Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units

Abstract

:1. Introduction

2. Materials and Methods

2.1. Alkali-Activated Hybrid Cement

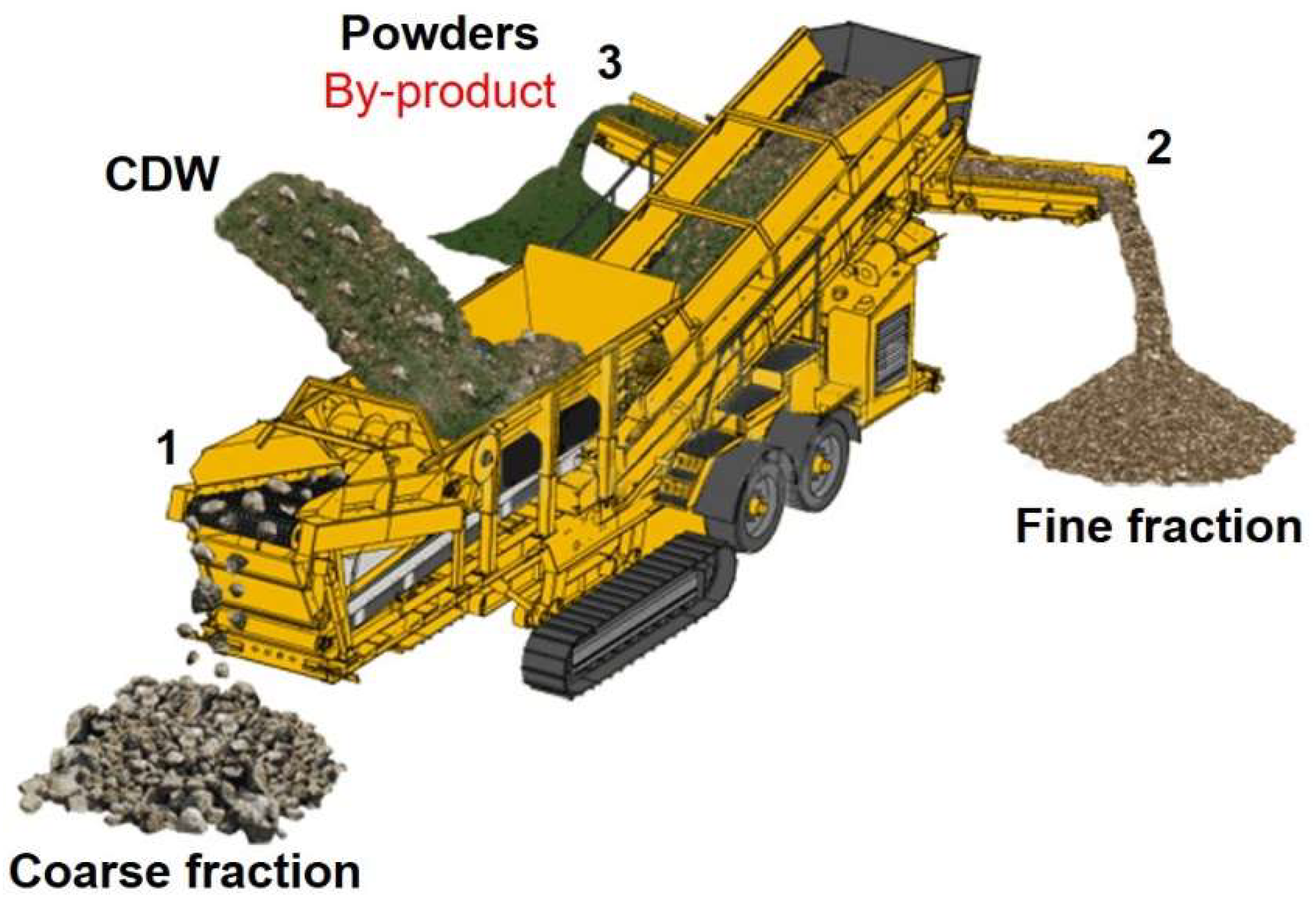

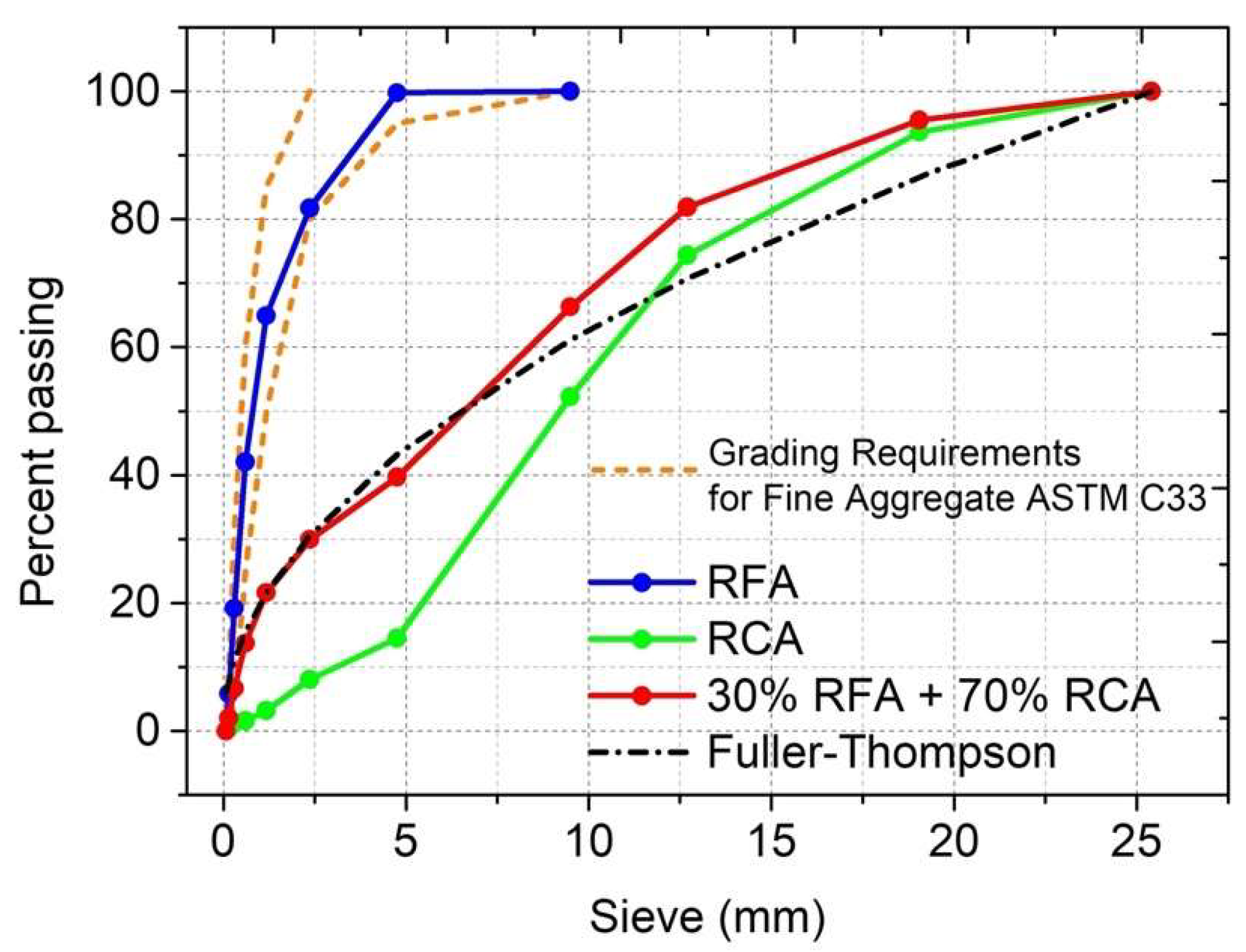

2.2. Recycled Aggregates

2.3. Design and Production of Mixtures (Mortars and Concretes)

2.4. Analysis of the Environmental Impact Associated with Raw Materials

2.5. Precast Concrete Elements

2.6. Experimental Tests

2.6.1. Mortars

2.6.2. Concretes

2.6.3. Prefabricated Concrete Elements

3. Results and Analysis

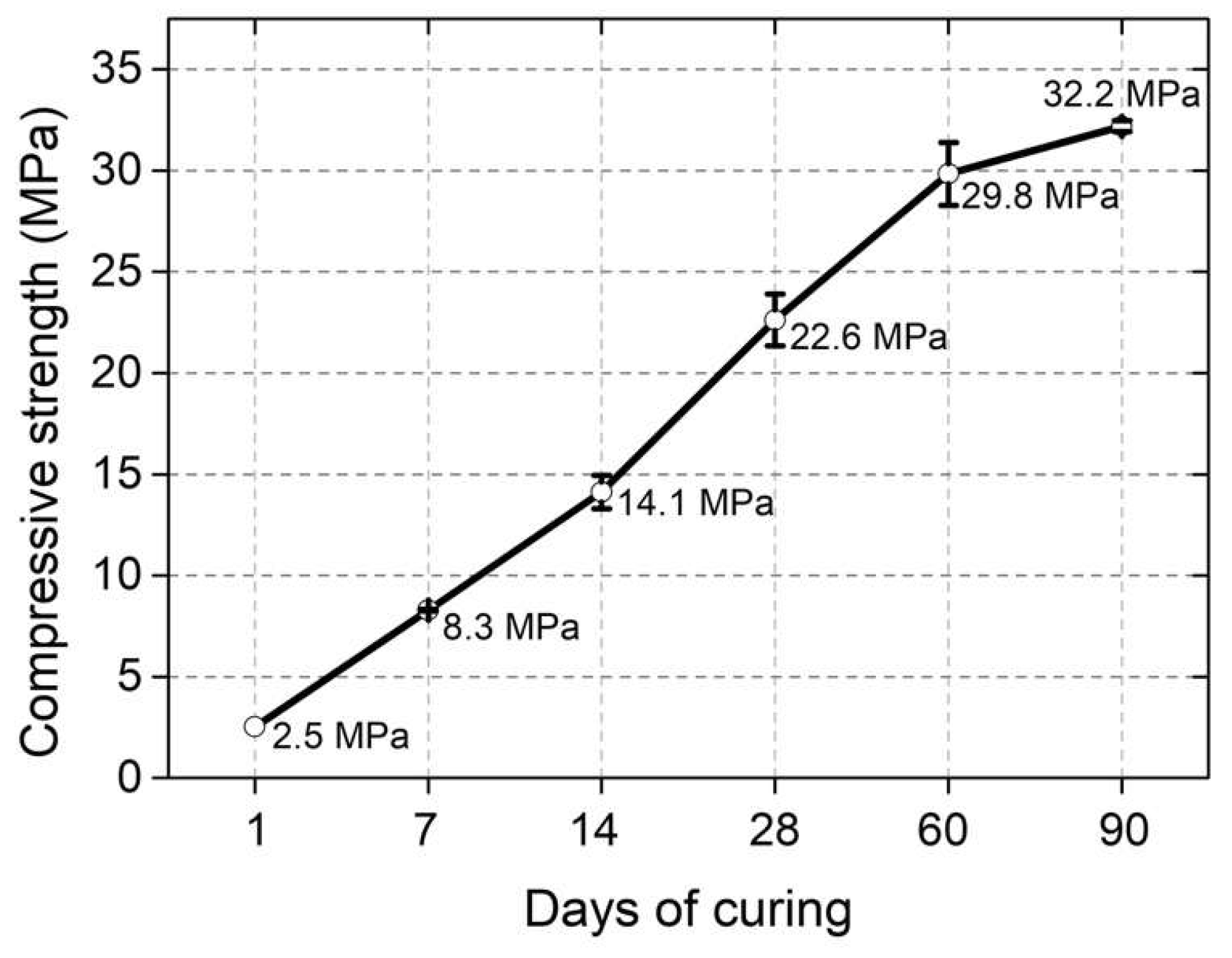

3.1. Mechanical Characterization of the Activated Alkali Mortars

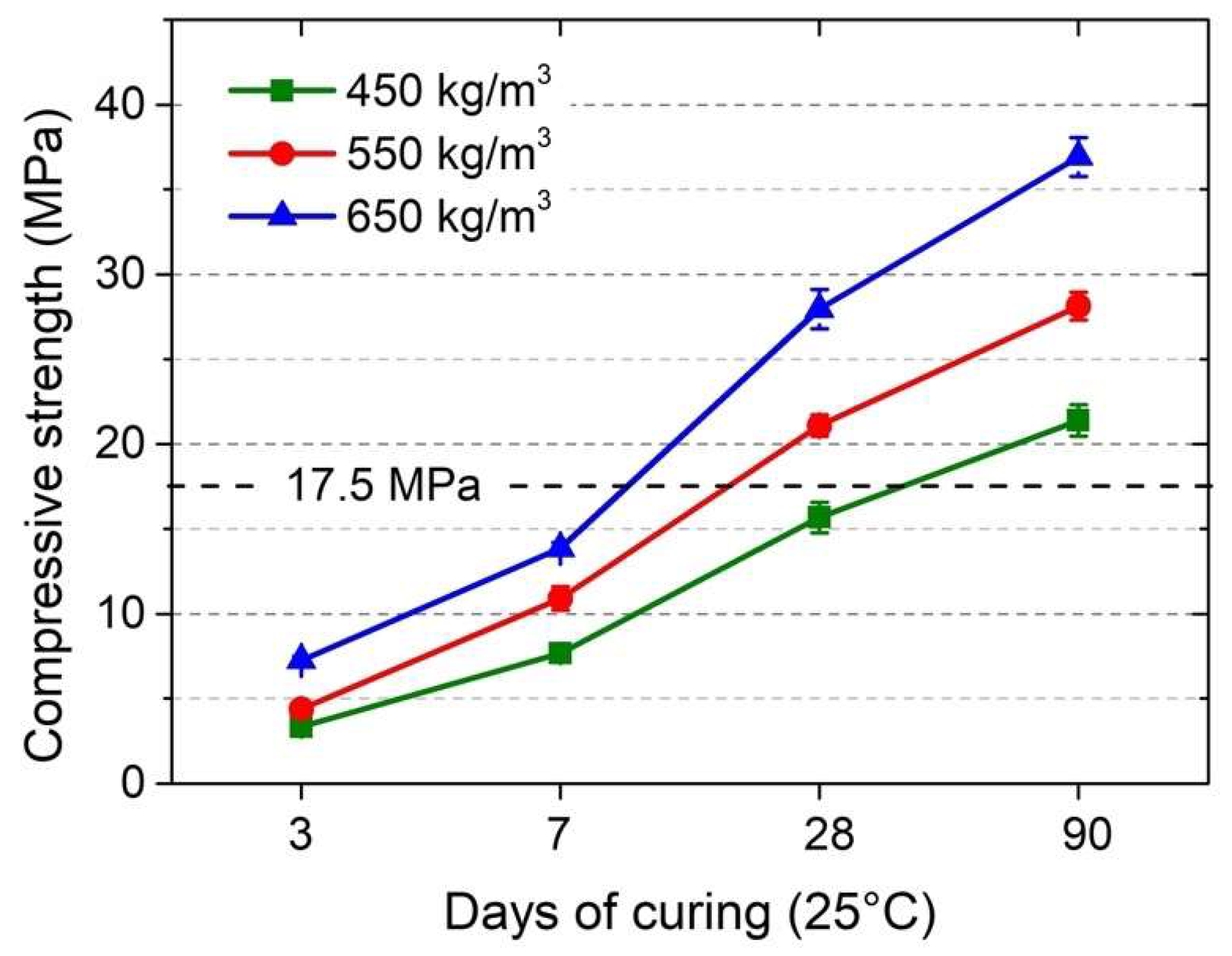

3.2. Physical–Mechanical and Microstructural Characterization of Alkali-Activated Concretes

3.3. Analysis of the Environmental Impact Associated with Raw Materials

3.4. Physical–Mechanical Characterization of Construction Applications (Prefabricated Elements)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Construction and Demolition Waste (CDW). 2016. Available online: http://ec.europa.eu/environment/waste/construction_demolition.htm (accessed on 13 March 2018).

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Sui, Y.; Ou, C.; Liu, S.; Zhang, J.; Tian, Q. Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar. Appl. Sci. 2020, 10, 998. [Google Scholar] [CrossRef] [Green Version]

- ASTM C33-18; American Society for Testing and Materials (ASTM). Standard Specification for Concrete Aggregates: West Conshohocken, PA, USA, 2018. [CrossRef]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Recycling of concrete, ceramic, and masonry waste via alkaline activation: Obtaining and characterization of hybrid cements. J. Build. Eng. 2022, 46, 103698. [Google Scholar] [CrossRef]

- El-Dieb, A.S.; Taha, M.R.; Abu-Eishah, S.I. The use of ceramic waste powder (CWP) in making eco-friendly concretes. In Ceramic Materials-Synthesis, Characterization, Applications and Recycling; Quesada, D.E., Villarejo, L.P., Sánchez Soto, P., Eds.; IntechOpen: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Robayo-Salazar, R.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept. Sustainability 2020, 12, 5775. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers—Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Lampris, C.; Lupo, R.; Cheeseman, C.R. Geopolymerisation of silt generated from construction and demolition waste washing plants. Waste Manag. 2009, 29, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Reig, L.; Tashima, M.M.; Borrachero, M.V.; Monzó, J.; Cheeseman, C.R.; Payá, J. Properties and microstructure of alkali-activated red clay brick waste. Constr. Build. Mater. 2013, 43, 98–106. [Google Scholar] [CrossRef] [Green Version]

- Komnitsas, K.; Zaharaki, D.; Vlachou, A.; Bartzas, G.; Galetakis, M. Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Adv. Powder Technol. 2015, 26, 368–376. [Google Scholar] [CrossRef] [Green Version]

- Robayo, R.A.; Mulford, A.; Munera, J.; Mejía de Gutiérrez, R. Alternative cements based on alkali-activated red clay brick waste. Constr. Build. Mater. 2016, 128, 163–169. [Google Scholar] [CrossRef]

- Vásquez, A.; Cárdenas, V.; Robayo-Salazar, R.; Mejia de Gutierrez, R. Geopolymer based on concrete demolition waste. Adv. Powder Technol. 2016, 27, 1173–1179. [Google Scholar] [CrossRef]

- Zaharaki, D.; Galetakis, M.; Komnitsas, K. Valorization of construction and demolition (C&D) and industrial wastes through alkali activation. Constr. Build. Mater. 2016, 121, 686–693. [Google Scholar] [CrossRef]

- Sassoni, E.; Pahlavan, P.; Franzoni, E.; Bignozzi, M.C. Valorization of brick waste by alkali-activation: A study on the possible use for masonry repointing. Ceram. Int. 2016, 42, 14685–14694. [Google Scholar] [CrossRef]

- Murillo, L.M.; Delvasto, S.; Gordillo, M. A study of a hybrid binder based on alkali-activated ceramic tile wastes and portland cement. In Sustainable and Nonconventional Construction Materials using Inorganic Bonded Fiber Composites; Woodhead Publishing: Cambridge, UK, 2017; pp. 291–311. [Google Scholar]

- Reig, L.; Sanz, M.A.; Borrachero, M.V.; Monzó, J.; Soriano, L.; Payá, J. Compressive strength and microstructure of alkali-activated mortars with high ceramic waste content. Ceram. Int. 2017, 43, 13622–13634. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Rivera, J.F.; Mejía de Gutiérrez, R. Alkali-activated building materials made with recycled construction and demolition wastes. Constr. Build. Mater. 2017, 149, 130–138. [Google Scholar] [CrossRef]

- Tuyan, M.; Andiç-Çakir, Ö.; Ramyar, K. Effect of alkali activator concentration and curing condition on strength and microstructure of waste clay brick powder-based geopolymer. Compos. Part Eng. 2018, 135, 242–252. [Google Scholar] [CrossRef]

- Fořt, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yehualaw, M.D.; Vo, D.-H.; Huynh, T.-P. Development of high-strength alkali-activated pastes containing high volumes of waste brick and ceramic powders. Constr. Build. Mater. 2019, 218, 519–529. [Google Scholar] [CrossRef]

- Valencia-Saavedra, W.; Robayo-Salazar, R.; Mejía de Gutiérrez, R. Alkali-Activated Hybrid Cements Based on Fly Ash and Construction and Demolition Wastes Using Sodium Sulfate and Sodium Carbonate. Molecules 2021, 26, 7572. [Google Scholar] [CrossRef] [PubMed]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Sahmaran, M. Development of optimized binary ceramic tile and concrete wastes geopolymer binders for in-situ applications. J. Build. Eng. 2021, 43, 102906. [Google Scholar] [CrossRef]

- Mendes, J.P.; Elyseu, F.; Nieves, L.J.J.; Zaccaron, A.; Bernardin, A.M.; Angioletto, E. Synthesis and characterization of geopolymers using clay ceramic waste as source of aluminosilicate. Sustain. Mater. Technol. 2021, 28, e00264. [Google Scholar] [CrossRef]

- Yıldırım, G.; Kul, A.; Özçelikci, E.; Şahmaran, M.; Aldemir, A.; Figueira, D.; Ashour, A. Development of alkali-activated binders from recycled mixed masonry-originated waste. J. Build. Eng. 2021, 33, 101690. [Google Scholar] [CrossRef]

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Pommer, V.; Vejmelková, E.; Černý, R.; Keppert, M. Alkali-activated waste ceramics: Importance of precursor particle size distribution. Ceram. Int. 2021, 47, 31574–31582. [Google Scholar] [CrossRef]

- Villaquirán-Caicedo, M.A.; Mejía de Gutiérrez, R. Comparison of different activators for alkaline activation of construction and demolition wastes. Constr. Build. Mater. 2021, 281, 122599. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Delgado-Plana, P.; Cabezas-Rodríguez, R.; de Gutiérrez, R.M.; Eliche-Quesada, D.; Pérez-Villarejo, L.; Bueno, S. Alkaline activation of high-crystalline low-Al2O3 Construction and Demolition Wastes to obtain geopolymers. J. Clean. Prod. 2022, 330, 129770. [Google Scholar] [CrossRef]

- Tan, J.; Cai, J.; Li, J. Recycling of unseparated construction and demolition waste (UCDW) through geopolymer technology. Constr. Build. Mater. 2022, 341, 127771. [Google Scholar] [CrossRef]

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute (ACI Committee 211): Farmington Hills, MI, USA, 2002.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC). NTC 6421-2021, Agregados Gruesos Reciclados Para uso en el Concreto Hidráulico (‘Coarse Recycled Aggregates for use in Hydraulic Concrete’). 2021. Available online: www.ecollection.icontec.org (accessed on 30 June 2022).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Swiss Centre for Life Cycle Inventories, Ecoinvent OpenLCA Database Version 3.6. 2019. Available online: https://www.ecoinvent.org/database.html (accessed on 30 June 2022).

- NTC 4026-1997; Unidades (Bloques y Ladrillos de Concreto) Para Mampostería Estructural (‘Loadbearing Concrete Mansonry units’). Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC): Bogotá, Colombia, 1997.

- NTC 2017-2018; Adoquines de Concreto Para Pavimentos (´Concrete Paving Blocks´). Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC): Bogotá, Colombia, 2018.

- ASTM C109-16; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM C348-14; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM C39-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM C293-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2013. [CrossRef]

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2020. [CrossRef]

- Ren, X.; Zhang, L. Experimental study of interfacial transition zones between geopolymer binder and recycled aggregate. Constr. Build. Mater. 2018, 167, 749–756. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Ministerio de Ambiente Vivienda y Desarrollo Territorial (República de Colombia). NSR-10, Reglamento Colombiano de Construcción Sismo Resistente (‘Colombian Regulations for Earthquake Resistant Construction’). 2010. Available online: https://web.archive.org/web/20120512184742/http://camacol.co/sites/default/files/secciones_internas/NSR-10_diario_oficial_26marzo10.pdf (accessed on 30 June 2022).

- ACI Committee 318; Building Code Requirements for Structural Concrete (ACI 318-08). American Concrete Institute (ACI Committee 211): Farmington Hills, MI, USA, 2008.

- Ministerio de Medio Ambiente (República de Colombia). Resolución No. 1257 de 2021, Por la Cual se Modifica la Resolución 0472 de 2017 Sobre la Gestión Integral de Residuos de Construcción y Demolición—RCD y se Adoptan Otras Disposiciones. 2021. Available online: https://www.minambiente.gov.co/wp-content/uploads/2021/12/Resolucion-1257-de-2021-Anexos.pdf (accessed on 30 June 2022).

- Robayo, R.; Mattey, P.; Delvasto, S. Mechanical behavior of a fluid concrete added with Rice husk ash (RHA) and reinforced with steel fibers. Rev. Constr. 2013, 12, 139–151. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Alsalman, A.; Assi, L.N.; Kareem, R.S.; Carter, K.; Ziehl, P. Energy and CO2 emission assessments of alkali-activated concrete and Ordinary Portland Cement concrete: A comparative analysis of different grades of concrete. Clean. Environ. Syst. 2021, 3, 100047. [Google Scholar] [CrossRef]

| Year | CDW Type | Addition | Optimal Synthesis Conditions | Application Type | Ref. | Country | ||

|---|---|---|---|---|---|---|---|---|

| Alkaline Activator | Cured | C.S. (MPa) | ||||||

| 2009 | Concrete | 20% MK | NaOH + Na2SiO3 | 60 °C (3d) | 33 | Paste | [14] | UK |

| 2013 | Masonry | - | NaOH + Na2SiO3 | 60 °C (7d) | 50 | Paste Mortar | [15] | Spain |

| 2015 | Concrete | - | NaOH + Na2SiO3 | 90 °C (7d) | 13 | Paste | [16] | Greece |

| Masonry | 58 | |||||||

| Tile | 50 | |||||||

| 2016 | Masonry | 0% | NaOH + Na2SiO3 | 25 °C | 54 | Paste | [17] | Colombia |

| 20% OPC | 103 | |||||||

| 2016 | Concrete | 0% | NaOH + Na2SiO3 | 25 °C | 26 | Paste | [18] | Colombia |

| 30% OPC | 34 | |||||||

| 10% MK | 46 | |||||||

| 2016 | Concrete | - | NaOH + Na2SiO3 | 80 °C (1d) | 8 | Paste | [19] | Greece |

| Masonry | 39 | |||||||

| Tile | 58 | |||||||

| 2016 | Masonry | - | NaOH + Na2SiO3 | 50 °C (1d) | - | Coating | [20] | Italy |

| 2017 | Ceramic | 15% OPC | NaOH + Na2SiO3 | 25 °C | 58 | Paste | [21] | Colombia |

| 25 | Mortar | |||||||

| 2017 | Ceramic | 5% Ca(OH)2 | NaOH + Na2SiO3 | 65 °C (3d) | 43 | Mortar | [22] | Spain |

| 2017 | Masonry | 0% | NaOH | 25 °C | 7 | Paste | [23] | Colombia |

| 10% OPC | 41 | |||||||

| 0% | NaOH + Na2SiO3 | 54 | ||||||

| 20% OPC | 103 | |||||||

| Concrete | 0% | NaOH | 7 | |||||

| 30% OPC | 10 | |||||||

| 0% | NaOH + Na2SiO3 | 26 | ||||||

| 30% OPC | 34 | |||||||

| 2018 | Masonry | - | NaOH + Na2SiO3 | 90 °C (5d) | 36 | Mortar | [24] | Turkey |

| 2018 | Masonry | - | NaOH + Na2SiO3 | 25 °C | 42 | Paste | [25] | R. Czech |

| 2019 | Masonry | 30% GBFS | NaOH + Na2SiO3 | 25 °C | 70 | Paste | [26] | Taiwan |

| 10% FA | ||||||||

| Ceramic | 30% GBFS | NaOH + Na2SiO3 | 25 °C | 60 | ||||

| 10% FA | ||||||||

| 2020 | CDW-Mixed | 10% OPC | NaOH + Na2SiO3 | 25 °C | 33 | Concrete | [12] | Colombia |

| 2021 | CDW-Mixed | 10–30% OPC | Na2SO4 | 25 °C | 31 | Paste | [27] | Colombia |

| Na2CO3 | 22 | |||||||

| 2021 | Concrete Ceramic | 15–45% MK 15–45% FA 15–45% GBFS | NaOH + Na2SiO3 | 25 °C 50 °C (1d) 75 °C (1d) 100 °C (1d) | 101 | Paste | [28] | Canada |

| 2021 | Ceramic | - | NaOH + Na2SiO3 | 45 °C (3d) | 28 | Paste | [29] | Brazil |

| 2021 | CDW-Mixed | - | NaOH + Na2SiO3 | 95 °C (3d) 105 °C (3d) 115 °C (3d) 125 °C (3d) | 80 | Paste | [30] | Turkey |

| 2021 | CDW-Mixed | - | NaOH Na2SiO3 Ca(OH)2 | 25 °C | 23 | Paste (3D) | [31] | Turkey |

| 2021 | Ceramic | - | NaOH + Na2SiO3 | 25 °C | 35 | Mortar | [32] | Czech Republic |

| 2021 | CDW-Mixed | 10–20% OPC | NaOH Na2SO4 | 25 °C | 16 | Paste | [33] | Colombia |

| 2022 | CDW-Mixed | - | NaOH Na2SiO3 Ca(OH)2 | 25 °C | 36 | Paste (3D) | [34] | Turkey |

| 2022 | CDW-Mixed | 10–20% OPC | NaOH + Na2SiO3 | 90 °C (2d) | 15 | Paste | [35] | Spain |

| 2022 | CDW-Mixed | - | NaOH + Na2SiO3 | 50 °C (7d) | 29 | Paste | [36] | Belgium |

| 2022 | CDW-Mixed | 10% OPC | NaOH + Na2SiO3 | 25 °C | 32 | Paste | [10] | Colombia |

| Characteristics | RFA | RCA | ||

|---|---|---|---|---|

| Standard | Result | Standard | Result | |

| Bulk density (kg/m3) | ASTM C128 | 2202.2 | ASTM C127 | 2318.9 |

| Absorption (%) | ASTM C128 | 8.96 | ASTM C127 | 5.82 |

| Unit weight (kg/m3) | ASTM C29 | 1440.4 | ASTM C29 | 1520.2 |

| Maximum size (mm) | N/A | ASTM C136 | 25.4 | |

| Fineness modulus | ASTM C136 | 3.17 | N/A | |

| Organic impurities | ASTM C40 | Organic plate No. 1 | N/A | |

| Resistance to degradation (%) | N/A | ASTM C131 | 28.2 | |

| Mortar Abbreviation | Material (kg Per Cubic Meter of Mortar) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Co | Ce | M | OPC | Alkaline Activator | Mixing Water | RFA | Total | ||

| NaOH | Na2SiO3 | ||||||||

| AA0.2—RFA1:1 | 254.3 | 254.3 | 254.3 | 84.8 | 33.9 | 135.6 | 206.4 | 847.6 | 2071.0 |

| AA0.2—RFA1:2 | 178.0 | 178.0 | 178.0 | 59.3 | 23.7 | 94.9 | 144.5 | 1186.6 | 2043.0 |

| AA0.3—RFA1:1 | 254.3 | 254.3 | 254.3 | 84.8 | 50.9 | 203.4 | 182.5 | 847.6 | 2131.8 |

| AA0.3—RFA1:2 | 178.0 | 178.0 | 178.0 | 59.3 | 35.6 | 142.4 | 127.7 | 1186.6 | 2085.6 |

| AA0.4—RFA1:1 | 254.3 | 254.3 | 254.3 | 84.8 | 67.8 | 271.2 | 158.5 | 847.6 | 2192.7 |

| AA0.4—RFA1:2 | 178.0 | 178.0 | 178.0 | 59.3 | 47.5 | 189.9 | 111.0 | 1186.6 | 2128.1 |

| Mortar Abbreviation | Material (kg Per Cubic Meter of Mortar) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Co | Ce | M | OPC | Alkaline Activator | Mixing Water | RFA | Sika Fiber AD | ||

| NaOH | Na2SiO3 | ||||||||

| Mortar—0%PP | 254.3 | 254.3 | 254.3 | 84.8 | 67.8 | 271.2 | 158.5 | 847.6 | 0.0 |

| Mortar—0.4%PP | 8.7 | ||||||||

| Mortar—0.8%PP | 17.4 | ||||||||

| Material | Proportions of Mixture (kg/m3) | |||

|---|---|---|---|---|

| 450 | 550 | 650 | ||

| Co | 135.0 | 165.0 | 195.0 | |

| Ce | 135.0 | 165.0 | 195.0 | |

| M | 135.0 | 165.0 | 195.0 | |

| OPC | 45.0 | 55.0 | 65.0 | |

| Na2SiO3 | 144.0 | 176.0 | 208.0 | |

| NaOH | 36.0 | 44.0 | 52.0 | |

| Mixing water | 84.2 | 102.9 | 121.6 | |

| RFA | Ce (No. 4) | 92.0 | 82.5 | 72.9 |

| Co (No. 4) | 92.0 | 82.5 | 72.9 | |

| Ce (No. 16) | 138.0 | 123.8 | 109.4 | |

| Co (No. 16) | 138.0 | 123.8 | 109.4 | |

| RCA | Co (No. 1—in.) | 912.2 | 818.1 | 723.2 |

| Co (No. 3/4—in.) | 161.0 | 144.4 | 127.6 | |

| Total | 2247 | 2247 | 2247 | |

| Concrete Abbreviation | Material (kg Per Cubic Meter of Concrete) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Co | Ce | M | OPC | Alkaline Activator | Mixing Water | RFA | RCA | Sika Fiber 600 | ||

| NaOH | Na2SiO3 | |||||||||

| Concrete—0%PP | 165.0 | 165.0 | 165.0 | 55.0 | 44.0 | 176.0 | 102.9 | 412.5 | 962.5 | 0.0 |

| Concrete—0.4%PP | 9.0 | |||||||||

| Concrete—0.8%PP | 18.0 | |||||||||

| Concrete | 28 Days | 90 Days | ||||

|---|---|---|---|---|---|---|

| Bulk Density, Dry (kg/m3) | Absorption (%) | Porosity (%) | Bulk Density, Dry (kg/m3) | Absorption (%) | Porosity (%) | |

| 450 kg/m3 | 1900.6 ± 0.1 | 14.5 ± 1.8 | 29.4 ± 2.5 | 1919.7 ± 0.1 | 14.4 ± 1.7 | 29.2 ± 2.1 |

| 550 kg/m3 | 1926.8 ± 0.1 | 14.0 ± 1.4 | 27.1 ± 2.7 | 1976.5 ± 0.1 | 12.9 ± 1.7 | 26.8 ± 1.5 |

| 650 kg/m3 | 1978.0 ± 0.1 | 12.0 ± 1.5 | 26.3 ± 2.1 | 2049.4 ± 0.0 | 10.9 ± 0.4 | 24.6 ± 0.5 |

| Material | Unit GWP (kg∙CO2∙eq/kg) | kg∙CO2∙eq/m3 of Concrete | |||||

|---|---|---|---|---|---|---|---|

| CDW (Alkali-Activated Hybrid Concrete) | OPC (Reference Concrete) | ||||||

| 450 | 550 | 650 | 450 | 550 | 650 | ||

| CDW | 3.80 × 10−3 | 1.54 | 1.88 | 2.22 | - | - | - |

| OPC | 8.45 × 10−1 | 38.03 | 46.48 | 54.93 | 380.25 | 464.75 | 549.25 |

| Na2SiO3 | 8.12 × 10−1 | 116.93 | 142.91 | 168.90 | - | - | - |

| NaOH | 1.46 | 52.56 | 64.24 | 75.92 | - | - | - |

| Water | 2.10 × 10−4 | 0.02 | 0.02 | 0.03 | 0.06 | 0.07 | 0.08 |

| RFA | 3.98 × 10−3 | 1.83 | 1.64 | 1.45 | 1.83 | 1.64 | 1.45 |

| RCA | 4.27 | 3.83 | 3.39 | 4.27 | 3.83 | 3.39 | |

| Total | 215.17 | 261.00 | 306.83 | 386.41 | 470.29 | 554.17 | |

| Building Applications | Property | Experimental Result |

|---|---|---|

| Solid block | Compressive strength (MPa) | 22.6 ± 0.7 |

| Density (kg/m3) | 1938.7 | |

| Absorption (%) | 11.6 | |

| Hollow block | Compressive strength (MPa) | 19.8 ± 1.5 |

| Density (kg/m3) | 1951.2 | |

| Absorption (%) | 11.3 | |

| Paver | Modulus of rupture (MPa) | 4.2 ± 0.4 |

| Density (kg/m3) | 2163.9 | |

| Absorption (%) | 10.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robayo-Salazar, R.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units. Sustainability 2022, 14, 9685. https://doi.org/10.3390/su14159685

Robayo-Salazar R, Valencia-Saavedra W, Mejía de Gutiérrez R. Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units. Sustainability. 2022; 14(15):9685. https://doi.org/10.3390/su14159685

Chicago/Turabian StyleRobayo-Salazar, Rafael, William Valencia-Saavedra, and Ruby Mejía de Gutiérrez. 2022. "Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units" Sustainability 14, no. 15: 9685. https://doi.org/10.3390/su14159685

APA StyleRobayo-Salazar, R., Valencia-Saavedra, W., & Mejía de Gutiérrez, R. (2022). Reuse of Powders and Recycled Aggregates from Mixed Construction and Demolition Waste in Alkali-Activated Materials and Precast Concrete Units. Sustainability, 14(15), 9685. https://doi.org/10.3390/su14159685