Exergy-Based Life Cycle Assessment of Buildings: Case Studies

Abstract

:1. Introduction

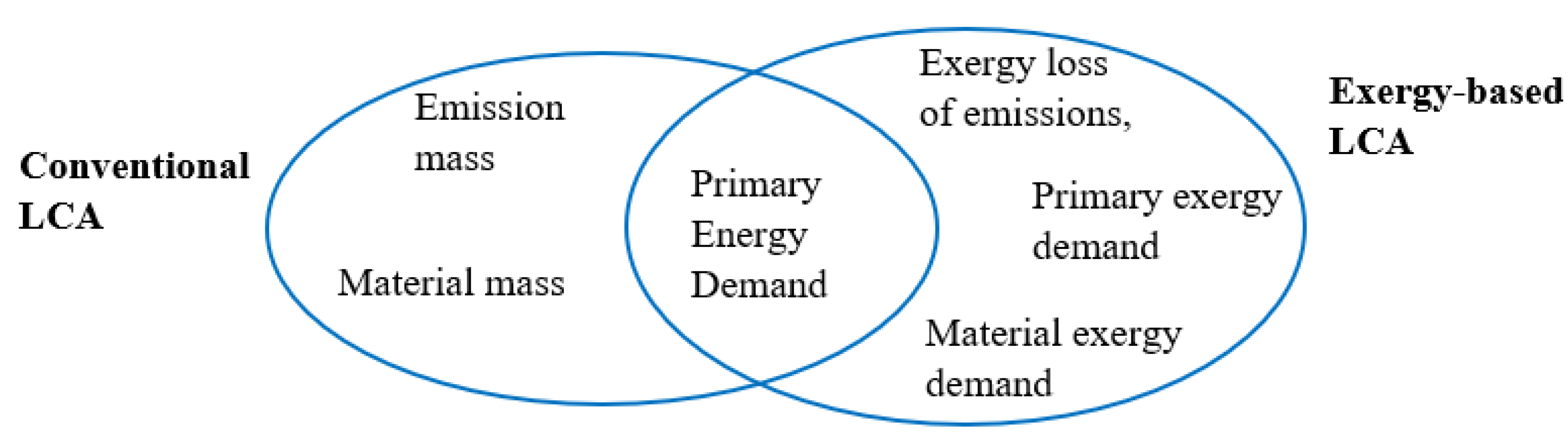

2. Literature Review: Relevance of Exergy to a Building Life Cycle Assessment

- An exergy-based LCA method can express environmental impacts as a single objective function, which enables comparison of the results;

- It can identify the unit process or building life cycle phase to be improved;

- An exergy-based LCA method can overcome the resource-use characterization problem found in the conventional LCA method, thereby reducing or eliminating subjectivity when interpreting the results;

- It can measure the exergy losses of the mass of materials, and emissions of buildings, which is essential for the environmental sustainability assessment of buildings;

- An exergy-based method can complement the conventional LCA method, to provide a more in-depth assessment.

3. Exergy-Based Life Cycle Assessment (Exe-LCA) of Buildings

3.1. Development of the Method for Exe-LCA of Buildings

- Applied to primary energy demand (PED) to ascertain the primary exergy demand (PExD).

- Applied to material mass (MM) to ascertain material exergy demand (MExD).

- Applied to emission mass (EM) to ascertain the exergy loss of emissions (ExLE).

3.1.1. Measure of Exergy of Material Mass, and Energy Demand

3.1.2. Measure of Exergy of Life Cycle Emission

3.2. Illustration of Exergy-Based LCA Method: Calculation of Standard Chemical Exergy of Emissions, SCExE

- Carbon Dioxide (CO2)

- Methane (CH4)

- Nitrous Oxide (N2O)

- Trichlorofluoromethane (CFC-11 or CFCl3)

- Difluorodichloromethane (CFC-12 or CCl2F2)

- Trifluoromethane (HFC-23 or CHF3)

- Difluorochloromethane (HCFC-22 or CHClF2)

- Hexafluoroethane (PFC-116 or C2F6)

- Nitrogen trifluoride (NF3)

- Sulfur hexafluoride (SF6)

4. Case Studies of Exergy-Based Life Cycle Assessment of Buildings

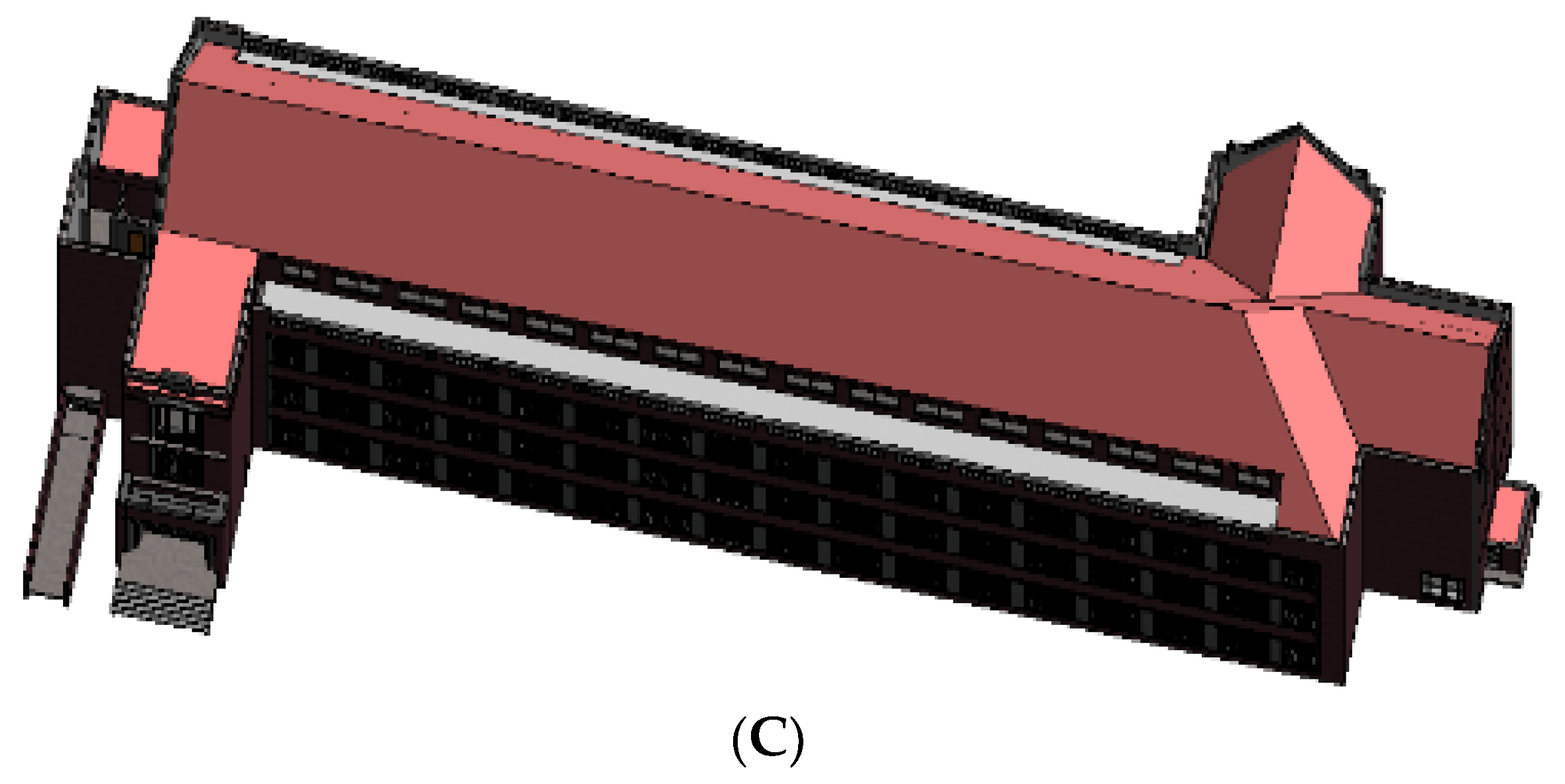

4.1. Choice of Case Study Buildings

4.2. Approach to Case Studies

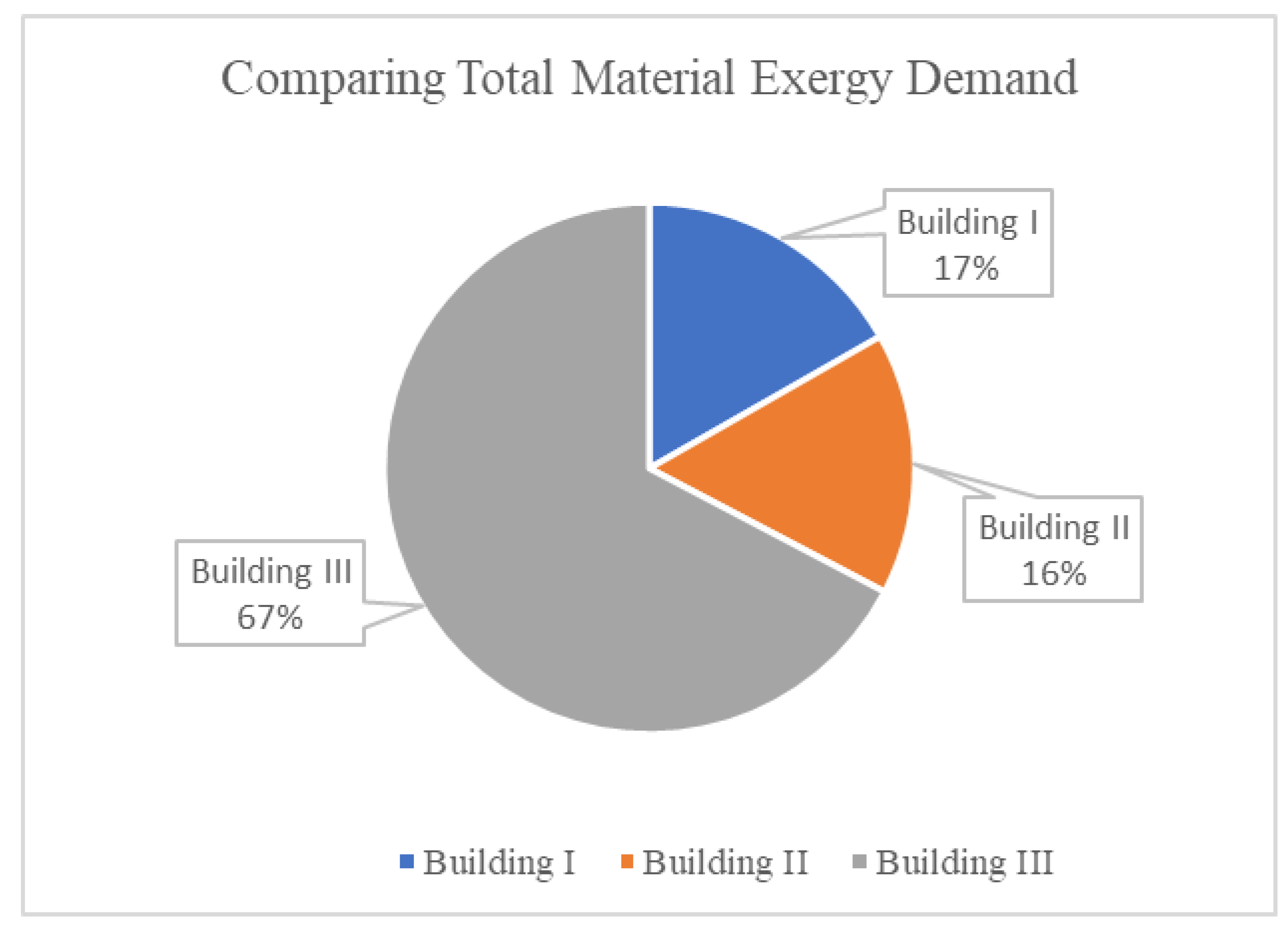

5. Results of the Case Study of Buildings

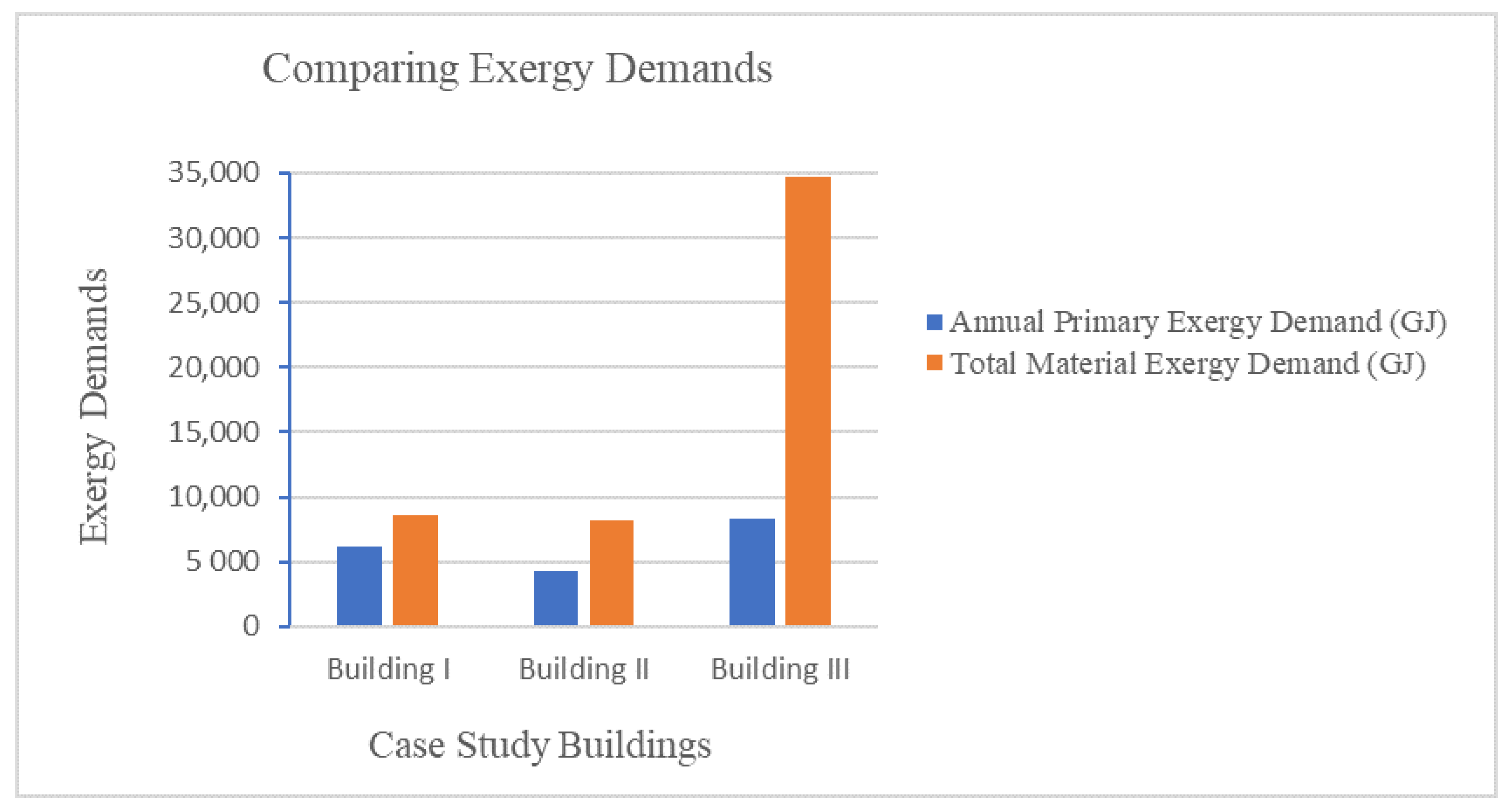

Results of Exe-LCA for Each Case Study

6. Discussion

7. Summary and Conclusions

- Unlike the conventional LCA method, the Exe-LCA method expresses environmental impacts as a single objective function, which enables a comparison of the results.

- As opposed to the conventional LCA method, the Exe-LCA method estimates the absolute environmental impact potential.

- The Exe-LCA method evokes a discussion on the accurate interpretation of results of environmental impact assessments.

- The successful application of the Exe-LCA method to the case-study building models showed that its theoretical benefits compared to a conventional LCA can be achieved.

- The results of the Exe-LCA method are in standard metrics, which paves the way for the competitive benchmarking of building sustainability assessments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Material Name | Material Mass, MM (kg) | Material Chemical Exergy (MJ/kg) | Material Exergy Demand (GJ) |

|---|---|---|---|

| Aluminum | 49,158 | 29.49 | 1449.669 |

| Brick | 139,125 | 0.18 | 25.043 |

| Ceramic | 2147 | 0.19 | 0.408 |

| Concrete | 1,212,298 | 0.54 | 654.641 |

| EPDM | 10,867 | 48.04 | 522.051 |

| Epoxy coating | 4201 | 36.18 | 151.992 |

| Fiberglass | 24,265 | 0.59 | 14.316 |

| Glass | 68,163 | 5.20 | 354.448 |

| Gypsum | 126,386 | 0.15 | 18.958 |

| HDPE | 1051 | 48.50 | 50.974 |

| Hollow core/mortar | 137,962 | 0.40 | 55.185 |

| Paint (acrylic) | 4843 | 39.30 | 190.330 |

| Paint (silicone) | 11,790 | 39.28 | 463.111 |

| Polyurethane foam | 5848 | 36.61 | 214.095 |

| Steel | 110,474 | 34.64 | 3826.819 |

| Wallpaper | 324 | 70.53 | 22.852 |

| Wood | 20,016 | 31.23 | 625.100 |

Appendix B

| Material Name | Material Mass, MM (kg) | Material Chemical Exergy (MJ/kg) | Material Exergy Demand, MExD (GJ) |

|---|---|---|---|

| Aluminum | 7299 | 29.49 | 215.248 |

| Brick | 452,569 | 0.18 | 81.462 |

| Carpet | 44,234 | 45.31 | 2004.243 |

| Ceramic | 5235 | 0.19 | 0.995 |

| Concrete | 2,927,124 | 0.54 | 1580.647 |

| EPDM | 9208 | 48.04 | 442.352 |

| Fiberglass | 26,667 | 0.59 | 15.734 |

| Glass | 15,500 | 5.20 | 80.600 |

| Gypsum | 100,597 | 0.15 | 15.090 |

| Hollow core/mortar | 48,219 | 0.40 | 19.288 |

| Paint (silicone) | 12,484 | 39.28 | 490.372 |

| Plastic (PVC) | 1234 | 22.25 | 27.457 |

| Polyurethane foam | 7603 | 36.61 | 278.346 |

| Steel | 86,130 | 34.64 | 2983.543 |

Appendix C

| Material Name | Material Mass (kg) | Material Chemical Exergy (MJ/kg) | Material Exergy Demand (MJ) |

|---|---|---|---|

| Aluminum | 36,806 | 29.49 | 1085.409 |

| Brick | 571,606 | 0.18 | 102.889 |

| Concrete | 6,931,514 | 0.54 | 3743.018 |

| EPDM | 28,162 | 48.04 | 1352.902 |

| Glass | 34,953 | 5.20 | 181.756 |

| Gypsum | 33,059 | 0.15 | 4.959 |

| Hollow core/mortar | 870,441 | 0.40 | 348.176 |

| Paint (acrylic) | 8376 | 39.30 | 329.177 |

| Paint (silicone) | 4203 | 39.28 | 165.094 |

| Polyurethane foam | 3735 | 36.61 | 136.738 |

| Steel | 787,632 | 34.64 | 27,283.572 |

| Wood | 213 | 31.23 | 6.652 |

References

- World Energy Statistics and Balances. Available online: https://www.iea.org/topics/energyefficiency/buildings/ (accessed on 20 September 2021).

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. (Eds.) Life Cycle Assessment—Theory and Practice; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Alshamrani, O.S.; Galal, K.; Alkass, S. Integrated LCA–LEED sustainability assessment model for structure and envelope systems of school buildings. Build. Env. 2014, 80, 61–70. [Google Scholar] [CrossRef]

- Simonen, K. Life Cycle Assessment, 1st ed.; Routledge: New York, USA, 2014. [Google Scholar]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Env. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Finnveden, G.; Arushanyan, Y.; Brandão, M. Exergy as a measure of resource use in life cycle assessment and other sustainability assessment tools. Resources 2016, 5, 23. [Google Scholar] [CrossRef] [Green Version]

- Morosuk, T.; Tsatsaronis, G.; Koroneos, C. Environmental impact reduction using exergy based methods. J. Clean. Prod. 2016, 118, 118–123. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, Y.; Li, S.; Hou, J.; Shi, J. Exergetic life cycle assessment of Fushun type shale oil production process. Energy Convers. Manag. 2018, 164, 508–517. [Google Scholar] [CrossRef]

- Rosen, M. Energy sustainability: A pragmatic approach and illustrations. Sustainability 2009, 1, 55–80. [Google Scholar] [CrossRef] [Green Version]

- Fiaschi, D.; Manfrida, G.; Mendecka, B.; Tosti, L.; Parisi, M.L. A comparison of different approaches for assessing energy outputs of combined heat and power geothermal plants. Sustainability 2021, 13, 4527. [Google Scholar] [CrossRef]

- Gaudreau, K.; Fraser, R.A.; Murphy, S. The tenuous use of exergy as a measure of resource value or waste impact. Sustainability 2009, 1, 1444–1463. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, R.; Moe, K. The Hierarchy of Energy in Architecture: Emergy Analysis, 1st ed.; Routledge: New York, USA, 2015. [Google Scholar]

- Shukuya, M.; Hammache, A. Introduction to the concept of exergy-for a better understanding of low-temperature-heating and high-temperature-cooling systems. VTT Tiedotteita. 2002. Research Notes, no. 2158, VTT Technical Research Centre of Finland, Espoo.. Available online: http://www.vtt.fi/inf/pdf/tiedotteet/2002/T2158.pdf (accessed on 19 October 2021).

- Bastianoni, S.; Facchini, A.; Susani, L.; Tiezzi, E. Emergy as a function of exergy. Energy 2007, 32, 1158–1162. [Google Scholar] [CrossRef]

- Guinee, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- De Meester, B.; Dewulf, J.; Verbeke, S.; Janssens, A.; Van Langenhove, H. Exergetic life-cycle assessment (ELCA) for resource consumption evaluation in the built environment. Build. Environ. 2009, 44, 11–17. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. Exergetic life cycle assessment: A review. Energies 2020, 13, 2684. [Google Scholar] [CrossRef]

- AZOCleanTech. An Introduction to Exergy. Interview Conducted by PROFESSOR Ibrahim Dincer on 22 July 2013. Available online: https://www.azocleantech.com/article.aspx?ArticleID=426 (accessed on 20 September 2021).

- Švajlenka, J.; Kozlovská, M.; Pošiváková, T. Analysis of selected building constructions used in industrial construction in terms of sustainability benefits. Sustainability 2018, 10, 4394. [Google Scholar] [CrossRef] [Green Version]

- Mora, T.D.; Bolzonello, E.; Cavalliere, C.; Peron, F. Key parameters featuring BIM-LCA integration in buildings: A practical review of the current trends. Sustainability 2020, 12, 7182. [Google Scholar] [CrossRef]

- Carvalho, J.P.; Alecrim, I.; Bragança, L.; Mateus, R. Integrating BIM-Based LCA and building sustainability assessment. Sustainability 2020, 12, 7468. [Google Scholar] [CrossRef]

- Cheng, B.; Li, J.; Tam, V.W.Y.; Yang, M.; Chen, D. A BIM-LCA approach for estimating the greenhouse gas emissions of large-scale public buildings: A case study. Sustainability 2020, 12, 685. [Google Scholar] [CrossRef] [Green Version]

- Palumbo, E.; Soust-Verdaguer, B.; Llatas, C.; Traverso, M. How to obtain accurate environmental impacts at early design stages in BIM when using environmental product declaration. A method to support decision-making. Sustainability 2020, 12, 6927. [Google Scholar] [CrossRef]

- Horn, R.; Ebertshäuser, S.; Bari, R.D.; Jorgji, O.; Traunspurger, R.; von Both, P. The BIM2LCA Approach: An Industry foundation classes (IFC)-Based interface to integrate life cycle assessment in integral planning. Sustainability 2020, 12, 6558. [Google Scholar] [CrossRef]

- Theißen, S.; Höper, J.; Drzymalla, J.; Wimmer, R.; Markova, S.; Meins-Becker, A.; Lambertz, M. Using open BIM and IFC to enable a comprehensive consideration of building services within a whole-building LCA. Sustainability 2020, 12, 5644. [Google Scholar] [CrossRef]

- Allan, K.; Phillips, A.R. Comparative Cradle-to-Grave Life Cycle assessment of low and mid-rise mass timber buildings with equivalent structural steel alternatives. Sustainability 2021, 13, 3401. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes; Hemisphere Publishing: New York, NY, USA, 1988. [Google Scholar]

- Dewulf, J.; Van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations in environmental science and technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Dixit, M.K.; Culp, C.H.; Fernandez-Solis, J.L. Calculating primary energy and carbon emission factors for the United States’ energy sectors. RSC Adv. 2014, 4, 54200–54216. [Google Scholar] [CrossRef]

- Wang, W.; Zmeureanu, R.; Rivard, H. Applying multi-objective genetic algorithms in green building design optimization. Build. Environ. 2005, 40, 1512–1525. [Google Scholar] [CrossRef]

- Bailey, R.G. Understanding Regional Ecosystem Patterns to Design Monitoring Networks and Sustainable Landscapes. In Proceedings of the Monitoring Science and Technology Symposium, Denver, CO, USA, 20–24 September 2004. [Google Scholar]

- Szargut, J.; Morris, D.R. Cumulative exergy consumption and cumulative degree of perfection of chemical processes. Int. J. energy Res. 1987, 11, 245–261. [Google Scholar] [CrossRef]

- Zhang, M. Analysis of Energy Conversion Systems, Including Material and Global Warming Aspects. Doctoral Dissertation, Oregon State University, Corvallis OR, USA, 1995. Available online: https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertations/kw52jc36k (accessed on 19 October 2021).

| Greenhouse Gas | SCExE (kJ/mol) | Molar Mass (g/mol) | SCExE in kg/MJ |

|---|---|---|---|

| CO2 | 19.8 | 44.01 | 2.22 |

| CH4 | 831.9 | 16.04 | 0.02 |

| N2O | 106.4 | 44.01 | 0.41 |

| CFC-11 | 577.9 | 137.37 | 0.24 |

| CFC-12 | 599.4 | 120.91 | 0.20 |

| HFC-23 | 622.6 | 70.01 | 0.11 |

| HCFC-22 | 644.5 | 86.47 | 0.13 |

| PFC-116 | 1077.8 | 138.01 | 0.13 |

| NF3 | 667.1 | 71.00 | 0.11 |

| SF6 | 728.2 | 146.06 | 0.20 |

| Total for units of global warming potential (kg/MJ) | 3.77 | ||

| Exergy-Based LCA Item | Building I | Building II | Building III |

|---|---|---|---|

| Annual Primary Exergy Demand (GJ) | 6.1 × 10³ | 4.3 × 10³ | 8.3 × 10³ |

| Total Material Exergy Demand (GJ) | 8.6 × 10³ | 8.2 × 10³ | 3.4 × 104 |

| Global Warming Potential (kg) | 2.3 × 107 | 1.6 × 107 | 3.1 × 107 |

| Acidification Potential (kg) | 7.0 × 105 | 5.0 × 105 | 1.0 × 106 |

| Eutrophication Potential (kg) | 2.5 × 106 | 1.8 × 106 | 3.4 × 106 |

| Ozone Depletion Potential (kg) | 2.7 × 106 | 1.9 × 106 | 3.6 × 106 |

| Smog Formation Potential (kg) | 1.7 × 106 | 1.2 × 106 | 2.4 × 106 |

| Criteria | Conventional LCA | Exe-LCA |

|---|---|---|

| Accuracy | Ignores energy quality of fuel source | Considers energy quality of fuel source |

| Comprehensiveness | Ignores depletion of non-fuel natural resource | Accounts for the depletion of non-fuel natural resource |

| Interpretation of results | Difficult to interpret due to variation in units | Uses a unified unit to express its results |

| Subjectivity | More subjective by use of weightings | Less subjective by eliminating weightings |

| Compatibility with other tools | More difficult | Easier as a single objective function |

| Potential for automation | Low | High |

| Priority areas for improvement | More difficult to establish | Easier to establish |

| Use in environmental legislation | Less useful for objective legislation and regulation | More useful for objective legislation and regulation |

| Application to industry | Less useful due to high subjectivity | More useful e.g., in eco-labeling, and product and process monitoring and development |

| Potential for decision support | Low | High |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nwodo, M.; Anumba, C.J. Exergy-Based Life Cycle Assessment of Buildings: Case Studies. Sustainability 2021, 13, 11682. https://doi.org/10.3390/su132111682

Nwodo M, Anumba CJ. Exergy-Based Life Cycle Assessment of Buildings: Case Studies. Sustainability. 2021; 13(21):11682. https://doi.org/10.3390/su132111682

Chicago/Turabian StyleNwodo, Martin, and Chimay J. Anumba. 2021. "Exergy-Based Life Cycle Assessment of Buildings: Case Studies" Sustainability 13, no. 21: 11682. https://doi.org/10.3390/su132111682

APA StyleNwodo, M., & Anumba, C. J. (2021). Exergy-Based Life Cycle Assessment of Buildings: Case Studies. Sustainability, 13(21), 11682. https://doi.org/10.3390/su132111682