Experimental Francis Turbine Cavitation Performances of a Hydro-Energy Plant

Abstract

:1. Introduction

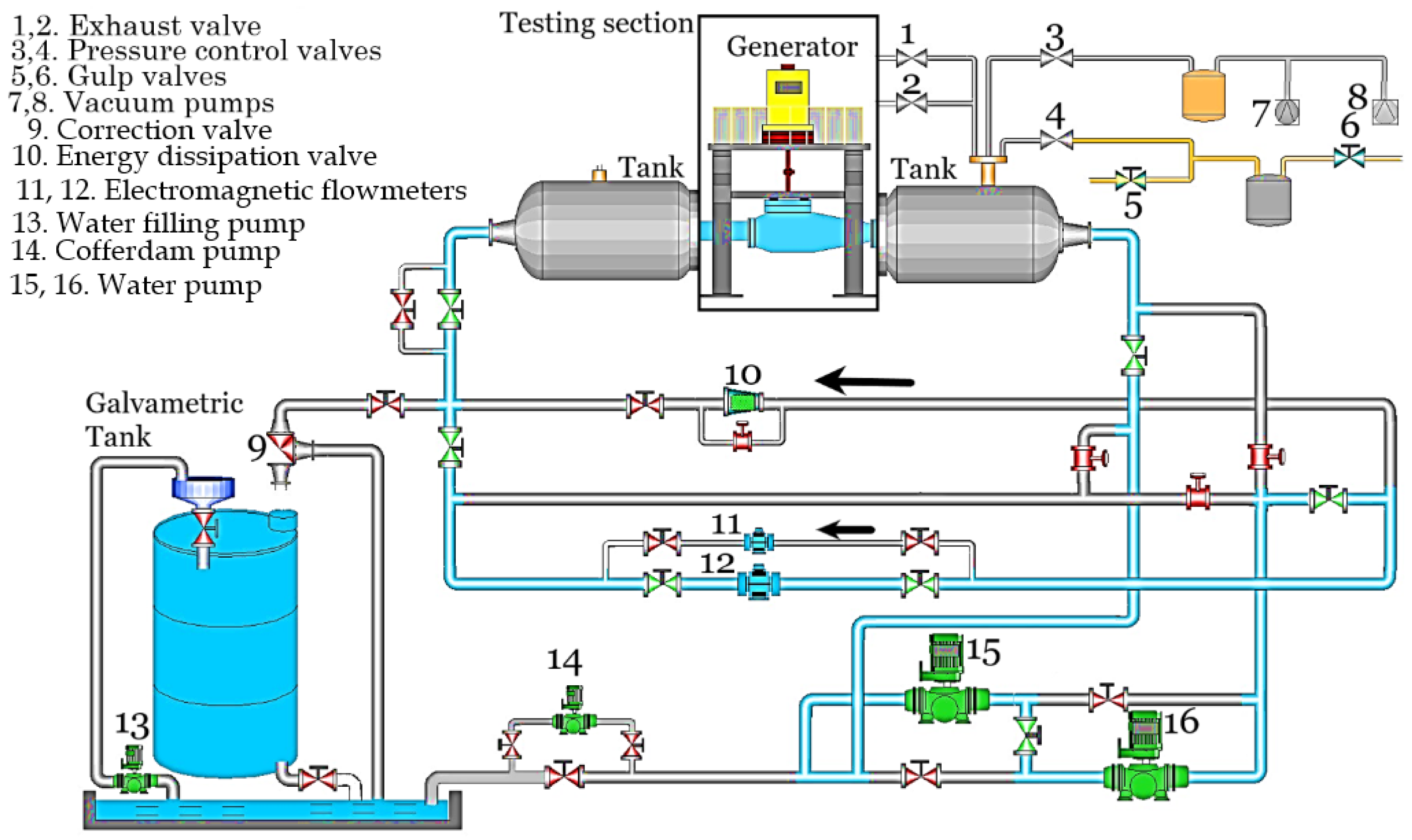

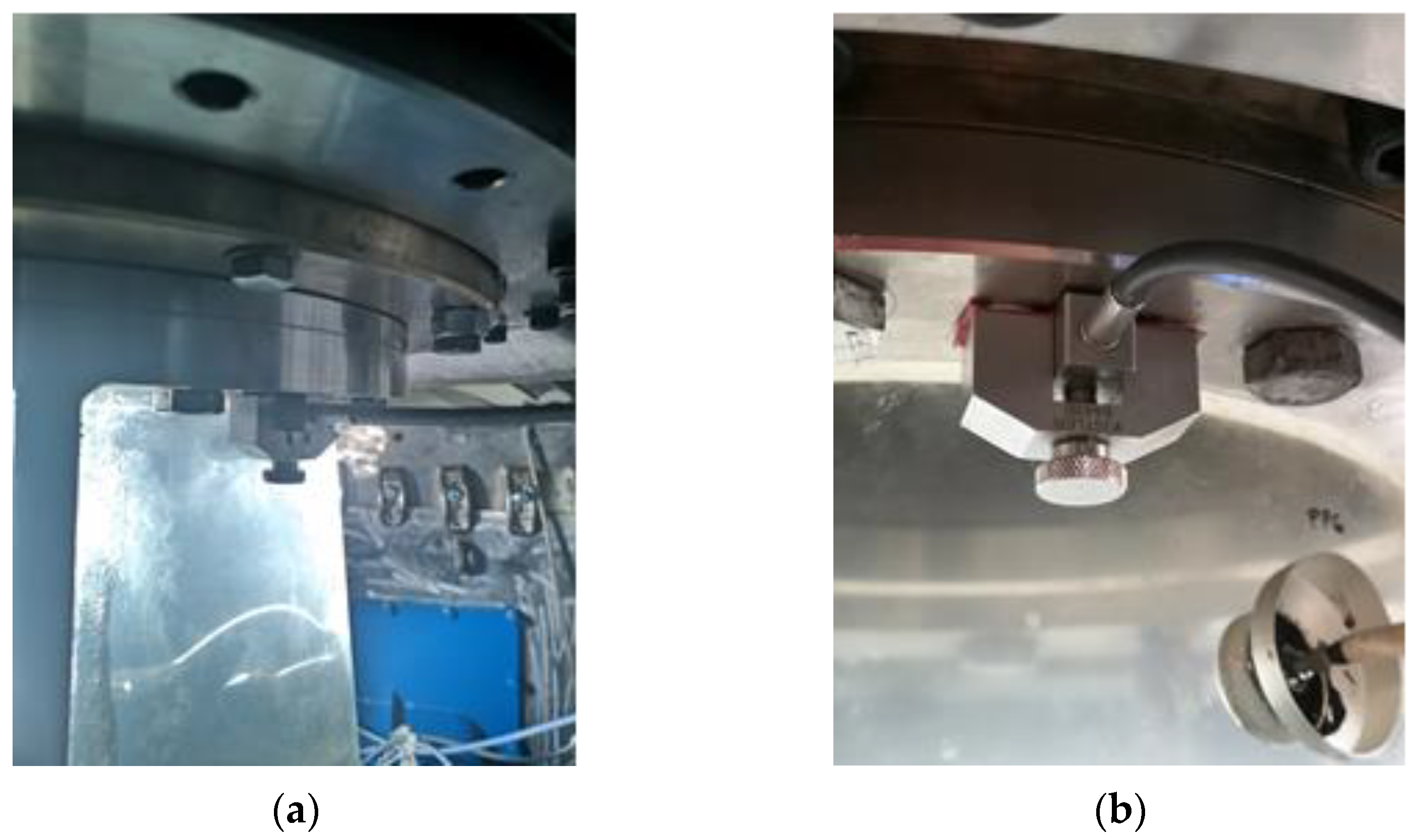

2. Materials and Methods

3. Results

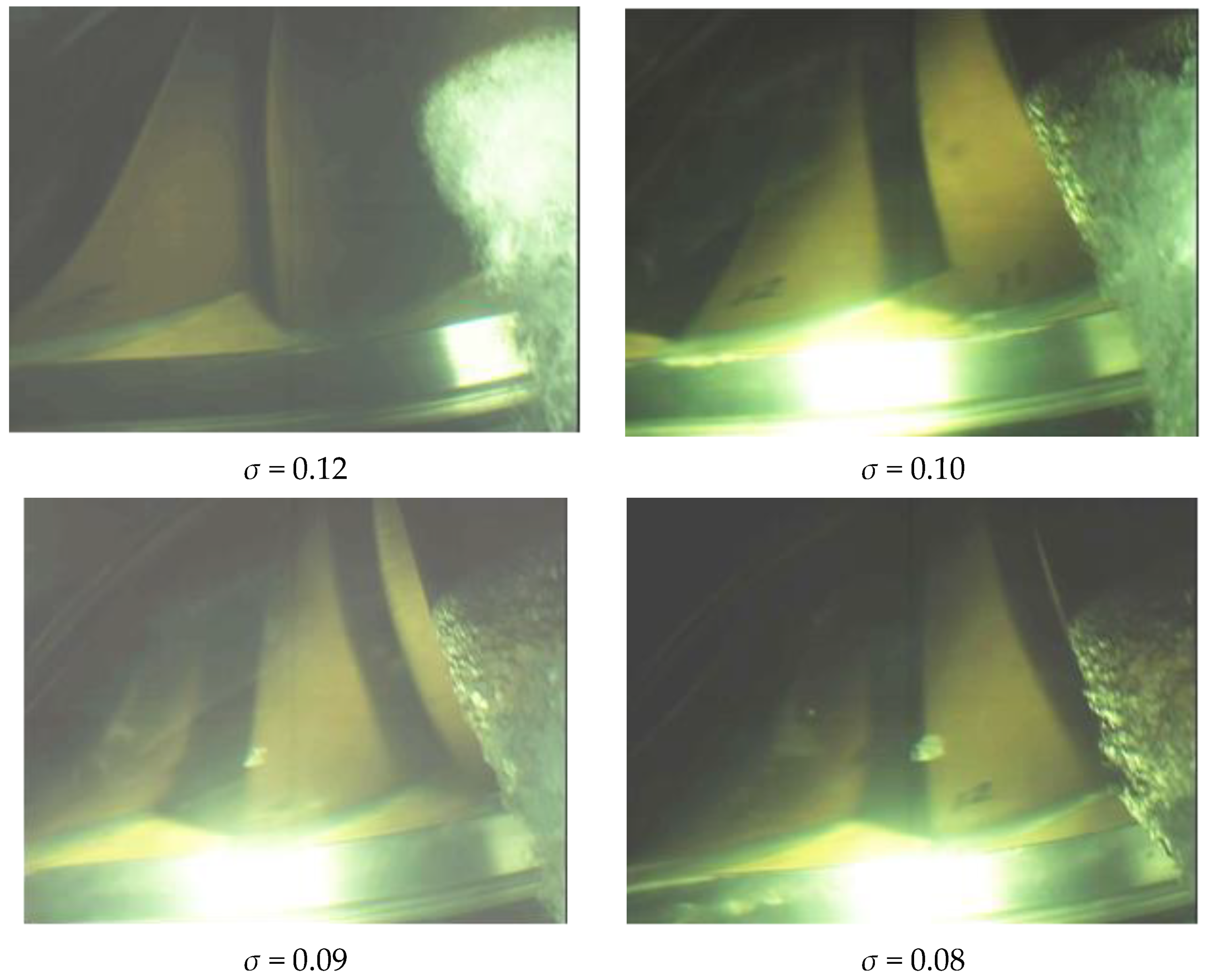

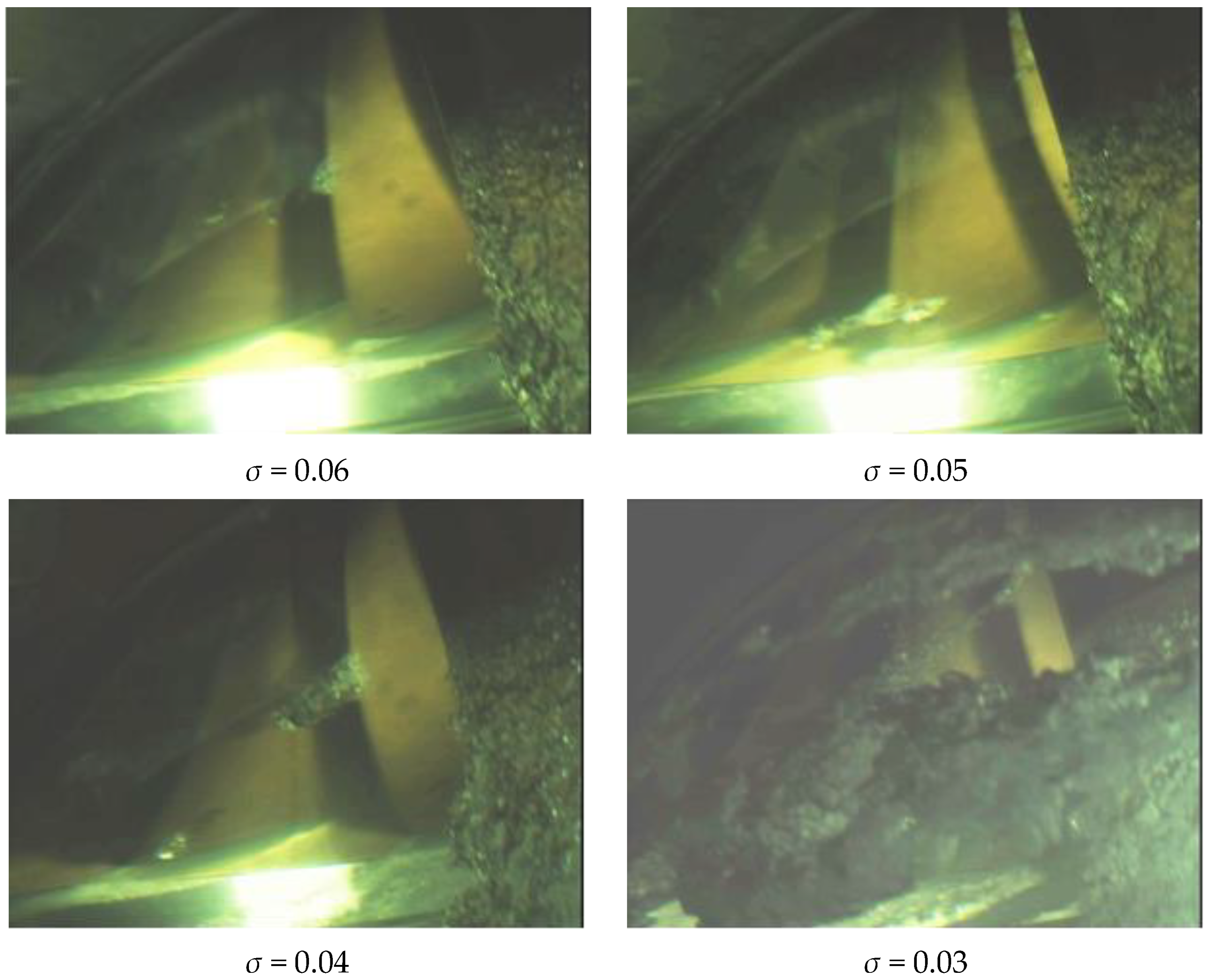

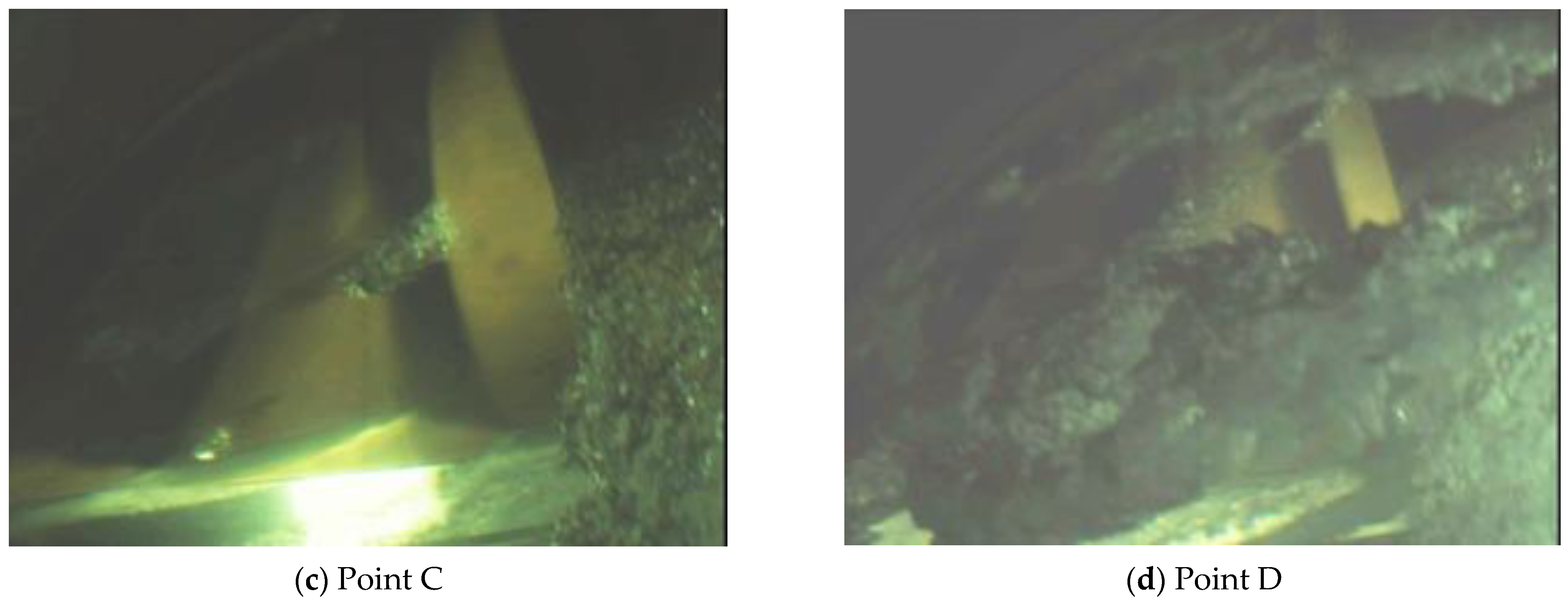

3.1. Cavitation Development and Its Influence on Hydraulic Stability

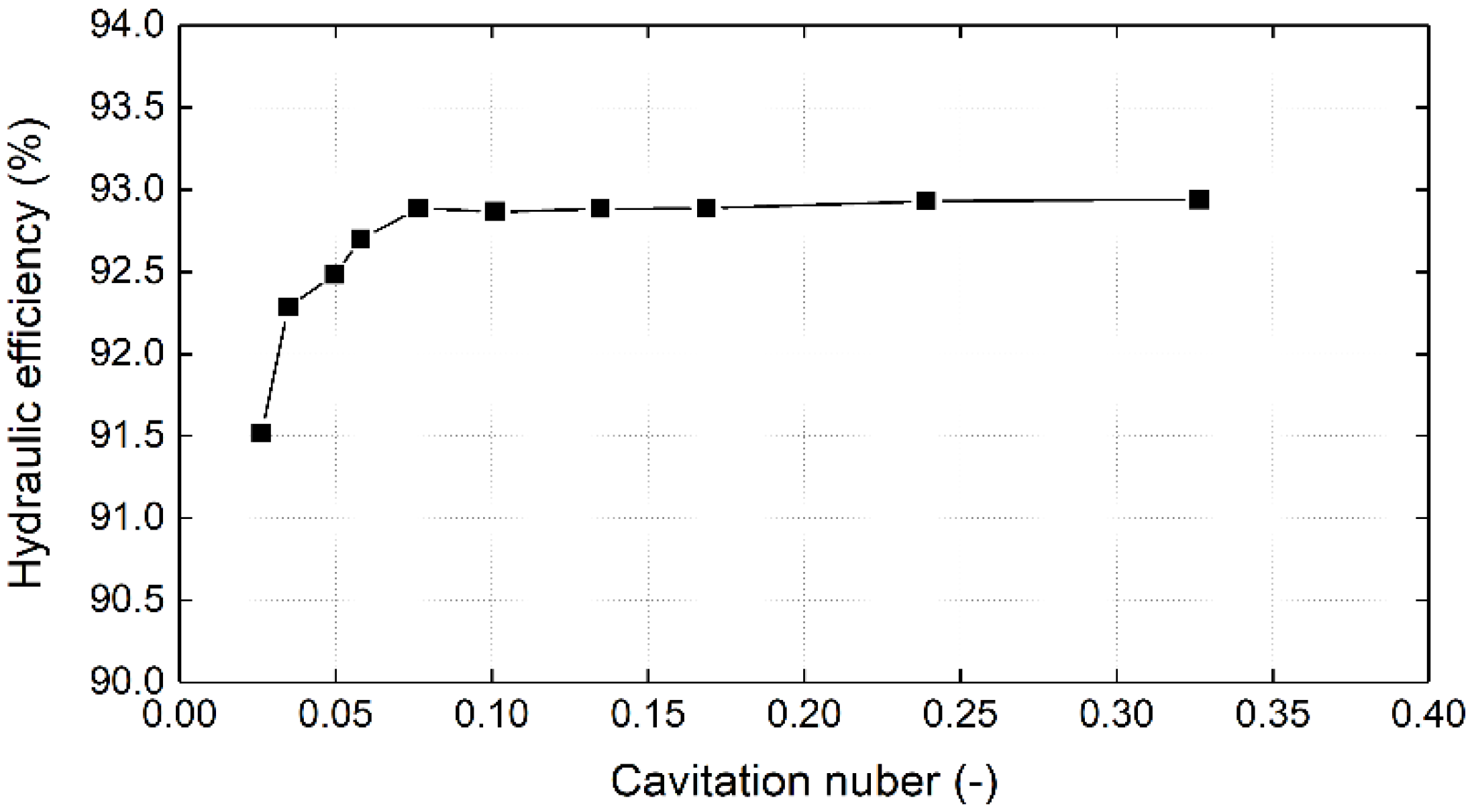

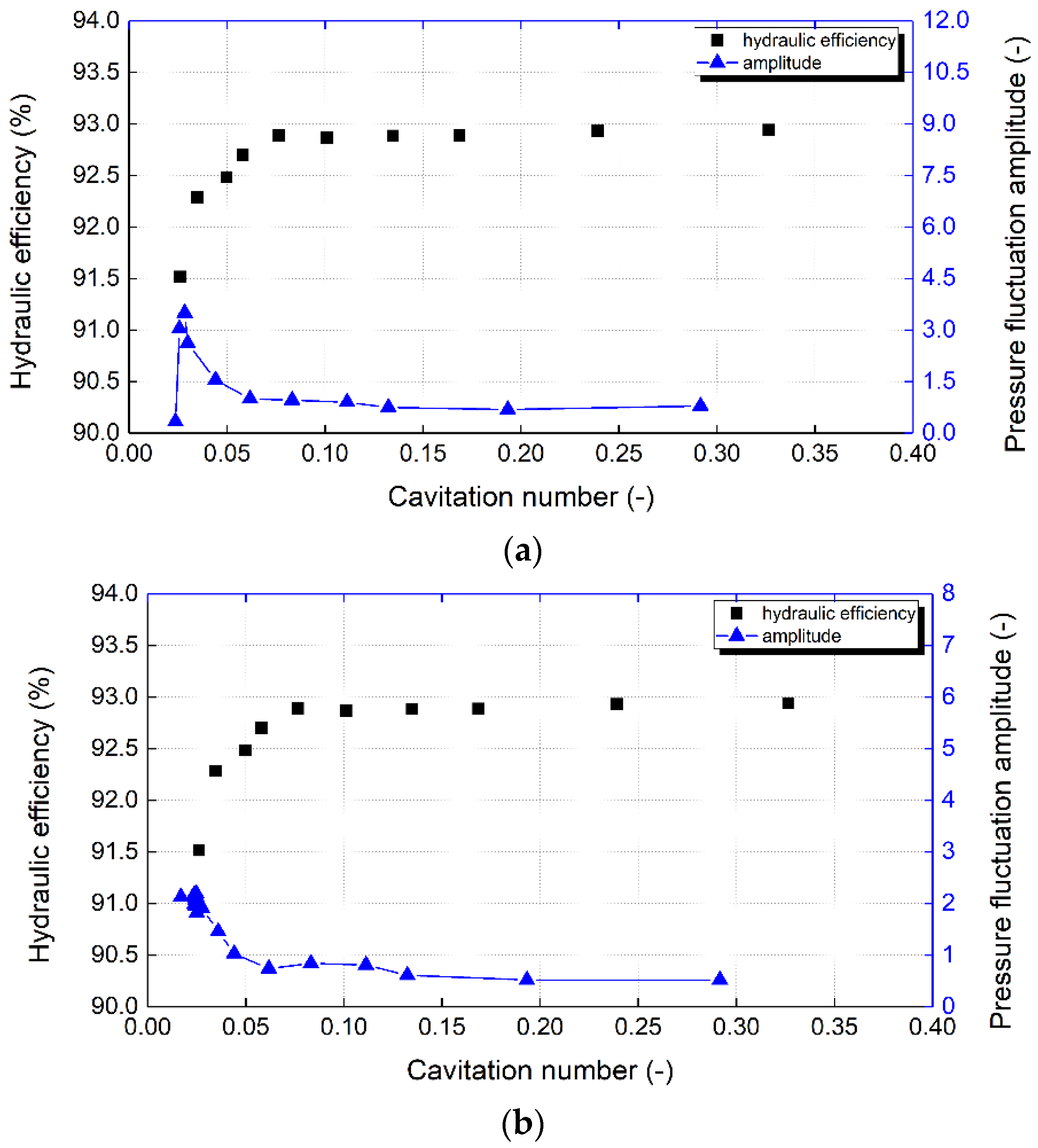

3.2. Influence of Cavitation Onset and Development on Turbine External Performance Characteristics

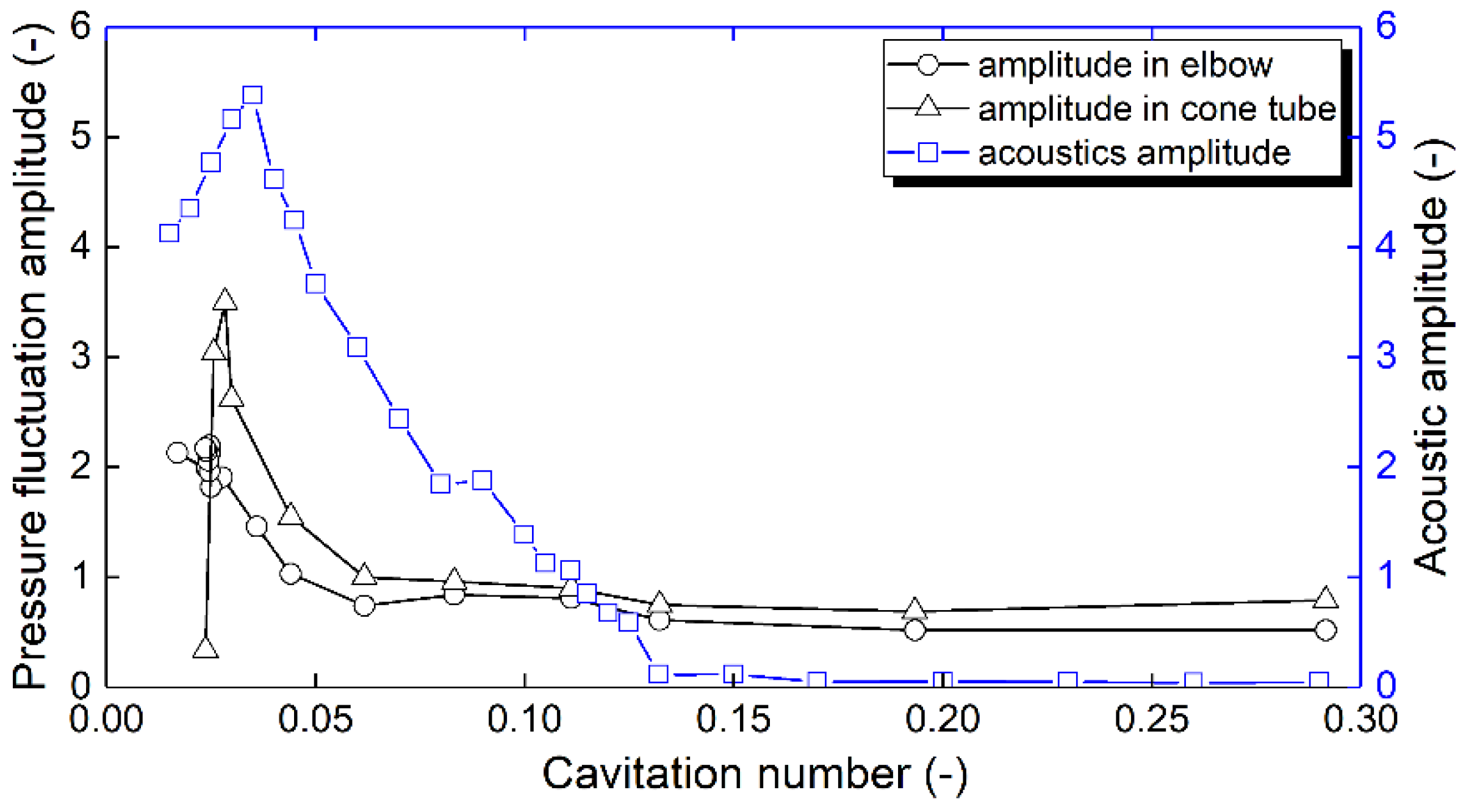

3.3. Influence of Turbine Cavitation on Its Pressure Pulsation Characteristics

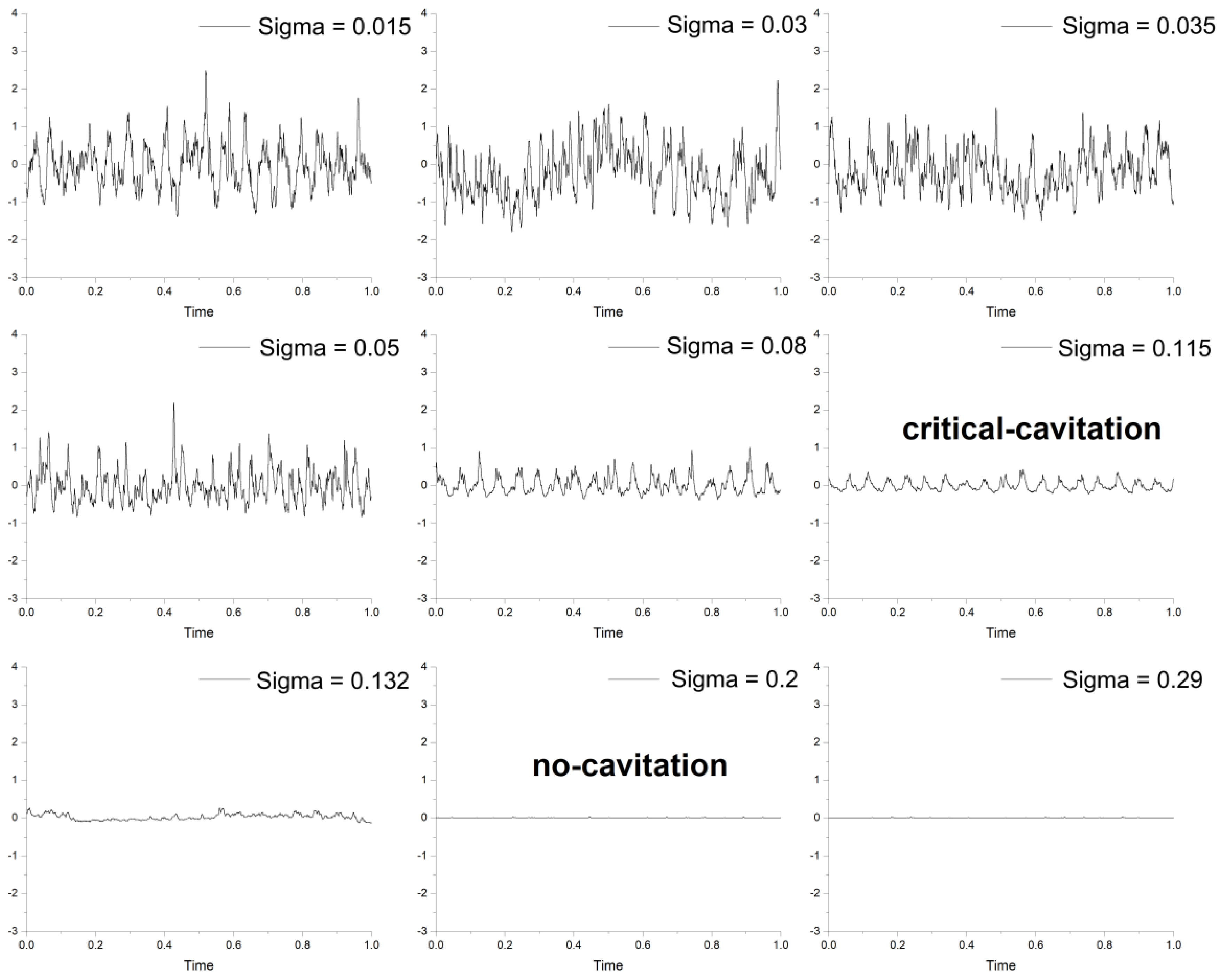

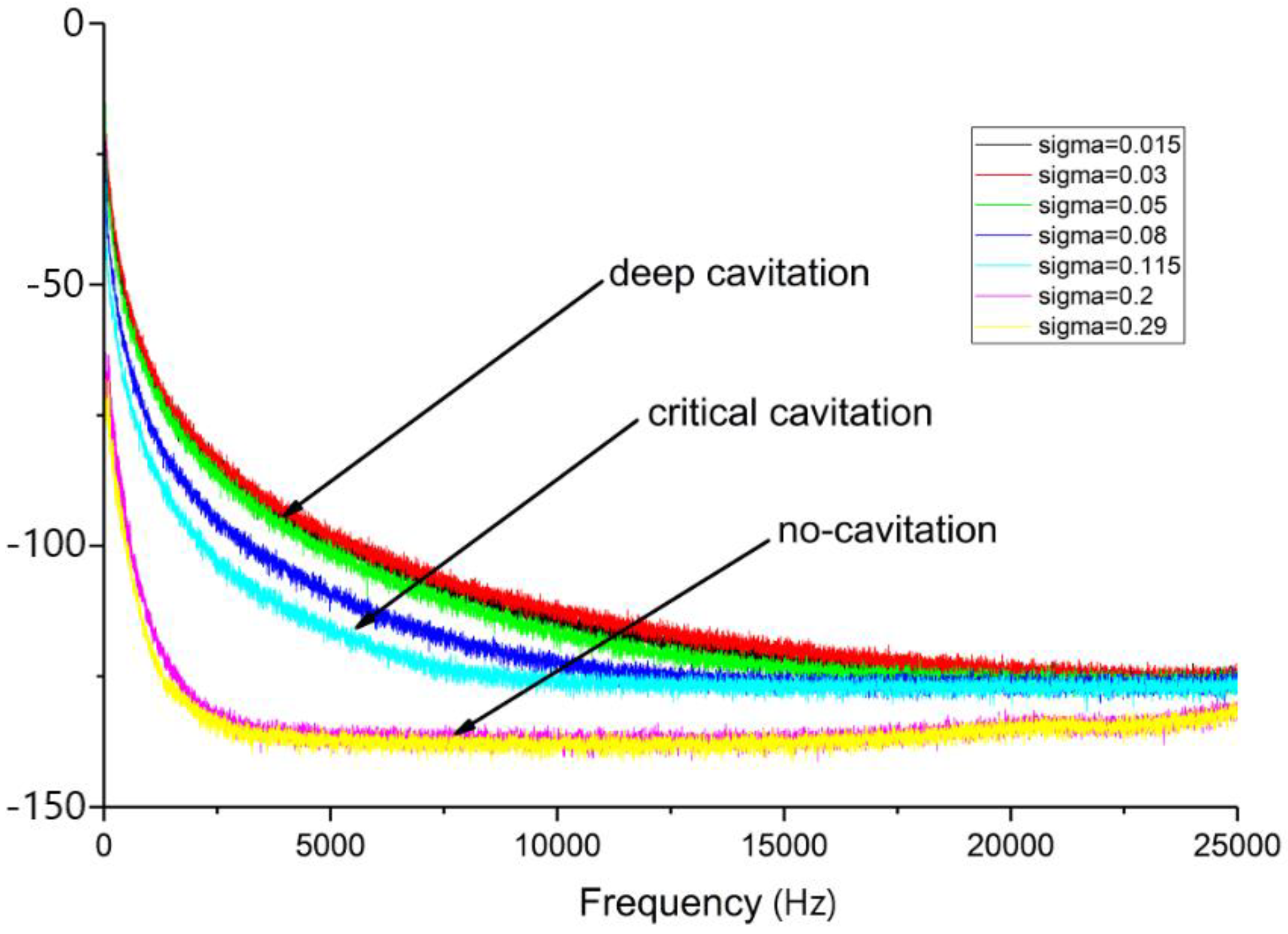

3.4. Relationship between Cavitation Development and Noise

4. Conclusions

- (a)

- Although the gap cavitation at the runner outlet and the local cavitation boosted by surface roughness of turbine components become more severe with the decrease of the cavitation coefficient, it has no obvious effect on the turbine performance parameters (efficiency, hydraulic head, and flow rate). When the airfoil cavitation develops, the occurred increase in flow rate and a correspondent hydraulic head decrease show that the cavitation phenomenon has a certain drag reduction effect on the flow. This drag reduction effect, however, disappears when the cavitation develops to deep cavitation state, which makes the flow rate decrease and hydraulic head increase.

- (b)

- The pressure pulsation at the cone and elbow tube is stable before the occurrence of airfoil cavitation, and it does not change with the change of the cavitation coefficient. When the airfoil cavitation just appears, both the turbine efficiency and the local pressure remarkably fluctuate, which again means that the airfoil cavitation affects the external characteristics of the turbine and its stability. When the cavitation gets serious, resulting in continuous cavitation zones formation and unsteady surge development near the wall of the draft tube’s cone, the pressure fluctuation within the same zone (draft tube’s cone zone) reaches the maximum. When the cavitation coefficient continues to decrease, a closed and stable annular cavitation zone is formed, which leads to the sharp drop of pressure fluctuation within the cone zone. On the other hand, the elbow tube presents a rising trend due to the gradual downward movement of the cavitation vortex boundary.

- (c)

- Through the analysis of acoustic data, it is shown that before cavitation occurs, the signal energy has no change and is in a low energy level. After cavitation occurs, cavitation bubbles develop and collapse more intensely. Therefore, the energy level of the whole signal changes step by step. The power spectral density shows that when cavitation has not occurred, the signal is dominated by low-frequency energy, and the overall energy of the high-frequency component is weak. When the incipient cavitation occurs, the high-frequency energy is increased, and the energy in the low-frequency region is also enhanced. The whole power spectral density curve is obviously away from the trend of non-cavitation. When cavitation continues to develop, there is a large number of cavitation bubbles on the runner blade, and the full band energy is enhanced. The trend of noise is basically the same as that of pressure fluctuation at the cone tube.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Liu, D.; Li, C.; Tan, X.; Lu, X.; Malik, O.P. Damping characteristics analysis of hydropower units under full operating conditions and control parameters: Accurate quantitative evaluation based on refined models. Appl. Energy 2021, 292, 116881. [Google Scholar] [CrossRef]

- Gøtske, E.K.; Victoria, M. Future operation of hydropower in Europe under high renewable penetration and climate change. iScience 2021, 24, 102999. [Google Scholar] [CrossRef] [PubMed]

- Selin Kocaman, A.; Abad, C.; Troy, T.J.; Tim Huh, W.; Modi, V. A stochastic model for a macroscale hybrid renewable energy system. Renew. Sustain. Energy Rev. 2016, 54, 688–703. [Google Scholar] [CrossRef] [Green Version]

- Binama, M.; Kan, K.; Chen, H.-X.; Zheng, Y.; Zhou, D.-Q.; Su, W.-T.; Ge, X.-F.; Ndayizigiye, J. A Numerical Investigation into the PAT Hydrodynamic Response to Impeller Rotational Speed Variation. Sustainability 2021, 13, 7998. [Google Scholar] [CrossRef]

- Briones-Hidrovo, A.; Uche, J.; Martínez-Gracia, A. Hydropower and environmental sustainability: A holistic assessment using multiple biophysical indicators. Ecol. Indic. 2021, 127, 107748. [Google Scholar] [CrossRef]

- Wang, H.; Ruan, J.; Wang, G.; Zhou, B.; Liu, Y.; Fu, X.; Peng, J. Deep Learning-Based Interval State Estimation of AC Smart Grids Against Sparse Cyber Attacks. IEEE Trans. Ind. Inform. 2018, 14, 4766–4778. [Google Scholar] [CrossRef]

- Victoria, M.; Zhu, K.; Brown, T.; Andresen, G.B.; Greiner, M. Early decarbonisation of the European energy system pays off. Nat. Commun. 2020, 11, 6223. [Google Scholar] [CrossRef]

- Rich, E. Hydropower Status Report; Henley, W., Ed.; International Hydropower Association (IHA) Central Office: London, UK, 2021. [Google Scholar]

- Trivedi, C.; Gandhi, B.; Michel, C.J. Effect of transients on Francis turbine runner life: A review. J. Hydraul. Res. 2013, 51, 121–132. [Google Scholar] [CrossRef]

- Jiao, P.H.; Chen, J.J.; Cai, X.; Wang, L.L.; Zhao, Y.L.; Zhang, X.H.; Chen, W.G. Joint active and reactive for allocation of renewable energy and energy storage under uncertain coupling. Appl. Energy 2021, 302, 117582. [Google Scholar] [CrossRef]

- Javaid, N.; Hafeez, G.; Iqbal, S.; Alrajeh, N.; Alabed, M.S.; Guizani, M. Energy Efficient Integration of Renewable Energy Sources in the Smart Grid for Demand Side Management. IEEE Access 2018, 6, 77077–77096. [Google Scholar] [CrossRef]

- Wang, H.; Lei, Z.; Zhang, X.; Zhou, B.; Peng, J. A review of deep learning for renewable energy forecasting. Energy Convers. Manag. 2019, 198, 111799. [Google Scholar] [CrossRef]

- Li, X.-B.; Binama, M.; Su, W.-T.; Cai, W.-H.; Muhirwa, A.; Li, B.; Li, F.-C. Runner blade number influencing RPT runner flow characteristics under off-design conditions. Renew. Energy 2020, 152, 876–891. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.; Cai, W.; Li, F.; Wei, X.; Muhirwa, A.; Gong, R.; Wekesa, D.W. Investigation on reversible pump turbine flow structures and associated pressure field characteristics under different guide vane openings. Sci. China Technol. Sci. 2019, 62, 2052–2074. [Google Scholar] [CrossRef]

- Khozaei, M.H.; Favrel, A.; Masuko, T.; Yamaguchi, N.; Miyagawa, K. Generation of Twin Vortex Rope in the Draft-Tube Elbow of a Francis Turbine During Deep Part-Load Operation. J. Fluids Eng. 2021, 143, 101206. [Google Scholar] [CrossRef]

- Trivedi, C.; Iliev, I.; Dahlhaug, O.G. Numerical Study of a Francis Turbine over Wide Operating Range: Some Practical Aspects of Verification. Sustainability 2020, 12, 4301. [Google Scholar] [CrossRef]

- Sentyabov, A.V.; Minakov, A.V.; Platonov, D.V.; Dekterev, D.A.; Zakharov, A.V.; Semenov, G.A. Numerical Investigation of the Influence of Special Structures On Suppression of Pressure Pulsations in The Draft Tube of a High-Head Hydraulic Turbine. J. Eng. Phys. Thermophys. 2019, 92, 1489–1500. [Google Scholar] [CrossRef]

- Brezovec, M.; Kuzle, I.; Krpan, M.; Holjevac, N. Analysis and treatment of power oscillations in hydropower plant Dubrava. IET Renew. Power Gener. 2020, 14, 80–89. [Google Scholar] [CrossRef]

- Gomes, P.J., Jr.; Favrel, A.; Landry, C.; Nicolet, C.; Avellan, F. Measurements of Cavitation Compliance in the Draft Tube Cone of a Reduced Scale Francis Turbine Operating at Part Load. In Proceedings of the 10th International Symposium on Cavitation (CAV2018), Baltimore, MD, USA, 14–16 May 2018; Katz, J., Ed.; ASME Press: Baltimore, MD, USA, 2018; p. 6. [Google Scholar]

- Binama, M.; Kan, K.; Chen, H.-X.; Zheng, Y.; Zhou, D.; Su, W.-T.; Muhirwa, A.; Ntayomba, J. Flow instability transferability characteristics within a reversible pump turbine (RPT) under large guide vane opening (GVO). Renew. Energy 2021, 179, 285–307. [Google Scholar] [CrossRef]

- Favrel, A.; Müller, A.; Landry, C.; Yamamoto, K.; Avellan, F. Study of the vortex-induced pressure excitation source in a Francis turbine draft tube by particle image velocimetry. Exp. Fluids 2015, 56, 215. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.-T.; Li, X.-B.; Li, F.-C.; Wei, X.-Z.; An, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Favrel, A.; Landry, C.; Müller, A.; Yamamoto, K.; Avellan, F. Hydro-acoustic resonance behavior in presence of a precessing vortex rope: Observation of a lock-in phenomenon at part load Francis turbine operation. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2014; Volume 22, p. 032035. [Google Scholar]

- Pereira, J.G., Jr.; Favrel, A.; Andolfatto, L.; Landry, C.; Alligné, S.; Nicolet, C.; Avellan, F. Procedure for predicting part load resonance in Francis turbine hydropower units based on swirl number and local cavitation coefficient similitude. Mech. Syst. Signal Processing 2019, 132, 84–101. [Google Scholar] [CrossRef]

- Alligne´, S.B.; Nicolet, C.; Avellan, F.O. Identification of Francis Turbine Helical Vortex Rope Excitation by CFD and Resonance Simulation with the Hydraulic System. In Proceedings of the ASME-JSME-KSME 2011 Joint Fluids Engineering Conference, Hamamatsu, Japan, 24–29 July 2011; ASME Press: Hamamatsu, Japan, 2011; pp. 481–493. [Google Scholar]

- Harvey, J.K. Some observations of the vortex breakdown phenomenon. J. Fluid Mech. 1962, 14, 585–592. [Google Scholar] [CrossRef]

- Lucca-Negro, O.; O’Doherty, T. Vortex breakdown: A review. Prog. Energy Combust. Sci. 2001, 27, 431–481. [Google Scholar] [CrossRef]

- Escudier, M. Vortex breakdown: Observations and explanations. Prog. Aerosp. Sci. 1988, 25, 189–229. [Google Scholar] [CrossRef]

- Dörfler, P.; Sick, M.; Coutu, A. Low-Frequency Phenomena in Swirling Flow. In Flow-Induced Pulsation and Vibration in Hydroelectric Machinery: Engineer’s Guidebook for Planning, Design and Troubleshooting; Dörfler, P., Sick, M., Coutu, A., Eds.; Springer: London, UK, 2013; pp. 33–67. [Google Scholar]

- Zhang, R.-K.; Mao, F.; Wu, J.-Z.; Chen, S.-Y.; Wu, Y.-L.; Liu, S.-H. Characteristics and Control of the Draft-Tube Flow in Part-Load Francis Turbine. J. Fluids Eng. 2009, 131, 021101. [Google Scholar] [CrossRef]

- Franc, J.-P.D.; Avellan, F.; Belahadji, B.; Billard, J.-Y.; Briançon-Marjollet, L.; Fréchou, D.; Fruman, D.; Karimi, A.; Kueny, J.-L.; Michel, J.-M. La Cavitation: Mécanismes Physiques et Aspects Industriels; Presses Universitaires de Grenoble PUG: Grenoble, France, 1995. [Google Scholar]

- Favrel, A.; Müller, A.; Landry, C.; Gomes, J.; Yamamoto, K.; Avellan, F. Dynamics of the precessing vortex rope and its interaction with the system at Francis turbines part load operating conditions. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2017; Volume 813, p. 012023. [Google Scholar]

- Yonezawa, K.; Konishi, D.; Miyagawa, K.; Avellan, F.; Doerfler, P.; Tsujimoto, Y. Cavitation surge in a small model test facility simulating a hydraulic power plant. Int. J. Fluid Mach. Syst. 2012, 5, 152–160. [Google Scholar] [CrossRef] [Green Version]

- Nishi, M.; Liu, S. An Outlook on the Draft-Tube-Surge Study. Int. J. Fluid Mach. Syst. 2013, 6, 33–48. [Google Scholar] [CrossRef] [Green Version]

- Müller, A.; Yamamoto, K.; Alligné, S.; Yonezawa, K.; Tsujimoto, Y.; Avellan, F. Measurement of the Self-Oscillating Vortex Rope Dynamics for Hydroacoustic Stability Analysis. J. Fluids Eng. 2015, 138, 021206. [Google Scholar] [CrossRef]

- Susan-Resiga, R.; Dan Ciocan, G.; Anton, I.; Avellan, F. Analysis of the Swirling Flow Downstream a Francis Turbine Runner. J. Fluids Eng. 2005, 128, 177–189. [Google Scholar] [CrossRef]

- Mustafa Kamal, M.; Abbas, A.; Kumar, R.; Prasad, V. The Cause and Control of Failure of Hydraulic Turbine Due to Cavitation: A Review. In Advances in Clean Energy Technologies; Baredar, P.V., Tangellapalli, S., Solanki, C.S., Eds.; Springer: Singapore, 2021; pp. 1099–1112. [Google Scholar]

- Tiwari, G.; Kumar, J.; Prasad, V.; Patel, V.K. Derivation of cavitation characteristics of a 3MW prototype Francis turbine through numerical hydrodynamic analysis. Mater. Today Proc. 2020, 26, 1439–1448. [Google Scholar] [CrossRef]

- Mohanta, R.K.; Chelliah, T.R.; Allamsetty, S.; Akula, A.; Ghosh, R. Sources of vibration and their treatment in hydro power stations—A review. Eng. Sci. Technol. Int. J. 2017, 20, 637–648. [Google Scholar] [CrossRef] [Green Version]

- Luo, Y.; Wang, Z.; Zhang, J.; Zeng, J.; Lin, J.; Wang, G. Vibration and fatigue caused by pressure pulsations originating in the vaneless space for a Kaplan turbine with high head. Eng. Comput. 2013, 30, 448–463. [Google Scholar] [CrossRef]

- Candel, I.; Bunea, F.; Dunca, G.; Bucur, D.M.; Ioana, C.; Reeb, B.; Ciocan, G.D. Detection of cavitation vortex in hydraulic turbines using acoustic techniques. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2014; Volume 22, p. 052007. [Google Scholar]

- Chatenet, Q.; Tahan, A.S.; Fouladirad, M.; Gagnon, M.; Remy, E. Maintenance Strategies Comparison for Francis Turbine Runner Subjected to Cavitation. Sustainability 2021, 13, 10838. [Google Scholar] [CrossRef]

- Avellan, F. Introduction to Cavitation in Hydraulic Machinery. In Proceedings of the 6th International Conference on Hydraulic Machinery and Hydrodynamics, Timișoara, Romania, 21–22 October 2004; Politehnica University of Timișoara: Timisoara, Romania, 2004; pp. 11–22. [Google Scholar]

- Escaler, X.; Egusquiza, E.; Farhat, M.; Avellan, F.; Coussirat, M. Detection of cavitation in hydraulic turbines. Mech. Syst. Signal Process. 2006, 20, 983–1007. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Zhou, L.; Wang, Z.; Liu, M.; Cheng, H. Numerical simulation for the tip leakage vortex cavitation. Ocean Eng. 2018, 151, 71–81. [Google Scholar] [CrossRef]

- Celebioglu, K.; Altintas, B.; Aradag, S.; Tascioglu, Y. Numerical research of cavitation on Francis turbine runners. Int. J. Hydrog. Energy 2017, 42, 17771–17781. [Google Scholar] [CrossRef]

- Sun, L.; Guo, P.; Luo, X. Numerical investigation on inter-blade cavitation vortex in a Franics turbine. Renew. Energy 2020, 158, 64–74. [Google Scholar] [CrossRef]

- Yamamoto, K.; Müller, A.; Favrel, A.; Avellan, F. Experimental evidence of inter-blade cavitation vortex development in Francis turbines at deep part load condition. Exp. Fluids 2017, 58, 142. [Google Scholar] [CrossRef]

- Yamamoto, K.; Müller, A.; Favrel, A.; Avellan, F. Physical Mechanism of Interblade Vortex Development at Deep Part Load Operation of a Francis Turbine. J. Fluids Eng. 2019, 141, 111113. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Nishi, M.; Wu, Y. Cavitating Turbulent Flow Simulation in a Francis Turbine Based on Mixture Model. J. Fluids Eng. 2009, 131, 051302. [Google Scholar] [CrossRef]

- Iliescu, M.S.; Ciocan, G.D.; Avellan, F. Analysis of the Cavitating Draft Tube Vortex in a Francis Turbine Using Particle Image Velocimetry Measurements in Two-Phase Flow. J. Fluids Eng. 2008, 130, 021105. [Google Scholar] [CrossRef]

- Decaix, J.; Müller, A.; Favrel, A.; Avellan, F.; Münch, C. URANS Models for the Simulation of Full Load Pressure Surge in Francis Turbines Validated by Particle Image Velocimetry. J. Fluids Eng. 2017, 139, 121103. [Google Scholar] [CrossRef]

- Krzemianowski, Z.; Steller, J. High specific speed Francis turbine for small hydro purposes-Design methodology based on solving the inverse problem in fluid mechanics and the cavitation test experience. Renew. Energy 2021, 169, 1210–1228. [Google Scholar] [CrossRef]

- Hoč Evar, M.; Širok, B.; Blagojevič, B.; Grabec, I. Experimental modeling of a cavitation vortex in the draft tube of a Francis turbine using artificial neural networks. J. Hydraul. Res. 2007, 45, 538–546. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, L.; Liang, Q.; Guan, Z.; Liu, D.; Wang, Z.; Kang, W. A method of evaluating the vortex rope strength in draft tube of Francis turbine. Renew. Energy 2020, 152, 770–780. [Google Scholar] [CrossRef]

- Yu, A.; Zou, Z.; Zhou, D.; Zheng, Y.; Luo, X. Investigation of the correlation mechanism between cavitation rope behavior and pressure fluctuations in a hydraulic turbine. Renew. Energy 2020, 147, 1199–1208. [Google Scholar] [CrossRef]

- Escaler, X.; Ekanger, J.V.; Francke, H.H.; Kjeldsen, M.; Nielsen, T.K. Detection of Draft Tube Surge and Erosive Blade Cavitation in a Full-Scale Francis Turbine. J. Fluids Eng. 2014, 137, 011103. [Google Scholar] [CrossRef] [Green Version]

- Rus, T.; Dular, M.; Širok, B.; Hočevar, M.; Kern, I. An Investigation of the Relationship Between Acoustic Emission, Vibration, Noise, and Cavitation Structures on a Kaplan Turbine. J. Fluids Eng. 2007, 129, 1112–1122. [Google Scholar] [CrossRef]

- Bajic, B. Multidimensional Diagnostics of Turbine Cavitation. J. Fluids Eng. 2002, 124, 943–950. [Google Scholar] [CrossRef]

- Battarra, M.; Mucchi, E. Incipient cavitation detection in external gear pumps by means of vibro-acoustic measurements. Measurement 2018, 129, 51–61. [Google Scholar] [CrossRef]

- Poddar, S.; Tandon, N. Detection of journal bearing vapour cavitation using vibration and acoustic emission techniques with the aid of oil film photography. Tribol. Int. 2016, 103, 95–101. [Google Scholar] [CrossRef]

- Požar, T.; Pirc, Ž.; Susič, E.; Petkovšek, R. Simplified detection of cavitation threshold in control valves. Appl. Acoust. 2020, 165, 107320. [Google Scholar] [CrossRef] [Green Version]

- Bajic´, B.; Keller, A. Spectrum Normalization Method in Vibro-Acoustical Diagnostic Measurements of Hydroturbine Cavitation. J. Fluids Eng. 1996, 118, 756–761. [Google Scholar] [CrossRef]

- Gruber, P.; Farhat, M.; Odermatt, P.; Etterlin, M.; Lerch, T.; Frei, M. The detection of cavitation in hydraulic machines by use of ultrasonic signal analysis. Int. J. Fluid Mach. Syst. 2015, 8, 264–273. [Google Scholar] [CrossRef] [Green Version]

- Dupont, P.; Caron, J.F.; Avellan, F.; Bourdon, P.; Lavigne, P.; Farhat, M.; Simoneau, R.; Dorey, J.M.; Archer, A.; Laperrousaz, E.; et al. Cavitation Erosion Prediction on Francis Turbines. Part 2 Model Tests and Flow Analysis. In Hydraulic Machinery and Cavitation; Cabrera, E., Espert, V., Martínez, F., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 574–583. [Google Scholar]

- Bourdon, P.; Farhat, M.; Simoneau, R.; Pereira, F.; Dupont, P.; Avellan, F.; Dorey, J.M. Cavitation Erosion Prediction on Francis Turbines—Part 1 Measurements on the Prototype. In Hydraulic Machinery and Cavitation; Cabrera, E., Espert, V., Martínez, F., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 534–543. [Google Scholar]

- Liu, Z.L.; Zhao, Y.; Guo, Q.B. An auto-test method based on acoustic theory of judging inception cavitation of runner blade of model Francis-turbine. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 163, p. 012061. [Google Scholar]

- Trivedi, C.; Iliev, I.; Dahlhaug, O.G.; Markov, Z.; Engstrom, F.; Lysaker, H. Investigation of a Francis turbine during speed variation: Inception of cavitation. Renew. Energy 2020, 166, 147–162. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, W.-T.; Zhao, W.; Binama, M.; Zhao, Y.; Huang, J.-Y.; Chen, X.-R. Experimental Francis Turbine Cavitation Performances of a Hydro-Energy Plant. Sustainability 2022, 14, 3263. https://doi.org/10.3390/su14063263

Su W-T, Zhao W, Binama M, Zhao Y, Huang J-Y, Chen X-R. Experimental Francis Turbine Cavitation Performances of a Hydro-Energy Plant. Sustainability. 2022; 14(6):3263. https://doi.org/10.3390/su14063263

Chicago/Turabian StyleSu, Wen-Tao, Wei Zhao, Maxime Binama, Yue Zhao, Jian-Ying Huang, and Xue-Ren Chen. 2022. "Experimental Francis Turbine Cavitation Performances of a Hydro-Energy Plant" Sustainability 14, no. 6: 3263. https://doi.org/10.3390/su14063263

APA StyleSu, W.-T., Zhao, W., Binama, M., Zhao, Y., Huang, J.-Y., & Chen, X.-R. (2022). Experimental Francis Turbine Cavitation Performances of a Hydro-Energy Plant. Sustainability, 14(6), 3263. https://doi.org/10.3390/su14063263