Cost-Effective Inspection of Rebar Spacing and Clearance Using RGB-D Sensors

Abstract

:1. Introduction

2. Research Background

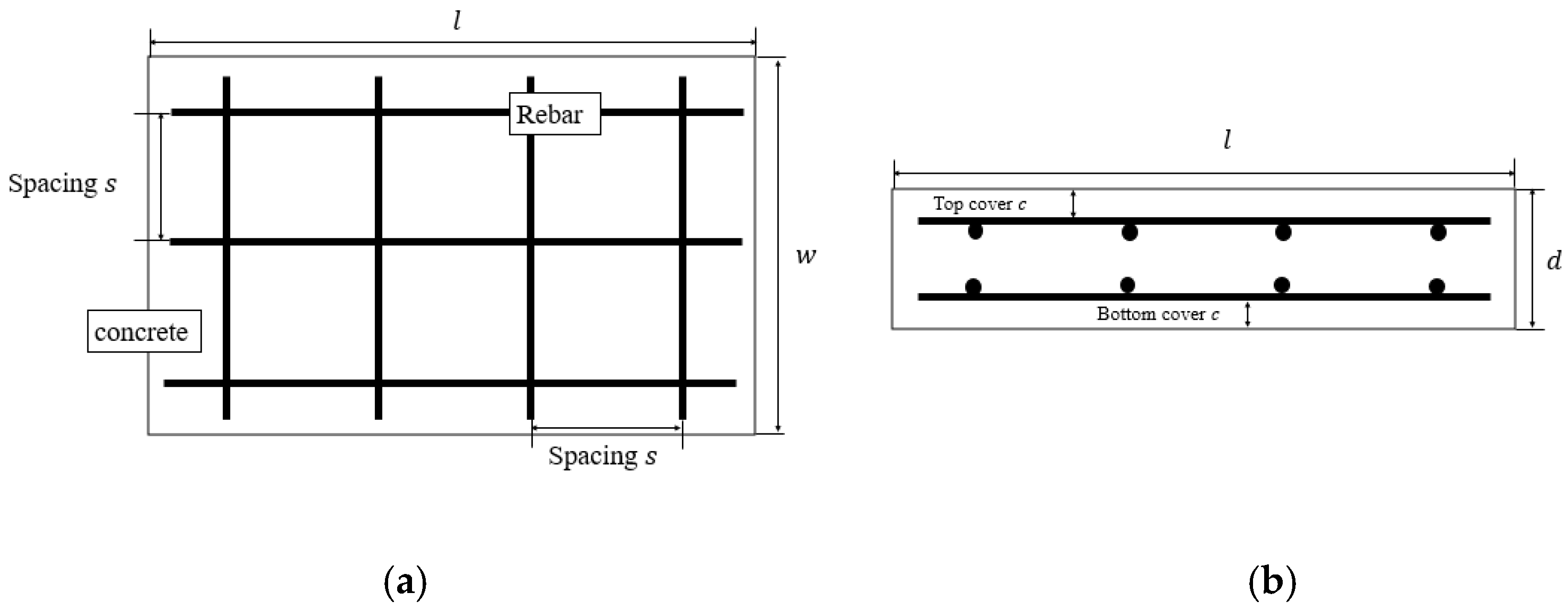

2.1. Specifications for Rebar Inspection, Concrete Cover

2.2. Literature Review

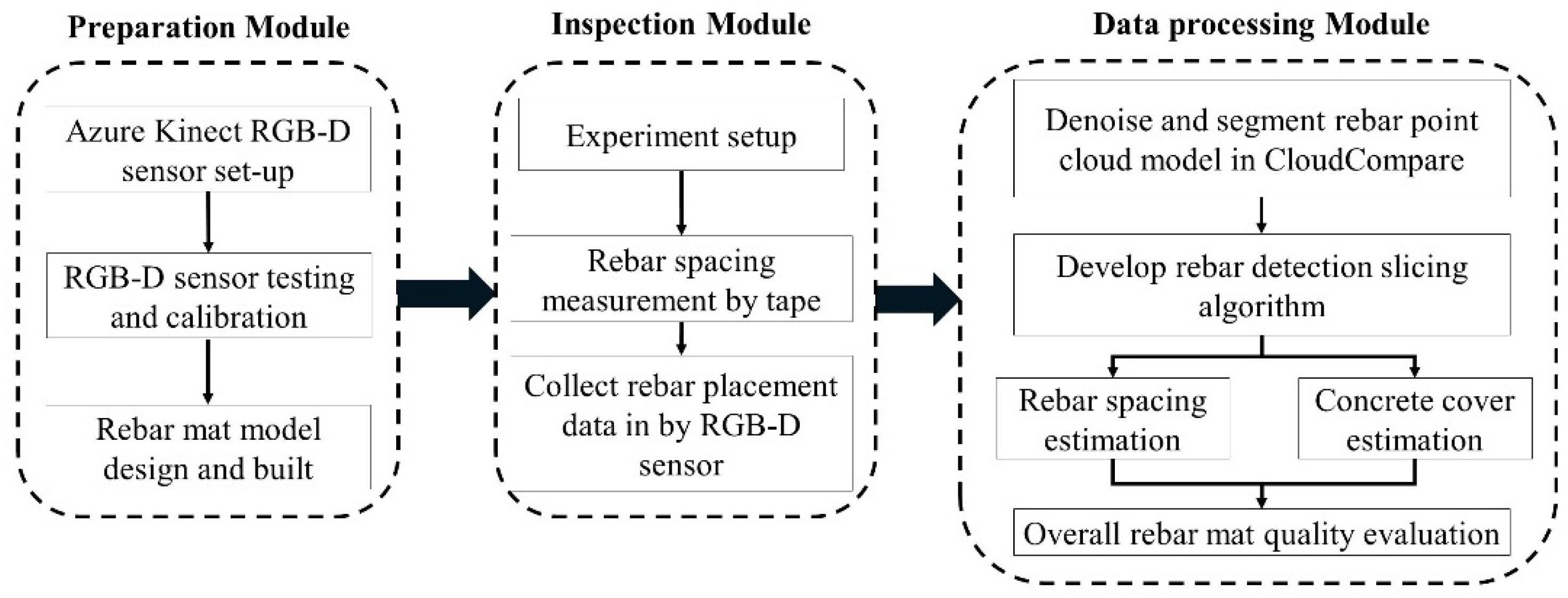

3. Methodology

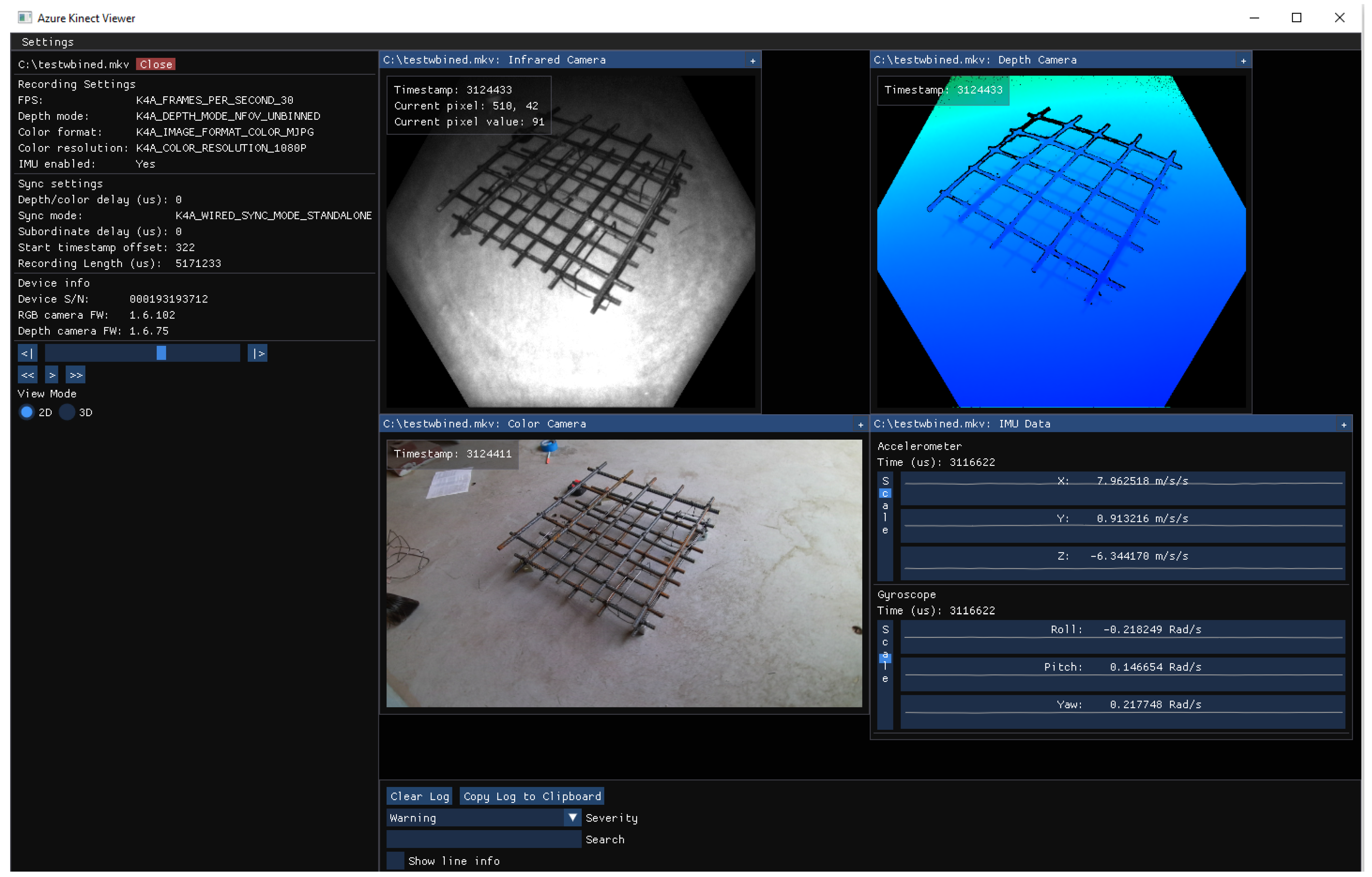

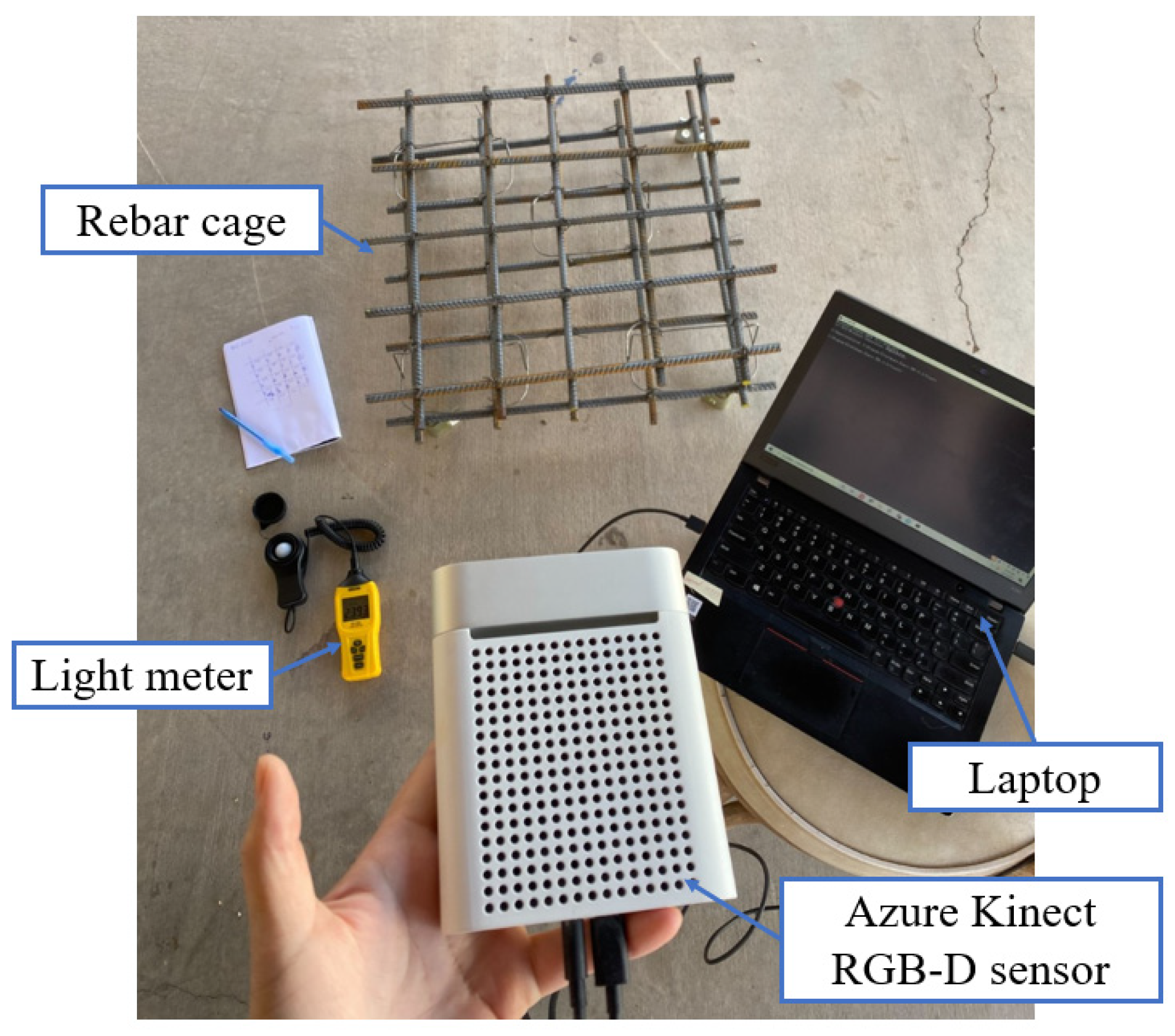

3.1. Data Acquisition

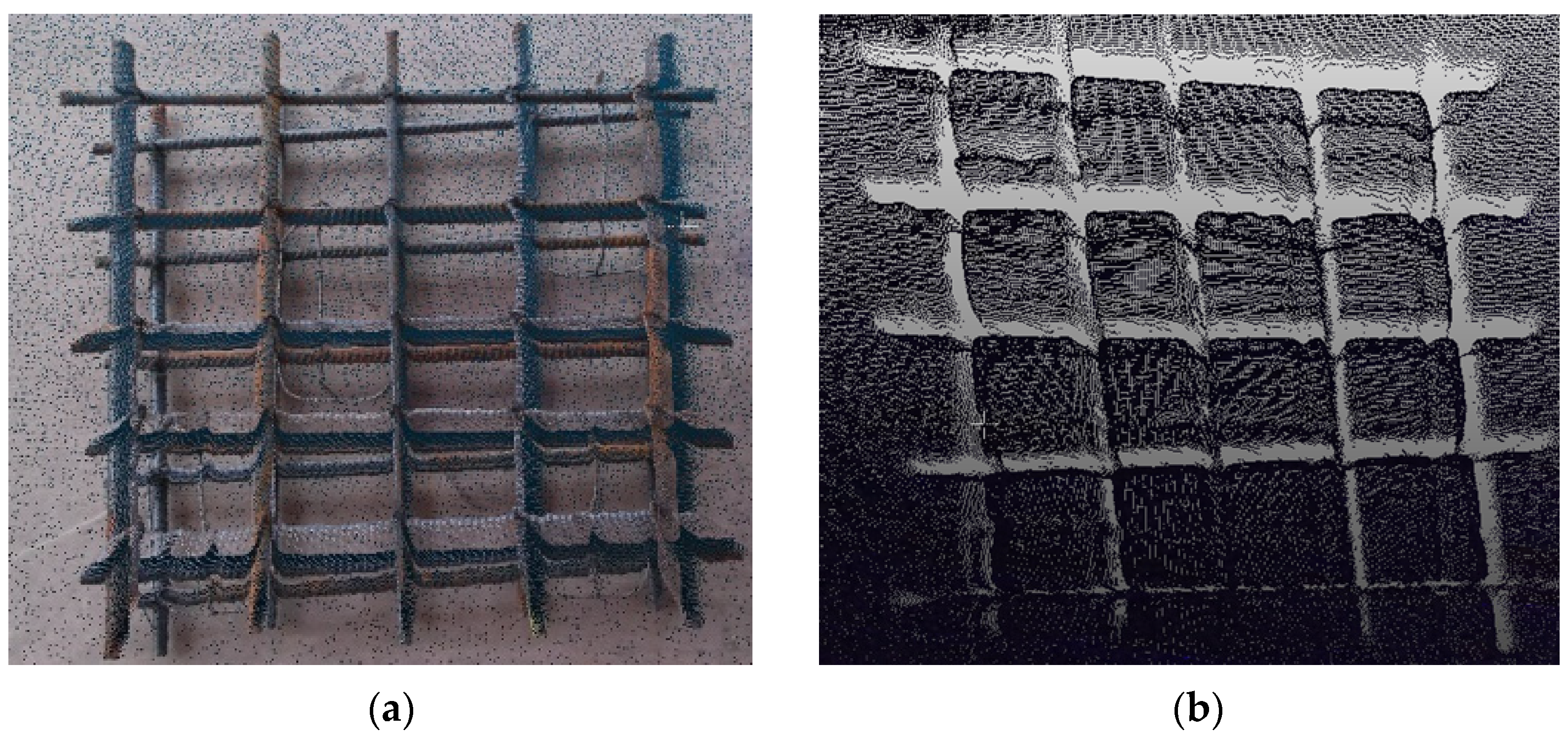

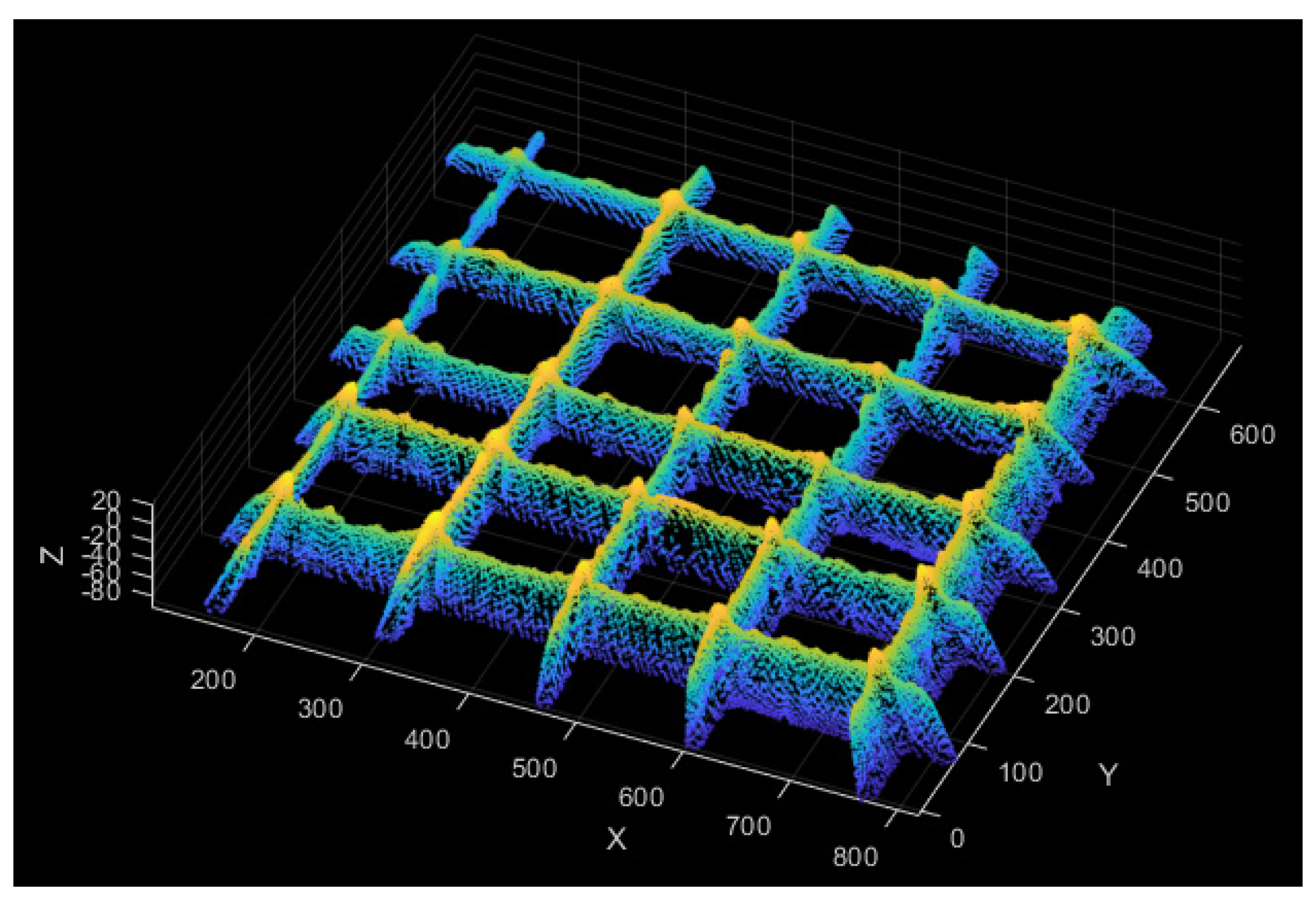

3.2. Data Processing

3.3. Rebar Spacing and Concrete Cover Estimation

4. Experiment Validation

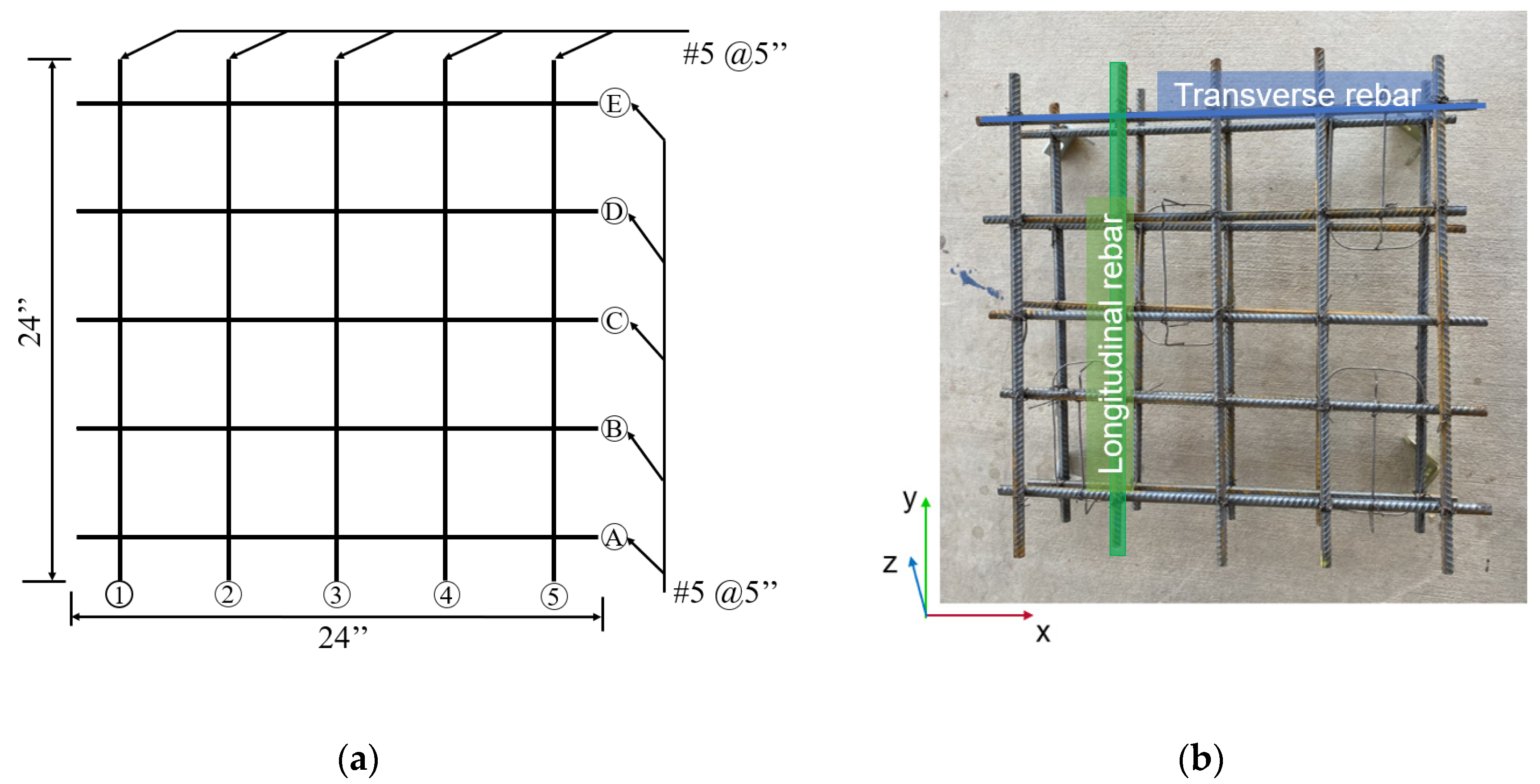

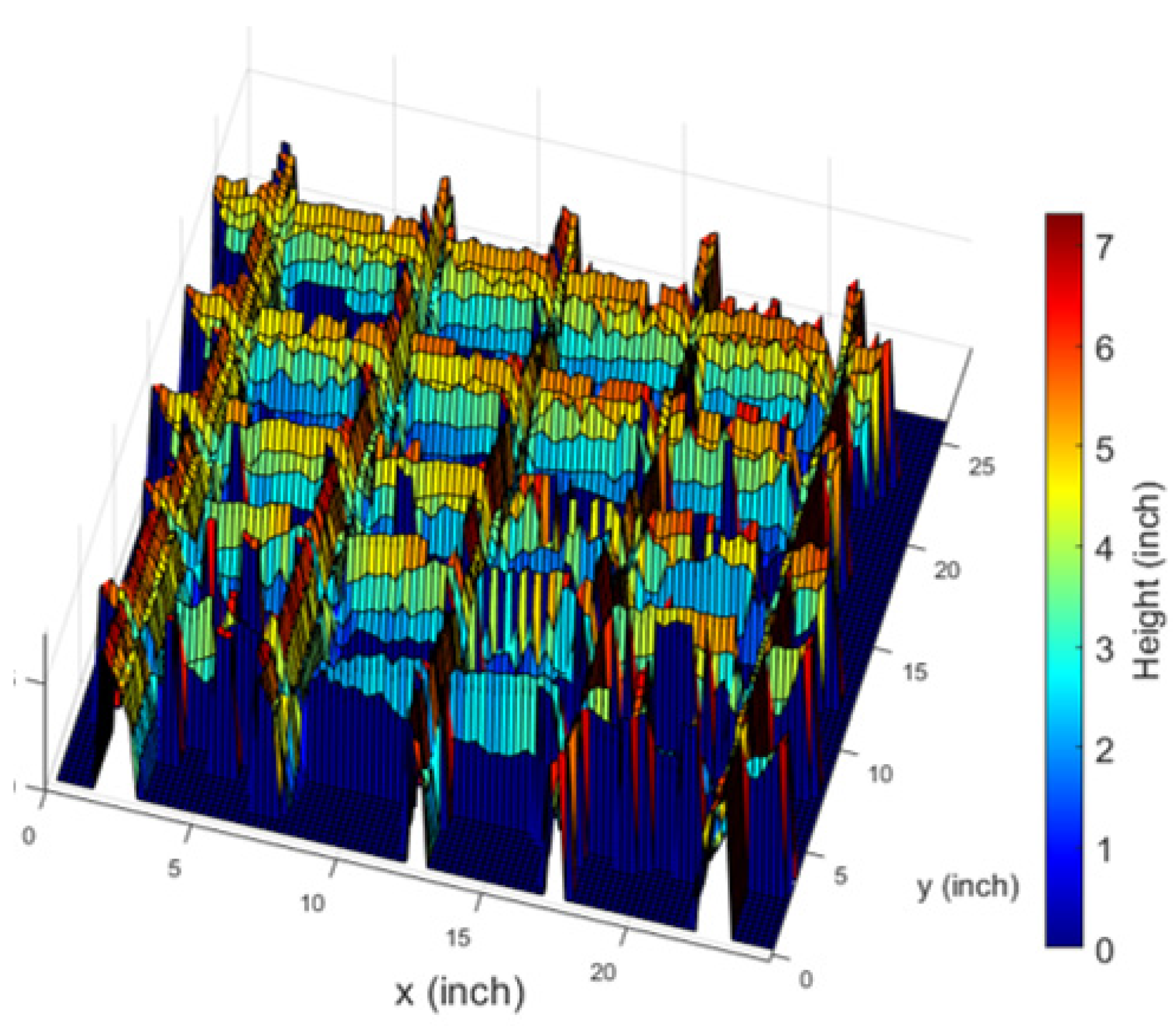

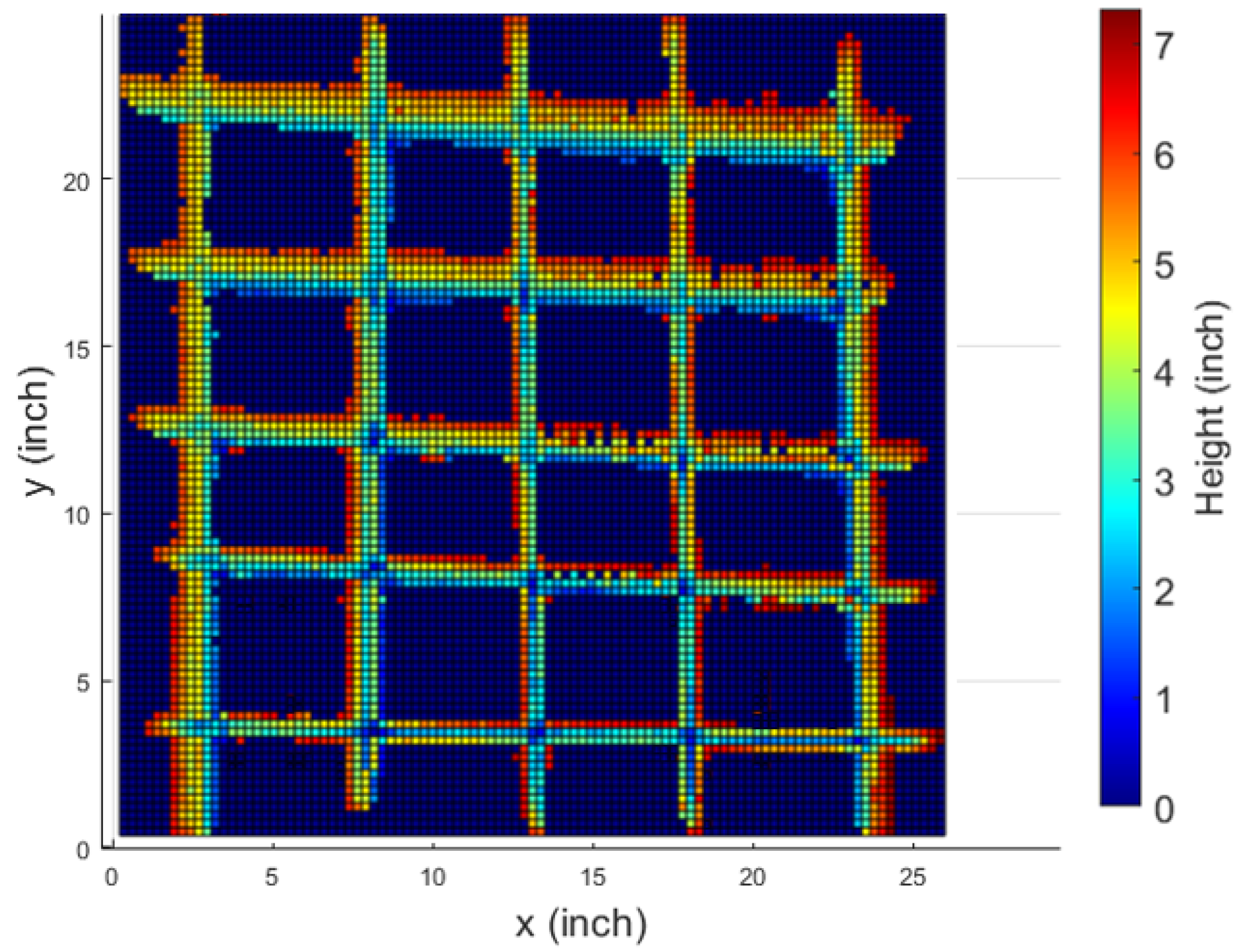

4.1. Rebar Specimen Description

4.2. Test Results

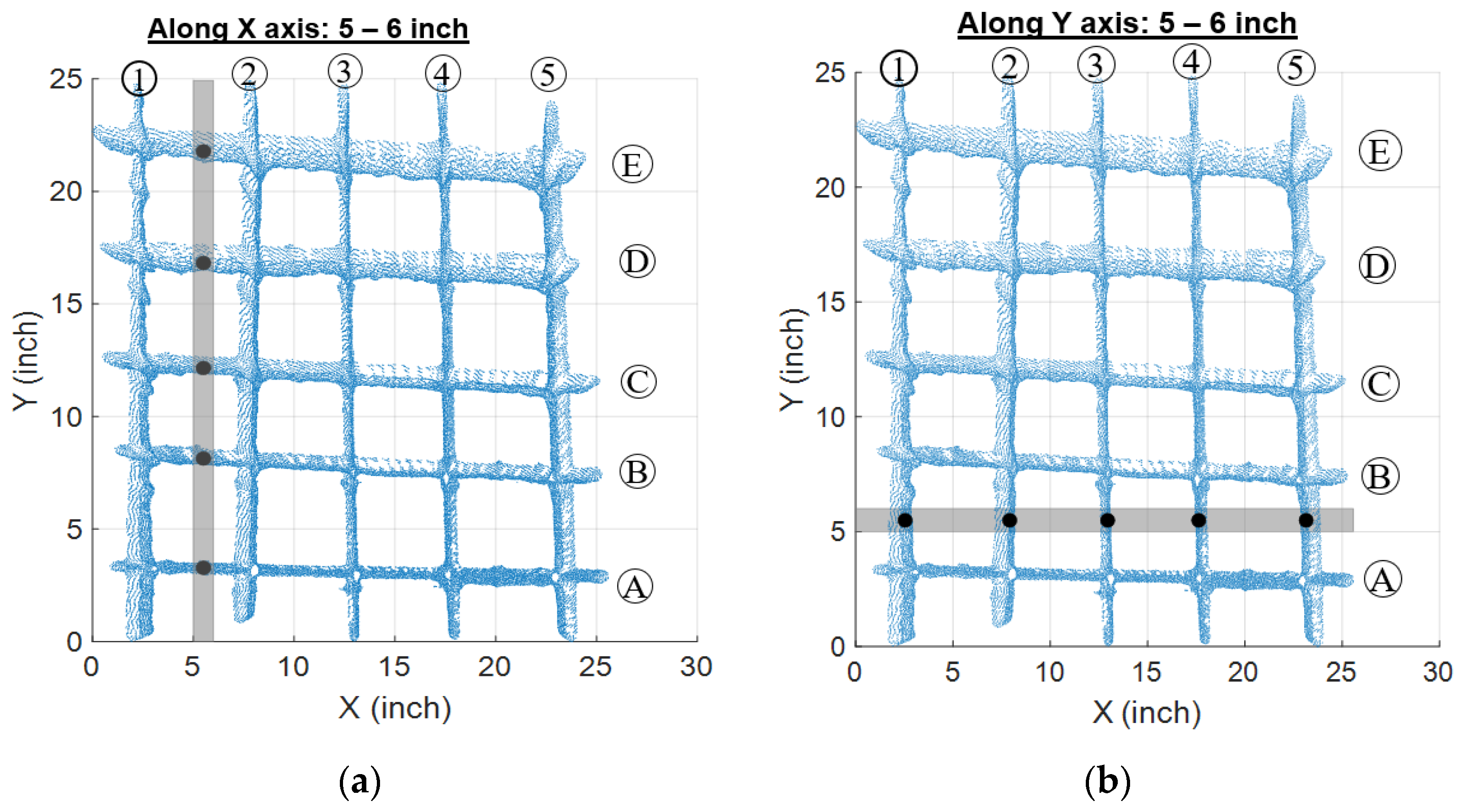

4.2.1. Rebar Spacing Estimation

Spacing Index

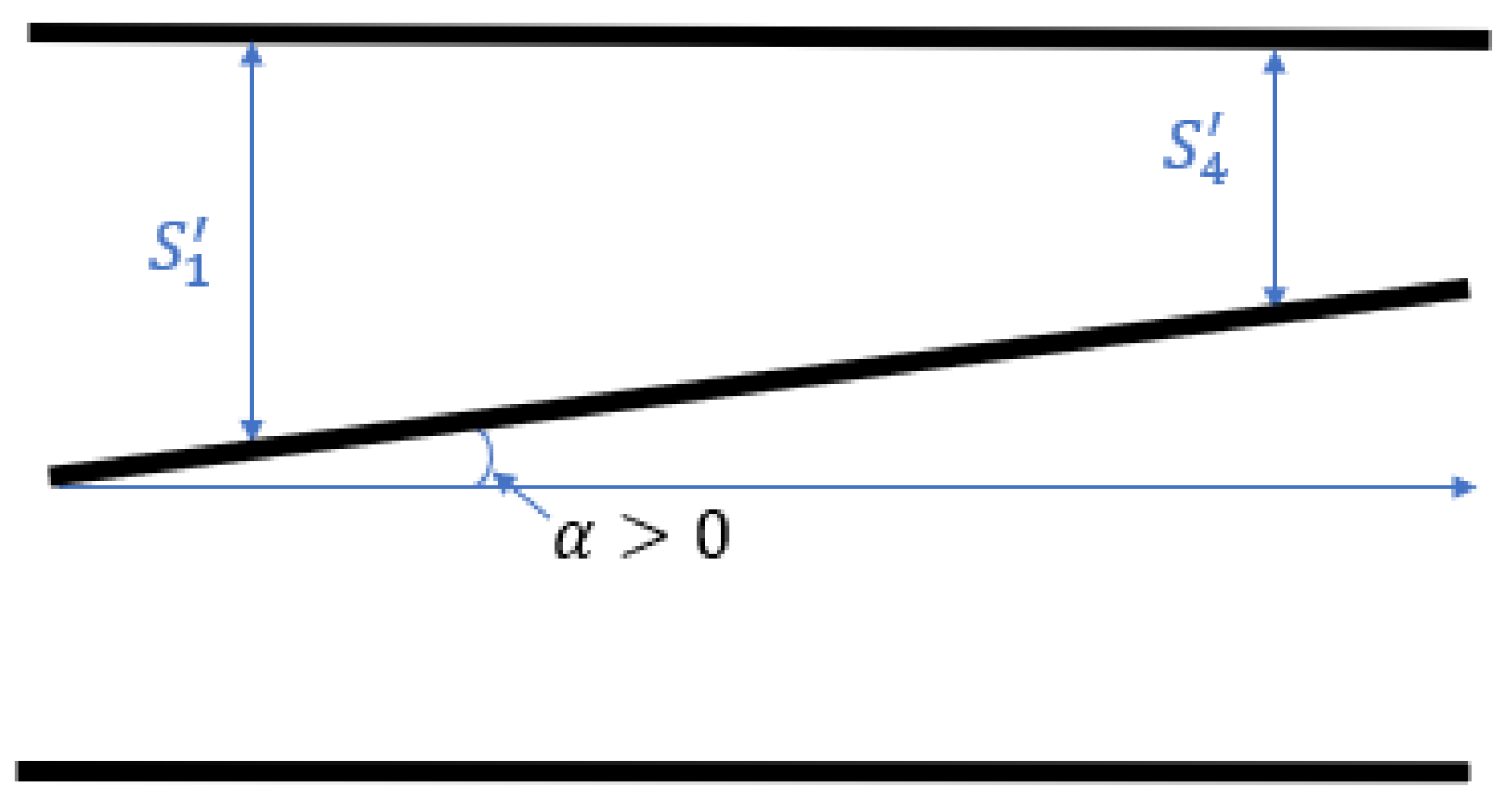

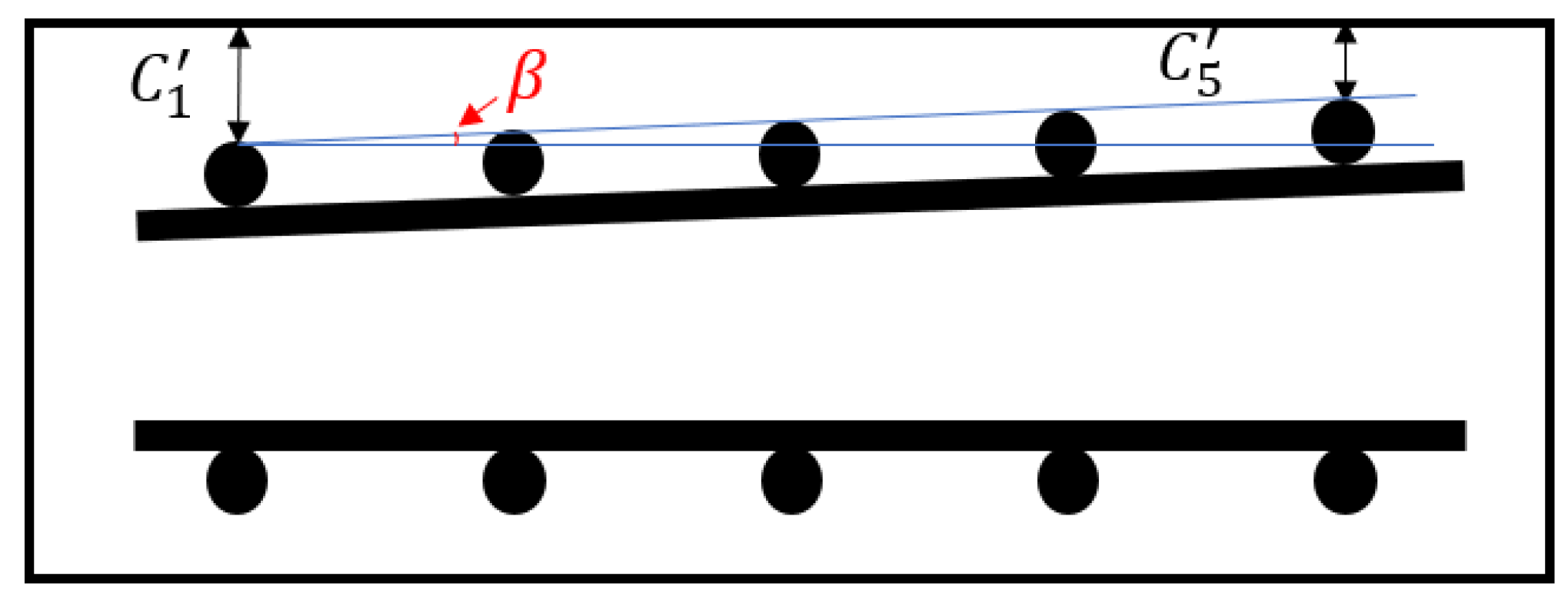

Angle Index

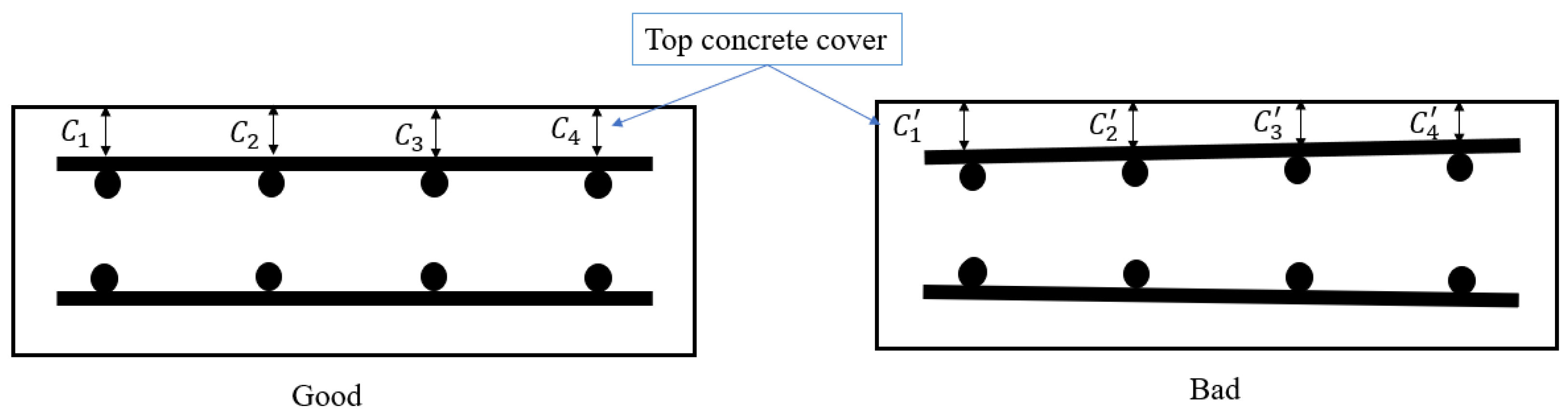

4.2.2. Concrete Cover Estimation

Concrete Cover Index

Concrete Cover Angle Index

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, H.-M.; Lee, H.-S.; Min, S.-H.; Lim, S.; Singh, J.K. Carbonation-Induced Corrosion Initiation Probability of Rebars in Concrete With/Without Finishing Materials. Sustainability 2018, 10, 3814. [Google Scholar] [CrossRef] [Green Version]

- Gordon, C.; Akinci, B. Technology and process assessment of using LADAR and embedded sensing for construction quality control. In Proceedings of the Construction Research Congress 2005: Broadening Perspectives, San Diego, CA, USA, 5–7 April 2005; pp. 1–10. [Google Scholar]

- Li, F.; Kim, M.-K.; Lee, D.-E. Geometrical model based scan planning approach for the classification of rebar diameters. Autom. Constr. 2021, 130, 103848. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Liu, M. Maintenance and management of civil infrastructure based on condition, safety, optimization, and life-cycle cost∗. Struct. Infrastruct. Eng. 2007, 3, 29–41. [Google Scholar] [CrossRef]

- Kwon, K.; Kim, D.; Kim, S. Cutting Waste Minimization of Rebar for Sustainable Structural Work: A Systematic Literature Review. Sustainability 2021, 13, 5929. [Google Scholar] [CrossRef]

- Han, K.; Gwak, J.; Golparvar-Fard, M.; Saidi, K.; Cheok, G.; Franaszek, M.; Lipman, R. Vision-based field inspection of concrete reinforcing bars. In Proceedings of the 13th International Conference on Construction Applications of Virtual Reality, London, UK, 30–31 October 2013. [Google Scholar]

- Li, V. Engineered Cementitious Composites (ECC): Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin, Germany, 2019; pp. 2–14. [Google Scholar]

- American Concrete Institute. ACI 117-10: Specification for Tolerances for Concrete Construction and Materials; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Reinforcing Steel Placing Tolerance. Available online: https://www.irebar.com/USPlacingTolerances.html (accessed on 10 November 2021).

- Kim, M.-K.; Thedja, J.P.P.; Wang, Q. Automated dimensional quality assessment for formwork and rebar of reinforced concrete components using 3D point cloud data. Autom. Constr. 2020, 112, 103077. [Google Scholar] [CrossRef]

- Wang, Q.; Cheng, J.C.; Sohn, H. Automated estimation of reinforced precast concrete rebar positions using col-ored laser scan data. Comput.–Aided Civ. Infrastruct. Eng. 2017, 32, 787–802. [Google Scholar] [CrossRef]

- Yuan, X.; Smith, A.; Sarlo, R.; Lippitt, C.D.; Moreu, F. Automatic evaluation of rebar spacing using LiDAR data. Autom. Constr. 2021, 131, 103890. [Google Scholar] [CrossRef]

- BahooToroody, F.; Khalaj, S.; Leoni, L.; De Carlo, F.; Di Bona, G.; Forcina, A. Reliability Estimation of Reinforced Slopes to Prioritize Maintenance Actions. Int. J. Environ. Res. Public Health 2021, 18, 373. [Google Scholar] [CrossRef]

- Di Bona, G.; Forcina, A.; Falcone, D.; Silvestri, L. Critical Risks Method (CRM): A New Safety Allocation Approach for a Critical Infrastructure. Sustainability 2020, 12, 4949. [Google Scholar] [CrossRef]

- Feng, C.W.; Chen, C.W. Using BIM and MR to improve the process of job site construction and inspection. WIT Trans. Built Environ. 2019, 192, 21–32. [Google Scholar]

- Yi, T.; Li, H.; Gu, M. Full-scale measurements of dynamic response of suspension bridge subjected to environmental loads using GPS technology. Sci. China Ser. E Technol. Sci. 2010, 53, 469–479. [Google Scholar] [CrossRef]

- Mahmoudzadeh, A.; Yeganeh, S.F.; Arezoomand, S.; Golroo, A. 3D Pavement Surface Reconstruction Using An RGB-D Sensor. Proceedings 2019, 42, 47. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Donia, S. Potentials of RGB-D Cameras in As-Built Indoor Environment Modeling. Comput. Civil Eng. 2013, 605–612. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.; Ahn, E.; Shin, M.; Sim, S.H. Crack identification method for concrete structures considering angle of view using RGB-D cam-era-based sensor fusion. Struct. Health Monit. 2021, 20, 500–512. [Google Scholar] [CrossRef]

- Koppula, H.S.; Anand, A.; Joachims, T.; Saxena, A. Semantic labeling of 3d point clouds for indoor scenes. Advances in neural information processing systems. Nips 2011, 2, 6. [Google Scholar]

- Kinect, D.K.A. Microsoft, Redmond, WA, US. Documentation Microsoft Docs. (n.d.) Available online: https://docs.microsoft.com/en-us/azure/kinect-dk/ (accessed on 14 June 2021).

- Bassier, M.; Van Genechten, B.; Vergauwen, M. Classification of sensor independent point cloud data of building objects using random forests. J. Build. Eng. 2019, 21, 468–477. [Google Scholar] [CrossRef]

- Tölgyessy, M.; Dekan, M.; Chovanec, Ľ.; Hubinský, P. Evaluation of the Azure Kinect and Its Comparison to Kinect V1 and Kinect V. Sensors 2021, 21, 413. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Truong-Hong, L.; O’Keeffe, E.; Laefer, D.F.; Mangina, E. Outlier detection of point clouds generating from low-cost UAVs for bridge inspection. In Proceedings of the Life-Cycle Analysis and Assessment in Civil Engineering, Ghent, Belgium, 28–31 October 2018. [Google Scholar]

- Bossio, A.; Lignola, G.P.; Fabbrocino, F.; Monetta, T.; Prota, A.; Bellucci, F.; Manfredi, G. Nondestructive assessment of corrosion of reinforcing bars through surface concrete cracks. Struct. Concr. 2017, 18, 104–117. [Google Scholar] [CrossRef]

- Intel Corporation (intel.com), Santa Clara, CA, US. Available online: https://www.intel.com/content/www/us/en/homepage.html (accessed on 10 November 2021).

| Items | Symbol | Allowable Tolerance |

|---|---|---|

| Rebar spacing | s | ±0.5 inch (±12.7 mm) |

| Concrete cover | c | ±3/8 inch (±9.5 mm) for concrete slab depth ≤12 inch (304.8 mm) |

| ±1/2 inch (±12.7 mm) for concrete slab depth >12 inch (304.8 mm) |

| Mode | NFOV Unbinned | NFOV 2 × 2 Binned | WFOV 2 × 2 Binned | WFOV Unbinned |

|---|---|---|---|---|

| Operating range (m) | 0.5–3.86 | 0.5–5.46 | 0.25–2.88 | 0.25–2.21 |

| Transverse Rebar | Spacing | Sensor (inch) | Designed (inch) | Error (E1) (inch) |

|---|---|---|---|---|

| A–B | 1A2B | 4.84 | 5.00 | −0.16 |

| 2A3B | 4.76 | 5.00 | −0.24 | |

| 3A4B | 4.40 | 5.00 | −0.60 | |

| 4A5B | 4.64 | 5.00 | −0.36 | |

| std | 0.19 | 0 | 0.19 | |

| B–C | 1B2C | 4.09 | 5.00 | −0.91 |

| 2B3C | 4.06 | 5.00 | −0.94 | |

| 3B4C | 4.04 | 5.00 | −0.96 | |

| 4B5C | 3.90 | 5.00 | −1.10 | |

| std | 0.08 | 0 | 0.08 | |

| C–D | 1C2D | 4.69 | 5.00 | −0.31 |

| 2C3D | 4.81 | 5.00 | −0.19 | |

| 3C4D | 4.96 | 5.00 | −0.04 | |

| 4C5D | 4.93 | 5.00 | −0.07 | |

| std | 0.12 | 0 | 0.12 | |

| D–E | 1D2E | 4.98 | 5.00 | −0.02 |

| 2D3E | 4.78 | 5.00 | −0.22 | |

| 3D4E | 4.61 | 5.00 | −0.39 | |

| 4D5E | 4.70 | 5.00 | −0.30 | |

| std | 0.16 | 0 | 0.16 |

| Longitudinal Rebar | Spacing | Sensor (inch) | Designed (inch) | E2 (inch) |

|---|---|---|---|---|

| 1–2 | 1A2B | 5.09 | 5.00 | 0.09 |

| 1B2C | 5.17 | 5.00 | 0.17 | |

| 1C2D | 5.40 | 5.00 | 0.40 | |

| 1D2E | 5.53 | 5.00 | 0.53 | |

| std | 0.20 | 0 | 0.20 | |

| 2–3 | 2A3B | 5.22 | 5.00 | 0.22 |

| 2B3C | 4.78 | 5.00 | −0.22 | |

| 2C3D | 4.64 | 5.00 | −0.36 | |

| 2D3E | 4.42 | 5.00 | −0.58 | |

| std | 0.34 | 0 | 0.34 | |

| 3–4 | 3A4B | 4.65 | 5.00 | −0.35 |

| 3B4C | 4.66 | 5.00 | −0.34 | |

| 3C4D | 4.73 | 5.00 | −0.27 | |

| 3D4E | 4.77 | 5.00 | −0.23 | |

| std | 0.06 | 0 | 0.06 | |

| 4–5 | 4A5B | 5.36 | 5.00 | 0.36 |

| 4B5C | 5.38 | 5.00 | 0.38 | |

| 4C5D | 5.40 | 5.00 | 0.40 | |

| 4D5E | 5.41 | 5.00 | 0.41 | |

| std | 0.02 | 0 | 0.02 |

| Transverse Rebar | (°) | Longitudinal Rebar | (°) |

|---|---|---|---|

| A | 1.64 | 1 | 1.09 |

| B | 2.99 | 2 | 1.43 |

| C | 2.73 | 3 | −1.12 |

| D | 1.91 | 4 | −1.67 |

| E | 2.45 | 5 | −2.60 |

| Rebar | (inch) | (inch) | (inch) | Rebar | (inch) | (inch) | (inch) | ||

|---|---|---|---|---|---|---|---|---|---|

| 1 | A | 1.57 | 1.50 | −0.07 | 4 | A | 1.44 | 1.50 | 0.06 |

| B | 1.53 | 1.50 | −0.03 | B | 1.49 | 1.50 | 0.01 | ||

| C | 1.43 | 1.50 | 0.07 | C | 1.42 | 1.50 | 0.08 | ||

| D | 1.45 | 1.50 | 0.05 | D | 1.14 | 1.50 | 0.36 | ||

| E | 1.49 | 1.50 | 0.01 | E | 1.15 | 1.50 | 0.35 | ||

| std | 0.06 | 0 | 0.06 | std | 0.17 | 0 | 0.17 | ||

| 2 | A | 1.53 | 1.50 | −0.03 | 5 | A | 1.54 | 1.50 | −0.04 |

| B | 1.50 | 1.50 | 0.00 | B | 1.55 | 1.50 | −0.05 | ||

| C | 1.42 | 1.50 | 0.08 | C | 1.53 | 1.50 | −0.03 | ||

| D | 1.37 | 1.50 | 0.13 | D | 1.58 | 1.50 | −0.08 | ||

| E | 1.32 | 1.50 | 0.18 | E | 1.61 | 1.50 | −0.11 | ||

| std | 0.09 | 0 | 0.09 | std | 0.03 | 0 | 0.03 | ||

| 3 | A | 1.51 | 1.50 | -0.01 | |||||

| B | 1.35 | 1.50 | 0.15 | ||||||

| C | 1.13 | 1.50 | 0.37 | ||||||

| D | 1.17 | 1.50 | 0.33 | ||||||

| E | 1.12 | 1.50 | 0.38 | ||||||

| std | 0.17 | 0 | 0.17 | ||||||

| Transverse Rebar | (°) | Longitudinal Rebar | (°) |

|---|---|---|---|

| 1 | 0.19 | A | −0.07 |

| 2 | 0.50 | B | 0.05 |

| 3 | 0.93 | C | 0.24 |

| 4 | 0.69 | D | 0.31 |

| 5 | −0.17 | E | 0.29 |

| Rebar Scanning | 5–30 s |

|---|---|

| Point-cloud data format transformation | 10–15 min |

| Point-cloud data preprocessing | 1–2 h |

| Rebar detection | 10–30 min |

| Total time | 80.08–165.5 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Moreu, F.; Hojati, M. Cost-Effective Inspection of Rebar Spacing and Clearance Using RGB-D Sensors. Sustainability 2021, 13, 12509. https://doi.org/10.3390/su132212509

Yuan X, Moreu F, Hojati M. Cost-Effective Inspection of Rebar Spacing and Clearance Using RGB-D Sensors. Sustainability. 2021; 13(22):12509. https://doi.org/10.3390/su132212509

Chicago/Turabian StyleYuan, Xinxing, Fernando Moreu, and Maryam Hojati. 2021. "Cost-Effective Inspection of Rebar Spacing and Clearance Using RGB-D Sensors" Sustainability 13, no. 22: 12509. https://doi.org/10.3390/su132212509

APA StyleYuan, X., Moreu, F., & Hojati, M. (2021). Cost-Effective Inspection of Rebar Spacing and Clearance Using RGB-D Sensors. Sustainability, 13(22), 12509. https://doi.org/10.3390/su132212509