Diesel Spray: Development of Spray in Diesel Engine

Abstract

1. Introduction

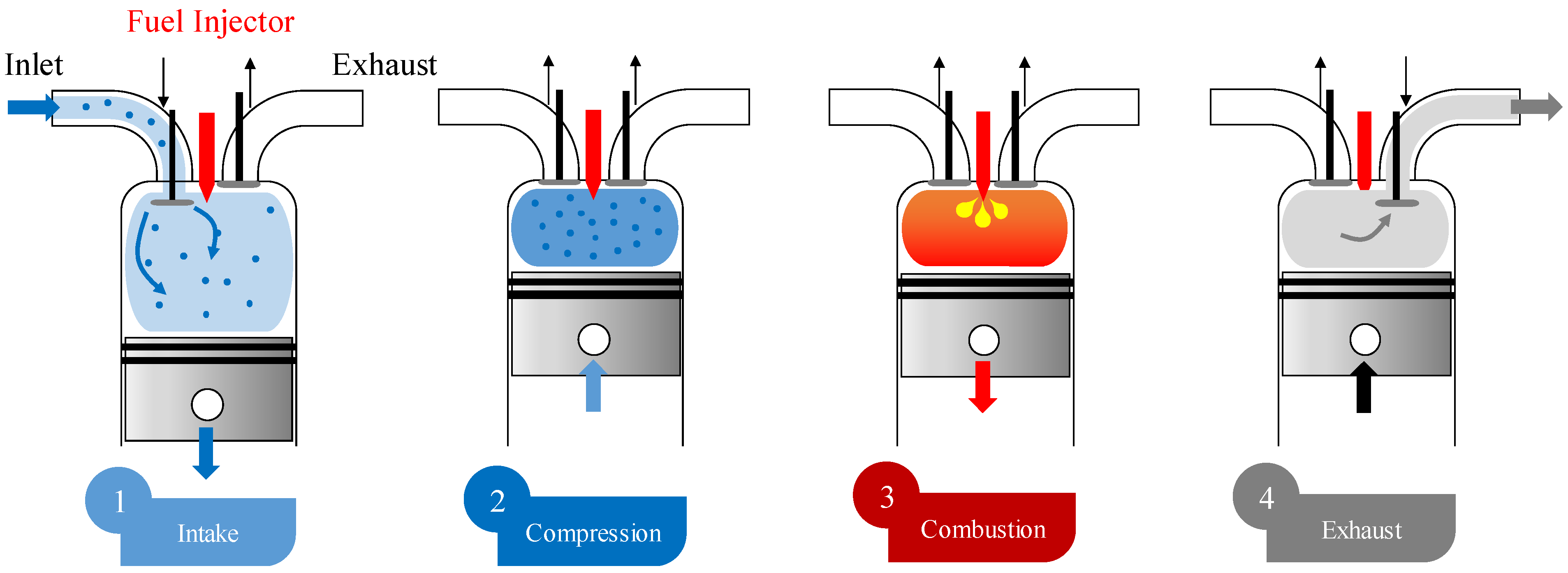

2. Diesel Combustion Process

3. Spray Atomization

- Spray core: high dense spray region, the closer to the injector is, the denser it is.

- Spray angle: a bigger spray angle gives wider spatial distribution.

- Break-up length: a part of the liquid in the spray that does not disintegrate.

- Spray tip penetration: the macroscopic development of diesel spray.

4. Factors Affecting Spray Evolution

5. Modeling of Turbulent Diesel Spray and Combustion

6. Optical Measurement Systems

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, J.; Yu, L.; Xue, R.; Zhuang, S.; Shan, Y. Global low-carbon energy transition in the post-COVID-19 era. Appl. Energy 2022, 307, 118205. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, W.; Xia, C.; Hou, Q. Application and Development of Selective Catalytic Reduction Technology for Marine Low-Speed Diesel Engine: Trade-Off among High Sulfur Fuel, High Thermal Efficiency, and Low Pollution Emission. Atmosphere 2022, 13, 731. [Google Scholar] [CrossRef]

- Mohan, S.; Dinesha, P.; Kumar, S. NOx reduction behaviour in copper zeolite catalysts for ammonia SCR systems: A review. Chem. Eng. J. 2020, 384, 123253. [Google Scholar] [CrossRef]

- Damma, D.; Ettireddy, P.R.; Reddy, B.M.; Smirniotis, P.G. A Review of Low Temperature NH3-SCR for Removal of NOx. Catalysts 2019, 9, 349. [Google Scholar] [CrossRef]

- Bytnerowicz, A.; Omasa, K.; Paoletti, E. Integrated effects of air pollution and climate change on forests: A northern hemisphere perspective. Environ. Pollut. 2007, 147, 438–445. [Google Scholar] [CrossRef]

- Veza, I.; Said, M.F.M.; Latiff, Z.A. Improved Performance, Combustion and Emissions of SI Engine Fuelled with Butanol: A Review. Int. J. Automot. Mech. Eng. 2020, 17, 7648–7666. [Google Scholar] [CrossRef]

- Rusli, M.Q.; Said, M.F.M.; Sulaiman, A.M.; Roslan, M.F.; Veza, I.; Perang, M.R.M.; Lau, H.L.N.; Wafti, N.S.A. Performance and Emission Measurement of a Single Cylinder Diesel Engine Fueled with Palm Oil Biodiesel Fuel Blends. IOP Conf. Series Mater. Sci. Eng. 2021, 1068, 012020. [Google Scholar] [CrossRef]

- Fan, B.; Pan, J.; Yang, W.; Chen, W.; Bani, S. The influence of injection strategy on mixture formation and combustion process in a direct injection natural gas rotary engine. Appl. Energy 2017, 187, 663–674. [Google Scholar] [CrossRef]

- Chen, W.; Pan, J.; Yang, W.; Liu, Y.; Fan, B.; Lu, Y.; Otchere, P. Stratified combustion characteristics analysis and assisted-ignition strategy optimization in a natural gas blended diesel Wankel engine. Fuel 2021, 292, 120192. [Google Scholar] [CrossRef]

- GWang, G.; Yu, W.; Li, X.; Yang, R. Influence of fuel injection and intake port on combustion characteristics of controllable intake swirl diesel engine. Fuel 2020, 262, 116548. [Google Scholar]

- Cao, D.N.; Hoang, A.T.; Luu, H.Q.; Bui, V.G.; Tran, T.T.H. Effects of injection pressure on the NOx and PM emission control of diesel engine: A review under the aspect of PCCI combustion condition. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 23, 2908–2920. [Google Scholar] [CrossRef]

- Sener, R.; Yangaz, M.U.; Gul, M.Z. Effects of injection strategy and combustion chamber modification on a single-cylinder diesel engine. Fuel 2020, 266, 117122. [Google Scholar] [CrossRef]

- Chen, H.; Su, X.; He, J.; Zhang, P.; Xu, H.; Zhou, C. Investigation on combustion characteristics of cyclopentanol/diesel fuel blends in an optical engine. Renew. Energy 2020, 167, 811–829. [Google Scholar] [CrossRef]

- Zhang, M.; Hong, W.; Xie, F.; Su, Y.; Liu, H.; Zhou, S. Combustion, performance and particulate matter emissions analysis of operating parameters on a GDI engine by traditional experimental investigation and Taguchi method. Energy Convers. Manag. 2018, 164, 344–352. [Google Scholar] [CrossRef]

- La Rocca, A.; Ferrante, A.; Haffner-Staton, E.; Cairns, A.; Weilhard, A.; Sans, V.; Carlucci, A.P.; Laforgia, D. Investigating the impact of copper leaching on combustion characteristics and particulate emissions in HPCR diesel engines. Fuel 2020, 263, 116719. [Google Scholar] [CrossRef]

- Dhahad, H.A.; Fayad, M.A.; Chaichan, M.T.; Jaber, A.A.; Megaritis, T. Influence of fuel injection timing strategies on performance, combustion, emissions and particulate matter characteristics fueled with rapeseed methyl ester in modern diesel engine. Fuel 2021, 306, 121589. [Google Scholar] [CrossRef]

- Attia, A.M.; Kulchitskiy, A.; Nour, M.; El-Seesy, A.I.; Nada, S.A. The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matters composition. Energy 2022, 239, 121951. [Google Scholar] [CrossRef]

- Song, J.; Lee, Z.; Song, J.; Park, S. Effects of injection strategy and coolant temperature on hydrocarbon and particulate emissions from a gasoline direct injection engine with high pressure injection up to 50 MPa. Energy 2018, 164, 512–522. [Google Scholar] [CrossRef]

- Wang, Z.; Dai, X.; Li, F.; Li, Y.; Lee, C.-F.; Wu, H.; Li, Z. Nozzle internal flow and spray primary breakup with the application of closely coupled split injection strategy. Fuel 2018, 228, 187–196. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Shao, K.; Liu, Y.; Chen, X.; Qian, Y. Analyzing the combustion and emissions of a DI diesel engine powered by primary alcohol (methanol, ethanol, n-butanol)/diesel blend with aluminum nano-additives. Fuel 2022, 328, 125222. [Google Scholar] [CrossRef]

- Ooi, J.B.; Chow, M.R.; Chee, K.M.; Pun, C.H.; Tran, M.-V.; Leong, J.C.K.; Lim, S. Effects of ethanol on the evaporation and burning characteristics of palm-oil based biodiesel droplet. J. Energy Inst. 2021, 98, 35–43. [Google Scholar]

- Wu, F.; Wang, H.; Yu, H.; Zang, X.; Pan, X.; Hua, M.; Jiang, J. Experimental study on the lower explosion limit and mechanism of methanol pre-mixed spray under negative pressure. Fuel 2022, 321, 124049. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, C.; Ning, Y.; Lv, X.; Yu, X.; Yan, X.; Yu, J. Experimental determination of the lower flammability limit and limiting oxygen concentration of propanal/air mixtures under elevated temperatures and pressures. Fuel 2022, 326, 124882. [Google Scholar] [CrossRef]

- Wang, H.; Luo, K.; Hawkes, E.R.; Chen, J.H.; Fan, J. Turbulence, evaporation and combustion interactions in n-heptane droplets under high pressure conditions using DNS. Combust. Flame 2021, 225, 417–427. [Google Scholar] [CrossRef]

- Rajasegar, R.; Niki, Y.; Li, Z.; García-Oliver, J.M.; Musculus, M.P. Influence of pilot-fuel mixing on the spatio-temporal progression of two-stage autoignition of diesel-sprays in low-reactivity ambient fuel-air mixture. Proc. Combust. Inst. 2021, 38, 5741–5750. [Google Scholar] [CrossRef]

- Dec, J.E. A conceptual model of DL diesel combustion based on laser-sheet imaging. SAE Trans. 1997, 106, 1319–1348. [Google Scholar]

- Demarco, R.; Jerez, A.; Liu, F.; Chen, L.; Fuentes, A. Modeling soot formation in laminar coflow ethylene inverse diffusion flames. Combust. Flame 2021, 232, 111513. [Google Scholar] [CrossRef]

- Wang, L.-Y.; Chatterjee, S.; An, Q.; Steinberg, A.M.; Gülder, L. Soot formation and flame structure in swirl-stabilized turbulent non-premixed methane combustion. Combust. Flame 2019, 209, 303–312. [Google Scholar] [CrossRef]

- Li, B.; Zhang, D.; Liu, J.; Tian, Y.; Gao, Q.; Li, Z. A Review of Femtosecond Laser-Induced Emission Techniques for Combustion and Flow Field Diagnostics. Appl. Sci. 2019, 9, 1906. [Google Scholar] [CrossRef]

- Ruan, C.; Chen, F.; Cai, W.; Qian, Y.; Yu, L.; Lu, X. Principles of non-intrusive diagnostic techniques and their applications for fundamental studies of combustion instabilities in gas turbine combustors: A brief review. Aerosp. Sci. Technol. 2019, 84, 585–603. [Google Scholar] [CrossRef]

- Cheng, Q.; Ahmad, Z.; Kaario, O.; Vuorinen, V.; Larmi, M. Experimental study on tri-fuel combustion using premixed methane-hydrogen mixtures ignited by a diesel pilot. Int. J. Hydrog. Energy 2021, 46, 21182–21197. [Google Scholar] [CrossRef]

- Beatrice, C.; Denbratt, I.; Di Blasio, G.; Di Luca, G.; Ianniello, R.; Saccullo, M. Experimental Assessment on Exploiting Low Carbon Ethanol Fuel in a Light-Duty Dual-Fuel Compression Ignition Engine. Appl. Sci. 2020, 10, 7182. [Google Scholar] [CrossRef]

- Abdelaal, M.; Hegab, A. Combustion and emission characteristics of a natural gas-fueled diesel engine with EGR. Energy Convers. Manag. 2012, 64, 301–312. [Google Scholar] [CrossRef]

- Gehmlich, R.; Mueller, C.; Ruth, D.; Nilsen, C.; Skeen, S.; Manin, J. Using ducted fuel injection to attenuate or prevent soot formation in mixing-controlled combustion strategies for engine applications. Appl. Energy 2018, 226, 1169–1186. [Google Scholar] [CrossRef]

- Rao, L.; Zhang, Y.; Kim, D.; Su, H.C.; Kook, S.; Kim, K.S.; Kweon, C.-B. Effect of after injections on late cycle soot oxidation in a small-bore diesel engine. Combust. Flame 2018, 191, 513–526. [Google Scholar] [CrossRef]

- Fayad, M.A.; Al-Salihi, H.A.; Dhahad, H.A.; Mohammed, F.M.; Al-Ogidi, B.R. Effect of post-injection and alternative fuels on combustion, emissions and soot nanoparticles characteristics in a common-rail direct injection diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–15. [Google Scholar] [CrossRef]

- Gad, H.; Ibrahim, I.; Abdel-Baky, M.; El-Samed, A.A.; Farag, T. Experimental study of diesel fuel atomization performance of air blast atomizer. Exp. Therm. Fluid Sci. 2018, 99, 211–218. [Google Scholar] [CrossRef]

- Zhang, P.; Su, X.; Yi, C.; Chen, H.; Xu, H.; Geng, L. Spray, atomization and combustion characteristics of oxygenated fuels in a constant volume bomb: A review. J. Traffic Transp. Eng. Engl. Ed. 2020, 7, 282–297. [Google Scholar] [CrossRef]

- Xia, J.; Huang, Z.; Xu, L.; Ju, D.; Lu, X. Experimental study on spray and atomization characteristics under subcritical, transcritical and supercritical conditions of marine diesel engine. Energy Convers. Manag. 2019, 195, 958–971. [Google Scholar] [CrossRef]

- YSun, Y.; Guan, Z.; Hooman, K. Cavitation in Diesel Fuel Injector Nozzles and its Influence on Atomization and Spray. Chem. Eng. Technol. 2019, 42, 6–29. [Google Scholar]

- Anez, J.; Ahmed, A.; Hecht, N.; Duret, B.; Reveillon, J.; Demoulin, F. Eulerian–Lagrangian spray atomization model coupled with interface capturing method for diesel injectors. Int. J. Multiph. Flow 2019, 113, 325–342. [Google Scholar] [CrossRef]

- Kim, Y.-I.; Kim, S.; Yang, H.-M.; Lee, K.-Y.; Choi, Y.-S. Analysis of internal flow and cavitation characteristics for a mixed-flow pump with various blade thickness effects. J. Mech. Sci. Technol. 2019, 33, 3333–3344. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Bai, X.R.; Long, X.P.; Ji, B.; Peng, X.X.; Farhat, M. Large eddy simulation of the tip-leakage cavitating flow with an insight on how cavitation influences vorticity and turbulence. Appl. Math. Model. 2020, 77, 788–809. [Google Scholar] [CrossRef]

- Mamaikin, D.; Knorsch, T.; Rogler, P.; Wensing, M. Experimental investigation of flow field and string cavitation inside a transparent real-size GDI nozzle. Exp. Fluids 2020, 61, 154. [Google Scholar] [CrossRef]

- Zhou, J.; Andersson, M. An analysis of surface breakup induced by laser-generated cavitation bubbles in a turbulent liquid jet. Exp. Fluids 2020, 61, 242. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Z.; Liu, J.; Wu, J.; Yu, Y.; Ding, J. Numerical Study on Primary Breakup of Disturbed Liquid Jet Sprays Using a VOF Model and LES Method. Processes 2022, 10, 1148. [Google Scholar] [CrossRef]

- Trummler, T.; Schmidt, S.J.; Adams, N.A. Investigation of condensation shocks and re-entrant jet dynamics in a cavitating nozzle flow by Large-Eddy Simulation. Int. J. Multiph. Flow 2020, 125, 103215. [Google Scholar] [CrossRef]

- Chryssakis, C.A.; Assanis, D.N.; Tanner, F.X. Atomization Models. In Handbook of Atomization and Sprays: Theory and Applications; Ashgriz, N., Ed.; Springer: Boston, MA, USA, 2011; pp. 215–231. [Google Scholar]

- Alozie, N.S.; Ganippa, L.C. Diesel Exhaust Emissions and Mitigations; IntechOpen: London, UK, 2019. [Google Scholar]

- Zhou, L.; Zhao, W.; Luo, K.H.; Wei, H.; Xie, M. Spray–turbulence–chemistry interactions under engine-like conditions. Prog. Energy Combust. Sci. 2021, 86, 100939. [Google Scholar] [CrossRef]

- Chintagunti, S.J.; Kalwar, A.; Kumar, D.; Agarwal, A.K. Spray Chamber Designs and Optical Techniques for Fundamental Spray Investigations. In Novel Internal Combustion Engine Technologies for Performance Improvement and Emission Reduction; Springer: Singapore, 2021; pp. 105–144. [Google Scholar]

- Hamdi, F.; Agrebi, S.; Idrissi, M.S.; Mondo, K.; Labiadh, Z.; Sadiki, A.; Chrigui, M. Impact of Spray Cone Angle on the Performances of Methane/Diesel RCCI Engine Combustion under Low Load Operating Conditions. Entropy 2022, 24, 650. [Google Scholar] [CrossRef]

- Zhan, C.; Luo, H.; Chang, F.; Nishida, K.; Ogata, Y.; Tang, C.; Feng, Z.; Huang, Z. Experimental study on the droplet characteristics in the spray tip region: Comparison between the free and impinging spray. Exp. Therm. Fluid Sci. 2020, 121, 110288. [Google Scholar] [CrossRef]

- Peraza, J.E.; Salvador, F.J.; Gimeno, J.; Ruiz, S. ECN Spray D visualization of the spray interaction with a transparent wall under engine-like conditions. Part I: Non-reactive impinging spray. Fuel 2022, 307, 121699. [Google Scholar] [CrossRef]

- Peraza, J.E.; Payri, R.; Gimeno, J.; Martí-Aldaraví, P. ECN Spray D visualization of the spray interaction with a transparent wall under engine-like conditions, Part II: Impinging spray combustion. Fuel 2022, 308, 121964. [Google Scholar] [CrossRef]

- Aizawa, T.; Kinoshita, T.; Akiyama, S.; Shinohara, K.; Miyagawa, Y. Infrared high-speed thermography of combustion chamber wall impinged by diesel spray flame. Int. J. Engine Res. 2021, 23, 1116–1130. [Google Scholar] [CrossRef]

- Yang, K.; Nishida, K.; Yamakawa, H. Effect of split injection ratio on combustion process of diesel spray into two-dimensional piston cavity. Fuel 2020, 260, 116316. [Google Scholar] [CrossRef]

- Mahmud, R.; Kurisu, T.; Nishida, K.; Ogata, Y.; Kanzaki, J.; Akgol, O. Effects of injection pressure and impingement distance on flat-wall impinging spray flame and its heat flux under diesel engine-like condition. Adv. Mech. Eng. 2019, 11, 1687814019862910. [Google Scholar] [CrossRef]

- Bothell, J.K.; Machicoane, N.; Li, D.; Morgan, T.B.; Aliseda, A.; Kastengren, A.L.; Heindel, T.J. Comparison of X-ray and optical measurements in the near-field of an optically dense coaxial air-assisted atomizer. Int. J. Multiph. Flow 2020, 125, 103219. [Google Scholar] [CrossRef]

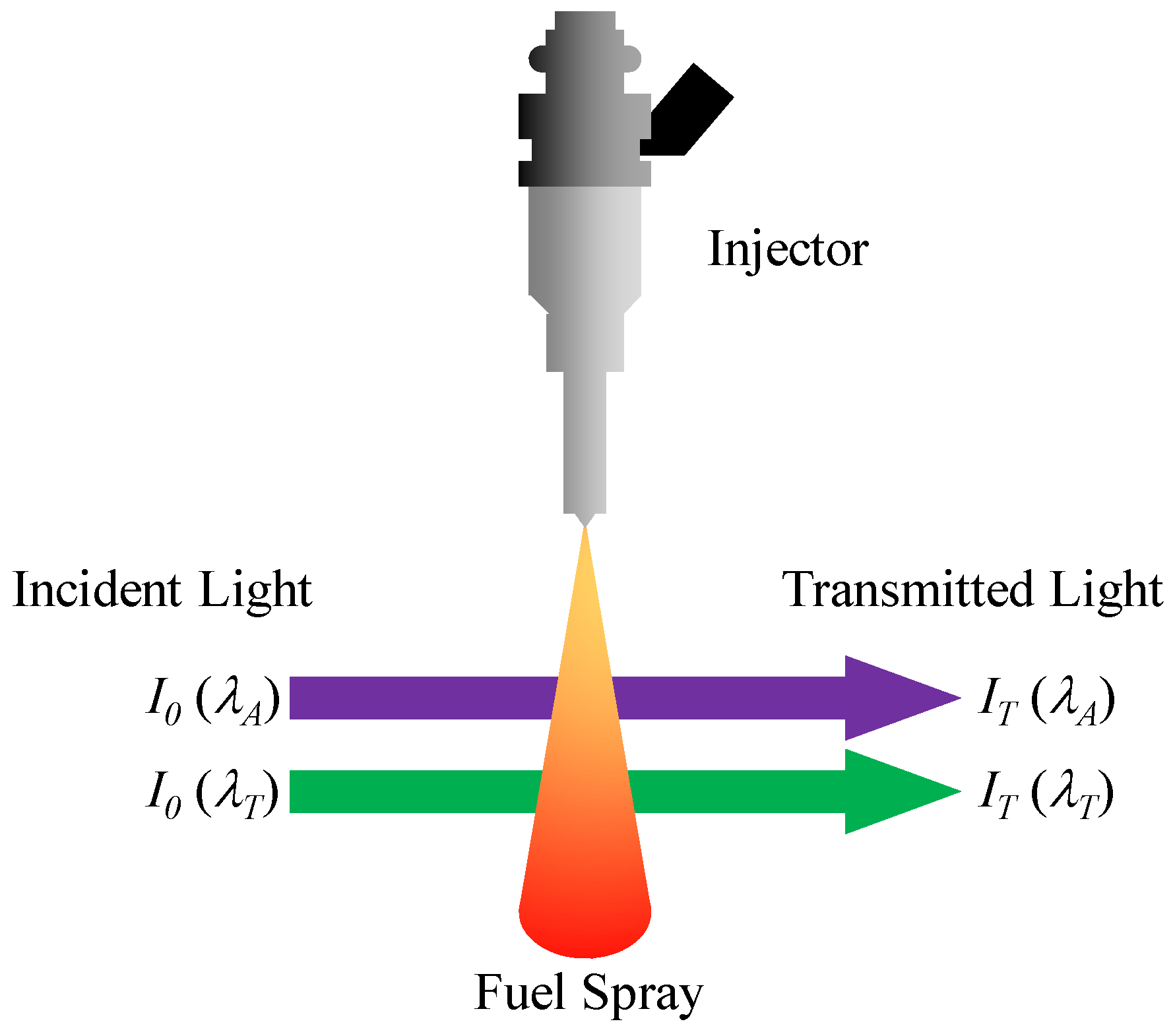

- Chen, R.; Nishida, K.; Shi, B. Quantitative investigation on the spray mixture formation for ethanol-gasoline blends via UV–Vis dual-wavelength laser absorption scattering (LAS) technique. Fuel 2019, 242, 425–437. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Kong, Q.; Li, B.; Wang, H. Sulfur dioxide absorption by charged droplets in electrohydrodynamic atomization. Int. Commun. Heat Mass Transf. 2022, 137, 106275. [Google Scholar] [CrossRef]

- Jia, H.; Wei, Z.; Yin, B.; Liu, Z. Analysis of elliptical diesel nozzle spray dynamics using a one-way coupled spray model. Int. J. Engine Res. 2021, 14680874211063352. [Google Scholar] [CrossRef]

- Xie, K.; Cui, Y.; Qiu, X.; Wang, J. Experimental study on flame characteristics and air entrainment of diesel horizontal spray burners at two different atmospheric pressures. Energy 2020, 211, 118906. [Google Scholar] [CrossRef]

- Wei, Y.; Li, T.; Zhou, X.; Zhang, Z. Time-resolved measurement of the near-nozzle air entrainment of high-pressure diesel spray by high-speed micro-PTV technique. Fuel 2020, 268, 117343. [Google Scholar] [CrossRef]

- Wei, Y.; Li, T.; Chen, R.; Zhou, X.; Zhang, Z.; Wang, X. Measurement and modeling of the near-nozzle ambient gas entrainment of high-pressure diesel sprays. Fuel 2022, 310, 122373. [Google Scholar] [CrossRef]

- Santos, E.G.; Shi, J.; Gavaises, M.; Soteriou, C.; Winterbourn, M.; Bauer, W. Investigation of cavitation and air entrainment during pilot injection in real-size multi-hole diesel nozzles. Fuel 2020, 263, 116746. [Google Scholar] [CrossRef]

- Hiroyasu, H.; Arai, M. Structures of fuel sprays in diesel engines. SAE Trans. 1990, 99, 1050–1061. [Google Scholar]

- Machicoane, N.; Bothell, J.K.; Li, D.; Morgan, T.B.; Heindel, T.J.; Kastengren, A.L.; Aliseda, A. Synchrotron radiography characterization of the liquid core dynamics in a canonical two-fluid coaxial atomizer. Int. J. Multiph. Flow 2019, 115, 1–8. [Google Scholar] [CrossRef]

- Kong, Q.; Yang, S.; Wang, Q.; Wang, Z.; Dong, Q.; Wang, J. Dynamics of electrified jets in electrohydrodynamic atomization. Case Stud. Therm. Eng. 2022, 29, 101725. [Google Scholar] [CrossRef]

- Berni, F.; Sparacino, S.; Riccardi, M.; Cavicchi, A.; Postrioti, L.; Borghi, M.; Fontanesi, S. A zonal secondary break-up model for 3D-CFD simulations of GDI sprays. Fuel 2022, 309, 122064. [Google Scholar] [CrossRef]

- Koukouvinis, P.; Vidal-Roncero, A.; Rodriguez, C.; Gavaises, M.; Pickett, L. High pressure/high temperature multiphase simulations of dodecane injection to nitrogen: Application on ECN Spray-A. Fuel 2020, 275, 117871. [Google Scholar] [CrossRef]

- Pielecha, I. The influence of petrol injection parameters on the structure of geometry of fuel spray injected from outward-opening injectors. Fuel 2018, 222, 64–73. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Martí-Aldaraví, P.; Martínez, M. Transient nozzle flow analysis and near field characterization of gasoline direct fuel injector using Large Eddy Simulation. Int. J. Multiph. Flow 2022, 148, 103920. [Google Scholar] [CrossRef]

- Cui, J.; Lai, H.; Feng, K.; Ma, Y. Quantitative analysis of the minor deviations in nozzle internal geometry effect on the cavitating flow. Exp. Therm. Fluid Sci. 2018, 94, 89–98. [Google Scholar] [CrossRef]

- Monieta, J.; Kasyk, L. Optimization of Design and Technology of Injector Nozzles in Terms of Minimizing Energy Losses on Friction in Compression Ignition Engines. Appl. Sci. 2021, 11, 7341. [Google Scholar] [CrossRef]

- Piscaglia, F.; Giussani, F.; Hèlie, J.; Lamarque, N.; Aithal, S. Vortex Flow and Cavitation in Liquid Injection: A Comparison between High-Fidelity CFD Simulations and Experimental Visualizations on Transparent Nozzle Replicas. Int. J. Multiph. Flow 2021, 138, 103605. [Google Scholar] [CrossRef]

- Yang, S.; Ma, Z.; Li, X.; Hung, D.L.; Xu, M. A review on the experimental non-intrusive investigation of fuel injector phase changing flow. Fuel 2020, 259, 116188. [Google Scholar] [CrossRef]

- Wang, C.; Adams, M.; Jin, T.; Sun, Y.; Röll, A.; Luo, F.; Gavaises, M. An analytical model of diesel injector’s needle valve eccentric motion. Int. J. Engine Res. 2022, 23, 469–481. [Google Scholar] [CrossRef]

- Gavaises, M.; Murali-Girija, M.; Rodriguez, C.; Koukouvinis, P.; Gold, M.; Pearson, R. Numerical simulation of fuel dribbling and nozzle wall wetting. Int. J. Engine Res. 2022, 23, 132–149. [Google Scholar] [CrossRef]

- Torres-Garcia, M.; García-Martín, J.F.; Aguilar, F.J.J.-E.; Barbin, D.F.; Alvarez-Mateos, P. Vegetable oils as renewable fuels for power plants based on low and medium speed diesel engines. J. Energy Inst. 2020, 93, 953–961. [Google Scholar] [CrossRef]

- Lee, Z.; Kim, T.; Park, S.; Park, S. Review on spray, combustion, and emission characteristics of recent developed direct-injection spark ignition (DISI) engine system with multi-hole type injector. Fuel 2020, 259, 116209. [Google Scholar] [CrossRef]

- Li, H.; Rutland, C.J.; Pérez, F.E.H.; Im, H.G. Large-eddy spray simulation under direct-injection spark-ignition engine-like conditions with an integrated atomization/breakup model. Int. J. Engine Res. 2021, 22, 731–754. [Google Scholar] [CrossRef]

- Guo, G.; He, Z.; Wang, Q.; Lai, M.-C.; Zhong, W.; Guan, W.; Wang, J. Numerical investigation of transient hole-to-hole variation in cavitation regimes inside a multi-hole diesel nozzle. Fuel 2021, 287, 119457. [Google Scholar] [CrossRef]

- Chouak, M.; Dufresne, L.; Seers, P. Large eddy simulation of a double-injection cycle and the impact of the needle motion on the sac-volume flow characteristics of a single-orifice diesel injector. Int. J. Engine Res. 2021, 22, 2464–2476. [Google Scholar] [CrossRef]

- Julien, L. Characteristics of Diesel Sprays at High Temperatures and Pressures. Ph.D. Thesis, The University of Brighton, Brighton, UK, 2006. [Google Scholar]

- Kale, R.; Banerjee, R. Experimental investigation on GDI spray behavior of isooctane and alcohols at elevated pressure and temperature conditions. Fuel 2019, 236, 1–12. [Google Scholar] [CrossRef]

- Zigan, L.; Schmitz, I.; Flügel, A.; Wensing, M.; Leipertz, A. Structure of evaporating single- and multicomponent fuel sprays for 2nd generation gasoline direct injection. Fuel 2011, 90, 348–363. [Google Scholar] [CrossRef]

- Han, J.-S.; Lu, P.-H.; Xie, X.-B.; Lai, M.-C.; Henein, N.A. Investigation of diesel spray primary break-up and development for different nozzle geometries. SAE Trans. 2002, 111, 2528–2548. [Google Scholar]

- Yu, S.; Yin, B.; Bi, Q.; Jia, H.; Chen, C. Effects of gasoline and ethanol on inner flows and swallowtail-like spray behaviors of elliptical GDI injector. Fuel 2021, 294, 120543. [Google Scholar] [CrossRef]

- Som, S.; Longman, D.; Ramírez, A.; Aggarwal, S. A comparison of injector flow and spray characteristics of biodiesel with petrodiesel. Fuel 2010, 89, 4014–4024. [Google Scholar] [CrossRef]

- Battistoni, M.; Grimaldi, C.N. Numerical analysis of injector flow and spray characteristics from diesel injectors using fossil and biodiesel fuels. Appl. Energy 2012, 97, 656–666. [Google Scholar] [CrossRef]

- Kostas, J.; Honnery, D.; Soria, J. A correlation image velocimetry-based study of high-pressure fuel spray tip evolution. Exp. Fluids 2011, 51, 667–678. [Google Scholar] [CrossRef]

- Wu, G.; Zhou, X.; Li, T. Temporal Evolution of Split-Injected Fuel Spray at Elevated Chamber Pressures. Energies 2019, 12, 4284. [Google Scholar] [CrossRef]

- Klein-Douwel, R.J.H.; Frijters, P.J.M.; Somers, L.M.T.; de Boer, W.A.; Baert, R.S.G. Macroscopic diesel fuel spray shadowgraphy using high speed digital imaging in a high pressure cell. Fuel 2007, 86, 1994–2007. [Google Scholar] [CrossRef]

- Chen, L.; Li, G.; Huang, D.; Zhang, Z.; Lu, Y.; Yu, X.; Roskilly, A.P. Experimental and numerical study on the initial tip structure evolution of diesel fuel spray under various injection and ambient pressures. Energy 2019, 186, 115867. [Google Scholar] [CrossRef]

- Ghasemi, A.; Li, X.; Hong, Z.; Yun, S. Breakup mechanisms in air-assisted atomization of highly viscous pyrolysis oils. Energy Convers. Manag. 2020, 220, 113122. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, H.; Liu, C.; Jia, M.; Xi, X. Numerical investigation into primary breakup of diesel spray with residual bubbles in the nozzle. Fuel 2019, 250, 265–276. [Google Scholar] [CrossRef]

- Sykes, D.; Turner, J.; Stetsyuk, V.; de Sercey, G.; Gold, M.; Pearson, R.; Crua, C. Quantitative characterisations of spray deposited liquid films and post-injection discharge on diesel injectors. Fuel 2021, 289, 119833. [Google Scholar] [CrossRef]

- Fauchais, P.L.; Heberlein, J.V.; Boulos, M.I. Overview of thermal spray. In Thermal Spray Fundamentals; Springer: Berlin/Heidelberg, Germany, 2014; pp. 17–72. [Google Scholar]

- Zhang, X.; Ranjith, P.G. Experimental investigation of effects of CO2 injection on enhanced methane recovery in coal seam reservoirs. J. CO2 Util. 2019, 33, 394–404. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.H.; Medwell, P.R.; Chan, Q.N. A Review of Hydrogen Direct Injection for Internal Combustion Engines: Towards Carbon-Free Combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef]

- Boretti, A. Advances in Diesel-LNG Internal Combustion Engines. Appl. Sci. 2020, 10, 1296. [Google Scholar] [CrossRef]

- McTaggart-Cowan, G.; Mann, K.; Huang, J.; Singh, A.; Patychuk, B.; Zheng, Z.X.; Munshi, S. Direct Injection of Natural Gas at up to 600 Bar in a Pilot-Ignited Heavy-Duty Engine. SAE Int. J. Engines 2015, 8, 981–996. [Google Scholar] [CrossRef]

- Hamzehloo, A.; Aleiferis, P. Gas dynamics and flow characteristics of highly turbulent under-expanded hydrogen and methane jets under various nozzle pressure ratios and ambient pressures. Int. J. Hydrog. Energy 2016, 41, 6544–6566. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Internal flow and spray characteristics for elliptical orifice with large aspect ratio under typical diesel engine operation conditions. Fuel 2018, 228, 62–73. [Google Scholar] [CrossRef]

- Zhao, J.; Grekhov, L.; Yue, P. Limit of Fuel Injection Rate in the Common Rail System under Ultra-High Pressures. Int. J. Automot. Technol. 2020, 21, 649–656. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, F.; Zhang, Z.; Gao, H. Experimental investigation on the spray characteristics of a self-pressurized hollow cone injector. Fuel 2020, 272, 117710. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the diesel and biodiesel spray characteristics emerging from equilateral triangular orifice under real diesel engine operation conditions. Fuel 2018, 224, 357–365. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Jia, H.; Ye, Z.; Xu, B.; Xu, H. Experimental study on the spray characteristics discharging from elliptical diesel nozzle at typical diesel engine conditions. Fuel 2018, 221, 28–34. [Google Scholar] [CrossRef]

- Dhanji, M.; Zhao, H. Investigations of split injection properties on the spray characteristics using a solenoid high-pressure injector. Int. J. Engine Res. 2022, 23, 262–284. [Google Scholar] [CrossRef]

- Aleiferis, P.; Papadopoulos, N. Heat and mass transfer effects in the nozzle of a fuel injector from the start of needle lift to after the end of injection in the presence of fuel dribble and air entrainment. Int. J. Heat Mass Transf. 2021, 165, 120576. [Google Scholar] [CrossRef]

- Brulatout, J.; Garnier, F.; Seers, P. Interaction between a diesel-fuel spray and entrained air with single- and double-injection strategies using large eddy simulations. Propuls. Power Res. 2020, 9, 37–50. [Google Scholar] [CrossRef]

- Zhan, C.; Feng, Z.; Zhang, M.; Tang, C.; Huang, Z. Experimental investigation on effect of ethanol and di-ethyl ether addition on the spray characteristics of diesel/biodiesel blends under high injection pressure. Fuel 2018, 218, 1–11. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Macroscopic and microscopic characteristics of biofuel spray (biodiesel and alcohols) in CI engines: A review. Fuel 2021, 292, 120303. [Google Scholar] [CrossRef]

- Luo, H.; Nishida, K.; Uchitomi, S.; Ogata, Y.; Zhang, W.; Fujikawa, T. Microscopic behavior of spray droplets under flat-wall impinging condition. Fuel 2018, 219, 467–476. [Google Scholar] [CrossRef]

- Hawi, M.; Kosaka, H.; Sato, S.; Nagasawa, T.; Elwardany, A.; Ahmed, M. Effect of injection pressure and ambient density on spray characteristics of diesel and biodiesel surrogate fuels. Fuel 2019, 254, 115674. [Google Scholar] [CrossRef]

- Zhang, P.; Su, X.; Chen, H.; Geng, L.; Zhao, X. Assessing fuel properties effects of 2,5-dimethylfuran on microscopic and macroscopic characteristics of oxygenated fuel/diesel blends spray. Sci. Rep. 2020, 10, 1427. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Feng, L.; Wang, H.; Zheng, Z.; Chen, B.; Zhang, D.; Yao, M. Spray characteristics of gasoline/PODE and diesel/PODE blends in a constant volume chamber. Appl. Therm. Eng. 2019, 159, 113850. [Google Scholar] [CrossRef]

- Ulu, A.; Yildiz, G.; Özkol, Ü.; Rodriguez, A.D. Experimental investigation of spray characteristics of ethyl esters in a constant volume chamber. Biomass Convers. Biorefin. 2022, 23, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.; Bu, S.; Zhang, L.; Yuan, H.; Xu, W.; Liu, L.; Zhang, Z. Experimental and numerical investigation on the evaporation performance of a cyclone-type spray desalination chamber. Desalination 2019, 467, 125–135. [Google Scholar] [CrossRef]

- Sun, Y.; Alkhedhair, A.M.; Guan, Z.; Hooman, K. Numerical and experimental study on the spray characteristics of full-cone pressure swirl atomizers. Energy 2018, 160, 678–692. [Google Scholar] [CrossRef]

- Badawy, T.; Xu, H.; Li, Y. Macroscopic spray characteristics of iso-octane, ethanol, gasoline and methanol from a multi-hole injector under flash boiling conditions. Fuel 2022, 307, 121820. [Google Scholar] [CrossRef]

- Feng, L.; Sun, X.; Pan, X.; Yi, W.; Cui, Y.; Wang, Y.; Wen, M.; Ming, Z.; Liu, H.; Yao, M. Gasoline spray characteristics using a high pressure common rail diesel injection system by the method of laser induced exciplex fluorescence. Fuel 2021, 302, 121174. [Google Scholar] [CrossRef]

- Shi, Z.; Lee, C.-F.; Wu, H.; Wu, Y.; Zhang, L.; Liu, F. Optical diagnostics of low-temperature ignition and combustion characteristics of diesel/kerosene blends under cold-start conditions. Appl. Energy 2019, 251, 113307. [Google Scholar] [CrossRef]

- Cao, T.; He, Z.; Si, Z.; El-Seesy, A.I.; Guan, W.; Zhou, H.; Wang, Q. Optical experimental study on cavitation development with different patterns in diesel injector nozzles at different fuel temperatures. Exp. Fluids 2020, 61, 185. [Google Scholar] [CrossRef]

- Shi, Z.; Lee, C.-F.; Wu, H.; Li, H.; Wu, Y.; Zhang, L.; Bo, Y.; Liu, F. Effect of injection pressure on the impinging spray and ignition characteristics of the heavy-duty diesel engine under low-temperature conditions. Appl. Energy 2020, 262, 114552. [Google Scholar] [CrossRef]

- Yan, J.; Gao, S.; Liu, W.; Chen, T.; Lee, T.H.; Lee, C.-F. Experimental study of flash boiling spray with isooctane, hexane, ethanol and their binary mixtures. Fuel 2021, 292, 120415. [Google Scholar] [CrossRef]

- Han, M.; Gordon, R.L.; Talei, M.; Lacey, J.S. Ignition of dense, inhomogeneous fuel sprays at elevated pressures and temperatures. Fuel 2022, 321, 123853. [Google Scholar] [CrossRef]

- Wu, S.; Yang, S.; Wooldridge, M.; Xu, M. Experimental study of the spray collapse process of multi-hole gasoline fuel injection at flash boiling conditions. Fuel 2019, 242, 109–123. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, Y.; Qian, Z.; Roskilly, A.P. Spray and engine performance of cerium oxide nanopowder and carbon nanotubes modified alternative fuel. Fuel 2022, 320, 123952. [Google Scholar] [CrossRef]

- Reuss, D.L.; Kim, N.; Sjöberg, M. The influence of intake flow and coolant temperature on gasoline spray morphology during early-injection DISI engine operation. Int. J. Engine Res. 2022, 14680874221104301. [Google Scholar] [CrossRef]

- Duy, T.-N.; Nguyen, V.-T.; Phan, T.-H.; Hwang, H.-S.; Park, W.-G. Numerical analysis of ventilated cavitating flow around an axisymmetric object with different discharged temperature conditions. Int. J. Heat Mass Transf. 2022, 197, 123338. [Google Scholar] [CrossRef]

- Podbevšek, D.; Lokar, Ž.; Podobnikar, J.; Petkovšek, R.; Dular, M. Experimental evaluation of methodologies for single transient cavitation bubble generation in liquids. Exp. Fluids 2021, 62, 167. [Google Scholar] [CrossRef]

- Sanli, H.; Alptekin, E.; Canakci, M. Using low viscosity micro-emulsification fuels composed of waste frying oil-diesel fuel-higher bio-alcohols in a turbocharged-CRDI diesel engine. Fuel 2022, 308, 121966. [Google Scholar] [CrossRef]

- Bari, S.; Hossain, S.; Saad, I. A review on improving airflow characteristics inside the combustion chamber of CI engines to improve the performance with higher viscous biofuels. Fuel 2019, 264, 116769. [Google Scholar] [CrossRef]

- Hamid, M.F.; Idroas, M.Y.; Sa’ad, S.; Yew Heng, T.; Che Mat, S.; Zainal Alauddin, Z.A.; Shamsuddin, K.A.; Shuib, R.K.; Abdullah, M.K. Numerical investigation of fluid flow and in-cylinder air flow characteristics for higher viscosity fuel applications. Processes 2020, 8, 439. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, H.; Geng, C.; Tang, Q.; Feng, L.; Wang, Y.; Yi, W.; Zheng, Z.; Yao, M. Optical diagnostics on the effects of fuel properties and coolant temperatures on combustion characteristic and flame development progress from HCCI to CDC via PPC. Fuel 2020, 269, 117441. [Google Scholar] [CrossRef]

- Venu, H.; Raju, V.D.; Lingesan, S.; Soudagar, M.E.M. Influence of Al2O3nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, Combustion and Emission Characteristics. Energy 2021, 215, 119091. [Google Scholar] [CrossRef]

- Jhalani, A.; Sharma, D.; Soni, S.L.; Sharma, P.K.; Sharma, S. A comprehensive review on water-emulsified diesel fuel: Chemistry, engine performance and exhaust emissions. Environ. Sci. Pollut. Res. 2019, 26, 4570–4587. [Google Scholar] [CrossRef]

- Khandavalli, S.; Sharma-Nene, N.; Kabir, S.; Sur, S.; Rothstein, J.P.; Neyerlin, K.C.; Mauger, S.A.; Ulsh, M. Toward Optimizing Electrospun Nanofiber Fuel Cell Catalyst Layers: Polymer–Particle Interactions and Spinnability. ACS Appl. Polym. Mater. 2021, 3, 2374–2384. [Google Scholar] [CrossRef]

- Geo, V.E.; Prabhu, C.; Thiyagarajan, S.; Maiyalagan, T.; Aloui, F. Comparative analysis of various techniques to improve the performance of novel wheat germ oil—An experimental study. Int. J. Hydrog. Energy 2020, 45, 5745–5756. [Google Scholar]

- Broumand, M.; Albert-Green, S.; Yun, S.; Hong, Z.; Thomson, M.J. Spray combustion of fast pyrolysis bio-oils: Applications, challenges, and potential solutions. Prog. Energy Combust. Sci. 2020, 79, 100834. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Lee, H.J.; Han, J.; Park, D.-C.; Lee, J. Viscosity effect on the pressure swirl atomization of an alternative aviation fuel. Fuel 2019, 240, 179–191. [Google Scholar] [CrossRef]

- Thongchai, S.; Lim, O. Influence of Biodiesel Blended in Gasoline-Based Fuels on Macroscopic Spray Structure from a Diesel Injector. Int. J. Automot. Technol. 2019, 20, 701–711. [Google Scholar] [CrossRef]

- Liu, F.; Li, Z.; Wang, Z.; Dai, X.; He, X.; Lee, C.-F. Microscopic study on diesel spray under cavitating conditions by injecting fuel into water. Appl. Energy 2018, 230, 1172–1181. [Google Scholar] [CrossRef]

- Das, S.K.; Kim, K.; Lim, O. Experimental study on non-vaporizing spray characteristics of biodiesel-blended gasoline fuel in a constant volume chamber. Fuel Process. Technol. 2018, 178, 322–335. [Google Scholar] [CrossRef]

- Ashikhmin, A.E.; Khomutov, N.A.; Piskunov, M.V.; Yanovsky, V.A. Secondary Atomization of a Biodiesel Micro-Emulsion Fuel Droplet Colliding with a Heated Wall. Appl. Sci. 2020, 10, 685. [Google Scholar] [CrossRef]

- Patiño-Camino, R.; Cova-Bonillo, A.; Lapuerta, M.; Rodríguez-Fernández, J.; Segade, L. Surface tension of diesel-alcohol blends: Selection among fundamental and empirical models. Fluid Phase Equilibria 2022, 555, 113363. [Google Scholar] [CrossRef]

- Singh, G.; Pham, P.; Kourmatzis, A.; Masri, A. Effect of electric charge and temperature on the near-field atomization of diesel and biodiesel. Fuel 2019, 241, 941–953. [Google Scholar] [CrossRef]

- Panchasara, H.; Ashwath, N. Effects of Pyrolysis Bio-Oils on Fuel Atomisation—A Review. Energies 2021, 14, 794. [Google Scholar] [CrossRef]

- Pham, P.X.; Nguyen, K.T.; Pham, T.V.; Nguyen, V.H. Biodiesels Manufactured from Different Feedstock: From Fuel Properties to Fuel Atomization and Evaporation. ACS Omega 2020, 5, 20842–20853. [Google Scholar] [CrossRef]

- Antonov, D.V.; Kuznetsov, G.V.; Strizhak, P.A.; Fedorenko, R.M. Micro-explosion of droplets containing liquids with different viscosity, interfacial and surface tension. Chem. Eng. Res. Des. 2020, 158, 129–147. [Google Scholar] [CrossRef]

- Park, S.; Park, K. Principles and droplet size distributions of various spraying methods: A review. J. Mech. Sci. Technol. 2022, 36, 4033–4041. [Google Scholar] [CrossRef]

- Emerson, P.; Crockett, J.; Maynes, D. Thermal atomization during droplet impingement on superhydrophobic surfaces: Influence of Weber number and micropost array configuration. Int. J. Heat Mass Transf. 2021, 164, 120559. [Google Scholar] [CrossRef]

- Shlegel, N.; Tkachenko, P.; Strizhak, P. Influence of viscosity, surface and interfacial tensions on the liquid droplet collisions. Chem. Eng. Sci. 2020, 220, 115639. [Google Scholar] [CrossRef]

- Hoang, A.T.; Le, A.T.; Pham, V.V. A core correlation of spray characteristics, deposit formation, and combustion of a high-speed diesel engine fueled with Jatropha oil and diesel fuel. Fuel 2019, 244, 159–175. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, P.; Luo, H.; Ogata, Y.; Nishida, K. Investigation on fuel adhesion characteristics of wall-impingement spray under cross-flow conditions. Fuel 2022, 320, 123925. [Google Scholar] [CrossRef]

- Zhuang, Y.; Chi, H.; Huang, Y.; Teng, Q.; He, B.; Chen, W.; Qian, Y. Investigation of water spray evolution process of port water injection and its effect on engine performance. Fuel 2020, 282, 118839. [Google Scholar] [CrossRef]

- Sathiyamoorthi, R.; Sankaranarayanan, G.; Munuswamy, D.B.; Devarajan, Y. Experimental study of spray analysis for Palmarosa biodiesel-diesel blends in a constant volume chamber. Environ. Prog. Sustain. Energy 2021, 40, e13696. [Google Scholar] [CrossRef]

- Biswal, A.; Kale, R.; Balusamy, S.; Banerjee, R.; Kolhe, P. Lemon peel oil as an alternative fuel for GDI engines: A spray characterization perspective. Renew. Energy 2019, 142, 249–263. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, S.; Guo, X.; Jia, C.; Huang, X.; Wang, Y.; Huang, H. Experimental Research on the Macroscopic and Microscopic Spray Characteristics of Diesel-PODE3-4 Blends. Energies 2021, 14, 5559. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, F.; Zhang, Z. Fundamental spray characteristics of air-assisted injection system using aviation kerosene. Fuel 2021, 286, 119420. [Google Scholar] [CrossRef]

- Suraj, C.; Sudarshan, G.; Anand, K.; Sundararajan, T. Effects of autooxidation on the fuel spray characteristics of Karanja biodiesel. Biomass Bioenergy 2021, 149, 106084. [Google Scholar] [CrossRef]

- Yan, J.; Gao, S.; Zhao, W.; Lee, T.H.; Lee, C.-F. Experimental study of sprays with isooctane, hexane, ethanol and their binary mixtures under different flash boiling intensities. Int. J. Heat Mass Transf. 2021, 179, 121715. [Google Scholar] [CrossRef]

- Mei, S.S.; Rahman, A.A.A.; Abidin, M.S.Z.; Mazlan, N.M. d2 Law and Penetration Length of Jatropha and Camelina Bio-Synthetic Paraffinic Kerosene Spray Characteristics at Take-Off, Top of Climb and Cruise. Aerospace 2021, 8, 249. [Google Scholar]

- Wang, Y.; Zhuang, Y.; Yao, M.; Qin, Y.; Zheng, Z. An experimental investigation into the soot particle emissions at early injection timings in a single-cylinder research diesel engine. Fuel 2022, 316, 123288. [Google Scholar] [CrossRef]

- Hwang, J.; Weiss, L.; Karathanassis, I.K.; Koukouvinis, P.; Pickett, L.M.; Skeen, S.A. Spatio-temporal identification of plume dynamics by 3D computed tomography using engine combustion network spray G injector and various fuels. Fuel 2020, 280, 118359. [Google Scholar] [CrossRef]

- Yi, P.; Li, T.; Wei, Y.; Zhou, X. Experimental and numerical investigation of low sulfur heavy fuel oil spray characteristics under high temperature and pressure conditions. Fuel 2021, 286, 119327. [Google Scholar] [CrossRef]

- Zhou, Z.-F.; Liang, L.; Murad, S.H.M.; Camm, J.; Davy, M. Investigation of fuel volatility on the heat transfer dynamics on piston surface due to the pulsed spray impingement. Int. J. Heat Mass Transf. 2021, 170, 121008. [Google Scholar] [CrossRef]

- He, X.; Li, Y.; Liu, C.; Sjöberg, M.; Vuilleumier, D.; Liu, F.; Yang, Q. Characteristics of spray and wall wetting under flash-boiling and non-flashing conditions at varying ambient pressures. Fuel 2020, 264, 116683. [Google Scholar] [CrossRef]

- Bao, J.; Qu, P.; Wang, H.; Zhou, C.; Zhang, L.; Shi, C. Implementation of various bowl designs in an HPDI natural gas engine focused on performance and pollutant emissions. Chemosphere 2022, 303, 135275. [Google Scholar] [CrossRef] [PubMed]

- Hoang, A.T. Combustion behavior, performance and emission characteristics of diesel engine fuelled with biodiesel containing cerium oxide nanoparticles: A review. Fuel Process. Technol. 2021, 218, 106840. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N.; Pugazhendhi, A. Performance, combustion and emission analysis of microalgae Spirulina in a common rail direct injection diesel engine. Fuel 2019, 255, 115855. [Google Scholar] [CrossRef]

- Hoang, A.T.; Le, A.T. A review on deposit formation in the injector of diesel engines running on biodiesel. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 584–599. [Google Scholar] [CrossRef]

- Jenny, P.; Roekaerts, D.; Beishuizen, N. Modeling of turbulent dilute spray combustion. Prog. Energy Combust. Sci. 2012, 38, 846–887. [Google Scholar] [CrossRef]

- Huang, H.; Lv, D.; Zhu, J.; Zhu, Z.; Chen, Y.; Pan, Y.; Pan, M. Development of a new reduced diesel/natural gas mechanism for dual-fuel engine combustion and emission prediction. Fuel 2019, 236, 30–42. [Google Scholar] [CrossRef]

- Pang, K.M.; Jangi, M.; Bai, X.-S.; Schramm, J.; Walther, J.H.; Glarborg, P. Effects of ambient pressure on ignition and flame characteristics in diesel spray combustion. Fuel 2019, 237, 676–685. [Google Scholar] [CrossRef]

- Finesso, R.; Hardy, G.; Mancarella, A.; Marello, O.; Mittica, A.; Spessa, E. Real-time simulation of torque and nitrogen oxide emissions in an 11.0 L heavy-duty diesel engine for model-based combustion control. Energies 2019, 12, 460. [Google Scholar] [CrossRef]

- Rubio, J.A.P.; Vera-García, F.; Grau, J.H.; Cámara, J.M.; Hernandez, D.A. Marine diesel engine failure simulator based on thermodynamic model. Appl. Therm. Eng. 2018, 144, 982–995. [Google Scholar] [CrossRef]

- Yu, F. Numerical Studies of Nuclear Containment Spray Process by Stochastic Field Method and CGCFD Approach. Ph.D. Thesis, Institut für Thermische Energietechnik und Sicherheit, Karlsruhe, Germany, 2020. [Google Scholar]

- Boel, E.; Koekoekx, R.; Dedroog, S.; Babkin, I.; Vetrano, M.R.; Clasen, C.; Van den Mooter, G. Unraveling Particle Formation: From Single Droplet Drying to Spray Drying and Electrospraying. Pharmaceutics 2020, 12, 625. [Google Scholar] [CrossRef]

- Sharma, M.; Goyal, D.K.; Kaushal, G.; Grover, N.K.; Bansal, A.; Goyal, K. CFD and experimental study of slurry erosion wear in Hydro-machinery. Mater. Today Proc. 2022, 62, 7581–7594. [Google Scholar] [CrossRef]

- Han, S.; Zhang, R.; Song, Y.; Xing, J.; Zhou, L.; Li, L.; Zhang, H.; Du, X. Numerical study of swirl cooling enhancement by adding mist to air: Effects of droplet diameter and mist concentration. Appl. Therm. Eng. 2022, 211, 118475. [Google Scholar] [CrossRef]

- Venkatachalam, P.; Sahu, S.; Anupindi, K. Investigation of cross-stream spray injection and wall impingement in a circular channel for SCR application. Therm. Sci. Eng. Prog. 2022, 32, 101229. [Google Scholar] [CrossRef]

- Fansler, T.D.; Parrish, S. Spray measurement technology: A review. Meas. Sci. Technol. 2014, 26, 012002. [Google Scholar] [CrossRef]

- Leipertz, A.; Wensing, M. Modern optical diagnostics in engine research. J. Phys. Conf. Ser. 2007, 85, 012001. [Google Scholar] [CrossRef]

- Xu, H.E.; Yue, W.U.; Xiao, M.A.; Yanfei, L.I.; Yunliang, Q.I.; Zechang, L.I.U.; Yifan, X.U.; Yang, Z.H.O.U.; Xiongwei, L.I.; Cong, L.I.U.; et al. A review of optical diagnostic platforms and techniques applied in internal combustion engines. Shiyan Liuti Lixue (J. Exp. Fluid Mech.) 2020, 34, 1–52. [Google Scholar]

- Qi, W.; Zhang, Y. Quantitative measurement of binary-component fuel vapor distributions via laser absorption and scattering imaging. Appl. Phys. B 2019, 125, 127. [Google Scholar] [CrossRef]

- Zhou, Y.; Wei, Z.; Zhu, Q.; Cao, Y.; Zhang, Y. Quantitative characterization on cyclic variation of mixture formation for flash boiling sprays. Energy 2022, 257, 124808. [Google Scholar] [CrossRef]

- Jin, Y.; Wu, Q.; Zhai, C.; Kim, J.; Luo, H.-L.; Ogata, Y.; Nishida, K. Evaporating characteristics of diesel sprays under split-injection condition with a negative dwell time. Energetic Mater. Front. 2021, 2, 265–271. [Google Scholar] [CrossRef]

- Kim, D.; Park, S.S.; Bae, C. Schlieren, Shadowgraph, Mie-scattering visualization of diesel and gasoline sprays in high pressure/high temperature chamber under GDCI engine low load condition. Int. J. Automot. Technol. 2018, 19, 1–8. [Google Scholar] [CrossRef]

- Mounaïm-Rousselle, C.; Pajot, O. Droplet sizing by Mie scattering interferometry in a spark ignition engine. Part. Part. Syst. Charact. Meas. Descr. Part. Prop. Behav. Powders Other Disperse Syst. 1999, 16, 160–168. [Google Scholar] [CrossRef]

- Idicheria, C.A.; Pickett, L.M. Quantitative mixing measurements in a vaporizing diesel spray by Rayleigh imaging. SAE Trans. 2007, 116, 490–504. [Google Scholar]

- Pickett, L.M.; Genzale, C.L.; Manin, J.; Malbec, L.-M.; Hermant, L. Measurement uncertainty of liquid penetration in evaporating diesel sprays. In Proceedings of the ILASS Americas, 23rd Annual Conference on Liquid Atomization and Spray Systems, Ventura, CA, USA, 15–18 May 2011. [Google Scholar]

- Egermann, J.; Taschek, M.; Leipertz, A. Spray/wall interaction influences on the diesel engine mixture formation process investigated by spontaneous Raman scattering. Proc. Combust. Inst. 2002, 29, 617–623. [Google Scholar] [CrossRef]

- Egermann, J.; Göttler, A.; Leipertz, A. Application of spontaneous Raman scattering for studying the diesel mixture formation process under near-wall conditions. SAE Trans. 2001, 110, 2182–2188. [Google Scholar]

- Emberson, D.; Ihracska, B.; Imran, S.; Diez, A. Optical characterization of Diesel and water emulsion fuel injection sprays using shadowgraphy. Fuel 2016, 172, 253–262. [Google Scholar] [CrossRef]

- Gupta, J.G.; Agarwal, A.K. Macroscopic and Microscopic Spray Characteristics of Diesel and Karanja Biodiesel Blends; SAE Technical Paper0148-7191; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Payri, R.; Salvador, F.; Bracho, G.; Viera, A. Differences between single and double-pass schlieren imaging on diesel vapor spray characteristics. Appl. Therm. Eng. 2017, 125, 220–231. [Google Scholar] [CrossRef]

- Bruneaux, G. Mixing process in high pressure diesel jets by normalized laser induced exciplex fluorescence: Part i: Free jet. SAE Trans. 2005, 114, 1444–1461. [Google Scholar]

- Adam, A.; Leick, P.; Bittlinger, G.; Schulz, C. Visualization of the evaporation of a diesel spray using combined Mie and Rayleigh scattering techniques. Exp. Fluids 2009, 47, 439–449. [Google Scholar] [CrossRef]

- Liu, R.; Huang, L.; Feng, M.; Ju, D.; Ma, Z.; Lu, X. Schlieren and Mie Scattering Visualization of Liquid and Vapor Phase Behavior for Large Nozzle Diameter Injectors Under Marine Diesel Engine Conditions. SSRN 2022. [Google Scholar] [CrossRef]

- Markov, V.; Sa, B.; Devyanin, S.; Grekhov, L.; Neverov, V.; Zhao, J. Numerical analysis of injection and spray characteristics of diesel fuel and rapeseed oil in a diesel engine. Case Stud. Therm. Eng. 2022, 35, 102129. [Google Scholar] [CrossRef]

- Guan, W.; He, Z.; Zhang, L.; El-Seesy, A.I.; Wen, L.; Zhang, Q.; Yang, L. Effect of asymmetric structural characteristics of multi-hole marine diesel injectors on internal cavitation patterns and flow characteristics: A numerical study. Fuel 2021, 283, 119324. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, X.; Naber, J.; Lee, S.-Y. Assessment of impinged flame structure in high-pressure direct diesel injection. Int. J. Engine Res. 2020, 21, 391–405. [Google Scholar] [CrossRef]

- Jardón-Pérez, L.E.; González-Rivera, C.; Trápaga-Martínez, G.; Amaro-Villeda, A.; Ramírez-Argáez, M.A. Experimental Study of Mass Transfer Mechanisms for Solute Mixing in a Gas-Stirred Ladle Using the Particle Image Velocimetry and Planar Laser-Induced Fluorescence Techniques. Steel Res. Int. 2021, 92, 2100241. [Google Scholar] [CrossRef]

- Bilsky, A.V.; Gobyzov, O.A.; Markovich, D.M. Evolution and recent trends of particle image velocimetry for an aerodynamic experiment (review). Thermophys. Aeromech. 2020, 27, 1–22. [Google Scholar] [CrossRef]

- Jena, A.; Singh, A.P.; Agarwal, A.K. Challenges and Opportunities of Particle Imaging Velocimetry as a Tool for Internal Combustion Engine Diagnostics. In Novel Internal Combustion Engine Technologies for Performance Improvement and Emission Reduction; Springer: Singapore, 2021; pp. 43–77. [Google Scholar]

| Technique | Application | Phenomena Capturing | References |

|---|---|---|---|

| Mie Scattering | Diesel, gasoline engine | Liquid distribution of spray | Kim et al. [191] |

| Mie Scattering | Gasoline engine | Droplet size | Mounaïm-Rousselle and Pajot [192] |

| Raman Scattering | Diesel engine | Spray-wall interaction | Egermann et al. [195] |

| Raman Scattering | Diesel engine | Spray-wall interaction (near wall condition) | Egermann et al. [196] |

| Raylaigh Scattering | Diesel engine | Vaporizing diesel spray | Idicheria and Pickett [193] |

| Raylaigh Scattering | Diesel engine | Liquid penetration | Pickett et al. [194] |

| Schlieren | Diesel, gasoline engine | Vapor distribution | Kim et al. [191] |

| Schlieren | Diesel engine | Vaporizing diesel spray | Payri et al. [199] |

| Shadowgraphy | Diesel, gasoline engine | Vapor distribution (a mare shadow) | Kim et al. [191] |

| Shadowgraphy | Diesel engine | Diesel—water emulsion fuel injection sprays | Emberson et al. [197] |

| Phase doppler interferometry (PDI) | Diesel engine | Macroscopic and microscopic spray | Gupta and Agrawal [198] |

| Laser-induced (exciplex) fluorescence (LIF/LIEF) | Gasoline engine | Mixing process | Bruneaux [200] |

| Combined (Mie-Rayleigh) | Diesel engine | Evaporation of diesel spray | Adam et al. [201] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djamari, D.W.; Idris, M.; Paristiawan, P.A.; Abbas, M.M.; Samuel, O.D.; Soudagar, M.E.M.; Herawan, S.G.; Chandran, D.; Yusuf, A.A.; Panchal, H.; et al. Diesel Spray: Development of Spray in Diesel Engine. Sustainability 2022, 14, 15902. https://doi.org/10.3390/su142315902

Djamari DW, Idris M, Paristiawan PA, Abbas MM, Samuel OD, Soudagar MEM, Herawan SG, Chandran D, Yusuf AA, Panchal H, et al. Diesel Spray: Development of Spray in Diesel Engine. Sustainability. 2022; 14(23):15902. https://doi.org/10.3390/su142315902

Chicago/Turabian StyleDjamari, Djati Wibowo, Muhammad Idris, Permana Andi Paristiawan, Muhammad Mujtaba Abbas, Olusegun David Samuel, Manzoore Elahi M. Soudagar, Safarudin Gazali Herawan, Davannendran Chandran, Abdulfatah Abdu Yusuf, Hitesh Panchal, and et al. 2022. "Diesel Spray: Development of Spray in Diesel Engine" Sustainability 14, no. 23: 15902. https://doi.org/10.3390/su142315902

APA StyleDjamari, D. W., Idris, M., Paristiawan, P. A., Abbas, M. M., Samuel, O. D., Soudagar, M. E. M., Herawan, S. G., Chandran, D., Yusuf, A. A., Panchal, H., & Veza, I. (2022). Diesel Spray: Development of Spray in Diesel Engine. Sustainability, 14(23), 15902. https://doi.org/10.3390/su142315902