Influence of a Multifunctional Epoxy Additive on the Performance of Polyamide 6 and PET Post-Consumed Blends during Processing

Abstract

1. Introduction

2. Materials

3. Methodology

3.1. Polymer Blends and Process for Preparation

3.2. Scanning Electron Microscopy (SEM)

3.3. Differential Scanning Calorimetry

3.4. Thermogravimetric Analysis (TGA)

3.5. Fourier-Transform Infrared Spectroscopy (FTIR)

4. Results and Discussion

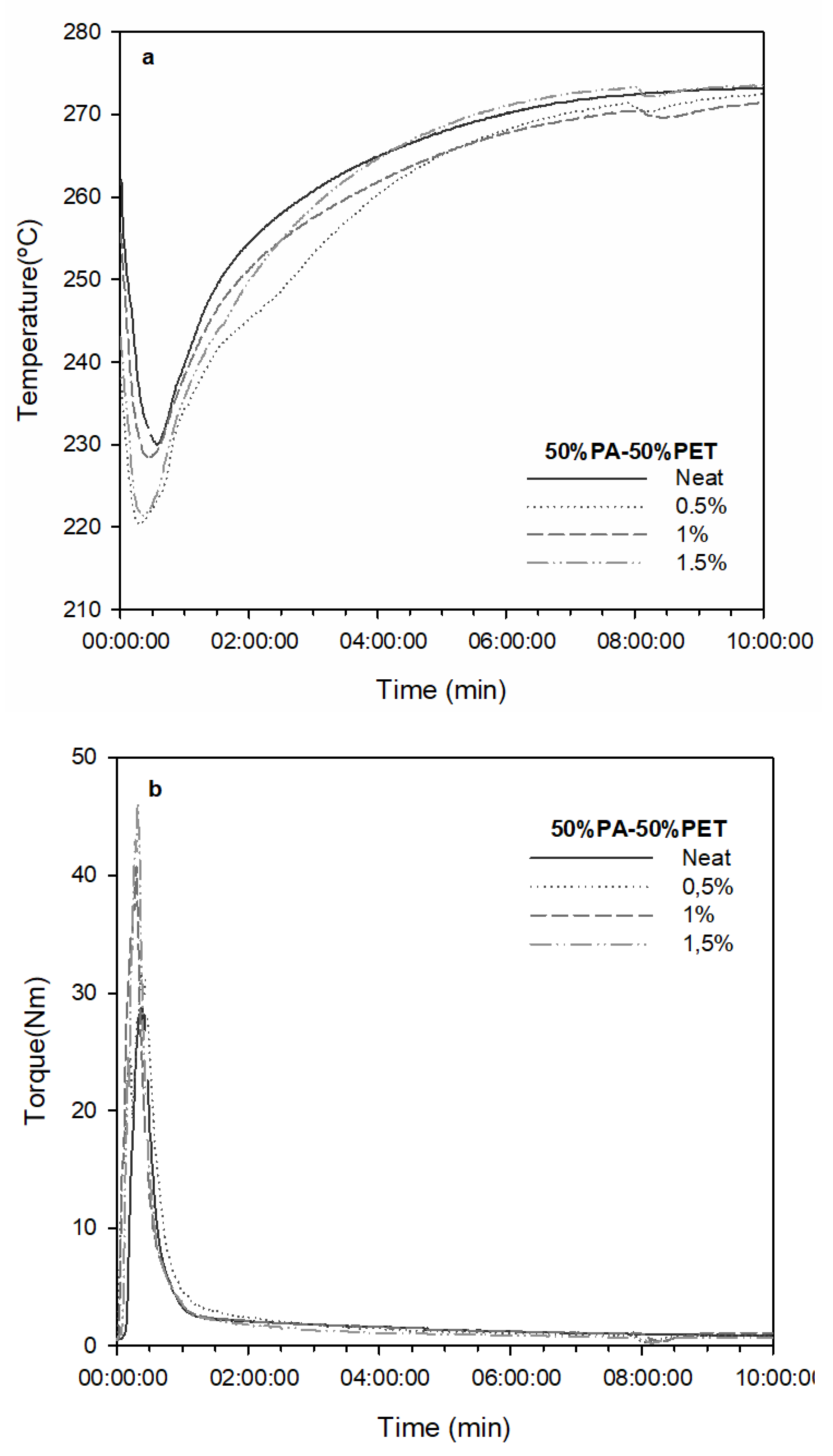

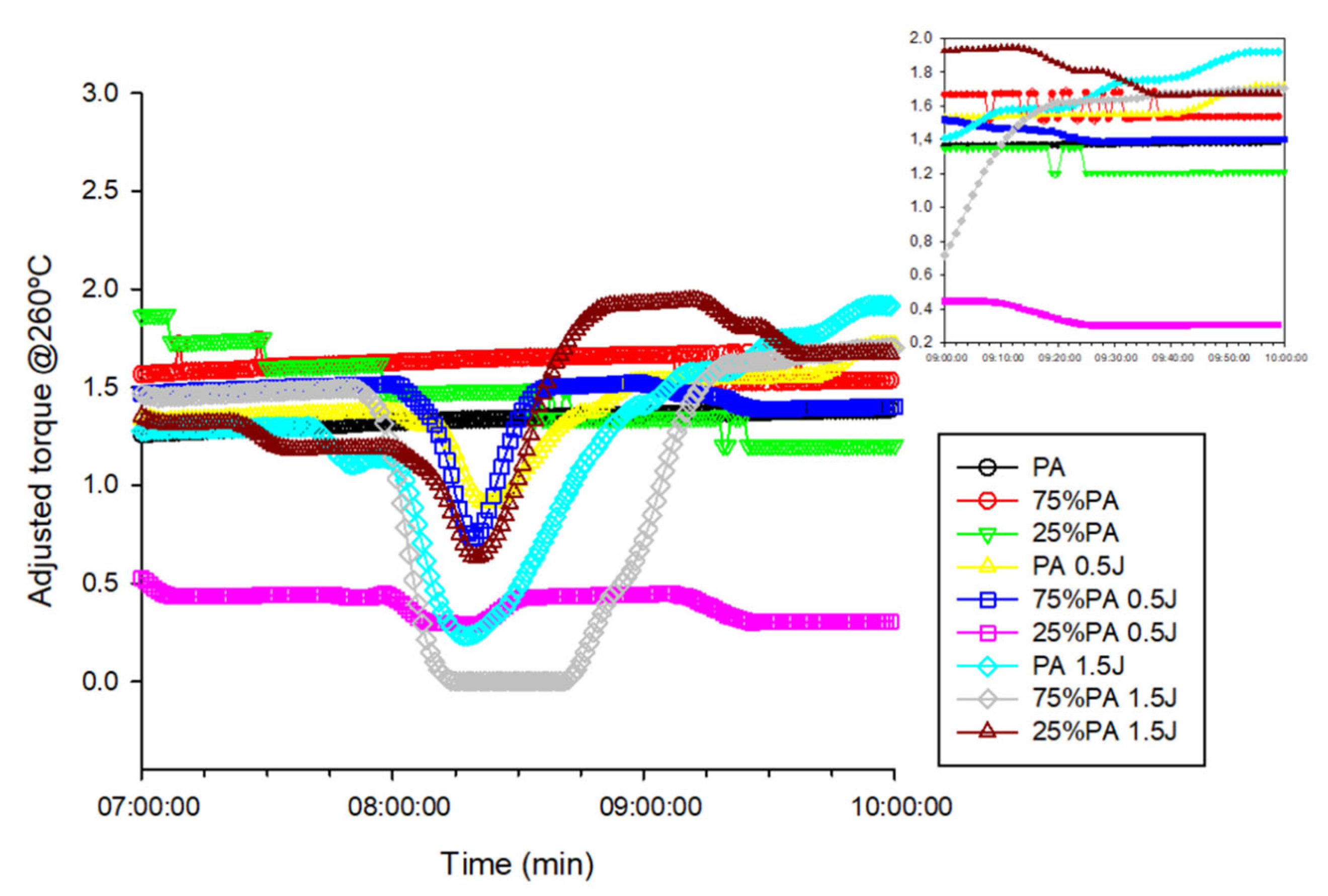

4.1. Analysis of Degradation during Processing

4.2. Scanning Electron Microscopy (SEM)

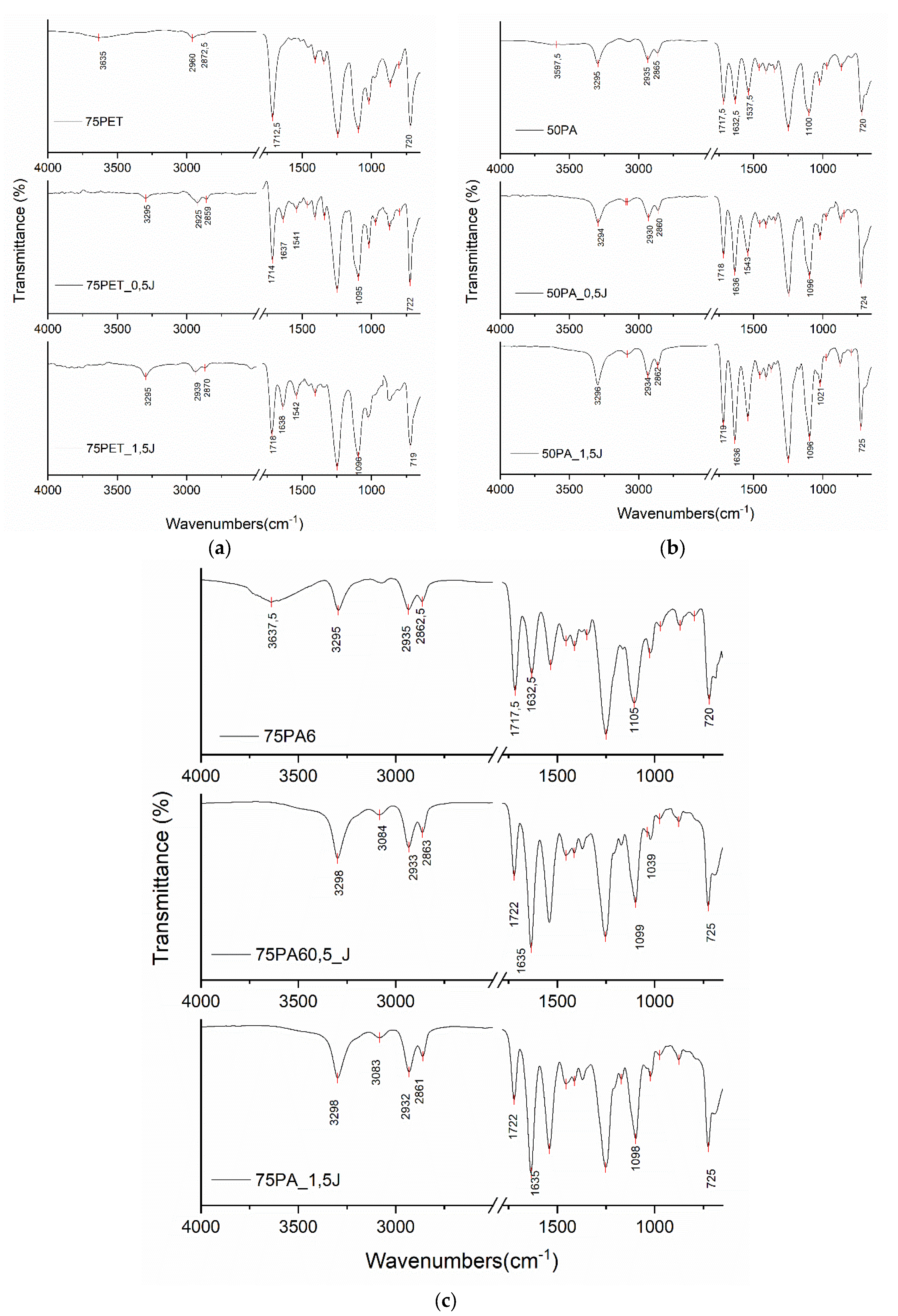

4.3. Fourier Transform Infrared Spectroscopy (FTIR)

4.4. Differential Scanning Calorimetry (DSC)

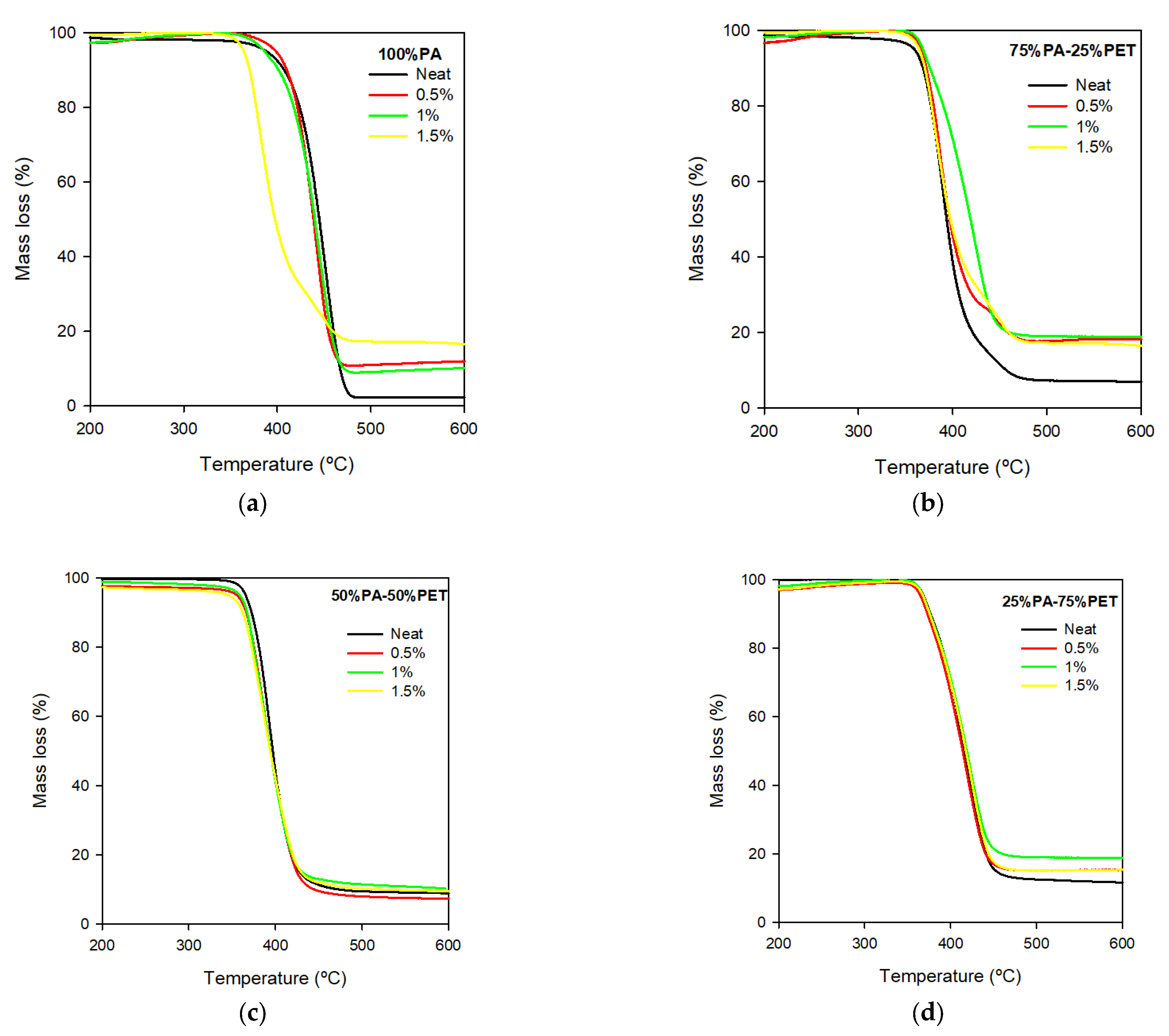

4.5. Thermogravimetric Analysis (TGA)

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamal, M.R.; Utracki, L.A.; Mirzadeh, A. Rheology of Polymer Alloys and Blends. In Polymer Blends Handbook; Springer: Dordrecht, The Netherlands, 2014; pp. 725–873. ISBN 9789400760646. [Google Scholar]

- Ekinci, A.; Öksüz, M.; Ates, M.; Aydin, I. Thermal and Mechanical Properties of Polypropylene/Post-Consumer Poly (Ethylene Terephthalate) Blends: Bottle-to-Bottle Recycling. J. Polym. Res. 2022, 29, 433. [Google Scholar] [CrossRef]

- Dong, W.; Zou, B.; Yan, Y.; Ma, P.; Chen, M. Effect of Chain-Extenders on the Properties and Hydrolytic Degradation Behavior of the Poly(Lactide)/Poly(Butylene Adipate-Co-Terephthalate) Blends. Int. J. Mol. Sci. 2013, 14, 20189–20203. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Savi, S.; Bianchi, S.; Castelvetro, V. Chain Extension and Branching of Poly(Ethylene Terephthalate) (PET) with Di- and Multifunctional Epoxy or Isocyanate Additives: An Experimental and Modelling Study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Malik, N.; Kumar, P.; Shrivastava, S.; Ghosh, S.B. An Overview on PET Waste Recycling for Application in Packaging. Int. J. Plast. Technol. 2017, 21, 1–24. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T.; Vuorinen, T. Mechanical Properties of Recycled Polymer Composites Made from Side-Stream Materials from Different Industries. Sustainability 2019, 11, 6054. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Del, M.; Rubio-Gámez, C. Reclaimed Polymers as Asphalt Binder Modifiers for More Sustainable Roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Karsli, N.G. A Study on the Fracture, Mechanical and Thermal Properties of Chain Extended Recycled Poly(Ethylene Terephthalate). J. Thermoplast. Compos. Mater. 2017, 30, 1157–1172. [Google Scholar] [CrossRef]

- Lin, X.; Qian, Q.; Xiao, L.; Chen, Q.; Huang, Q.; Zhang, H. Influence of Reactive Compatibilizer on the Morphology, Rheological, and Mechanical Properties of Recycled Poly(Ethylene Terephthalate)/Polyamide 6 Blends. J. Macromol. Sci. Part B 2014, 53, 1543–1552. [Google Scholar] [CrossRef]

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for Replacing PET on Packaging, Fiber, and Film Materials with Biobased Counterparts. Green Chem. 2021, 23, 8795–8820. [Google Scholar] [CrossRef]

- Loaeza, D.; Cailloux, J.; Santana Pérez, O.; Sánchez-Soto, M.; Maspoch, M.L. Impact of Titanium Dioxide in the Mechanical Recycling of Post-Consumer Polyethylene Terephthalate Bottle Waste: Tensile and Fracture Behavior. Polymer 2021, 13, 310. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, A.; Morawiec, J.; Pazzagli, F.; Pracella, M.; Galeski, A. Recycling of Postconsumer Poly(Ethylene Terephthalate) and High-Density Polyethylene by Compatibilized Blending. J. Appl. Polym. Sci. 2002, 86, 1473–1485. [Google Scholar] [CrossRef]

- Rosmmi, N.H.M.; Khan, Z.I.; Mohamad, Z.; Majid, R.A.; Othman, N.; Man, S.H.C.; Karim, K.J.A. Impact Strength and Morphology of Sustainably Sourced Recycling Polyethylene Terephthalate Blends. Chem. Eng. Trans. 2021, 83, 265–270. [Google Scholar] [CrossRef]

- Shi, Y.; Xu, J.; Wang, S.; Yang, S.; Jin, J. Effect of Copoly(Ester-Amide 6)(PET-PA6) on Compatibility of PET/PA6 Blended Fibers. Mater. Sci. Forum 2020, 993, 709–717. [Google Scholar] [CrossRef]

- Ma, G.Q.; Yang, H.; Li, L.; Sun, Z.B.; Miao, X.R.; Bian, F.G.; Xu, J.Z.; Zhong, G.J.; Gao, X.Q.; Li, Z.M. Structure of Polyamide 6/Poly(Ethylene Terephthalate) Blends under High Cooling Rate and Shear Stress and Their Moisture-Sensitive Properties. Polymer 2020, 203, 122817. [Google Scholar] [CrossRef]

- Yan, Y.; Huang, Y.H.; Wang, Y.; Xiao, Z.C.; Yang, M.B. Polyamide 6 (PA6)/Polyethylene Terephthalate (PET) Blends with Gradient and Encapsulation Structure Developed by Injection Molding. Polymer 2019, 180, 121679. [Google Scholar] [CrossRef]

- Matos Costa, A.R.; Lima, J.C.; dos Santos, R.; Barreto, L.S.; Henrique, M.A.; de Carvalho, L.H.; de Almeida, Y.M.B. Rheological, Thermal and Morphological Properties of Polyethylene Terephthalate/Polyamide 6/Rice Husk Ash Composites. J. Appl. Polym. Sci. 2021, 138, 50916. [Google Scholar] [CrossRef]

- Mandelkern, L.; Alamo, R.G. Thermodynamic Quantities Governing Melting. In Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007; pp. 165–186. [Google Scholar]

- Qiu, T.Y.; Song, M.; Zhao, L.G. Testing, Characterization and Modelling of Mechanical Behaviour of Poly (Lactic-Acid) and Poly (Butylene Succinate) Blends. Mech. Adv. Mater. Mod. Process. 2016, 2, 7. [Google Scholar] [CrossRef]

- Tuna, B.; Benkreira, H. Chain Extension of Polyamide 6/Organoclay Nanocomposites. Polym. Eng. Sci. 2019, 59, 1233–1241. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering Properties of Concrete with Waste Recycled Plastic: A Review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic Degradation and Its Environmental Implications with Special Reference to Poly(Ethylene Terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- Ghanbari, A.; Heuzey, M.C.; Carreau, P.J.; Ton-That, M.T. A Novel Approach to Control Thermal Degradation of PET/Organoclay Nanocomposites and Improve Clay Exfoliation. Polymer 2013, 54, 1361–1369. [Google Scholar] [CrossRef]

- Wenyong, D.; Xu, W.; Yongjin, L. Formation of Co-Continuous PLLA/PC Blends with Significantly Improved Physical Properties by Reactive Comb Polymers. J. Appl. Polym. Sci. 2018, 135, 46047. [Google Scholar] [CrossRef]

- Xu, M.; Yan, H.; He, Q.; Wan, C.; Liu, T.; Zhao, L.; Park, C.B. Chain Extension of Polyamide 6 Using Multifunctional Chain Extenders and Reactive Extrusion for Melt Foaming. Eur. Polym. J. 2017, 96, 210–220. [Google Scholar] [CrossRef]

- Nofar, M.; Oğuz, H. Development of PBT/Recycled-PET Blends and the Influence of Using Chain Extender. J. Polym. Environ. 2019, 27, 1404–1417. [Google Scholar] [CrossRef]

- Hongsriphan, N.; Kaew-Ngam, C.; Saengdet, P.; Kongtara, N. Mechanical Enhancement of Biodegradable Poly(Butylene Succinate) by Biobased Polyamide11. Eng. J. 2021, 25, 295–304. [Google Scholar] [CrossRef]

- Khan, Z.I.; Habib, U.; Mohamad, Z.B.; Raji, A.M. Enhanced Mechanical Properties of a Novel Compatibilized Recycled Polyethylene Terephthalate/Polyamide 11 (RPET/PA11) Blends. Express Polym. Lett. 2021, 15, 1206–1215. [Google Scholar] [CrossRef]

- Yan, Y.; Gooneie, A.; Ye, H.; Deng, L.; Qiu, Z.; Reifler, F.A.; Hufenus, R. Morphology and Crystallization of Biobased Polyamide 56 Blended with Polyethylene Terephthalate. Macromol. Mater. Eng. 2018, 303, 1800214. [Google Scholar] [CrossRef]

- Marinho, V.A.D.; Pereira, C.A.B.; Vitorino, M.B.C.; Silva, A.S.; Carvalho, L.H.; Canedo, E.L. Degradation and Recovery in Poly(Butylene Adipate-Co-Terephthalate)/Thermoplastic Starch Blends. Polym. Test. 2017, 58, 166–172. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, W.; Zhang, H.; Wu, C. Influence of Chain Extension on the Compatibilization and Properties of Recycled Poly(Ethylene Terephthalate)/Linear Low Density Polyethylene Blends. Polym. Degrad. Stab. 2009, 94, 1135–1141. [Google Scholar] [CrossRef]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef] [PubMed]

- Duarte, I.S.; Tavares, A.A.; Lima, P.S.; Andrade, D.L.A.C.S.; Carvalho, L.H.; Canedo, E.L.; Silva, S.M.L. Chain Extension of Virgin and Recycled Poly(Ethylene Terephthalate): Effect of Processing Conditions and Reprocessing. Polym. Degrad. Stab. 2016, 124, 26–34. [Google Scholar] [CrossRef]

- Alves, T.S.; Silva Neto, J.E.; Silva, S.M.L.; Carvalho, L.H.; Canedo, E.L. Process Simulation of Laboratory Internal Mixers. Polym. Test. 2016, 50, 94–100. [Google Scholar] [CrossRef]

- Tavares, A.A.; Silva, D.F.A.; Lima, P.S.; Andrade, D.L.A.C.S.; Silva, S.M.L.; Canedo, E.L. Chain Extension of Virgin and Recycled Polyethylene Terephthalate. Polym. Test. 2016, 50, 26–32. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, G.; Ma, H.; Zhou, S.; Zhang, H. Improved Compatibility of PET/HDPE Blend by Using GMA Grafted Thermoplastic Elastomer. Polym. Technol. Mater. 2020, 59, 1887–1898. [Google Scholar] [CrossRef]

- Bimestre, B.H.; Saron, C. Chain Extension of Poly (Ethylene Terephthalate) by Reactive Extrusion with Secondary Stabilizer. Mater. Res. 2012, 15, 467–472. [Google Scholar] [CrossRef]

- Mejri, M.; Toubal, L.; Cuillière, J.C.; François, V. Fatigue Life and Residual Strength of a Short- Natural-Fiber-Reinforced Plastic vs Nylon. Compos. Part B Eng. 2017, 110, 429–441. [Google Scholar] [CrossRef]

- Lu, C.; Chen, T.; Zhao, X.; Ren, X.; Cai, X. Chemical Modification of Polyamide-6 by Chain Extension with 2,2′-Bis(2-Oxazoline). J. Polym. Sci. Part B Polym. Phys. 2007, 45, 1976–1982. [Google Scholar] [CrossRef]

- Buccella, M.; Dorigato, A.; Pasqualini, E.; Caldara, M.; Fambri, L. Chain Extension Behavior and Thermo-Mechanical Properties of Polyamide 6 Chemically Modified with 1,1′-Carbonyl-Bis-Caprolactam. Polym. Eng. Sci. 2014, 54, 158–165. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, W.; Yu, Y.; Li, B.; Wu, C. Structure and Properties of Compatibilized Recycled Poly(Ethylene Terephthalate)/Linear Low Density Polyethylene Blends. Eur. Polym. J. 2007, 43, 3662–3670. [Google Scholar] [CrossRef]

- Vinogradova, S.V.; Slonimskii, G.L.; Vygodskii, Y.S.; Askadskii, A.A.; Mzhel’skii, A.I.; Churochkina, N.A.; Korshak, V.V. The Structure and Properties of Aromatic Polyimides. Polym. Sci. USSR 1969, 11, 3098–3116. [Google Scholar] [CrossRef]

| Composition (PET/PA6) | T (°C) | Z (Nm) | Z* (Nm) | dZ/dt | Rz (%/min) | |

|---|---|---|---|---|---|---|

| No additive | 100%/0 | 271.1 ± 0.055 | 1.3 ± 0.004 | 2.1 ± 0.006 | −0.1 ± 0.007 | −5.6 |

| 75%/25% | 266.5 ± 0.535 | 0.8 ± 0.250 | 1.0 ± 0.081 | −0.09 ± 0.018 | −28.6 | |

| 50%/50% | 269.2 ± 0.073 | 0.9 ± 0.004 | 1.4 ± 0.006 | −0.1 ± 0.006 | −7.4 | |

| 25%/75% | 268.8 ± 0.091 | 1.1 ± 0.004 | 1.6 ± 0.005 | −0.06 ± 0.008 | −4.1 | |

| 0/100% | 269.6 ± 0.085 | 0.9 ± 0.001 | 1.3 ± 0.001 | −0.03 ± 0.008 | 2.5 | |

| 0.5 J | 0/100% | 266.0 ± 0.656 | 1.0 ± 0.196 | 1.2 ± 0.043 | 0.46 ± 0.038 | 28.6 |

| 25%/75% | 273.4 ± 0.012 | 0.7 ± 0.001 | 1.1 ± 0.0464 | 0.0166 ± 1.1000 × 10−3 | 1.5 | |

| 50%/50% | 266.9 ± 0.6714 | 1.1 ± 0.2040 | 1.4 ± 0.041 | −0.0716 ± 0.0178 | −5.1 | |

| 75%/25% | 271.5 ± 0.047 | 0.9 ± 0.007 | 1.3 ± 0.010 | −0.2 ± 0.008 | −13.6 | |

| 1.0 J | 0/100% | 271.2 ± 0.059 | 1.1 ± 0.006 | 1.6 ± 0.011 | 0.2 ± 0.012 | 13.9 |

| 25%/75% | 268.7 ± 0.549 | 1.1 ± 0.165 | 1.4 ± 0.041 | 0.3 ± 0.011 | 15.6 | |

| 50%/50% | 272.1 ± 0.028 | 0.8 ± 0.321 | 1.3 ± 0.058 | −0.1 ±0.027 | 7.3 | |

| 75%/25% | 272.4 ± 0.056 | 2.9 ± 0.029 | 4.5 ± 0.047 | 0.5 ± 0.093 | 12.1 | |

| 1.5 J | 0/100% | 270.6 ± 0.527 | 0.8 ± 0.151 | 1.1 ± 0.059 | 0.9± 0.023 | 50.1 |

| 25%/75% | 270.5 ± 0.064 | 0.6 ± 0.005 | 0.9 ± 0.009 | 0.1 ± 0.017 | 17.4 | |

| 50%/50% | 270.5 ± 0.052 | 1.0 ± 0.015 | 1.5 ± 0.023 | 0.4 ± 0.029 | 28.2 | |

| 75%/25% | 266.5 ± 0.535 | 1.3 ± 0.222 | 1.6 ± 0.065 | −0.5 ± 0.044 | −36.6 |

| F2 | Composition | Tpc | ΔHm | ΔXm | Cmaxm | Tpm (PET) (℃) | Tpm (PA6) |

|---|---|---|---|---|---|---|---|

| (PET/PA6) | (℃) | (J/g) | (%) | (min−1) | (°C) | ||

| No additive | 0%/100% | 172.6 | 48.3 | 34.5 | 0.7 | 248.2 | - |

| 75%/25% | 184.7 | 55.1 (PA6) | 23.9 (PA6) | 1.1 (PA6) | 247.3 | 209.9 | |

| 37.9 (PET) | 27.1 (PET) | 0.8 (PET) | 217.7 | ||||

| 50%/50% | 189.3 (PA6) | 62.0 (PA6) | 26.9 (PA6) | 1.0 (PA6) | 247 | 210.3 | |

| 200.3 (PET) | 38.2 (PET) | 27.3 (PET) | 0.8 (PET) | 217.6 | |||

| 25%/75% | 188.1 (PA6) | 63.0 (PA6) | 27.3 (PA6) | 0.9 (PA6) | 245.5 | 207.1 | |

| 197.4 (PET) | 38.9 (PET) | 22.8 (PET) | 0.7 (PET) | 216 | |||

| 100%/0% | 196.9 | 58 | 25.2 | 1.08 | - | 218.8 | |

| 0.5 J | 75%/25% | 187.9 (PA6) | 70.9 (PA6) | 30.8 (PA6) | 0.8 (PA6) | 242.3 | 210.3 |

| 211.7 (PET) | 109.4 (PET) | 47.5 (PET) | 0.7 (PET) | 216.8 | |||

| 50%/50% | 189.8 (PA6) | 62.5 | 27.2 | 0.9 | 243.1 | 211.1 | |

| 210.7 (PET) | 38 | 27.1 | 0.7 | 247 | 217.9 | ||

| 25%/75% | 175.8 (PA6) | 76.1 (PA6) | 33.1 (PA6) | 0.7 (PA6) | 246.1 | 210.2 | |

| 188.9 (PET) | 40.6 (PET) | 29.1 (PET) | 0.8 (PET) | 217.4 | |||

| 0%/100% | 185.9 | 64.4 | 28 | 0.7 | - | 211.2 | |

| 218.9 | |||||||

| 1.0 J | 75%/25% | 186.8 (PA6) | 47.3 (PA6) | 20.6 (PA6) | 1.1 (PA6) | 248.3 | 210.3 |

| 201.8 (PET) | 34.0 (PET) | 24.3 (PET) | 0.7 (PET) | 219.1 | |||

| 50%/50% | 188.7 (PA6) | 53.2 (PA6) | 23.1 (PA6) | 1.0 (PA6) | 246.2 | 211.2 | |

| 203.7 (PET) | 25.5 (PET) | 18.2 (PET) | 0.8 (PET) | 218.4 | |||

| 25%/75% | 175.4 (PA6) | 61.3 (PA6) | 26.6 (PA6) | 1.9 (PA6) | 246.6 | 211.8 | |

| 189.1 (PET) | 29.1 (PET) | 20.8 (PET) | 0.9 (PET) | 218.6 | |||

| 0/100% | 188.8 | 45.9 | 19.9 | 1.08 | 210.7 | ||

| 219.1 | |||||||

| 1.5 J | 75%/25% | 185.3 (PA6) | 27.92 (PET) | 19.9 (PET) | 0.6 (PET) | 246.5 | 208.4 |

| 204.7 (PET) | 49.03 (PA6) | 21.3 (PA6) | 0.9 (PA6) | 217.6 | |||

| 50%/50% | 183.8 (PA6) | 65.2 (PA6) | 28.3 (PA6) | 0.9 (PA6) | 240.8 | 205.9 | |

| 210.6 (PET) | 38.9 (PET) | 27.8 (PET) | 0.7 (PET) | 246.6 | 214.9 | ||

| 25%/75% | 172.8 (PA6) | 61.3 (PA6) | 26.6 (PA6) | 0.8 (PA6) | 246.1 | 211.9 | |

| 188.1 (PET) | 28.5 (PET) | 20.4 (PET) | 0.8 (PET) | 218.2 | |||

| 0/100% | 184.7 | 54.6 | 23.7 | 0.9 | - | 211.8 | |

| 220 |

| 9 | Composition | Mass Loss Range | T1/2 | Δm | Residue at 700 °C |

|---|---|---|---|---|---|

| (%PET/%PA) | (°C) | (°C) | (%) | ||

| No additive | 0/100 | 422.9–470.6 | 444.2 | 92.8 | 2.3 |

| 25/75 | 370.3–414.3 | 392.3 | 84 | 7.9 | |

| 50/50 | 373.0–415.5 | 394.2 | 84.4 | 12.2 | |

| 75/25 | 379.2–443.8 | 411.5 | 85.4 | 12.7 | |

| 100/0 | 412.8–457.2 | 434.9 | 85.5 | 13 | |

| 0.50% | 0/100 | 414.4–457.6 | 436.0/442.2 | 81.7 | 13.4 |

| 25/75 | 369.7–418.9 | 394.3/388.3 | 81.2 | 25.1 | |

| 50/50 | 363.6–420.2 | 391.9/386.8 | 91.2 | 7.3 | |

| 75/25 | 378.6–441.2 | 409.9/419.4 | 84.3 | 20.3 | |

| 1.00% %J | 0/100 | 406.1–462.6 | 434.3 | 91.1 | 12.7 |

| 25/75 | 366.4–421.4 | 393.9 | 83.1 | 18.9 | |

| 50/50 | 362.4–421.6 | 392.0/388.2 | 85.2 | 10.2 | |

| 75/25 | 375.1–444.5 | 409.8 | 81.2 | 22.4 | |

| 1.50% | 0/100 | 411.4–450.2 | 430.8/435 | 86.5 | 14.8 |

| 25/75 | 363.6–423.4 | 393.5/447.7 | 83.1 | 17.4 | |

| 50/50 | 363.7–421.9 | 392.8/386.8 | 87.2 | 9.4 | |

| 75/25 | 378.6–447.2 | 411.9 | 84.7 | 20.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, A.R.d.M.; Henrique, M.A.; Luna, C.B.B.; Carvalho, L.H.d.; Almeida, Y.M.B.d. Influence of a Multifunctional Epoxy Additive on the Performance of Polyamide 6 and PET Post-Consumed Blends during Processing. Sustainability 2022, 14, 16658. https://doi.org/10.3390/su142416658

Costa ARdM, Henrique MA, Luna CBB, Carvalho LHd, Almeida YMBd. Influence of a Multifunctional Epoxy Additive on the Performance of Polyamide 6 and PET Post-Consumed Blends during Processing. Sustainability. 2022; 14(24):16658. https://doi.org/10.3390/su142416658

Chicago/Turabian StyleCosta, Anna Raffaela de Matos, Mariana Alves Henrique, Carlos Bruno Barreto Luna, Laura Hecker de Carvalho, and Yêda Medeiros Bastos de Almeida. 2022. "Influence of a Multifunctional Epoxy Additive on the Performance of Polyamide 6 and PET Post-Consumed Blends during Processing" Sustainability 14, no. 24: 16658. https://doi.org/10.3390/su142416658

APA StyleCosta, A. R. d. M., Henrique, M. A., Luna, C. B. B., Carvalho, L. H. d., & Almeida, Y. M. B. d. (2022). Influence of a Multifunctional Epoxy Additive on the Performance of Polyamide 6 and PET Post-Consumed Blends during Processing. Sustainability, 14(24), 16658. https://doi.org/10.3390/su142416658