Digital Atlas of Tactics to Designing Sustainable Factories

Abstract

:1. Introduction

1.1. Existing Design-Support Tools to Mitigate the Negative Impact of Factories on the Landscape

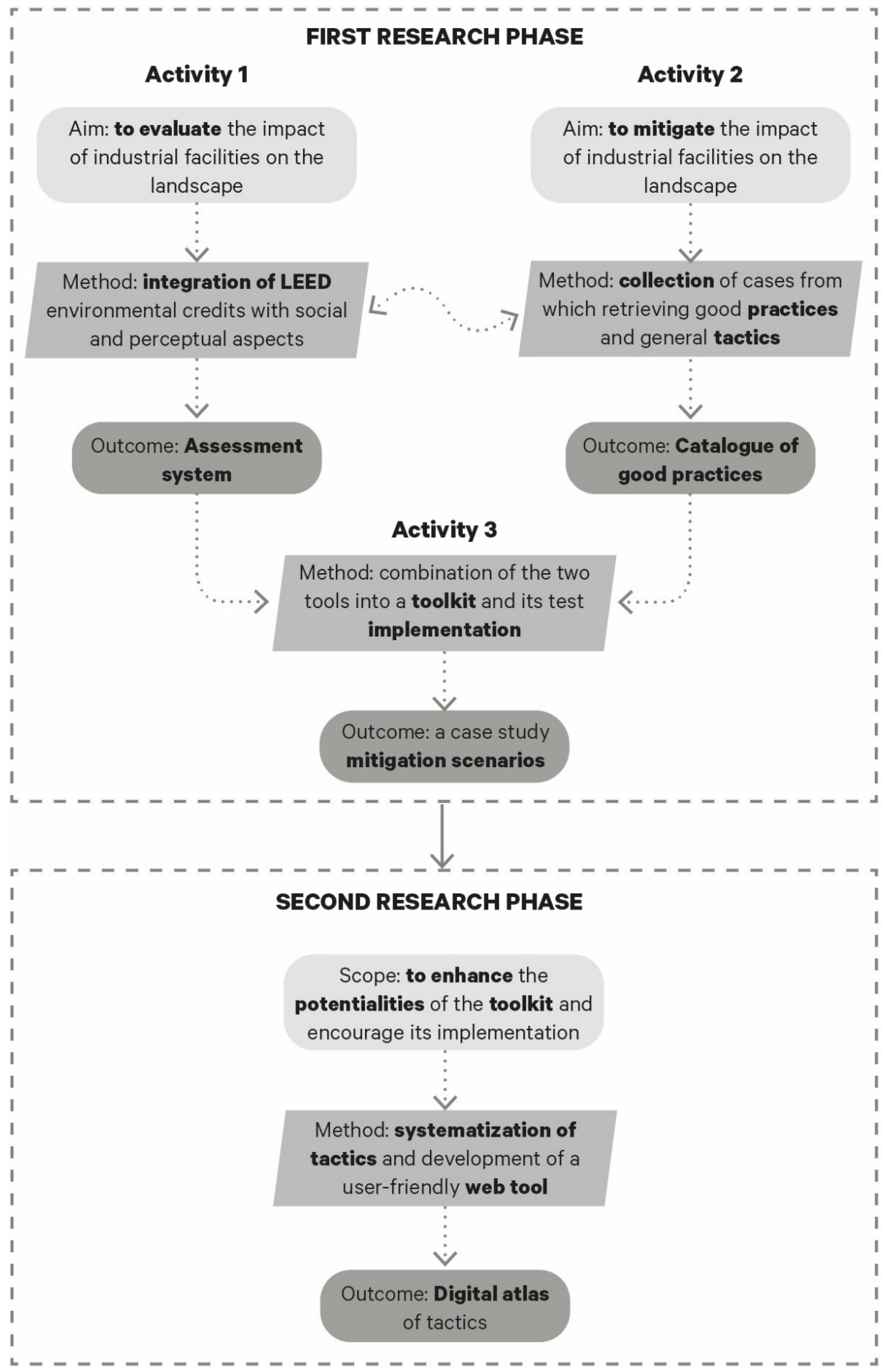

1.2. A Research Project Supporting a Holistic, Sustainable Design of Factories

- To make it possible for potential users to find and understand tactics suitable to their project peculiarities.

- To make the effectiveness of the tactic(s) in which they are interested clear to users.

- To highlight mutual synergies among tactics and thus promote holistic, sustainable design and related benefits.

- To make it simple to the final users to search for tactics through their own mental scheme (i.e., open, flexible, and multi-facet searches).

2. Materials and Methods

- Collection of tactics, from the identification of eligibility criteria and the analysis of real-world case studies to the description of tactics.

- Definition of a weighting matrix for tactics, which can guide the users in selecting the most suitable to their goals.

- Definition of a faceted classification for tactics and its implementation, to highlight mutual links among tactics.

- Definition of the architecture of the Digital Atlas to meet the needs and preferences of potential users.

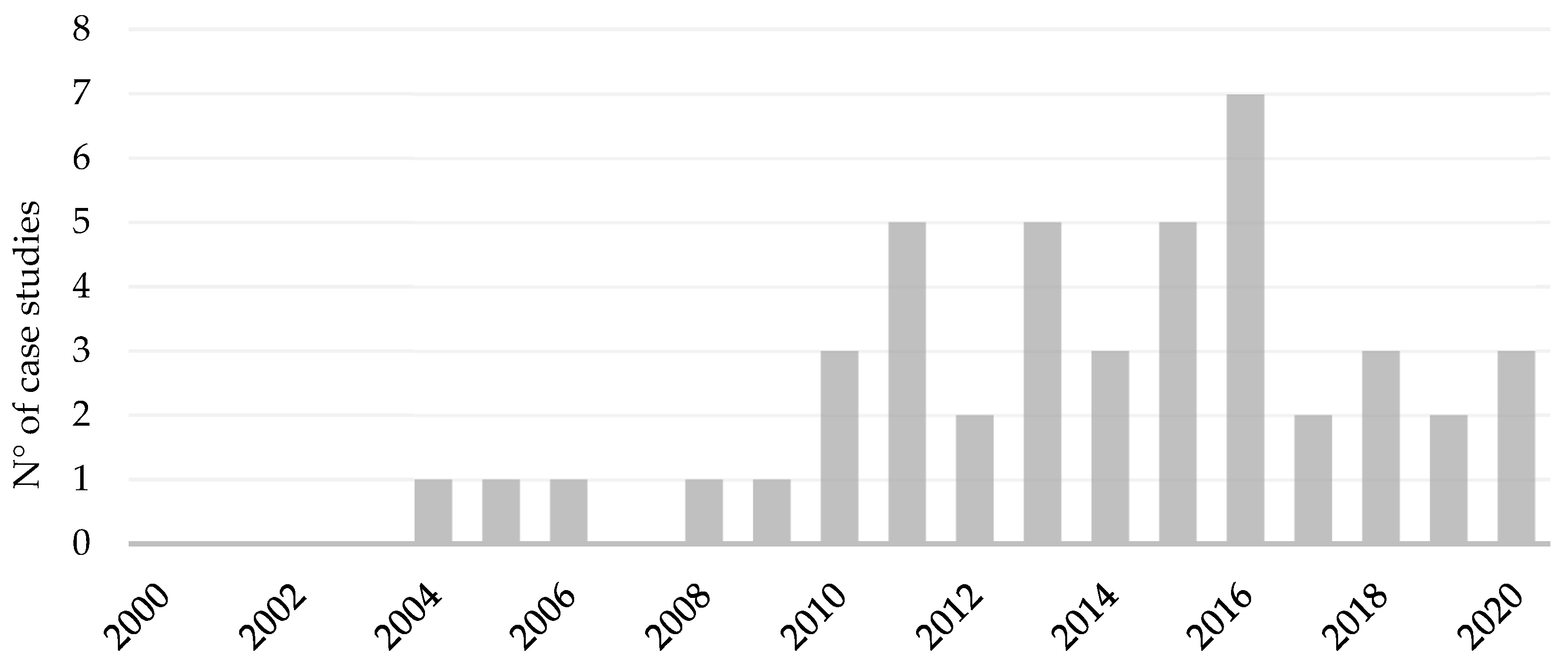

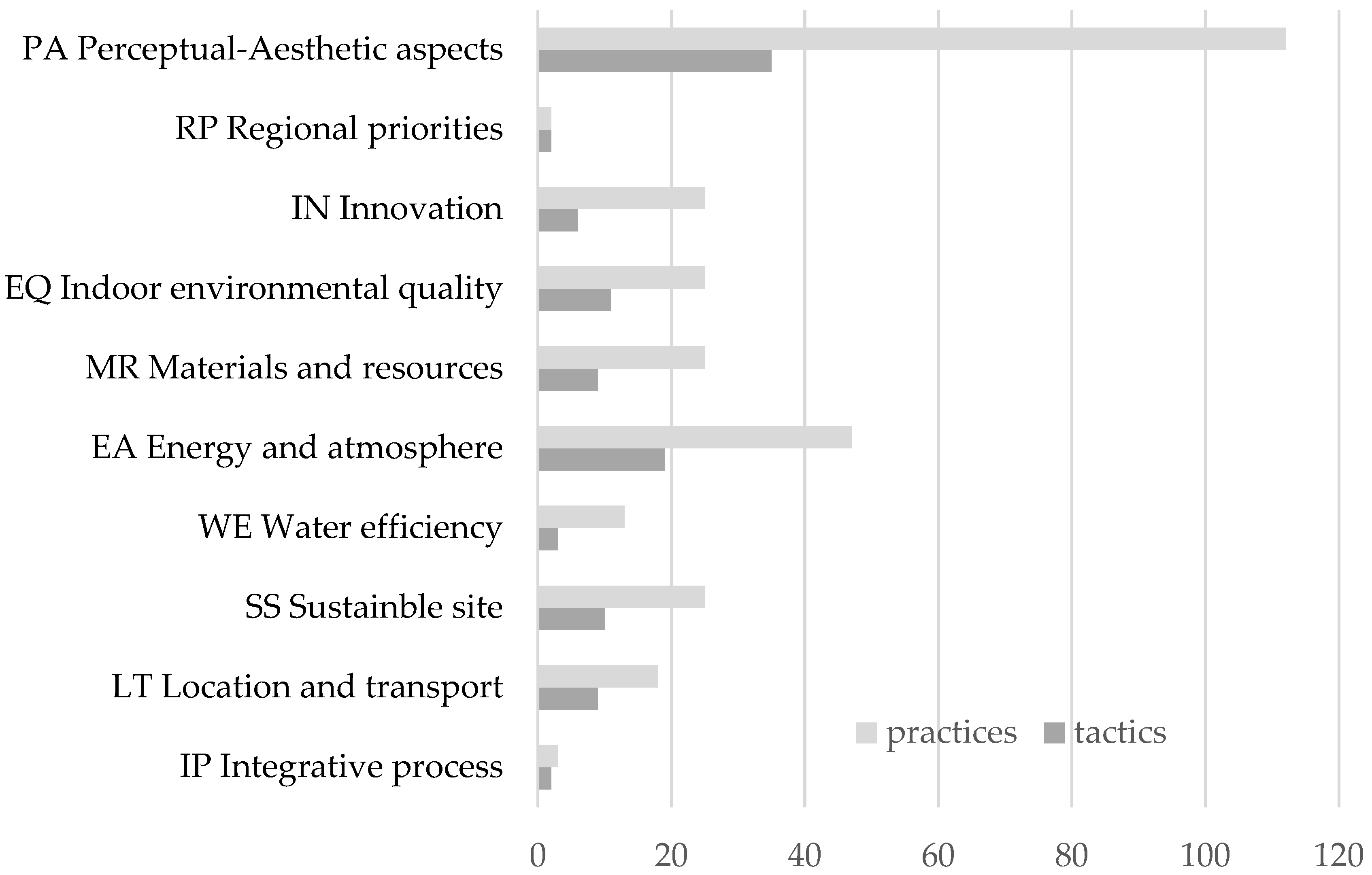

2.1. Collection of Tactics

- When a practice recurs the same in at least two cases, it is converted into a tactic.

- When two practices have a common denominator, a general tactic is extracted.

2.2. Weighing Matrix

2.3. Faceted Classification

- (i)

- The system of classification (whether taxonomy, faceted, or mixed).

- (ii)

- The type of interface (direct selection of category/attribute, Simple Query Interface (SQI), multiple filters, or a combination of them).

- (iii)

- The list of categories and attributes (when available, divided per level).

2.4. Architecture of the Digital Atlas

- What will the user look for?

- How will the user search for it?

- What language would he/she most likely use?

- How should search results be illustrated and organized to best serve the user?

3. Results

3.1. Collection of Tactics

3.2. Weighting Matrix

3.3. Faceted Classification

- (i)

- Type (i.e., Technological, Formal, functional, or management)

- (ii)

- Building part (e.g., Load-Bearing structure)

- (iii)

- Impact category (e.g., Climate change)

- (iv)

- Material (e.g., Wood)

- (v)

- Type of intervention (i.e., new construction, renovation, or suitable to both)

- (vi)

- General strategy (e.g., energy efficiency)

- (vii)

- Level (i.e., site, building, process, or not scale-dependent)

3.4. Architecture of the Digital Atlas

- Firstly, the content to be shown once the user accesses the atlas has been defined: tactics are the primary object of the search, then associated practices and case studies can be illustrated and references to bibliography or webography provided.

- The user will probably use keywords or access interesting categories to search tactics. Hence, the search interface might combine an SQI—as in many architectural portals—with a horizontal menu including multiple choices or filters. The two modes will allow users to follow the most suitable for them.

- The SQI will make use of an information-retrieval system linking typed words with synonyms or semantic fields connected to available tactics. An automatic filling tool for words can also be implemented to help non technicians.

- Results of the user search must be clear to both designers and entrepreneurs. Most relevant data should be highlighted, and the shift to linked information (tactics or supplementary materials) must be easy. Possibly, the user should be able to track the browsing and save preferred contents (either on the digital portal or by downloading a pdf version). Correlated tactics must be highlighted to the user basing the selection on the type of search (attributes or categories) the user is interested in.

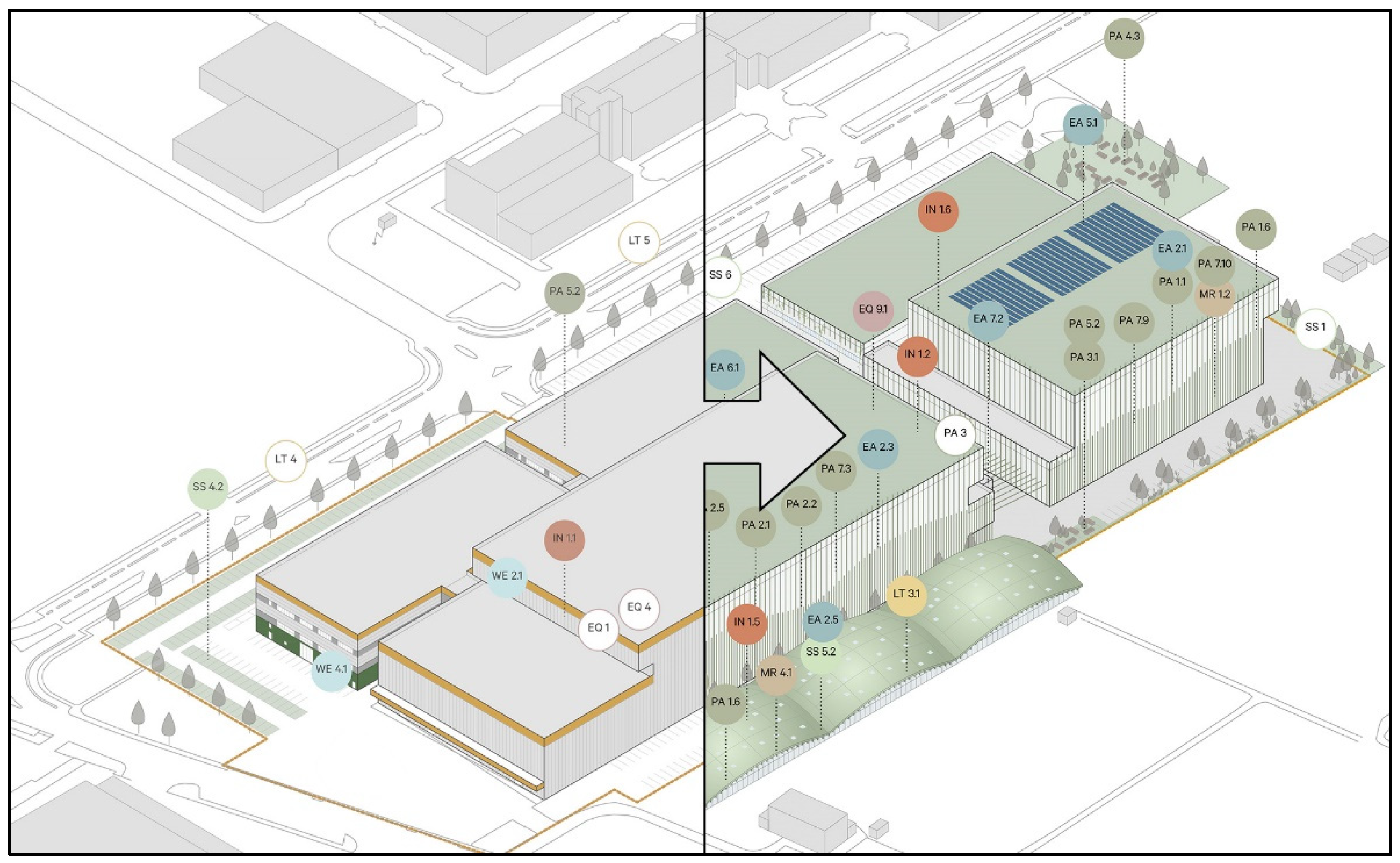

3.5. Possible Implementation of the Atlas

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- May, G.; Stahl, B.; Taisch, M. Energy management in manufacturing: Toward eco-factories of the future-A focus group study. Appl. Energy 2016, 164, 628–638. [Google Scholar] [CrossRef]

- Herrmann, C.; Blume, S.; Kurle, D.; Schmidt, C.; Thiede, S. The positive impact factory-Transition from eco-efficiency to eco-effectiveness strategies in manufacturing. Procedia CIRP 2015, 29, 19–27. [Google Scholar] [CrossRef]

- Delpiano, A.; Trombetti, G. (Eds.) EnergiApea. Vincere la Sfida Energetica; Tipografia Metropolitana Bologna: Bologna, Italy, 2011. [Google Scholar]

- Busquets i Fabregas, J. (Ed.) Per una Corretta Visione del Paesaggio: Linee Guida Traduzione; Generalitat de Catalunya: Barcelona, Spain, 2007.

- Cassatella, C.; Gambino, R. Linee Guida per i Paesaggi Industriali, un’Esperienza di Ricerca. In Proceedings of the XXXIV Conferenza Italiana di Scienze Regionali, Palermo, Italy, 2–3 September 2013; pp. 1–14. [Google Scholar]

- Cipriani, L. Vita e Morte del Paesaggio Industriale. Indagini e Proposte per la Marca Trevigiana in Trasformazione; Università degli Studi di Trento: Trento, Italy, 2012. [Google Scholar]

- Dombrowski, U.; Riechel, C. Sustainable Factory Profile: A Concept to Support the Design of Future Sustainable Industries. In Proceedings of the 11th Global Conference on Sustainable Manufacturing, Berlin, Germany, 23–25 September 2013; pp. 72–77. [Google Scholar]

- Pal, U. Identifying the path to successful green manufacturing. J. Miner. Met. Mater. Soc. 2002, 54, 25. [Google Scholar] [CrossRef]

- Kaur, G.P.; Gupta, P.; Syal, M. Adoption of green practices in industrial buildings: An action research on capacity building of stakeholders towards green factories. Int. J. Sustain. Land Use Urban Plan. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Grant, J. Planning and designing for eco-efficiency industrial landscapes. J. Clean. Prod. 1997, 5, 75–78. [Google Scholar] [CrossRef]

- Lowe, E.A.; Moran, S.R.; Holmes, D.B. Fieldbook for the Development of Eco-Industrial Parks; Final Report; Indigo Development: Oakland, CA, USA, 1996. [Google Scholar]

- ARUP. Redefining the Green Factory. Available online: https://www.arup.com/perspectives/redefining-the-green-factory?utm_medium=social&utm_source=twitter&utm_campaign=green_factory_perspective_250322&utm_content=global (accessed on 24 March 2022).

- Center of Excellence on Green Productivity. Overview and Case Studies on Green Factory in R.O.C. Taiwan. 2013. Available online: http://www.apo-coegp.org (accessed on 30 March 2022).

- Bartolucci, L.; Cordiner, S.; Mulone, V.; Santarelli, M.; Lombardi, P.; Arendarski, B. Towards Net Zero Energy Factory: A multi-objective approach to optimally size and operate industrial flexibility solutions. Int. J. Electr. Power Energy Syst. 2022, 137, 107796. [Google Scholar] [CrossRef]

- Klingmann, A. Brandscapes. Architecture in the Experience Economy; MIT Press: Cambridge, MA, USA, 2007. [Google Scholar]

- Qualizza, G. Inventare lo spazio di una green factory. In Green Marketing per le Aree Industriali. Metodologie, Strumenti e Pratiche; Cavallo, M., Esposti, P.D., Konstantinou, K., Eds.; Franco Angeli: Milano, Italy, 2012; pp. 220–238. [Google Scholar]

- Schönborn, G.; Berlin, C.; Pinzone, M.; Hanisch, C.; Georgoulias, K.; Lanz, M. Why social sustainability counts: The impact of corporate social sustainability culture on financial success. Sustain. Prod. Consum. 2019, 17, 1–10. [Google Scholar] [CrossRef]

- European Union. New European Bauhaus. 2020. Available online: https://europa.eu/new-european-bauhaus/about/about-initiative_en (accessed on 3 June 2021).

- OECD. OECD Sustainable Manufacturing Tookit-Start-Up Guide. 2011. Available online: www.oecd.org/innovation/green/toolkit (accessed on 13 October 2020).

- Eurostat. Manufacturing Statistics-NACE Rev. 2. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Manufacturing_statistics_-_NACE_Rev._2#:~:text=The%20manufacturing%20sector%20employed%20more,in%20the%20EU%20in%202017.&text=Almost%202%20million%20enterprises%20were,in%20the%20EU%20in%202017 (accessed on 27 May 2021).

- U.S. GBC. LEED and Industrial Facilities. Available online: https://www.usgbc.org/articles/leed-and-industrial-facilities-meet-four-top-users-leed-videos (accessed on 25 October 2020).

- BREEAM Industrial. Available online: https://www.breeam.com/tag/industrial/ (accessed on 23 October 2020).

- DGNB Industrial Site. Available online: https://www.dgnb-system.de/en/districts/industrial-sites/index.php (accessed on 12 October 2020).

- CASBEE. Available online: http://www.ibec.or.jp/CASBEE/english/ (accessed on 27 October 2020).

- GREEN STAR Industrial v1. Available online: https://www.gbca.org.au/uploads/61/2877/Industrial%20Fact%20Sheet.pdf?_ga=2.161795772.1400222791.1604067905-1340215372.1604067905 (accessed on 12 October 2020).

- Zimmermann, R.K.; Skjelmose, O.; Jensen, K.G.; Jensen, K.K.; Birgisdottir, H. Categorizing Building Certification Systems According to the Definition of Sustainable Building. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 092060. [Google Scholar] [CrossRef]

- Provincia di Milano. Adeguamento del PTCP alla LR 12/2005. Repertorio delle Misure di Mitigazione e Compensazione Paesistico-Ambientali; Piano Territoriale di Coordinamento Provinciale: Milan, Italy, 2012; pp. 1–193. [Google Scholar]

- O.P.U.Q.P. Linee Guida per i Paesaggi Industriali in Sardegna; Allegato alla Delibera G.R. n.24/12 del 19.05.2015; O.P.U.Q.P: Cagliari, Italy, 2015. [Google Scholar]

- Wiendhahl, H.; Reichardt, J.; Nyhuis, P. Handbook Factory Planning and Design; Springer: London, UK, 2015. [Google Scholar]

- The Plan Art & Architecture. Corporate Identity. Architecture in Detail; Scripta Maneant: Reggio Emilia, Italy, 2011. [Google Scholar]

- Wang, T. A Sustainable Industrial Site Redevelopment Planning Support System; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2019. [Google Scholar]

- Gothmann, K.; Jain, P.; Nikov, K.; Vest, H. Sustainable Industrial Areas (SIA); Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Bonn, Germany, 2015. [Google Scholar]

- Divisare. Available online: https://divisare.com/ (accessed on 16 February 2022).

- ArchDaily. Available online: https://www.archdaily.com/ (accessed on 16 February 2022).

- Architecture & Design. Available online: https://www.architecturendesign.net/ (accessed on 16 February 2022).

- Archilovers. Available online: https://www.archilovers.com/ (accessed on 16 February 2022).

- U.S. GBC. LEED Core Concepts Guide; U.S. Green Building Council: London, UK, 2014. [Google Scholar]

- European Commission. The European Green Deal. COM (2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Marchi, L.; Antonini, E. A tool to evaluate what makes a factory sustainable. Int. J. Sustain. Build. Technol. Urban Dev. 2021, 12, 142–153. [Google Scholar] [CrossRef]

- Marchi, L. Towards the Harmonization of Industrial Facilities with the Landscape. A catalogue of good practices. SMC-Sustain. Mediterr. Constr. 2020, 12, 156–160. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development (A/RES/70/1). 2015. Available online: https://documents-dds-ny.un.org/doc/UNDOC/GEN/N15/291/89/PDF/N1529189.pdf?OpenElement (accessed on 30 March 2022).

- DGNB System Version 2020 International. Available online: https://www.dgnb-system.de/en/system/version-2020-international/index.php (accessed on 3 February 2022).

- BREEAM. Available online: https://www.breeam.com/ (accessed on 20 July 2021).

- LEED. Available online: https://www.usgbc.org/leed (accessed on 21 July 2021).

- U.S. GBC. LEED v4. Impact Category and Point Allocation Development Process; U.S. Green Building Council: Washington, DC, USA, 2013. [Google Scholar]

- Scapicchio, S. Sistemi di Classificazione di Organismi e Prodotti Edilizi Ipotesi Metodologica e Sperimentazione Applicativa su Organismi edilizi pre-Moderni; Università degli Studi di Napoli “Federico II: Napoli, Italy, 2009. [Google Scholar]

- Hjørland, B. Facet analysis: The logical approach to knowledge organization. Inf. Process. Manag. 2013, 49, 545–557. [Google Scholar] [CrossRef]

- Rosati, L. Sense-Making. Organizzare il Mare dell’Informazione e Creare Valore con le Persone; UX University: Roma, Italy, 2019. [Google Scholar]

- Afsari, K.; Eastman, C.M. A Comparison of Construction Classification Systems Used for Classifying Building Product Models. In Proceedings of the 52nd ASC Annual International Conference Proceedings, Provo, UT, USA, 13–16 April 2016; pp. 1–8. [Google Scholar] [CrossRef]

- BibLus. IFC and Classification Systems in the Construction Industry. 9 March 2020. Available online: http://biblus.accasoftware.com/en/ifc-and-classification-systems-in-the-construction-industry/ (accessed on 31 March 2021).

- Sharp, D. The 42 Best Architecture Websites in the World. 2021. Available online: https://vanityprojects.com/top-architecture-websites/ (accessed on 16 April 2021).

- ArchINFORM. Available online: https://www.archinform.net/index.htm (accessed on 21 February 2022).

- The Plan. Available online: https://www.theplan.it/eng (accessed on 21 February 2022).

- Spiteri, L.F. The Classification Research Group and the Theory of Integrative Levels; Faculty of Information Studies, University of Toronto: Toronto, ON, Canada, 1995. [Google Scholar]

- Uniclass2. Available online: https://www.thenbs.com/our-tools/uniclass-2015 (accessed on 2 February 2022).

- Marchi, L. Designing Sustainable Factories; Springer International Publishing: Cham, Switzerland, 2022; Volume 72. [Google Scholar]

- Despeisse, M. Sustainable Manufacturing Tactics and Improvement Methodology. A Structured and Systematic Approach to Identify Improvement Opportunities; School of Applied Science, Cranfield University: Cranfield, UK, 2013. [Google Scholar]

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial ecology at factory level-A conceptual model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef] [Green Version]

| Relative Efficacy | Benefit Duration | Controllability of Effect |

|---|---|---|

| Negative (−1) | <1 year (0) | None (0) |

| None (0) | 1–3 years (1) | Occupants (1) |

| Low (1) | 11–30 years (2) | Operation and Maintenance (2) |

| Med (2) | 11–30 years (3) | Owner (3) |

| High (3) | >30 years (4) | Passive (4) |

| Category | Tactics |

|---|---|

| Integrative Process | IP 1.1 Stakeholders engagement IP 1.2 Multidisciplinary design team |

| Location and Transport | LT 4.2 Urban location LT 6.1 Bike racks and showers |

| Sustainable Site | SS 1.1 Site ventilation and cooling SS 5.2 Green folded surfaces |

| Water Efficiency | WE 1.1 Outdoor reuse of rainwater WE 2.1 Water-saving technologies |

| Energy and Atmosphere | EA 2.1 Ventilated façade EA 2.5 Ground thermal proprieties |

| Materials and Resources | MR 1.2 Modular structure and/or components MR 5.1 Recovery of construction and demolition waste |

| Indoor Environmental Quality | EQ 2.1 Eco-friendly finishing EQ 6.1 Smart lighting |

| Innovation | IN 1.2 Recovery of heat/energy from processes IN 1.5 Treatment and reuse of process water |

| Regional Priorities | RP 1.1 Sharing of facilities in consortium RP 1.2 Sharing of services and mixed use |

| Perceptual aesthetic aspects | PA 1.3 Landform PA 4.1 Multifunction facility |

| Tactic | Climate Change | Health and Well-Being | Water Resource | Biodiversity | Material Resource | Green Economy | Community |

|---|---|---|---|---|---|---|---|

| IP 1.1 Stakeholder engagement | 0 | 6 | 0 | 0 | 0 | 0 | 4 |

| IP 1.2 Multidisciplinary design team | 10 | 1 | 3 | 3 | 3 | 2 | 0 |

| LT 3.1 Building extension | 6 | 5 | 1 | 5 | 7 | 6 | 5 |

| (ii) Building Part | (iii) Impact Category | (iv) Material | (vi) General Strategy |

|---|---|---|---|

| Load-bearing structure | Climate change | Wood | Energy efficiency |

| Vertical envelope | Health and well-being | Concrete | Renewable resources |

| Top horizontal envelope | Water resource | Metals | Bioclimatic |

| Low horizontal envelope | Biodiversity | Glass | Sustainable mobility |

| Internal partition | Material resource | Coating and paint | Community engagement |

| Systems | Green economy | Vegetation a/o water | Well-Being of workers |

| Outdoor equipment | Community | Visual mitigation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, L.; Antonini, E. Digital Atlas of Tactics to Designing Sustainable Factories. Sustainability 2022, 14, 4321. https://doi.org/10.3390/su14074321

Marchi L, Antonini E. Digital Atlas of Tactics to Designing Sustainable Factories. Sustainability. 2022; 14(7):4321. https://doi.org/10.3390/su14074321

Chicago/Turabian StyleMarchi, Lia, and Ernesto Antonini. 2022. "Digital Atlas of Tactics to Designing Sustainable Factories" Sustainability 14, no. 7: 4321. https://doi.org/10.3390/su14074321

APA StyleMarchi, L., & Antonini, E. (2022). Digital Atlas of Tactics to Designing Sustainable Factories. Sustainability, 14(7), 4321. https://doi.org/10.3390/su14074321