Automotive Electrification Challenges Shown by Real-World Driving Data and Lifecycle Assessment

Abstract

:1. Introduction

2. Literature Review

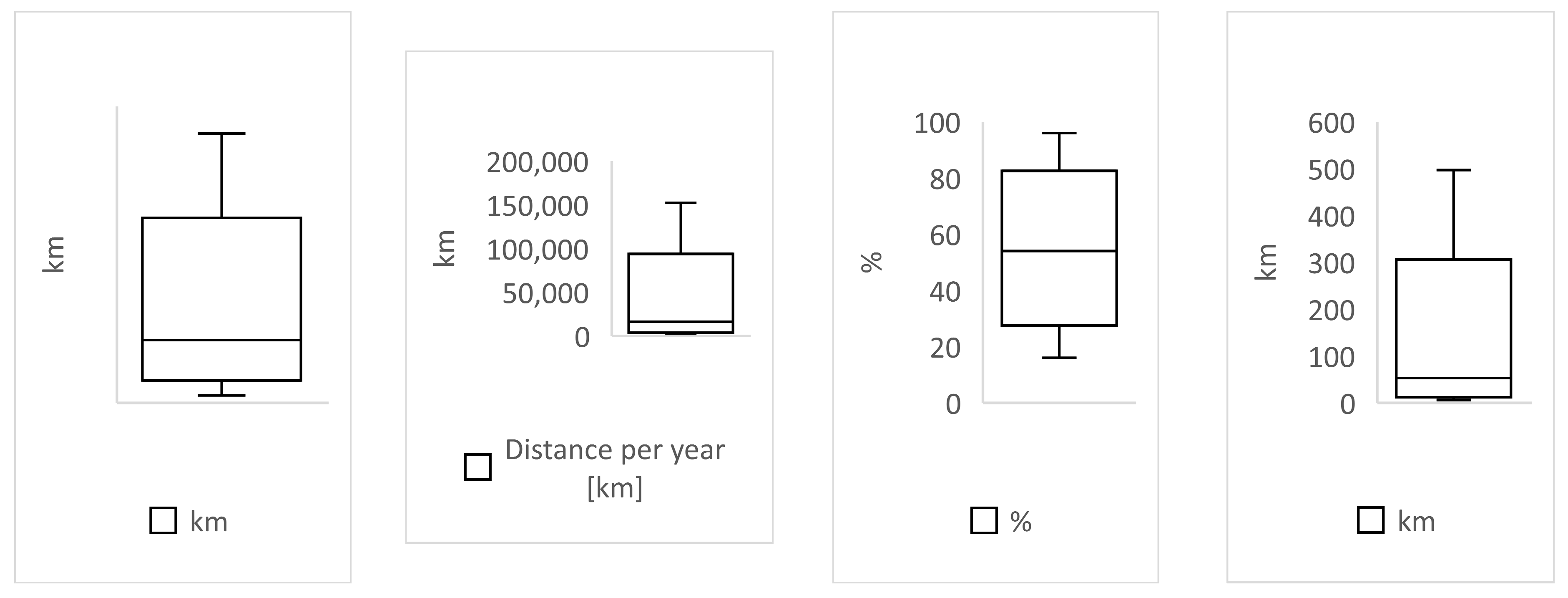

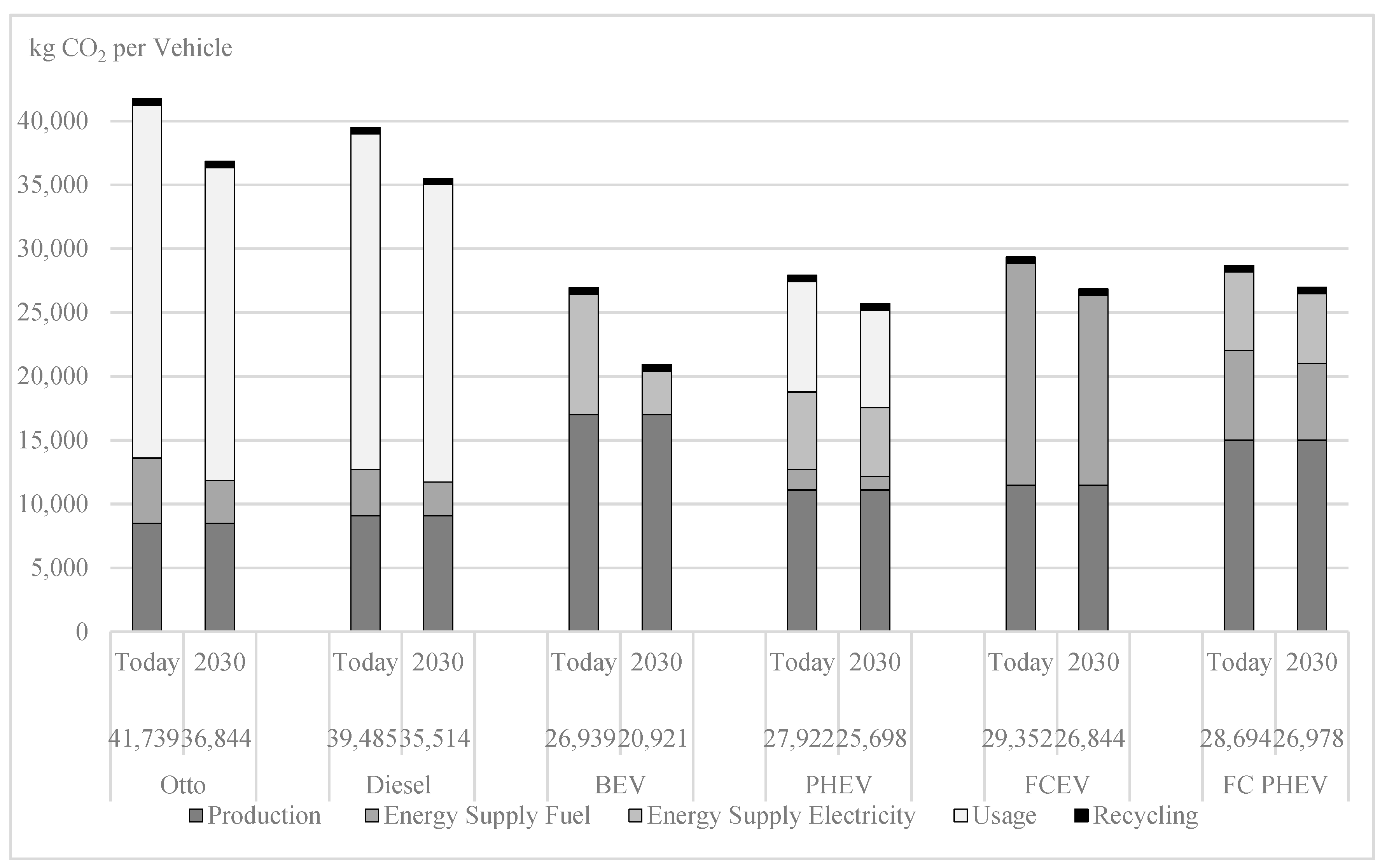

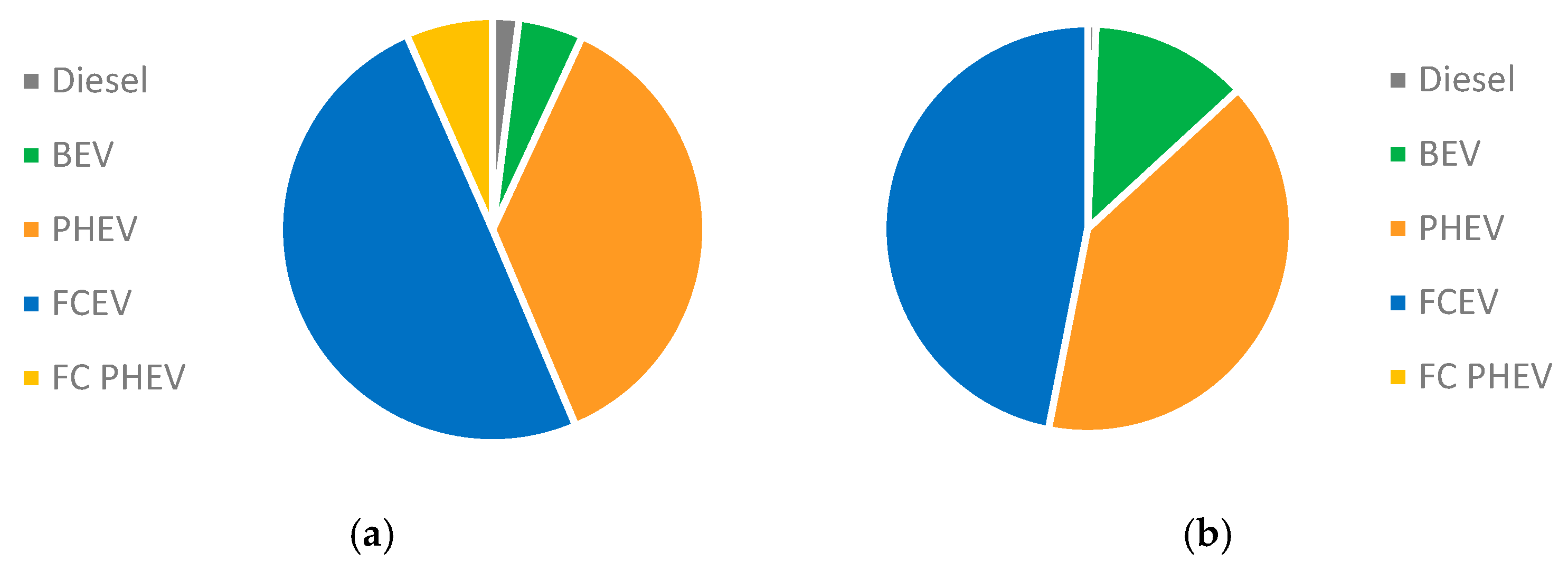

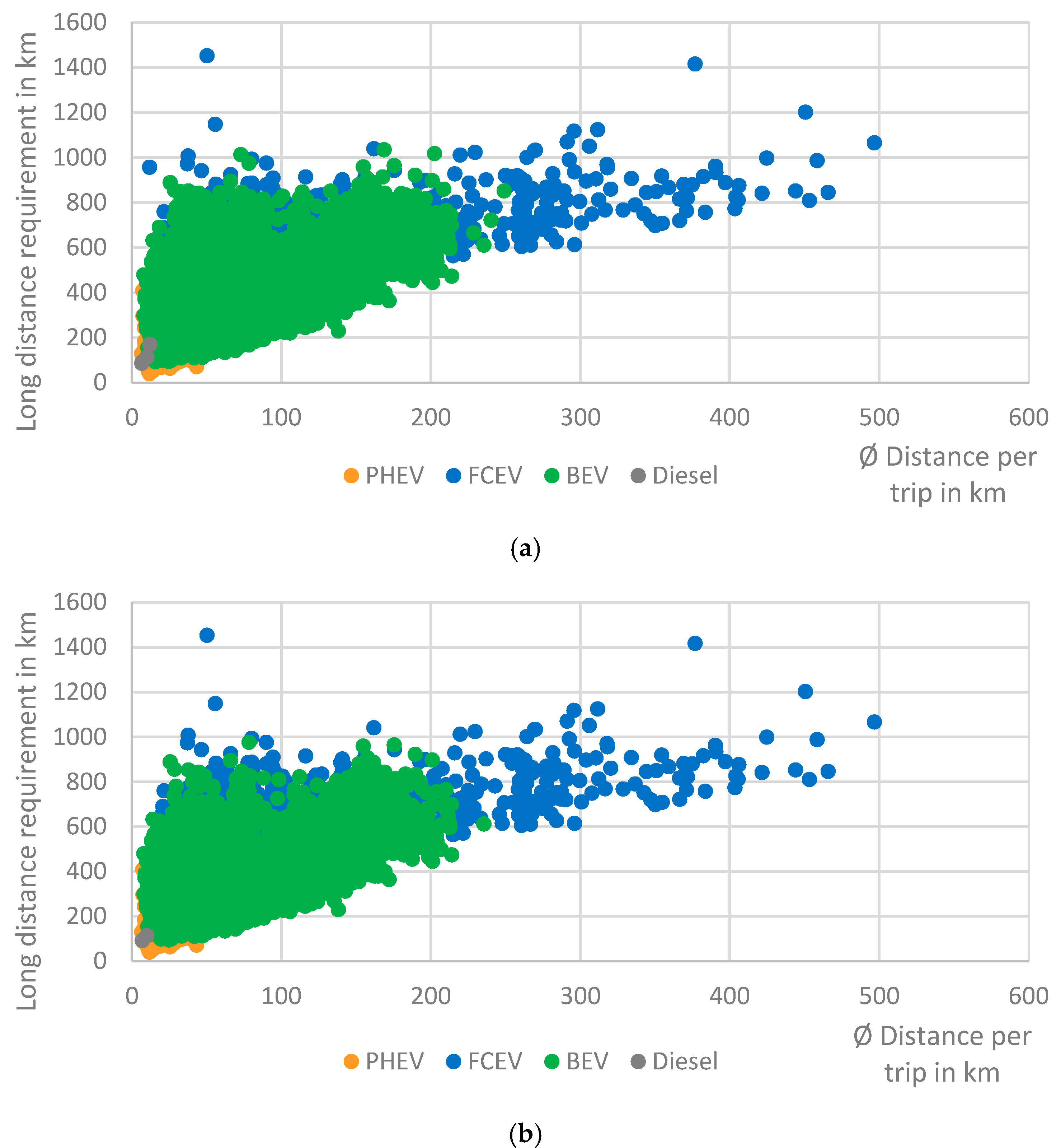

3. Methods: Analysis of the Environmentally Optimal Drivetrain Mix

4. Results

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EO | Engine OTTO |

| EP | Emissions during production |

| LD | Lifecycle distance |

| FC | Fuel consumption |

| EFS | Emissions during fuel supply |

| EDU | Emissions during driving usage |

| EL | Emissions for end of life/recycling |

| ED | Engine Diesel |

| EB | BEV |

| EES | Emissions required for electricity supply |

| EPH | PHEV |

| EF | FCEV |

References

- Xue, C.; Zhou, H.; Wu, Q.; Wu, X.; Xu, X. Impact of Incentive Policies and Other Socio-Economic Factors on Electric Vehicle Market Share: A Panel Data Analysis from the 20 Countries. Sustainability 2021, 13, 2928. [Google Scholar] [CrossRef]

- Zhao, J.; Zeng, D.; Che, L.; Zhou, T.; Hu, J. Research on the profit change of new energy vehicle closed-loop supply chain members based on government subsidies. Environ. Technol. Innov. 2020, 19, 100937. [Google Scholar] [CrossRef]

- BMU. Wie Umweltfreundlich Sind Elektroautos?: Eine Ganzheitliche Bilanz. 2018. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Pools/Broschueren/elektroautos_bf.pdf (accessed on 3 April 2019).

- Helms, H.; Jöhrens, J.; Kämper, C.; Giegrich, J.; Liebich, A. Weiterentwicklung und Vertiefte Analyse der Umweltbilanz von Elektrofahrzeugen. 2016. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/texte_27_2016_umweltbilanz_von_elektrofahrzeugen.pdf (accessed on 25 December 2021).

- Teufel, D.; Arnold, S.; Bauer, P.; Schwarz, T. Ökologische Folgen von Elektroautos: Ist die Staatliche Förderung von Elektro- und Hybridautos Sinnvoll? UPI-Bericht Nr. 79. 2015. Available online: https://www.upi-institut.de/UPI79_Elektroautos.pdf (accessed on 25 December 2021).

- Hawkins, T.R.; Gausen, O.M.; Strømman, A.H. Environmental impacts of hybrid and electric vehicles—A review. Int. J. Life Cycle Assess. 2012, 17, 997–1014. [Google Scholar] [CrossRef]

- Ortego, A.; Calvo, G.; Valero, A.; Iglesias-Émbil, M.; Valero, A.; Villacampa, M. Assessment of strategic raw materials in the automobile sector. Resour. Conserv. Recycl. 2020, 161, 104968. [Google Scholar] [CrossRef]

- Mas-Peiro, J.; Neidhardt, M.; Schmuelling, B.; Pou, J.O.; Gonzalez-Olmos, R. Fuel Cell Electric Vehicles: A Platinum and Other Raw Material Perspective Based on Vehicle Design and Technology Data. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2022, 3, 19–29. [Google Scholar] [CrossRef]

- Centre, J.R.; Institute for Environment and Sustainability. Well-to-Wheels Analysis of Future Automotive Fuels and Power Trains in the European Context: Report Version 3c. 2011. Available online: https://data.europa.eu/doi/10.2788/78759 (accessed on 25 December 2021).

- International Organization for Standardization. ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework, 2nd ed.; ISO/TC 207/SC 5 Life Cycle Assessment, 2006, 13.020.10 Environmental Management 13.020.60 Product Life-Cycles. Available online: https://www.iso.org/standard/37456.html (accessed on 4 December 2021).

- Larminie, J.; Lowry, J. Electric Vehicle Technology Explained, 2nd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2012; ISBN 1118361148. [Google Scholar]

- Schreiner, K. Verbrennungsmotor—Kurz und Bündig; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017; ISBN 9783658194260. [Google Scholar]

- Bieker, G. A Global Comparison of the Life-Cycle Greenhouse gas Emissions of Combustion Engine and Electric Passenger Cars | International Council on Clean Transportation. 2021. Available online: https://theicct.org/publications/global-LCA-passenger-cars-jul2021 (accessed on 6 January 2022).

- Petrauskienė, K.; Galinis, A.; Kliaugaitė, D.; Dvarionienė, J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability 2021, 13, 957. [Google Scholar] [CrossRef]

- Buchal, C.; Karl, H.-D.; Sinn, H.-W. Kohlemotoren, Windmotoren und Dieselmotoren: Was zeigt die CO2-Bilanz? ifo Schnelld. 2019, 72, 40–54. [Google Scholar]

- Agora Verkehrswende. Klimabilanz von Elektroautos: Einflussfaktoren und Verbesserungspotenzial. 2019. Available online: https://www.agora-verkehrswende.de/fileadmin/Projekte/2018/Klimabilanz_von_Elektroautos/Agora-Verkehrswende_22_Klimabilanz-von-Elektroautos_WEB.pdf (accessed on 19 February 2022).

- Macioszek, E. Electric Vehicles—Problems and Issues. In Scientific and Technical Conference Transport Systems Theory and Practice; Springer: Cham, Switzerland, 2020; pp. 169–183. [Google Scholar]

- Sun, B.; Gu, T.; Xie, M.; Wang, P.; Gao, S.; Zhang, X. Strategy Design and Performance Analysis of an Electromechanical Flywheel Hybrid Scheme for Electric Vehicles. Sustainability 2022, 14, 11017. [Google Scholar] [CrossRef]

- Macioszek, E. E-mobility Infrastructure in the Górnośląsko—Zagłębiowska Metropolis, Poland, and Potential for Development. In Proceedings of the 5th World Congress on New Technologies, Lisbon, Portugal, 18–20 August 2019. [Google Scholar]

- Rosenfeld, D.C.; Lindorfer, J.; Fazeni-Fraisl, K. Comparison of advanced fuels—Which technology can win from the life cycle perspective? J. Clean. Prod. 2019, 238, 117879. [Google Scholar] [CrossRef]

- Sacchi, R.; Bauer, C.; Cox, B.; Mutel, C. When, where and how can the electrification of passenger cars reduce greenhouse gas emissions? Renew. Sustain. Energy Rev. 2022, 162, 112475. [Google Scholar] [CrossRef]

- Nordelöf, A.; Romare, M.; Tivander, J. Life cycle assessment of city buses powered by electricity, hydrogenated vegetable oil or diesel. Transp. Res. Part D Transp. Environ. 2019, 75, 211–222. [Google Scholar] [CrossRef]

- Candelaresi, D.; Valente, A.; Iribarren, D.; Dufour, J.; Spazzafumo, G. Comparative life cycle assessment of hydrogen-fuelled passenger cars. Int. J. Hydrogen Energy 2021, 46, 35961–35973. [Google Scholar] [CrossRef]

- Harzendorf, F.; Wulf, C.; Haase, M.; Baumann, M.; Ersoy, H.; Zapp, P. Domestic value added as an indicator for sustainability assessment: A case study on alternative drivetrains in the passenger car sector. Clean Technol. Environ. Policy 2022, 24, 3145–3169. [Google Scholar] [CrossRef]

- Koj, J.C.; Wulf, C.; Linssen, J.; Schreiber, A.; Zapp, P. Utilisation of excess electricity in different Power-to-Transport chains and their environmental assessment. Transp. Res. Part D Transp. Environ. 2018, 64, 23–35. [Google Scholar] [CrossRef]

- Haase, M.; Wulf, C.; Baumann, M.; Ersoy, H.; Koj, J.C.; Harzendorf, F.; Mesa Estrada, L.S. Multi-criteria decision analysis for prospective sustainability assessment of alternative technologies and fuels for individual motorized transport. Clean Technol. Environ. Policy 2022, 24, 3171–3197. [Google Scholar] [CrossRef]

- Kraftfahrt-Bundesamt. Fahrzeugzulassungen (FZ): Neuzulassungen von Kraftfahrzeugen nach Umwelt-Merkmalen, Flensburg. 2018. Available online: https://www.kba.de/SharedDocs/Downloads/DE/Statistik/Fahrzeuge/FZ14/fz14_2018_pdf.pdf;jsessionid=5331E57BF5C2F573BD1A571C098001B0.live21321?__blob=publicationFile&v=1 (accessed on 20 September 2020).

- HSBC Research Team. Asia EV Battery: Charge! The Race to Be the Liion King Heats up. 2019. Available online: https://www.research.hsbc.com/R/34/TLk9KTp (accessed on 13 June 2019).

- European Environment Agency. Electric Vehicles from Life Cycle and Circular Economy Perspectives: TERM 2018: Transport and Environment Reporting Mechanism (TERM) Report; EEA report; European Environment Agency: Luxembourg, 2018. [Google Scholar]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future material demand for automotive lithium-based batteries. Commun. Mater. 2020, 1, 99. [Google Scholar] [CrossRef]

- Choi, W. A Study on State of Charge and State of Health Estimation in Consideration of Lithium-Ion Battery Aging. Sustainability 2020, 12, 10451. [Google Scholar] [CrossRef]

- Moon, J.; Kim, Y.J.; Cheong, T.; Song, S.H. Locating Battery Swapping Stations for a Smart e-Bus System. Sustainability 2020, 12, 1142. [Google Scholar] [CrossRef] [Green Version]

- Laurikko, J.; Granström, R.; Haakana, A. Realistic estimates of EV range based on extensive laboratory and field tests in Nordic climate conditions. World Electr. Veh. J. 2013, 6, 192–203. [Google Scholar] [CrossRef] [Green Version]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh. J. 2019, 10, 2. [Google Scholar] [CrossRef] [Green Version]

- Sarrafan, K.; Sutanto, D.; Muttaqi, K.M.; Town, G. Accurate range estimation for an electric vehicle including changing environmental conditions and traction system efficiency. IET Electr. Syst. Transp. 2017, 7, 117–124. [Google Scholar] [CrossRef]

- Daimler AG. Umweltzertifikat Mercedes-Benz A-Klasse. 2018. Available online: https://www.daimler.com/dokumente/nachhaltigkeit/produkt/daimler-umweltzertifikat-mb-a-klasse.pdf (accessed on 25 December 2021).

- Daimler AG. Environmental Certificate Mercedes-Benz GLC. 2015. Available online: https://www.daimler.com/images/sustainability/produkt/new-enviromentalcertificates/daimler-umweltzertifikat-compact-mb-glc.pdf (accessed on 25 December 2021).

- Daimler AG. Environmental Certificate Mercedes-Benz E-Class. 2016. Available online: https://www.daimler.com/documents/sustainability/product/daimler-environmental-certificate-mb-e-class.pdf (accessed on 25 December 2021).

- Horn, J. Stromer im Test: Wie gut ist der VW e-UP im Alltag? AUTO BILD. 13 February 2014. Available online: https://www.autobild.de/artikel/vw-e-up-test-4544079.html (accessed on 25 December 2021).

- Daimler AG. Umwelt-Zertifikat Mercedes-Benz S-Klasse: Inklusive S 500 Plug-in Hybrid. 2015. Available online: https://www.daimler.com/sustainability/environmental-certificates/ (accessed on 6 June 2019).

- Daimler AG. 360° Environmental Check: Mercedes-Benz GLC F-Cell. 2018. Available online: https://www.daimler.com/documents/sustainability/product/daimler-environmental-check-lifecycle-compact-glc-f-cell-en.pdf (accessed on 25 December 2021).

- Kroher, T. Elektro, Gas, Benzin, Diesel & Hybrid—Die Ökobilanz unserer Autos. 2019. Available online: https://www.adac.de/der-adac/motorwelt/reportagen-berichte/auto-innovation/studie-oekobilanz-pkw-antriebe-2018/## (accessed on 29 April 2019).

- Sternberg, A.; Hank, C.; Hebling, C. Treibhausgas-Emissionen für Batterie- und Brennstoffzellenfahrzeuge mit Reichweiten über 300 km. 2019. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/news/2019/ISE_Ergebnisse_Studie_Treibhausgasemissionen.pdf (accessed on 25 December 2021).

- BloombergNEF. Electric Vehicle Outlook 2019. 2019. Available online: https://legacy-assets.eenews.net/open_files/assets/2019/05/15/document_ew_02.pdf (accessed on 25 December 2021).

- Volkswagen AG Newsroom. Klimabilanz von E-Fahrzeugen & Life Cycle Engineering. 2019. Available online: https://uploads.volkswagen-newsroom.com/system/production/uploaded_files/14448/file/da01b16ac9b580a3c8bc190ea2af27db4e0d4546/Klimabilanz_von_E-Fahrzeugen_Life_Cycle_Engineering.pdf?1556110703 (accessed on 29 December 2021).

- Tietge, U.; Díaz, S.; Mock, P.; Bandivadekar, A.; Dornoff, J. From Laboratory to Road: A 2018 Update of Official and “Real-World” Fuel Consumption and CO2 Values for Passenger Cars in Europe. 2019. Available online: https://theicct.org/sites/default/files/publications/Lab_to_Road_2018_corrected-jul2021.pdf (accessed on 29 December 2021).

- Jato. SUV Become Best Selling Segment in Europe—JATO. Available online: https://www.jato.com/suv-takes-over-as-the-best-selling-segment-in-europe-for-the-first-time/ (accessed on 18 February 2022).

- Archsmith, J.; Kendall, A.; Rapson, D. From Cradle to Junkyard: Assessing the Life Cycle Greenhouse Gas Benefits of Electric Vehicles. Res. Transp. Econ. 2015, 52, 72–90. [Google Scholar] [CrossRef] [Green Version]

- Ellingsen, L.A.-W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Figenbaum, E. Perspectives on Norway’s supercharged electric vehicle policy. Environ. Innov. Soc. Transit. 2017, 25, 14–34. [Google Scholar] [CrossRef] [Green Version]

- Holland, S.P.; Mansur, E.T.; Muller, N.Z.; Yates, A.J. Are There Environmental Benefits from Driving Electric Vehicles? The Importance of Local Factors. Am. Econ. Rev. 2016, 106, 3700–3729. [Google Scholar] [CrossRef] [Green Version]

- Kampker, A. Elektromobilproduktion, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9783642420221. [Google Scholar]

- Korthauer, R. Handbuch Lithium-Ionen-Batterien, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 9783642306532. [Google Scholar]

- Tanç, B.; Arat, H.T.; Baltacıoğlu, E.; Aydın, K. Overview of the next quarter century vision of hydrogen fuel cell electric vehicles. Int. J. Hydrogen Energy 2019, 44, 10120–10128. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between hydrogen and electric vehicles by life cycle assessment: A case study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Shen, H.; Yi, E.; Cheng, L.; Amores, M.; Chen, G.; Sofie, S.W.; Doeff, M.M. Solid-state electrolyte considerations for electric vehicle batteries. Sustain. Energy Fuels 2019, 3, 1647–1659. [Google Scholar] [CrossRef]

- Ulvestad, A. A Brief Review of Current Lithium Ion Battery Technology and Potential Solid State Battery Technologies. 2018. Available online: https://arxiv.org/pdf/1803.04317 (accessed on 1 November 2022).

- Franco Gonzalez, A.; Yang, N.-H.; Liu, R.-S. Silicon Anode Design for Lithium-Ion Batteries: Progress and Perspectives. J. Phys. Chem. C 2017, 121, 27775–27787. [Google Scholar] [CrossRef]

- Tidblad, A.A.; Edström, K.; Hernández, G.; de Meatza, I.; Landa-Medrano, I.; Jacas Biendicho, J.; Trilla, L.; Buysse, M.; Ierides, M.; Horno, B.P.; et al. Future Material Developments for Electric Vehicle Battery Cells Answering Growing Demands from an End-User Perspective. Energies 2021, 14, 4223. [Google Scholar] [CrossRef]

- Northvolt. Environment | Northvolt. Available online: https://northvolt.com/environment/ (accessed on 4 January 2022).

- Automotive Cells Co. |Tackling Climate Change. Available online: https://www.acc-emotion.com/csr/climate (accessed on 4 August 2022).

- Verkor. Lithium-Ion Batteries: Ramp up and Accelerate Their Manufacture in Europe. Available online: https://verkor.com/en/drive/ (accessed on 4 January 2022).

- Kosai, S.; Nakanishi, M.; Yamasue, E. Vehicle energy efficiency evaluation from well-to-wheel lifecycle perspective. Transp. Res. Part D Transp. Environ. 2018, 65, 355–367. [Google Scholar] [CrossRef]

- Khaligh, A.; D’Antonio, M. Global Trends in High-Power On-Board Chargers for Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3306–3324. [Google Scholar] [CrossRef]

- Zhang, B.; Niu, N.; Li, H.; Wang, Z.; He, W. Could fast battery charging effectively mitigate range anxiety in electric vehicle usage? Evidence from large-scale data on travel and charging in Beijing. Transp. Res. Part D Transp. Environ. 2021, 95, 102840. [Google Scholar] [CrossRef]

- Tschöke, H. Die Elektrifizierung des Antriebsstrangs: Basiswissen; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2015; ISBN 9783658046446. [Google Scholar]

- Merker, G.P.; Schwarz, C.; Teichmann, R. Grundlagen Verbrennungsmotoren: Funktionsweise, Simulation, Messtechnik, 5, Vollständig Überarbeitete, Aktualisierte und Erweiterte Auflage; Vieweg+Teubner Verlag: Wiesbaden, Germany, 2011; ISBN 9783834883063. [Google Scholar]

- Sayed, K.; Kassem, A.; Saleeb, H.; Alghamdi, A.S.; Abo-Khalil, A.G. Energy-Saving of Battery Electric Vehicle Powertrain and Efficiency Improvement during Different Standard Driving Cycles. Sustainability 2020, 12, 10466. [Google Scholar] [CrossRef]

- BMU. Kurzinformationen Elektromobilität Bezüglich Strom- und Ressourcenbedarf. Available online: https://www.bmu.de/fileadmin/Daten_BMU/Download_PDF/Verkehr/emob_strom_ressourcen_bf.pdf (accessed on 29 December 2021).

- Neidhardt, M.; Mas-Peiro, J.; Schulz-Moenninghoff, M.; Pou, J.O.; Gonzalez-Olmos, R.; Kwade, A.; Schmuelling, B. Forecasting the Global Battery Material Flow: Analyzing the Break-Even Points at Which Secondary Battery Raw Materials Can Substitute Primary Materials in the Battery Production. Appl. Sci. 2022, 12, 4790. [Google Scholar] [CrossRef]

- Hyundai Motor Deutschland GmbH. Hyundai Ioniq Elektro | Technische Daten. 2018. Available online: https://www1.hyundai.news/fileadmin/de/Pressemappen/Ioniq_Elektro/Ioniq_Elektro_2018_3_Technische_Daten.pdf (accessed on 5 March 2020).

- Audi AG. Preisliste A3|S3|A3 Sportback|A3 Sportback g-tron|A3 Sportback e-Tron|S3 Sportback. 2017. Available online: https://www.audi.de/dam/nemo/models/misc/pdf/my-2017/preislisten/preisliste_a3_s3_a3-sportback_a3-sportback-g-tron_a3-sportback-e-tron_s3-sportback.pdf (accessed on 5 May 2020).

- EV Specifications. 2020 Mercedes-Benz EQC 400 4MATIC—Specifications and Price. Available online: https://www.evspecifications.com/en/model/c7d2a8 (accessed on 5 January 2022).

- Tesla Inc. European Union Energy Label. Available online: https://www.tesla.com/en_EU/support/european-union-energy-label (accessed on 5 January 2022).

- Auto Motor Sport. Mercedes GLC 350 e im Fahrbericht. 9 December 2015. Available online: https://www.auto-motor-und-sport.de/fahrbericht/mercedes-glc-350-e-fahrbericht/technische-daten/ (accessed on 5 January 2022).

- Ultimate Specs. Kia Niro 1.6 GDi PHEV Technical Specs, Dimensions. Available online: https://www.ultimatespecs.com/car-specs/Kia/111441/Kia-Niro-16-GDi-PHEV.html (accessed on 5 January 2022).

- Kia Corporation. Explore the Range. Available online: https://www.kia.com/eu/vehicles/kia-range/ (accessed on 5 January 2022).

- Motor Sport. Mitsubishi Outlander 2.4 PHEV Motion Auto 4WD. Available online: http://motor.sport.es/tm_ficha.php?id=801857420180901&fecha=20180901&mercado=es&site=sport&impresion=true (accessed on 5 January 2022).

- Hyundai Motor Deutschland GmbH. Der Hyundai NEXO: Pressetext. Available online: https://www.hyundai.news/de/modelle/e-modelle/nexo/pressemappe/der-hyundai-nexo-pressetext.html (accessed on 5 January 2022).

- Daimler AG. Mercedes-Benz EQ: GLC F-CELL with EQ Power. Available online: https://www.la.mercedes-benz.com/en/passengercars/mercedes-benz-cars/models/e-mobility/project-eq/experience-eq.pi.html/mercedes-benz-cars/models/e-mobility/project-eq/experience-eq/future-of-mobility/f-cell (accessed on 5 January 2022).

- EV Compare. Tesla Model X 90D Specs, Price, Photos, Offers and Incentives. Available online: https://evcompare.io/cars/tesla/tesla_model_x_90d/ (accessed on 6 January 2022).

- Auto Data. 2018 Mercedes-Benz E-class (W213) E 300 de (306 Hp) Plug-In Hybrid G-TRONIC|Technical Specs, Data, Fuel Consumption, Dimensions. Available online: https://www.auto-data.net/en/mercedes-benz-e-class-w213-e-300-de-306hp-plug-in-hybrid-g-tronic-35192 (accessed on 6 January 2022).

- International Fleet World. Road Test: Volvo S90 T8—International Fleet World. Available online: https://internationalfleetworld.com/road-test-volvo-s90-t8/ (accessed on 6 January 2022).

- AutoScout24. Volvo S90 T8 Twin Engine AWD. Available online: https://www.autoscout24.com/offers/volvo-s90-t8-twin-engine-awd-inscription-360-standheizu-electric-gasoline-grey-55f0007e-e53f-454b-aa84-b622ded2dd93?source=list_searchresults&cldtidx=16&sort=standard&lastSeenGuidPresent=false&cldtsrc=listPage (accessed on 6 January 2022).

- White, A. The Volvo XC90 Has a Wide Range of Common and Inconvenient Problems. 5 April 2020. Available online: https://www.motorbiscuit.com/the-volvo-xc90-has-a-wide-range-of-common-and-inconvenient-problems/ (accessed on 6 January 2022).

- FichasMotor. BMW 5 Series Sedan (G30) 530e (252 Cv) Plug-in Hybrid iPerformance Steptronic | FICHA TÉCNICA. FichasMotor. 1 January 2019. Available online: https://fichasmotor.com/bmw/bmw-5-series-sedan-g30-530e-252-cv-plug-in-hybrid-iperformance-steptronic/ (accessed on 6 January 2022).

- H2.LIVE. Toyota MIRAI—H2.LIVE. Available online: https://h2.live/en/fuelcell-cars/toyota-mirai/ (accessed on 6 January 2022).

- Luo, Y.; Wu, Y.; Li, B.; Mo, T.; Li, Y.; Feng, S.-P.; Qu, J.; Chu, P.K. Development and application of fuel cells in the automobile industry. J. Energy Storage 2021, 42, 103124. [Google Scholar] [CrossRef]

- BloombergNEF. New Energy Outlook 2018—Data Viewer. Available online: https://about.bnef.com/new-energy-outlook/ (accessed on 3 March 2019).

- ADAC e.V. Ökobilanz Gängiger Antriebstechniken: Konventionelle Antriebe sind Lange Nicht am Ende. 2019. Available online: https://www.adac.de/infotestrat/umwelt-und-innovation/abgas/oekobilanz/default.aspx?ComponentId=317354&SourcePageId=47733## (accessed on 28 June 2019).

| Compact Size | SUV Size | Upper-Mid Size | |

|---|---|---|---|

| Lifecycle base distance | 160,000 km [26] | 200,000 km [27] | 250,000 km [28] |

| Lifecycle base period | 12 years | 12 years | 12 years |

| Driving Range BEV * | 280 km | 458 km | 413 km |

| Electric range PHEV * | 50 km | 50 km | 52 km |

| Electric range FC-PHEV * | - | - | 49 km |

| Driving Range FCEV * | - | 756 km | 525 km |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neidhardt, M.; Mas-Peiro, J.; Schneck, A.; Pou, J.O.; Gonzalez-Olmos, R.; Kwade, A.; Schmuelling, B. Automotive Electrification Challenges Shown by Real-World Driving Data and Lifecycle Assessment. Sustainability 2022, 14, 15972. https://doi.org/10.3390/su142315972

Neidhardt M, Mas-Peiro J, Schneck A, Pou JO, Gonzalez-Olmos R, Kwade A, Schmuelling B. Automotive Electrification Challenges Shown by Real-World Driving Data and Lifecycle Assessment. Sustainability. 2022; 14(23):15972. https://doi.org/10.3390/su142315972

Chicago/Turabian StyleNeidhardt, Michael, Jordi Mas-Peiro, Antonia Schneck, Josep O. Pou, Rafael Gonzalez-Olmos, Arno Kwade, and Benedikt Schmuelling. 2022. "Automotive Electrification Challenges Shown by Real-World Driving Data and Lifecycle Assessment" Sustainability 14, no. 23: 15972. https://doi.org/10.3390/su142315972

APA StyleNeidhardt, M., Mas-Peiro, J., Schneck, A., Pou, J. O., Gonzalez-Olmos, R., Kwade, A., & Schmuelling, B. (2022). Automotive Electrification Challenges Shown by Real-World Driving Data and Lifecycle Assessment. Sustainability, 14(23), 15972. https://doi.org/10.3390/su142315972