Improvement of a Truss-Reinforced, Half-Concrete Slab Floor System for Construction Sustainability

Abstract

:1. Introduction

- (1)

- (2)

- (3)

- (4)

- (5)

- (6)

- (1)

- to perform an experimental study on the structural performance of STBT- versus SBT-reinforced half slabs to understand the impacts of using the steel tubes in the half slab;

- (2)

- to study why precast half-concrete slabs cost more than traditional cast-in-place slabs by comparing their component designs; and

- (3)

- to propose a new cost-effective half slab floor system that is more environmentally friendly and labor friendly based on the above two objectives.

2. Experimental Description

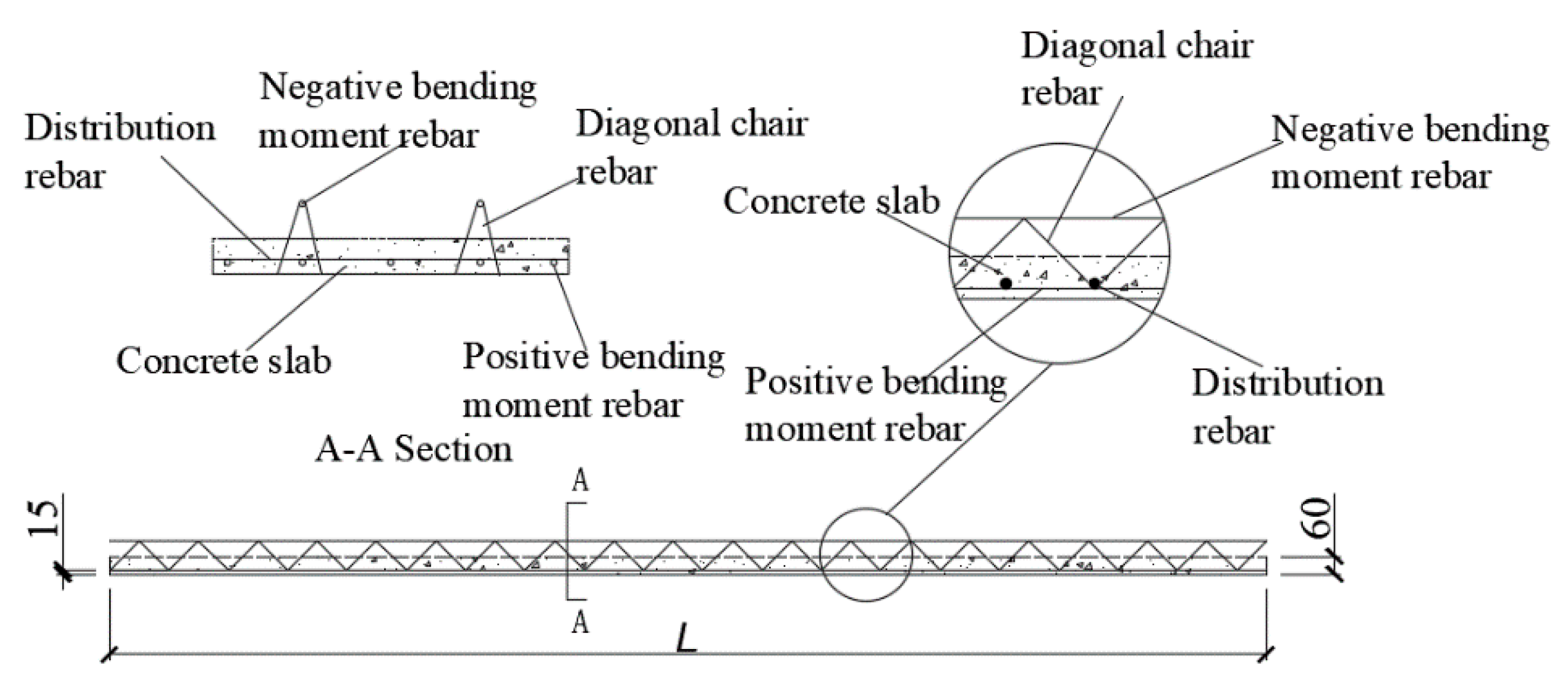

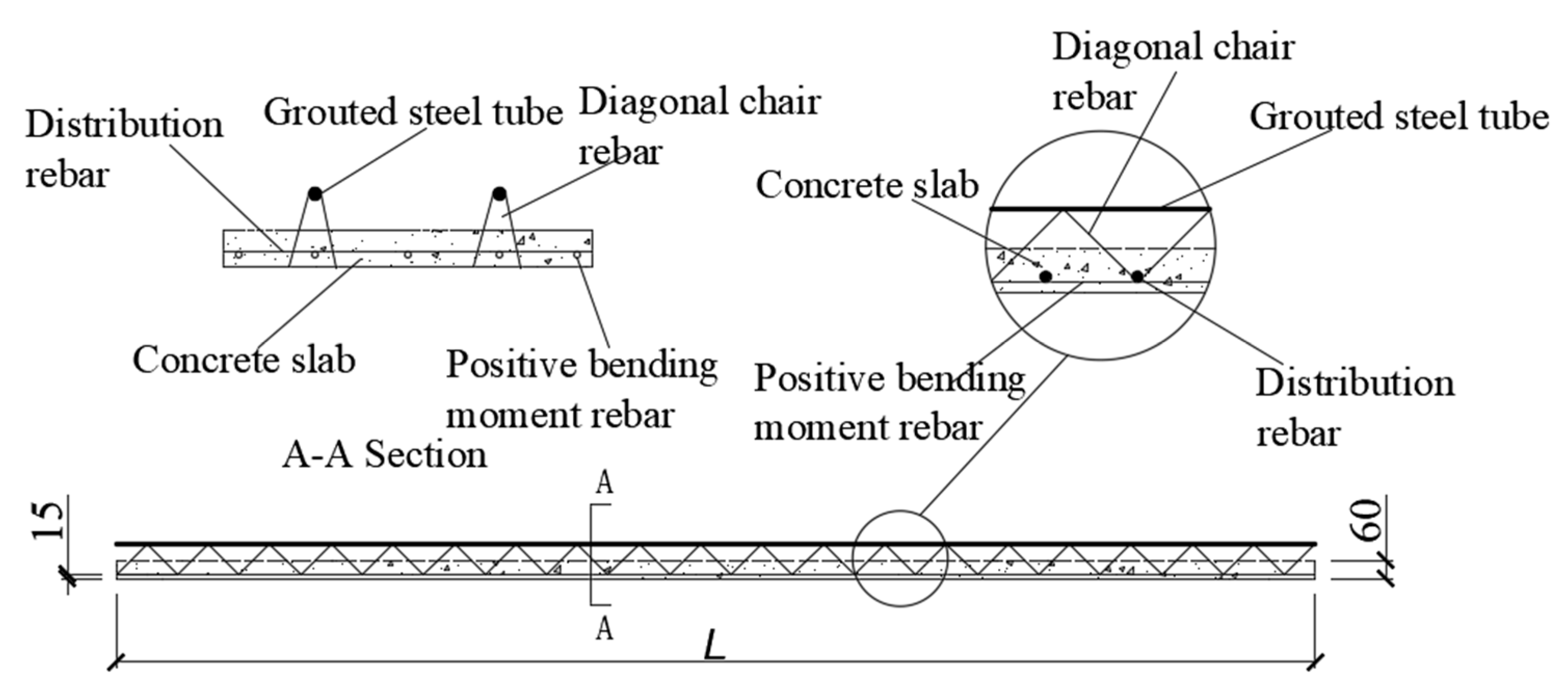

2.1. Specimen Design and Production

2.2. Material Properties

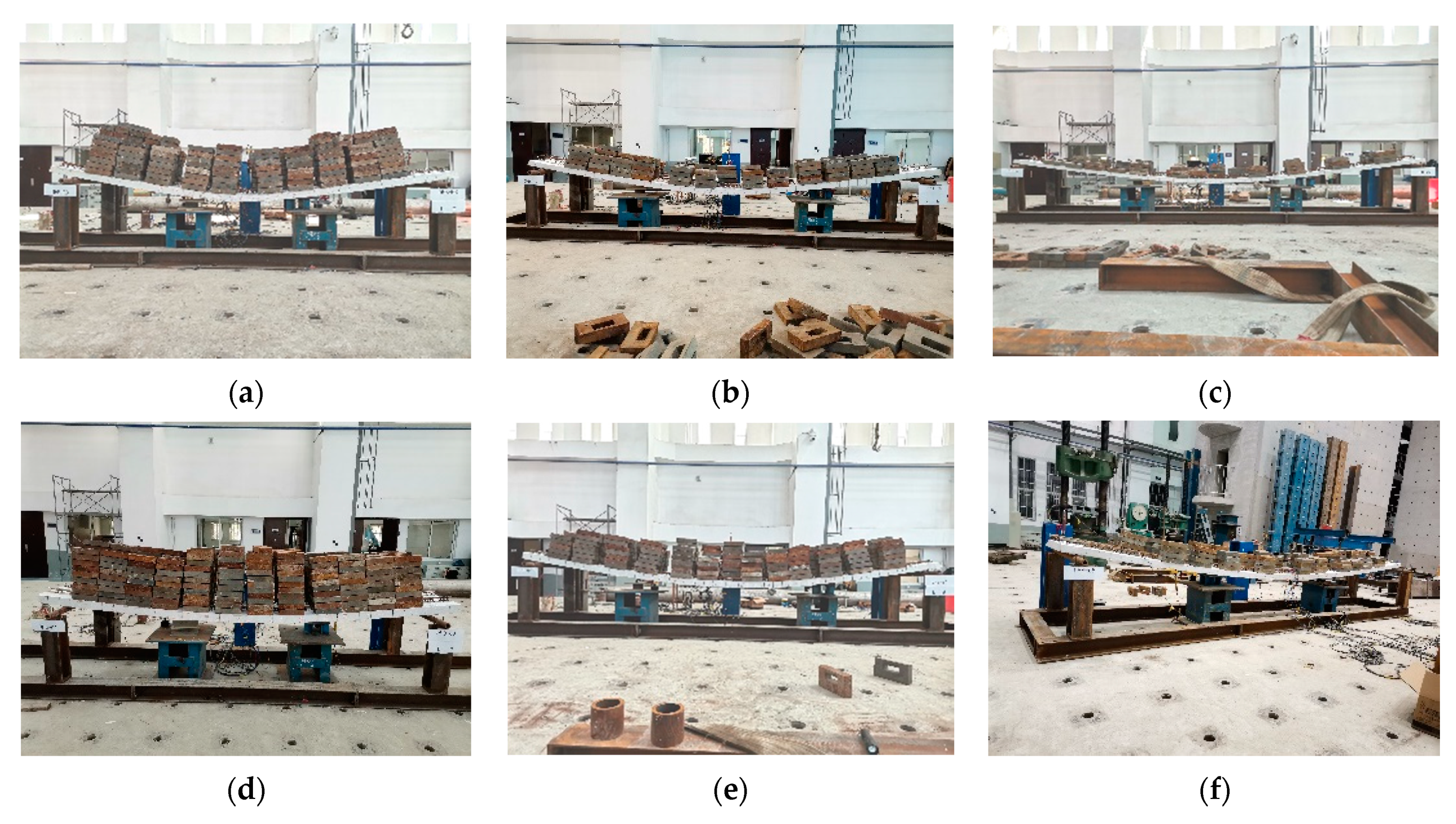

2.3. Loading Device and Measurement

2.4. Loading Scheme and Procedure

3. Test Results and Analysis

3.1. Crack Development and Failure Mode

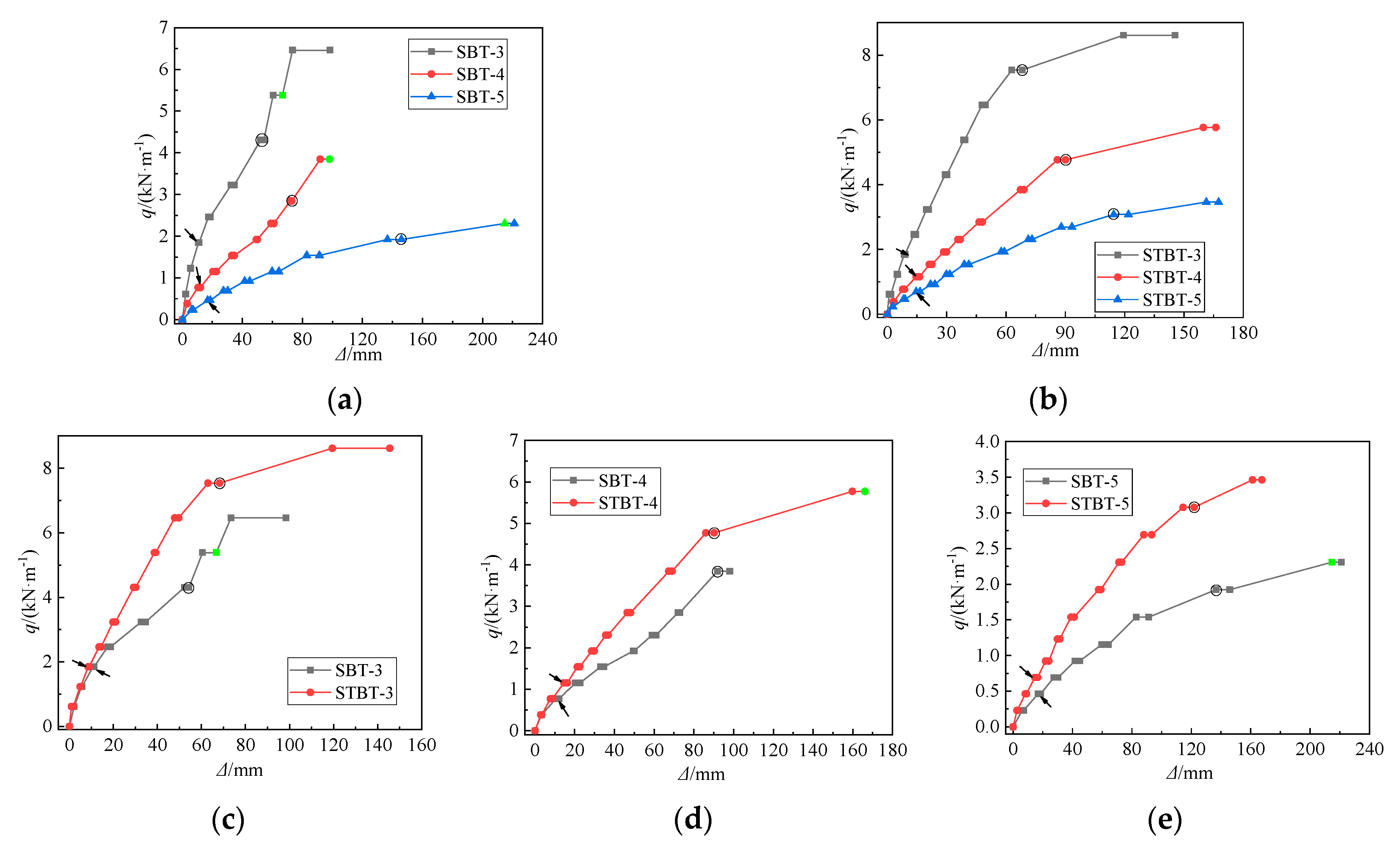

3.2. Load Deformation Curves

3.3. Steel Strain Curves

3.4. Load Bearing Capacity

4. Half Slab System Improvement and Discussion

4.1. Cost Assessment of Half Slabs

4.2. Proposed Slab System

- (1)

- As the steel tube used in the truss has good structural performance, it can be used effectively to resist the tensile force in the precast slab.

- (2)

- To reduce the concrete volume in the half slab floor system, the cast-in-place concrete topping layer (at least 60 mm thick) needs to be replaced by a light board subfloor resting on the steel tubes. Thus, this design concept changes the present wet–dry half slab floor system into a completely dry system and the amount of steel in the cast-in-place layer can be reduced.

- (3)

- The steel trusses are used to support the light subfloor, which is placed on the steel tubes. The subfloor can be made of plywood, OSB (oriented strand board), a precast concrete panel, or green material certified board. The open space between the subfloor and the precast slab has electrical wiring, plumbing, heat insulation, and sound insulation materials and other built-in services.

- (4)

- Since the light subfloor rests on the steel tubes, it is better to use square or rectangular tubes.

5. Conclusions

- (1)

- The failure mode of the prefabricated STBT-reinforced half slab was typical bending failure. The bending cracks were mainly distributed within 3 m of the middle span, and the cracks were evenly distributed. When the final failure occurred, the steel tube did not have out-of-plane and/or in-plane buckling, and its mechanical performance was better than the compressive steel bar in the SBT-reinforced half slab.

- (2)

- For the three spans adopted in the experiment, with the increase of the span, the crack load, yield load, and maximum load of the prefabricated truss-reinforced half slab were reduced. Compared with the SBT-reinforced specimens, the load characteristic values of the STBT-reinforced specimens were significantly improved. Therefore, a steel tube truss can be used instead of a steel bar truss to improve the load bearing capacity of the prefabricated steel truss–reinforced half slab.

- (3)

- The prefabricated STBT-reinforced half slab had greater initial stiffness and resistance to deformation when compared to the SBT-reinforced half slab. Therefore, we recommended using the STBT form for the prefabricated half slab with a larger span.

- (4)

- Due to the fact that good structural performance of the steel tube was observed, after having studied the half slab component design, a dry prefabricated steel tube/bar truss–reinforced half slab system that can reduce the concrete volume and steel amount used in the present slab system was proposed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boafa, F.E.; Kim, J.H.; Kim, J.T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef] [Green Version]

- Navaratnam, S.; Ngo, T.; Gunawardena, T.; Henderson, D. Performance Review of Prefabricated Building Systems and Future Research in Australia. Buildings 2019, 9, 38. [Google Scholar] [CrossRef] [Green Version]

- Bhosale, A.; Kulkarni, S. Comparative Study of Prefabrication Constructions with Cast-in-Situ Constructions. Int. J. Adv. Eng. Res. Dev. 2017, 4, 779–785. [Google Scholar]

- Vyas, V.S. Survey of Precast Concrete Method and Cast-in-Situ Concrete Method. Int. J. Eng. Tech. Res. 2016, 3, 71–73. [Google Scholar]

- Holla, B.R.K.; Siddhant-Anant, S.; Mohammad, M.A.; Periwal, A.; Kapoor, A. Time, Cost, Productivity and Quality analysis of Precast Concrete System. Int. J. Innov. Sci. Eng. Technol. 2016, 3, 252–257. [Google Scholar]

- Vinoth-Kumar, K.V.; Nagavinothini, R. Investigation on the Effective Usage of Prefabricated Elements in Construction Projects and developing a Module to reduce time and cost. Int. J. Sci. Eng. Technol. Res. 2016, 5, 856–859. [Google Scholar]

- Mire, A.; Singh, R.C. Study of Precast Construction. Int. J. Mech. Prod. Eng. 2017, 5, 101–103. [Google Scholar]

- Dineshkumar, N.; Kathirvel, P. Comparative Study on Prefabrication Construction with Cast In-Situ Construction of Residential Buildings. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 527–532. [Google Scholar]

- Murali, K.; Sambath, K. Prefabrication as a Solution to Improve Productivity of Construction Industry, Tamilnadu, India. Int. J. Sci. Res. Publ. 2020, 10, 616–620. [Google Scholar]

- Jiang, Y.; Zhao, D.; Wang, D.; Xing, Y. Sustainable Performance of Buildings through Modular Prefabrication in the Construction Phase: A Comparative Study. Sustainability 2019, 11, 5658. [Google Scholar] [CrossRef] [Green Version]

- Asamoah, R.O.; Ankra, J.S.; Offei-Nyako, A.; Tutu, E.O. Cost Analysis of Precast and Cast-in-Place Concrete Construction for Selected Public Buildings in Ghana. J. Constr. Eng. 2016, 5, 8785129. [Google Scholar] [CrossRef] [Green Version]

- Nanyama, N.; Basua, R.; Sawhneyb, A.; Vikrama, H.; Lodhaa, G. Implementation of Precast Technology in India—Opportunities and Challenges. Procedia Eng. 2017, 196, 144–151. [Google Scholar] [CrossRef]

- Karthikeyan, V.; Vinodhini, E.; Aparna, P.; Monika, R.; Sathish-Kumar, R. Study on Comparison between Prefabricated and Conventional Structures. Int. J. Civ. Eng. Technol. 2018, 9, 1–8. [Google Scholar]

- Mao, C.; Xie, F.; Hou, L.; Wu, P.; Wang, J.; Wang, X. Cost analysis for sustainable off-site construction based on a multiple-case study in China. Habitat Int. 2016, 57, 215–222. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost e benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the Promotion of Prefabricated Construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major Barriers to Off-Site Construction: The Developer’s Perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Murali, K.; Sambath, K. Sustainable Performance Criteria for Prefabrication Construction System. Int. J. Sci. Res. Publ. 2020, 10, 455–458. [Google Scholar]

- Smorgon, Australian Steel Company. Smorgon ARC-Transfor Design Manual. Available online: https://www.diamondprecast.com.au/wp-content/uploads/2019/07/Diamond-Precast-Perth-Flooring-Transfloor-Manual-Specifications.pdf (accessed on 20 January 2021).

- Chen, P.; Yun, Y.; Ding, H. High-efficiency Application of Large-scale Laminated Floor in Prefabricated Frame Structure. Constr. Technol. 2019, 48, 18–22. (In Chinese) [Google Scholar]

- Ke, Y. Research and Application of High-efficiency Storage of Prefabricated Laminated Floor. China Concr. 2020, 10, 80–83. (In Chinese) [Google Scholar]

- Wu, L.; Chen, H.; Liu, Y. Experimental Study on Static Performance of Precast Concrete laminated Hollow Floor Slab. J. Build. Struct. 2018, 39, 36–42. (In Chinese) [Google Scholar]

- WBK Engineering Services. Affordable Housing in India with Precast Construction. Available online: https://wbkengineers.com/article/10/nbm--cw-article-affordable-housing-in-india-with-precast-construction.html (accessed on 20 January 2021).

- Great Magtech Electric. Basic Prefabricated Components of Prefabricated Concrete Structures. Available online: https://www.precastconcretemagnet.com/news/basic-prefabricated-components-of-prefabricate-18339526.html (accessed on 20 January 2020).

- Liu, X.; Wang, Y.; Deng, Y. Experimental Study on Flexural Performance of Height-adjustable Fabricated Reinforced Truss Composite Floor. Ind. Constr. 2020, 50, 10–18. (In Chinese) [Google Scholar]

- Hou, H.; Lan, R.; Feng, M.; Zhang, S.; Zhang, B. Experimental Study on Flexural Performance of Grouted Steel Tube Truss Concrete Composite Slab. Ind. Constr. 2017, 47, 29–33. (In Chinese) [Google Scholar]

- Szydlowski, R.; Szreniawa, M. New Concept of Semi-precast Concrete Slab on Pre-tensioned Boards. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 245, p. 22090. [Google Scholar]

- Arjun, T.N.; Bhat, P.K. Structural Benefits of Precast-Prestressed Slab System in Buildings. Int. J. Civ. Eng. Technol. 2018, 9, 956–963. [Google Scholar]

- Zhou, G.; Zhang, X.; Wang, S.; Zhang, B.; Zhang, S. Research on Short-term Stiffness of Prestressed Concrete Steel Tube Truss Composite Slab during Construction Stage. Build. Struct. 2020, 50, 21–24. (In Chinese) [Google Scholar]

- Yu, J.; He, M.; Zhao, Y.; Zhang, B.; Tang, Y. Experimental Study on Densely Spliced Prestressed Concrete Steel Tube Truss Composite Slab. Ind. Constr. 2020, 50, 58–66. (In Chinese) [Google Scholar]

- Liu, W.; Cui, S.; Liu, C.; Shi, L. Experimental and Theoretical Study on the Flexural Performance of Prestressed Concrete Steel Truss Composite Slab. J. Build. Struct. 2020, 11, 1–13. (In Chinese) [Google Scholar]

- Yang, X. Experimental Study on Anchorage Performance of Reinforced Steel at the End of Superimposed Slabs with Prestressed Steel and Pipe Tubular Truss. Master’s Thesis, Shandong University of Architecture, Jinan, China, 2019. (In Chinese). [Google Scholar]

- Wang, S. Study on the Mechanical Behaviors of Prestressed Concrete Composite Slab with Grouted-round-steel Tube Truss. Master’s Thesis, Shandong University of Architecture, Jinan, China, 2019. (In Chinese). [Google Scholar]

- Saheed, S. Flextural and Shear Behavior of Lightweight Expanded Polystyrene Precast Concrete Half-Slab. Master’s Thesis, University Putra, Seri Kembangan, Malaysia, 2014. [Google Scholar]

- Saheed, S.; Aziz, F.; Amran, M.; Vatin, N.; Fediuk, R.; Ozbakkaloglu, T.; Murali, G.; Mosaberpanah, M. Structural Performance of Shear Loaded Precast EPS-Foam Concrete Half-Shaped Slabs. Sustainability 2020, 12, 9679. [Google Scholar] [CrossRef]

- Yavuz, Y.; Waleed, A.M.T.; Jaafar, M.S.; Laseimma, S. AAC-concrete Light Weight Precast Composite Floor Slab. Constr. Build. Mater. 2013, 40, 405–410. [Google Scholar]

- Liu, J.; Hu, H.; Li, J.; Chen, Y.F.; Zhang, L. Flexural behavior of prestressed concrete composite slab with precast inverted T-shaped ribbed panels. Eng. Struct. 2020, 215, 110687. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Y.; Zhou, X.; Yang, Y.; Wang, Y. Failure Mode and Ultimate Bearing Capacity of Precast Ribbed Panels Used for Concrete Composite Slabs. Adv. Struct. Eng. 2013, 16, 2005–2017. [Google Scholar] [CrossRef]

- Park, S.-W.; Seok, K.-Y.; Kim, G.-C.; Kang, J.-W. Flexural Capacity evaluation of One-way Hollow Half Slab and General Hollow Slab. J. Arch. Inst. Korea Struct. Constr. 2014, 30, 13–20. [Google Scholar] [CrossRef]

- Bae, J.-H.; Hwang, H.-H.; Park, S.-Y. Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint. Materials 2019, 12, 3040. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chin, W.J.; Park, Y.H.; Cho, J.-R.; Lee, J.-Y.; Yoon, Y.-S. Flexural Behavior of a Precast Concrete Deck Connected with Headed GFRP Rebars and UHPC. Materials 2020, 13, 604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- You, Y.-J.; Kim, H.-Y.; Ryu, G.-S.; Koh, K.-T.; Ahn, G.-H.; Kang, S.-H. Strengthening of Concrete Element with Precast Textile Reinforced Concrete Panel and Grouting Material. Materials 2020, 13, 3856. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Chang, L. Experimental Research and Numerical Analysis on Fiber Reinforced Plasterboard-Reinforced Concrete Composite Floor Slabs. Adv. Mater. Res. 2011, 250–253, 455–459. [Google Scholar]

- Cho, K.; Shin, Y.-S.; Kim, T. Effects of Half-Precast Concrete Slab System on Construction Productivity. Sustainability 2017, 9, 1268. [Google Scholar] [CrossRef] [Green Version]

- Effendi, M.C.; Pandulu, G.D. Analysis of the Use of the Half Slab Method on Implementation Time Construction of the Caspian Tower Surabaya Apartment Project. Proceeding of the National Seminar on Industrial Technology. Environ. Infrastruct. 2020, 3, D1.1–D1.7. (In Indoneasian) [Google Scholar]

- Ministry of Housing and Urban-Rural Development, PRC. Code for Design of Concrete Structures (GB50010-2010); China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- Ministry of Housing and Urban-Rural Development, PRC. Technical Specification for Concrete Composite Slab with Precast Ribbed Panel (JGJ/T 258-2011); China Architecture and Building Press: Beijing, China, 2011. (In Chinese)

- Ministry of Housing and Urban-Rural Development, PRC. Technical Specification for Precast Concrete Structures (JGJ1-2014); China Architecture and Building Press: Beijing, China, 2011. (In Chinese)

- Xie, L.; Chen, Y.; Xia, B.; Hua, C. Importance-Performance Analysis of Prefabricated Building Sustainability: A Case Study of Guangzhou. Adv. Civ. Eng. 2020, 2020, 1–17. [Google Scholar] [CrossRef]

| Specimen Number | Positive Reinforcement | Negative Reinforcement | Cross Section (mm) | Span (mm) |

|---|---|---|---|---|

| SBT-3 | 5 Ø10 | 2 Ø10 | 600 × 60 | 3900 |

| SBT-4 | 5 Ø10 | 2 Ø10 | 600 × 60 | 4800 |

| SBT-5 | 5 Ø10 | 2 Ø10 | 600 × 60 | 5700 |

| STBT-3 | 5 Ø10 | 2 D20 Tube | 600 × 60 | 3900 |

| STBT-4 | 5 Ø10 | 2 D20 Tube | 600 × 60 | 4800 |

| STBT-5 | 5 Ø10 | 2 D20 Tube | 600 × 60 | 5700 |

| Material | Grouting | Concrete |

|---|---|---|

| Compressive strength, fcu (MPa) | 63.6 | 41.2 |

| Steel Type | Yield Strength, fcu (MPa) | Yield Strain, εy × 10−6 | Tensile Strength, ft (MPa) | Modulus of Elasticity, Es (MPa) |

|---|---|---|---|---|

| Ø10 Bar | 422 | 2087 | 530 | 2.0 × 105 |

| D20 Tube | 325 | 1923 | 634 | 1.7 × 105 |

| Slab | Crack | Yield | Maximum | |||||

|---|---|---|---|---|---|---|---|---|

| Mid-Span Deflection, Δcr/mm | Load (kN) | Measured Value/Calculated Value | Mid-Span Deflection, Δcr/mm | Load (kN) | Mid-Span Deflection, Δcr/mm | Load (kN) | Measured Value/Calculated Value | |

| SBT-3 | 11.2 | 1.9 | 0.86 | 54.3 | 4.3 | 73.4 | 6.5 | 0.76 |

| SBT-4 | 12.1 | 0.8 | 0.64 | 91.9 | 3.8 | 98.1 | 3.8 | 0.70 |

| SBT-5 | 18.6 | 0.5 | 0.77 | 145.9 | 1.9 | 221.1 | 2.3 | 0.64 |

| STBT-3 | 8.9 | 1.8 | 0.82 | 68.2 | 7.5 | 145.5 | 8.9 | 1.03 |

| STBT-4 | 16.3 | 1.2 | 1.00 | 90.1 | 4.8 | 166.1 | 5.8 | 1.07 |

| STBT-5 | 16.5 | 0.7 | 1.17 | 114.5 | 3.1 | 167.5 | 3.5 | 0.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Yang, H.-C. Improvement of a Truss-Reinforced, Half-Concrete Slab Floor System for Construction Sustainability. Sustainability 2021, 13, 3731. https://doi.org/10.3390/su13073731

Qi J, Yang H-C. Improvement of a Truss-Reinforced, Half-Concrete Slab Floor System for Construction Sustainability. Sustainability. 2021; 13(7):3731. https://doi.org/10.3390/su13073731

Chicago/Turabian StyleQi, Jiarui, and Hsi-Chi Yang. 2021. "Improvement of a Truss-Reinforced, Half-Concrete Slab Floor System for Construction Sustainability" Sustainability 13, no. 7: 3731. https://doi.org/10.3390/su13073731

APA StyleQi, J., & Yang, H.-C. (2021). Improvement of a Truss-Reinforced, Half-Concrete Slab Floor System for Construction Sustainability. Sustainability, 13(7), 3731. https://doi.org/10.3390/su13073731