Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices

Abstract

:1. Introduction

- I.

- To identify the best refrigerant with low GWP and high performance out of the 27 refrigerants for retail food refrigeration in supermarkets based on their thermal properties using TOPSIS, EDAS, and MOORA techniques of MCDM methodology.

- II.

- To integrate technical, economic, social, environmental, and resource aspects in the assessment index method to select novel refrigerants in the retail food refrigeration industry.

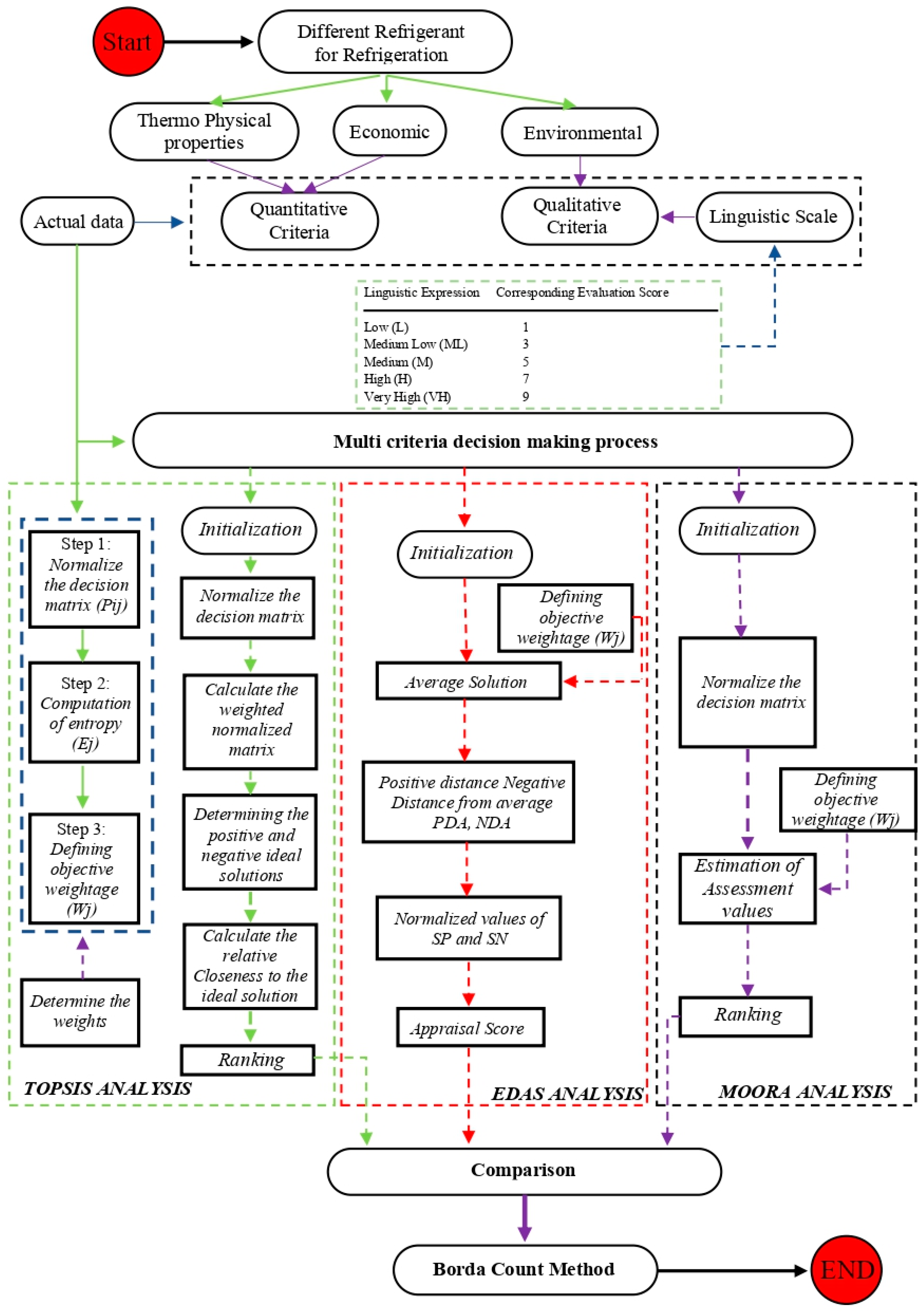

2. Research Methodology

2.1. Features of Refrigerants

2.2. Decision Tree Model

3. Optimization Methodology

3.1. Entropy Technique

3.2. Multi-Criteria Decision Making

3.3. TOPSIS Technique

- ✓

- The term “weights” refers to how much a certain aspect should be considered.

- ✓

- The term “impact” refers to whether a particular item has a positive or negative effect.

3.4. EDAS Technique

3.5. MOORA Technique

4. Results and Discussion

4.1. TOPSIS Technique

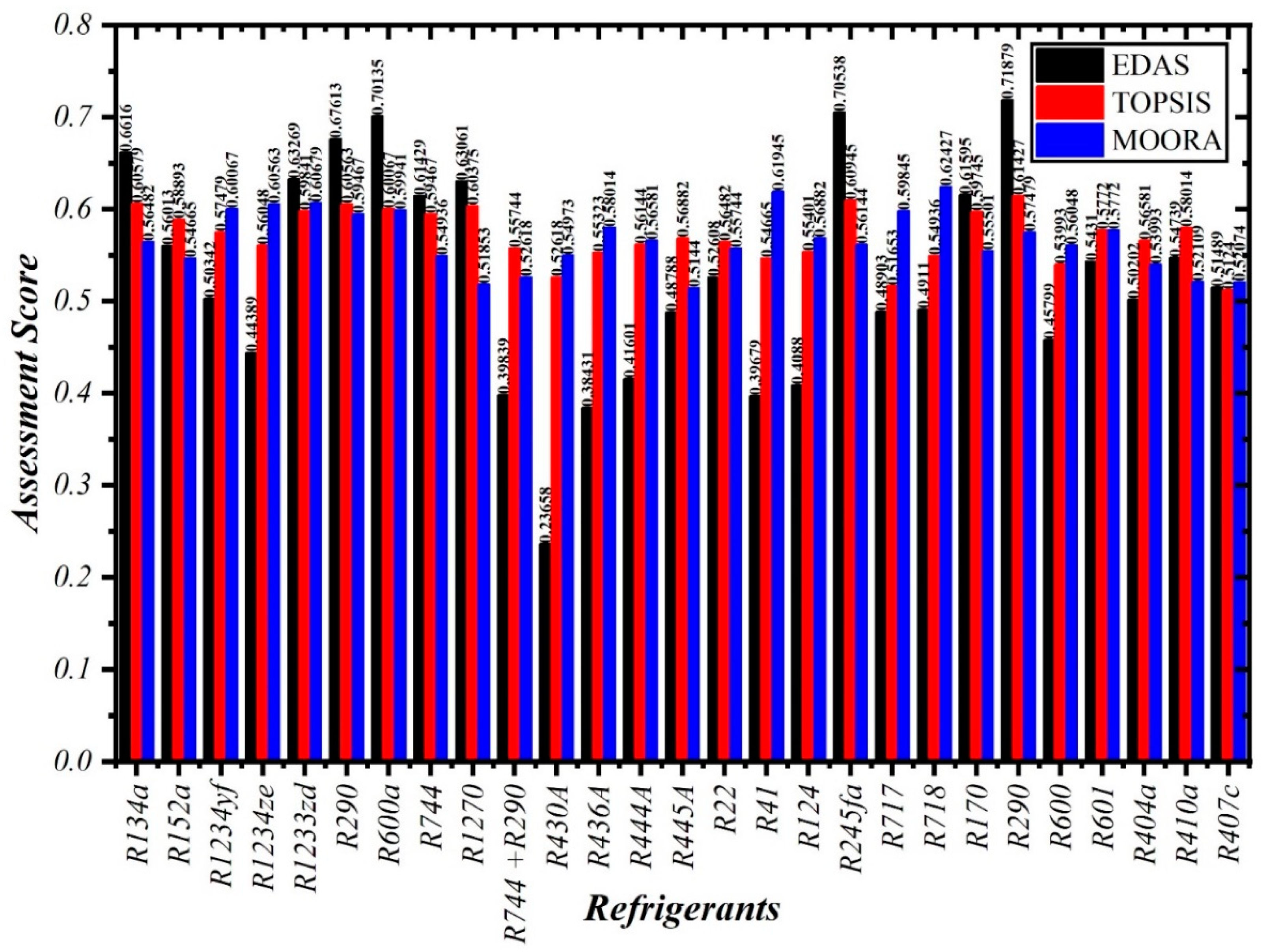

4.2. EDAS Technique

4.3. MOORA Technique

- R290 i.e., Propane, R245fa, R600a, R290, and R134a were observed to have the same rank (Rank 1, 2, 3, 4, and 5, respectively) with all the proposed MCDM techniques.

- R290 followed by R245fa can be considered the best choice of refrigerant for the supermarket application.

- A strong correlation was observed between EDAS, TOPSIS and MOORA, owing to the fact that, they exhibited identical results in ranking the selected alternatives.

- All of the above procedures are effective illustrations of quantitative methods. Each technique; however, has advantages and disadvantages.

5. Conclusions

- EDAS, TOPSIS, and MOORA techniques can be successfully employed for the selection of the best refrigerant out of 27 chosen refrigerants.

- R290, i.e., propane aces the ranking by all the three techniques of evaluation, followed by R245fa and R600a.

- R41 is not the promising refrigerant per the EDAS and MOORA technique while R407C is not the favorable refrigerant per the TOPSIS technique of MCDM methodology.

- A strong correlation was observed between EDAS, TOPSIS, and MOORA, owing to the fact that they exhibited identical results in ranking the selected alternatives.

- All of the above procedures are effective illustrations of quantitative methods. Each technique, however, has advantages and disadvantages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | |

| Standardized value of the i th index in the j th sample | |

| Measured value of the i th indicator in the j th sample | |

| Entropy value Ei of the i th index | |

| Weight value | |

| Element of normalized matrix R | |

| Average solution | |

| Positive distance from average | |

| Negative distance from average | |

| Normalized values of SP | |

| Normalized values of SN | |

| Appraisal score | |

| Assessment value | |

References

- Effatpanah, S.K.; Ahmadi, M.H.; Aungkulanon, P.; Maleki, A.; Sadeghzadeh, M.; Sharifpur, M.; Chen, L. Comparative Analysis of Five Widely-Used Multi-Criteria Decision-Making Methods to Evaluate Clean Energy Technologies: A Case Study. Sustainability 2022, 14, 1403. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Kumar, R.; Assad, M.E.H.; Ngo, P.T.T. Applications of Machine Learning Methods in Modeling Various Types of Heat Pipes: A Review. J. Therm. Anal. Calorim. 2021, 146, 2333–2341. [Google Scholar] [CrossRef]

- Jagtap, H.P.; Bewoor, A.K.; Kumar, R.; Ahmadi, M.H.; El Haj Assad, M.; Sharifpur, M. RAM Analysis and Availability Optimization of Thermal Power Plant Water Circulation System Using PSO. Energy Reports 2021, 7, 1133–1153. [Google Scholar] [CrossRef]

- Sabbagh, O.; Fanaei, M.A.; Arjomand, A.; Hossein Ahmadi, M. Multi-Objective Optimization Assessment of a New Integrated Scheme for Co-Production of Natural Gas Liquids and Liquefied Natural Gas. Sustain. Energy Technol. Assess. 2021, 47, 101493. [Google Scholar] [CrossRef]

- Zolghadri, A.; Maddah, H.; Ahmadi, M.H.; Sharifpur, M. Predicting Parameters of Heat Transfer in a Shell and Tube Heat Exchanger Using Aluminum Oxide Nanofluid with Artificial Neural Network (Ann) and Self-Organizing Map (Som). Sustainability 2021, 13, 8824. [Google Scholar] [CrossRef]

- Lohakare, P.; Bewoor, A.; Kumar, R.; Said, N.M.; Sharifpur, M. Benchmark Using Multi Criteria Decision Making (MCDM) Technique to Optimally Select Piston Material. Eng. Anal. Bound. Elem. 2022, 142, 52–60. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Bayat, R.; Ashouri, M.; Feidt, M. Thermo-Economic Optimization of Stirling Heat Pump by Using Non-Dominated Sorting Genetic Algorithm. Energy Convers. Manag. 2015, 91, 315–322. [Google Scholar] [CrossRef]

- Kumar, R.; Nadda, R.; Kumar, S.; Razak, A.; Sharifpur, M.; Aybar, H.S.; Ahamed Saleel, C.; Afzal, A. Influence of Artificial Roughness Parametric Variation on Thermal Performance of Solar Thermal Collector: An Experimental Study, Response Surface Analysis and ANN Modelling. Sustain. Energy Technol. Assess. 2022, 52, 102047. [Google Scholar] [CrossRef]

- Sharma, J.; Soni, S.; Paliwal, P.; Saboor, S.; Chaurasiya, P.K.; Sharifpur, M.; Khalilpoor, N.; Afzal, A. A Novel Long Term Solar Photovoltaic Power Forecasting Approach Using LSTM with Nadam Optimizer: A Case Study of India. Energy Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Melaibari, A.A.; Khetib, Y.; Alanazi, A.K.; Sajadi, S.M.; Sharifpur, M.; Cheraghian, G. Applying Artificial Neural Network and Response Surface Method to Forecast the Rheological Behavior of Hybrid Nano-antifreeze Containing Graphene Oxide and Copper Oxide Nanomaterials. Sustainability 2021, 13, 11505. [Google Scholar] [CrossRef]

- Mehrabi, M.; Sharifpur, M.; Meyer, J.P. Application of the FCM-Based Neuro-Fuzzy Inference System and Genetic Algorithm-Polynomial Neural Network Approaches to Modelling the Thermal Conductivity of Alumina-Water Nanofluids. Int. Commun. Heat Mass Transf. 2012, 39, 971–977. [Google Scholar] [CrossRef]

- Sharifpur, M.; Adio, S.A.; Meyer, J.P. Experimental Investigation and Model Development for Effective Viscosity of Al2O3-Glycerol Nanofluids by Using Dimensional Analysis and GMDH-NN Methods. Int. Commun. Heat Mass Transf. 2015, 68, 208–219. [Google Scholar] [CrossRef]

- Jokar, M.A.; Ahmadi, M.H.; Sharifpur, M.; Meyer, J.P.; Pourfayaz, F.; Ming, T. Thermodynamic Evaluation and Multi-Objective Optimization of Molten Carbonate Fuel Cell-Supercritical CO2 Brayton Cycle Hybrid System. Energy Convers. Manag. 2017, 153, 538–556. [Google Scholar] [CrossRef]

- Daneshfar, R.; Bemani, A.; Hadipoor, M.; Sharifpur, M.; Muhammad, H.; Mahariq, I.; Abdeljawad, T. Estimating the Heat Capacity of Non-Newtonian Ionanofluid Systems Using ANN, ANFIS, and SGB Tree Algorithms. Appl. Sci. 2020, 10, 6432. [Google Scholar] [CrossRef]

- Toghyani, S.; Kasaeian, A.; Ahmadi, M.H. Multi-Objective Optimization of Stirling Engine Using Non-Ideal Adiabatic Method. Energy Convers. Manag. 2014, 80, 54–62. [Google Scholar] [CrossRef]

- Sivalingam, V.; Ganesh Kumar, P.; Prabakaran, R.; Sun, J.; Velraj, R.; Kim, S.C. An Automotive Radiator with Multi-Walled Carbon-Based Nanofluids: A Study on Heat Transfer Optimization Using MCDM Techniques. Case Stud. Therm. Eng. 2022, 29, 101724. [Google Scholar] [CrossRef]

- Poongavanam, G.; Sivalingam, V.; Prabakaran, R.; Salman, M.; Kim, S.C. Selection of the Best Refrigerant for Replacing R134a in Automobile Air Conditioning System Using Different MCDM Methods: A Comparative Study. Case Stud. Therm. Eng. 2021, 27, 101344. [Google Scholar] [CrossRef]

- Vats, P.; Singh, T.; Dubey, V.; Kumar Sharma, A. Optimization of Machining Parameters in Turning of AISI 1040 Steel Using Hybrid MCDM Technique. Mater. Today Proc. 2022, 50, 1758–1765. [Google Scholar] [CrossRef]

- Junankar, A.A.; Parate, S.R.; Dethe, P.K.; Dhote, N.R.; Gadkar, D.G.; Gadkar, D.D.; Gajbhiye, S.A. Optimization of Bearing Steel Turning Parameters under CuO and ZnO Nanofluid-MQL Using MCDM Hybrid Approach. Mater. Today Proc. 2021, 47, 4292–4297. [Google Scholar] [CrossRef]

- Subasi, A.; Erdem, K. An Integrated Optimization Methodology for Heat Transfer Enhancement: A Case Study on Nanofluid Flow in a Pipe Equipped with Inserts. Int. J. Heat Mass Transf. 2021, 172, 121187. [Google Scholar] [CrossRef]

- Yang, K.; Zhu, N.; Chang, C.; Wang, D.; Yang, S.; Ma, S. A Methodological Concept for Phase Change Material Selection Based on Multi-Criteria Decision Making (MCDM): A Case Study. Energy 2018, 165, 1085–1096. [Google Scholar] [CrossRef]

- Deepa, D.; Thanigaivelan, R.; Venkateshwaran, M. Identifying a Suitable Micro-Fin Material for Natural Convective Heat Transfer Using Multi-Criteria Decision Analysis Methods. Mater. Today Proc. 2021, 45, 1655–1659. [Google Scholar] [CrossRef]

- Jajimoggala, S.; Murali Krishna, N.; Syed, K. Selection of Optimal Hot Extrusion Process Parameters for AA6061using Hybrid MCDM Technique. Mater. Today Proc. 2019, 18, 278–290. [Google Scholar] [CrossRef]

- Vishwakarma, D.K.; Kumar, N.; Padap, A.K. Modelling and Optimization of Aging Parameters for Thermal Properties of Al 6082 Alloy Using Response Surface Methodology. Mater. Res. Express 2017, 4, 046502. [Google Scholar] [CrossRef]

- Ilangkumaran, M.; Karthikeyan, M.; Ramachandran, T.; Boopathiraja, M.; Kirubakaran, B. Risk Analysis and Warning Rate of Hot Environment for Foundry Industry Using Hybrid MCDM Technique. Saf. Sci. 2014, 72, 133–143. [Google Scholar] [CrossRef]

- Simsek, Y.; Watts, D.; Escobar, R. Sustainability Evaluation of Concentrated Solar Power (CSP) Projects under Clean Development Mechanism (CDM) by Using Multi Criteria Decision Method (MCDM). Renew. Sustain. Energy Rev. 2018, 93, 421–438. [Google Scholar] [CrossRef]

- Mukhametzyanov, I.Z. Specific Character of Objective Methods for Determining Weights of Criteria in MCDM Problems: Entropy, CRITIC, SD. Decis. Mak. Appl. Manag. Eng. 2021, 4, 76–105. [Google Scholar] [CrossRef]

- Kizielewicz, B.; Więckowski, J.; Shekhovtsov, A.; Wątróbski, J.; Depczyński, R.; Sałabun, W. Study towards the Time-Based Mcda Ranking Analysis—A Supplier Selection Case Study. Facta Univ. Ser. Mech. Eng. 2021, 19, 381–399. [Google Scholar] [CrossRef]

- El-Araby, A.; Sabry, I.; El-Assal, A. A Comparative Study of Using Mcdm Methods Integrated with Entropy Weight Method for Evaluating Facility Location Problem. Oper. Res. Eng. Sci. Theory Appl. 2022, 5, 121–138. [Google Scholar] [CrossRef]

- Li, X.; Wang, K.; Liuz, L.; Xin, J.; Yang, H.; Gao, C. Application of the Entropy Weight and TOPSIS Method in Safety Evaluation of Coal Mines. Procedia Eng. 2011, 26, 2085–2091. [Google Scholar] [CrossRef] [Green Version]

- Batool, B.; Abosuliman, S.S.; Abdullah, S.; Ashraf, S. EDAS Method for Decision Support Modeling under the Pythagorean Probabilistic Hesitant Fuzzy Aggregation Information. J. Ambient Intell. Humaniz. Comput. 2021. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Domínguez, L.; Sánchez Mojica, K.Y.; Ovalles Pabón, L.C.; Cordero Diáz, M.C. Application of the MOORA Method for the Evaluation of the Industrial Maintenance System. J. Phys. Conf. Ser. 2018, 1126, 012018. [Google Scholar] [CrossRef]

| s. No | Refrigerants | Critical Temperature, °C | Critical Pressure, Bar | Saturated Pressure, Bar | Liquid Density, kg/m3 | Vapor Density, kg/m3 | Thermal Conductivity of Refrigerant, W/m-K | Viscosity of Liquid, µPa.s | Pressure at 60 Deg C | ODP | GWP | Toxicity and Flammability | Cost Per kg, USD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | R134a | 102 | 41 | 3.49 | 1278.J | 17.1 | 0.089 | 250 | 16.8 | 0 | 1430 | I | 5 |

| 2 | R152a | 113.4 | 45.1 | 3.14 | 947.7 | 9.89 | 0.106 | 206 | 15 | 0 | 124 | 2 | 5.5 |

| 3 | R1234yf | 95 | 34 | 3.73 | 1160.4 | 20.7 | 0.074 | 196 | 16.4 | 1 | 1 | 1 | 12.33 |

| 4 | R1234ze (E) | 109.4 | 36.3 | 2.59 | 1111.5 | 40.6 | 0.078 | 269 | 12.7 | 1 | 1 | 1 | 53 |

| 5 | R1233zd (E) | 166.6 | 36.2 | 0.59 | 1319.8 | 35.6 | 0.081 | 470 | 38.7 | 1 | 1 | 1 | 39.5 |

| 6 | R290 | 96.74 | 42.5 | 5.51 | 521.75 | 11.9 | 0.103 | 119 | 21.2 | 0 | 3 | 4 | 5.98 |

| 7 | R600a | 134.6 | 36.3 | 1.87 | 574.8 | 5.01 | 0.097 | 187 | 8.69 | 0 | 4 | 4 | 10 |

| 8 | R744 | 30.98 | 73.8 | 39.7 | 896.03 | 114 | 0.104 | 90.8 | 0 | 1 | 1 | 10.91 | |

| 9 | R1270 | 91.06 | 45.5 | 6.76 | 538.6 | 14.2 | 0.093 | 115 | 25.2 | 0 | 1 | 4 | 4.5 |

| 10 | R744 + R290 | 57 | 67.9 | 29.9 | 644.9 | 78.3 | 0.083 | 87.7 | 8.69 | 0 | 3 | 4 | 9 |

| 11 | R430A | 106.9 | 40.8 | 3.5 | 802.l | 10.7 | 0.984 | 180 | 15.7 | 2 | 2208 | 4 | 7 |

| 12 | R436A | 115.9 | 42.7 | 3.85 | 548.01 | 8.66 | 0.1 | 146 | 15.1 | 2 | 1805 | 4 | 8 |

| 13 | R444A | 101.2 | 42.3 | 4.47 | 1199.l | 28.5 | 0.9 | 225 | 19.8 | 1 | 2506 | 1 | 50 |

| 14 | R445A | 104.7 | 44.9 | 4.67 | 1190 | 29.4 | 0.95 | 220 | 19.4 | 1 | 2472 | 1 | 46 |

| 15 | R22 | 96.3 | 49.9 | 5.8 | 1030.5 | 5.6 | 0.092 | 206.3 | 2.42 | 0.06 | 1810 | 1 | 7.97 |

| 16 | R41 | 44.28 | 59 | 9.4 | 1038.5 | 9.4 | 0.142 | 147.3 | 39.3 | 0 | 2 | 1 | 12 |

| 17 | R124 | 22.43 | 36.2 | 1.9 | 1424.2 | 16.4 | 0.0743 | 328.1 | 9.96 | 1 | 609 | 1 | 25.33 |

| 18 | R245fa | 154.2 | 36.5 | 0.69 | 1390.9 | 10.7 | 0.094 | 540.8 | 4.63 | 1 | 1370 | 1 | 10.67 |

| 19 | R717(Ammonia) | 132.4 | 113.3 | 4.9 | 633.1 | 0.7 | 0.547 | 162.9 | 26.1 | 0 | 0 | 2 | 3 |

| 20 | R718(Water) | 373.99 | 220.6 | 0.0087 | 999.7 | 0.068 | 0.57 | 1518.3 | 0.1995 | 1 | 0 | 1 | 0.01 |

| 21 | R170(Ethane) | 32.18 | 48.7 | 26.88 | 387.7 | 0.7 | 0.086 | 54.3 | 0 | 6 | 4 | 5.8 | |

| 22 | R290(Propane) | 96.68 | 42.5 | 5.35 | 523.1 | 15.1 | 0.103 | 120.5 | 21.1 | 0 | 3 | 4 | 13.4 |

| 23 | R600(Butane) | 151.98 | 38 | 1.19 | 596.8 | 9.2 | 0.113 | 194.4 | 6.34 | 0 | 4 | 4 | 12.3 |

| 24 | R601(Pentane) | 196.55 | 337 | 1.84 | 576 | 8.4 | 0.097 | 189.1 | 8.69 | 0 | 4 | 4 | 15.6 |

| 25 | R404A | 72.05 | 37.29 | 7.1 | 1132.9 | 16.3 | 0.075 | 167.2 | 29.1 | 0 | 180 | 1 | 23.1 |

| 26 | R410A | 71.36 | 49.03 | 9.5 | 1147.6 | 15.7 | 0.111 | 158.7 | 38.5 | 0 | 120 | 1 | 22.5 |

| 27 | R407C | 86.03 | 46.3 | 6.75 | 1215.7 | 14.8 | 0.102 | 197.2 | 28.1 | 0 | 230 | 1 | 17.8 |

| Objective | High | Low | Low | Low | High | High | Low | Low | Low | Low | Low | Low |

| Refrigerants | Assessment Score | Ranking |

|---|---|---|

| R134a | 0.661595 | 5 |

| R152a | 0.560129 | 10 |

| R1234yf | 0.503422 | 14 |

| R1234ze (E) | 0.443894 | 20 |

| R1233zd (E) | 0.632693 | 6 |

| R290 | 0.676133 | 4 |

| R600a | 0.701347 | 3 |

| R744 | 0.614293 | 9 |

| R1270 | 0.630613 | 7 |

| R744 + R290 | 0.398386 | 23 |

| R430A | 0.236577 | 26 |

| R436A | 0.384311 | 25 |

| R444A | 0.416013 | 21 |

| R445A | 0.487884 | 18 |

| R22 | 0.526079 | 13 |

| R41 | 0.396785 | 27 |

| R124 | 0.408803 | 22 |

| R245fa | 0.705378 | 2 |

| R717 (Ammonia) | 0.48903 | 17 |

| R718 (Water) | 0.491104 | 16 |

| R170 (Ethane) | 0.61595 | 8 |

| R290 (Propane) | 0.718788 | 1 |

| R600 (Butane) | 0.457986 | 19 |

| R601 (Pentane) | 0.543101 | 12 |

| R404A | 0.502021 | 15 |

| R410A | 0.547391 | 11 |

| R407C | 0.51489 | 24 |

| Refrigerants | Assessment Score | Ranking |

|---|---|---|

| R134a | 0.605788 | 5 |

| R152a | 0.588928 | 10 |

| R1234yf | 0.574792 | 13 |

| R1234ze (E) | 0.56048 | 18 |

| R1233zd (E) | 0.598414 | 7 |

| R290 | 0.605625 | 4 |

| R600a | 0.600674 | 3 |

| R744 | 0.594666 | 9 |

| R1270 | 0.603746 | 6 |

| R744 + R290 | 0.557436 | 19 |

| R430A | 0.526175 | 25 |

| R436A | 0.553233 | 21 |

| R444A | 0.561435 | 17 |

| R445A | 0.568823 | 14 |

| R22 | 0.564821 | 16 |

| R41 | 0.546647 | 23 |

| R124 | 0.554006 | 20 |

| R245fa | 0.609451 | 2 |

| R717 (Ammonia) | 0.516533 | 26 |

| R718 (Water) | 0.549363 | 22 |

| R170 (Ethane) | 0.597454 | 8 |

| R290 (Propane) | 0.614269 | 1 |

| R600 (Butane) | 0.539931 | 24 |

| R601 (Pentane) | 0.577198 | 12 |

| R404A | 0.565808 | 15 |

| R410A | 0.580136 | 11 |

| R407C | 0.512399 | 27 |

| Refrigerants | Assessment Score | Ranking |

|---|---|---|

| R134a | 0.56482 | 5 |

| R152a | 0.54665 | 10 |

| R1234yf | 0.60067 | 16 |

| R1234ze (E) | 0.60563 | 23 |

| R1233zd (E) | 0.60679 | 6 |

| R290 | 0.59467 | 4 |

| R600a | 0.59941 | 3 |

| R744 | 0.54936 | 9 |

| R1270 | 0.51853 | 7 |

| R744 + R290 | 0.52618 | 22 |

| R430A | 0.54973 | 26 |

| R436A | 0.58014 | 25 |

| R444A | 0.56581 | 21 |

| R445A | 0.5144 | 11 |

| R22 | 0.55744 | 15 |

| R41 | 0.61945 | 27 |

| R124 | 0.56882 | 19 |

| R245fa | 0.56144 | 2 |

| R717 (Ammonia) | 0.59845 | 14 |

| R718 (Water) | 0.62427 | 17 |

| R170 (Ethane) | 0.55501 | 8 |

| R290 (Propane) | 0.57479 | 1 |

| R600 (Butane) | 0.56048 | 20 |

| R601 (Pentane) | 0.5772 | 13 |

| R404A | 0.53993 | 18 |

| R410A | 0.52109 | 12 |

| R407C | 0.52074 | 24 |

| Refrigerants | EDAS | TOPSIS | MOORA |

|---|---|---|---|

| R134a | 5 | 5 | 5 |

| R152a | 10 | 10 | 10 |

| R1234yf | 14 | 13 | 16 |

| R1234ze (E) | 20 | 18 | 23 |

| R1233zd (E) | 6 | 7 | 6 |

| R290 | 4 | 4 | 4 |

| R600a | 3 | 3 | 3 |

| R744 | 9 | 9 | 9 |

| R1270 | 7 | 6 | 7 |

| R744 + R290 | 23 | 19 | 22 |

| R430A | 26 | 25 | 26 |

| R436A | 25 | 21 | 25 |

| R444A | 21 | 17 | 21 |

| R445A | 18 | 14 | 11 |

| R22 | 13 | 16 | 15 |

| R41 | 27 | 23 | 27 |

| R124 | 22 | 20 | 19 |

| R245fa | 2 | 2 | 2 |

| R717 (Ammonia) | 17 | 26 | 14 |

| R718 (Water) | 16 | 22 | 17 |

| R170 (Ethane) | 8 | 8 | 8 |

| R290 (Propane) | 1 | 1 | 1 |

| R600 (Butane) | 19 | 24 | 20 |

| R601 (Pentane) | 12 | 12 | 13 |

| R404A | 15 | 15 | 18 |

| R410A | 11 | 11 | 12 |

| R407C | 24 | 27 | 24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souayeh, B.; Bhattacharyya, S.; Hdhiri, N.; Alam, M.W. Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices. Sustainability 2022, 14, 11663. https://doi.org/10.3390/su141811663

Souayeh B, Bhattacharyya S, Hdhiri N, Alam MW. Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices. Sustainability. 2022; 14(18):11663. https://doi.org/10.3390/su141811663

Chicago/Turabian StyleSouayeh, Basma, Suvanjan Bhattacharyya, Najib Hdhiri, and Mir Waqas Alam. 2022. "Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices" Sustainability 14, no. 18: 11663. https://doi.org/10.3390/su141811663

APA StyleSouayeh, B., Bhattacharyya, S., Hdhiri, N., & Alam, M. W. (2022). Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices. Sustainability, 14(18), 11663. https://doi.org/10.3390/su141811663