Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment

Abstract

:1. Introduction

2. Methodology

2.1. Waste Management Systems

2.2. Technical Performance

Energy Recovery

2.3. Environmental Performance

2.4. Financial Performance

2.5. Eco-Efficiency Analysis

2.6. Application: Abu Dhabi, UAE

3. Results and Discussion

3.1. Technical Performance

Energy Recovery

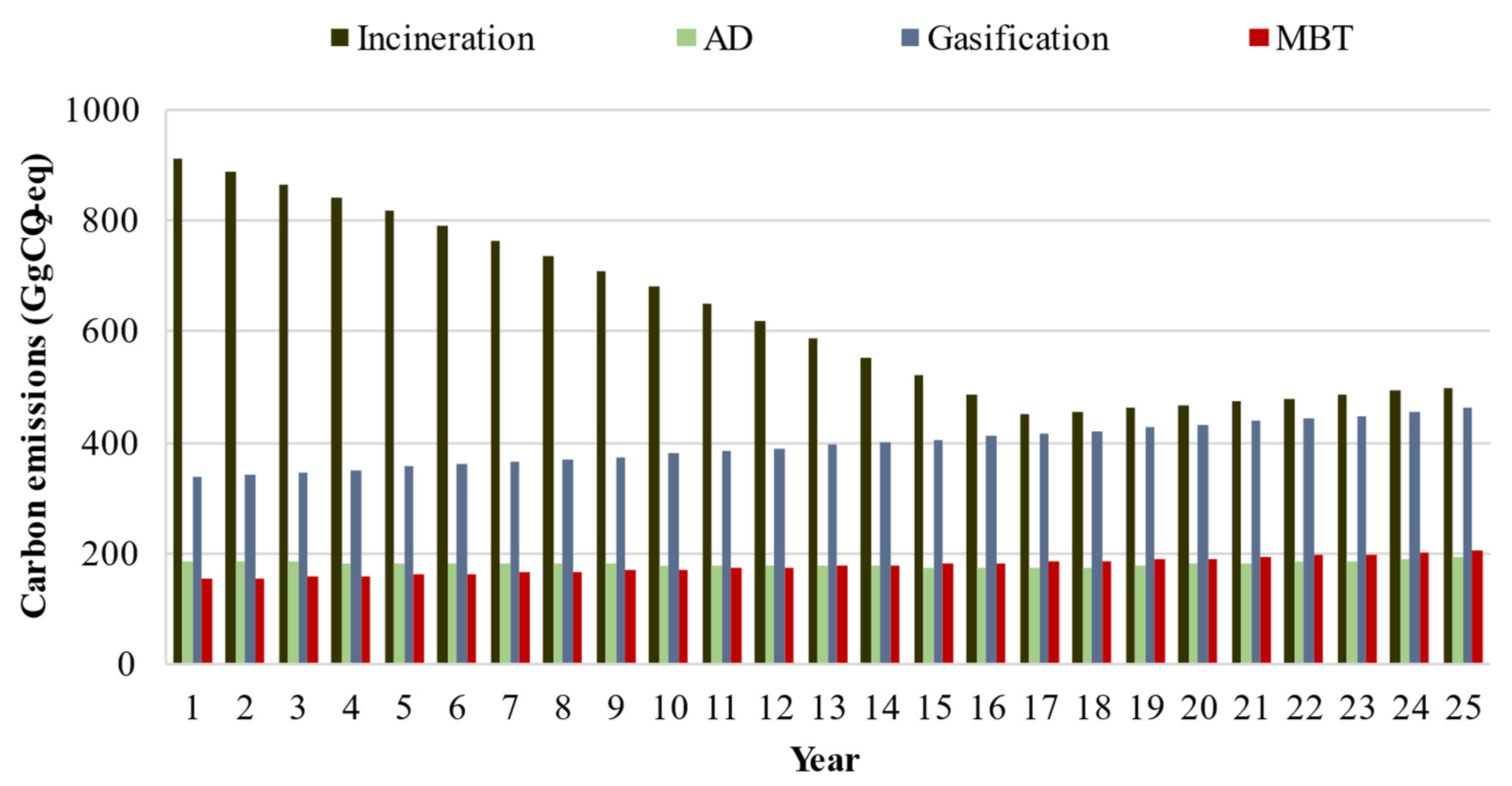

3.2. Environmental Performance

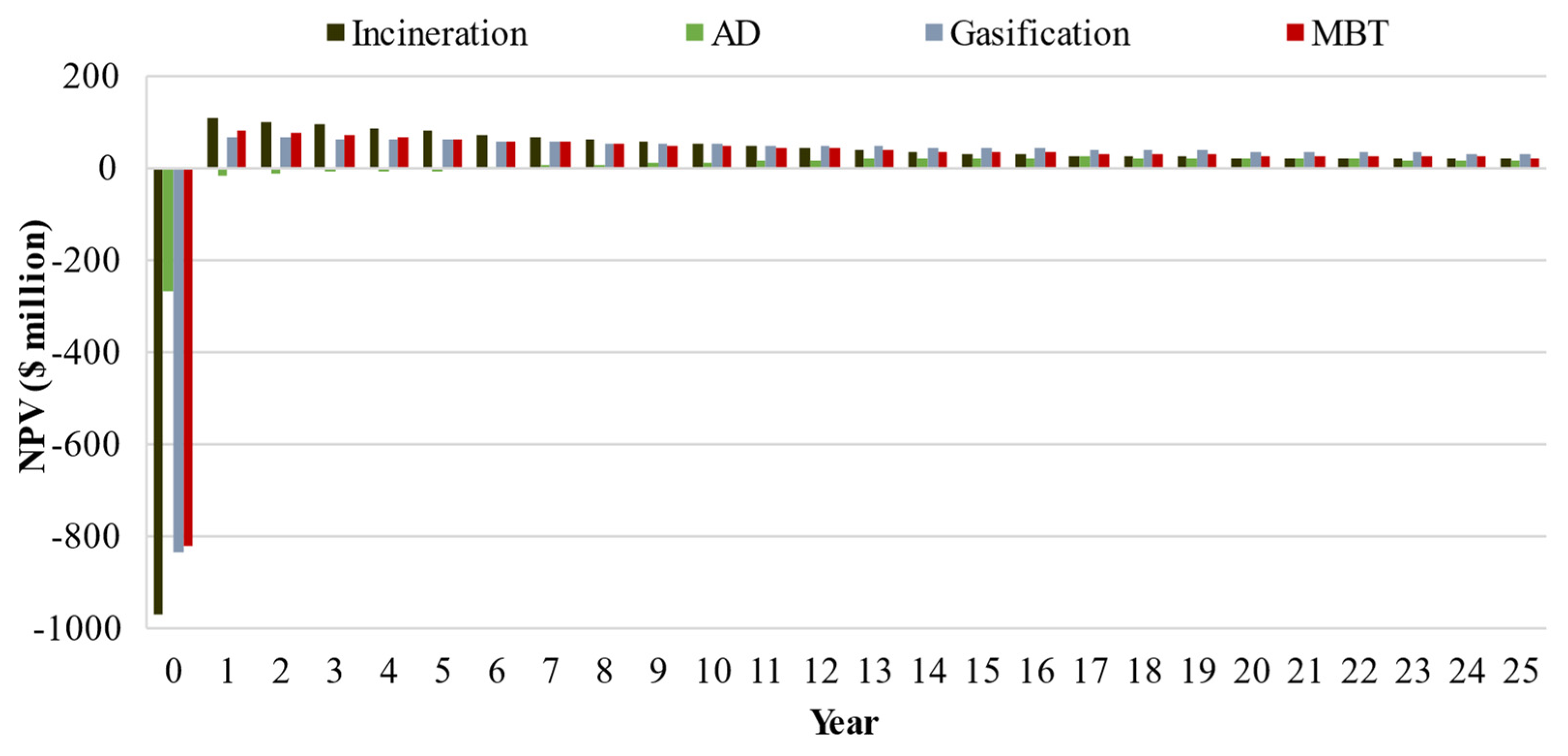

3.3. Life Cycle Costing Analysis

3.4. Eco-Efficiency Analysis

3.5. Suggested Reforms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| CAPEX | Capital costs |

| EI | Eco-efficiency index |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HHV | High heating value |

| IPCC | Intergovernmental panel climate change |

| IRR | Internal rate of return |

| ISWM | Integrated solid waste management |

| LCC | Life cycle costing |

| LCOE | Levelized cost of electricity |

| MBT | Mechanical biological treatment |

| MRF | Material recovery facility |

| MSW | Municipal solid waste |

| NPV | Net present value |

| OPEX | Operation and maintenance costs |

| PI | Profitability index |

| PP | Payback period |

| RDF | Refused derived fuel |

| UAE | United Arab Emirates |

| WTE | Waste-to-energy |

References

- Vlachokostas, C.; Michailidou, A.; Achillas, C. Multi-Criteria Decision Analysis towards Promoting Waste-to-Energy Management Strategies: A Critical Review. Renew. Sustain. Energy Rev. 2021, 138, 110563. [Google Scholar] [CrossRef]

- Hadidi, L.A.; Omer, M.M. A Financial Feasibility Model of Gasification and Anaerobic Digestion Waste-to-Energy (WTE) Plants in Saudi Arabia. Waste Manag. 2017, 59, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.; Harjunkoski, I. Performance Analysis of Waste-to-Energy Technologies for Sustainable Energy Generation in Integrated Supply Chains. Comput. Chem. Eng. 2020, 140, 106905. [Google Scholar] [CrossRef]

- Matter, A.; Dietschi, M.; Zurbrügg, C. Improving the Informal Recycling Sector through Segregation of Waste in the Household—The Case of Dhaka Bangladesh. Habitat Int. 2013, 38, 150–156. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal Solid Waste as a Valuable Renewable Energy Resource: A Worldwide Opportunity of Energy Recovery by Using Waste-To-Energy Technologies. Energy Procedia 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Abdallah, M.; Arab, M.; Shabib, A.; El-Sherbiny, R.; El-Sheltawy, S. Characterization and Sustainable Management Strategies of Municipal Solid Waste in Egypt. Clean Technol. Environ. Policy 2020, 22, 1371–1383. [Google Scholar] [CrossRef]

- Abdallah, M.; Elfeky, A. Impact of Waste Processing Byproducts on the Carbon Footprint of Integrated Waste-to-Energy Strategies. J. Environ. Manag. 2021, 280, 111839. [Google Scholar] [CrossRef]

- Belgiorno, V.; de Feo, G.; Della Rocca, C.; Napoli, R.M.A. Energy from Gasification of Solid Wastes. Waste Manag. 2003, 23, 1–15. [Google Scholar] [CrossRef]

- Fuss, M.; Vergara-Araya, M.; Barros, R.T.V.; Poganietz, W.R. Implementing Mechanical Biological Treatment in an Emerging Waste Management System Predominated by Waste Pickers: A Brazilian Case Study. Resour. Conserv. Recycl. 2020, 162, 105031. [Google Scholar] [CrossRef]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. Optimization of Waste to Energy Routes through Biochemical and Thermochemical Treatment Options of Municipal Solid Waste in Hyderabad, Pakistan. Energy Convers. Manag. 2016, 124, 333–343. [Google Scholar] [CrossRef]

- Patel, N. Municipal Solid Waste and Its Role in Sustainability. IEA Bioenergy 2003, 3, 4–9. [Google Scholar]

- Arena, U. Process and Technological Aspects of Municipal Solid Waste Gasification. A Review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef] [PubMed]

- Medina Jimenez, A.C.; Bereche, R.P.; Nebra, S. Three Municipal Solid Waste Gasification Technologies Analysis for Electrical Energy Generation in Brazil. Waste Manag. Res. 2019, 37, 631–642. [Google Scholar] [CrossRef]

- Scaglia, B.; Salati, S.; di Gregorio, A.; Carrera, A.; Tambone, F.; Adani, F. Short Mechanical Biological Treatment of Municipal Solid Waste Allows Landfill Impact Reduction Saving Waste Energy Content. Bioresour. Technol. 2013, 143, 131–138. [Google Scholar] [CrossRef]

- Trulli, E.; Ferronato, N.; Torretta, V.; Piscitelli, M.; Masi, S.; Mancini, I. Sustainable Mechanical Biological Treatment of Solid Waste in Urbanized Areas with Low Recycling Rates. Waste Manag. 2018, 71, 556–564. [Google Scholar] [CrossRef]

- Bezama, A.; Aguayo, P.; Konrad, O.; Navia, R.; Lorber, K.E. Investigations on Mechanical Biological Treatment of Waste in South America: Towards More Sustainable MSW Management Strategies. Waste Manag. 2007, 27, 228–237. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Albi, M.; Jarlard, C. Key Factors Influencing the Environmental Performance of Pyrolysis, Gasification and Incineration Waste-to-Energy Technologies. Energy Convers. Manag. 2019, 196, 497–512. [Google Scholar] [CrossRef] [Green Version]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of Waste-to-Energy Technologies of Gasification and Incineration Using Life Cycle Assessment: Case Studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300. [Google Scholar] [CrossRef]

- Barrena, R.; d’Imporzano, G.; Ponsá, S.; Gea, T.; Artola, A.; Vázquez, F.; Sánchez, A.; Adani, F. In Search of a Reliable Technique for the Determination of the Biological Stability of the Organic Matter in the Mechanical-Biological Treated Waste. J. Hazard. Mater. 2009, 162, 1065–1072. [Google Scholar] [CrossRef] [Green Version]

- Donovan, S.M.; Bateson, T.; Gronow, J.R.; Voulvoulis, N. Modelling the Behaviour of Mechanical Biological Treatment Outputs in Landfills Using the GasSim Model. Sci. Total Environ. 2010, 408, 1979–1984. [Google Scholar] [CrossRef]

- Zdanevitch, I.; Bour, O.; Llinas, L.; Lejal, S. Comparison of Polluting Potentials of Liquid Emissions from MBT Plants. Energy Convers. Manag. 2009, 196, 399–400. [Google Scholar]

- di Lonardo, M.C.; Lombardi, F.; Gavasci, R. Characterization of MBT Plants Input and Outputs: A Review. Rev. Environ. Sci. Biotechnol. 2012, 11, 353–363. [Google Scholar] [CrossRef]

- Fei, F.; Wen, Z.; Huang, S.; de Clercq, D. Mechanical Biological Treatment of Municipal Solid Waste: Energy Efficiency, Environmental Impact and Economic Feasibility Analysis. J. Clean. Prod. 2018, 178, 731–739. [Google Scholar] [CrossRef]

- Montejo, C.; Tonini, D.; del Carmen Márquez, M.; Fruergaard Astrup, T. Mechanical-Biological Treatment: Performance and Potentials. An LCA of 8 MBT Plants Including Waste Characterization. J. Environ. Manag. 2013, 128, 661–673. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thibodeau, C.; Monette, F.; Bulle, C.; Glaus, M. Comparison of Black Water Source-Separation and Conventional Sanitation Systems Using Life Cycle Assessment. J. Clean. Prod. 2014, 67, 45–57. [Google Scholar] [CrossRef]

- Mabalane, P.N.; Oboirien, B.O.; Sadiku, E.R.; Masukume, M. A Techno-Economic Analysis of Anaerobic Digestion and Gasification Hybrid System: Energy Recovery from Municipal Solid Waste in South Africa. Waste Biomass Valorization 2020, 12, 1167–1184. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Pezzola, L.; Mussi, R.; Bromberg, L.; Heywood, J.; Kasseris, E. A Novel Low-Cost Tar Removal Technology for Small-Scale Biomass Gasification to Power. Biomass Bioenergy 2021, 149, 106085. [Google Scholar] [CrossRef]

- Yassin, L.; Lettieri, P.; Simons, S.J.R.; Germanà, A. Techno-Economic Performance of Energy-from-Waste Fluidized Bed Combustion and Gasification Processes in the UK Context. Chem. Eng. J. 2009, 146, 315–327. [Google Scholar] [CrossRef]

- Paes, M.X.; de Medeiros, G.A.; Mancini, S.D.; Bortoleto, A.P.; Puppim de Oliveira, J.A.; Kulay, L.A. Municipal Solid Waste Management: Integrated Analysis of Environmental and Economic Indicators Based on Life Cycle Assessment. J. Clean. Prod. 2020, 254, 119848. [Google Scholar] [CrossRef]

- Rigamonti, L.; Borghi, G.; Martignon, G.; Grosso, M. Life Cycle Costing of Energy Recovery from Solid Recovered Fuel Produced in MBT Plants in Italy. Waste Manag. 2019, 99, 154–162. [Google Scholar] [CrossRef]

- Bourtsalas, A.T.; Triantafyllou, V. Financial and Environmental Assessment of Four Advanced European MBT Facilities. 2019. Available online: http://uest.ntua.gr/heraklion2019/proceedings/pdf/HERAKLION2019_Bourtsalas_Triantafyllou.pdf (accessed on 10 February 2022).

- Abdalla, H.; Rahmat-Ullah, Z.; Abdallah, M.; Alsmadi, S.; Elashwah, N. Eco-Efficiency Analysis of Integrated Grey and Black Water Management Systems. Resour. Conserv. Recycl. 2021, 172, 105681. [Google Scholar] [CrossRef]

- ISO. 14045 Environmental Management—Ecoefficiency Assessment of Product Systems—Principles, Requirements and Guidelines; ISO: Geneva, Switzerland, 2012; ISBN 2831886376. [Google Scholar]

- Abdallah, M.; Shanableh, A.; Shabib, A.; Adghim, M. Financial Feasibility of Waste to Energy Strategies in the United Arab Emirates. Waste Manag. 2018, 82, 207–219. [Google Scholar] [CrossRef] [PubMed]

- Calì, G.; Deiana, P.; Bassano, C.; Meloni, S.; Maggio, E.; Mascia, M.; Pettinau, A. Syngas Production, Clean-up and Wastewater Management in a Demo-Scale Fixed-Bed Updraft Biomass Gasification Unit. Energies 2020, 13, 2594. [Google Scholar] [CrossRef]

- Economopoulos, A.P. Technoeconomic Aspects of Alternative Municipal Solid Wastes Treatment Methods. Waste Manag. 2010, 30, 707–715. [Google Scholar] [CrossRef]

- Christensen, T.H.; Boldrin, A.; Körner, I.; Krogmann, U. Composting: Mass Balances and Product Quality. Solid Waste Technol. Manag. 2010, 2, 569–582. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2017; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017; p. 92. ISBN 978-3-9815934-2-6. [Google Scholar]

- Ouda, O.K.M.; Raza, S.A.; Nizami, A.S.; Rehan, M.; Al-Waked, R.; Korres, N.E. Waste to Energy Potential: A Case Study of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 61, 328–340. [Google Scholar] [CrossRef]

- Arafat, H.A.; Jijakli, K. Modeling and Comparative Assessment of Municipal Solid Waste Gasification for Energy Production. Waste Manag. 2013, 33, 1704–1713. [Google Scholar] [CrossRef]

- IPCC 2006. IPCC Guidelines for National Greenhouse Gas Inventories: Vol 5 Chapter 3 Solid Waste Disposal. 2006 IPCC Guidel. Natl. Greenh. Gas Invent. 2006, 4, 6.1–6.49. [Google Scholar]

- Abdallah, M.; Hamdan, S.; Shabib, A. A Multi-Objective Optimization Model for Strategic Waste Management Master Plans. J. Clean. Prod. 2021, 284, 124714. [Google Scholar] [CrossRef]

- Ouda, O.K.M.; Raza, S.A.; Al-Waked, R.; Al-Asad, J.F.; Nizami, A.S. Waste-to-Energy Potential in the Western Province of Saudi Arabia. J. King Saud Univ. Eng. Sci. 2017, 29, 212–220. [Google Scholar] [CrossRef] [Green Version]

- Zainal, Z.A.; Rifau, A.; Quadir, G.A.; Seetharamu, K.N. Experimental Investigation of a Downdraft Biomass Gasifier. Biomass Bioenergy 2002, 23, 283–289. [Google Scholar] [CrossRef]

- Pipatti, R.; Sharma, C.; Yamada, M. Chapter 2: Waste Generation and Compositon and Management Data. IPCC Guidel. Natl. Greenh. Gas Invent. 2006, 5, 23. [Google Scholar]

- Rogoff, M.J.; Screve, F. Introduction and Overview, Waste-To-Energy. Res. Transp. Econ. 2011, 10, 1–9. [Google Scholar] [CrossRef]

- Abdallah, M.; Rahmat-Ullah, Z.; Metawa, A. Dynamic Multi-Objective Optimization of Integrated Waste Management Using Genetic Algorithms. In Soft Computing Techniques in Solid Waste and Wastewater Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 257–274. [Google Scholar]

- Intergovernmental Panel on Climate Change. Climate Change 2007: The Physical Science Basis: Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007; ISBN 9780521705967. [Google Scholar]

- Statistics Centre of Abu Dhabi Waste Statistics; Abu Dhabi, 2018. Available online: https://data.abudhabi/dataset/waste-statistics-2018 (accessed on 10 February 2022).

- Groot, K.I. Activating Household Waste Separation Behaviour in High-Rise Rotterdam. 2019. Available online: https://repository.tudelft.nl/islandora/object/uuid:220f7d4f-81a8-4236-80f8-42ab3c0eb1be/datastream/OBJ/download (accessed on 10 February 2022).

- Sarbassov, Y.; Sagalova, T.; Tursunov, O.; Venetis, C.; Xenarios, S.; Inglezakis, V. Survey on Household Solid Waste Sorting at Source in Developing Economies: A Case Study of Nur-Sultan City in Kazakhstan. Sustainability 2019, 11, 6496. [Google Scholar] [CrossRef] [Green Version]

- Santoso, A.N. Farizal Community Participation in Household Waste Management: An Exploratory Study in Indonesia. E3S Web Conf. 2019, 125, 07013. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A Review on Technological Options of Waste to Energy for Effective Management of Municipal Solid Waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Judge, A. 2017 Briefing Report: Mechanical Biological Treatment-15 Years of UK Experience. 2017. Available online: https://www.tolvik.com/wp-content/uploads/2017/09/Tolvik-2017-Briefing-Report-Mechanical-Biological-Treatment.pdf (accessed on 10 February 2022).

- Ministery of Environment and water Ministerial Resolution Number (476) of the Year 2007 Concerning by-Law of AGCC Fertilizers and Agricultural Soil Conditioners Law; Abu Dhabi, 2007. Available online: https://www.moccae.gov.ae/assets/download/e4e8ae38/476.pdf.aspx?view=true (accessed on 10 February 2022).

- Gesell, G.; Fryklind, K.; Spott, B. Case Study of WTE and Gasification. In Proceedings of the North American Waste-to-Energy Conference, Lancaster, PN, USA, 19 February 2018; pp. 1–8. [Google Scholar]

- Nadan, M.K. Waste to Energy: Biogas from Municipal Solid Waste for Power Generation. Adv. Glob. Change Res. 2020, 68, 129–149. [Google Scholar] [CrossRef]

- Khan, M.S.M.; Kaneesamkandi, Z. Biodegradable Waste to Biogas: Renewable Energy Option for the Kingdom of Saudi Arabia. Int. J. Innov. Appl. Stud. 2013, 4, 101–113. [Google Scholar]

- Korai, M.S.; Mahar, R.B.; Uqaili, M.A. The Feasibility of Municipal Solid Waste for Energy Generation and Its Existing Management Practices in Pakistan. Renew. Sustain. Energy Rev. 2017, 72, 338–353. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; Jaramillo, D.; Játiva, E.; Kaparaju, P. Waste-To-Energy Technologies: An Opportunity of Energy Recovery from Municipal Solid Waste, Using Quito-Ecuador as Case Study. Energy Procedia 2017, 134, 327–336. [Google Scholar] [CrossRef]

- The Word Bank CO2 Emissions (Metric Tons per Capita)—United Arab Emirates. Available online: https://data.worldbank.org/indicator/EN.ATM.CO2E.PC?locations=AE (accessed on 10 February 2022).

- United Arab Emirates Ministry of Energy & Industry United Arab Emirates 4rth National National Communication Report. 2018. Available online: https://www.moei.gov.ae/en/open-data.aspx (accessed on 10 February 2022).

- Sun, Y.; Qin, Z.; Tang, Y.; Huang, T.; Ding, S.; Ma, X. Techno-Environmental-Economic Evaluation on Municipal Solid Waste (MSW) to Power/Fuel by Gasification-Based and Incineration-Based Routes. J. Environ. Chem. Eng. 2021, 9, 106108. [Google Scholar] [CrossRef]

- Kourkoumpas, D.S.; Karellas, S.; Kouloumoundras, S.; Koufodimos, G.; Grammelis, P.; Kakaras, E. Comparison of Waste-to-Energy Processes by Means of Life Cycle Analysis Principles Regarding the Global Warming Potential Impact: Applied Case Studies in Greece, France and Germany. Waste Biomass Valorization 2015, 6, 605–621. [Google Scholar] [CrossRef]

- University of Arkansas Implementing Incentives Programs to Increase Recycling Participation. 2010. Available online: https://sustainability.uark.edu/_resources/pdfs/acad-cap-2013-teague.pdf (accessed on 10 February 2022).

| Facility | By-Products | Fate of by-Products | Fraction (%) | References |

|---|---|---|---|---|

| Incineration | Heat | Energy generation | 90 | [34] |

| Ash | Landfill | 10 | ||

| Anaerobic digestion (AD) | Biogas | Energy generation | 60 | [34] |

| Digestate | Market/Incineration/Landfill | 40 | ||

| Gasification | Syngas | Energy generation | 80 | [35] |

| Ash and slag | Landfill | 20 | ||

| Mechanical sorting * | Recyclables | Market | 30 | [36] |

| Biodegradables | Composting facility | 30 | ||

| RDF | Market | 18 | ||

| Rejects | Landfill | 22 | ||

| Aerobic composting * | Emissions | - | 70 | [37] |

| Compost | Market | 30 |

| Parameter | Definition | Computation | Remarks | Interpretation |

|---|---|---|---|---|

| Net present value (NPV) | Present value of projected future cash flows during the assessment period | NPV = ∑ (CLt − COt) × (1 + i)−t | CIt and COt are the cash inflow and outflow in year t ($) t is the economic life of the project (years) i is the discount rate (%) | Positive NPV indicates a profitable project |

| Internal rate of return (IRR) | Discounted cash flow criterion that estimates the return of potential investments | Computed by a built-in function in Microsoft Excel given the annual cash flows | - | IRR greater than the discount rate implies a profitable project |

| Payback period (PP) | Time required to recover initial expenses | Determined from a curve (cumulative NPV over the lifespan of the project) | Intersection between the curve and the zero NPV line indicates the value of PP | PP less than the design period indicates a profitable project |

| Profitability index (PI) | Describes the relation between initial expenses and benefits of a project | PI = [PVP − ∑ [(OPEXt + Lt)/(1 + i)t]/CAPEX] | PVP is the present value of cash inflow ($) OPEXt is the operation and maintenance cost in year t i is the discount rate (%) t is the economic life of the project (years) Lt is the total cost of landfilling in year t CAPEX is the initial investment cost | PI indicates the profitability of the project based on the initial investments only |

| Levelized cost of electricity (LCOE) | Minimum electricity generation requirement to recover cost and reach a breakeven point for a project | LCOE = [CAPEX + ∑ [(OPEXt + Lt)/(1 + i)t]/(Et/(1 + i)t)] | CAPEX is the initial investment cost OPEXt is the operation and maintenance cost in year t Lt is the total cost of landfilling in year t t is the economic life of the project (years) Et is the amount of electricity generated in year t (MWh) i is the discount rate (%) | LCOE less than the electricity tariff indicates a profitable project |

| Parameter * | Incineration | Anaerobic Digestion (AD) | Gasification | Mechanical Biological Treatment (MBT) |

|---|---|---|---|---|

| CAPEX ($/ton) | 550 | 300 | 500 | 450 |

| OPEX (% of CAPEX) | 10 | 5.5 | 12 | 8 |

| Strategy | Carbon Footprint (Ggco2-Eq) | NPV ($ Million) | IRR (%) | PI | PP (Year) | LCOE ($/Kwh) | EI |

|---|---|---|---|---|---|---|---|

| Incineration | 14,230 | 248 | 8 | 1.16 | 17 | 0.134 | 0.46 |

| AD | 4539 | 33 | 7 | 1.12 | 25 | 0.120 | 0.99 |

| Gasification | 9922 | 364 | 9 | 1.44 | 16 | 0.108 | 0.19 |

| MBT | 4442 | 284 | 9 | 1.35 | 17 | 0.141 | 0.11 |

| Strategy | Reform | Carbon Footprint (GgCO2-eq) | NPV ($ Million) | IRR (%) | PI | PP (year) | LCOE ($/kWh) | EI |

|---|---|---|---|---|---|---|---|---|

| Incineration | No reform | 14,230 | 248 | 8 | 1.16 | 17 | 0.134 | 0.46 |

| Reform 1: Recycling incentive program | 12,909 | 150 | 7 | 1.15 | 20 | 0.141 | 0.6 | |

| AD | No reform | 4539 | 33 | 7 | 1.12 | 25 | 0.120 | 0.99 |

| Reform 2: Less stringent bylaws on digestate usage | 3820 | 270 | 9 | 1.89 | 19 | 0.131 | 0.12 | |

| Reform 3: Increased food waste source separation | 4445 | 125 | 8 | 1.16 | 21 | 0.109 | 0.25 | |

| Gasification | No reform | 9922 | 364 | 9 | 1.44 | 16 | 0.108 | 0.19 |

| Reform 3: Increased food waste source separation | 9436 | 455 | 10 | 1.54 | 15 | 0.103 | 0.15 | |

| MBT | No reform | 4442 | 284 | 9 | 1.35 | 17 | 0.141 | 0.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdeljaber, A.; Zannerni, R.; Masoud, W.; Abdallah, M.; Rocha-Meneses, L. Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment. Sustainability 2022, 14, 3899. https://doi.org/10.3390/su14073899

Abdeljaber A, Zannerni R, Masoud W, Abdallah M, Rocha-Meneses L. Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment. Sustainability. 2022; 14(7):3899. https://doi.org/10.3390/su14073899

Chicago/Turabian StyleAbdeljaber, Abdulrahman, Rawan Zannerni, Wedad Masoud, Mohamed Abdallah, and Lisandra Rocha-Meneses. 2022. "Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment" Sustainability 14, no. 7: 3899. https://doi.org/10.3390/su14073899

APA StyleAbdeljaber, A., Zannerni, R., Masoud, W., Abdallah, M., & Rocha-Meneses, L. (2022). Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment. Sustainability, 14(7), 3899. https://doi.org/10.3390/su14073899