Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies

Abstract

:1. Introduction

2. Methodology Development

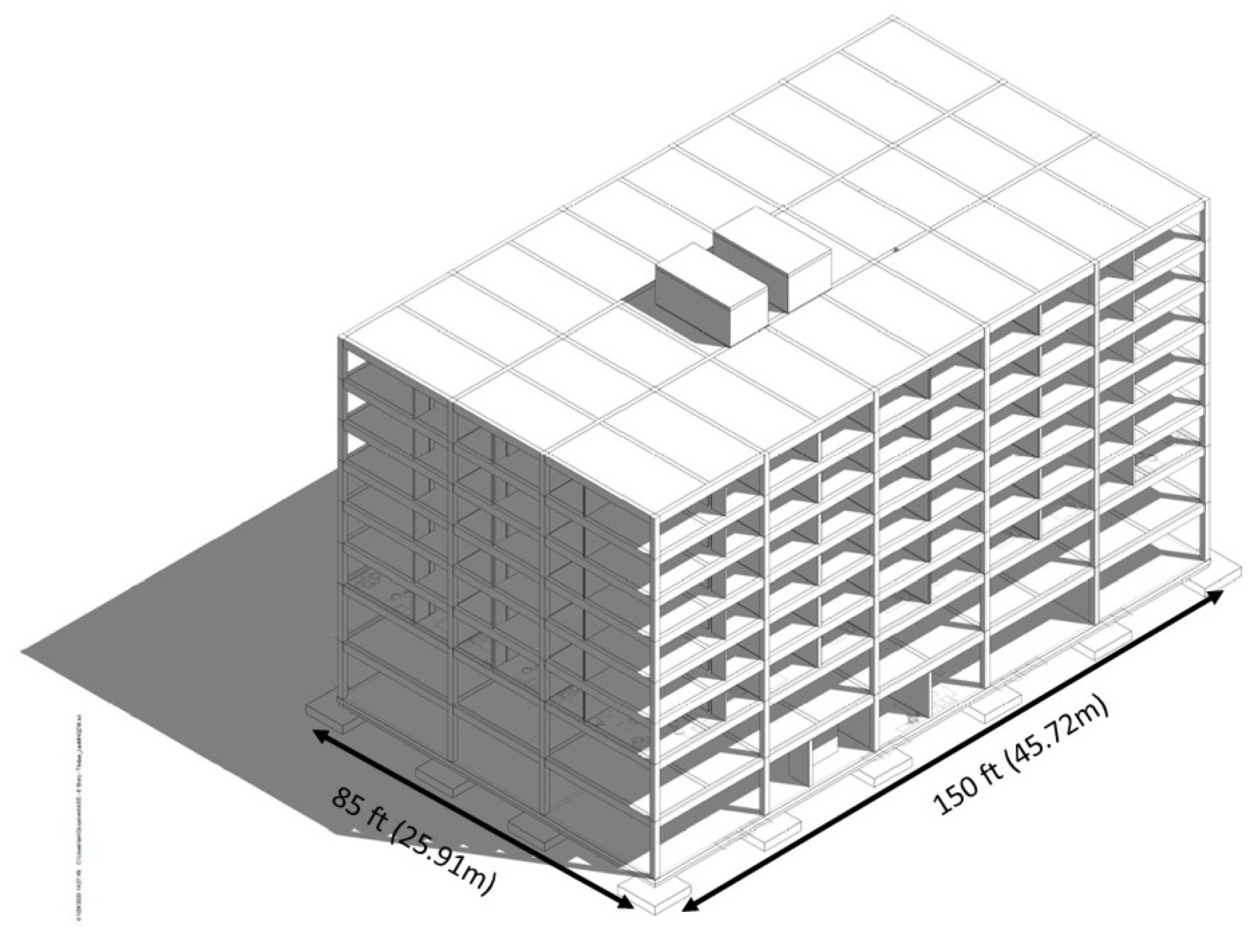

2.1. Building Designs

2.2. Bill of Materials Take-Off

2.3. Whole-Building Life-Cycle Assessment

2.3.1. Goal and Scope

2.3.2. Reference Unit

2.3.3. System Boundary

2.3.4. Life-Cycle Inventory

2.3.5. Life-Cycle Impact Assessment

3. Discussion

3.1. Life-Cycle Inventory for Building Material, Energy, and Fuel Used in the Building Structures

3.1.1. Data Quality for the Prospective LCI/LCA

- Consistency: The assessment draws from several databases (Table 3) that are consistent with the system boundary and scope;

- Reproducibility: Most LCI data used is publicly available or referenced to particular data sets such that reproducibility is possible.

3.1.2. The Prospective LCIs for Each Material Designed in the Mass Timber and Concrete Buildings

3.2. Building LCA Assumptions

3.2.1. Building Site Assumptions

3.2.2. Material Assumptions

3.2.3. Structural Assumptions

3.2.4. Transportation Assumptions

3.2.5. Construction and Installation Assumptions

- M = mass of the material being lifted in kg

- h = height at which the material is being lifted. Half of the building height was assumed.

3.3. Comparative Building LCA

3.3.1. Functional Equivalents

3.3.2. Comparable Building Designs

3.4. Contribution Analysis from WBLCA

3.5. Carbon Storage in Mass Timber Buildings

4. Conclusions and Recommendation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Summary for Policymakers. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021; In Press. [Google Scholar]

- Gu, H.; Nepal, P.; Arvanitis, M.; Alderman, D. Carbon impacts of engineered wood products in construction. In Engineered Wood Products for Construction; IntechOpen: London, UK, 2021; pp. 233–246. [Google Scholar] [CrossRef]

- Hart, J.; D’Amic, B.; Pomponi, F. Whole-life embodied carbon in multistory buildings: Steel, concrete and timber structures. J. Ind. Ecol. 2021, 25, 403–418. [Google Scholar] [CrossRef]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.; Graedel, T.E.; Schellnhuber, J. Building as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Dodoo, A.; Nguyen, T.; Dorn, M.; Olsson, A.; Bader, T.K. Exploring the synergy between structural engineering design solutions and life cycle carbon footprint of cross-laminated timber in multi-storey buildings. Wood Mater. Sci. Eng. 2021, 1–13. [Google Scholar] [CrossRef]

- Amy Androff. Trees Are Climate Change, Carbon Storage Heroes. USDA Forest Service, Forest Products Laboratory—Lab Notes. 2021. Available online: https://www.fpl.fs.fed.us/labnotes/?p=27893 (accessed on 19 December 2021).

- WoodWorks. Building Trends: Mass Timber; 2021; Available online: https://www.woodworks.org/publications-media/building-trends-mass-timber/ (accessed on 19 December 2021).

- Architecture 2030. Available online: https://architecture2030.org/why-the-building-sector/ (accessed on 19 December 2021).

- Bastin, J.-F.; Finegold, Y.; Garcia, C.; Mollicone, D.; Rezende, M.; Routh, D.; Zohner, C.M.; Crowther, T.W. The global tree restoration potential. Science 2019, 365, 76–79. [Google Scholar] [CrossRef] [PubMed]

- Griscom, B.W.; Adams, J.; Ellis, P.W.; Houghton, R.A.; Lomax, G.; Miteva, D.A.; Schlesinger, W.H.; Shoch, D.; Siikamäki, J.V.; Smith, P.; et al. Natural climate solutions. Proc. Natl. Acad. Sci. USA 2017, 114, 11645–11650. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lippke, B.; Puettmann, M.; Oneil, E.; Oliver, C.D. The Plant a Trillion Trees Campaign to Reduce Global Warming-Fleshing Out the Concept. J. Sustain. For. 2021, 40, 1–31. [Google Scholar] [CrossRef]

- Carlisle, S.; Waldman, B.; Lewis, M.; Simonen, K. 2021 Carbon Leadership Forum Material Baseline Report. (Version 2); University of Washington Carbon Leadership Forum: Seattle, WA, USA, 2021. [Google Scholar]

- Kwok, A.; Zalusky, H.; Rasmussen, L.; Rivera, I.; McKay, H. Cross-Laminated Timber Buildings: A WBLCA Case Study Series. 2020. Available online: https://tallwoodinstitute.org/ (accessed on 10 December 2021).

- International Organization for Standardization. ISO 21931. Sustainability in Building Construction—Framework for Methods of Assessment of the Environmental Performance of Construction Works; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- European Committee for Standardization. EN 15978. Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; European Committee for Standardization: Brussels, Belgium, 2011; pp. 1–60. [Google Scholar]

- Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of conventional and mass timber buildings in regions with potential for mass timber penetration. Sustainability special issue–Mass Timber and Sustainable Building Construction. Sustainability 2021, 13, 13987. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14040:2006(E). Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.; Chen, C.X.; Pierobon, F.; Ganguly, I.; Simonen, K. Life Cycle Assessment of Katerra’s Cross-Laminated Limber (CLT) and Catalyst Building: Final Report; University of Washington: Seattle, WA, USA, 2019; pp. 1–63. [Google Scholar]

- Bowers, T.; Puettmann, M.E.; Ganguly, I.; Eastin, I. Cradle-to-gate life-cycle impact analysis of glued-laminated (glulam) timber: Environmental impacts from glulam produced in the US Pacific northwest and southeast. For. Prod. J. 2017, 67, 368–380. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 21930 Sustainability in Buildings and Civil Engineering Works. In Core Rules for Environmental Product Declarations of Construction Products and Services; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044. Environmental Management—Life Cycle Assessment—Requirement and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Frühwald, E.; Serrano, E.; Toratti, T.; Emilsson, A.; Thelandersson, S. Design of Safe Timber Structures—How Can We Learn from Structural Failures in Concrete, Steel and Timber? Research report TVBK-3053; Lund University: Lund, Switzerland, 2008; pp. 0349–0496. [Google Scholar]

- Brischke, C.; Alfredsen, G.; Humar, M.; Conti, E.; Cookson, L.; Emmerich, L.; Flæte, P.O.; Fortino, S.; Francis, L.; Hundhausen, U.; et al. Modelling the Material Resistance of Wood—Part 3: Relative Resistance in above and in Ground Situations—Results of a Global Survey. Forests 2021, 12, 590. [Google Scholar] [CrossRef]

- Bowick, M. Wood Innovation and Design Centre Prince George, BC: An Environmental Building Declaration According to EN 15978 Standard; Athena Sustainable Materials Institute: Ottawa, ON, Canada, 2015; pp. 1–54. [Google Scholar]

- Ganguly, I.; Pierobon, F.; Hall, E.S. Global warming mitigating role of wood products from Washington State’s Private forests. Forests 2020, 11, 194. [Google Scholar] [CrossRef] [Green Version]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the US PNW. J. Build Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Pierobon, F.; Jones, S.; Maples, I.; Ganguly, I. Global warming benefits of storing carbon in mass timber buildings in the United States. Sustainability 2021. Under Review. [Google Scholar]

- Hradil, P.; Talja, A.; Wahlström, M.; Huuhka, S.; Lahdensivu, J.; Pikkuvirta, J. Re-use of structural elements: Environmentally efficient recovery of building components. VTT Technology; Vol. 200. VTT Technical Research Centre of Finland. 2014. Available online: http://www.vtt.fi/inf/pdf/technology/2014/T200.pdf (accessed on 19 December 2021).

| Mass Timber Construction Type | Stories | Residential | Office/Commercial | Building Height | Total Floor Area | ||

|---|---|---|---|---|---|---|---|

| Feet | Meters | ft2 | m2 | ||||

| Type IV-C | 8 | 6 stories | 2 stories | 85 | 26 | 102,000 | 9476 |

| Type IV-B | 12 | 8 stories | 4 stories | 156 | 48 | 153,000 | 14,214 |

| Type IV-A | 18 | 12 stories | 6 stories | 234 | 71 | 229,500 | 21,321 |

| 8-Story | 12-Story | 18-Story | ||||||

|---|---|---|---|---|---|---|---|---|

| Assembly | Material: Name | Unit | Timber | Concrete | Timber | Concrete | Timber | Concrete |

| Columns and Beams | Concrete | m3 | - | 93 | - | 385 | - | 586 |

| Glulam | m3 | 859 | - | 1376 | - | 2265 | - | |

| Rebar | - | 285,609 | ||||||

| Exterior Walls | Aluminum stud | kg | - | 740 | - | 1562 | - | 2411 |

| CLT | m3 | 172 | - | 365 | - | 564 | - | |

| 3-5/8” Fiberglass mat | m2 | - | 1638 | - | 3479 | - | 5387 | |

| 5/8” Gypsum board | m2 | 1638 | 1638 | 3479 | 3479 | 5387 | 5387 | |

| 5” Mineral wool | m2 | 1638 | - | 3479 | - | 5387 | - | |

| 1-1/2” Polystyrene | m2 | - | 1638 | - | 3479 | - | 5387 | |

| Floors | 3/8” Acoustic mat | m2 | 8271 | - | 12,095 | - | 18,317 | - |

| CLT | m3 | 1444 | - | 2112 | - | 3199 | - | |

| Concrete | m3 | 372 | 2293 | - | 2865 | 374 | 4666 | |

| Gypsum concrete | m3 | 420 | - | 614 | 1537 | 931 | - | |

| 3/8” PE vapor barrier | m2 | 1220 | 1214 | 1533 | - | 1227 | 1229 | |

| Rebar | kg | 5401 | 41,697 | - | 54,551 | 5,444 | 87,245 | |

| Foundation | Concrete | m3 | 458 | 674 | 1402 | 1874 | 602 | 818 |

| Rebar | kg | 23,981 | 20,366 | 102,676 | 187,233 | 28,755 | 34,696 | |

| Interior Walls | CLT | m3 | 461 | - | 801 | - | - | - |

| Concrete | m3 | - | 516 | - | 961 | 1479 | 1419 | |

| 3-5/8” Fiberglass mat | m2 | 3375 | 3511 | 5774 | 5934 | 8506 | 8830 | |

| 5/8” Gypsum board | m2 | 29,566 | 24,041 | 84,107 | 40,707 | 148,456 | 60,959 | |

| 5-1/2” Mineral wool | m2 | - | - | - | - | - | - | |

| Rebar | kg | - | 73,125 | - | 145,244 | - | 214,477 | |

| Steel stud | kg | 15,756 | 16,302 | 25,350 | 25,974 | 37,674 | 38,844 | |

| Exterior Brace Framing | kg | 10,534 | - | 16,272 | - | 24,369 | - | |

| Assembly | Material | 8-Story | 12-Story | 18-Story | ||||

|---|---|---|---|---|---|---|---|---|

| Unit | Timber | Concrete | Timber | Concrete | Timber | Concrete | ||

| Columns and Beams | Concrete | m3 | - | 93 | - | 385 | - | 586 |

| Glulam | m3 | 758 | - | 1207 | - | 1733 | - | |

| Rebar | kg | - | 59,392 | - | 139,608 | - | 285,609 | |

| Exterior Walls | Aluminum stud | kg | - | 738 | - | 1550 | - | 2400 |

| CLT | m3 | 172 | - | 364 | - | 564 | - | |

| 3-5/8” Fiberglass mat | m2 | - | 1638 | - | 3479 | - | 5387 | |

| 5/8” Gypsum board | m2 | 1638 | 1638 | 3479 | 3479 | 5387 | 5387 | |

| 5” Mineral wool | m2 | 1638 | - | 3479 | - | 5387 | ||

| 1-1/2” Polystyrene | m2 | - | 1638 | - | 3479 | - | 5387 | |

| Floors | 3/8” Acoustic mat | m2 | 8229 | - | 12,053 | - | 18,277 | - |

| CLT | m3 | 1437 | - | 2105 | - | 3192 | - | |

| Concrete | m3 | 372 | 2293 | - | 2865 | 370 | 6894 | |

| Gypsum concrete | m3 | 418 | - | 612 | - | 928 | - | |

| 3/8” PE vapor barrier | m2 | 1220 | 1214 | 1533 | 1537 | 1214 | 1229 | |

| Rebar | kg | 5401 | 41,697 | - | 54,551 | 5388 | 87,245 | |

| Foundation | Concrete | m3 | 367 | 674 | 1402 | 1874 | 601 | 818 |

| Rebar | kg | 12,498 | 20,366 | 102,743 | 187,233 | 28,741 | 34,696 | |

| Interior Walls | CLT | m3 | 1152 | - | 2053 | - | 1835 | - |

| Concrete | m3 | - | 516 | - | 961 | 1474 | 1419 | |

| 3-5/8” Fiberglass mat | m2 | 280 | 3511 | 500 | 5934 | 757 | 8830 | |

| 5/8” Gypsum board | m2 | 13,724 | 24,041 | 74,381 | 40,707 | 175,872 | 60,959 | |

| 3” Mineral wool | m2 | 3287 | - | 5617 | - | 8317 | - | |

| Rebar | kg | - | 73,125 | - | 145,206 | 202,066 | 214,477 | |

| Steel stud | kg | 8112 | 16,302 | 13,182 | 25,974 | 19,812 | 38,844 | |

| Exterior Brace Framing | kg | |||||||

| 8-Story | 12-Story | 18-Story | ||||||

|---|---|---|---|---|---|---|---|---|

| Assembly | Material: Name | Unit | Timber | Concrete | Timber | Concrete | Timber | Concrete |

| Columns and Beams | Concrete | m3 | - | 93 | - | 385 | - | 586 |

| Glulam | m3 | 752 | - | 1207 | - | 1733 | - | |

| Rebar | kg | - | 59,392 | - | 139,608 | - | 386,927 | |

| Exterior Walls | Aluminum stud | kg | - | 730 | 1534 | - | 2375 | |

| CLT | m3 | 172 | - | 364 | 564 | |||

| 3-5/8” Fiberglass mat | m2 | 1638 | 3479 | - | 5387 | |||

| 5/8” Gypsum board | m2 | 1638 | 1638 | 3479 | 3479 | 5387 | 5387 | |

| 5” Mineral wool | m2 | 1638 | - | 3479 | - | 5387 | - | |

| 1-1/2” Polystyrene | m2 | - | 1638 | - | 3,479 | - | 5387 | |

| Floors | 3/8” Acoustic mat | m2 | 8229 | - | 12,053 | 18,277 | - | |

| CLT | m3 | 1437 | - | 2105 | - | 3192 | ||

| Concrete | m3 | 372 | 2293 | - | 2865 | 370 | 4666 | |

| Gypsum concrete | m3 | 418 | - | 612 | - | 928 | - | |

| 3/8” PE vapor barrier | m2 | 1218 | 1214 | 1533 | 1537 | 18,277 | 1229 | |

| Rebar | kg | 5401 | 41,697 | - | 54,551 | 8364 | 87,245 | |

| Foundation | Concrete | m3 | 367 | 674 | 1402 | 1874 | 601 | 818 |

| Rebar | kg | 12,498 | 20,366 | 102,743 | 187,233 | 28,741 | 34,699 | |

| Interior Walls | CLT | m3 | 1153 | - | 2053 | - | 1835 | - |

| Concrete | m3 | - | 516 | - | 961 | 1474 | 1419 | |

| 3-5/8” Fiberglass mat | m2 | 280 | 323 | 500 | 5934 | 757 | 8830 | |

| 5/8” Gypsum board | m2 | 13,724 | 24,041 | 74,381 | 40,707 | 175,872 | 60,959 | |

| 5-1/2” Mineral wool | m2 | 3287 | - | 5617 | - | 8317 | ||

| Rebar | kg | - | 73,125 | - | 145,206 | 202,066 | 214,477 | |

| Steel stud | kg | 8112 | 16,302 | 13,300 | 25,974 | 19,812 | 38,844 | |

| Exterior Brace Framing | kg | |||||||

| Reporting Category by ISO 21930:2017 | Indicator Name | Abbreviation | Units | Method |

|---|---|---|---|---|

| Core Mandatory Impact Indicators | Global warming potential, fossil | GWP | kg CO2e | TRACI |

| Core Mandatory Impact Indicators | Depletion potential of the stratospheric ozone layer | ODP | kg CFC11e | TRACI |

| Core Mandatory Impact Indicators | Acidification potential of soil and water sources | AP | kg SO2e | TRACI |

| Core Mandatory Impact Indicators | Eutrophication potential | EP | kg PO4e | TRACI |

| Core Mandatory Impact Indicators | Formation potential of tropospheric ozone | SFP | kg O3e | TRACI |

| Core Mandatory Impact Indicators | Abiotic depletion potential (ADP fossil) for fossil resources; | ADPf | MJ, NCV | CML |

| Core Mandatory Impact Indicators | Abiotic depletion potential (ADP element) for fossil resources; | ADPe | kg, Sbe | CML |

| Core Mandatory Impact Indicators | Fossil fuel depletion | FFD | MJ Suplus | TRACI |

| Use of Primary Resources | Renewable primary energy carrier used as energy | RPRE | MJ, NCV | CED |

| Use of Primary Resources | Nonrenewable primary energy carrier used as energy | NRPRE | MJ, NCV | CED |

| Mandatory Inventory Parameters | Consumption of freshwater resources | FW | m3 | Manual from LCI |

| Indicators Describing Waste | Hazardous waste disposed | HWD | kg | Manual |

| Indicators Describing Waste | Nonhazardous waste disposed | NHWD | kg | Manual |

| Additional Inventory Parameters for Transparency | Biogenic Carbon Removal from Product | BCRP | kg CO2e | Manual |

| Additional Inventory Parameters for Transparency | Biogenic Carbon Emission from Product | BCEP | kg CO2e | Manual |

| Additional Inventory Parameters for Transparency | Biogenic Carbon Emission from Combustion of Waste from Renewable Sources Used in Production Processes | BCEW | kg CO2e | Manual from LCI |

| Additional Inventory Parameters for Transparency | Calcination Carbon Emissions | CCE | kg CO2e | Manual |

| Material/Energy/Fuel | LCI Process | Database/Data Source |

|---|---|---|

| Acoustic panel | Gypsum plaster board, at plant/US US-EI U | US-EI 2.2 |

| Aluminum stud | Galvanized steel sheet, at plant NREL/RNA U | US-EI 2.2 |

| CLT | CLT | [18,19] |

| Concrete | Concrete, 3000 psi | Athena impact estimator |

| Concrete | Concrete, 4000 psi | Athena impact estimator |

| Concrete | Concrete, 5000 psi | Athena impact estimator |

| Construction energy | Diesel, combusted in industrial equipment NREL/US U | US-EI 2.2 |

| Electricity | Regional Grids WECC, NPCC, WECC | Ecoinvent |

| Exterior Brace Framing | Hot rolled sheet, steel, at plant NREL/RNA U | US-EI 2.2 |

| Glulam | Glulam | CORRIM and [19] |

| Gypsum concrete | Proxy process | US-EI 2.2 |

| Gypsum wallboard | Gypsum fibre board, at plant/US US-EI U | US-EI 2.2 |

| Insulation | Glass wool mat, at plant/US US-EI U | US-EI 2.2 |

| Insulation | Rock wool, packed, at plant/US US-EI U | US-EI 2.2 |

| Insulation | Polystyrene, extruded (XPS), at plant/US- US-EI U | US-EI 2.2 |

| Polystyrene Insulated Sheathing | Polystyrene, extruded (XPS), at plant/US- US-EI U | US-EI 2.2 |

| Rail Transport | Transport, train, diesel powered NREL/US U | US-EI 2.2 |

| Rebar | Reinforcing steel, at plant/US- US-EI U | US-EI 2.2 |

| Rectangular Mullion: 3–5/8” C Stud | Galvanized steel sheet, at plant NREL/RNA U | US-EI 2.2 |

| Road Transport | Transport, combination truck, diesel powered NREL/US U | US-EI 2.2 |

| Geographic Regions | Mass Timber Production | Species |

|---|---|---|

| Northeast (NE) | Lincoln, Maine | Eastern Spruce and White Pine |

| Pacific Northwest (PNW) | Seattle, Washington | Douglas-fir, Western Hemlock |

| Southeast (SE) | Dothan, Alabama | Southern Pine |

| Category | Concrete Compressive Strength (psi) |

|---|---|

| Below Grade Foundation Walls | 4000 |

| Grade Beams | 4000 |

| Slabs-on-grade | 4000 |

| Pile caps | 4000 |

| Spread footings | 3000 |

| Superstructure | |

| Floors | 5000 |

| Columns | 5000 |

| Shaft walls | 5000 |

| Stories | Building Design | |

|---|---|---|

| Mass Timber | Concrete | |

| 8 | Spread Footing | Spread Footing |

| 12 | Mat Footing | Mat Footing |

| 18 | Piles and Spread Footing | Piles and Spread Footing |

| PNW | NE | SE | ||||

|---|---|---|---|---|---|---|

| Material Name | Truck | Rail | Truck | Rail | Truck | Rail |

| Kilometer (Km) | ||||||

| 25 ga steel, Galvanized steel sheet | 30 | 1321 | 16 | 918 | 16 | 1151 |

| Acoustic Mat, Gypsum plaster board | 219 | - | 391 | 41 | ||

| Aluminum,3-5/8” Metal Stud | 30 | 1321 | 292 | 16 | 1371 | |

| CLT | 473 | - | 460 | 354 | ||

| Concrete | 52 | - | 17 | 9 | ||

| Exterior Brace Framing | 87 | 1321 | - | - | - | |

| Extruded Polystyrene Insulated Sheathing | 285 | - | 98 | 42 | ||

| Fiberglass Batt, Glass wool mat | 16 | 1321 | 98 | 42 | ||

| Glulam | 490 | - | 460 | 332 | ||

| GYP, Gypsum wallboard | 219 | - | 391 | 27 | ||

| Gypsum concrete | 219 | - | 391 | 41 | ||

| Mineral Wool, Rock wool | 285 | - | 98 | 42 | ||

| Polyethylene film membrane | 16 | 2253 | 637 | 82 | ||

| Rebar | 32 | - | 53 | 31 | ||

| Diesel Use (L) | ||||||

|---|---|---|---|---|---|---|

| Region | Timber | Concrete | Timber | Concrete | Timber | Concrete |

| 8 | 12 | 18 | ||||

| PNW | 11,856 | 22,481 | 23,519 | 44,990 | 42,835 | 64,171 |

| NE | 10,943 | 21,677 | 23,585 | 43,517 | 43,726 | 61,842 |

| SE | 11,997 | 21,639 | 25,574 | 43,424 | 46,819 | 62,270 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, H.; Liang, S.; Pierobon, F.; Puettmann, M.; Ganguly, I.; Chen, C.; Pasternack, R.; Wishnie, M.; Jones, S.; Maples, I. Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies. Sustainability 2021, 13, 14034. https://doi.org/10.3390/su132414034

Gu H, Liang S, Pierobon F, Puettmann M, Ganguly I, Chen C, Pasternack R, Wishnie M, Jones S, Maples I. Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies. Sustainability. 2021; 13(24):14034. https://doi.org/10.3390/su132414034

Chicago/Turabian StyleGu, Hongmei, Shaobo Liang, Francesca Pierobon, Maureen Puettmann, Indroneil Ganguly, Cindy Chen, Rachel Pasternack, Mark Wishnie, Susan Jones, and Ian Maples. 2021. "Mass Timber Building Life Cycle Assessment Methodology for the U.S. Regional Case Studies" Sustainability 13, no. 24: 14034. https://doi.org/10.3390/su132414034