Research on Safety Evaluation of Municipal Sewage Treatment Plant Based on Improved Best-Worst Method and Fuzzy Comprehensive Method

Abstract

:1. Introduction

2. Materials and Methods

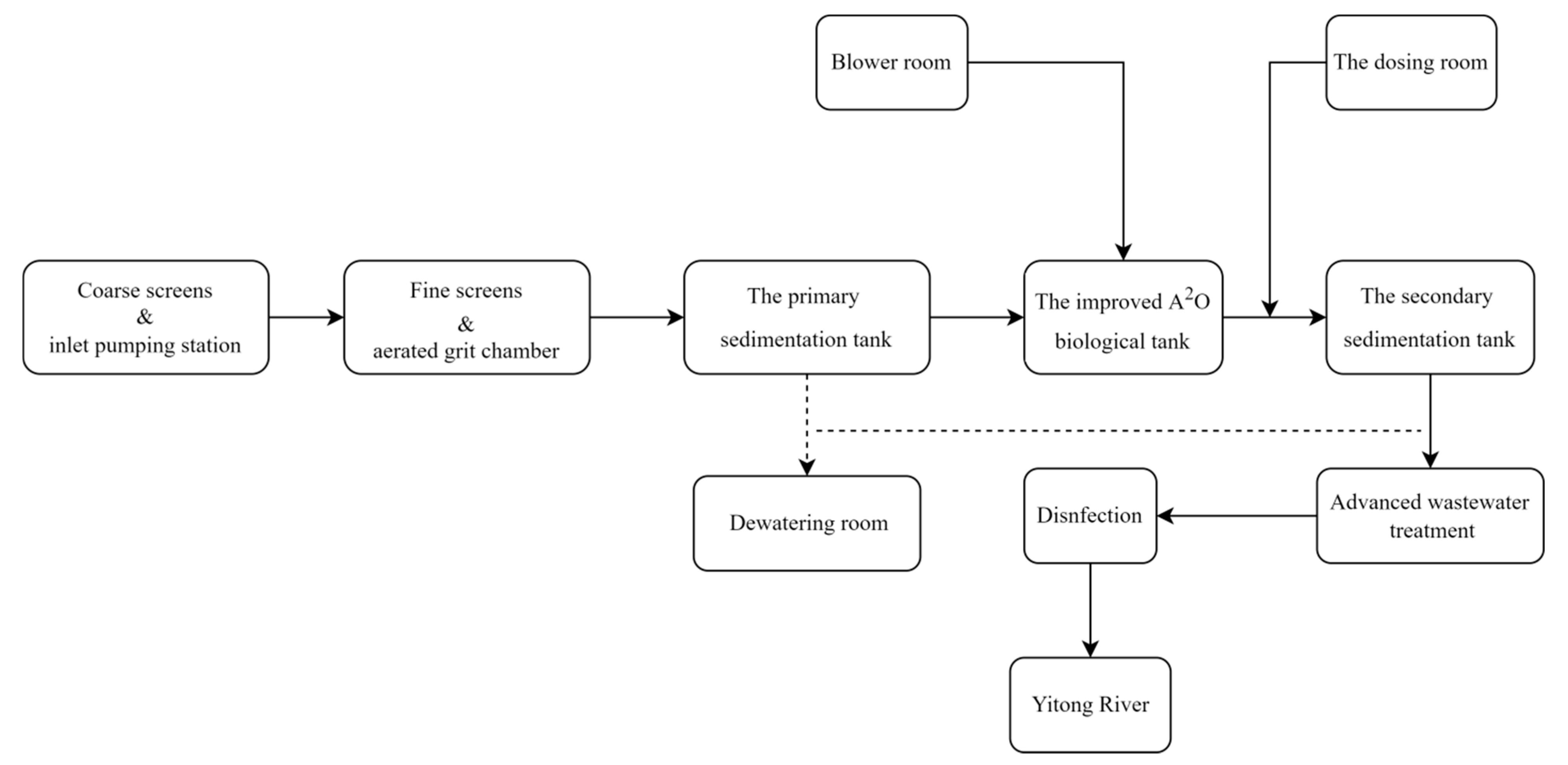

2.1. Research Object

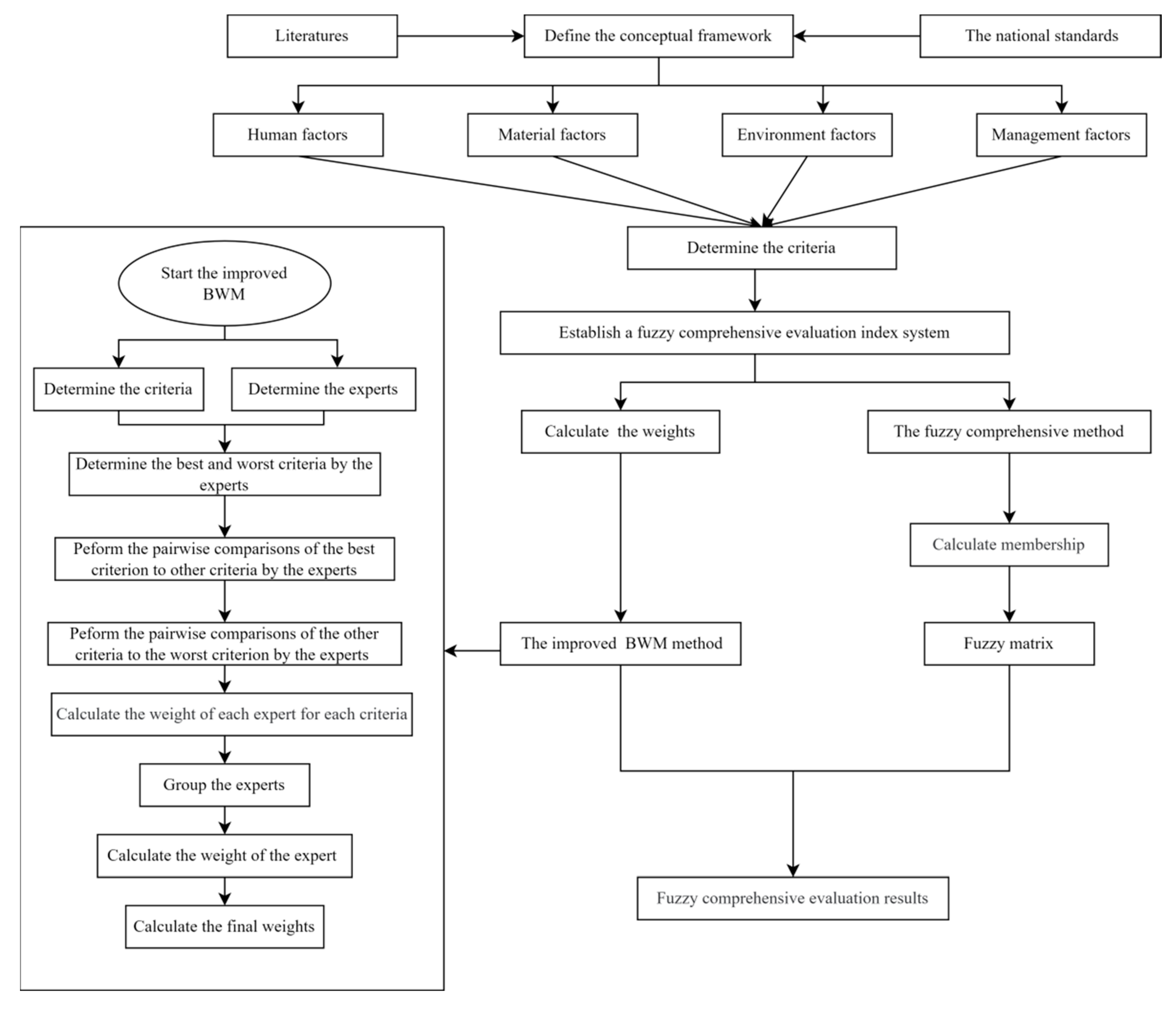

2.2. Evaluation Framework

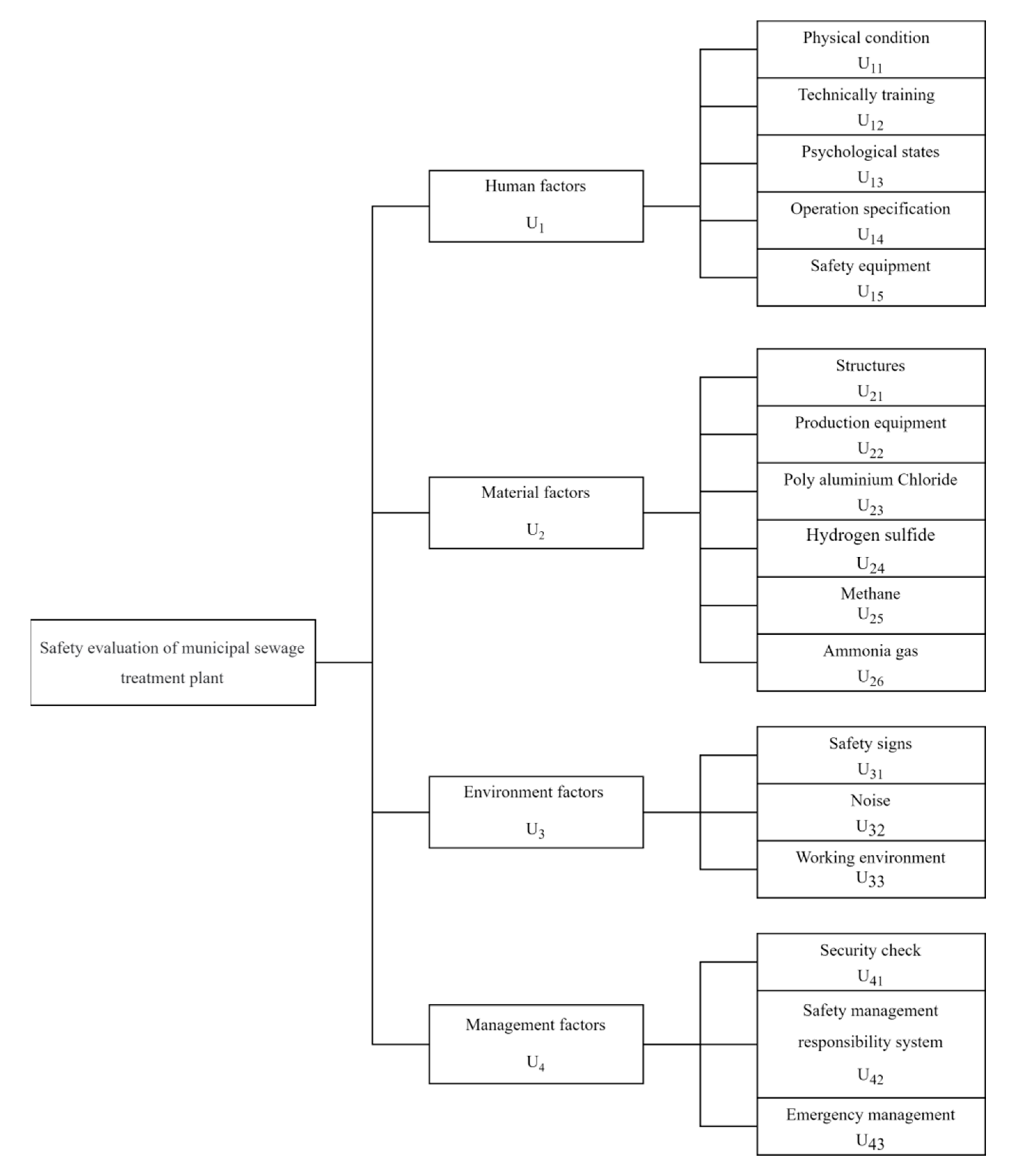

2.3. Fuzzy Comprehensive Evaluation Index System

2.4. The Fuzzy Comprehensive Evaluation

2.5. Improved BWM to Determine the Weight

- Determine experts and decision criteria.

- 2.

- Experts determine the best and worst criteria.

- 3.

- Using Table 2 as the assessment scale, the preference of uB over the other criteria is determined and the vector is obtained.

- 4.

- The preference degree of all criteria compared with uW is determined, and the vector is obtained, where aBW is uB’s preference degree compared with uW.

- 5.

- Calculate the weight of each expert for each criterion.

- 6.

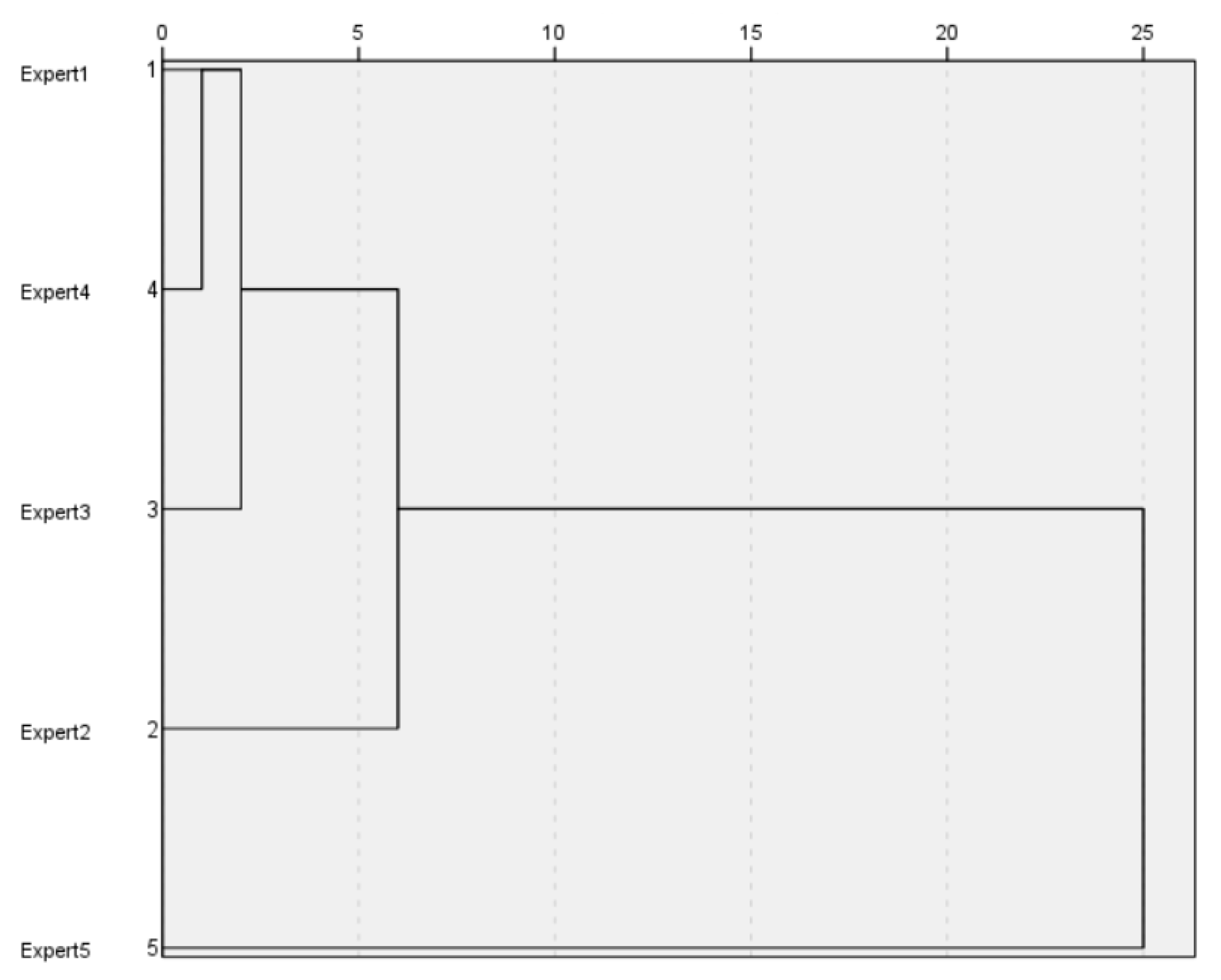

- Group the experts

- 7.

- Calculate the weight of the expert.

- 8.

- Calculate the final weights.

3. Results

3.1. Single-Factor Membership Calculation

3.2. Improved BWM Method to Determine the Weight

3.3. Fuzzy Comprehensive Evaluation of Municipal Sewage Treatment Plant

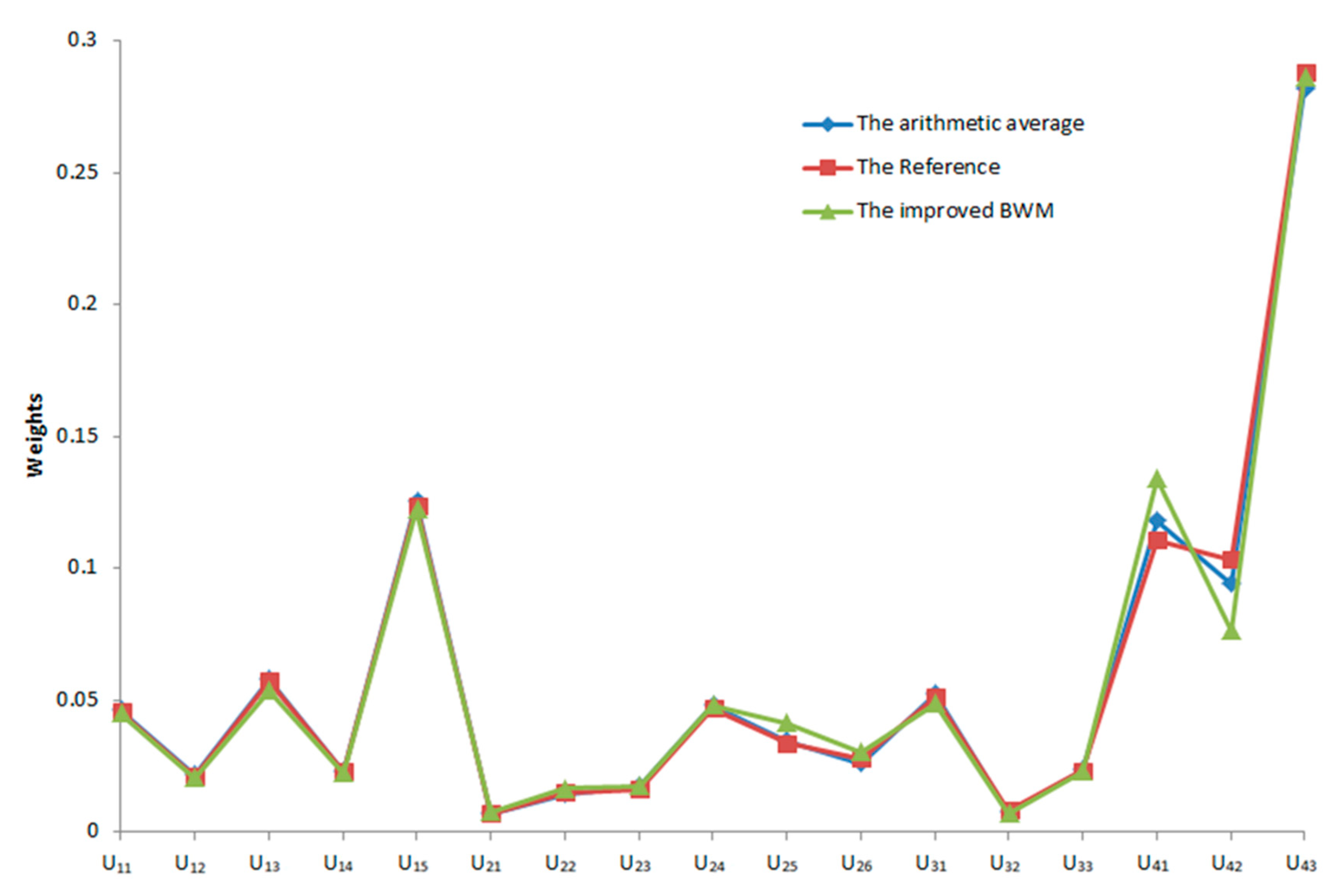

3.4. Analysis of Weighting Values

4. Conclusions

- This paper evaluates the safety status of municipal sewage treatment plants from the four aspects of human factors, material factors, environmental factors, and management factors, as well as the corresponding 17 secondary indexes, and combines the improved BWM method and fuzzy comprehensive evaluation method. The safety status of the municipal sewage treatment plant is safe.

- The improved BWM and the fuzzy comprehensive method are combined to take full advantage of their strengths. The improved BWM reduces the subjective element by classifying experts. The fuzzy comprehensive method fuzzes quantitative and qualitative indicators, combining the two to produce more objective and reliable evaluation results.

- The improved BWM is compared and analyzed with the BWM arithmetic average and the method in Reference [51], and the results show that the improved BWM is an acceptable alternative to the two other approaches when compared.

- This paper focuses on the safety evaluation within a sewage treatment plant. In future work, a sewage treatment plant may pose a number of risks to the surrounding environment: (1) Air pollution, such as formaldehyde, benzene and other harmful gases, can damage the respiratory system of the surrounding residents. (2) Light pollution. The strong light from the sewage treatment plant at night may cause disturbances to the surrounding nocturnal animals, and may also affect the growth and development of plants. (3) Water pollution, such as chemicals and heavy metal ions, poses a threat to the surrounding land and human health.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boretti, A.; Rosa, L. Reassessing the projections of the world water development report. NPJ Clean Water 2019, 2, 15. [Google Scholar] [CrossRef]

- Zhao, C.; Yang, Y.; Yang, S.; Xiang, H.; Wang, F.; Chen, X.; Zhang, H.; Yu, Q. Impact of spatial variations in water quality and hydrological factors on the food-web structure in urban aquatic environments. Water Res. 2018, 153, 121–133. [Google Scholar] [CrossRef]

- Hautier, Y.; Tilman, D.; Isbell, F.; Seabloom, E.W.; Borer, E.T.; Reich, P.B. Anthropogenic environmental changes affect ecosystem stability via biodiversity. Science 2015, 348, 336–340. [Google Scholar] [CrossRef]

- Warren, V.W.M.; Campos, R.A.; Zárate, G.A.I.; Romero, C.L.A. A Current Review of Water Pollutants in American Continent: Trends and Perspectives in Detection, Health Risks, and Treatment Technologies. Int. J. Environ. Res. Public Health 2023, 20, 4499. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Akhavan, O. Nanomaterials for Photocatalytic Degradations of Analgesic, Mucolytic and Anti-Biotic/Viral/Inflammatory Drugs Widely Used in Controlling SARS-CoV-2. Catalysts 2022, 12, 667. [Google Scholar] [CrossRef]

- Lemessa, F.; Simane, B.; Seyoum, A.; Gebresenbet, G. Assessment of the Impact of Industrial Wastewater on the Water Quality of Rivers around the Bole Lemi Industrial Park (BLIP), Ethiopia. Sustainability 2023, 15, 4290. [Google Scholar] [CrossRef]

- GOAL 6: Clean Water and Sanitation|UNEP, UN Environment Programme. Available online: https://www.unep.org/explore-topics/sustainable-development-goals/why-do-sustainable-development-goals-matter/goal-6 (accessed on 29 September 2021).

- Janzen, N.; Banzhaf, S.; Scheytt, T.; Bester, K. Vertical flow soil filter for the elimination of micro pollutants from storm and waste water. Chemosphere 2009, 77, 1358–1365. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Chen, J.; Huang, Y.; Lu, H.; Yuan, W.; Yang, Q.; Hu, J.; Yu, B.; Wang, D.; et al. Physical pretreatment of petroleum refinery wastewater instead of chemicals addition for collaborative removal of oil and suspended solids. J. Clean. Prod. 2021, 278, 123821. [Google Scholar] [CrossRef]

- Dietze, A.; Wiesmann, U.; Gnirss, R. Phosphorus removal with membrane filtration for surface water treatment. Water Supply 2003, 3, 23–30. [Google Scholar] [CrossRef]

- Saleh, I.A.; Zouari, N.; Al-Ghouti, M.A. Removal of pesticides from water and wastewater: Chemical, physical and biological treatment approaches. Environ. Technol. Innov. 2020, 19, 101026. [Google Scholar] [CrossRef]

- Meidanchi, A.; Akhavan, O. Superparamagnetic zinc ferrite spinel–graphene nanostructures for fast wastewater purification. Carbon 2014, 69, 230–238. [Google Scholar] [CrossRef]

- Khosravikia, M. Quantitative model for predicting the electroosmotic flow in dualdigital object iden. Electrophoresis 2023, 44, 733–743. [Google Scholar] [CrossRef]

- Fakhraee, M.; Akhavan, O. Ultrahigh permeable C2N-inspired graphene nanomesh membranes versus highly strained C2N for reverse osmosis desalination. J. Phys. Chem. B 2019, 123, 8740–8752. [Google Scholar] [CrossRef]

- Taziki, M.; Ahmadzadeh, H.; Murry, M.A.; Lyon, S.R. Nitrate and nitrite removal from wastewater using algae. Curr. Biotechnol. 2015, 4, 426–440. [Google Scholar] [CrossRef]

- Khosravikia, M.; Rahbar-Kelishami, A. A simulation study of an applied approach to enhance drug recovery through electromembrane extraction. J. Mol. Liq. 2022, 358, 119210. [Google Scholar] [CrossRef]

- Akhavan, O.; Choobtashani, M.; Ghaderi, E. Protein degradation and RNA efflux of viruses photocatalyzed by graphene eleiological treatment approaches. e Lemi Industrial Park. J. Phys. Chem. C 2012, 116, 9653–9659. [Google Scholar] [CrossRef]

- Berglund, B.; Dienus, O.; Sokolova, E.; Berglind, E.; Matussek, A.; Pettersson, T.; Lindgren, P. Occurrence and removal efficiency of parasitic protozoa in Swedish wastewater treatment plants. Sci. Total Environ. 2017, 598, 821–827. [Google Scholar] [CrossRef]

- Akhavan, O. Lasting antibacterial activities of Ag04.02/Ag/a-TiO2 nanocomposite thin film photocatalysts under solar light irradiation. J. Colloid Interface Sci. 2009, 336, 117–124. [Google Scholar] [CrossRef]

- Polo-López, M.I.; Castro-Alférez, M.; Oller, I.; Fernández-Ibáñez, P. Assessment of solar photo-Fenton, photocatalysis, and H2O2 for removal of phytopathogen fungi spores in synthetic and real effluents of urban wastewater. Chem. Eng. J. 2014, 257, 122–130. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E.; Rahimi, K. Adverse effects of graphene incorporated in TiO2 photocatalyst on minuscule animals under solar light irradiation. J. Mater. Chem. 2012, 22, 23260–23266. [Google Scholar] [CrossRef]

- Lu, R.; Frederiksen, M.W.; Uhrbrand, K.; Li, Y.; Madsen, A.M. Wastewater treatment plant workers’ exposure and methods for risk evaluation of their exposure. Ecotoxicol. Environ. Safety 2020, 205, 111365. [Google Scholar] [CrossRef]

- Lin, Z. Safety risk analysis and prevention and control of municipal wastewater treatment plant based on AHP. Saf. Health 2014, 4, 41–43. [Google Scholar]

- Shinta, F.R.; Karnaningroem, N.; Mardyanto, M.A. Risk management of wastewater treatment in the wastewater treatment plant of PT. X. IPTEK. J. Proc. Ser. 2019, 5, 140–149. [Google Scholar] [CrossRef]

- Alizadeh, S.S.; Solimanzadeh, Y.; Mousavi, S.; Safari, G.H. Risk assessment of physical unit operations of wastewater treatment plant using fuzzy FMEA method: A case study in the northwest of Iran. Environ. Monit. Assess. 2022, 194, 609. [Google Scholar] [CrossRef]

- Mohammad, Y.; Arman, N.; Esmaeil, Z.; Rouzbeh, A. A reliable risk analysis approach using an extension of best-worst method based on democratic-autocratic decision-making style. J. Clean. Prod. 2020, 256, 120418. [Google Scholar] [CrossRef]

- Mohsenzade, H.; Ara, H.R.; Dashti, A.; Roosta, H.; Nakhaee, H. Risk assessment for gas chlorination units of water and wastewater treatment with FMEA method. J. Water Wastewater Sci. Eng. 2020, 5, 31–40. [Google Scholar] [CrossRef]

- Kumari, S.; Ahmad, K.; Khan, Z.A.; Ahmad, S. Failure mode and effects analysis of common effluent treatment plants of humid sub-tropical regions using fuzzy based MCDM methods. Eng. Fail. Anal. 2023, 145, 107010. [Google Scholar] [CrossRef]

- Karamountzou, S.; Vagiona, D.G. Suitability and Sustainability Assessment of Existing Onshore Wind Farms in Greece. Sustainability 2023, 15, 2095. [Google Scholar] [CrossRef]

- Li, M.; Guo, Y.; Luo, D.; Ma, C. A Hybrid Variable Weight Theory Approach of Hierarchical Analysis and Multi-Layer Perceptron for Landslide Susceptibility Evaluation: A Case Study in Luanchuan County, China. Sustainability 2023, 15, 1908. [Google Scholar] [CrossRef]

- Saaty, T.L. Fundamentals of the analytic network process-dependence and feedback in decision-making with a single network. J. Syst. Sci. Syst. Eng. 2004, 13, 129–157. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making the analytic hierarchy and network processes (AHP/ANP). J. Syst. Sci. Syst. Eng. 2004, 13, 1–35. [Google Scholar] [CrossRef]

- Tsai, J.F.; Shen, S.P.; Lin, M.H. Applying a Hybrid MCDM Model to Evaluate Green Supply Chain Management Practices. Sustainability 2023, 15, 2148. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method: Some properties and a linear model. Omega 2016, 64, 126–130. [Google Scholar] [CrossRef]

- Brunelli, M.; Rezaei, J. A multiplicative best-worst method for multi-criteria decision making. Oper. Res. Lett. 2019, 47, 12–15. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China. Discharge Standard of Pollutants for Municipal Waste-Water Treatment Plant: GB18918-2002, 1st ed.; China Environment Publishing Group: Beijing, China, 2002; pp. 5–6. [Google Scholar]

- Xu, H. Location of the Central Plant and Operation Mechanism of Joint Operation Wastewater Treatment Plants in Small Towns. Master’s Thesis, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Lou, W. Research of Safety Evaluation on Sha Ying Sewage Treatment Plant of Shengli Oilfield. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2014. [Google Scholar]

- Xi, G. The System Simulation of Risk Control in Oily Sewage Treatment Process. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2015. [Google Scholar]

- Standardization Administration of the People’s Republic of China. Classification and Code for the Hazardous and Harmful Factors in Process: GB13861-2022, 1st ed.; China Standards Press: Beijing, China, 2022; pp. 9–27. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Specification for Operation, Maintenance and Safety of Municipal Wastewater Treatment Plant: CJJ60-2011, 1st ed.; China Architecture & Building Press: Beijing, China, 2011; pp. 5–25. [Google Scholar]

- Yang, T.; Wang, T.; Peng, H.; Duan, H.H. Evaluation on emergency response vulnerability for work safety accidents in small and micro enterprises. China Saf. Sci. J. 2021, 31, 176–183. [Google Scholar] [CrossRef]

- Li, J.; Deng, C.C.C.; Xu, J.; Ma, Z.; Shuai, P.; Zhang, L. Safety Risk Assessment and Management of Panzhihua Open Pit (OP)-Underground (UG) Iron Mine Based on AHP-FCE, Sichuan Province, China. Sustainability 2023, 15, 4497. [Google Scholar] [CrossRef]

- Shao, T.; Yang, P.; Jiang, H.; Shao, Q. An Analysis of Public Service Satisfaction of Tourists at Scenic Spots: The Case of Xiamen City. Sustainability 2023, 15, 2752. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Zolfani, S.H.; Kahvand, M.; Khazaelpour, P. Landfill location selection for healthcare waste of urban areas using hybrid BWM-grey MARCOS model based on GIS. Sustain. Cities Soc. 2021, 67, 102712. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Hua, Z.S.; Zha, Y. Calculation of the weights and the amalgamation of the matrixes in AHP group decision. Oper. Res. Manag. Sci. 2003, 12, 16–21. [Google Scholar]

- Abualigah, L.; Diabat, A. Advances in Sine cosine algorithm: A comprehensive survey. Artif. Intell. Rev. 2021, 54, 2567–2608. [Google Scholar] [CrossRef]

- Xu, Z.X.; Guo, H.C.; Yu, Y.J. A multi-criteria group decision model for eco-industrial park construction mode selection. Res. Environ. Sci. 2007, 20, 123–129. [Google Scholar]

- Liang, F.; Brunelli, M.; Rezaei, J. Consistency issues in the best-worst method: Measurements and thresholds. Omega 2020, 96, 1–11. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation coefficients: Appropriate use and interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

| Criterion | Risk Grade Standard of Each Criterion | |||||

|---|---|---|---|---|---|---|

| Safe | Relatively Safe | Fair | Relatively Dangerous | Dangerous | ||

| Human factors U1 | Physical condition U11 | The proportion of regular physical examinations of workers is greater than 90%. | The proportion of regular physical examinations of workers is greater than 80%. | The proportion of regular physical examinations of workers is greater than 70%. | The proportion of regular physical examinations of workers is greater than 60%. | The proportion of regular physical examinations of workers is greater than 50%. |

| Technically training U12 | After training, all employees hold certificates and pass regular assessment. | Some employees hold certificates after training and fail to pass the regular assessment. | Some employees do not hold certificates and fail to pass the regular assessment. | |||

| Psychological states U13 | Employees are emotionally stable during working hours. | Some employees have big mood swings during working hours. | Some employees experience psychological abnormalities during working hours. | |||

| Operation specification U14 | All employees master the operation specification of this position and are able to handle faults skillfully. | Some employees master the operation specification of this position and can handle the faults skillfully. | Some employees basically master the operation specification of this position and can handle the faults. | Some employees fail to master the operating specifications of this position but are able to handle faults. | Some employees fail to master the operation specification of this position and fail to handle the faults. | |

| Safety equipment U15 | The safety protection device is fully equipped, and the damaged and old equipment is regularly updated, and the wearing rate is 100%. | The safety protection device is equipped with sound, regularly updated damaged and old equipment, and the wearing rate is high. | Sound configuration of safety protection equipment, high wearing rate. | Safety and protection equipment is well equipped. | Incomplete configuration of safety protection equipment. | |

| Material factors U2 | Structures U21 | No damage to the main structure. | From 1 to 3 main structures are in disrepair. | From 4 to 5 main structures are in disrepair. | From 6 to 7 main structures are in disrepair. | 8 or more main structures are damaged. |

| Production equipment U22 | The appearance of the production equipment is clean and tidy, and the integrity rate is more than 95%. | A small part of the appearance of the production equipment is not clean, and the integrity rate of more than 95%. | Part of the production equipment looks untidy, the integrity rate of more than 95%. | Part of the production equipment looks untidy, the integrity rate is less than 95%. | Most of the production equipment is not neat in appearance, and the integrity rate is less than 95%. | |

| Poly aluminium Chloride U23 | The packaging is complete and lossless, no moisture, pollution, character, or color meets the product requirement. | Some of the packaging is damaged, but there is no moisture, the character and color meet the product requirement. | Some of the packaging is damaged, wet, and the character and color do not meet the product requirement. | |||

| Hydrogen sulfide U24 | Concentrations below 10 mg/m3. | Concentrations above 10 mg/m3. | ||||

| Methane U25 | Volumetric concentration below 1%. | Volumetric concentration above 1%. | ||||

| Ammonia gas U26 | Concentrations below 20 mg/m3. | Concentrations above 20 mg/m3. | ||||

| Environment factors U3 | Safety signs U31 | Very complete. | Complete. | Generally. | Incomplete. | Very incomplete. |

| Noise U32 | Take measures to reduce noise, all kinds of equipment in operation noise should be less than 85 dB. | Measures are taken to reduce noise, and the noise of some equipment is greater than 85 dB in operation. | No measures are taken to reduce noise, and most of the equipment has noise greater than 85 dB in operation. | |||

| Working environment U33 | The platform is flat, the light is good, and the traffic road meets the transportation requirement. | The platform is slightly flat, the light is good, and the traffic road meets the transportation requirement. | The platform is uneven, the light is good, and the traffic road meets the transportation requirement. | The platform is uneven, the poor light, and the traffic road is generally designed. | The platform is uneven, the light is poor, and the traffic road is poorly designed. | |

| Management factors U4 | Security check U41 | The safety inspection program is complete and comprehensive and can be implemented. | The safety inspection program is complete and well established and can be largely implemented. | The safety inspection program is basically complete and complete and can basically be implemented. | Safety inspection program complete, some not implemented. | Inadequate safety checks and failure to implement. |

| Safety management responsibility system U42 | The system is well-established and can be implemented | The system has been improved and basically implemented | The system has been basically improved and implemented | The system is basically perfect but fails to be implemented | The system needs to be improved and fails to be improved | |

| Emergency management U43 | Very complete. | Complete. | Generally. | Imperfect. | Very imperfect. | |

| Sore auv | Standard |

|---|---|

| 1 | This means that, compared with uu and uv two criteria, the former is equally important as the latter |

| 2 | This means that, compared with the two criteria of uu and uv, the former ranges from equally important to moderately important |

| 3 | This means that uu is moderately important compared with uv |

| 4 | This means that, compared with the two criteria of uu and uv, the former is between moderately important and highly important |

| 5 | This means that, compared with uu and uv, the former is more important than the latter |

| 6 | This means that, compared with the two criteria of uu and uv, the former is between highly important and very important |

| 7 | This means that, compared with the two criteria of uu and uv, the former is more important than the latter |

| 8 | This means that, compared with the two criteria of uu and uv, the former is between very important and completely important |

| 9 | This means that, compared with uu and uv two criteria, the former is more important than the latter |

| Criterion | Order of Evaluation | |||||

|---|---|---|---|---|---|---|

| Safe | Relatively Safe | Fair | Relatively Dangerous | Dangerous | ||

| Human factors U1 | Physical condition U11 | 0 | 1 | 0 | 0 | 0 |

| Technically training U12 | 0.4 | 0.6 | 0 | 0 | 0 | |

| Psychological states U13 | 0.8 | 0.2 | 0 | 0 | 0 | |

| Operation specification U14 | 0.2 | 0.6 | 0.2 | 0 | 0 | |

| Safety equipment U15 | 0.4 | 0.6 | 0 | 0 | 0 | |

| Material factors U2 | Structures U21 | 0 | 1 | 0 | 0 | 0 |

| Production equipment U22 | 0 | 1 | 0 | 0 | 0 | |

| Poly aluminium Chloride U23 | 0 | 0.6 | 0.4 | 0 | 0 | |

| Hydrogen sulfide U24 | 1 | 0 | 0 | 0 | 0 | |

| Methane U25 | 1 | 0 | 0 | 0 | 0 | |

| Ammonia gas U26 | 1 | 0 | 0 | 0 | 0 | |

| Environment factors U3 | Safety signs U31 | 0.2 | 0.4 | 0.2 | 0.2 | 0 |

| Noise U32 | 0 | 0 | 0.8 | 0.2 | 0 | |

| Working environment U33 | 0 | 0 | 0.8 | 0.2 | 0 | |

| Management factors U4 | Security check U41 | 0 | 0 | 1 | 0 | 0 |

| Safety management responsibility system U42 | 0.6 | 0.2 | 0.2 | 0 | 0 | |

| Emergency management U43 | 0.8 | 0 | 0.2 | 0 | 0 | |

| First-Order Index | The Weight of the First-Order Index | Secondary Index | The Weight of Improved BWM |

|---|---|---|---|

| U1 | 0.264 | U11 | 0.169 |

| U12 | 0.076 | ||

| U13 | 0.205 | ||

| U14 | 0.087 | ||

| U15 | 0.463 | ||

| U2 | 0.161 | U21 | 0.047 |

| U22 | 0.102 | ||

| U23 | 0.110 | ||

| U24 | 0.317 | ||

| U25 | 0.237 | ||

| U26 | 0.187 | ||

| U3 | 0.079 | U31 | 0.613 |

| U32 | 0.091 | ||

| U33 | 0.296 | ||

| U4 | 0.496 | U41 | 0.268 |

| U42 | 0.152 | ||

| U43 | 0.580 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Liu, X.; Pan, D.; Zhang, Y.; Zhang, J.; Ke, K. Research on Safety Evaluation of Municipal Sewage Treatment Plant Based on Improved Best-Worst Method and Fuzzy Comprehensive Method. Sustainability 2023, 15, 8796. https://doi.org/10.3390/su15118796

Wu J, Liu X, Pan D, Zhang Y, Zhang J, Ke K. Research on Safety Evaluation of Municipal Sewage Treatment Plant Based on Improved Best-Worst Method and Fuzzy Comprehensive Method. Sustainability. 2023; 15(11):8796. https://doi.org/10.3390/su15118796

Chicago/Turabian StyleWu, Junnan, Xin Liu, Dianqi Pan, Yichen Zhang, Jiquan Zhang, and Kai Ke. 2023. "Research on Safety Evaluation of Municipal Sewage Treatment Plant Based on Improved Best-Worst Method and Fuzzy Comprehensive Method" Sustainability 15, no. 11: 8796. https://doi.org/10.3390/su15118796