Experimental Study on Tensile Characteristics of Layered Carbonaceous Slate Subject to Water–Rock Interaction and Weathering

Abstract

:1. Introduction

2. Brazilian Disc Specimens and Test Setup

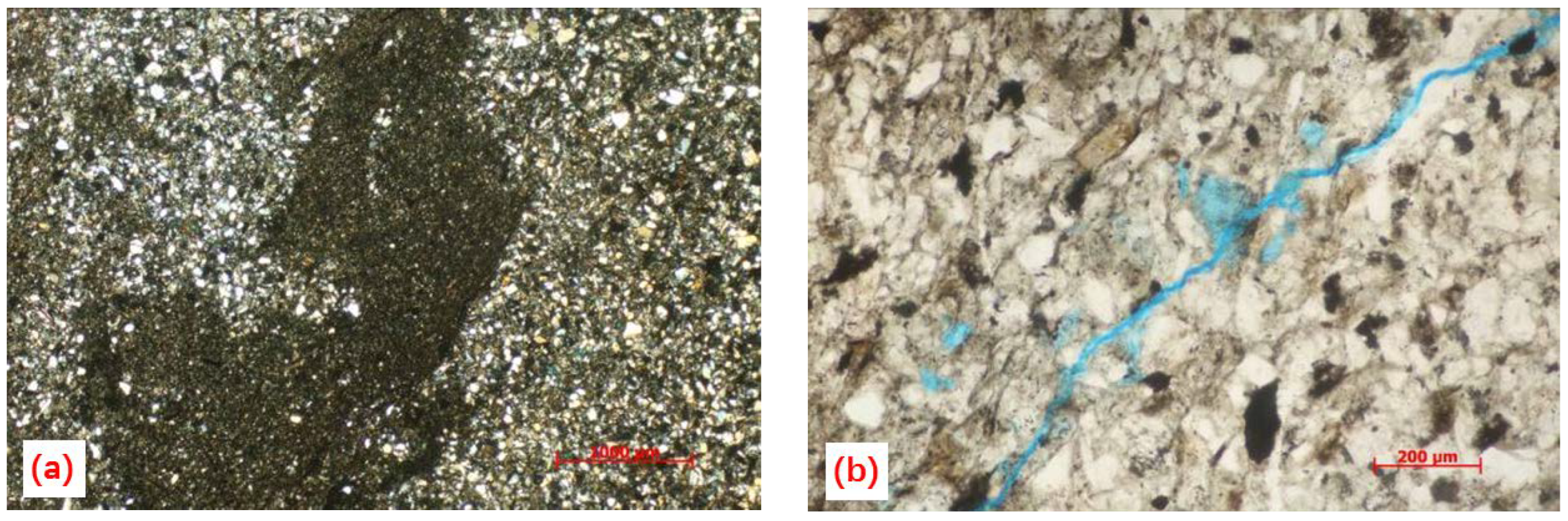

2.1. Properties of Carbonaceous Slate

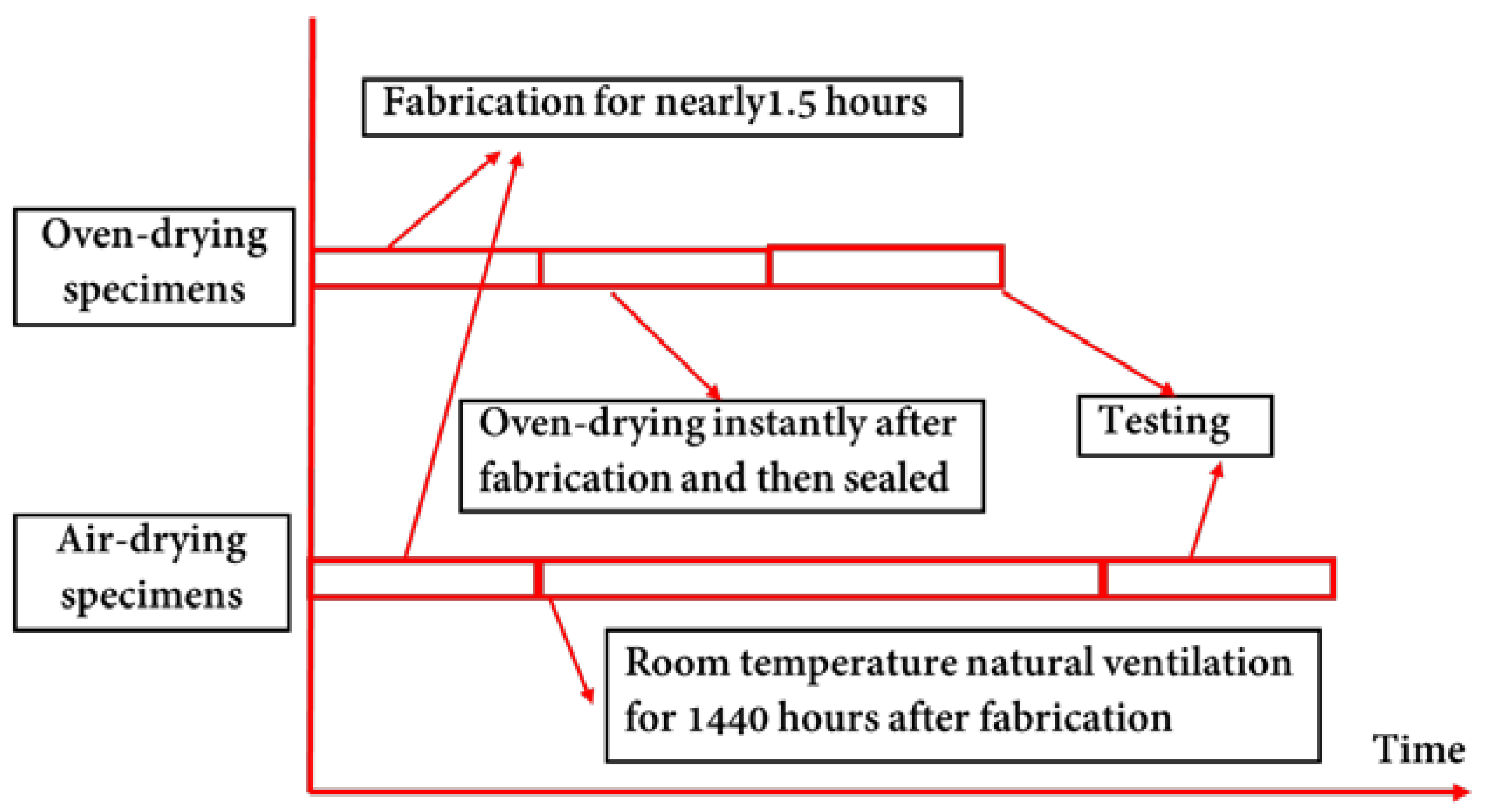

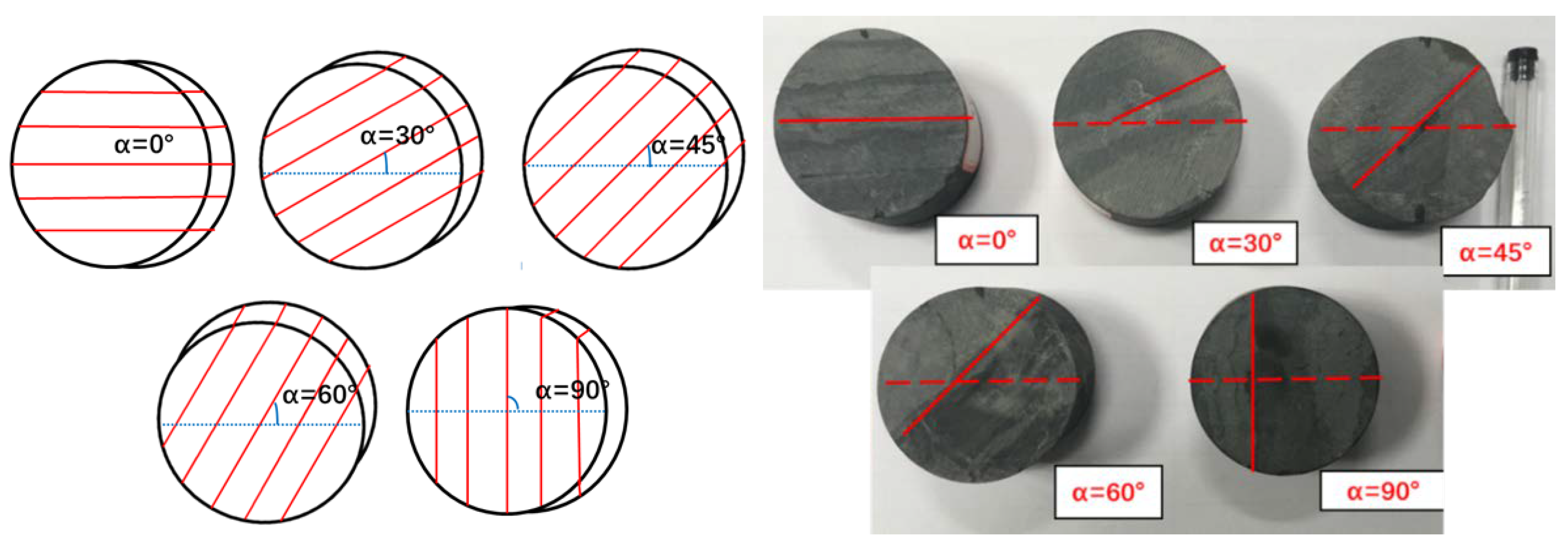

2.2. Brazilian Disc Specimens

2.3. Brazilian Test Setup

3. Analysis of Test Results

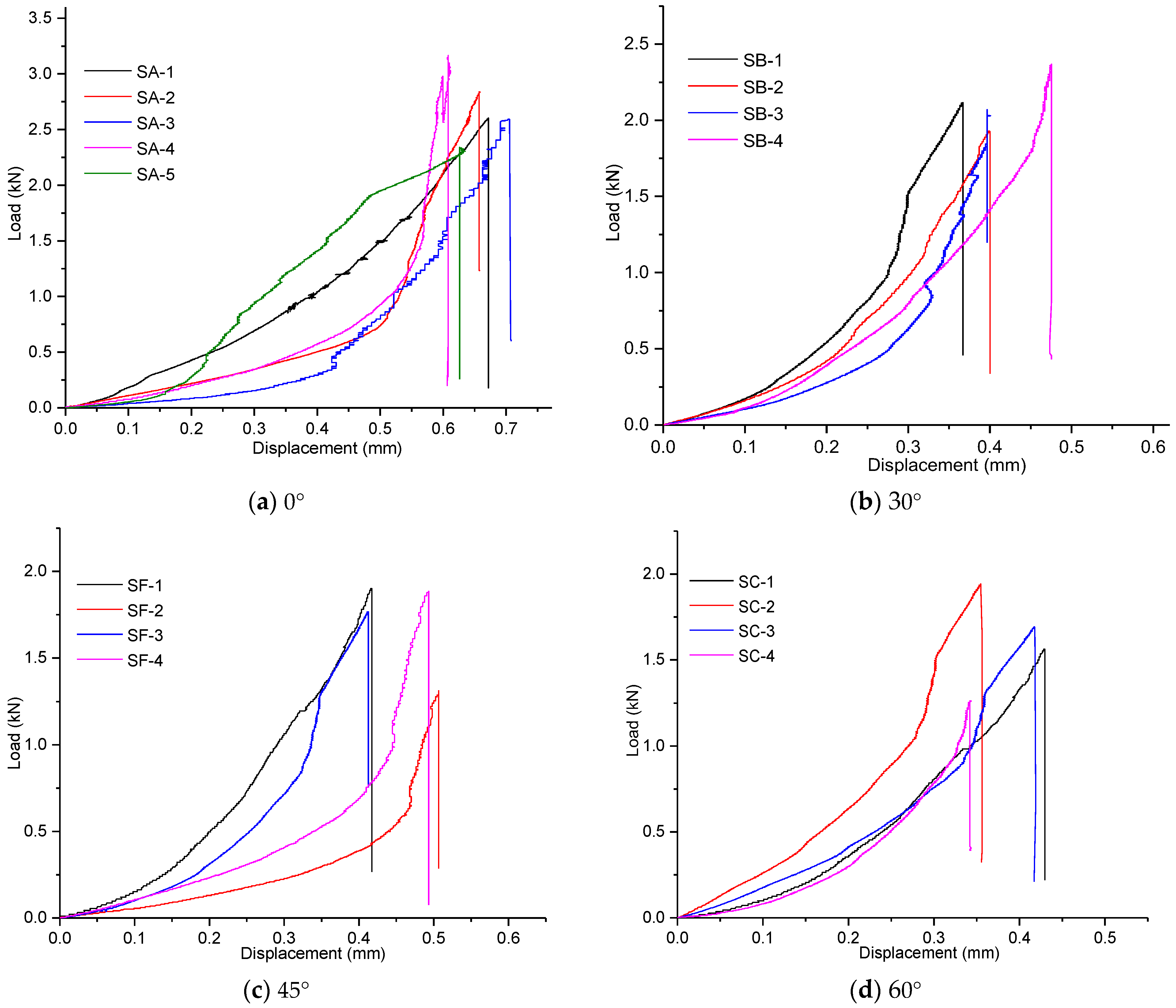

3.1. Mechanical Response

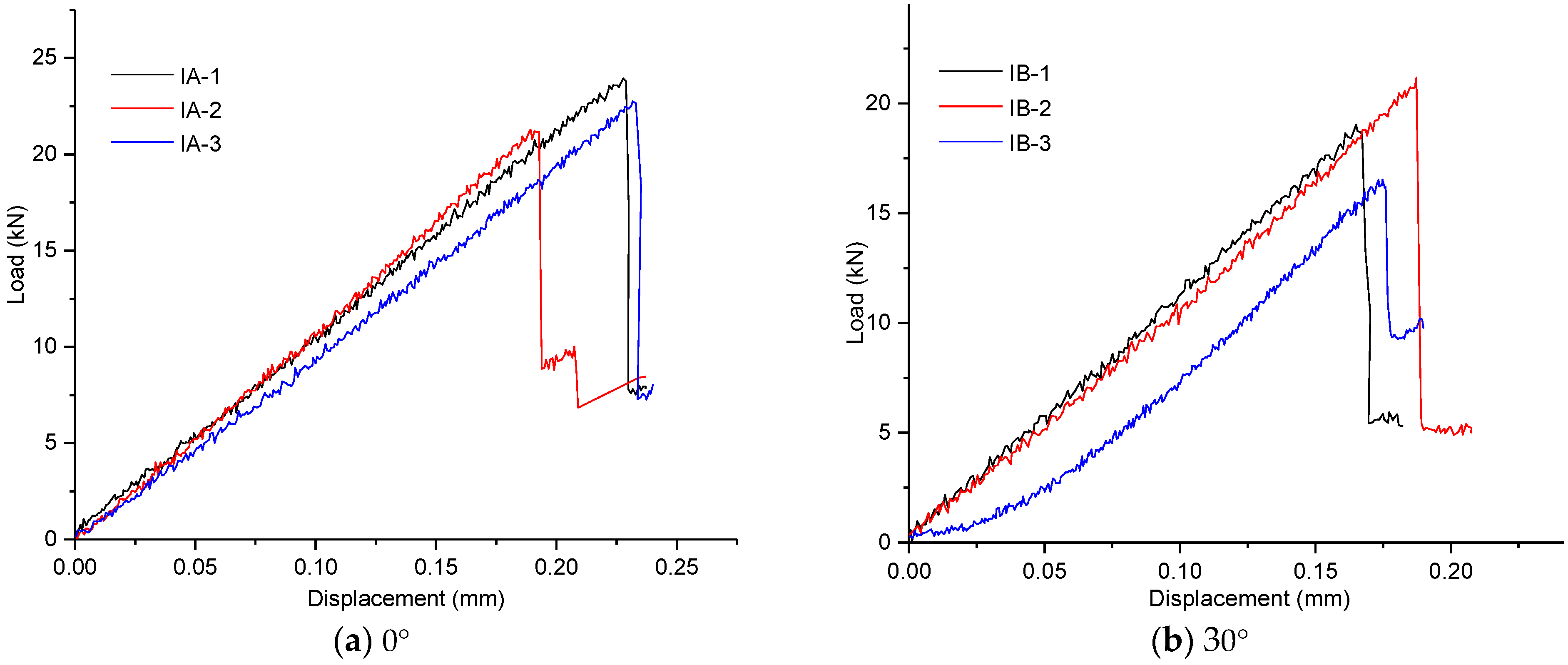

3.1.1. Load-Displacement Curves of Oven-Drying Specimens

3.1.2. Load-Displacement Curves of Air-Drying Specimens

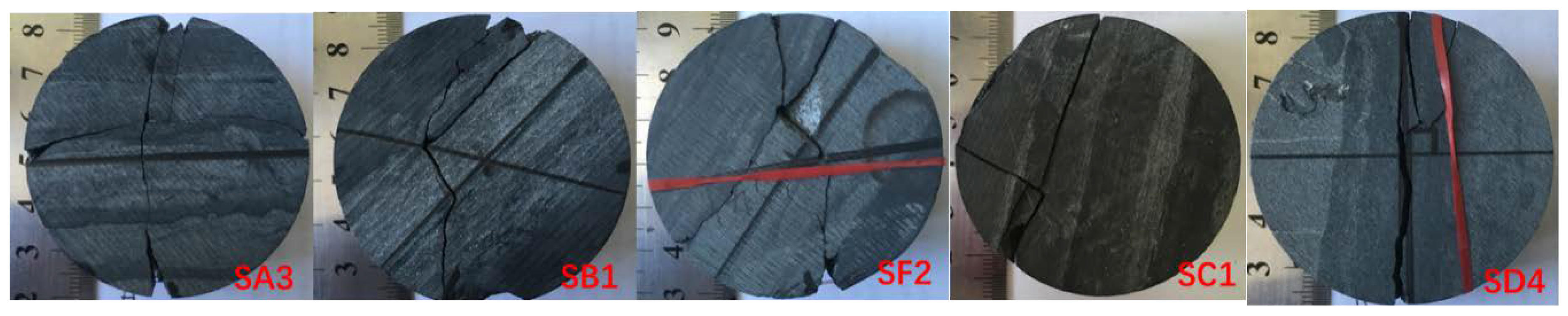

3.2. Splitting Failure Morphology

3.2.1. Splitting Failure Morphology of Oven-Drying Specimens

3.2.2. Splitting Failure Morphology of Air-Drying Specimens

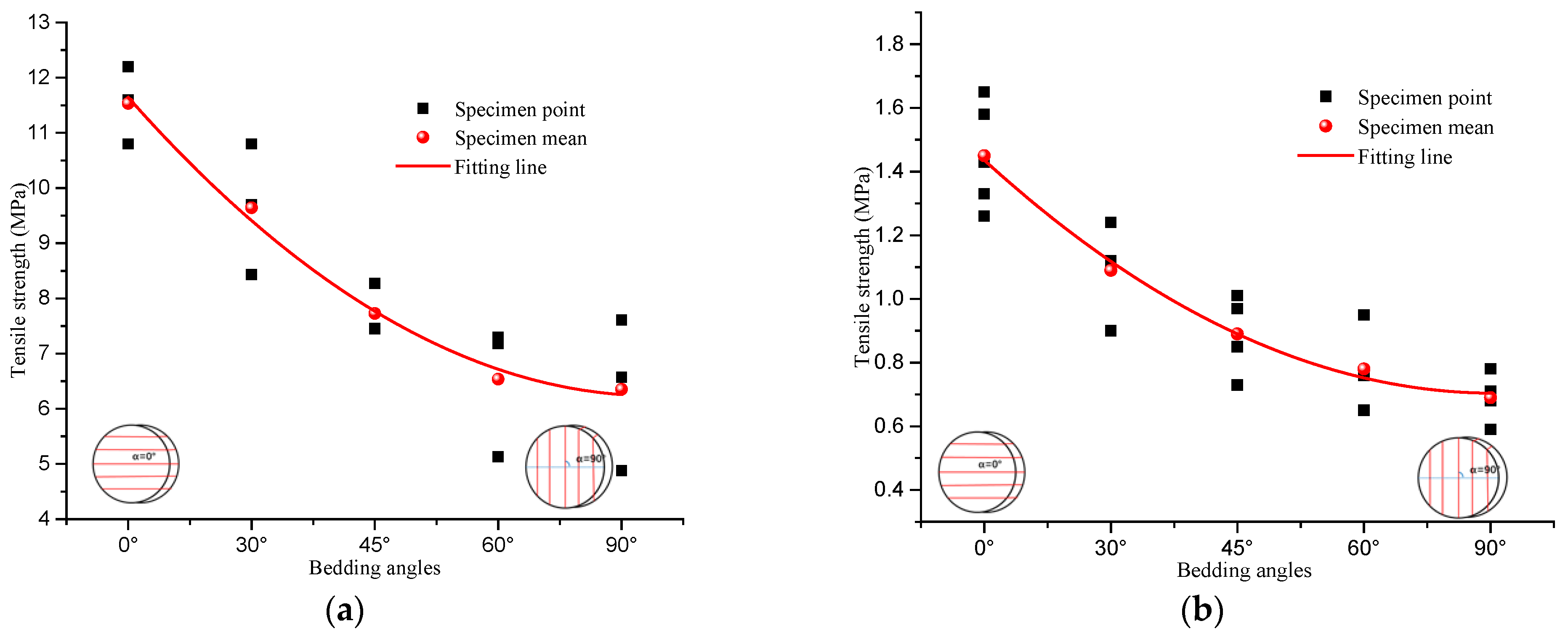

3.3. Tensile Strength

3.3.1. Tensile Strength of Oven-Drying Specimens

3.3.2. Tensile Strength of Air-Drying Specimens

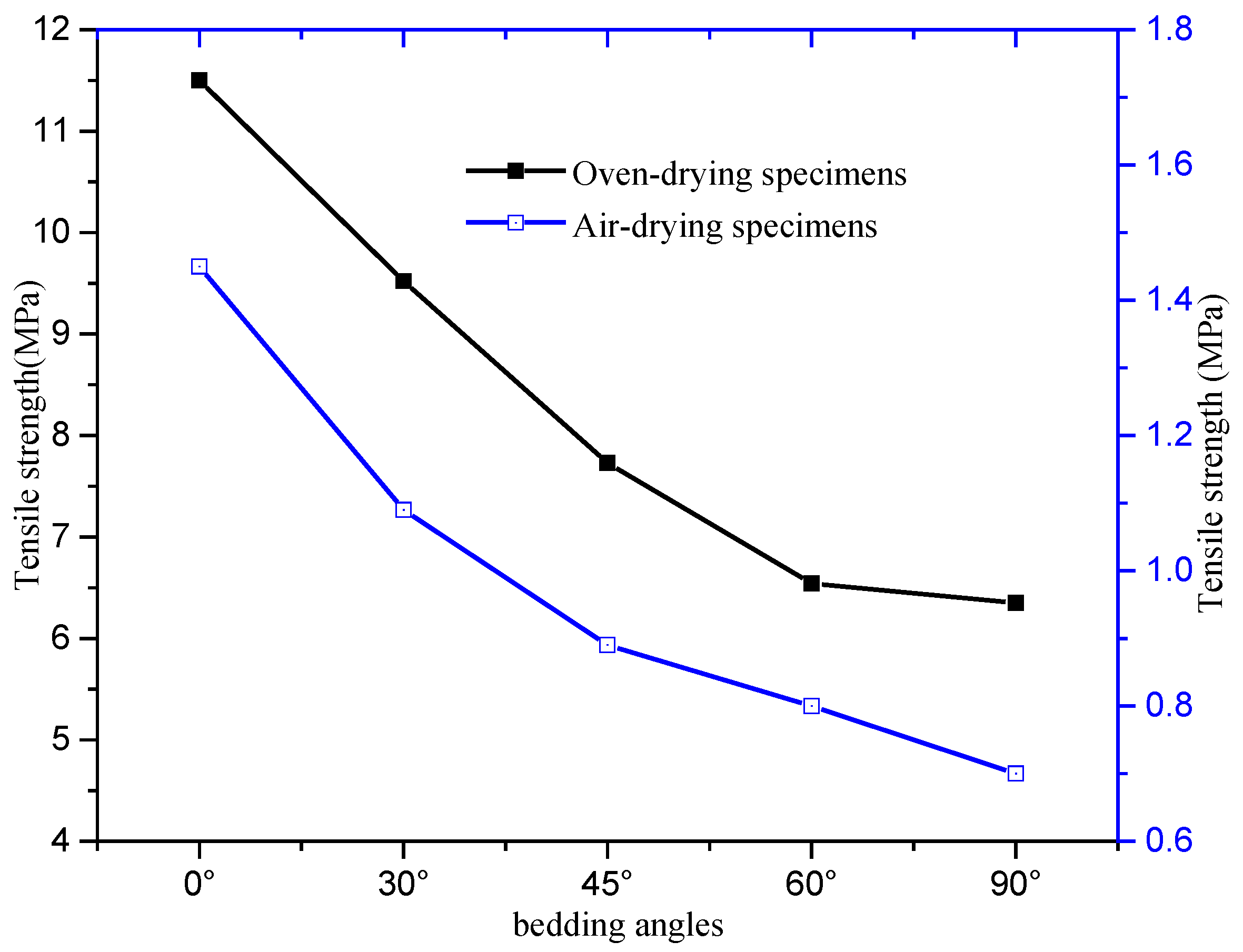

3.4. Degradation Effect of Natural Weathering under WRI

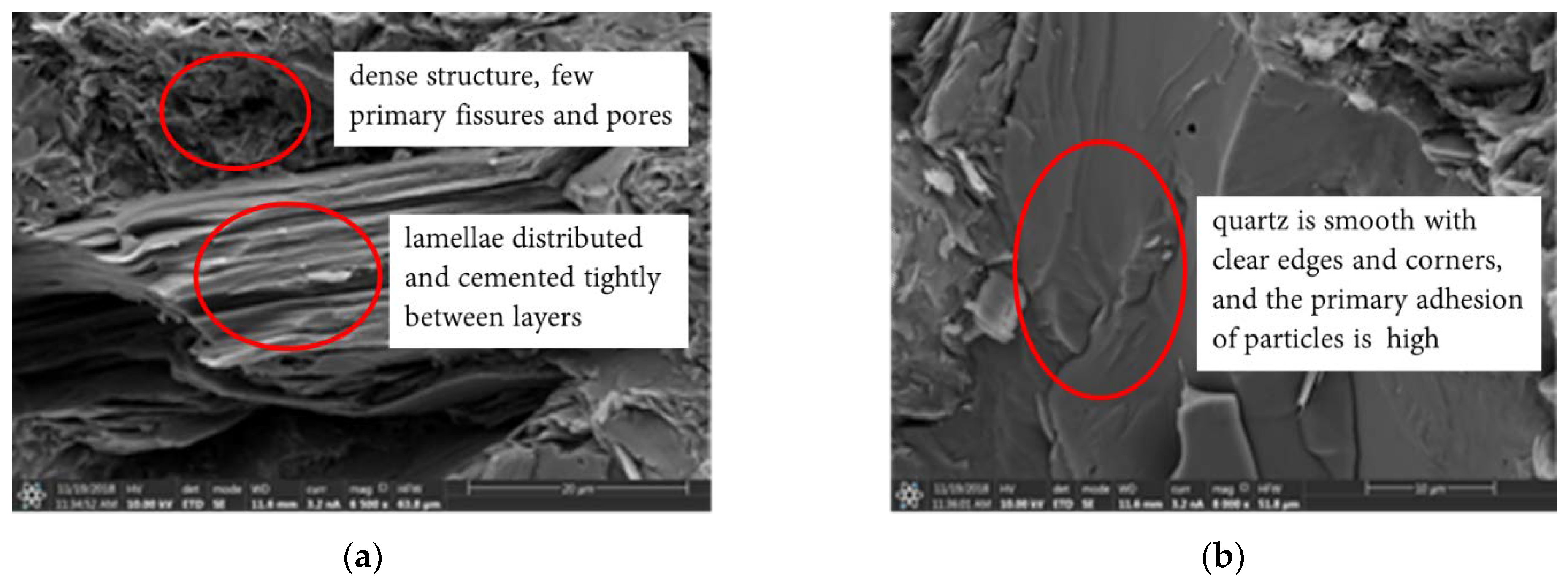

4. Mechanism of Natural Weathering after WRI

5. Conclusions

- The load-displacement curves of oven-drying specimens can be divided into linear elastic and failure drop phases, while the air-drying specimens develop from a process of compaction, linear elastic and failure drop phases, and great difference in failure displacement and load from the two kinds of carbonaceous slate specimens.

- For oven-drying specimens, the failure mode is less affected by the bedding, and the failure morphology extends nearly symmetrically along the loading axis. However, the failure morphology is all significantly affected by the bedding for the air-drying specimens, and can be divided into pure tension failure, combined tension-shear failure between the matrix and the bedding plane under the different bedding angles.

- The magnitude of the peak load is all related to the bedding. With the increase in the bedding angles, the corresponding tensile strength all gradually decreases, in turn as 1.45, 1.09 and 0.89, 0.78, 0.69 MPa for the air-drying specimens, while they are 11.50, 9.52, 7.73, 6.54, 6.35 MPa for the oven-drying specimens, respectively. The softening coefficients are 0.13, 0.11, 0.12, 0.12 and 0.11, respectively. It can be concluded that the clay-rich minerals are vulnerable to WRI and the degradation effect caused by natural weathering.

- The degradation mechanism of WRI caused by the fabrication process and the subsequent natural weathering is such that the physicochemical reaction under the gradual evaporation of water, such as the deterioration of the mineral composition and its structure, the gradual development of microcracks and other cumulative damage degradation, effects the weakening of the mineral particles’ mechanics. The degradation of microstructure is reflected in the macroscopic mechanical response by our parallel experiments and SEM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Huang, T. Rock Physics; Peking University Press: Beijing, China, 2001; pp. 154–196. [Google Scholar]

- Cho, J.W.; Kim, H.; Jeon, S.; Min, K.B. Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int. J. Rock Mech. Min. Sci. 2012, 50, 158–169. [Google Scholar] [CrossRef]

- Dan, D.Q.; Konietzky, H.; Herbst, M. Brazilian tensile strength tests on some anisotropic rocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 1–7. [Google Scholar] [CrossRef]

- Tavallali, A.; Debecker, B.; Vervoort, A. Evaluation of Brazilian tensile strength in transversely isotropic sandstone. In Proceedings of the Congress of the International Society for Rock Mechanics, Lisbon, Portugal, 9–13 July 2007. [Google Scholar]

- Tavallali, A.; Vervoort, A. Failure of layered sandstone under Brazilian test conditions: Effect of micro-scale parameters on macro-scale behavior. Rock Mech. Rock Eng. 2010, 43, 641–653. [Google Scholar] [CrossRef]

- Khanlari, G.; Rafiei, B.; Abdilor, Y. An Experimental Investigation of the Brazilian Tensile Strength and Failure Patterns of Laminated Sandstones. Rock Mech. Rock Eng. 2015, 48, 843–852. [Google Scholar] [CrossRef]

- Mousavi Nezhad, M.; Fisher, Q.J.; Gironacci, E.; Rezania, M. Experimental Study and Numerical Modeling of Fracture Propagation in Shale Rocks During Brazilian Disk Test. Rock Mech. Rock Eng. 2018, 51, 1755–1775. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.G.; Xu, G.L.; Huang, P.; Zhao, X.; Fu, Y.; Su, C. Mechanical and anisotropic properties of silty slate. Rock Soil Mech. 2018, 288, 200–209. (In Chinese) [Google Scholar]

- Li, Z.; Xu, G.; Huang, P.; Zhao, X.; Fu, Y. Experimental Study on Anisotropic Properties of Silurian Silty Slates. Geotech. Geol. Eng. 2017, 35, 1755–1766. [Google Scholar] [CrossRef]

- Debecker, B.; Vervoort, A. Experimental observation of fracture patterns in layered slate. Int. J. Fract. 2009, 159, 51–62. [Google Scholar] [CrossRef]

- Debecker, B.; André, V. Two-dimensional discrete element simulations of the fracture behavior of slate. Int. J. Rock Mech. Min. Sci. 2013, 61, 161–170. [Google Scholar] [CrossRef]

- Garcia-Fernandez, C.C.; Gonzalez-Nicieza, C.; Alvarez-Fernandez, M.I.; Gutierrez-Moizant, R.A. New methodology for estimating the shear strength of layering in slate by using the Brazilian test. Bull. Eng. Geol. Environ. 2019, 78, 2283–2297. [Google Scholar] [CrossRef]

- Tang, S. The effects of water on the strength of black sandstone in a brittle regime. Eng. Geol. 2018, 239, 167–178. [Google Scholar] [CrossRef]

- Nara, Y.; Morimoto, K.; Hiroyoshi, N.; Yoneda, T.; Kaneko, K.; Benson, P.M. Influence of relative humidity on fracture toughness of rock: Implications for subcritical crack growth. Int. J. Solids Struct. 2012, 49, 2471–2481. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, J.; Zhang, D.; Peng, H. Effects of Wetting and Cyclic Wetting–Drying on Tensile Strength of Sandstone with a Low Clay Mineral Content. Rock Mech. Rock Eng. 2016, 50, 485–491. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Ma, D.; Cao, W.; Chen, L.; Zhou, J. Effects of water content on fracture and mechanical behavior of sandstone with a low clay mineral content. Eng. Fract. Mech. 2018, 193, 47–65. [Google Scholar] [CrossRef]

- Mao, H.; Yang, C.; Huang, X.; Wang, X. Experimental and theoretical study of slate mechanics under different water-bearing conditions. Rock Soil Mech. 2006, 27, 1637–1642. (In Chinese) [Google Scholar]

- Yang, C.; Mao, H.; Wang, X.; Li, X.; Chen, J. Study on variation of microstructure and mechanical properties of water-weakening slates. Rock Soil Mech. 2006, 27, 2090–2098. (In Chinese) [Google Scholar]

- Gholami, R.; Rasouli, V. Mechanical and Elastic Properties of Transversely Isotropic Slate. Rock Mech. Rock Eng. 2014, 47, 1763–1773. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Gao, J. Tensile strength of slate based on Brazil test under dry and saturated conditions. J. Cent. South Univ. (Nat. Sci. Ed.) 2017, 48, 1044–1048. (In Chinese) [Google Scholar]

- ISRM. Suggested methods for determining tensile strength of rock materials. Int. J. Rock Mech. Min. Sci. Geomech. 1978, 15, 99–103. [Google Scholar] [CrossRef]

- ISRM. Suggested methods for determining: Water content, porosity, density, absorption and related properties. Swelling and slake-durability index properties. Int. J. Roch Mech. Min. Sci. 1979, 16, 141–156. [Google Scholar]

- Sun, Q.C.; Wei, C.; Sha, X.M.; Zhou, B.H.; Zhang, G.D.; Xu, Z.H.; Cao, L. Study on the Influence of Water–Rock Interaction on the Stability of Schist Slope. Sustainability 2020, 12, 7141. [Google Scholar] [CrossRef]

- Deng, H.; Yuan, X.; Wang, L.; Zhu, M.; Luo, Q.; He, M. Experimental research on changes in the mechanical property law of reservoir bank sandstone under immersion-air dry circulation. Environ. Eng. Manag. J. 2013, 12, 1785–1789. [Google Scholar]

- Mahabadi, O.K.; Tatone, B.S.A.; Grasselli, G. Influence of microscale heterogeneity and microstructure on the tensile behavior of crystalline rocks. J. Geophys. Res. Solid Earth 2014, 119, 5324–5341. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Maruvanchery, V.; Liu, G. Water effects on rock strength and stiffness degradation. Acta Geotech. 2016, 11, 713–737. [Google Scholar] [CrossRef]

- Lin, M.L.; Jeng, F.S.; Tsai, L.S.; Huang, T.H. Wetting weakening of tertiary sandstones-microscopic mechanism. Environ. Geol. 2005, 48, 265–275. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Jong, M.C. Water Saturation Effects on the Brazilian Tensile Strength of Gypsum and Assessment of Cracking Processes Using High-Speed Video. Rock Mech. Rock Eng. 2014, 47, 1103–1115. [Google Scholar] [CrossRef]

- Wang, J.; Xie, L.; Xie, H.; Ren, L.; He, B.; Li, C.; Yang, Z.; Gao, C. Effect of layer orientation on acoustic emission characteristics of anisotropic shale in Brazilian tests. J. Nat. Gas Sci. Eng. 2016, 36, 1120–1129. [Google Scholar] [CrossRef]

- Asnin, S.N.; Nnko, M.; Josephat, S.; Mahecha, A.; Mshiu, E.; Bertotti, G.; Brehme, M. Identifcation of water–rock interaction of surface thermal water in Songwe medium temperature geothermal area, Tanzania. Environ. Earth Sci. 2022, 81, 513. [Google Scholar] [CrossRef]

- Xu, Z.H.; Feng, G.L.; Sun, Q.C.; Zhang, G.D.; He, Y.M. A Modified Model for Predicting the Strength of Drying-Wetting Cycled Sandstone Based on the P-Wave Velocity. Sustainability 2020, 12, 5655. [Google Scholar] [CrossRef]

| Angles | Oven-Drying Specimens | Mean | SD | Air-Drying Specimens | Mean | SD | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0° | 12.19 | 10.81 | 11.60 | 11.53 | 0.21 | 1.33 | 1.65 | 1.43 | 1.58 | 1.26 | 1.45 | 0.16 |

| 30° | 9.70 | 10.80 | 8.43 | 9.64 | 1.19 | 1.12 | 0.90 | 1.10 | 1.24 | - | 1.09 | 0.14 |

| 45° | 7.45 | 7.56 | 8.17 | 7.73 | 0.47 | 0.97 | 0.73 | 0.85 | 1.01 | - | 0.89 | 0.13 |

| 60° | 5.13 | 7.30 | 7.18 | 6.54 | 1.22 | 0.76 | 0.95 | 0.77 | 0.65 | - | 0.78 | 0.12 |

| 90° | 4.88 | 6.57 | 7.61 | 6.35 | 1.38 | 0.59 | 0.71 | 0.68 | 0.78 | - | 0.69 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, E.; Wei, Y.; Chen, Z.; Archbold, P.; Mullarney, B. Experimental Study on Tensile Characteristics of Layered Carbonaceous Slate Subject to Water–Rock Interaction and Weathering. Sustainability 2023, 15, 885. https://doi.org/10.3390/su15010885

Li E, Wei Y, Chen Z, Archbold P, Mullarney B. Experimental Study on Tensile Characteristics of Layered Carbonaceous Slate Subject to Water–Rock Interaction and Weathering. Sustainability. 2023; 15(1):885. https://doi.org/10.3390/su15010885

Chicago/Turabian StyleLi, Erqiang, Yanqing Wei, Zhanyang Chen, Paul Archbold, and Brian Mullarney. 2023. "Experimental Study on Tensile Characteristics of Layered Carbonaceous Slate Subject to Water–Rock Interaction and Weathering" Sustainability 15, no. 1: 885. https://doi.org/10.3390/su15010885

APA StyleLi, E., Wei, Y., Chen, Z., Archbold, P., & Mullarney, B. (2023). Experimental Study on Tensile Characteristics of Layered Carbonaceous Slate Subject to Water–Rock Interaction and Weathering. Sustainability, 15(1), 885. https://doi.org/10.3390/su15010885