Mechanical and Shape Memory Properties of 3D-Printed Cellulose Nanocrystal (CNC)-Reinforced Polylactic Acid Bionanocomposites for Potential 4D Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Summary of Filament Production

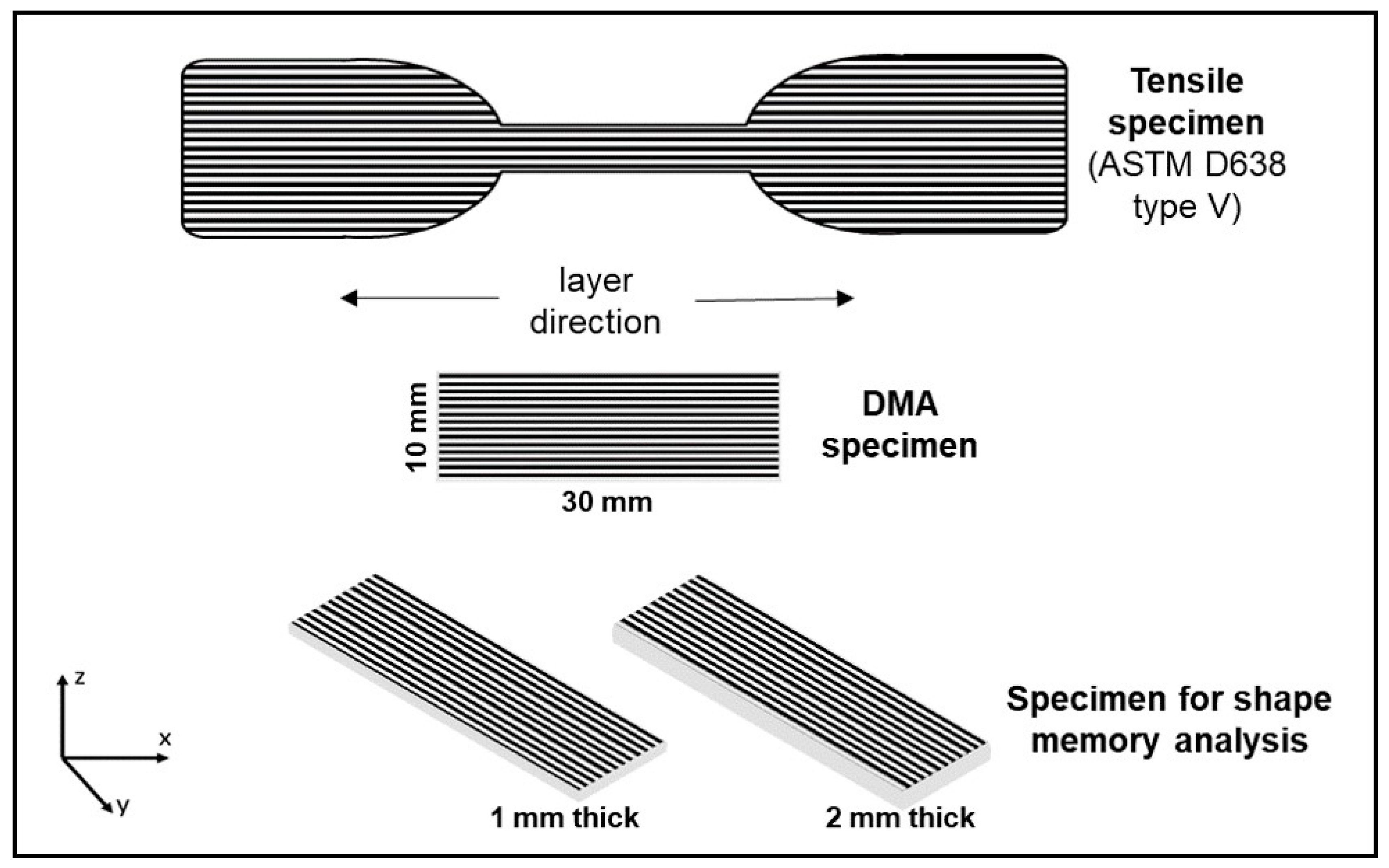

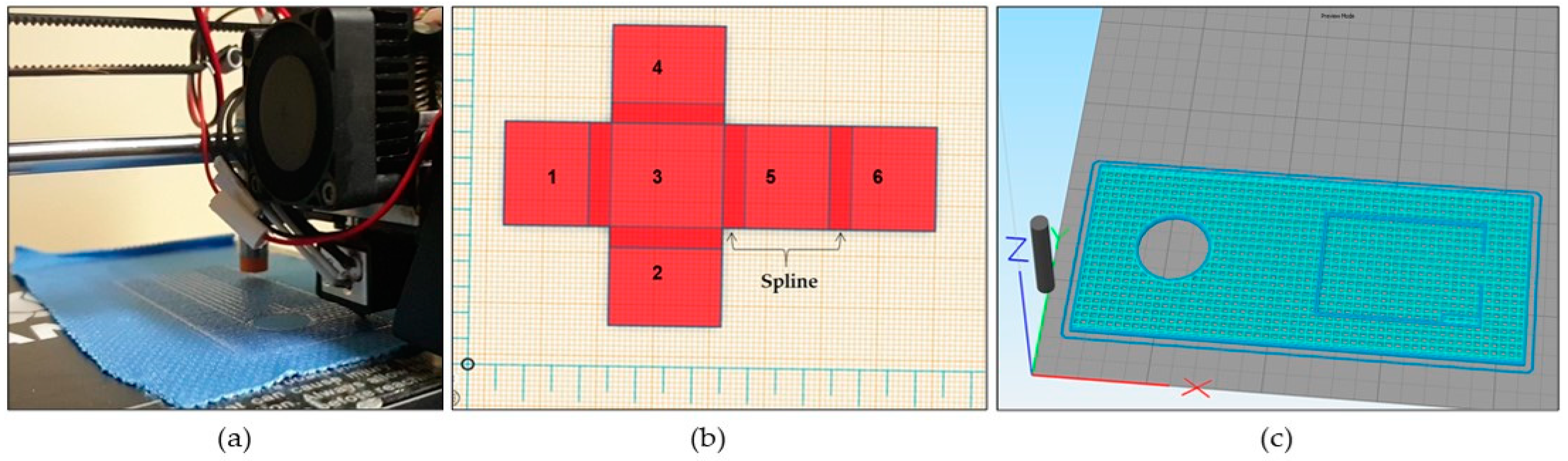

2.2. Design and 3D Printing of Tensile Test Specimen

2.3. Dynamic Mechanical Analysis (DMA)

2.3.1. Temperature Sweep Analysis

2.3.2. Deflection Temperature under Load (DTUL)

2.3.3. Static 3-Point Bending

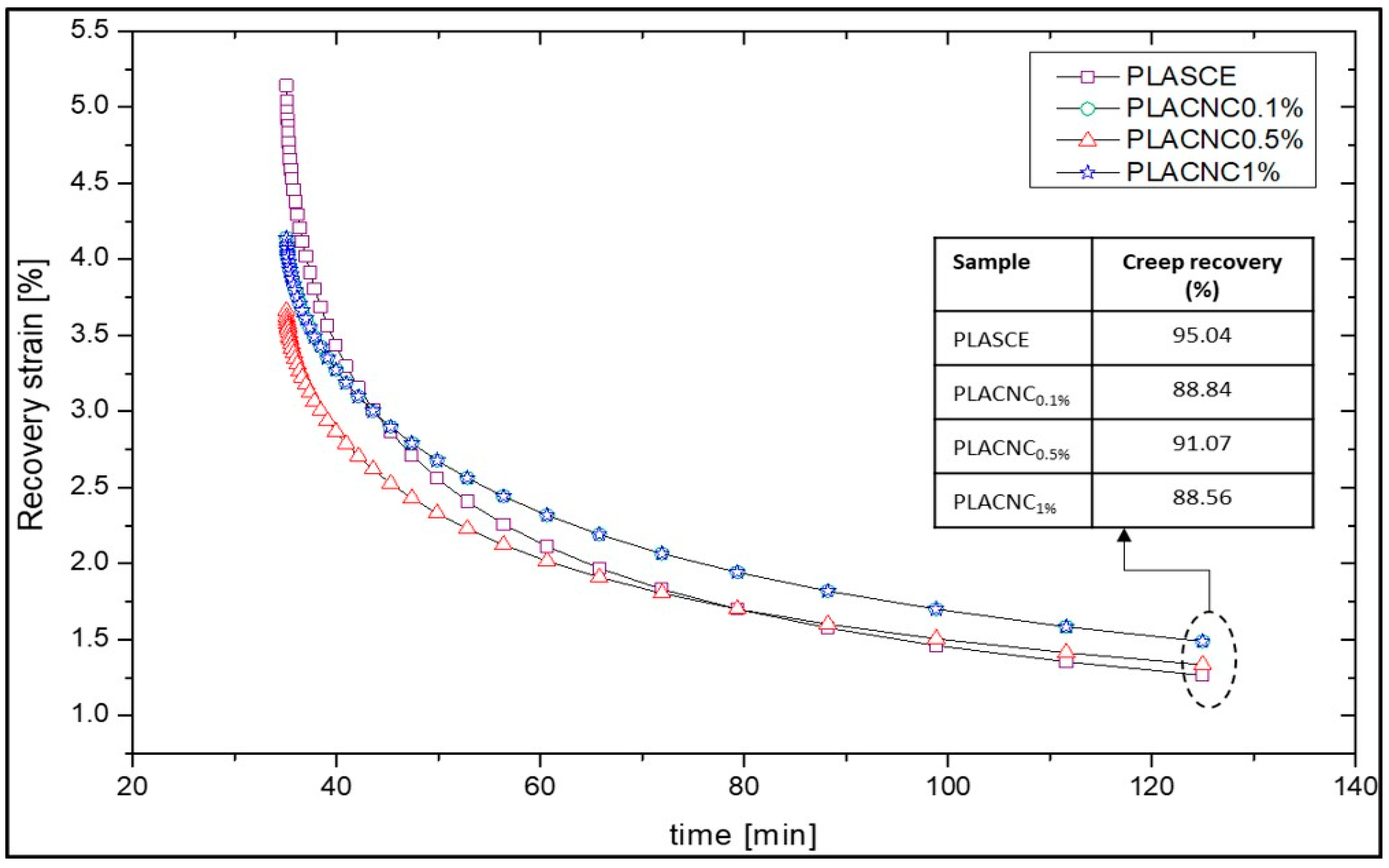

2.3.4. Creep Deformation and Recovery Analysis

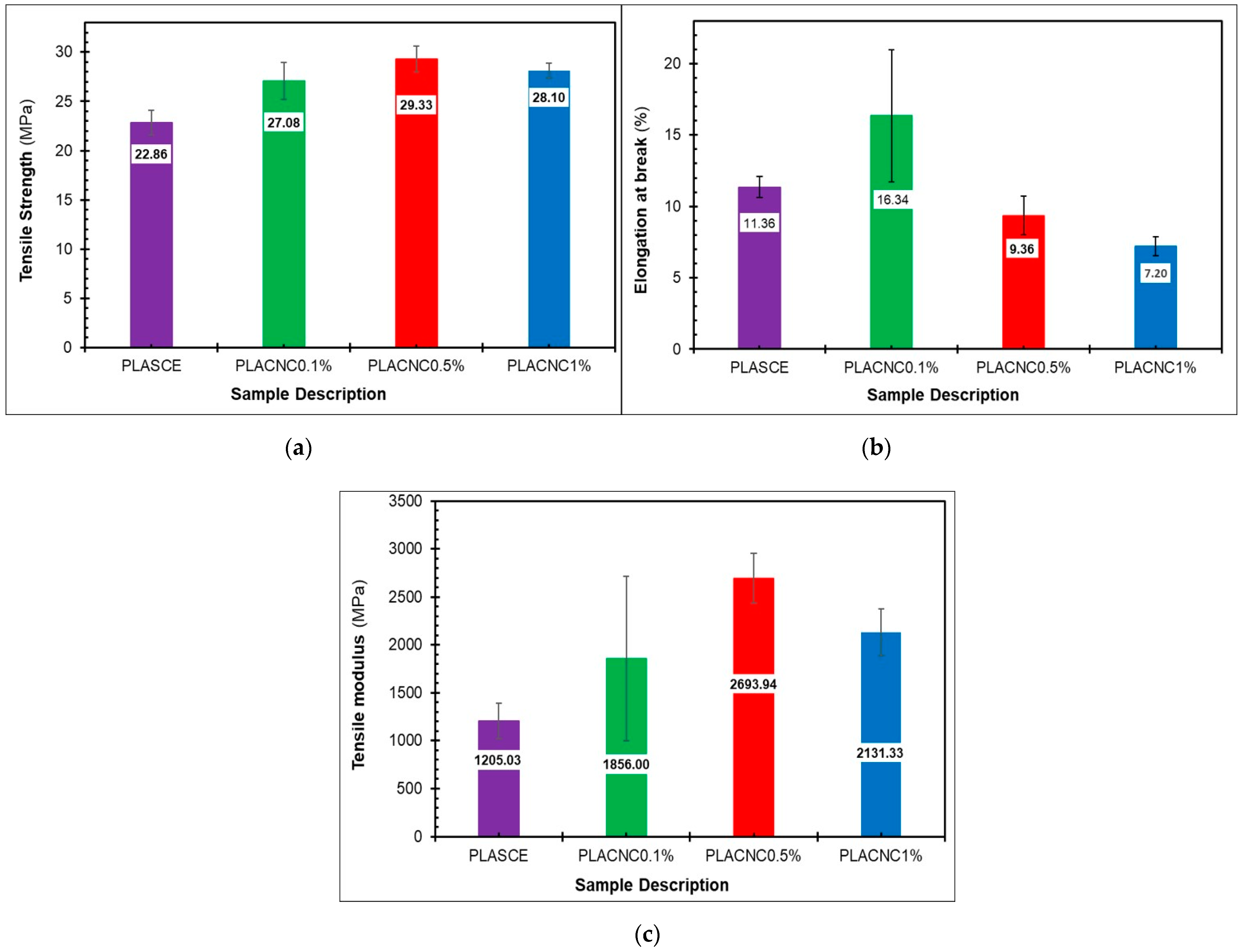

2.4. Uniaxial Tensile Analysis of 3D Printed PLA/CNC Specimen

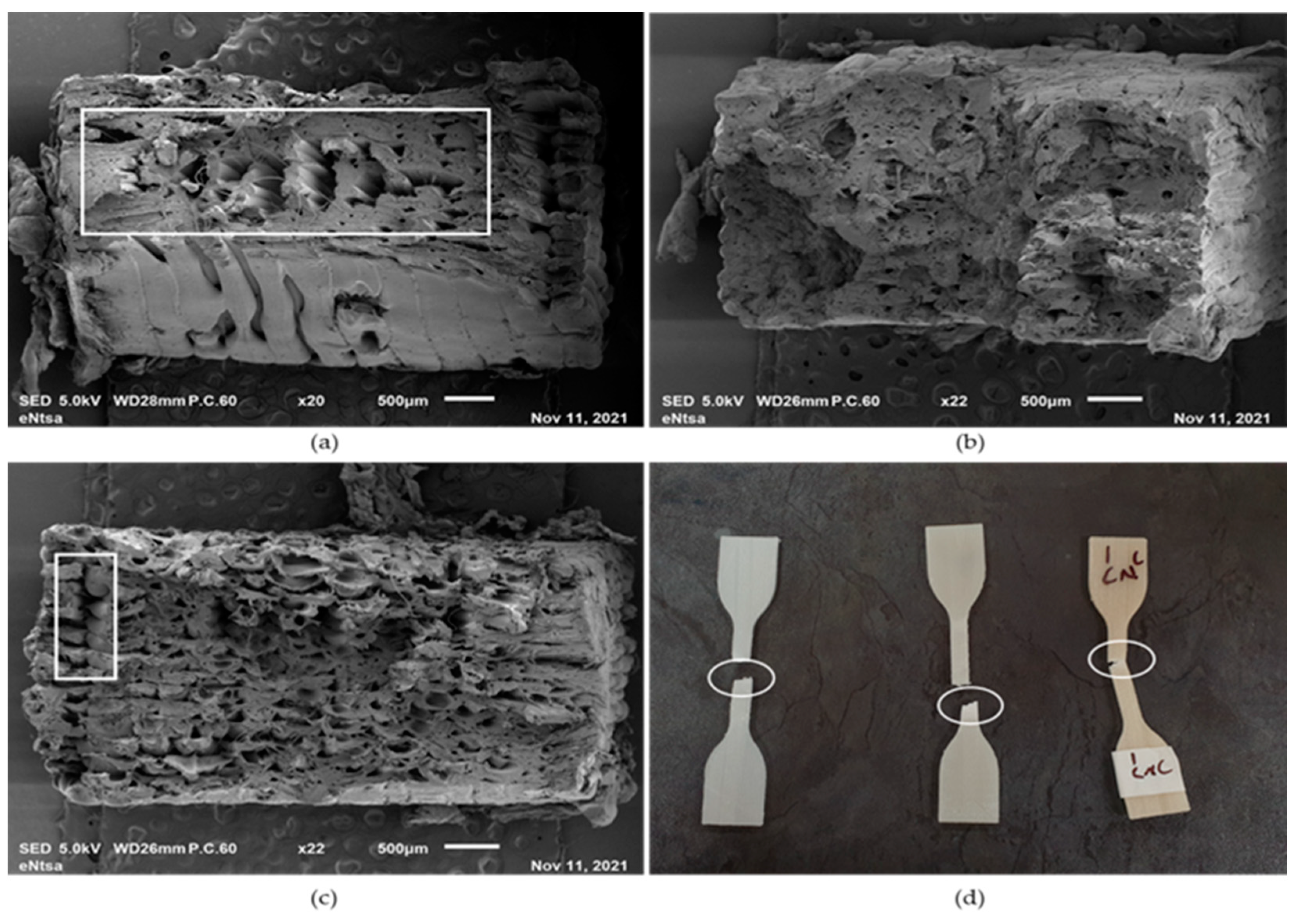

2.5. Morphological Analysis of Tensile Fracture Surfaces

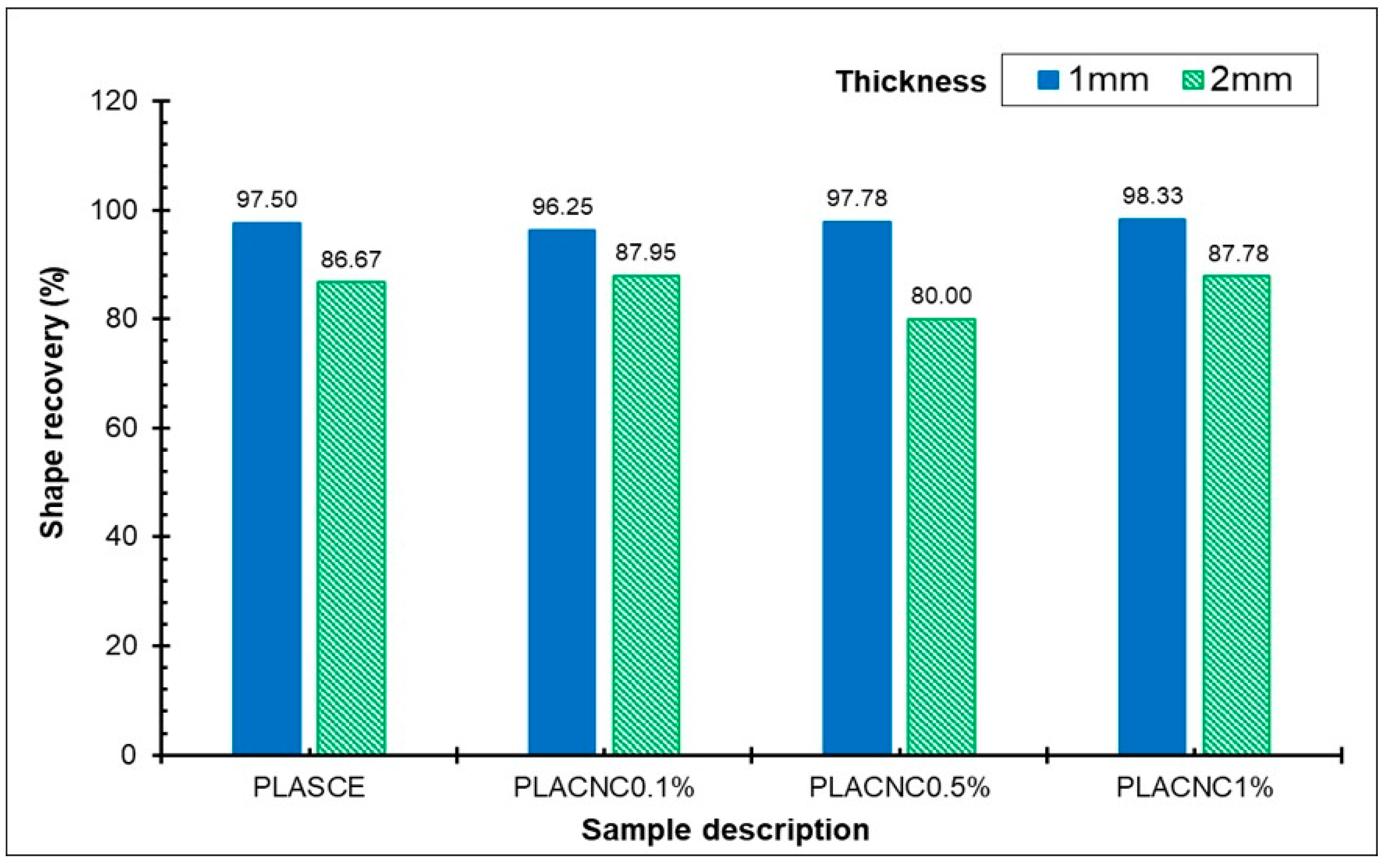

2.6. Shape Recovery Analysis of PLA/CNC Bionanocomposites

3. Results

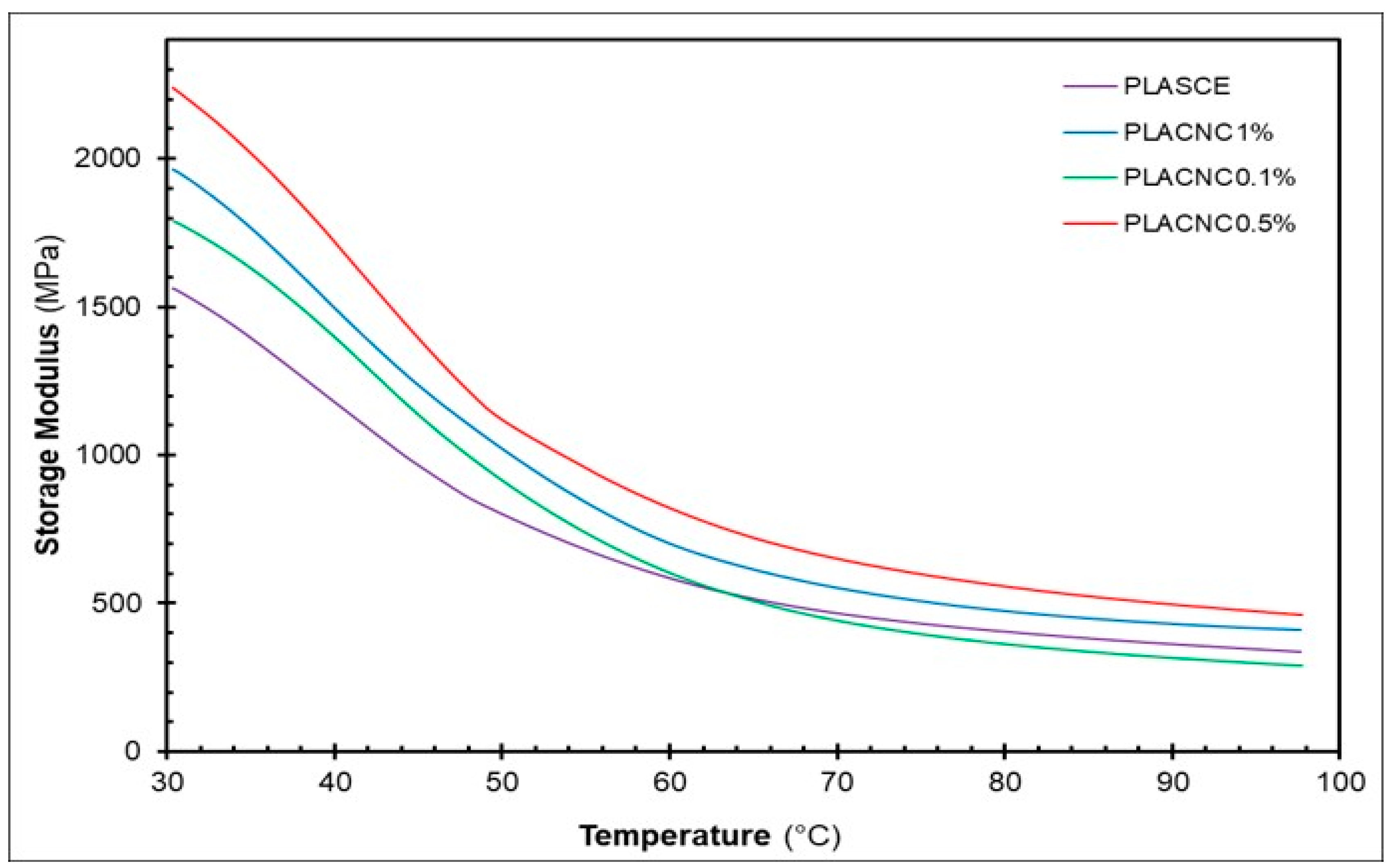

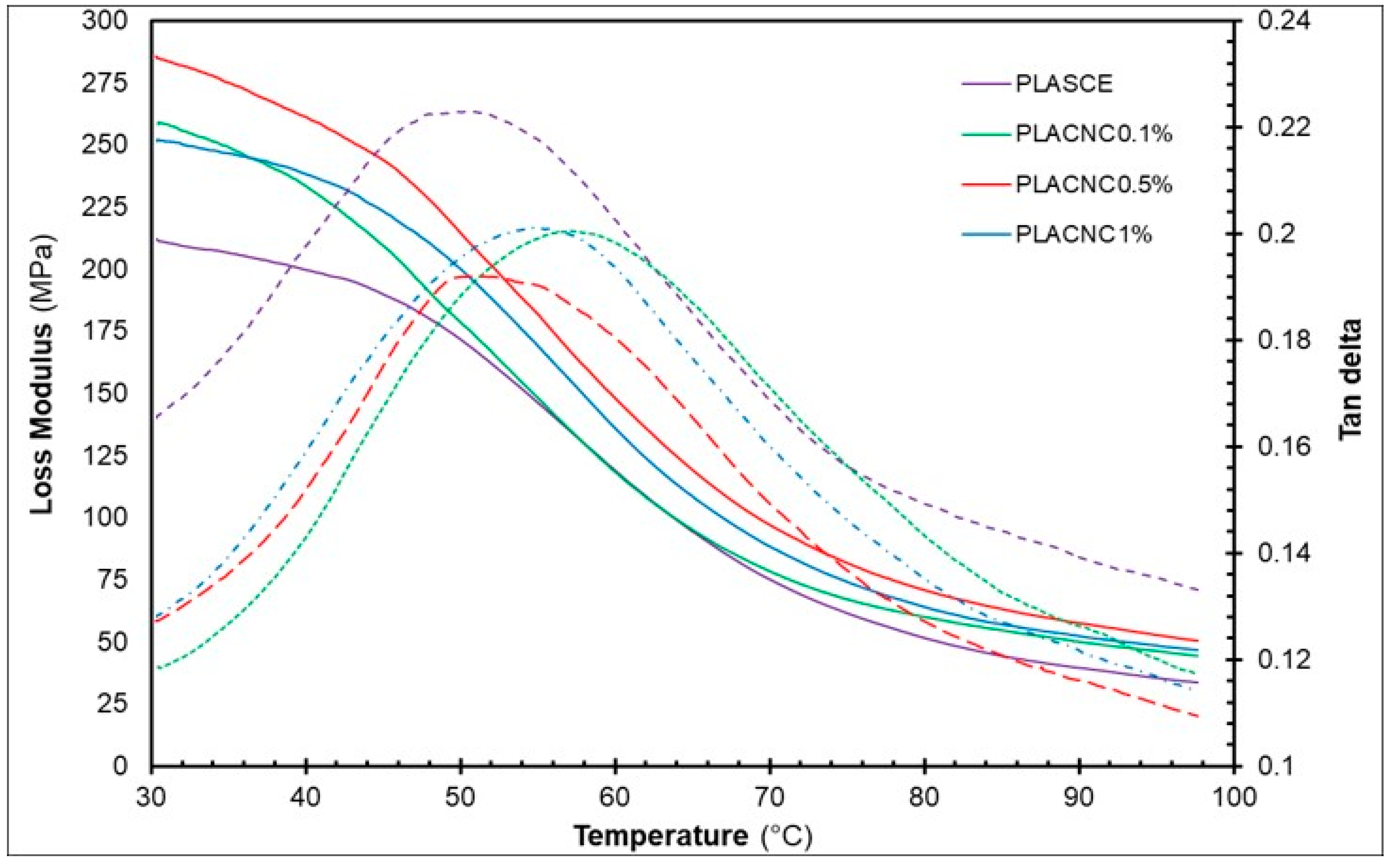

3.1. Temperature Ramp Analysis

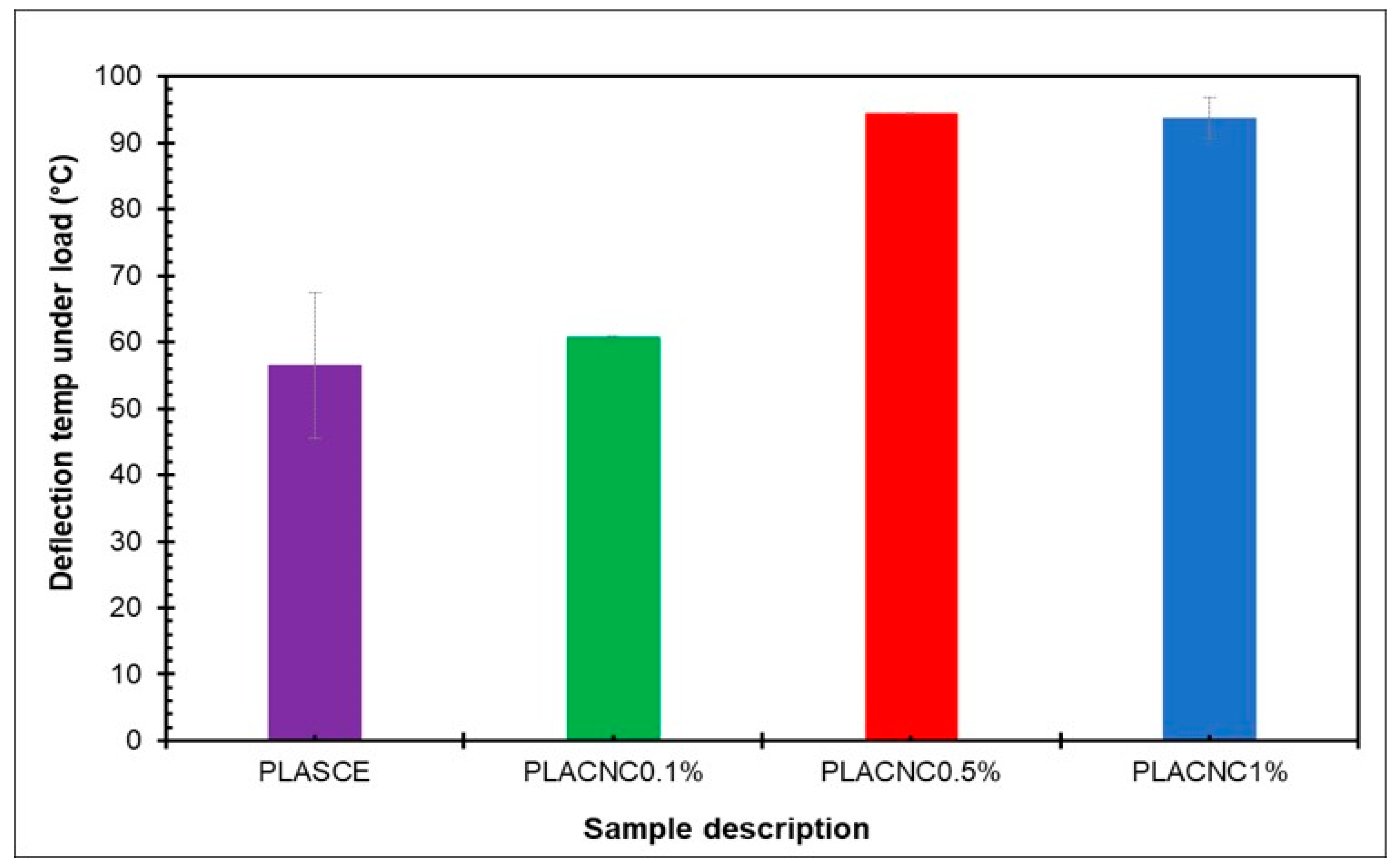

3.2. Results of Deflection Temperature under Load (DTUL)

3.3. Response to Static 3-Point Bending

3.4. Creep and Recovery Behaviour

3.5. Tensile Analysis of 3D Printed Bionanocomposites

3.6. Morphology of Tensile Fracture Surfaces

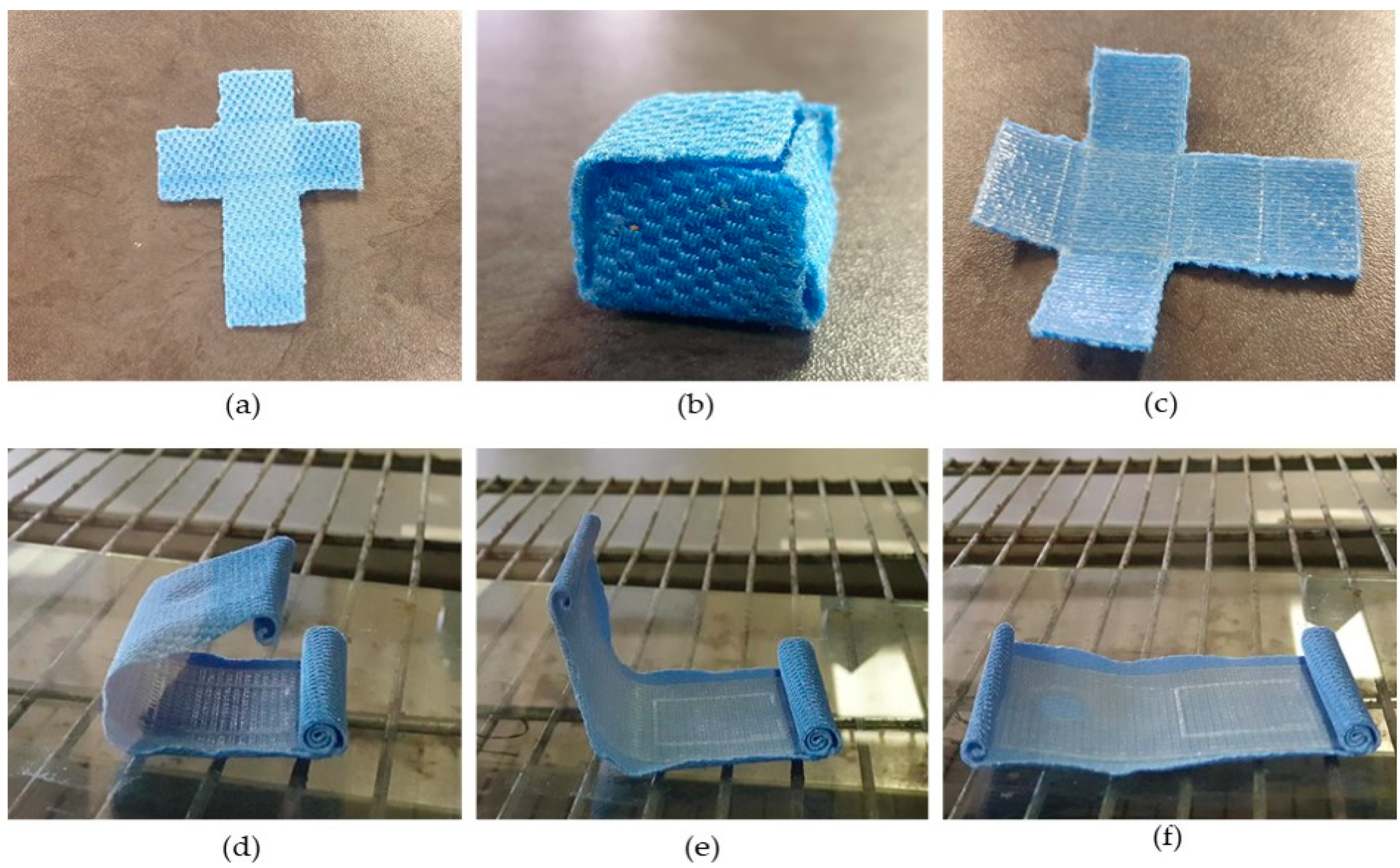

3.7. Effect of Wall Thickness on Shape Recovery Behaviour

3.8. Demonstration Prototypes for 4D Applications

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Behl, M.; Razzaq, M.Y.; Lendlein, A. Multifunctional shape-memory polymers. Adv. Mater. 2010, 22, 3388–3410. [Google Scholar] [CrossRef] [PubMed]

- Kunzelman, J.; Chung, T.; Mather, P.T.; Weder, C. Shape memory polymers with built-in threshold temperature sensors. J. Mater. Chem. 2008, 18, 1082–1086. [Google Scholar] [CrossRef]

- El Feninat, F.; Laroche, G.; Fiset, M.; Mantovani, D. Shape memory materials for biomedical applications. Adv. Eng. Mater. 2002, 4, 91–104. [Google Scholar] [CrossRef]

- Rossiter, J.; Walters, P.; Stoimenov, B. Printing 3D dielectric elastomer actuators for soft robotics. Electroact. Polym. Actuator Devices 2009, 7287, 149–158. [Google Scholar]

- Ge, Q.; Westbrook, K.K.; Mather, P.T.; Dunn, M.L.; Qi, H.J. Thermomechanical behavior of a two-way shape memory composite actuator. Smart Mater. Struct. 2013, 22, 055009. [Google Scholar]

- Liu, Y.; Gall, K.; Dunn, M.L.; McCluskey, P. Thermomechanics of shape memory polymer nanocomposites. Mech. Mater. 2004, 36, 929–940. [Google Scholar] [CrossRef]

- Sharma, N.; Raj, T.; Jangra, K. Applications of nickel-titanium alloy. J. Eng. Technol. 2015, 5, 1. [Google Scholar] [CrossRef]

- Meier, H.; Haberland, C.; Frenzel, J.; Zarnetta, R. Selective Laser Melting of NiTi Shape Memory Components. In Innovative Developments in Design and Manufacturing; CRC Press: Boca Raton, FL, USA, 2009; pp. 251–256. [Google Scholar]

- Huang, W.; Yang, B.; An, L.; Li, C.; Chan, Y. Water-driven programmable polyurethane shape memory polymer: Demonstration and mechanism. Appl. Phys. Lett. 2005, 6, 114105. [Google Scholar] [CrossRef]

- Du, H.; Zhang, J. Solvent induced shape recovery of shape memory polymer based on chemically cross-linked poly (vinyl alcohol). Soft Matter 2010, 6, 3370–3376. [Google Scholar] [CrossRef]

- Wang, X.; Lu, H.; Shi, X.; Yu, K.; Fu, Y.Q. A thermomechanical model of multi-shape memory effect for amorphous polymer with tunable segment compositions. Compos. Part B Eng. 2019, 160, 298–305. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Progress Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Barbier, M.; Le Guen, M.J.; McDonald-Wharry, J.; Bridson, J.H.; Pickering, K.L. Quantifying the Shape Memory Performance of a Three-Dimensional-Printed Biobased Polyester/Cellulose Composite Material. 3D Print. Addit. Manuf. 2021, 8, 193–200. [Google Scholar] [CrossRef]

- Behl, M.; Lendlein, A. Actively moving polymers. Soft Matter 2007, 3, 58–67. [Google Scholar] [CrossRef]

- Monzón, M.; Paz, R.; Pei, E.; Ortega, F.; Suárez, L.; Ortega, Z.; Alemán, M.E.; Plucinski, T.; Clow, N. 4D printing: Processability and measurement of recovery force in shape memory polymers. Intern. J. Adv. Manuf. Technol. 2017, 89, 1827–1836. [Google Scholar] [CrossRef]

- Wu, T.; Frydrych, M.; O’Kelly, K.; Chen, B. Poly (glycerol sebacate urethane)-cellulose nanocomposites with water-active shape-memory effects. Biomacromolecules 2014, 15, 2663–2671. [Google Scholar] [CrossRef] [PubMed]

- Jing, X.; Mi, H.-Y.; Huang, H.-X.; Turng, L.-S. Shape memory thermoplastic polyurethane (TPU)/poly (ε-caprolactone)(PCL) blends as self-knotting sutures. J. Mech. Behav. Biomed. Mater. 2016, 64, 94–103. [Google Scholar] [CrossRef] [PubMed]

- Baker, R.M.; Tseng, L.-F.; Iannolo, M.T.; Oest, M.E.; Henderson, J.H. Self-deploying shape memory polymer scaffolds for grafting and stabilizing complex bone defects: A mouse femoral segmental defect study. Biomaterial 2016, 76, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Senatov, F.; Zadorozhnyy, M.Y.; Niaza, K.; Medvedev, V.; Kaloshkin, S.; Anisimova, N.Y.; Kiselevskiy, M.V.; Yang, K.-C. Shape memory effect in 3D-printed scaffolds for self-fitting implants. Eur. Polym. J. 2017, 93, 222–231. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.; Kaloshkin, S.; Estrin, Y. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Leist, S.K.; Gao, D.; Chiou, R.; Zhou, J. Investigating the shape memory properties of 4D printed polylactic acid (PLA) and the concept of 4D printing onto nylon fabrics for the creation of smart textiles. Virtual Phys. Prototype. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Ganguly, S.; Das, P. Synthesis and Production of Polylactic Acid (PLA). In Polylactic Acid-Based Nanocellulose and Cellulose Composites; CRC Press: Boca Raton, FL, USA, 2022; pp. 29–50. [Google Scholar]

- Wei, Z.; Sandstroröm, R.; Miyazaki, S. Shape-memory materials and hybrid composites for smart systems: Part I Shape-memory materials. J. Mater. Sci. 1998, 33, 3743–3762. [Google Scholar] [CrossRef]

- Grijpma, D.; Penning, J.; Pennings, A. Chain entanglement, mechanical properties and drawability of poly (lactide). Colloid Polym. Sci. 1994, 272, 1068–1081. [Google Scholar] [CrossRef]

- Sun, Y.-C.; Wan, Y.; Nam, R.; Chu, M.; Naguib, H.E. 4D-printed hybrids with localized shape memory behaviour: Implementation in a functionally graded structure. Sci. Rep. 2019, 9, 18754. [Google Scholar] [CrossRef] [PubMed]

- Barmouz, M.; Behravesh, A.H. Shape memory behaviors in cylindrical shell PLA/TPU-cellulose nanofiber bio-nanocomposites: Analytical and experimental assessment. Compos. Part A Appl. Sci. Manuf. 2017, 101, 160–172. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- John, M.J.; Dyanti, N.; Mokhena, T.; Agbakoba, V.; Sithole, B. Design and development of cellulosic bionanocomposites from forestry waste residues for 3d printing applications. Material 2021, 14, 3462. [Google Scholar] [CrossRef]

- Cao, L.; Liu, C.; Zou, D.; Zhang, S.; Chen, Y. Using cellulose nanocrystals as sustainable additive to enhance mechanical and shape memory properties of PLA/ENR thermoplastic vulcanizates. Carbohydr. Polym. 2020, 230, 115618. [Google Scholar] [CrossRef]

- Saralegi, A.; Gonzalez, M.L.; Valea, A.; Eceiza, A.; Corcuera, M.A. The role of cellulose nanocrystals in the improvement of the shape-memory properties of castor oil-based segmented thermoplastic polyurethanes. Compos. Sci. Technol. 2014, 92, 27–33. [Google Scholar] [CrossRef]

- Hassouna, F.; Raquez, J.-M.; Addiego, F.; Dubois, P.; Toniazzo, V.; Ruch, D. New approach on the development of plasticized polylactide (PLA): Grafting of poly (ethylene glycol)(PEG) via reactive extrusion. Eur. Polym. J. 2011, 47, 2134–2144. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Haq, M.I.U. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Op. Compos. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Yang, Z.; Jia, S.; Niu, Y.; Lv, X.; Fu, H.; Zhang, Y.; Liu, D.; Wang, B.; Li, Q. Bean-Pod-Inspired 3D-Printed Phase Change Microlattices for Solar-Thermal Energy Harvesting and Storage. Small 2021, 17, 2101093. [Google Scholar] [CrossRef] [PubMed]

- Huda, M.; Drzal, L.; Mohanty, A.; Misra, M. The effect of silane treated-and untreated-talc on the mechanical and physico-mechanical properties of poly (lactic acid)/newspaper fibers/talc hybrid composites. Compos. Part B Eng. 2007, 38, 367–379. [Google Scholar] [CrossRef]

- Hedenberg, P.; Gatenholm, P. Conversion of plastic/cellulose waste into composites. I. Model of the interphase. J. Appl. Polym. Sci. 1995, 56, 641–651. [Google Scholar] [CrossRef]

- Hassouna, F.; Raquez, J.-M.; Addiego, F.; Toniazzo, V.; Dubois, P.; Ruch, D. New development on plasticized poly (lactide): Chemical grafting of citrate on PLA by reactive extrusion. Eur. Polym. J. 2012, 48, 404–415. [Google Scholar] [CrossRef]

- Yong, A.X.; Sims, G.D.; Gnaniah, S.J.; Ogin, S.L.; Smith, P.A. Heating rate effects on thermal analysis measurement of T g in composite materials. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 43–51. [Google Scholar] [CrossRef]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polimer. 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Wunderlich, B. Thermal Analysis; Academic Press: San Diego, CA, USA, 1990; pp. 171–180. [Google Scholar]

- Li, H.; Cao, Z.; Wu, D.; Tao, G.; Zhong, W.; Zhu, H.; Qiu, P.; Liu, C. Crystallisation, mechanical properties and rheological behaviour of PLA composites reinforced by surface modified microcrystalline cellulose. Plast. Rubber Compos. 2016, 45, 181–187. [Google Scholar] [CrossRef]

- Serizawa, S.; Inoue, K.; Iji, M. Kenaf-fiber-reinforced poly (lactic acid) used for electronic products. J. Appl. Polym. Sci. 2006, 100, 618–624. [Google Scholar] [CrossRef]

- Dong, J.; Mei, C.; Han, J.; Lee, S.; Wu, Q. 3D printed poly (lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Addit. Manuf. 2019, 28, 621–628. [Google Scholar] [CrossRef]

- Zhao, L.; Wei, Y.; Zhang, G.W.; Xi, F. Short-term creep properties and creep model of wood-plastic composites. Polym. Compos. 2022, 43, 924–933. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterial 2018, 8, 49. [Google Scholar] [CrossRef] [PubMed]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman press: Valleyford, WA, USA, 1996. [Google Scholar]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Herrera, N.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Chacón, J.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

| Sample Description | Filament Diameter (mm) | CNC c Content (wt.%) | Tensile Strength (MPa) | Elongation at Break (%) | Melting Temp (°C) | Glass Transition Temp (°C) |

|---|---|---|---|---|---|---|

| PLASCE a | 1.66 (±0.05) | 0 | 28.9 (±1.52) | 15.8 (±4.34) | 166.43 | 56.72 |

| PLACNC0.1%b | 1.68 (±0.05) | 0.1 | 35.3 (±1.79) | 15.4 (±4.31) | 164.16 | 56.29 |

| PLACNC0.5%b | 1.67 (±0.06) | 0.5 | 33.4 (±2.07) | 13.1 (±4.61) | 163.59 | 54.48 |

| PLACNC1%b | 1.74(±0.04) | 1 | 35.1 (±4.07) | 25.5 (±5.38) | 165.30 | 49.22 |

| Static Bending Force (at 30° C) | ||

|---|---|---|

| Sample Description | Flexural Modulus, E (MPa) | Flexural Strain εmax (%) |

| PLASCE | 1291.86 (±130.40) | 1.42 (±0.14) |

| PLACNC0.1% | 1892.17 (±59.72) | 0.99 (±0.03) |

| PLACNC0.5% | 1871.16 (±54.06) | 0.97 (±0.03) |

| PLACNC1% | 1674.18 (±186.73) | 0.99 (±0.19) |

| Sample Description | Findley Model Parameters | ||

|---|---|---|---|

| k | n | R2 | |

| PLASCE | 1.7689 | 0.3387 | 0.9995 |

| PLACNC0.1% | 0.6119 | 0.5785 | 0.9994 |

| PLACNC0.5% | 0.7185 | 0.4838 | 0.9994 |

| PLACNC1% | 0.9617 | 0.4424 | 0.9999 |

| Sample Description | CNC a Content (wt.%) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|---|

| PLASCE | 0 | 22.86 ±1.24 | 1205.08 ±185.80 | 11.36 ±0.72 |

| PLACNC0.1% | 0.1 | 27.08 ±1.87 | 1856.00 ±857.01 | 16.34 ±4.64 |

| PLACNC0.5% | 0.5 | 29.33 ±1.32 | 2693.94 ±257.07 | 9.36 ±1.36 |

| PLACNC1% | 1 | 28.10 ±0.75 | 2131.33 ±246.09 | 7.20 ±0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agbakoba, V.C.; Hlangothi, P.; Andrew, J.; John, M.J. Mechanical and Shape Memory Properties of 3D-Printed Cellulose Nanocrystal (CNC)-Reinforced Polylactic Acid Bionanocomposites for Potential 4D Applications. Sustainability 2022, 14, 12759. https://doi.org/10.3390/su141912759

Agbakoba VC, Hlangothi P, Andrew J, John MJ. Mechanical and Shape Memory Properties of 3D-Printed Cellulose Nanocrystal (CNC)-Reinforced Polylactic Acid Bionanocomposites for Potential 4D Applications. Sustainability. 2022; 14(19):12759. https://doi.org/10.3390/su141912759

Chicago/Turabian StyleAgbakoba, Victor Chike, Percy Hlangothi, Jerome Andrew, and Maya Jacob John. 2022. "Mechanical and Shape Memory Properties of 3D-Printed Cellulose Nanocrystal (CNC)-Reinforced Polylactic Acid Bionanocomposites for Potential 4D Applications" Sustainability 14, no. 19: 12759. https://doi.org/10.3390/su141912759

APA StyleAgbakoba, V. C., Hlangothi, P., Andrew, J., & John, M. J. (2022). Mechanical and Shape Memory Properties of 3D-Printed Cellulose Nanocrystal (CNC)-Reinforced Polylactic Acid Bionanocomposites for Potential 4D Applications. Sustainability, 14(19), 12759. https://doi.org/10.3390/su141912759