, and Evaluation of Monitoring Methods”. Ph.D. Thesis, University of Bayreuth, Bayreuther Graduiertenschule für Mathematik und Naturwissenschaften, Bayreuth, Germany, January 2020. [Google Scholar]

- Zettler, E.R.; Mincer, T.J.; Amaral-Zettler, L.A. Life in the “Plastisphere”: Microbial communities on plastic marine debris. Environ. Sci. Technol. 2013, 47, 7137–7146. [Google Scholar] [CrossRef]

- Wagner, M.; Engwall, M.; Hollert, H. Editorial: (Micro)Plastics and the environment. Environ. Sci. Eur. 2014, 26. [Google Scholar] [CrossRef] [Green Version]

- Koerner, R.; Hsuan, Y.; Koerner, G. Lifetime predictions of exposed geotextiles and geomembranes. Geosynth. Int. 2017, 24, 198–212. [Google Scholar] [CrossRef]

- Li, J.; Cui, X.; Jin, Q.; Wang, Y. Laboratory investigation of the durability of a new smart geosynthetic material. Constr. Build. Mater. 2018, 169, 28–33. [Google Scholar] [CrossRef]

- Guerra, A.; Bezerra, J.; Fullen, M.A.; Mendonça, J.; Jorge, M. The effects of biological geotextiles on gully stabilization in São Luís. Braz. Nat. Hazards 2015, 75, 2625–2636. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Smets, T.; Fullen, M.A.; Poesen, J.; Booth, C.A. Efectiveness of geotextiles in reducing runoff and soil loss: A synthesis. Catena 2010, 81, 184–195. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Y. Evaluation of statistical strength of bamboo fiber and mechanical properties of fiber reinforced green composites. J. Cent. South Univ. Technol. 2008, 15, 564–567. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.K.; Thayer, K.; Misra, M.; Drzal, L.T. Novel biocomposites sheet molding compounds for low cost housing panel applications. J. Polym. Environ. 2005, 13, 169–175. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, H.J.; Yu, W.R. Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties. Fibers Polym. 2009, 10, 83–90. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. S 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Bambach, M.R. Durability of Natural Fibre Epoxy Composite Structural Columns: High Cycle Compression Fatigue and Moisture Ingress. Compos. Part C Open Access. 2020, 2. [Google Scholar] [CrossRef]

- Bongarde, U.; Shinde, V. Review on natural fiber reinforcement polymer composites. Int. J. Eng. Sci. Innov. Technol. 2014, 3, 431–436. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of different natural fiber treatments: A literature review. Int. J. Environ. Sci. Technol. 2019, 16, 629–642. [Google Scholar] [CrossRef]

- Pickering, K.; Beckermann, G.; Alam, S.; Foreman, N. Optimising industrial hemp fibre for composites. Compos. Part A Appl. S. 2007, 38, 461–468. [Google Scholar] [CrossRef]

- Broda, J.; Przybyło, S.; Kobiela-Mendrek, K.; Biniaś, D.; Rom, M.; Grzybowska-Pietras, J.; Laszczak, R. Biodegradation of sheep wool geotextiles. Int. Biodeter. Biodegr. 2016, 115, 31–38. [Google Scholar] [CrossRef]

- Prosenjit, S.; Debasis, R.; Suvendu, M.; Basudam, A.; Ramkrishna, S.; Sukumar, R. Durability of transesterified jute geotextiles. Geotext. Geomembranes 2012, 35, 69–75. [Google Scholar]

- Grześkiewicz, H. Uprawa ziemniaków wczesnych pod agrowłókniną. Wieś Mazowiecka 2002, 3, 17. [Google Scholar]

- Wołoszyn, E. Meteorologia i Klimtologia w Zarysie; Wydawnictwo Politechniki Gdańskiej: Gdańsk, Poland, 2009. [Google Scholar]

- Evangeline, S.Y.; Sayida, M.K.; Girish, M.S. Long-Term Performance of Rural Roads Reinforced with Coir Geotextile—A Field Study. J. Nat. Fibers 2019, 1–18. [Google Scholar] [CrossRef]

- Siwek, P.; Libik, A.; Gryza, I.; Ciechańska, D.; Niekraszewicz, A. Wpływ osłon z włókniny biodegradowalnej na plon i jakość cebuli zimującej. In Proceedings of the Conference Proekologiczna Uprawa Warzyw—Problemy i Perspektywy, Siedlce, Poland, 24–25 June 2010; ELPIL: Siedlce, Poland; pp. 150–152. [Google Scholar]

- Marques, A.R.; Vianna, C.R.; Monteiro, M.L.; Pires, B.O.S.; de Carvalho Urashima, D.; Pontes, P.P. Utilizing coir geotextile with grass and legume on soil of Cerrado, Brazil: An alternative strategy in improving the input of nutrients in degraded pasture soil? Appl. Soil Ecol. 2016, 107, 290–297. [Google Scholar] [CrossRef]

| Species/Variety | Share In | ||||

|---|---|---|---|---|---|

| Mixture | Pure Sowing | Mixture | Mixture | ||

| % | kg·ha−1 | kg·18 m−2 | |||

| Festuca rubra L. Reda C/11 | 30 | 90 | 27 | 0.049 | |

| Festuca pratensis L. Cykada C/1 | 5 | 120 | 6 | 0.011 | |

| Poa pratensis L. Struga B | 30 | 60 | 18 | 0.032 | |

| Lolium perenne L. Solen C/1 | 20 | 90 | 18 | 0.032 | |

| Trifolium repens L. Haifa | 15 | 60 | 9 | 0.016 | |

| Type of Fabric | Basis Weight of Fabrics | Amount of Water Retained | Amount of Water Retained | |

|---|---|---|---|---|

| After 2 h of Drying | After 24 h of Drying | |||

| g·m−2 | % | |||

| Wool + feathers | 100.00 | 450 d | 61.33 c | 10.67 b |

| SB 9/14/1-5 | 29.18 | 115 b | 32.56 b | 8.03 a |

| SB 12/14/2 | 77.32 | 309 c | 54.37 c | 8.01 a |

| SB 11/14/1 | 96.62 | 396 d | 62.63 c | 10.81 b |

| Pegas Agro | 17.82 | 70 a | 10.04 a | 8.04 a |

| Variant | Percent Moisture of the Soil Surface Layer | ||||

|---|---|---|---|---|---|

| Year 2019 | Year 2020 | Mean | |||

| July | August | October | July | ||

| A—Control | 12.6 | 18.1 | 43.4 | 30.6 | 26.2 a |

| B—Variant | 11.8 | 17.3 | 44.0 | 32.3 | 26.3 a |

| C—Wool + feathers | 20.0 | 23.7 | 54.9 | 49.6 | 37.0 c |

| D—SB 9/14/1-5 | 16.3 | 19.4 | 54.2 | 42.4 | 33.1 b |

| E—SB 12/14/2 | 18.8 | 20.3 | 55.7 | 45.8 | 35.2 c |

| F—SB 11/14/1 | 19.2 | 21.8 | 58.7 | 45.3 | 36.2 c |

| G—Pegas Agro | 13.9 | 19.2 | 51.4 | 37.4 | 30.5 b |

| Variant | Percent of Soil Sodding | |||

|---|---|---|---|---|

| Year 2019 | Year 2020 | |||

| July | August | October | July | |

| A—Control | 15.2 a | 26.3 a | 36.8 a | 45.8 a |

| B—Variant | 18.3 a | 38.4 b | 42.0 a | 68.3 b |

| C—Wool + feathers | 70.6 c | 79.9 d | 92.3 d | 100.0 d |

| D—SB 9/14/1-5 | 68.6 c | 80.5 d | 94.8 d | 100.0 d |

| E—SB 12/14/2 | 62.3 c | 77.7 d | 88.3 c | 95.6 d |

| F—SB 11/14/1 | 71.0 c | 78.8 d | 83.2 c | 94.8 d |

| G—Pegas Agro | 42.5 b | 57.8 c | 73.4 b | 85.1 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kacorzyk, P.; Strojny, J.; Białczyk, B. The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain. Sustainability 2021, 13, 5828. https://doi.org/10.3390/su13115828

Kacorzyk P, Strojny J, Białczyk B. The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain. Sustainability. 2021; 13(11):5828. https://doi.org/10.3390/su13115828

Chicago/Turabian StyleKacorzyk, Piotr, Jacek Strojny, and Barbara Białczyk. 2021. "The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain" Sustainability 13, no. 11: 5828. https://doi.org/10.3390/su13115828

APA StyleKacorzyk, P., Strojny, J., & Białczyk, B. (2021). The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain. Sustainability, 13(11), 5828. https://doi.org/10.3390/su13115828