Typology, Structural Characterization and Sustainability of Integrated Broiler Farming System in Epirus, Greece

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Data Collection and Sample Determination

2.3. Data Processing

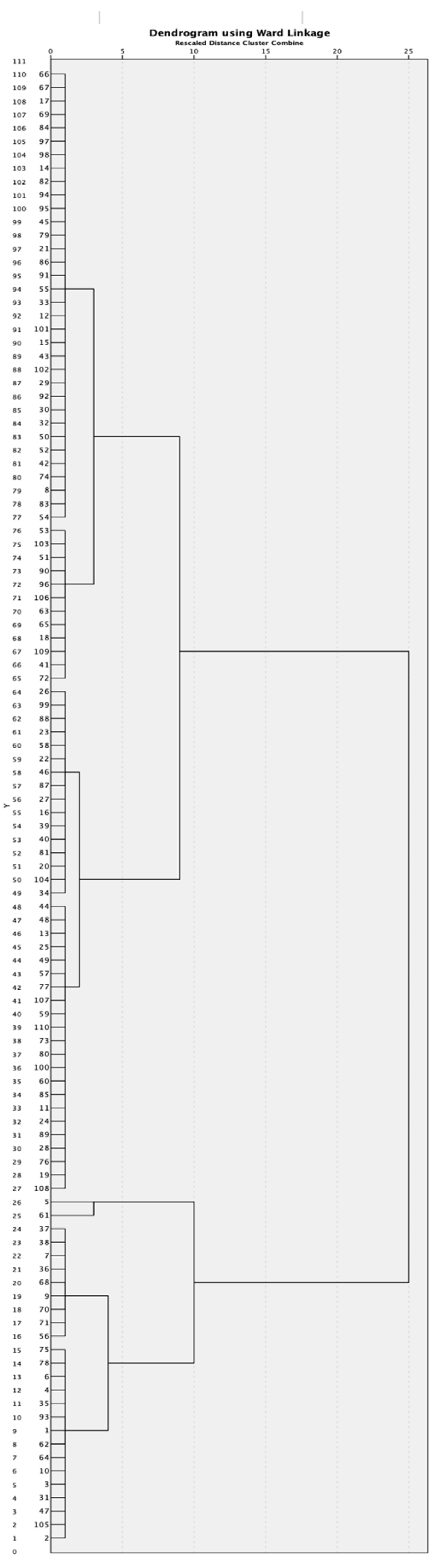

2.4. Hierarchical Cluster Analysis

- Number of production cycles per year;

- Feed conversion ratio (kg of total feed/kg of final body weight);

- Average days of a production cycle–length;

- Total feed consumption (kg/year);

- Mortality (%): the index was obtained by subtracting from the number of day-old chicks placed for fattening the final output related to the total number of chickens taken to the slaughterhouse;

- Gross farm profit (euros-€).

2.5. European Production Efficiency Factor

3. Results

3.1. Hierarchical Cluster Analysis

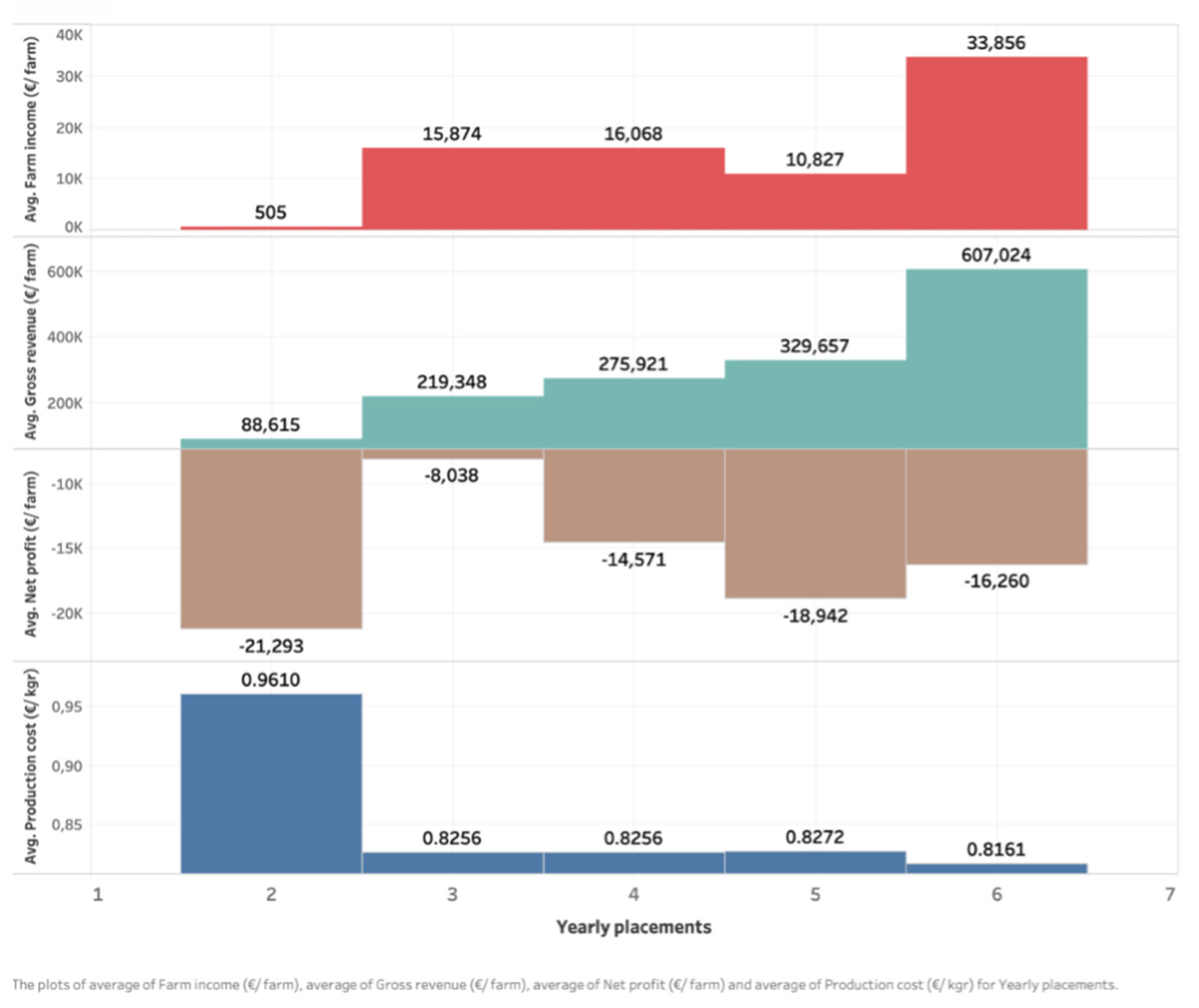

3.2. Characteristics and Interpretation of Clusters—Structural Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elstat, Hellenic Statistical Authority. 2018. Available online: www.statistics.gr (accessed on 26 March 2019).

- Camargo-Barros, G.S.; Zen, S.D.; Piedade-Bacchi, M.R.; Galvão de Miranda, S.H.; Narrod, C.; Tiongco, M. Policy, technical, and environmental determinants and implications of the scaling-up of swine, broiler, layer and milk production in Brazil. In Annex V, Final Report of IFPRI-FAO Livestock Industrialization Project: Phase II; International Food Policy Research Institute: Washington, DC, USA, 2003. [Google Scholar]

- Iliopoulos, C.; Theodorakopoulou, I. Measuring and Communicating the True Value of Membership: The Case of the Pindos Poultry Co-operative. In Sustainable Co-operative Enterprise: Case Studies of Organisational Resilience in the Co-operative Business Model; Chapter 17; Mazzarol, T., Reboud, S., Limnios, E.M., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2014; pp. 223–239. [Google Scholar]

- Burgos, S.; Hong Hanh, P.T.; Roland-Holst, D.; Burgos, S.A. Characterization of Poultry Production Systems in Vietnam. Int. J. Poult. Sci. 2007, 6, 709–712. [Google Scholar] [CrossRef]

- Keramidou, I.; Mimis, A.; Pappa, E. Performance evaluation of the poultry sector in Greece. J. Food Agric. Environ. 2011, 9, 431–437. [Google Scholar]

- Koutoulis, K. Present and future of poultry industry in Greece. In Proceedings of the 12th Pan-Hellenic Veterinary Congress, Athens, Greece, 5–8 April 2012. [Google Scholar]

- Eurostat Trade Statistics. 2018. Available online: https://ec.europa.eu/eurostat/web/main/data/database (accessed on 26 March 2019).

- Eurostat. Sustainable Development in the European Union; Key Messages; Office for Official Publications of the European Communities: Luxembourg, 2015; Available online: https://ec.europa.eu/eurostat/documents/3217494/6975281/KS-GT-15-001-EN-N.pdf (accessed on 26 March 2019).

- Dormady, N.; Roa-Henriquez, A.; Rose, A. The Resilience of the Firm. A Production Theory Approach. Int. J. Prod. Econ. 2017, 208, 446–460. [Google Scholar] [CrossRef]

- Unay-Gailhard, I.; Balmann, A.; Appel, F. Dimensions of SURE-Farm Farm Typology for Farm Resilience Assessments. In Working Paper (727520); Leibniz Institute of Agricultural Development in Transition Economies (IAMO): Madrid, Spain, 2018. [Google Scholar]

- Andersen, E. Regional Typologies of Farming Systems Contexts, SEAMLESS Report No.53, SEAMLESS 2010 Integrated Project, EU 6th Framework Programme, Contract no. 010036-2. Available online: http://www.seamless-ip.org/Reports/Report_53_PD4.4.3.pdf (accessed on 26 March 2019).

- Kruskal, J. The Relationship between Multidimensional Scaling and Clustering. In Classification and Clustering; Van Ryzin, J., Ed.; Academic Press Inc.: New York, NY, USA, 1977; pp. 17–45. [Google Scholar]

- Souza, F.; Milani, A.; Furlan, R.; Nogueira, W.; Fernandez Alarcon, M.F.; Almeida, E. Cluster Analysis to Study the Typology and Productivity in Broiler Facilities. In Proceedings of the International Conference of Agricultural Engineering (CIGR-Ageng2012), Valencia, Spain, 6–12 July 2012. [Google Scholar]

- Worapol, A.; Manakant, I.; Jaroon, W.; Thanapol, N.; Surangkanang, C.; Prayat, S.; Komvut, T.; Neti, J.; Khlahan, S.; Tawinwaang, T. Poultry Production Clusters (PPCs) after AI Outbreaks in Thailand: Past, Present and Future Direction. Int. J. Poult. Sci. 2012, 11, 541–550. [Google Scholar]

- Thevenot, A.; Aubin, J.; Tillard, E.; Vayssieres, J. Accounting for farm diversity in Life Cycle Assessment studies—The case of poultry production in a tropical island. J. Clean. Prod. 2013, 57, 280–292. [Google Scholar] [CrossRef]

- Rymuza, K.; Grużewska, A.; Biesieda-Drzazga, B. Multidimensional analyses in studies on broiler chicken production results. Europ. Poult. Sci. 2014, 78, 22. [Google Scholar]

- Gocsik, E.; Brooshooft, S.D.; De Jong, I.C.; Saatkamp, H.W. Cost efficiency of animal welfare in broiler production systems: A pilot study using the Welfare Quality® assessment protocol. Agric. Syst. 2016, 146, 55–69. [Google Scholar] [CrossRef]

- Roskam, J.L.; Oude Lansink, A.G.J.M.; Saatkamp, H.W. The relation between technical farm performance and antimicrobial use of broiler farms. Poult. Sci. 2020, 99, 1349–1356. [Google Scholar]

- Bastianoni, S.; Boggia, A.; Castellini, C.; Di Stefano, C.; Niccolucci, V.; Novelli, E.; Paolotti, L.; Pizzigallo, A. Measuring Environmental Sustainability of Intensive Poultry-Rearing System. In Genetic Engineering, Biofertilisation, Soil Quality and Organic Farming; Lichtfouse, E., Ed.; Springer: Dordrecht, The Netherlands, 2010; Volume 4, pp. 277–309. [Google Scholar]

- Castellini, C.; Bastianoni, S.; Granai, C.; Dal Bosco, A.; Brunetti, M. Sustainability of poultry production using the emergy approach: Comparison of conventional and organic rearing systems. Agric. Ecosyst. Environ. 2006, 114, 343–350. [Google Scholar] [CrossRef]

- Vaarst, M.; Steenfeldt, S.; Horsted, K. Sustainable development perspectives of poultry production. Worlds Poult. Sci. J. 2015, 71, 609–620. [Google Scholar] [CrossRef]

- Chotteau, P.; Beaumond, N.; Deblitz, C.; Hoste, R.; Magdelaine, P.; Mottet, A.; De Roest, K.; Roguet, C.; Sarzeaud, P.; Topliff, M.; et al. The Impact of Increased Operating Costs on Meat Livestock in the EU. Study for the European Parliament. Paris. Institut de l’ Elevage. 2009. Available online: http://www.europarl.europa.eu/RegData/etudes/etudes/join/2009/419109/IPOLAGRI_ET(2009)419109_EN.pdf (accessed on 18 March 2019).

- Van Horne, P.L.M. Competitiveness of the EU poultry Meat Sector, Base Year 2017. In Wageningen Economic Research Report 2018-116; Wageningen University & Research: Wageningen, The Netherlands, December 2018. [Google Scholar] [CrossRef]

- Leinonen, I.; Kyriazakis, I. How can we improve the environmental sustainability of poultry production? Proc. Nutr. Soc. 2016, 75, 265–273. [Google Scholar] [CrossRef]

- Gerber, P.; Opio, C.; Steinfeld, H. Poultry Production and the Environment—A Review; Animal Production and Health Division, FAO: Rome, Italy, 2007; Available online: http://www.fao.org/ag/againfo/home/events/bangkok2007/docs/part2/2_2.pdf (accessed on 11 March 2019).

- Sell-Kubiak, E.; Wimmers, K.; Reyer, H.; Szwaczkowski, T. Genetic aspects of feed efficiency and reduction of environmental footprint in broilers: A review. J. Appl. Genet. 2017, 58, 487–498. [Google Scholar] [CrossRef]

- Hume, D.A.; Whitelaw, C.B.A.; Archibald, A.L. The future of animal production: Improving productivity and sustainability. J. Agric. Sci. 2011, 149, 9–16. [Google Scholar] [CrossRef]

- De Verdal, H.; Mignon-Grasteau, S.; Bastianelli, D.; Même, N.; Le Bihan-Duval, E.; Narcy, A. Reducing the environmental impact of poultry breeding by genetic selection. J. Anim. Sci. 2013, 91, 613–622. [Google Scholar] [CrossRef] [PubMed]

- Kawsar, M.H.; Chowdhury, S.D.; Raha, S.K.; Hossain, M.M. An analysis of factors affecting the profitability of small-scale broiler farming in Bangladesh. Worlds Poult. Sci. J. 2013, 69, 676–686. [Google Scholar] [CrossRef]

- Martins, J.M.S.; Carvalho, C.M.C.; Litz, F.H.; Silveira, M.M.; Moraes, C.A.; Silva, M.C.A.; Fagundes, N.S.; Fernandes, E.A. Productive and Economic Performance of Broiler Chickens Subjected to Different Nutritional Plans. Braz. J. Poult. Sci. 2016, 18, 209–216. [Google Scholar] [CrossRef][Green Version]

- Kamran, Z.; Sarwar, M.; Nisa, M.; Nadeem, M.A.; Mahmood, S.; Babar, M.E.; Ahmed, S. Effect of low-protein diets having constant energy-to-protein ratio on performance and carcass characteristics of broiler chickens from one to thirty-five days of age. Poult. Sci. 2008, 87, 468–474. [Google Scholar] [CrossRef] [PubMed]

- Moosavi, M.; Eslami, M.; Chaji, M.; Boujarpour, M. Economic value of diets with different levels of energy and protein with constant ratio on broiler chickens. J. Anim. Vet. Adv. 2011, 10, 709–711. [Google Scholar] [CrossRef][Green Version]

- Willems, O.W.; Miller, S.P.; Wood, B.J. Assessment of residual body weight gain and residual intake and body weight gain as feed efficiency traits in the Turkey (Meleagris gallopavo). Genet. Sel. Evol. 2013, 45, 26–65. [Google Scholar] [CrossRef]

- Lourenço, I.C.; Branco, M.C. Determinants of corporate sustainability performance in emerging markets: The Brazilian case. J. Clean. Prod. 2013, 57, 134–141. [Google Scholar] [CrossRef]

- Reyer, H.; Hawken, R.; Murani, E.; Ponsuksili, S.; Wimmers, K. The genetics of feed conversion efficiency traits in a commercial broiler line. Sci. Rep. 2015, 5, 16387. [Google Scholar] [CrossRef]

- Marcu, A.; Vacaru-Opris, I.; Gabi, D.; Liliana, P.C.; Marcu, A.; Marioara, N.; Ioan, P.; Dorel, D.; Bartolomeu, K.; Cosmin, M. The Influence of Genetics on Economic Efficiency of Broiler Chickens Growth. Anim. Sci. Biotech. 2013, 46, 339–346. [Google Scholar]

- Tolimir, N.; Milošević, N.; Ceranić, C.; Škrbić, Z.; Maslovarić, M. The effect of feeding programmes on broiler performance and production efficiency. In Proceedings of the International Symposium on Animal Science, Belgrade-Zemun, Serbia, 23–25 September 2014; Available online: http://agris.fao.org/agris-search/search.do?recordID=RS2017000916 (accessed on 11 March 2019).

- Szőllősi, L.; Szűcs, I.; Nábrádi, A. Economic issues of broiler production length. Econ. Agric. 2014, 61, 633–646. [Google Scholar] [CrossRef]

- Tandoğan, M.; Cicek, H. Technical Performance and Cost Analysis of Broiler Production in Turkey. Braz. J. Poult. Sci. 2016, 18, 169–174. [Google Scholar] [CrossRef][Green Version]

- Abdel-Latif, M.A.; El-Far, A.H.; Elbestawy, A.R.; Ghanem, R.; Mousa, S.A.; Abd El-Hamid, H.S. Exogenous dietary lysozyme improves the growth performance and gut microbiota in broiler chickens targeting the antioxidant and non-specific immunity mRNA expression. PLoS ONE 2017, 12, e0185153. [Google Scholar]

- El-Menawey, M.; Attallah, A.; Abdel-Aziz, Y.; Yossif, M.; Gharib, H. Characterization and constrains of semi-intensive broiler production system in rural sector of Al-Sharkia and El-Qalioba governorates, Egypt. Egypt. Poult. Sci. J. 2019, 39, 311–326. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Guidelines for Development of a Classification System Related to Farm Typology. 2018. Available online: http://www.fao.org/3/ca6391en/ca6391en.pdf (accessed on 26 March 2019).

- Neyman, J. On the two different aspects of the representative methods. J. R. Stat. Soc. 1934, 97, 558–606. [Google Scholar] [CrossRef]

- Cochran, W.G. Sampling Techniques; John Wiley & Sons: New Delhi, India, 1977. [Google Scholar]

- Brannen, J. Mixing Methods: The Entry of Qualitative and Quantitative Approaches into the Research Process. Int. J. Soc. Res. Methodol. 2005, 8, 173–184. [Google Scholar] [CrossRef]

- Daoutopoulos, G.; Kazakopoulos, L.; Koussi, M. Agricultural Sociology; Zygos Publications: Thessaloniki, Greece, 2005. [Google Scholar]

- Siardos, G. Social Research Methodology; Ziti Publications: Thessaloniki, Greece, 2009. [Google Scholar]

- Iraizoz, B.; Gorton, M.; Davidova, S. Segmenting farms for analysing agricultural trajectories: A case study of the Navarra region in Spain. Agric. Syst. 2007, 93, 143–169. [Google Scholar] [CrossRef]

- Norušis, M.J. IBM SPSS Statistics 19. In Statistical Procedures Companion; Prentice Hall: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, L.R. Multivariate Data Analysis, 6th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Everitt, B.S.; Landau, S.; Leese, M.; Stahl, D. Cluster Analysis; John Wiley & Sons: Chichester, UK, 2011. [Google Scholar]

- Khan., M.; Afzal, M. Profitability analysis of different farm size of broiler poultry in district dir (lower). Sarhad J. Agric. 2018, 34, 389–394. [Google Scholar] [CrossRef]

- Emaikwu, K.K.; Chikwendu, D.O.; Sania, S. Determinants of flock size in broiler production in Kaduna State of Nigeria. J. Agric. Ext. Rural Dev. 2011, 3, 202–211. [Google Scholar]

- Baba, M.D.; Attahiru, M.; Sanda, A.Y. Estimating Resource Productivity and Efficiency of Smallholder Broiler Production in Bida Metropolis, Niger State, Nigeria. N. Y. Sci. J. 2016, 9, 24–28. [Google Scholar]

- Wang, B.Y.; Chien, L.H.; Roan, S.W. POMA-BROILER: A Computer Simulation Model to Evaluate the Optimal Market Age of Broilers. J. Anim. Vet. Adv. 2012, 11, 2493–2502. [Google Scholar]

- Samarakoon, S.M.R.; Samarasinghe, K. Strategies to improve the cost effectiveness of broiler production. Trop. Agric. Res. 2012, 23, 338–346. [Google Scholar] [CrossRef]

- Goliomytis, M.; Panopoulou, E.; Rogdakis, E. Growth Curves for Body Weight and Major Component Parts, Feed Consumption, and Mortality of Male Broiler Chickens Raised to Maturity. Poult. Sci. 2003, 82, 1061–1068. [Google Scholar] [CrossRef] [PubMed]

| Regional Unit | Number of Farms | Total Production (Number of Chickens/Year) |

|---|---|---|

| Ioannina | 767 | 26,475,000 |

| Arta | 214 | 15,000,000 |

| Preveza | 23 | 700,000 |

| Thesprotia | - | - |

| Total | 1004 | 42,175,000 |

| Regional Unit | Size Categories | Total | |||

|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | ||

| Arta | 12 | 10 | 2 | 1 | 25 |

| Ioannina | 49 | 26 | 4 | 2 | 81 |

| Preveza | 2 | 1 | 1 | - | 4 |

| Total | 63 | 37 | 7 | 3 | 110 |

| Cluster | Regional Unit | Total | % | ||

|---|---|---|---|---|---|

| Arta | Ioannina | Preveza | |||

| C1 | 11 | 35 | 0 | 46 | 41.8 |

| C2 | 8 | 30 | 0 | 38 | 34.6 |

| C3 | 1 | 1 | 0 | 2 | 1.8 |

| C4 | 5 | 15 | 4 | 24 | 21.8 |

| Total | 25 | 81 | 4 | 110 | 100 |

| Variable | Mean Value | C1 | C2 | C3 | C4 | p | SD |

|---|---|---|---|---|---|---|---|

| Number of farms (n) | 110 | 46 | 38 | 2 | 24 | ||

| Production cycles/year/farm | 5.07 | 5.22 b | 4.58 a | 6.00 c | 5.50 b | <0.001 | 0.93 |

| Feed conversion ratio | 1.81 | 1.77 a | 1.86 a | 2.24 b | 1.78 a | 0.004 | 0.21 |

| Annual rest period (days) | 81.25 | 78.24 | 85.18 | 79.00 | 80.96 | 0.618 | 23.69 |

| Consumed feed (tn) | 673.42 | 565.42 b | 271.25 a | 4156.25 d | 1226.97 c | <0.001 | 107.75 |

| Mortality (%) | 2.91 | 3.05 c | 2.98 bc | 1.56 a | 2.65 b | 0.046 | 0.35 |

| Gross profit (€) | 27,979 | 27,546 c | 11,798 b | −202,419 a | 73,628 d | <0.001 | 56,942 |

| Farm size (broilers/production cycle) | 29,468 | 26,847 b | 14,118 a | 127,000 d | 50,666 c | <0.001 | 20,288 |

| Total number of broilers/year | 152,049 | 134,736 b | 62,329 a | 752,000 d | 277,923 c | <0.001 | 120,700 |

| Total live weight of broilers/year (tn/year) | 372.11 | 323.47 b | 147.76 a | 1846.95 d | 697.68 c | <0.001 | 304.16 |

| Average days of a production cycle-length | 45.26 | 45.17 | 44.94 | 42.50 | 46.20 | 0.349 | 3.50 |

| Average slaughter weight (kg) | 2.49 | 2.48 | 2.45 | 2.48 | 2.58 | 0.107 | 0.20 |

| Average selling price/ kg of live weight (€) | 1.11 | 1.11 | 1.09 | 1.12 | 1.12 | 0.137 | 0.02 |

| Total production days/year | 229.87 | 235.97 b | 205.79 a | 255.00 c | 254.25 c | <0.001 | 45.73 |

| Land (ha) | 1.09 | 1.01 b | 0.73 a | 3.00 d | 1.64 c | <0.001 | 0.92 |

| Total Fixed Capital (€) | 37,187 | 32,289 b | 13,981 a | 170,268 d | 72,226 c | <0.001 | 30,500 |

| Average Gross Revenue (€) | 413,953 | 357,999 b | 161,779 a | 2,056,270 d | 783,612 c | <0.001 | 340,681 |

| Average Net Profit (€) | −16,678 | −12,516 b | −9743 c | −366,669 a | −6469 d | <0.001 | 6411 |

| Average Farm Income (€) | 20,093 | 19,928 c | 7357 b | −217,853 a | 60,406 d | <0.001 | 55,583 |

| Average Return on Capital (%) | 18.90 | −4.02 b | 48.7 d | −20.5 a | 12.4 c | 0.018 | 10.6 |

| Average production cost (€/kg of live weight) | 0.82 | 0.82 a | 0.83 a | 0.94 b | 0.81 a | 0.014 | 0.12 |

| Variable | Mean Value | C1 | C2 | C3 | C4 |

|---|---|---|---|---|---|

| Number of farms (n) | 110 | 46 | 38 | 2 | 24 |

| Farm size (number of broilers) | 29.47 | 26.85 | 14.12 | 127.00 | 50.67 |

| Total number of broilers/year | 152.05 | 134.74 | 62.33 | 752.00 | 277.92 |

| Total Fixed Capital (€) | 244.65 | 239.65 | 224.32 | 226.42 | 260.00 |

| Average Gross Revenue (€) | 2722.48 | 2656.97 | 2595.54 | 2734.40 | 2819.56 |

| Average Net Profit (€) | −109.69 | −92.90 | −156.32 | −487.59 | −23.28 |

| Average Farm Income (€) | 132.15 | 147.90 | 118.04 | −289.70 | 217.35 |

| Average | C1 (n = 46) | C2 (n = 38) | C3 (n = 2) | C4 (n = 24) | |

|---|---|---|---|---|---|

| EPEF | 295.10 | 300.73 | 284.36 | 256.44 | 305.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dotas, V.; Gourdouvelis, D.; Hatzizisis, L.; Kaimakamis, I.; Mitsopoulos, I.; Symeon, G. Typology, Structural Characterization and Sustainability of Integrated Broiler Farming System in Epirus, Greece. Sustainability 2021, 13, 13084. https://doi.org/10.3390/su132313084

Dotas V, Gourdouvelis D, Hatzizisis L, Kaimakamis I, Mitsopoulos I, Symeon G. Typology, Structural Characterization and Sustainability of Integrated Broiler Farming System in Epirus, Greece. Sustainability. 2021; 13(23):13084. https://doi.org/10.3390/su132313084

Chicago/Turabian StyleDotas, Vassilios, Dimitrios Gourdouvelis, Lampros Hatzizisis, Ioannis Kaimakamis, Ioannis Mitsopoulos, and George Symeon. 2021. "Typology, Structural Characterization and Sustainability of Integrated Broiler Farming System in Epirus, Greece" Sustainability 13, no. 23: 13084. https://doi.org/10.3390/su132313084

APA StyleDotas, V., Gourdouvelis, D., Hatzizisis, L., Kaimakamis, I., Mitsopoulos, I., & Symeon, G. (2021). Typology, Structural Characterization and Sustainability of Integrated Broiler Farming System in Epirus, Greece. Sustainability, 13(23), 13084. https://doi.org/10.3390/su132313084