Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Methods

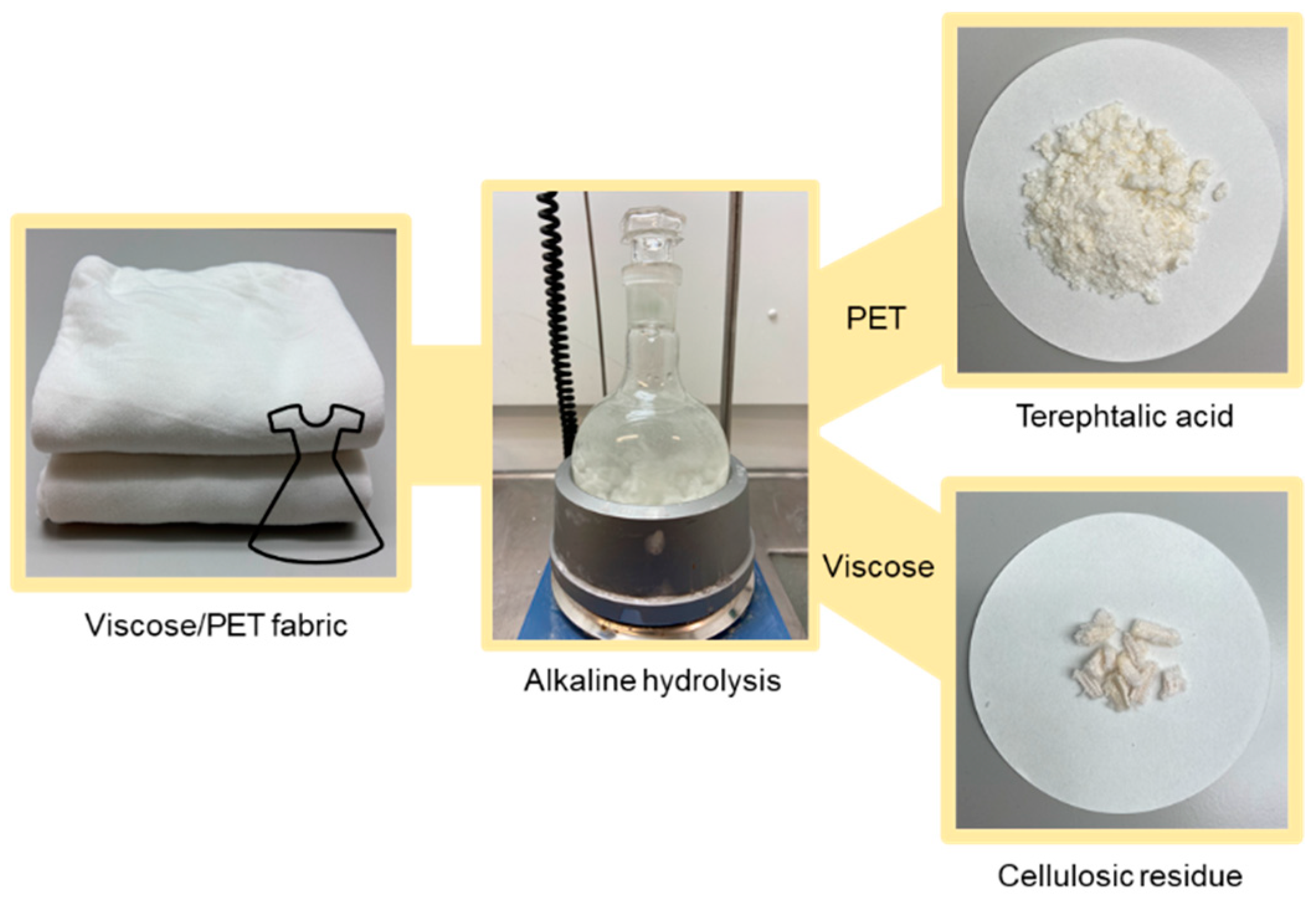

2.2.1. Hydrolysis

2.2.2. Composition

2.2.3. Intrinsic Viscosity

2.2.4. WAXS

2.2.5. FTIR Spectroscopy

2.2.6. NMR Spectroscopy

2.2.7. Upscaled Process Layout

3. Results and Discussion

3.1. Experimental Study

Characterization of Reaction Products

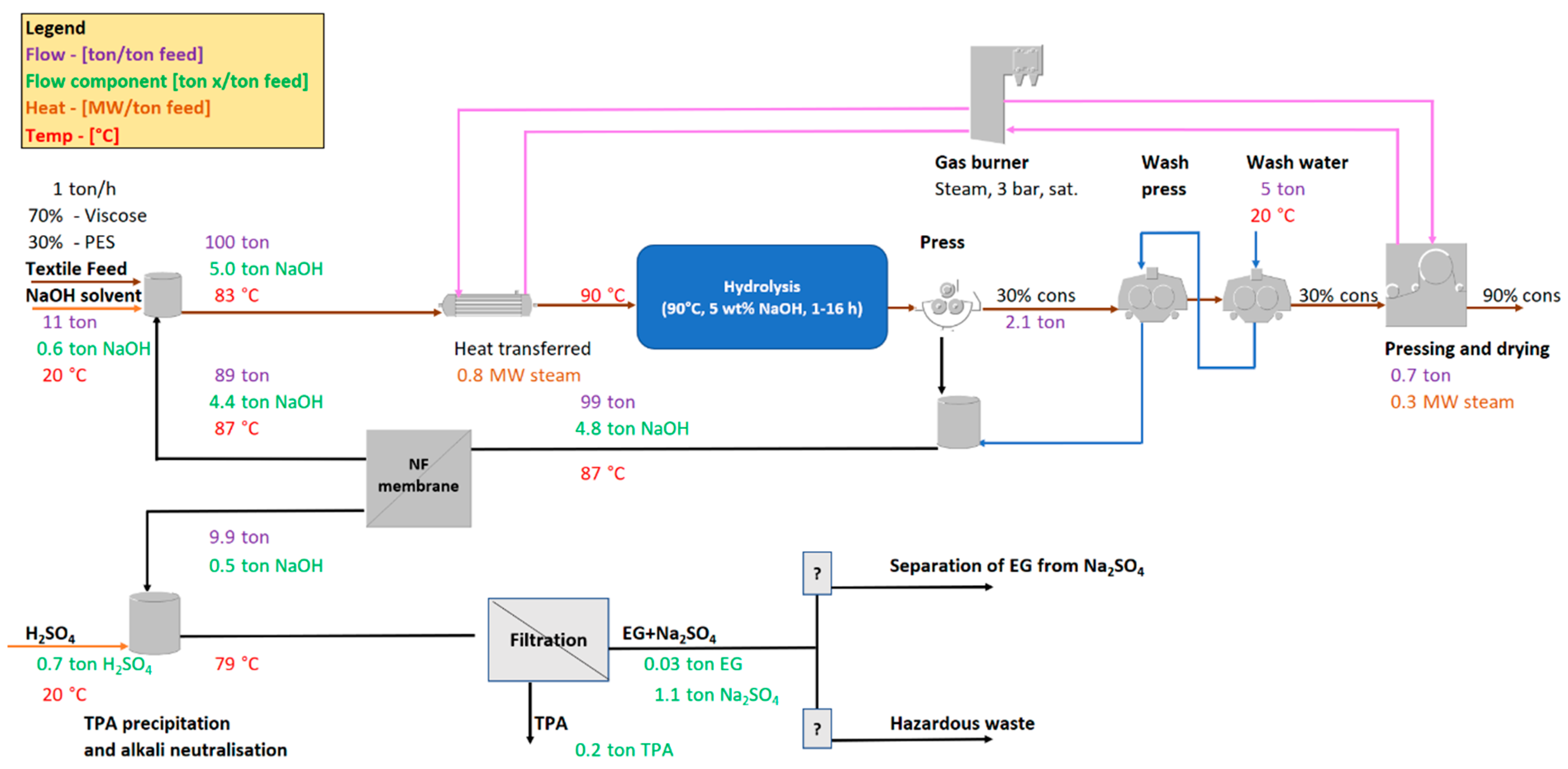

3.2. Upscaled Process Layout

3.2.1. Use of Experimental Data

3.2.2. Proposed Process Layout

- There is no heat loss from the heat exchangers;

- The hydrolysis reactor is assumed to be well-insulated, so that the temperature of 90 °C can be held constantly during the reaction, with no need for supporting heat;

- The viscose fraction is still pumpable at a consistency of 30%;

- For the heating of water, the specific heat capacity is 4.2 kJ kg K−1.

3.2.3. Suggestions for Process Optimization

- Lower the textile-to-solvent ratio during hydrolysis significantly from 1:100. Assuming the same alkali consumption for a textile-to-solvent ratio of 1:10 would mean an input of 0.50 ton NaOH/ton textile, a residual alkali of 0.35 ton/ton textile, and a value of ~193 EUR/ton textile that is neutralized. Initial experimental results show that wetting of the cut fabric is possible down to a textile-to-solvent ratio of 1:15, and that full depolymerization of neat PET textile is achieved after 24 h of hydrolysis at this ratio.

- Lower the concentration of NaOH in the solvent from 5 wt%. Similar to the reduction of the textile-to-solvent ratio, this process change must also be experimentally evaluated to determine the lowest possible NaOH concentration without the risk of decreased yields.

- Separate the TPA salt in the filtrate from the dewatering press before precipitation (Figure 7) with a nano filtration (NF) membrane and/or ion exchange technology. By doing so, the permeate, with most of the residual alkali, could be recycled, and mixed back in with the textile feed. There are pH-stable NF membranes that appear as promising candidates which are able to withstand the alkaline filtrate, with a cutoff down to 200 Dalton [33]. The TPA salt (TPA-Na2) has a molecular weight of 210 g/mol, and might possibly be effectively separated in the NF membrane, although this should also be verified experimentally.

- Instead of having a gas burner, low pressure steam could be bought from the pulp mill. This removes the capital expenditure (gas burner) of the viscose/PET process, and, further, the pulp mill steam should be less expensive, as well as renewable, compared to natural gas.

- If it is not possible to separate the EG/Na2SO4 fraction, the existing infrastructure at the pulp mill may offer some alternatives for its disposal. If the EG/Na2SO4 stream can be treated as a normal effluent, it could simply be sent to the wastewater treatment plant. Otherwise, it could perhaps be evaporated, and subsequently incinerated in the recovery boiler; however, this would be at the expense of increased energy consumption in the mill’s evaporation plant. Furthermore, it must be investigated whether the amount of Na2SO4 in the stream will significantly alter the pulp mill’s Na/S balance, possibly increasing the NaOH makeup demand, as well as the associated costs.

- The chemicals used in the viscose/PET process, NaOH and H2SO4, are already used in the pulp mill. The viscose/PET process can potentially directly use the prepared solutions of these chemicals from the pulp mill.

- Other economic benefits related to infrastructure, such as a reduced need for land and ground preparation, shared buildings, and utilities infrastructure (e.g., power substation, fresh- and cooling water), as well as shipping and/or transportation.

4. Conclusions

Future Suggestions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Fiber Year GmbH. The Fiber Year 2019; The Fiber Year GmbH: Speicher, Switzerland, 2019. [Google Scholar]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Haslinger, S.; Hummel, M.; Anghelescu-Hakala, A.; Määttänen, M.; Sixta, H. Upcycling of cotton polyester blended textile waste to new man-made cellulose fibers. Waste Manag. 2019, 97, 88–96. [Google Scholar] [CrossRef] [PubMed]

- De Silva, R.; Wang, X.; Byrne, N. Recycling textiles: The use of ionic liquids in the separation of cotton polyester blends. RSC Adv. 2014, 4, 29094–29098. [Google Scholar] [CrossRef]

- Baghaei, B.; Compiet, S.; Skrifvars, M. Mechanical properties of all-cellulose composites from end-of-life textiles. J. Polym. Res. 2020, 27, 260. [Google Scholar] [CrossRef]

- Ouchi, A.; Toida, T.; Kumaresan, S.; Ando, W.; Kato, J. A new methodology to recycle polyester from fabric blends with cellulose. Cellulose 2010, 17, 215–222. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A.; Ipsmiller, W. Enzymatic textile recycling—Best practices and outlook. Waste Manag. Res. 2021, 39, 1277–1290. [Google Scholar] [CrossRef]

- Sinha, V.; Patel, M.R.; Patel, J.V. PET waste management by chemical recycling: A review. J. Polym. Environ. 2010, 18, 8–25. [Google Scholar] [CrossRef]

- Palme, A.; Peterson, A.; de la Motte, H.; Theliander, H.; Brelid, H. Development of an efficient route for combined recycling of PET and cotton from mixed fabrics. Text. Cloth. Sustain. 2017, 3, 4. [Google Scholar] [CrossRef]

- Brelid, H.; Bogren, J. A Process for Separation of the Cellulosic Part from a Polyester and Cellulose Composition. U.S. Patent WO2020013755A1, 2 September 2021. [Google Scholar]

- Glaus, M.A.; Van Loon, L.R. Degradation of cellulose under alkaline conditions: New insights from a 12 years degradation study. Environ. Sci. Technol. 2008, 42, 2906–2911. [Google Scholar] [CrossRef]

- Rollins, M.L.; Tripp, V.W. Optical and electron microscopic studies of cotton fiber structure. Text. Res. J. 1954, 24, 345–357. [Google Scholar] [CrossRef]

- Broadbent, A.D. Artificially made fibres based on cellulose. In Basic Principles of Textile Coloration; Sociaty of Dyers and Colourists: Bradford, UK, 2001; pp. 92–106. [Google Scholar]

- Luo, M.; Roscelli, V.A.; Neogi, A.N.; Sealey, J.E., II; Jewell, R.A. Lyocell Fibers, and Compositions for Making the Same. U.S. Patent CA2323437C, 9 July 2001. [Google Scholar]

- Sixta, H.; Potthast, A.; Krotschek, A.W. Chemical pulping processes: Sections 4.1–4.2.5. In Handbook of Pulp; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; pp. 109–229. [Google Scholar]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Östlund, Å.; Wedin, H.; Bolin, L.; Berlin, J. Textilåtervinning—Tekniska Möjligheter och Utmaningar; Naturvårdsverket: Stockholm, Swedish, 2015. [Google Scholar]

- Vanzetto, A.B.; Beltrami, L.V.R.; Zattera, A.J. Textile waste as precursors in nanocrystalline cellulose synthesis. Cellulose 2021, 28, 6967–6981. [Google Scholar] [CrossRef]

- Ruiz-Caldas, M.X.; Carlsson, J.; Sadiktsis, I.; Jaworski, A.; Nilsson, U.; Mathew, A. Cellulose Nanocrystals from Postconsumer Cotton and Blended Fabrics: A Study on Their Properties, Chemical Composition, and Process Efficiency. ACS Sustain. Chem. Eng. 2022, 10, 3787–3798. [Google Scholar] [CrossRef]

- Sanchis-Sebastiá, M.; Ruuth, E.; Stigsson, L.; Galbe, M.; Wallberg, O. Novel sustainable alternatives for the fashion industry: A method of chemically recycling waste textiles via acid hydrolysis. Waste Manag. 2021, 121, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Sofokleous, M.; Christofi, A.; Malamis, D.; Mai, S.; Barampouti, E.M. Bioethanol and biogas production: An alternative valorisation pathway for green waste. Chemosphere 2022, 296, 133970. [Google Scholar] [CrossRef]

- Sanchis-Sebastiá, M.; Novy, V.; Stigsson, L.; Galbe, M.; Wallberg, O. Towards circular fashion—Transforming pulp mills into hubs for textile recycling. RSC Adv. 2021, 11, 12321–12329. [Google Scholar] [CrossRef]

- Immergut, E.H.; Schurz, J.; Mark, H. Viskositätszahl-Molekulargewichts-Beziehung für Cellulose und Untersuchungen von Nitrocellulose in verschiedenen Lösungsmitteln. Mon. Chem. Verwandte Teile And. Wiss. 1953, 84, 219–249. [Google Scholar] [CrossRef]

- Borysiak, S.; Garbarczyk, J. Applying the WAXS method to estimate the supermolecular structure of cellulose fibres after mercerisation. Fibres Text. East. Eur. 2003, 11, 104–106. [Google Scholar]

- Knill, C.J.; Kennedy, J.F. Degradation of cellulose under alkaline conditions. Carbohydr. Polym. 2002, 51, 281–300. [Google Scholar] [CrossRef]

- Kumar, S.; Guria, C. Alkaline hydrolysis of waste poly(ethylene terephthalate): A modified shrinking core model. J. Macromol. Sci. Part A 2005, 42, 237–251. [Google Scholar] [CrossRef]

- Wennerström, M.; Bylund, S. Method for Controlling Viscosity in Dissolving Pulps. AI Patent WO 2017/105322, 22 June 2017. [Google Scholar]

- Prado, K.S.; Gonzales, D.; Spinacé, M.A.S. Recycling of viscose yarn waste through one-step extraction of nanocellulose. Int. J. Biol. Macromol. 2019, 136, 729–737. [Google Scholar] [CrossRef] [PubMed]

- European Commision. From the Sugar Platform to Biofuels and Biochemicals. 2015. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/EC%20Sugar%20Platform%20final%20report.pdf (accessed on 23 January 2022).

- BISFA. Terminology of Man-Made Fibres. 2017. Available online: http://www.bisfa.org/wp-content/uploads/2018/06/2017-BISFA-Terminology-final.pdf (accessed on 19 April 2022).

- Wagman, D.D.; Evans, W.H.; Parker, V.B.; Schumm, R.H.; Halow, I.; Bailey, S.M.; Churney, K.L. The NBS tables of chemical thermodynamic properties. Selected values for inorganic and C1 and C2 organic substances in SI units. J. Phys. Chem. Ref. Data 1982, 11, 38, 58, 232–299. [Google Scholar]

- Ruiz, J.; Rincón, C.; Contreras, L.; Sidney, R.R.; Almarza, C. Sustainable and negative carbon footprint solid-based NaOH technology for CO2 capture. ACS Sustain. Chem. Eng. 2020, 8, 19003–19012. [Google Scholar] [CrossRef]

- Koch. Available online: Https://www.kochseparation.com/wp-content/uploads/2020/10/Selro-NF-MPS-34-2-5-and-4-inch-elements.pdf (accessed on 15 February 2022).

- Recyctec. Available online: https://www.recyctec.se/en/ (accessed on 15 February 2022).

- Stena Recycling. Available online: https://www.stenarecycling.se/en/ (accessed on 15 February 2022).

| Sample | Composition PET/Viscose | Form | Intrinsic Viscosity (T0) (mL g−1) |

|---|---|---|---|

| A | 0/100 | Fabric | |

| A1 | 0/100 | Never laundered, cut | 167 |

| A2 | 0/100 | Laundered, cut | 170 |

| A3 | 0/100 | Laundred, shredded | 171 |

| B | 30/70 | Filaments | 196 |

| C | 30/70 | Garment from blended fibers | n.d. |

| Time of Hydrolysis (min) | Viscose Mass Loss (%) | PET Mass Loss (%) |

|---|---|---|

| 60 | 8.0 | 15.6 |

| 160 | 10.6 | 35.1 |

| 260 | 10.0 | 56.2 |

| 360 | 10.4 | 68.5 |

| 1440 | 11.6 | 99.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peterson, A.; Wallinder, J.; Bengtsson, J.; Idström, A.; Bialik, M.; Jedvert, K.; de la Motte, H. Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose. Sustainability 2022, 14, 7272. https://doi.org/10.3390/su14127272

Peterson A, Wallinder J, Bengtsson J, Idström A, Bialik M, Jedvert K, de la Motte H. Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose. Sustainability. 2022; 14(12):7272. https://doi.org/10.3390/su14127272

Chicago/Turabian StylePeterson, Anna, Johan Wallinder, Jenny Bengtsson, Alexander Idström, Marta Bialik, Kerstin Jedvert, and Hanna de la Motte. 2022. "Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose" Sustainability 14, no. 12: 7272. https://doi.org/10.3390/su14127272

APA StylePeterson, A., Wallinder, J., Bengtsson, J., Idström, A., Bialik, M., Jedvert, K., & de la Motte, H. (2022). Chemical Recycling of a Textile Blend from Polyester and Viscose, Part I: Process Description, Characterization, and Utilization of the Recycled Cellulose. Sustainability, 14(12), 7272. https://doi.org/10.3390/su14127272