Sustainable Coatings on Metallic Alloys as a Nowadays Challenge

Abstract

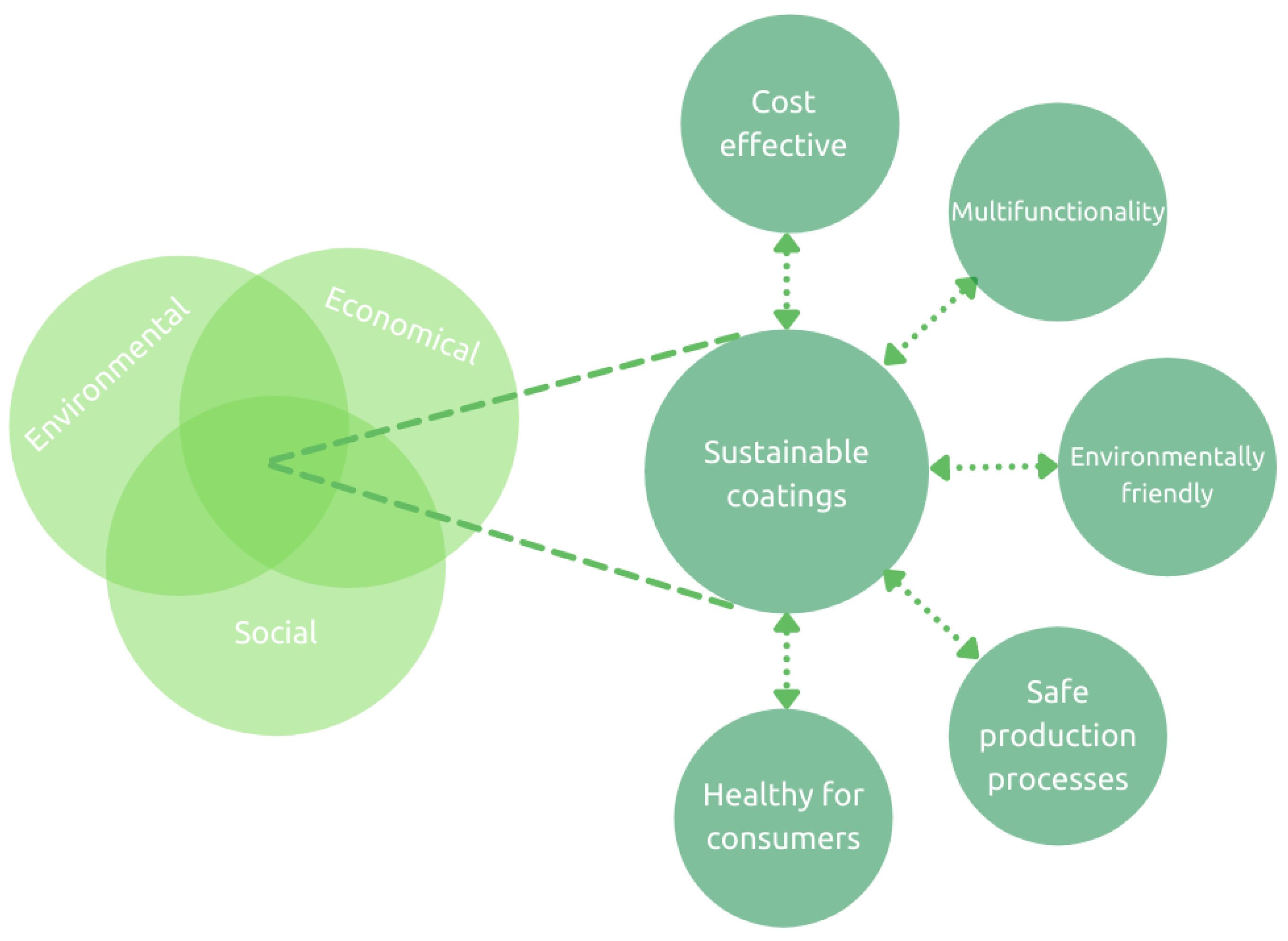

:1. Introduction

2. Methods

2.1. Methods in the Present Narrative Review Elaboration

2.2. Methods for the Development of Sustainable Coatings

3. Trends in Enhancing Coatings Performances on CoCr Alloys and Other Metallic Alloys (Including High-Entropy Alloys)

4. New Challenges in Coatings on Biodegradable Mg Alloys

5. Nanofabrication Aspects of Green Procedures in Enhancing Coatings Multifunctionality (Green Corrosion Inhibitors, Biomimetic Coatings, Bioinspired Coating Based on Superhydrophilic and Superhydrophobic Coatings, Smart Additives)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, C.E.; Xu, W.; Hu, W.Y.; Hodgson, P.D. Hydroxyapatite/titania sol-gel coatings on titanium-zirconium alloy for biomedical applications. Acta Biomater. 2007, 3, 403–410. [Google Scholar] [CrossRef]

- Calderon Moreno, J.M.; Osiceanu, P.; Vasilescu, C.; Anastasescu, M.; Drob, S.I.; Popa, M. Obtaining, structural and corrosion characterization of anodized nanolayers on Ti-20Zr alloy surface. Surf. Coat. Technol. 2013, 235, 792–802. [Google Scholar] [CrossRef]

- Ionita, D.; Grecu, M.; Ungureanu, C.; Demetrescu, I. Antimicrobial activity of the surface coatings on TiAlZr implant biomaterial. J. Biosci. Bioeng. 2011, 112, 630–634. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.; Chen, C.; Zhao, Z. Review of the biocompatibility of micro-arc oxidation coated titanium alloys. Mater. Des. 2015, 85, 640–652. [Google Scholar] [CrossRef]

- Wang, D.; Bierwagen, G.P. Sol-gel coatings on metals for corrosion protection. Prog. Org. Coat. 2009, 64, 327–338. [Google Scholar] [CrossRef]

- Ionita, D.; Golgovici, F.; Mazare, A.; Badulescu, M.; Demetrescu, I.; Pandelea-Dobrovicescu, G.R. Corrosion and antibacterial characterization of Ag-DLC coatingon a new CoCrNbMoZr dental alloy. Mater. Corros. 2018, 69, 1403–1411. [Google Scholar] [CrossRef]

- Perry, K.K. The Dynamics of Industrial Development in a Resource-Rich Developing Society: A Political Economy Analysis. J. Dev. Soc. 2018, 34, 1–33. [Google Scholar] [CrossRef]

- VerLoren van Themaat, W.; Reuder, B. Treaty on European Union (TEU). In European Competition Law; Edward Elgar Publishing: Cheltenham, UK, 2018; pp. 3–4. [Google Scholar]

- Rai, P.; Mehrotra, S.; Priya, S.; Gnansounou, E.; Sharma, S.K. Recent advances in the sustainable design and applications of biodegradable polymers. Bioresour. Technol. 2021, 325, 124739. [Google Scholar] [CrossRef]

- Florez, L.; Castro-Lacouture, D. Optimization model for sustainable materials selection using objective and subjective factors. Mater. Des. 2013, 46, 310–321. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, A.; Fernandes, T.; Ayoko, G.A. Nanomaterials and the Environment. J. Nanomater. 2014, 2014, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Roghanian, N.; Banthia, N. Development of a sustainable coating and repair material to prevent bio-corrosion in concrete sewer and waste-water pipes. Cem. Concr. Compos. 2019, 100, 99–107. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Sun, J. Bioinspired self-healing superhydrophobic coatings. Angew. Chem. Int. Ed. 2010, 49, 6129–6133. [Google Scholar] [CrossRef]

- Pal, K.; Kyzas, G.Z.; Kralj, S.; Gomes de Souza, F. Sunlight sterilized, recyclable and super hydrophobic anti-COVID laser-induced graphene mask formulation for indelible usability. J. Mol. Struct. 2021, 1233, 130100. [Google Scholar] [CrossRef]

- Rani, B.E.A.; Basu, B.B.J. Green inhibitors for corrosion protection of metals and alloys: An overview. Int. J. Corros. 2012, 2012, 1–15. [Google Scholar] [CrossRef]

- Obot, I.B.; Umoren, S.A.; Ankah, N.K. Pyrazine derivatives as green oil field corrosion inhibitors for steel. J. Mol. Liq. 2019, 277, 749–761. [Google Scholar] [CrossRef]

- Huang, G.; Chen, W.; Wu, T.; Guo, H.; Fu, C.; Xue, Y.; Wang, K.; Song, P. Multifunctional graphene-based nano-additives toward high-performance polymer nanocomposites with enhanced mechanical, thermal, flame retardancy and smoke suppressive properties. Chem. Eng. J. 2021, 410, 127590. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P.; Chouhan, A.; Khatri, O.P. Effect of Graphene-Based Nanoadditives on the Tribological and Rheological Performance of Paraffin Grease. J. Mater. Eng. Perform. 2020, 29, 2235–2247. [Google Scholar] [CrossRef]

- Pourhashem, G. Coating a Sustainable Future. Coatings 2020, 10, 713. [Google Scholar] [CrossRef]

- Tyagi, P.; Salem, K.S.; Hubbe, M.A.; Pal, L. Advances in barrier coatings and film technologies for achieving sustainable packaging of food products—A review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Stoian, A.B.; Demetrescu, I.; Ionita, D. Nanotubes and nano pores with chitosan construct on TiZr serving as drug reservoir. Colloids Surf. B Biointerfaces 2020, 185, 110535. [Google Scholar] [CrossRef]

- Jariya, S.A.I.; Ravichandran, K.; Narayanan, T.S.N.S. Development of novel multi-functional composite coatings on titanium: Evaluation of structural characteristics, bioactivity and corrosion behaviour. J. Alloys Compd. 2021, 855, 157290. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, C.; Wang, L.; Long, X.; Zhang, J.; Zuo, Y.; Jiao, F. Tannic acid-based complex coating modified membranes with photo-Fenton self-cleaning property for sustainable oil-in-water emulsion separation. Sep. Purif. Technol. 2021, 272, 118893. [Google Scholar] [CrossRef]

- Le, K.H.; Nguyen, M.D.B.; Tran, L.D.; Nguyen Thi, H.P.; Van Tran, C.; Van Tran, K.; Nguyen Thi, H.P.; Dinh Thi, N.; Yoon, Y.S.; Nguyen, D.D.; et al. A novel antimicrobial ZnO nanoparticles-added polysaccharide edible coating for the preservation of postharvest avocado under ambient conditions. Prog. Org. Coat. 2021, 158, 106339. [Google Scholar] [CrossRef]

- Choudhary, K.; Saini, R.; Upadhyay, G.K.; Purohit, L.P. Sustainable behavior of cauliflower like morphology of Y-doped ZnO:CdO nanocomposite thin films for CO2 gas sensing application at low operating temperature. J. Alloys Compd. 2021, 879, 160479. [Google Scholar] [CrossRef]

- Singh, M.; Ohji, T.; Asthana, R. Green and Sustainable Manufacturing of Advanced Material; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Wuebbles, D.J.; Fahey, D.W.; Hibbard, K.A.; DeAngelo, B.; Doherty, S.; Hayhoe, K.; Horton, R.; Kossin, J.P.; Taylor, P.C.; Waple, A.M.; et al. Executive Summary. Climate Science Special Report: Fourth National Climate Assessment; U.S. Global Change Research Program: Washington, DC, USA, 2017; Volume I. [Google Scholar]

- Gottardo, S.; Mech, A.; Drbohlavová, J.; Małyska, A.; Bøwadt, S.; Riego Sintes, J.; Rauscher, H. Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact 2021, 21, 100297. [Google Scholar] [CrossRef]

- Sánchez Jiménez, A.; Puelles, R.; Pérez-Fernández, M.; Gómez-Fernández, P.; Barruetabeña, L.; Jacobsen, N.R.; Suarez-Merino, B.; Micheletti, C.; Manier, N.; Trouiller, B.; et al. Safe(r) by design implementation in the nanotechnology industry. NanoImpact 2020, 20, 100267. [Google Scholar] [CrossRef]

- Fiameni, S.; Battiston, S.; Castellani, V.; Barison, S.; Armelao, L. Implementing sustainability in laboratory activities: A case study on aluminum titanium nitride based thin fi lm magnetron sputtering deposition onto commercial laminated steel. J. Clean. Prod. 2021, 285, 124869. [Google Scholar] [CrossRef]

- Salieri, B.; Barruetabeña, L.; Rodríguez-Llopis, I.; Jacobsen, N.R.; Manier, N.; Trouiller, B.; Chapon, V.; Hadrup, N.; Jiménez, A.S.; Micheletti, C.; et al. Integrative approach in a safe by design context combining risk, life cycle and socio-economic assessment for safer and sustainable nanomaterials. NanoImpact 2021, 23, 100335. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z. On sustainable manufacturing of Cr-Ni alloy coatings by laser cladding and high-efficiency turning process chain and consequent corrosion resistance. J. Clean. Prod. 2017, 161, 676–687. [Google Scholar] [CrossRef]

- Ma, M.; Han, A.; Zhang, Z.; Lian, Y.; Zhao, C.; Zhang, J. The role of Si on microstructure and high-temperature oxidation of CoCr2FeNb0.5Ni high-entropy alloy coating. Corros. Sci. 2021, 185, 109417. [Google Scholar] [CrossRef]

- Fu, Y.; Huang, C.; Du, C.; Li, J.; Dai, C.; Luo, H.; Liu, Z.; Li, X. Evolution in microstructure, wear, corrosion, and tribocorrosion behavior of Mo-containing high-entropy alloy coatings fabricated by laser cladding. Corros. Sci. 2021, 191, 109727. [Google Scholar] [CrossRef]

- Gu, Z.; Xi, S.; Sun, C. Microstructure and properties of laser cladding and CoCr2.5FeNi2Tix high-entropy alloy composite coatings. J. Alloys Compd. 2020, 819, 152986. [Google Scholar] [CrossRef]

- Jiao, H.; Song, W.; Chen, H.; Wang, M.; Jiao, S.; Fang, D. Sustainable recycling of titanium scraps and purity titanium production via molten salt electrolysis. J. Clean. Prod. 2020, 261, 121314. [Google Scholar] [CrossRef]

- Peng, J.; Yuan, S.; Geng, H.; Zhang, X.; Zhang, M.; Xu, F.; Lin, D.; Gao, Y.; Wang, H. Robust and multifunctional superamphiphobic coating toward effective. Chem. Eng. J. 2022, 428, 131162. [Google Scholar] [CrossRef]

- Pathak, S.; Saha, G.C. Development of sustainable cold spray coatings and 3D additive manufacturing components for repair/manufacturing applications: A critical review. Coatings 2017, 7, 122. [Google Scholar] [CrossRef] [Green Version]

- Cirisano, F.; Ferrari, M. Superhydrophobicity and Durability in Recyclable Polymers Coating. Sustainability 2021, 13, 8244. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, G.; Tong, Q.; Yang, W.; Hao, W. Fluorine-free superhydrophobic coatings from polydimethylsiloxane for sustainable chemical engineering: Preparation methods and applications. Chem. Eng. J. 2021, 426, 130829. [Google Scholar] [CrossRef]

- Wang, S.; Li, L.; Li, J.; Wang, J.; Pan, E.; Lu, J.; Zhang, Y.; Yang, J. Sustainable synthesis of highly water-selective ZSM-5 membrane by wet gel conversion. J. Memb. Sci. 2021, 635, 119431. [Google Scholar] [CrossRef]

- Niu, J.; Wang, H.; Chen, J.; Chen, X.; Han, X.; Liu, H. Bio-inspired zwitterionic copolymers for antifouling surface and oil-water separation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 626, 127016. [Google Scholar] [CrossRef]

- Boillot, P.; Peultier, J. Use of stainless steels in the industry: Recent and future developments. Procedia Eng. 2014, 83, 309–321. [Google Scholar] [CrossRef] [Green Version]

- Morral, F.R. Cobalt-Base Alloys In Aerospace. Sp. Congr. Proc. 1970, 3. Available online: https://commons.erau.edu/cgi/viewcontent.cgi?article=3128&context=space-congress-proceedings (accessed on 12 September 2021).

- Konieczny, B.; Szczesio-Wlodarczyk, A.; Sokolowski, J.; Bociong, K. Challenges of co-cr alloy additive manufacturing methods in dentistry-the current state of knowledge (Systematic review). Materials 2020, 13, 3524. [Google Scholar] [CrossRef]

- Ionita, D.; Pirvu, C.; Stoian, A.B.; Demetrescu, I. The Trends of TiZr Alloy Research as a Viable Alternative for Ti and Ti16 Zr Roxolid Dental Implants. Coatings 2020, 10, 422. [Google Scholar] [CrossRef]

- Negrescu, A.M.; Necula, M.G.; Gebaur, A.; Golgovici, F.; Nica, C.; Curti, F.; Iovu, H.; Costache, M.; Cimpean, A. In vitro macrophage immunomodulation by poly(ε-caprolactone) based-coated AZ31 Mg Alloy. Int. J. Mol. Sci. 2021, 22, 909. [Google Scholar] [CrossRef] [PubMed]

- Muralikrishna, P.V.S.; Kishore, P.S.; Ramanaiah, N.; Pathanjali, V.V.S.P.K. Nickel base alloy with metal matrix composite zirconium boride with inorganic coatings for high temperature environments. Mater. Today Proc. 2020, 39, 1287–1290. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, T.; Xiao, M.; Shen, Y. Effect of Nb content on microstructure and properties of laser cladding FeNiCoCrTi0.5Nbx high-entropy alloy coating. Optik 2019, 198, 163316. [Google Scholar] [CrossRef]

- Tan, A.W.Y.; Lek, J.Y.; Sun, W.; Bhowmik, A.; Marinescu, I.; Buenconsejo, P.J.; Dong, Z.; Liu, E. Microstructure, mechanical and tribological properties of cold sprayed Ti6Al4V–CoCr composite coatings. Compos. Part B Eng. 2020, 202, 108280. [Google Scholar] [CrossRef]

- Cheol Lee, G.; Noh, H.; Yeom, H.; Jo, H.; Kyun Kim, T.; Kim, M.; Sridharan, K.; Sun Park, H. Zirconium-silicide coating on zircaloy-4 substrate for accident tolerance: Effects on oxidation resistance and boiling. Ann. Nucl. Energy 2019, 126, 350–358. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Wang, T.; Chai, L.; Deng, C.; Wang, Y.; Huang, Y. Microstructure and properties of pure titanium coating on Ti-6Al-4V alloy by laser cladding. Surf. Coat. Technol. 2021, 416, 127137. [Google Scholar] [CrossRef]

- Kumar, A.M.; Yusuf, A.; Hussein, M.A.; Umoren, S.A.; Ramakrishna, S.; Saravanan, S. Preparation and characterization of Pectin/Polypyrrole based multifunctional coatings on TiNbZr alloy for orthopaedic applications. Carbohydr. Polym. 2020, 242, 116285. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Z.; Zhang, J.; Qin, G.; Zhang, E. Construction of a TiO2/Cu2O multifunctional coating on Ti-Cu alloy and its influence on the cell compatibility and antibacterial properties. Surf. Coat. Technol. 2021, 421, 127438. [Google Scholar] [CrossRef]

- Hassim, M.H.; Idris, M.H.; Yajid, M.A.M.; Samion, S. Mechanical and wear behaviour of nanostructure TiO2-Ag coating on cobalt chromium alloys by air plasma spray and high velocity oxy-fuel. J. Mater. Res. Technol. 2019, 8, 2290–2299. [Google Scholar] [CrossRef]

- Singh, B.; Singh, G.; Sidhu, B.S. In vitro investigation of Nb–Ta alloy coating deposited on CoCr alloy for biomedical implants. Surf. Coat. Technol. 2019, 377, 124932. [Google Scholar] [CrossRef]

- Dinu, M.; Cojocaru, M.; Braic, V.; Tarcolea, M.; Braic, M.; Miculescu, F.; Vladescu, A.; Cotrut, C.M. Improvement of the tribological performance in corrosive environment of CoCr alloy by TiSiON coatings. Appl. Surf. Sci. 2015, 332, 295–299. [Google Scholar] [CrossRef]

- Bansal, P.; Singh, G.; Sidhu, H.S. Investigation of corrosion behavior and surface properties of plasma sprayed HA/Sr reinforced coatings on CoCr alloys. Mater. Chem. Phys. 2020, 253, 123330. [Google Scholar] [CrossRef]

- Olms, C.; Yahiaoui-Doktor, M.; Remmerbach, T.W. Contact allergies to dental materials. Swiss Dent. J. 2019, 129, 571–579. [Google Scholar]

- Al-Imam, H.; Benetti, A.R.; Özhayat, E.B.; Pedersen, A.M.L.; Johansen, J.D.; Thyssen, J.P.; Jellesen, M.S.; Gotfredsen, K. Cobalt release and complications resulting from the use of dental prostheses. Contact Dermat. 2016, 75, 377–383. [Google Scholar] [CrossRef]

- Zigante, M.; Rincic Mlinaric, M.; Kastelan, M.; Perkovic, V.; Trinajstic Zrinski, M.; Spalj, S. Symptoms of titanium and nickel allergic sensitization in orthodontic treatment. Prog. Orthod. 2020, 21, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Hostýnek, J.J.; Reagan, K.E.; Maibach, H.I. Nickel Allergic Hypersensitivity: Prevalence and Incidence by Country, Gender, Age, and Occupation. In Nickel and the Skin; CRC Press: Boca Raton, FL, USA, 2019; pp. 39–82. [Google Scholar]

- Isik, M.; Avila, J.D.; Bandyopadhyay, A. Alumina and tricalcium phosphate added CoCr alloy for load-bearing implants. Addit. Manuf. 2020, 36, 101553. [Google Scholar] [CrossRef]

- Castellanos, M.I.; Zenses, A.S.; Grau, A.; Rodríguez-Cabello, J.C.; Gil, F.J.; Manero, J.M.; Pegueroles, M. Biofunctionalization of REDV elastin-like recombinamers improves endothelialization on CoCr alloy surfaces for cardiovascular applications. Colloids Surf. B Biointerfaces 2015, 127, 22–32. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Regulation (EU) 2017/745 of the European Parliament and of the Council of 5 April 2017 on Medical Devices, Amending Directive 2001/83/EC, Regulation (EC) No 178/2002 and Regulation (EC) No 1223/2009 and Repealing Council Directives 90/385/EEC and 93/42/EE. Off. J. Eur. Union. 2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32017R0745 (accessed on 12 September 2021).

- Vaicelyte, A.; Janssen, C.; Le Borgne, M.; Grosgogeat, B. Cobalt–Chromium Dental Alloys: Metal Exposures, Toxicological Risks, CMR Classification, and EU Regulatory Framework. Crystals 2020, 10, 1151. [Google Scholar] [CrossRef]

- Padrós, R.; Giner-Tarrida, L.; Herrero-Climent, M.; Punset, M.; Gil, F.J. Corrosion resistance and ion release of dental prosthesis of COCR obtained by CAD-CAM milling, casting and laser sintering. Metals 2020, 10, 827. [Google Scholar] [CrossRef]

- Hamza, G.; Sallam, H.; Eldwakhly, E. Effect of surface treatment of milled cobalt–chromium alloy on shear bond strength to porcelain. J. Arab Soc. Med. Res. 2019, 14, 113. [Google Scholar] [CrossRef]

- Totea, G.; Ionita, D.; Demetrescu, I. Influence of Doping Ions on the Antibacterial Activity of Biomimetic Coating on CoCrMo Alloy. J. Bionic Eng. 2015, 12, 583–591. [Google Scholar] [CrossRef]

- Băilă, D.-I.; Vițelaru, C.; Trușcă, R.; Constantin, L.R.; Păcurar, A.; Parau, C.A.; Păcurar, R. Thin Films Deposition of Ta2O5 and ZnO by E-Gun Technology on Co-Cr Alloy Manufactured by Direct Metal Laser Sintering. Materials 2021, 14, 3666. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N.; Jayaganthan, R.; Sood, R. An investigation on erosion behavior of HVOF sprayed WC-CoCr coatings. Appl. Surf. Sci. 2011, 258, 1225–1234. [Google Scholar] [CrossRef]

- Lindahl, C.; Xia, W.; Engqvist, H.; Snis, A.; Lausmaa, J.; Palmquist, A. Biomimetic calcium phosphate coating of additively manufactured porous CoCr implants. Appl. Surf. Sci. 2015, 353, 40–47. [Google Scholar] [CrossRef]

- Alvarez-Vera, M.; Hdz-García, H.M.; Díaz-Guillén, J.C.; Muñoz-Arroyo, R.; Acevedo-Davila, J.L.; Mtz-Enriquez, A.I.; Badillo, C.K.F. Tribological performance of Ti nanolayer coating post plasma nitriding treatment on Co based alloy. Wear 2021, 477, 1–9. [Google Scholar] [CrossRef]

- Weng, W.; Biesiekierski, A.; Lin, J.; Li, Y.; Wen, C. Impact of rare earth elements on nanohardness and nanowear properties of beta-type Ti-24Nb-38Zr-2Mo alloy for medical applications. Materialia 2020, 12, 100772. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, J.; He, J.; Fan, W.; Yu, H.; Zhong, X.; Liu, Z. Development of cost-effective nanocrystalline multi-component (Ce,La,Y)-Fe-B permanent magnetic alloys containing no critical rare earth elements of Dy, Tb, Pr and Nd. J. Mater. Sci. Technol. 2021, 76, 215–221. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, E.; Pak, C. Effect of rare-earth elements in Pd ternary alloy catalysts on activity toward oxygen reduction reaction. Catal. Today 2021, 359, 106–111. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy design strategies and future trends in high-entropy alloys. Jom 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and development of high entropy alloys for structural applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends. Addit. Manuf. 2019, 25, 252–262. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, S.; Lee, C.; Shi, Y.; Feng, R.; Xie, X.; Hamblin, D.; Coleman, A.M.; Straka, B.; Shortt, H.; et al. A review of the serrated-flow phenomenon and its role in the deformation behavior of high-entropy alloys. Metals 2020, 10, 1101. [Google Scholar] [CrossRef]

- Ma, N.; Liu, S.; Liu, W.; Xie, L.; Wei, D.; Wang, L.; Li, L.; Zhao, B.; Wang, Y. Research Progress of Titanium-Based High Entropy Alloy: Methods, Properties, and Applications. Front. Bioeng. Biotechnol. 2020, 8, 1–18. [Google Scholar] [CrossRef]

- Wang, X.R.; Wang, Z.Q.; Lin, T.S.; He, P. Mass transfer trends of AlCoCrFeNi high-entropy alloy coatings on TC11 substrate via electrospark—Computer numerical control deposition. J. Mater. Process. Technol. 2017, 241, 93–102. [Google Scholar] [CrossRef]

- Yan, X.H.; Li, J.S.; Zhang, W.R.; Zhang, Y. A brief review of high-entropy films. Mater. Chem. Phys. 2018, 210, 12–19. [Google Scholar] [CrossRef]

- Gu, Z.; Su, X.; Peng, W.; Guo, W.; Xi, S.; Zhang, X.; Tu, H.; Gao, Y.; Wu, H. An important improvement of strength and ductility on a new type of CoCr2.5FeNi2TiW0.5 high entropy alloys under two different protective gases by selective laser melting. J. Alloys Compd. 2021, 868. [Google Scholar] [CrossRef]

- Liu, J.; Cui, Z.; Ma, D.; Lu, J.; Cui, Y.; Li, C.; Liu, W.; Hao, Z.; Hu, P.; Yao, M.; et al. Investigation of oxidation behaviors of coated Zircaloy as accident-tolerant fuel with CrAlN and CrAlSiN coatings in high-temperature steam. Corros. Sci. 2020, 175, 108896. [Google Scholar] [CrossRef]

- Meng, Y.; Zeng, S.; Teng, Z.; Han, X.; Zhang, H. Control of the preferential orientation Cr coatings deposited on zircaloy substrates and study of their oxidation behavior. Thin Solid Films 2021, 730, 138699. [Google Scholar] [CrossRef]

- Liu, J.; Hao, Z.; Cui, Z.; Ma, D.; Lu, J.; Cui, Y.; Li, C.; Liu, W.; Xie, S.; Hu, P.; et al. Oxidation behavior, thermal stability, and the coating/substrate interface evolution of CrN-coated Zircaloy under high-temperature steam. Corros. Sci. 2021, 185, 109416. [Google Scholar] [CrossRef]

- Slobodyan, M. High-energy surface processing of zirconium alloys for fuel claddings of water-cooled nuclear reactors. Nucl. Eng. Des. 2021, 382, 111364. [Google Scholar] [CrossRef]

- Umretiya, R.V.; Elward, B.; Lee, D.; Anderson, M.; Rebak, R.B.; Rojas, J.V. Mechanical and chemical properties of PVD and cold spray Cr-coatings on Zircaloy-4. J. Nucl. Mater. 2020, 541, 50–65. [Google Scholar] [CrossRef]

- Song, L.; Huang, B.; Li, J.; Ma, X.; Liu, M.; Jiang, J.; Hu, Y. Effects of ion irradiation on Cr, CrN, and TiAlCrN coated Zircaloy-4 for accident tolerant fuel claddings. Ann. Nucl. Energy 2021, 156, 108206. [Google Scholar] [CrossRef]

- Molaei, M.; Attarzadeh, N.; Fattah-alhosseini, A. Tailoring the biological response of zirconium implants using zirconia bioceramic coatings: A systematic review. J. Trace Elem. Med. Biol. 2021, 66, 126756. [Google Scholar] [CrossRef]

- Nartita, R.; Ionita, D.; Demetrescu, I. A Combined Scientometric and Critical Approach in Reviewing TiZr Implant Alloys and Coating Performances. Coatings 2021, 11, 392. [Google Scholar] [CrossRef]

- Fattah-alhosseini, A.; Chaharmahali, R.; Keshavarz, M.K.; Babaei, K. Surface characterization of bioceramic coatings on Zr and its alloys using plasma electrolytic oxidation (PEO): A review. Surf. Interfaces 2021, 25, 101283. [Google Scholar] [CrossRef]

- Vidal, E.; Guillem-Marti, J.; Ginebra, M.; Combes, C.; Rupérez, E.; Rodriguez, D. Multifunctional homogeneous calcium phosphate coatings: Toward antibacterial and cell adhesive titanium scaffolds. Surf. Coat. Technol. 2021, 405, 126557. [Google Scholar] [CrossRef]

- Mohanta, M.; Thirugnanam, A. Drug release studies of titanium-based polyethylene glycol coating as a multifunctional substrate. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Wu, S.; Shen, X.; Chen, M.; Yie, K.H.R.; Zhou, Z.; Al-Baadani, M.A.; Fang, K.; Al-Bishari, A.M.; Deng, Z.; Liu, J.; et al. Multifunctional TaCu-nanotubes coated titanium for enhanced bacteriostatic, angiogenic and osteogenic properties. Mater. Sci. Eng. C 2021, 120, 111777. [Google Scholar] [CrossRef] [PubMed]

- Demetrescu, I.; Dumitriu, C.; Totea, G.; Nica, C.; Dinischiotu, A.; Ionita, D. Zwitterionic Cysteine Drug Coating Influence in Functionalization of Implantable Ti50Zr Alloy for Antibacterial, Biocompatibility and Stability Properties. Pharmaceutics 2018, 10, 220. [Google Scholar] [CrossRef] [Green Version]

- Bai, H.; Zhong, L.; Kang, L.; Liu, J.; Zhuang, W.; Lv, Z.; Xu, Y. A review on wear-resistant coating with high hardness and high toughness on the surface of titanium alloy. J. Alloys Compd. 2021, 882, 160645. [Google Scholar] [CrossRef]

- Velumani, S.; Regmi, G.; Lee, M.; Castaneda, H.; Kuttolamadom, M.; Qian, X.; Kassiba, A. Engineered Zr/Zn/Ti oxide nanocomposite coatings for multifunctionality. Appl. Surf. Sci. 2021, 563, 150353. [Google Scholar] [CrossRef]

- Atif, M.; Nawaz, R.; Zia, M.; Adrees, M.; Rizwan, M.; Ali, S.; Ahmad, S.; Tasleem, S. Ecotoxicology and Environmental Safety Synthesis, characterization and advanced sustainable applications of titanium dioxide nanoparticles: A review. Ecotoxicol. Environ. Saf. 2021, 212, 111978. [Google Scholar] [CrossRef]

- Chen, J.; Lu, S.; Tan, L.; Etim, I.P.; Yang, K. Comparative study on effects of different coatings on biodegradable and wear properties of Mg-2Zn-1Gd-0.5Zr alloy. Surf. Coat. Technol. 2018, 352, 273–284. [Google Scholar] [CrossRef]

- Fang, H.; Wang, C.; Zhou, S.; Li, G.; Tian, Y.; Suga, T. Exploration of the enhanced performances for silk fibroin/sodium alginate composite coatings on biodegradable Mg-Zn-Ca alloy. J. Magnes. Alloys 2020. [Google Scholar] [CrossRef]

- Istrate, B.; Rau, J.V.; Munteanu, C.; Antoniac, I.V.; Saceleanu, V. Properties and in vitro assessment of ZrO2-based coatings obtained by atmospheric plasma jet spraying on biodegradable Mg-Ca and Mg-Ca-Zr alloys. Ceram. Int. 2020, 46, 15897–15906. [Google Scholar] [CrossRef]

- Li, J.; Chen, L.; Zhang, X.; Guan, S. Enhancing biocompatibility and corrosion resistance of biodegradable Mg-Zn-Y-Nd alloy by preparing PDA/HA coating for potential application of cardiovascular biomaterials. Mater. Sci. Eng. C 2020, 109, 110607. [Google Scholar] [CrossRef]

- Tan, J.K.E.; Balan, P.; Birbilis, N. Advances in LDH coatings on Mg alloys for biomedical applications: A corrosion perspective. Appl. Clay Sci. 2021, 202, 105948. [Google Scholar] [CrossRef]

- Xavier, J.R.; Raja Beryl, J.; Vinodhini, S.P. Novel multifunctional nanocomposites for superior barrier, hydrophobic and mechanical properties of Mg alloy in marine environment. Surf. Coat. Technol. 2021, 421, 127475. [Google Scholar] [CrossRef]

- Fattah-alhosseini, A.; Chaharmahali, R. Enhancing corrosion and wear performance of PEO coatings on Mg alloys using graphene and graphene oxide additions: A review. FlatChem 2021, 27, 100241. [Google Scholar] [CrossRef]

- Witecka, A.; Yamamoto, A.; Idaszek, J.; Chlanda, A.; Świeszkowski, W. Influence of biodegradable polymer coatings on corrosion, cytocompatibility and cell functionality of Mg-2.0Zn-0.98Mn magnesium alloy. Colloids Surf. B Biointerfaces 2016, 144, 284–292. [Google Scholar] [CrossRef]

- Heimann, R.B. Magnesium alloys for biomedical application: Advanced corrosion control through surface coating. Surf. Coat. Technol. 2021, 405, 126521. [Google Scholar] [CrossRef]

- Khalili, M.A.; Tamjid, E. Controlled biodegradation of magnesium alloy in physiological environment by metal organic framework nanocomposite coatings. Sci. Rep. 2021, 11, 1–13. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Pabla, B.S.; Uddin, M.S. Synthesis, characterization, corrosion and bioactivity investigation of nano-HA coating deposited on biodegradable Mg-Zn-Mn alloy. Surf. Coat. Technol. 2018, 346, 9–18. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Yang, Y.X.; Li, J.A.; Zeng, R.C.; Guan, S.K. Advances in coatings on magnesium alloys for cardiovascular stents—A review. Bioact. Mater. 2021, 6, 4729–4757. [Google Scholar] [CrossRef] [PubMed]

- Asadi, H.; Suganthan, B.; Ghalei, S.; Handa, H.; Ramasamy, R.P. A multifunctional polymeric coating incorporating lawsone with corrosion resistance and antibacterial activity for biomedical Mg alloys. Prog. Org. Coat. 2021, 153, 106157. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Chen, J.; Zou, Y.; Ouyang, J.; Jia, D.; Zhou, Y. Simple and scalable synthesis of super-repellent multilayer nanocomposite coating on Mg alloy with mechanochemical robustness, high-temperature endurance and electric protection. J. Magnes. Alloys 2021. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, T.C.; Zhang, Y.; Rao, J.; Yuan, S. A route for large-scale preparation of multifunctional superhydrophobic coating with electrochemically-modified kaolin for efficient corrosion protection of magnesium alloys. J. Magnes. Alloys 2021. [Google Scholar] [CrossRef]

- Ouyang, Y.; Li, L.X.; Xie, Z.H.; Tang, L.; Wang, F.; Zhong, C.J. A self-healing coating based on facile pH-responsive nanocontainers for corrosion protection of magnesium alloy. J. Magnes. Alloys 2020, 15–18. [Google Scholar] [CrossRef]

- Xue, K.; Liang, L.X.; Cheng, S.C.; Liu, H.P.; Cui, L.Y.; Zeng, R.C.; Li, S.Q.; Wang, Z.L. Corrosion resistance, antibacterial activity and drug release of ciprofloxacin-loaded micro-arc oxidation/silane coating on magnesium alloy AZ31. Prog. Org. Coat. 2021, 158, 106357. [Google Scholar] [CrossRef]

- Shi, H.; Hong, L.; Pan, K.; Wei, W.; Liu, X.; Li, X. Biodegradable polyacrylate copolymer coating for bio-functional magnesium alloy. Prog. Org. Coat. 2021, 159, 106422. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Sheng, Y.; Liu, C.; Xue, Z.; Tong, P.; Guan, S. Designing HA/PEI nanoparticle composite coating on biodegradable Mg–Zn–Y-Nd alloy to direct cardiovascular cells fate. Smart Mater. Med. 2021, 2, 124–133. [Google Scholar] [CrossRef]

- Kang, M.H.; Cheon, K.H.; Jo, K.I.; Ahn, J.H.; Kim, H.E.; Jung, H.D.; Jang, T.S. An asymmetric surface coating strategy for improved corrosion resistance and vascular compatibility of magnesium alloy stents. Mater. Des. 2020, 196, 109182. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Ismail, A.F.; Aziz, M.; Hadisi, Z.; Omidi, M.; Chen, X. Antibacterial activity and corrosion resistance of Ta2O5 thin film and electrospun PCL/MgO-Ag nanofiber coatings on biodegradable Mg alloy implants. Ceram. Int. 2019, 45, 11883–11892. [Google Scholar] [CrossRef]

- Song, Y.; Shan, D.; Han, E.H. A novel biodegradable nicotinic acid/calcium phosphate composite coating on Mg-3Zn alloy. Mater. Sci. Eng. C 2013, 33, 78–84. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Wang, Y.-L.; Tian, Y.-Q.; Chen, L.-S. Research Progress on Surface Protective Coatings of Biomedical Degradable Magnesium alloys. J. Alloys Compd. 2021, 885, 161001. [Google Scholar] [CrossRef]

- Shahri, Z.; Allahkaram, S.R.; Soltani, R.; Jafari, H. Study on corrosion behavior of nano-structured coatings developed on biodegradable as cast Mg–Zn–Ca alloy by plasma electrolyte oxidation. Surf. Coat. Technol. 2018, 347, 225–234. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Hamzah, E.; Ebrahimi-Kahrizsangi, R.; Daroonparvar, M.; Medraj, M. Fabrication and characterization of hydrophobic microarc oxidation/poly-lactic acid duplex coating on biodegradable Mg-Ca alloy for corrosion protection. Vacuum 2016, 125, 185–188. [Google Scholar] [CrossRef]

- Ly, X.; Yang, S.; Nguyen, T. Effect of equal channel angular pressing as the pretreatment on microstructure and corrosion behavior of micro-arc oxidation (MAO) composite coating on biodegradable Mg-Zn-Ca alloy. Surf. Coat. Technol. 2020, 395, 125923. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Singh, M.; Verma, K.; Chaudhary, B.; Singh, S. Multi-objective particle swarm optimization of EDM parameters to deposit HA-coating on biodegradable Mg-alloy. Vacuum 2018, 158, 180–190. [Google Scholar] [CrossRef]

- Saji, V.S. Recent progress in superhydrophobic and superamphiphobic coatings for magnesium and its alloys. J. Magnes. Alloys 2021, 9, 748–778. [Google Scholar] [CrossRef]

- Yazici, M.; Gulec, A.E.; Gurbuz, M.; Gencer, Y.; Tarakci, M. Biodegradability and antibacterial properties of MAO coatings formed on Mg-Sr-Ca alloys in an electrolyte containing Ag doped hydroxyapatite. Thin Solid Films 2017, 644, 92–98. [Google Scholar] [CrossRef]

- Ionita, D.; Dilea, M.; Titorencu, I.; Demetrescu, I. Merit and demerit effects of silver nanoparticles in the bioperformance of an electrodeposited hydroxyapatite: Nanosilver composite coating. J. Nanopart. Res. 2012, 14. [Google Scholar] [CrossRef]

- Wright, P.F. Potential risks and benefits of nanotechnology: Perceptions of risk in sunscreens. Med. J. Aust. 2016, 204, 369–370. [Google Scholar] [CrossRef] [PubMed]

- Vardaki, M.; Pantazi, A.; Demetrescu, I.; Enachescu, M. Assessing the Functional Properties of TiZr Nanotubular Structures for Biomedical Applications, through Nano-Scratch Tests and Adhesion Force Maps. Molecules 2021, 26, 900. [Google Scholar] [CrossRef] [PubMed]

- Macak, J.M.; Hildebrand, H.; Marten-Jahns, U.; Schmuki, P. Mechanistic aspects and growth of large diameter self-organized TiO2 nanotubes. J. Electroanal. Chem. 2008, 621, 254–266. [Google Scholar] [CrossRef]

- Ivanova, A.A.; Surmeneva, M.A.; Shugurov, V.V.; Koval, N.N.; Shulepov, I.A.; Surmenev, R.A. Physico-mechanical properties of Ti-Zr coatings fabricated via ion-assisted arc-plasma deposition. Vacuum 2018, 149, 129–133. [Google Scholar] [CrossRef]

- Montemor, M.F. Functional and smart coatings for corrosion protection: A review of recent advances. Surf. Coat. Technol. 2014, 258, 17–37. [Google Scholar] [CrossRef]

- Presuel-Moreno, F.; Jakab, M.A.; Tailleart, N.; Goldman, M.; Scully, J.R. Corrosion-resistant metallic coatings. Mater. Today 2008, 11, 14–23. [Google Scholar] [CrossRef]

- Zheludkevich, M.L.; Salvado, I.M.; Ferreira, M.G.S. Sol-gel coatings for corrosion protection of metals. J. Mater. Chem. 2005, 15, 5099–5111. [Google Scholar] [CrossRef]

- Dennis, R.V.; Patil, V.; Andrews, J.L.; Aldinger, J.P.; Yadav, G.D.; Banerjee, S. Hybrid nanostructured coatings for corrosion protection of base metals: A sustainability perspective. Mater. Res. Express 2015, 2, 32001. [Google Scholar] [CrossRef]

- Metroke, T.L.; Parkhill, R.L.; Knobbe, E.T. Passivation of metal alloys using sol-gel-derived materials—A review. Prog. Org. Coat. 2001, 41, 233–238. [Google Scholar] [CrossRef]

- Hughes, A.E.; Cole, I.S.; Muster, T.H.; Varley, R.J. Designing green, self-healing coatings for metal protection. NPG Asia Mater. 2010, 2, 143–151. [Google Scholar] [CrossRef]

- Grigoriev, D.; Akcakayiran, D.; Schenderlein, M.; Shchukin, D. Protective Organic Coatings with Anticorrosive and Other Feedback-Active Features: Micro- and Nanocontainers-Based Approach. Corrosion 2014, 70, 446–463. [Google Scholar] [CrossRef]

- Mîndroiu, M.; Pîrvu, C.; Cîmpean, A.; Demetrescu, I. Corrosion and biocompatibility of PPy/PEG coating electrodeposited on Ti6Al7Nb alloy. Mater. Corros. 2013, 64, 926–931. [Google Scholar] [CrossRef]

- Gaur, S.; Khanna, A.S. Functional Coatings by Incorporating Nanoparticles. Nano Res. Appl. 2015, 1, 1–8. [Google Scholar]

- Abdus Samad, U.; Alam, M.A.; Anis, A.; Sherif, E.-S.M.; Al-Mayman, S.I.; Al-Zahrani, S.M. Effect of Incorporated ZnO Nanoparticles on the Corrosion Performance of SiO2 Nanoparticle-Based Mechanically Robust Epoxy Coatings. Materials 2020, 13, 3767. [Google Scholar] [CrossRef] [PubMed]

- Ramezanzadeh, M.; Ramezanzadeh, B.; Mahdavian, M.; Bahlakeh, G. Development of metal-organic framework (MOF) decorated graphene oxide nanoplatforms for anti-corrosion epoxy coatings. Carbon 2020, 161, 231–251. [Google Scholar] [CrossRef]

- Verma, P.; Anoop, S.; Sasidhara Rao, V.; Sharma, A.K.; Uma Rani, R. Multiwalled carbon nanotube-poly vinyl alcohol nanocomposite multifunctional coatings on aerospace alloys. Mater. Today Proc. 2018, 5, 21205–21216. [Google Scholar] [CrossRef]

- Farag, A.A. Applications of nanomaterials in corrosion protection coatings and inhibitors. Corros. Rev. 2020, 1–20. [Google Scholar] [CrossRef]

- Dharmaraj, B.M.; Subramani, R.; Dhanaraj, G.; Louis, K. Multifunctional halloysite nanotube based composite coatings on titanium as metal implant for orthopedic applications. Compos. Part C Open Access 2020, 3, 100077. [Google Scholar] [CrossRef]

- Xosé Fernández Sánchez-Romate, X.; Jiménez Suárez, A.; González Prolongo, S. Smart Coatings with Carbon Nanoparticles. In 21st Century Surface Science—A Handbook; IntechOpen: London, UK, 2020. [Google Scholar]

- Othman, N.H.; Che Ismail, M.; Mustapha, M.; Sallih, N.; Kee, K.E.; Ahmad Jaal, R. Graphene-based polymer nanocomposites as barrier coatings for corrosion protection. Prog. Org. Coat. 2019, 135, 82–99. [Google Scholar] [CrossRef]

- Kumar, S.S.A.; Bashir, S.; Ramesh, K.; Ramesh, S. New perspectives on Graphene/Graphene oxide based polymer nanocomposites for corrosion applications: The relevance of the Graphene/Polymer barrier coatings. Prog. Org. Coat. 2021, 154, 106215. [Google Scholar] [CrossRef]

- Kim, S.; Le, T.H.; Park, C.S.; Park, G.; Kim, K.H.; Kim, S.; Kwon, O.S.; Lim, G.T.; Yoon, H. A solution-processable, nanostructured, and conductive graphene/polyaniline hybrid coating for metal-corrosion protection and monitoring. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef]

- Murugan, N.; Murugan, C.; Sundramoorthy, A.K. In vitro and in vivo characterization of mineralized hydroxyapatite/polycaprolactone-graphene oxide based bioactive multifunctional coating on Ti alloy for bone implant applications. Arab. J. Chem. 2018, 11, 959–969. [Google Scholar] [CrossRef]

- Chen, C.; Qiu, S.; Cui, M.; Qin, S.; Yan, G.; Zhao, H.; Wang, L.; Xue, Q. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 2017, 114, 356–366. [Google Scholar] [CrossRef]

- Bibber, J.W. Chromium-Free Conversion Coatings for Zinc and Its Alloys. J. Appl. Surf. Finish. 2007, 2, 273–275. [Google Scholar]

- Bierwagen, G.; Brown, R.; Battocchi, D.; Hayes, S. Active metal-based corrosion protective coating systems for aircraft requiring no-chromate pretreatment. Prog. Org. Coat. 2010, 68, 48–61. [Google Scholar] [CrossRef]

- Dennis, R.V.; Viyannalage, L.T.; Aldinger, J.P.; Rout, T.K.; Banerjee, S. Nanostructured magnesium composite coatings for corrosion protection of low-alloy steels. Ind. Eng. Chem. Res. 2014, 53, 18873–18883. [Google Scholar] [CrossRef]

- Dennis, R.V.; Fleer, N.A.; Davidson, R.D.; Banerjee, S. Graphene Coatings for the Corrosion Protection of Base Metals. In Graphene Technology: From Laboratory to Fabrication; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2016; pp. 155–176. ISBN 9783527687541. [Google Scholar]

- Chen, L.; Duan, Y.; Cui, M.; Huang, R.; Su, R.; Qi, W.; He, Z. Biomimetic surface coatings for marine antifouling: Natural antifoulants, synthetic polymers and surface microtopography. Sci. Total Environ. 2021, 766, 144469. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Han, H.; Wang, F.; Yan, Y.; Shi, X.; Liang, H.; Zhang, X.; Shuai, Y. Efficient radiative cooling coating with biomimetic human skin wrinkle structure. Nano Energy 2021, 89, 106377. [Google Scholar] [CrossRef]

- Liu, D.; Ma, Z.; Zhao, H.; Ren, L.; Zhang, W. Nano-indentation of biomimetic artificial bone material based on porous Ti6Al4V substrate with Fe22Co22Ni22Ti22Al12 high entropy alloy coating. Mater. Today Commun. 2021, 28, 102659. [Google Scholar] [CrossRef]

- Sartori, M.; Graziani, G.; Sassoni, E.; Pagani, S.; Boi, M.; Maltarello, M.C.; Baldini, N.; Fini, M. Nanostructure and biomimetics orchestrate mesenchymal stromal cell differentiation: An in vitro bioactivity study on new coatings for orthopedic applications. Mater. Sci. Eng. C 2021, 123, 112031. [Google Scholar] [CrossRef]

- Lv, D.; Li, P.; Zhou, L.; Wang, R.; Chen, H.; Li, X.; Zhao, Y.; Wang, J.; Huang, N. Synthesis, evaluation of phospholipid biomimetic polycarbonate for potential cardiovascular stents coating. React. Funct. Polym. 2021, 163, 104897. [Google Scholar] [CrossRef]

- Rahman, M.; Dutta, N.K.; Choudhury, N.R. Microroughness induced biomimetic coating for biodegradation control of magnesium. Mater. Sci. Eng. C 2021, 121, 111811. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, G.; Wang, T.; Liu, K.; Lu, J.; Wang, D. Preparation of biomimetic hair-like composite coatings with water-collecting and superamphiphobic properties. Prog. Org. Coat. 2021, 158, 106372. [Google Scholar] [CrossRef]

- Zhang, W.; Fan, S.; Wang, Y.; Lang, X.; Li, G. Preparation and performance of biomimetic superhydrophobic coating on X80 pipeline steel for inhibition of hydrate adhesion. Chem. Eng. J. 2021, 419, 129651. [Google Scholar] [CrossRef]

- Rajan, R.A.; Ngo, C.V.; Yang, J.; Liu, Y.; Rao, K.S.; Guo, C. Femtosecond and picosecond laser fabrication for long-term superhydrophilic metal surfaces. Opt. Laser Technol. 2021, 143, 107241. [Google Scholar] [CrossRef]

- Tran, N.G.; Chun, D.M. Green manufacturing of extreme wettability contrast surfaces with superhydrophilic and superhydrophobic patterns on aluminum. J. Mater. Process. Technol. 2021, 297, 117245. [Google Scholar] [CrossRef]

- Goharshenas Moghadam, S.; Parsimehr, H.; Ehsani, A. Multifunctional superhydrophobic surfaces. Adv. Colloid Interface Sci. 2021, 290, 102397. [Google Scholar] [CrossRef]

- Stoian, A.B.; Vardaki, M.; Ionita, D.; Enachescu, M.; Prodana, M.; Brancoveanu, O.; Demetrescu, I. Nanopores and nanotubes ceramic oxides elaborated on titanium alloy with zirconium by changing anodization potentials. Ceram. Int. 2018, 44, 7026–7033. [Google Scholar] [CrossRef]

- Bauer, S.; Park, J.; Faltenbacher, J.; Berger, S.; Von Der Mark, K.; Schmuki, P. Size selective behavior of mesenchymal stem cells on ZrO2 and TiO2 nanotube arrays. Integr. Biol. 2009, 1, 525–532. [Google Scholar] [CrossRef]

- Ion, R.; Stoian, A.B.; Dumitriu, C.; Grigorescu, S.; Mazare, A.; Cimpean, A.; Demetrescu, I.; Schmuki, P. Nanochannels formed on TiZr alloy improve biological response. Acta Biomater. 2015, 24, 370–377. [Google Scholar] [CrossRef] [PubMed]

- Ion, R.; Mazare, A.; Dumitriu, C.; Pirvu, C.; Schmuki, P.; Cimpean, A. Nanochannelar topography positively modulates osteoblast differentiation and inhibits osteoclastogenesis. Coatings 2018, 8, 294. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.-P.; Guan, J.-J.; Yang, J.; Wang, Y.; Zhang, C.-Q.; Ke, Q.-F. Hybrid nanostructured hydroxyapatite–chitosan composite scaffold: Bioinspired fabrication, mechanical properties and biological properties. J. Mater. Chem. B 2015, 3, 4679–4689. [Google Scholar] [CrossRef]

- Ionita, D.; Vardaki, M.; Stan, M.S.; Dinischiotu, A.; Demetrescu, I. Enhance Stability and in vitro Cell Response to a Bioinspired Coating on Zr Alloy with Increasing Chitosan Content. J. Bionic Eng. 2017, 14, 459–467. [Google Scholar] [CrossRef]

- Li, L.; Zhang, G.; Su, Z. One-Step Assembly of Phytic Acid Metal Complexes for Superhydrophilic Coatings. Angew. Chem. Int. Ed. 2016, 55, 9093–9096. [Google Scholar] [CrossRef]

- Ding, L.; Wang, Y.; Xiong, J.; Lu, H.; Zeng, M.; Zhu, P.; Ma, H. Plant-inspired layer-by-layer self-assembly of super-hydrophobic coating for oil spill cleanup. Polymers 2019, 11, 2047. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Milne, A.J.B.; Amirfazli, A. The Cassie equation: How it is meant to be used. Adv. Colloid Interface Sci. 2012, 170, 48–55. [Google Scholar] [CrossRef]

- Iacono, S.T.; Jennings, A.R. Recent Studies on Fluorinated Silica Nanometer-Sized Particles. Nanomaterials 2019, 9, 684. [Google Scholar] [CrossRef] [Green Version]

- Lettieri, M.; Masieri, M.; Frigione, M. Novel nano-filled coatings for the protection of built heritage stone surfaces. Nanomaterials 2021, 11, 301. [Google Scholar] [CrossRef] [PubMed]

- Jiaqiang, E.; Jin, Y.; Deng, Y.; Zuo, W.; Zhao, X.; Han, D.; Peng, Q.; Zhang, Z. Wetting Models and Working Mechanisms of Typical Surfaces Existing in Nature and Their Application on Superhydrophobic Surfaces: A Review. Adv. Mater. Interfaces 2018, 5, 1–39. [Google Scholar] [CrossRef]

- Shchukina, E.; Wang, H.; Shchukin, D.G. Nanocontainer-based self-healing coatings: Current progress and future perspectives. Chem. Commun. 2019, 55, 3859–3867. [Google Scholar] [CrossRef] [PubMed]

- Mendoza-Fong, J.R.; García-Alcaraz, J.L.; Díaz-Reza, J.R.; Jiménez-Macías, E.; Blanco-Fernández, J. The role of green attributes in production processes as well as their impact on operational, commercial, and economic benefits. Sustainability 2019, 11, 1294. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Coating | Parameter | Uncoated Alloy | Coated Alloy | Ref. |

|---|---|---|---|---|---|

| 45 steel | FeNiCoCrTi0.5Nb0.5 | Hardness (HV) | 852 | 294 | [49] |

| Q235 steel | CoCr2.5FeNi2Ti | Icorr in simulated saturated salty water solution (µA m−2) | 4.531 × 10−4 | 1.386 × 10−4 | [35] |

| Microhardness (HV) | 192 | 450 | |||

| Wear weight loss (mg) | 5.8 | 3.2 | |||

| Ti64 | Ti64+CoCr | Porosity (%) | 0.9 | 3.2 | [50] |

| Hardness (HV) | 360 | 430 | |||

| Friction coefficient µ | 0.56 | 0.8 | |||

| Wear rate (×10−4 mm3/Nm) | 7.9 | 1.7 | |||

| Zircaloy-4 | ZrSi2 | Pool boiling (kW/m2) | 858 | 813 | [51] |

| Leidenfrost temperature (°C) | 300 | 345 | |||

| Ti-6Al-4V | Ti | Microhardness (HV) | 332.7 | 433.8 | [52] |

| Wear volume (mm3) | 0.08 | 0.02 | |||

| Wear width (µm) | 1.96 | 1.52 | |||

| TiNbZr | Pectin/polypyrrole loaded with gentamicin | Icorr in simulated body fluid (SBF) (µA cm−2) | 1.715 × 10−2 | 0.032 × 10−2 | [53] |

| Growth inhibition (%)—S. Aureus | No antibacterial activity | 86.82 | |||

| Growth inhibition (%)—P. Aeruginosa | No antibacterial activity | 80.00 | |||

| Cell density (a.u.) | 0.55 | 0.75 | |||

| Ti-5Cu | TiO2/Cu2O | Contact angle (°) | 61 | 18 | [54] |

| Surface roughness (µm) | 0.221 | 0.427 | |||

| Icorr in 0.9% NaCl (µA cm−2) | 1.85 × 10−7 | 0.47 × 10−7 | |||

| Corrosion resistance of the inner layer (MΩ cm2) | 3.52 | 4.86 | |||

| Antibacterial rate on S. aureus (%) | 83.4% | >99% | |||

| CoCr | TiO2–Ag | Wear (µm) | 20 | 5 | [55] |

| Wear loss (mg) | 0.3 | 0.1 | |||

| Frictional force (N) | 1.85 | 0.94 | |||

| CoCr | Nb-Ta | Surface roughness (µm) | 1.16 | 3.49 | [56] |

| Contact angle (°) | 90 | 120 | |||

| Microhardness (HV) | 500 | 800 | |||

| Icorr in Ringer’s solution (µA cm−2) | 3.03 | 0.369 | |||

| MTS cell proliferation (absorbance) | 0.23 | 0.39 | |||

| Hemolysis ratio (%) | 4.8 | 3.11 | |||

| CoCr | TiSiON | Friction coefficient µ | 0.34 | 0.06 | [57] |

| Wear rate K (×10−5 mm3/Nm) | 3.5 | 0.6 | |||

| CoCr | HA+12%Sr | Surface roughness (µm) | 1.2 | 4.6 | [58] |

| Microhardness (HV) | 480 | 310 | |||

| Contact angle (°) | 93.81 | 56.12 | |||

| Icorr in Ringer’s solution (µA cm−2) | 2.59 | 0.08 | |||

| CoCrNbMoZr | Diamond-like carbon–Ag | Contact angle (°) | 77 | 66 | [6] |

| Icorr in simulated body fluid (SBF) (µA cm−2) | 2.268 | 0.498 | |||

| Icorr in artificial saliva (µA cm−2) | 1.127 | 0.390 | |||

| Corrosion resistance due to the surface oxide layer in SBF (Ω) | 715.1 | 1185 | |||

| Corrosion resistance due to the surface oxide layer in artificial saliva (Ω) | 3055 | 4509 | |||

| Growth inhibition index (I%)—S. Aureus | No antibacterial activity | 61.75 | |||

| Growth inhibition index (I%)—P. Aeruginosa | No antibacterial activity | 56.4 |

| Substrate | Coating | Coating’s Characteristic | Method Used | Results | Ref. |

|---|---|---|---|---|---|

| MgAlZn (AZ31) | Nanocontainers of 2-mercaptobenzothiazole loaded with mesoporous silica nanoparticles and layered double hydroxide nanosheets shell | Nanocontainers with uniform spherical shape with an approximate diameter of 90 nm after loading and encapsulation | Dip coating | -highly improved corrosion resistance | [118] |

| MgAlZn (AZ31) | Micro-arc oxidation/ciprofloxacin-polymethyltrimethoxysilane | Bird-like structure, approximate thickness of 35 μm | Micro-arc oxidation and dipping | -increased corrosion resistance -long-term drug release -efficient inhibition on S. aureus and E. Coli | [119] |

| MgAlZn (AZ31) | MgO and polytetrafluoroethylene nanoparticles | Polymer-like, porous multilayer with rough surface texture | Plasma-induced thermal-filed assisted crosslink deposition | -superhydrophobic -improved mechanical properties -high-temperature resistance -self-cleaning -low friction coefficient | [116] |

| MgAlZn (AZ31) | 2-methylene-1,3-dioxepane,vinyl acetate, 7-(2-methacryloyloxyethoxy)-4-methylcoumarin, and dopamine methacrylamide | Biodegradable copolymer coating | Electrophoretic deposition and UV irradiation treatment | -increased corrosion resistance -good cytocompatibility | [120] |

| MgZnYNd | hyaluronic acid/polyethyleneimine nanoparticles after fluorination/poly-dopamine treatment | Hydrophilic surface with different roughness depending on the size of the nanoparticles | Dip coating | -improved corrosion resistance -better biocompatibility | [121] |

| MgYNdZr (WE43) | poly(etherimide) and sirolimus loaded poly(lactic-co-glycolic acid) | Polymer asymmetric coating, consisting of an inner single layer and an outside/side sirolimus loaded double layer | Sequential spray coating | -great substrate adhesion -improved cytocompatibility and corrosion resistance -slow release rate of sirolimus | [122] |

| MgZnMn | nano-hydroxyapatite (nHA) | Cubical nanoparticles with interconnected surface porosities of 5–10 μm. Coating thickness between 12 and 22 μm depending on the nHA concentration | Electric discharge machining | -very reduced degradation rate -increased microhardness -improved cytocompatibility | [113] |

| MgCaZn | Ta2O5 and poly (ε-caprolactone)/MgO-Ag | Dense film of Ta2O5, with no cracks or pores covered with nanofibers (200–360 nm diameter) with porous structure | Magnetron sputtering and electrospinning coating | -improved corrosion resistance -antibacterial activity | [123] |

| MgZnCa | Silk fibroin/sodium alginate | Uniform coating, without cracks, with an average thickness of 5 μm | Micro-drop deposition | -improved mechanical properties and corrosion resistance | [104] |

| MgZnYNd | poly-dopamine/hyaluronic acid (HA) | Surface with particles of several micrometers and various roughness depending on the molecular weight of the HA used | Dip coating | -improved corrosion resistance -pro-endothelialization ability | [106] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nartita, R.; Ionita, D.; Demetrescu, I. Sustainable Coatings on Metallic Alloys as a Nowadays Challenge. Sustainability 2021, 13, 10217. https://doi.org/10.3390/su131810217

Nartita R, Ionita D, Demetrescu I. Sustainable Coatings on Metallic Alloys as a Nowadays Challenge. Sustainability. 2021; 13(18):10217. https://doi.org/10.3390/su131810217

Chicago/Turabian StyleNartita, Radu, Daniela Ionita, and Ioana Demetrescu. 2021. "Sustainable Coatings on Metallic Alloys as a Nowadays Challenge" Sustainability 13, no. 18: 10217. https://doi.org/10.3390/su131810217

APA StyleNartita, R., Ionita, D., & Demetrescu, I. (2021). Sustainable Coatings on Metallic Alloys as a Nowadays Challenge. Sustainability, 13(18), 10217. https://doi.org/10.3390/su131810217