A Life Cycle Assessment Approach for Vegetables in Large-, Mid-, and Small-Scale Food Systems in the Midwest US

Abstract

:1. Introduction

1.1. Large-Scale (Conventional, Distant) Food Systems

1.2. Mid-Scale (Commercial, Local) Food Systems

1.3. Small-Scale (Home Garden) Food Systems

1.4. Using a Life Cycle Assessment Approach for Food Systems Modeling

1.5. Objectives

2. Materials and Methods

2.1. Large-Scale (LS) Scenario

2.2. Mid-Scale (MS) Scenario

2.3. Small-Scale (SS) Scenario

2.4. Linear Model

2.5. Hotspots and Tradeoffs

2.6. Environmental Impact Scores

3. Results

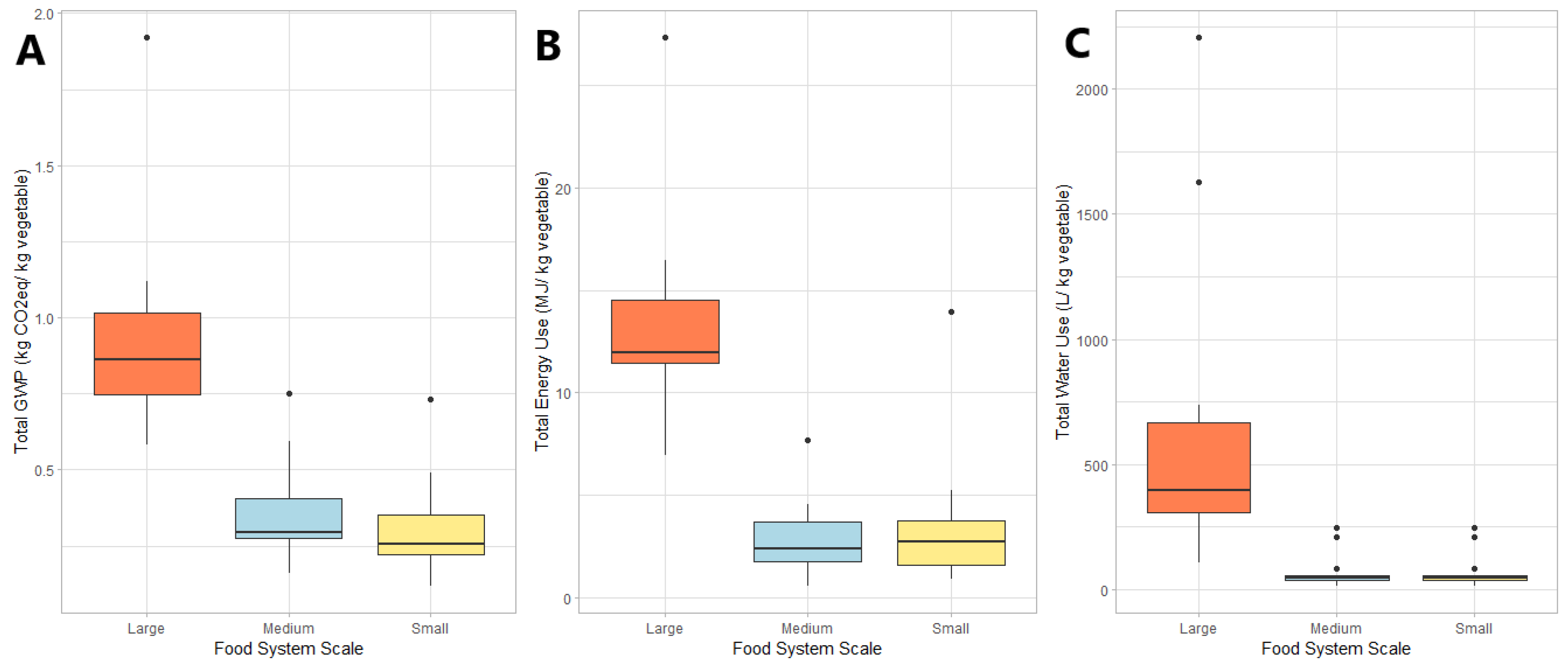

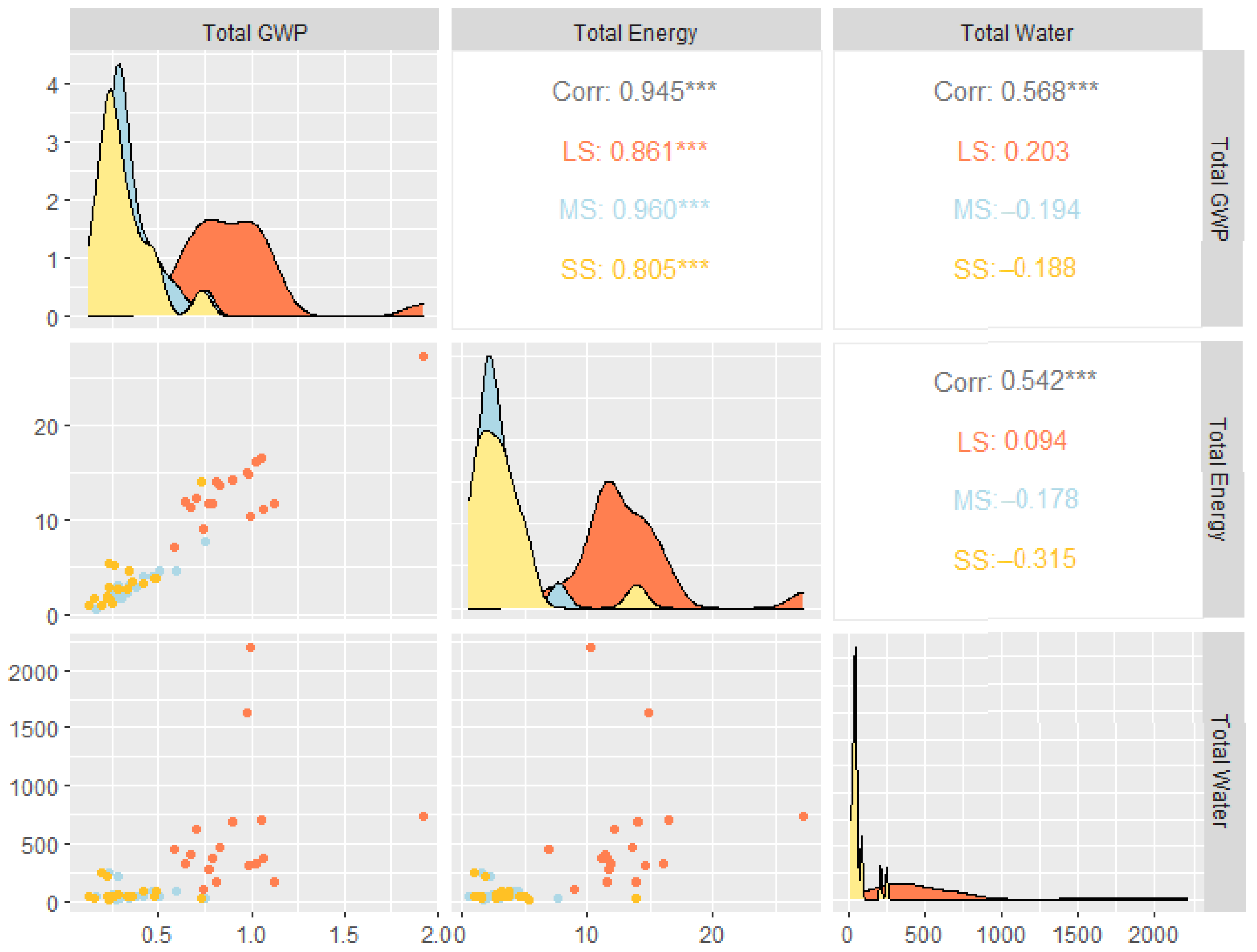

3.1. Global Warming Potential, Energy, and Water Use by Scale

3.2. Hotspots and Tradeoffs for GWP, Energy, and Water Use by Scale and Vegetable Type

3.3. Environmental Impact Score by Vegetable Type

4. Discussion

4.1. Environmental Outputs by Scale

4.2. Hotspots and Tradeoffs for Environmental Outputs

4.3. Environmental Impact Score by Vegetable Type

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nilsson, M.; Griggs, D.; Visbeck, M. Policy: Map the interactions between Sustainable Development Goals. Nature 2016, 534, 320–322. [Google Scholar] [CrossRef]

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate change and food systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef] [Green Version]

- Ballew, M.T.; Leiserowitz, A.; Roser-Renouf, C.; Rosenthal, S.A.; Kotcher, J.E.; Marlon, J.R.; Lyon, E.; Goldberg, M.H.; Maibach, E.W. Climate change in the american mind: Data, tools, and trends. Environment 2019, 61, 4–18. [Google Scholar] [CrossRef]

- Roser-Renouf, C.; Maibach, E.W.; Leiserowitz, A.; Zhao, X. The genesis of climate change activism: From key beliefs to political action. Clim. Chang. 2014, 125, 163–178. [Google Scholar] [CrossRef] [Green Version]

- O’Brien, K.; Selboe, E.; Hayward, B.M. Exploring youth activism on climate change: Dutiful, disruptive, and dangerous dissent. Ecol. Soc. 2018, 23, 42–55. [Google Scholar] [CrossRef] [Green Version]

- IPCC. Summary for Policymakers. In IPCC Special Report on the Ocean and Cryosphere in a Changing Climate; Pörtner, H.-O., Roberts, D.C., Masson-Delmotte, V., Zhai, P., Tignor, M., Poloczanska, E., Mintenbeck, K., Alegría, A., Nicolai, M., Okem, A., et al., Eds.; IPCC: Geneva, Switzerland, 2019; pp. 1–24. Available online: https://www.ipcc.ch/site/assets/uploads/sites/3/2019/11/03_SROCC_SPM_FINAL.pdf (accessed on 25 January 2021).

- Benis, K.; Ferrão, P. Potential mitigation of the environmental impacts of food systems through urban and peri-urban agriculture (UPA)—A life cycle assessment approach. J. Clean. Prod. 2017, 140, 784–795. [Google Scholar] [CrossRef]

- Heller, M.C.; Keoleian, G.A.; Willett, W.C. Toward a life cycle-based, diet-level framework for food environmental impact and nutritional quality assessment: A critical review. Environ. Sci. Technol. 2013, 47, 12632–12647. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Heller, M.C.; Willits-Smith, A.; Meyer, R.; Keoleian, G.A.; Rose, D. Greenhouse gas emissions and energy use associated with production of individual self-selected US diets. Environ. Res. Lett. 2018, 13, 044004. [Google Scholar] [CrossRef]

- Goldstein, B.; Hauschild, M.; Fernández, J.; Birkved, M. Urban versus conventional agriculture, taxonomy of resource profiles: A review. Agron. Sustain. Dev. 2016, 36, 9. [Google Scholar] [CrossRef]

- Gava, O.; Bartolini, F.; Venturi, F.; Brunori, G.; Zinnai, A.; Pardossi, A. A reflection of the use of the life cycle assessment tool for agri-food sustainability. Sustainability 2018, 11, 71. [Google Scholar] [CrossRef] [Green Version]

- Rehkamp, S.; Azzam, A.; Gustafson, C.R. US dietary shifts and the associated CO2 emissions from farm energy use. Food Stud. Interdiscip. J. 2017, 7, 11–22. [Google Scholar] [CrossRef]

- Notarnicola, B.; Salomone, R.; Petti, L.; Renzulli, P.A.; Roma, R.; Cerutti, A.K. Life Cycle Assessment in the Agri-Food Sector: Case Studies, Methodological Issues, and Best Practices; Springer: Cham, Switzerland, 2016; Volume 21, pp. 1–390. [Google Scholar] [CrossRef] [Green Version]

- de Vries, M.; de Boer, I.J.M. Comparing environmental impacts for livestock products: A review of life cycle assessments. Livest. Sci. 2010, 128, 1–11. [Google Scholar] [CrossRef]

- Cucurachi, S.; Scherer, L.; Guinée, J.; Tukker, A. Life cycle assessment of food systems. One Earth 2019, 1, 292–297. [Google Scholar] [CrossRef] [Green Version]

- Peters, C.J.; Picardy, J.; Darrouzet-Nardi, A.F.; Wilkins, J.L.; Griffin, T.S.; Fick, G.W. Carrying capacity of U.S. agricultural land: Ten diet scenarios. Elem. Sci. Anthr. 2016, 4, 000116. [Google Scholar] [CrossRef] [Green Version]

- Kulak, M.; Graves, A.; Chatterton, J. Reducing greenhouse gas emissions with urban agriculture: A Life Cycle Assessment perspective. Landsc. Urban Plan. 2013, 111, 68–78. [Google Scholar] [CrossRef]

- Donati, M.; Menozzi, D.; Zighetti, C.; Rosi, A.; Zinetti, A.; Scazzina, F. Towards a sustainable diet combining economic, environmental and nutritional objectives. Appetite 2016, 106, 48–57. [Google Scholar] [CrossRef]

- Garnett, T. Three perspectives on sustainable food security: Efficiency, demand restraint, food system transformation. What role for life cycle assessment? J. Clean. Prod. 2014, 73, 10–18. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef] [Green Version]

- Mohareb, E.A.; Heller, M.C.; Guthrie, P.M. Cities’ role in mitigating united states food system greenhouse gas emissions. Environ. Sci. Technol. 2018, 52, 5545–5554. [Google Scholar] [CrossRef] [PubMed]

- Hallström, E.; Carlsson-Kanyama, A.; Börjesson, P. Environmental impact of dietary change: A systematic review. J. Clean. Prod. 2015, 91, 1–11. [Google Scholar] [CrossRef]

- Weber, C.L.; Matthews, H.S. Food-miles and the relative climate impacts of food choices in the United States. Environ. Sci. Technol. 2008, 42, 3508–3513. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoppe, R.A.; MacDonald, J.M. America’s Diverse Family Farms, 2016 Edition; USDA-ERS: Washington, DC, USA, 2016; EIB-164; 16p.

- Mohareb, E.; Heller, M.; Novak, P.; Goldstein, B.; Fonoll, X.; Raskin, L. Considerations for reducing food system energy demand while scaling up urban agriculture. Environ. Res. Lett. 2017, 12, 125004. [Google Scholar] [CrossRef]

- FAO. Climate-Smart Agriculture Sourcebook; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; ISBN 978-92-5-107720-7. [Google Scholar]

- Knight, L.; Riggs, W. Nourishing urbanism: A case for a new urban paradigm. Int. J. Agric. Sustain. 2010, 8, 116–126. [Google Scholar] [CrossRef]

- Saha, M.; Eckelman, M.J. Growing fresh fruits and vegetables in an urban landscape: A geospatial assessment of ground level and rooftop urban agriculture potential in Boston, USA. Landsc. Urban Plan. 2017, 165, 130–141. [Google Scholar] [CrossRef]

- Grewal, S.S.; Grewal, P.S. Can cities become self-reliant in food? Cities 2012, 29, 1–11. [Google Scholar] [CrossRef]

- Krouse, L.; Galluzzo, T. Iowa’s Local Food Systems: A Place to Grow; The Iowa Policy Project: Mount Vernon, IA, USA, 2007; pp. 1–24. [Google Scholar]

- Schnell, S.M. Food miles, local eating, and community supported agriculture: Putting local food in its place. Agric. Hum. Values 2013, 30, 615–628. [Google Scholar] [CrossRef]

- Wells, H.; Bond, J.; Thornsbury, S. Vegetables and pulses outlook. Change 2016, 2015, 16. [Google Scholar]

- Kreidenweis, U.; Lautenbach, S.; Koellner, T. Regional or global? The question of low-emission food sourcing addressed with spatial optimization modelling. Environ. Model. Softw. 2016, 82, 128–141. [Google Scholar] [CrossRef]

- Goldstein, B.; Hauschild, M.; Fernandez, J.; Birkved, M. Testing the environmental performance of urban agriculture as a food supply in northern climates. J. Clean. Prod. 2016, 135, 984–994. [Google Scholar] [CrossRef] [Green Version]

- United States Environmental Protection Agency. 2018 Wasted Food Report; US-EPA: Washington, DC, USA, 2020.

- Buzby, J.; Wells, H.; Hyman, J. The Estimated Amount, Value, and Calories of Postharvest Food Losses at the Retail and Consumer Levels in the United States; USDA-ERS: Washington, DC, USA, 2014; EIB-121.

- Martinez, S.; Hand, M.; da Pra, M.; Pollack, S.; Ralston, K.; Smith, T.; Vogel, S.; Clark, S.; Lohr, L.; Low, S.; et al. Local food systems: Concepts, impacts, and issues. Local Food Syst. Backgr. Issues 2010, 97, 1–75. [Google Scholar]

- Li, T.; Messer, K.D. Is This Food “Local”? Evidence from a Framed Field Experiment. J. Agric. Resour. Econ. 2020, 45, 179–198. [Google Scholar] [CrossRef]

- Thebo, A.L.; Drechsel, P.; Lambin, E.F. Global assessment of urban and peri-urban agriculture: Irrigated and rainfed croplands. Environ. Res. Lett. 2014, 9, 114002. [Google Scholar] [CrossRef]

- Pagano, M.; Bowman, A. Vacant Land in Cities: An Urban Resource; Center on Urban and Metropolitan Policy, The Brooking Institution: Washington, DC, USA, 2000; pp. 1–9. [Google Scholar]

- Gimenez-Escalante, P.; Garcia-Garcia, G.; Rahimifard, S. A method to assess the feasibility of implementing distributed Localised Manufacturing strategies in the food sector. J. Clean. Prod. 2020, 266, 121934. [Google Scholar] [CrossRef]

- Opitz, I.; Berges, R.; Piorr, A.; Krikser, T. Contributing to food security in urban areas: Differences between urban agriculture and peri-urban agriculture in the Global North. Agric. Hum. Values 2016, 33, 341–358. [Google Scholar] [CrossRef] [Green Version]

- Gray, L.; Guzman, P.; Glowa, K.M.; Drevno, A.G. Can home gardens scale up into movements for social change? The role of home gardens in providing food security and community change in San Jose, California. Local Environ. 2014, 19, 187–203. [Google Scholar] [CrossRef]

- Guitart, D.; Pickering, C.; Byrne, J. Past results and future directions in urban community gardens research. Urban For. Urban Green. 2012, 11, 364–373. [Google Scholar] [CrossRef] [Green Version]

- Enshayan, K. Community economic impact assessment for a multi-county local food system in northeast Iowa. Leopold Cent. Complet. Grant Rep. 2009, 330, 1–4. [Google Scholar]

- Telesetsky, A. Community-based urban agriculture as affirmative environmental justice. Univ. Detroit Mercy Law Rev. 2014, 91, 259–276. [Google Scholar]

- Kirkpatrick, J.B.; Davison, A. Home-grown: Gardens, practices and motivations in urban domestic vegetable production. Landsc. Urban Plan. 2018, 170, 24–33. [Google Scholar] [CrossRef]

- Cleveland, D.A.; Phares, N.; Nightingale, K.D.; Weatherby, R.L.; Radis, W.; Ballard, J.; Campagna, M.; Kurtz, D.; Livingston, K.; Riechers, G.; et al. The potential for urban household vegetable gardens to reduce greenhouse gas emissions. Landsc. Urban Plan. 2017, 157, 365–374. [Google Scholar] [CrossRef]

- Schreinemachers, P.; Simmons, E.B.; Wopereis, M.C.S. Tapping the economic and nutritional power of vegetables. Glob. Food Sec. 2018, 16, 36–45. [Google Scholar] [CrossRef]

- Algert, S.J.; Baameur, A.; Diekmann, L.O.; Gray, L.; Ortiz, D. Vegetable output, cost savings, and nutritional value of low-income families’ home gardens in San Jose, CA. J. Hunger Environ. Nutr. 2016, 11, 328–336. [Google Scholar] [CrossRef]

- Taylor, J.R.; Lovell, S.T. Urban home food gardens in the Global North: Research traditions and future directions. Agric. Hum. Values 2014, 31, 285–305. [Google Scholar] [CrossRef]

- Morton, L.W.; Bitto, E.A.; Oakland, M.J.; Sand, M. Accessing food resources: Rural and urban patterns of giving and getting food. Agric. Hum. Values 2008, 25, 107–119. [Google Scholar] [CrossRef]

- Nicholls, E.; Ely, A.; Birkin, L.; Basu, P.; Goulson, D. The contribution of small-scale food production in urban areas to the sustainable development goals: A review and case study. Sustain. Sci. 2020, 33, 341–358. [Google Scholar] [CrossRef] [Green Version]

- Masset, E.; Haddad, L.; Cornelius, A.; Isaza-Castro, J. Effectiveness of agricultural interventions that aim to improve nutritional status of children: Systematic review. BMJ 2012, 344, 1–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Braungart, M.; Mcdonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions–a strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Oldfield, T.L.; White, E.; Holden, N.M. The implications of stakeholder perspective for LCA of wasted food and green waste. J. Clean. Prod. 2018, 170, 1554–1564. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H.; Verghese, K.; Clune, S. The influence of packaging attributes on consumer behaviour in food-packaging life cycle assessment studies-A neglected topic. J. Clean. Prod. 2014, 73, 100–108. [Google Scholar] [CrossRef]

- Badami, M.G.; Ramankutty, N. Urban agriculture and food security: A critique based on an assessment of urban land constraints. Glob. Food Secur. 2015, 4, 8–15. [Google Scholar] [CrossRef]

- Rothwell, A.; Ridoutt, B.; Page, G.; Bellotti, W. Environmental performance of local food: Trade-offs and implications for climate resilience in a developed city. J. Clean. Prod. 2016, 114, 420–430. [Google Scholar] [CrossRef]

- Yue, W.; Cai, Y.; Su, M.; Yang, Z.; Dang, Z. A hybrid copula and life cycle analysis approach for evaluating violation risks of GHG emission targets in food production under urbanization. J. Clean. Prod. 2018, 190, 655–665. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Environmental Management: Life Cycle Assessment; Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006; p. 14044. [Google Scholar]

- Penman, J.; Gytarsky, M.; Hiraishi, T.; Irving, W.; Krug, T. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Hayama, Japan, 2006; pp. 1–12. [Google Scholar]

- US Census Bureau. Urban Areas Facts. Available online: https://www.census.gov/programs-surveys/geography/guidance/geo-areas/urban-rural/ua-facts.html (accessed on 21 May 2021).

- USDA-NASS. 2017 Census of Agriculture-Iowa State Data Table 36; USDA-NASS: Washington, DC, USA, 2017; pp. 454–469.

- United States Department of Agriculture Economic Research Service. Food Availability (Per Capita) Data System. 2021. Available online: https://www.ers.usda.gov/data-products/food-availability-per-capita-data-system/ (accessed on 2 February 2019).

- USDA-NASS. Table 13: Energy Expense for All Well Pumps and Other Irrigation Pumps by Type of Energy Used: 2018; 2017 Census of Agriculture, 2018 IWMS Entire Farm Data; USDA-NASS: Washington, DC, USA, 2017.

- USDA-NASS. Table 7. Irrigation by Estimated Quantity of Water Applied: 2018 and 2013; Census of Agriculture 2017, 2018 IWMS Farm Data; USDA-NASS: Washington, DC, USA, 2018.

- Tripp, P.; Wilson, G. Wholesale and Retail Product Specifications: Guidance and Best Practices for Fresh Produce for Small Farms and Food Hubs; North Carolina Growing Together: Raleigh, NC, USA, 2014; pp. 1–30. [Google Scholar]

- Boyette, M.; Sanders, D.C.; Rutledge, G.A. Packaging Requirements for Fresh Fruits and Vegetables: Postharvest Technology Series; North Carolina State Extension Publications: Raleigh, NC, USA, 1996; AG-414-08; Available online: https://content.ces.ncsu.edu/packaging-requirements-for-fresh-fruits-and-vegetables (accessed on 12 August 2020).

- Google. Google Maps. Available online: https://maps.google.com/ (accessed on 7 April 2020).

- United Nations Environment Programme. UNEP Food Waste Index Report 2021; UNEP: Nairobi, Kenya, 2021; pp. 3–99. ISBN 9789280738513. [Google Scholar]

- Gregoire, M.B.; Arendt, S.W.; Strohbehn, C.H. Iowa producers’ perceived benefits and obstacles in marketing to local restaurants and institutional foodservice operations. J. Ext. 2005, 43, 1RBI1. [Google Scholar]

- Enderton, A.; Bregendahl, C.; Swenson, D.; Adcock, L.; Alexa, W.; Topaloff, A. Iowa Commercial Horticulture Survey Results 2015; Iowa Dept. of Ag. and Land Stewardship: Des Moines, IA, USA; Iowa State Univ. Extension and Outreach: Ames, IA, USA, 2017; pp. 1–41.

- Audsley, E.; Stacey, K.; Parsons, D.; Williams, A. Estimation of the Greenhouse Gas Emissions from Agricultural Pesticide Manufacture and Use; Cranfield University: Cranfield, UK, 2009; pp. 1–20. [Google Scholar]

- Egel, D.; Maynard, E.; Meyers, S.; Babadoost, M.; Lewis, D.; Rivard, C.; Kennelly, M.; Hausbeck, M.; Phillips, B.; Szendrei, Z.; et al. Midwest Vegetable Production Guide for Commercial Growers; Cooperative Extension Publications: Orono, ME, USA, 2020; pp. 1–264. Available online: Mwveguide.org (accessed on 21 March 2021).

- USDA-NASS. Vegetables 2018 Summary; USDA-NASS: Washington, DC, USA, 2019.

- USDA-NASS. 2017 Census of Agriculture: United States Summary and State Data; United States Summ. State Data; USDA-NASS: Washington, DC, USA, 2019.

- Thompson, J.R.; Tyndall, J.; Moore, M.; Naeve, L. Using spatially explicit supply/demand and local participants ’ perspectives to integrate urban agriculture with community planning. Leopold Cent. Complet. Grant Rep. 2015, 494, 1–4. [Google Scholar]

- US EPA; Atwood, D.; Paisley-Jones, C. Pesticides Industry SALES and Usage 2008–2012 Market Estimates; US EPA: Washington, DC, USA, 2017; pp. 1–41.

- The National Gardening Association. National Gardening Association Special Report: Garden to Table: A 5 Year Look at Food Gardening in America; The National Gardening Association: South Burlington, VT, USA, 2014; pp. 1–24. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018; Available online: https://www.R-project.org/ (accessed on 5 January 2021).

- Dietary Guidelines Advisory Committee 2015–2020 Dietary Guidelines for Americans; U.S. Department of Health and Human Services and U.S. Department of Agriculture: Washington, DC, USA, 2015; pp. 1–122.

- Stoessel, F.; Juraske, R.; Pfister, S.; Hellweg, S. Life Cycle Inventory and Carbon and Water FoodPrint of Fruits and Vegetables: Application to a Swiss Retailer. Environ. Sci. Technol. 2012, 46, 3253–3262. [Google Scholar] [CrossRef]

- McDougall, R.; Kristiansen, P.; Rader, R. Small-scale urban agriculture results in high yields but requires judicious management of inputs to achieve sustainability. Proc. Natl. Acad. Sci. USA 2019, 116, 129–134. [Google Scholar] [CrossRef] [Green Version]

- Huttinger, L.; Evans, C.; Forgie, J.; Stevenson, M. Evaluating the Environmental Impacts of Packaging Fresh Tomatoes Using Life-Cycle Thinking & Assessment: A Sustainable Materials Management Demonstration Project; EPA: Washington, DC, USA, 2010; pp. 1–70.

- Tourte, L.; Smith, R.; Murdock, J.; Sumner, D.A. Sample Costs to Produce and Harvest Iceberg Lettuce; UC California Cooperative Extension-Agricultural Issues Center: La Jolla, CA, USA, 2017; pp. 1–17. [Google Scholar]

- Tourte, L.; Smith, R.; Murdock, J.; Sumner, D.A. Sample Costs to Produce and Harvest Romaine Hearts; UC California Cooperative Extension-Agricultural Issues Center: La Jolla, CA, USA, 2019; pp. 1–17. [Google Scholar]

- Tindula, G.N.; Orang, M.N.; Snyder, R.L. Survey of Irrigation Methods in California in 2010. J. Irrig. Drain. Eng. 2013, 139, 233–238. [Google Scholar] [CrossRef]

- Koike, S.T.; Cahn, M.; Cantwell, M.; Fennimore, S.; Lestrange, M.; Natwick, E.; Smith, R.F.; Takele, E. Cauliflower Production in California; University of California, Agriculture and Natural Resources: La Jolla, CA, USA, 2009; Volume 7219, pp. 1–6. ISBN 978-1-60107-011-1. [Google Scholar]

| Food System Scenarios | Large-Scale Conventional | Mid-Scale Commercial Local | Small-Scale Home Garden |

|---|---|---|---|

| Fertilizer/Pesticides | Assumptions for conventional production from FoodCarbonScope™ | Iowa vegetable farm pesticide assumptions based on estimates by a horticulture extension specialist | Home garden pesticide assumptions based on USDA household pesticide use averages |

| Electricity/Fuel | Assumptions for conventional production from FoodCarbonScope™ | Iowa vegetable farm fuel assumptions based on estimates by a horticulture extension specialist | Home garden electricity and fuel assumptions based on rototilling for one hour/season/garden |

| Packaging | Shipping carton and plastic produce bags based on shipping conventions | No packaging | No packaging |

| Transportation | Travel was of variable distance (km from state and county with highest production for each vegetable) by semi-truck trailer | Travel was 160 km round trip by single-unit truck (round trip was assumed based on the smaller scale, shorter distances, and selling the majority of vegetables direct-to-consumer) | No transportation |

| Food Waste | Estimated waste was 31% for retail and consumer based on USDA estimates of between 30% and 40%. Waste was transported 90 km by single unit truck to an uncategorized landfill | Estimated waste was 24% accounting for consumer and distribution waste. Waste was transported 90 km by single unit truck to an uncategorized landfill | Estimated waste was 21% accounting for consumer waste only. Waste was transported 90 km by single unit truck to an uncategorized landfill |

| Impact Score | Large Scale | Mid-Scale | Small-Scale | |||

|---|---|---|---|---|---|---|

| Low Impact | Potato | 37 | Leaf lettuce | 9 | Head lettuce | 7 |

| Head lettuce | 39 | Onion | 11 | Carrot | 8 | |

| Leaf lettuce | 40 | Head lettuce | 12 | Leaf lettuce | 8 | |

| Onion | 41 | Carrot | 12 | Onion | 9 | |

| Pumpkin | 41 | Cabbage | 16 | Tomato | 10 | |

| Carrot | 42 | Potato | 16 | Cabbage | 11 | |

| Moderate | Cabbage | 44 | Sweet corn | 18 | Pumpkin | 15 |

| Pea | 44 | Pumpkin | 19 | Squash | 16 | |

| Cucumber | 44 | Bell pepper | 20 | Sweet corn | 17 | |

| Squash | 45 | Squash | 21 | Cucumber | 18 | |

| Spinach | 46 | Tomato | 21 | Potato | 19 | |

| Tomato | 47 | Cucumber | 24 | Bell pepper | 19 | |

| High Impact | Bell pepper | 48 | Romaine lettuce | 24 | Romaine lettuce | 23 |

| Snap bean | 48 | Cauliflower | 26 | Pea | 25 | |

| Cauliflower | 50 | Peas | 27 | Cauliflower | 25 | |

| Broccoli | 51 | Broccoli | 28 | Broccoli | 27 | |

| Sweet corn | 52 | Spinach | 29 | Spinach | 27 | |

| Romaine lettuce | 53 | Snap bean | 31 | Snap bean | 31 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stone, T.F.; Thompson, J.R.; Rosentrater, K.A.; Nair, A. A Life Cycle Assessment Approach for Vegetables in Large-, Mid-, and Small-Scale Food Systems in the Midwest US. Sustainability 2021, 13, 11368. https://doi.org/10.3390/su132011368

Stone TF, Thompson JR, Rosentrater KA, Nair A. A Life Cycle Assessment Approach for Vegetables in Large-, Mid-, and Small-Scale Food Systems in the Midwest US. Sustainability. 2021; 13(20):11368. https://doi.org/10.3390/su132011368

Chicago/Turabian StyleStone, Tiffanie F., Janette R. Thompson, Kurt A. Rosentrater, and Ajay Nair. 2021. "A Life Cycle Assessment Approach for Vegetables in Large-, Mid-, and Small-Scale Food Systems in the Midwest US" Sustainability 13, no. 20: 11368. https://doi.org/10.3390/su132011368

APA StyleStone, T. F., Thompson, J. R., Rosentrater, K. A., & Nair, A. (2021). A Life Cycle Assessment Approach for Vegetables in Large-, Mid-, and Small-Scale Food Systems in the Midwest US. Sustainability, 13(20), 11368. https://doi.org/10.3390/su132011368