Comprehensive Laboratory Evaluation of Crack Resistance for an Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI)

Abstract

:1. Introduction

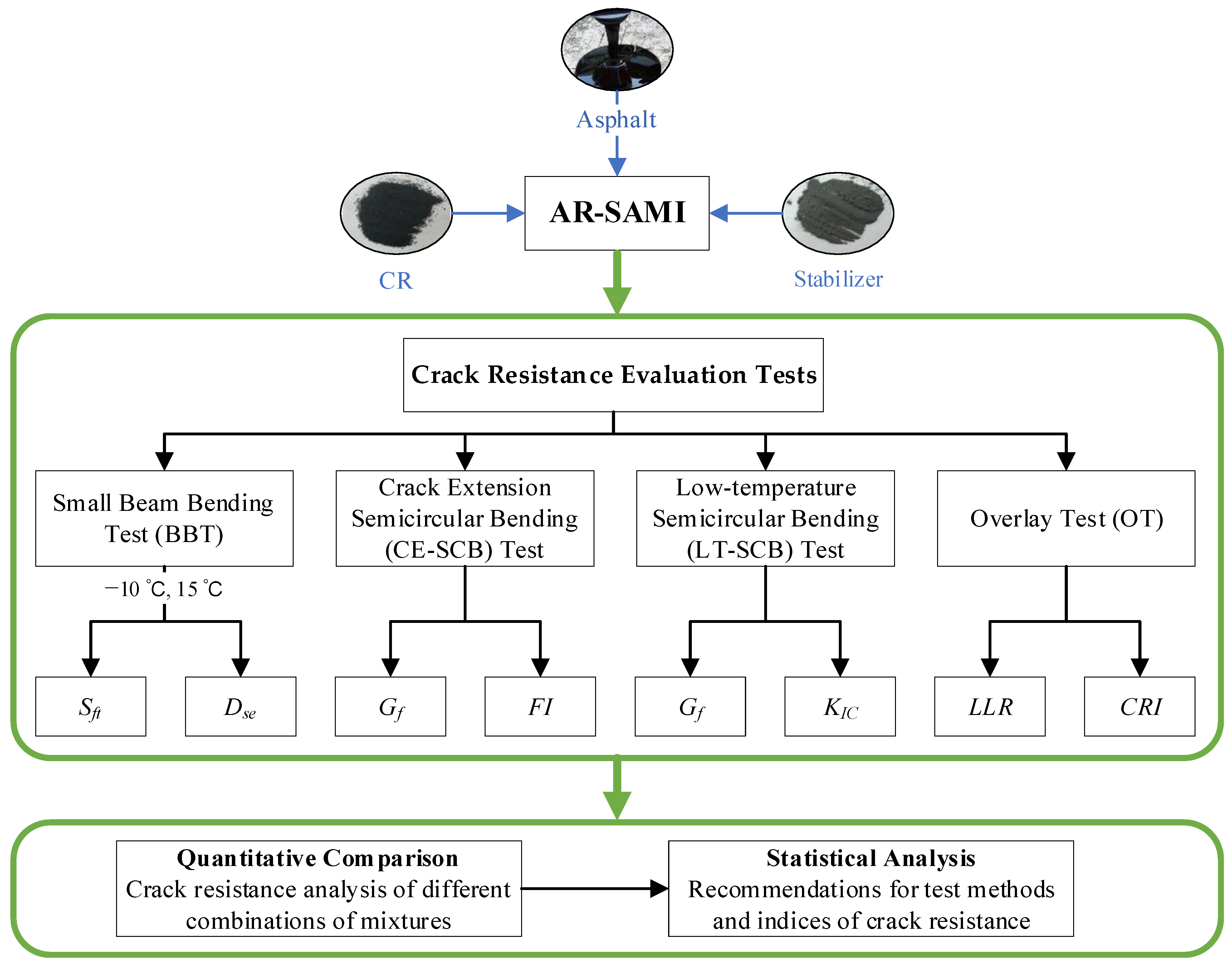

2. Materials and Methods

2.1. Crumb Rubber Modified Asphalt

2.2. Aggregate

2.3. Mixture Design

2.4. Gradation Evaluation by Bailey Method

2.5. Crack Resistance Evaluation Test Methods

2.5.1. Small Beam Bending Test (BBT)

2.5.2. Crack Extension Semicircular Bending (CE-SCB) Test

2.5.3. Low-Temperature Semicircular Bending (LT-SCB) Test

2.5.4. Overlay Test (OT)

3. Results and Discussion

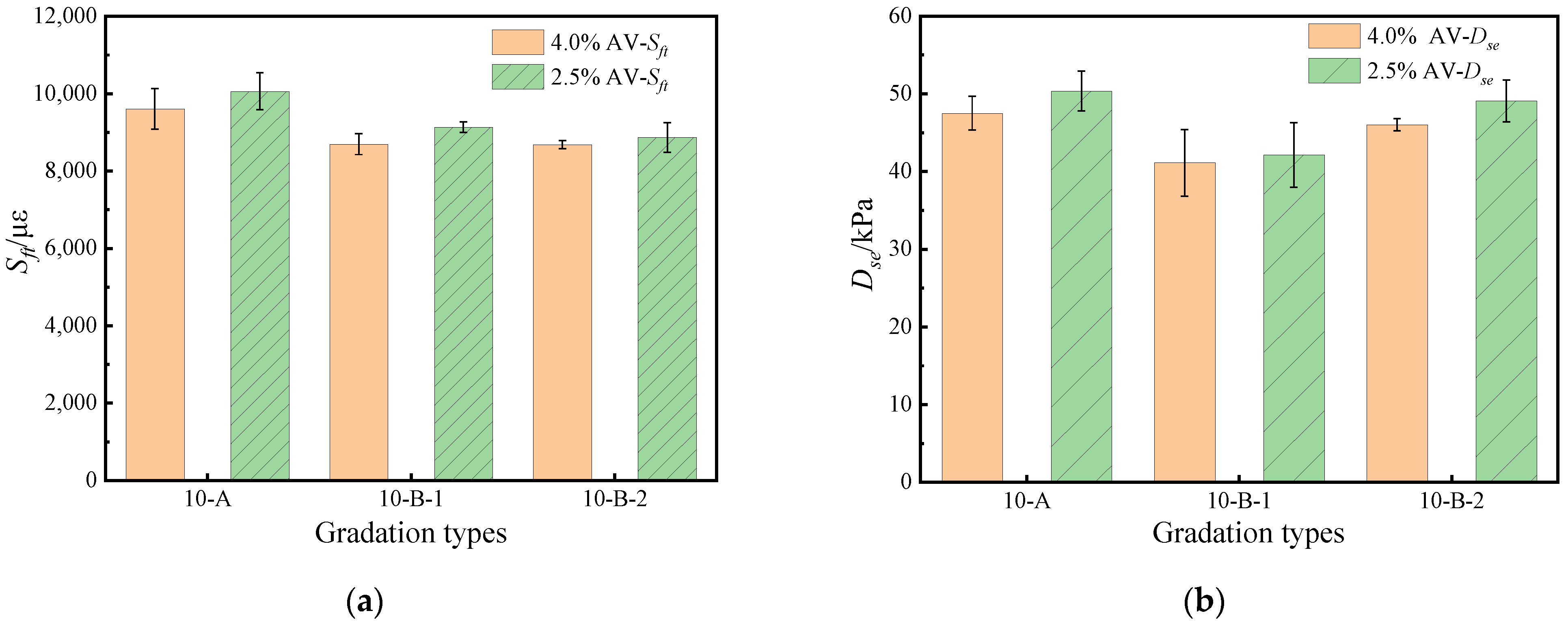

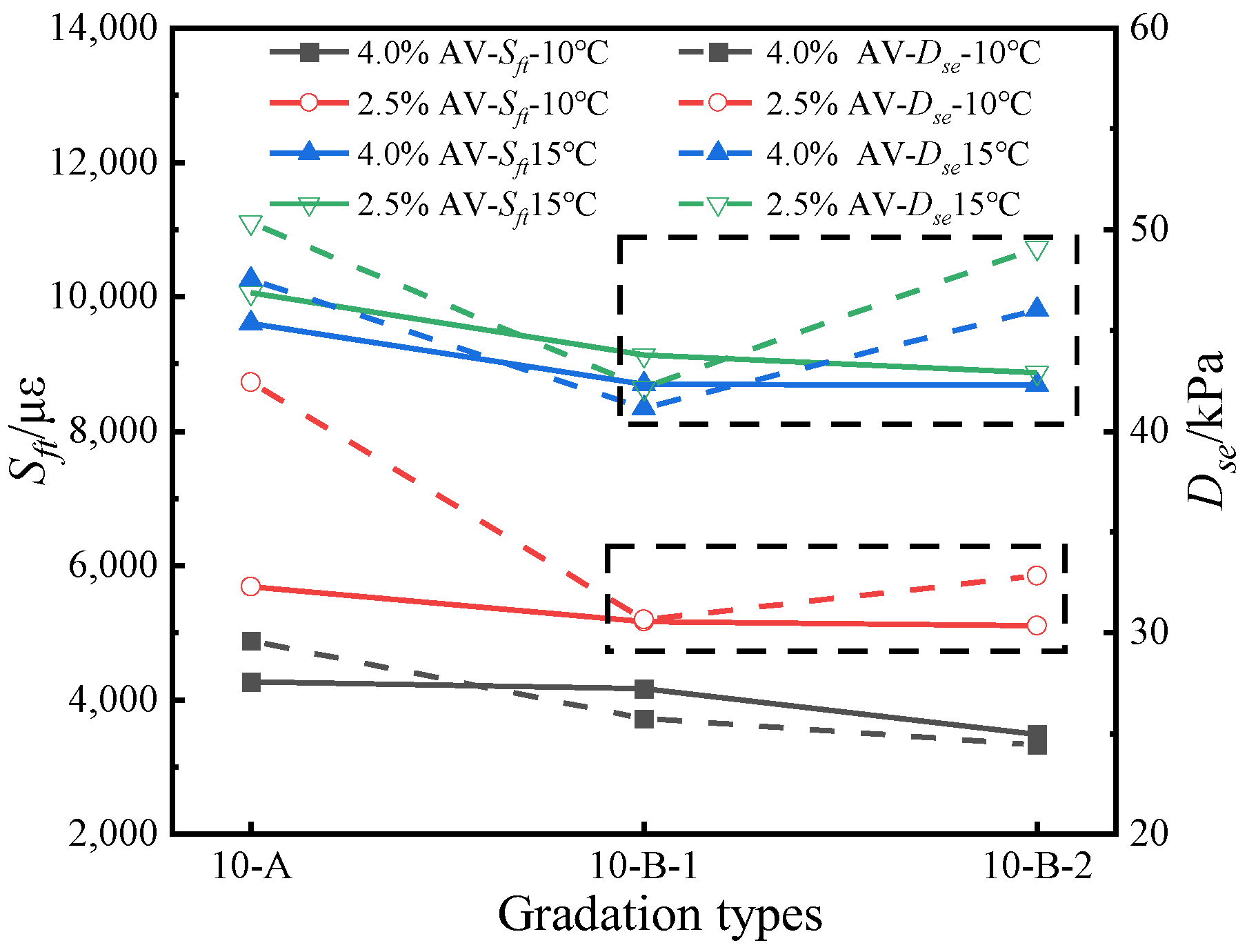

3.1. Small Beam Bending Test

3.2. Crack Extension Semicircular Bending Test

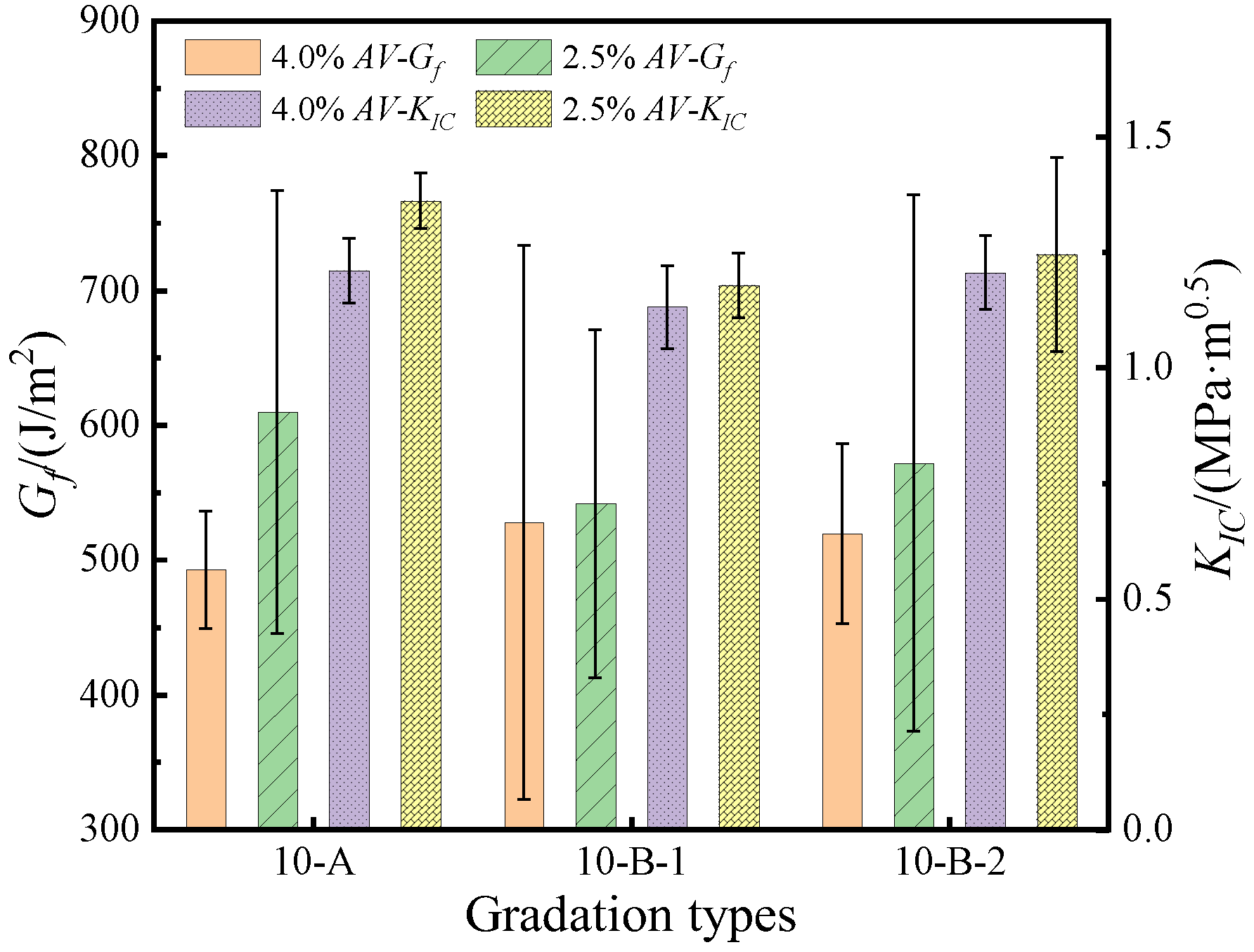

3.3. Low-Temperature Semicircular Bending Test

3.4. Overlay Test

3.5. Correlation Analysis of Evaluation Indices

- Evaluation of crack resistance: The two indices of the LT-SCB test were significantly correlated with the Dse of −10 °C BBT. So, the Dse of −10 °C BBT could be a substitute to evaluate the results of the LT-SCB test. However, indices of the LT-SCB test were not significantly related to the Sft of the −10 °C BBT. Considering only Sft was used in China [31], it is necessary to add Dse to evaluate crack resistance. In addition, studies have shown that asphalt mixtures are more likely to form cracks at low temperatures [33]. Therefore, instead of 15 °C BBT, −10 °C BBT results can be used to evaluate crack resistance.

- Evaluation of crack expansion resistance: Indices of the CE-SCB test were not significantly related to other test indices. However, there was a significant correlation between the two indices of this test. Since FI considered the post-peak load characteristics, it could better reflect the resistance of crack expansion. Therefore, the FI could be used to evaluate the crack expansion resistance of AR-SAMI.

- Evaluation of fatigue crack resistance: There was a significant correlation between the two indicators in the OT. The two OT indices were significantly correlated with the −10 °C Sft. However, considering the significant differences between the two test conditions and crack types, a more general correlation still needs further verification. Therefore, using CRI to evaluate the fatigue crack resistance performance of AR-SAMI is still recommended.

3.6. Comprehensive Comparative Analysis of Crack Resistance

4. Conclusions

- All test methods showed that the crack resistance indices of AR-SAMI were significantly improved when the air voids were reduced from 4.0% to 2.5%. Therefore, the comprehensive crack resistance of AR-SAMI may perform better when the design air voids are decreased.

- The gradation 10-A, which contains more fine aggregate, performed better on most crack resistance indices. However, its crack extension resistance was poor. The CE-SCB and the LT-SCB tests showed that the 10-B type (including 10-B-1 and 10-B-2) with more coarse aggregate had better crack extension resistance under pre-existing cracks.

- There are differences in the evaluation results of different test methods and indices due to the differences in the evaluation mechanism. The test evaluation methods and corresponding indices should be selected according to the engineering characteristics of applications. The crack resistance should be designed in a targeted and comprehensive balance method. Considering the validity, comprehensiveness, and simplicity of the evaluation tests and indices, the test methods and indices in Table 7 were recommended for the comprehensive evaluation of the crack resistance of AR-SAMI.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Zhong, Y. Reflective crack in semi-rigid base asphalt pavement under temperature-traffic coupled dynamics using XFEM. Constr. Build. Mater. 2019, 214, 280–289. [Google Scholar] [CrossRef]

- Oshone, M.; Dave, E.V.; Sias, J.E. Asphalt mix fracture energy based reflective cracking performance criteria for overlay mix selection and design for pavements in cold climates. Constr. Build. Mater. 2019, 211, 1025–1033. [Google Scholar] [CrossRef]

- Idris, I.I.; Sadek, H.; Hassan, M. State-of-the-Art Review of the Evaluation of Asphalt Mixtures’ Resistance to Reflective Cracking in Laboratory. J. Mater. Civil Eng. 2020, 32, 0312004. [Google Scholar] [CrossRef]

- Rith, M.; Lee, S.W. Development of cohesive-zone-based prediction model for reflective cracking in asphalt overlay. Int. J. Pavement Eng. 2022, 23, 1050–1059. [Google Scholar] [CrossRef]

- Shan, J.; Zhang, Y.; Wu, S.; Wu, Q.; Jiao, Y.; Du, Y. Cracking behavior of asphalt pavement with a graded gravel layer based on computational granular mechanics. Constr. Build. Mater. 2022, 345, 128199. [Google Scholar] [CrossRef]

- Fang, H.; Luo, H.; Zhu, H. The feasibility of continuous construction of the base and asphalt layers of asphalt pavement to solve the problem of reflective cracks. Constr. Build. Mater. 2016, 119, 80–88. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Ahmadi, S. Reflective cracking reduction by a comparison between modifying asphalt overlay and sand asphalt interlayer: An experimental evaluation. Int. J. Pavement Eng. 2021, 22, 192–200. [Google Scholar] [CrossRef]

- Baek, C. Performance Evaluation of Fiber-Reinforced, Stress Relief Asphalt Layers to Suppress Reflective Cracks. Appl. Sci. 2020, 10, 7701. [Google Scholar] [CrossRef]

- Haslett, K.; Dave, E.; Sias, J.; Linder, E. Statistical Analysis Framework to Evaluate Asphalt Concrete Overlay Reflective Cracking Performance. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 132–146. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Morian, N.E.; Sebaaly, P.E.; Piratheepan, M. Reflective cracking relief interlayer for asphalt pavement rehabilitation: From development to demonstration. Road Mater. Pavement 2017, 18, 30–57. [Google Scholar] [CrossRef]

- Pasquini, E.; Pasetto, M.; Canestrari, F. Geocomposites against reflective cracking in asphalt pavements: Laboratory simulation of a field application. Road Mater. Pavement 2015, 16, 815–835. [Google Scholar] [CrossRef]

- Zeng, Z.; Guo, Y.; Li, P.; Shen, A.; Zhai, C. Performance research of fiber-reinforced asphalt rubber as a stress-absorbing membrane interlayer. J. Adhes. Sci. Technol. 2021, 35, 2047–2063. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, Z.; Luo, Y. Material Composition Design and Anticracking Performance Evaluation of Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI). Adv. Mater. Sci. Eng. 2018, 2018, 8560604. [Google Scholar] [CrossRef] [Green Version]

- Ogundipe, O.M.; Thom, N.H.; Collop, A.C. Evaluation of performance of stress-absorbing membrane interlayer (SAMI) using accelerated pavement testing. Int. J. Pavement Eng. 2013, 14, 569–578. [Google Scholar] [CrossRef]

- Karki, P.; Mraiza, Z.; Karnei, E.; Hu, S. Performance-graded asphalt binder selection catalog for asphalt overlays. Constr. Build. Mater. 2022, 319, 126012. [Google Scholar] [CrossRef]

- Peng, W.; Li, P.; Gong, W.; Tian, S.; Wang, Z.; Liu, S.; Liu, Z. Preparation and mechanism of rubber-plastic alloy crumb rubber modified asphalt with low viscosity and stabilized performance. Constr. Build. Mater. 2023, 388, 131687. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Asgharzadeh, S.M.; Sadeghi, J.; Peivast, P.; Pedram, M. Fatigue properties of crumb rubber asphalt mixtures used in railways. Constr. Build. Mater. 2018, 184, 248–257. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Fazaeli, H.; Aghajani, S.; Moghadas Nejad, F. Effect of temperature and air void on mixed mode fracture toughness of modified asphalt mixtures. Constr. Build. Mater. 2015, 95, 545–555. [Google Scholar] [CrossRef]

- Zhang, Q. Effect of Grading Type on the Performance of Warm-Mix Rubber-Asphalt Mixture. IOP Conf. Ser. Earth Environ. Sci. 2020, 526, 12152. [Google Scholar] [CrossRef]

- Pan, R.; Li, Y. Effect of warm mix rubber modified asphalt mixture as stress absorbing layer on anti-crack performance in cold region. Constr. Build. Mater. 2020, 251, 118985. [Google Scholar] [CrossRef]

- Wang, S.; Yan, K.; Ge, D.; Hong, Z. Laboratory research on the performance of stress-absorption interlayer (SAI) of waste tire rubber and amorphous ploy alpha olefin modified asphalt. Constr. Build. Mater. 2019, 223, 830–840. [Google Scholar] [CrossRef]

- Thives, L.P.; Pais, J.C.; Pereira, P.A.A.; Minhoto, M.C.; Trichês, G. Performance of Asphalt Rubber Mixture Overlays to Mitigate Reflective Cracking. Materials 2022, 15, 2375. [Google Scholar] [CrossRef] [PubMed]

- Pei, Z.; Yi, J.; Mao, Q.; Feng, D.; Wang, D. DEM analysis of the evolution of reflection cracks in old cement concrete pavement with an ATB layer. Int. J. Pavement Eng. 2022, 1–10. [Google Scholar] [CrossRef]

- Li, C.; Zhou, H.; Wu, Z.; Wang, Z. International Conference on Transportation Engineering. In Alleviating Crack Properties of Crack Alleviating Mixture; American Society of Civil Engineers: Reston, VA, USA, 2009. [Google Scholar]

- AASHTO TP 124-16; American Association of State Highway and Transportation Officials Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using Semicircular Bend Geometry (SCB) at Intermediate Temperature. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- AASHTO TP 105-13; American Association of State Highway and Transportation Officials Standard Method of Test for Determining the Fracture Energy of Asphalt Mixtures Using the Semicircular Bend Geometry (SCB). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019; p. 13.

- Germann, F.P.; Lytton, R.L. Methodology for Predicting the Reflection Cracking Life of Asphalt Concrete Overlays; Texas A&M University: College Station, TX, USA, 1979; pp. 25–45. [Google Scholar]

- Nam, B.H.; Golestani, B.; Noori, M.; Tatari, O.; An, J. Investigation of Reflective Cracking Mitigation Techniques; Department of Civil, Environmental, and Construction Engineering University of Central Florida: Orlando, FL, USA, 2014; pp. 1–153. [Google Scholar]

- Zhou, F.; Newcomb, D.; Gurganus, C.; Banihashemrad, S. Field Validation of Laboratory Tests to Assess Cracking Resistance of Asphalt Mixtures: An Experimental Design (2016); National Academy of Sciences: Washington, DC, USA, 2016. [Google Scholar]

- JTG F40-2004; Ministry of Communications of the People’s Republic of China Technical Specifications for Construction of Highway Asphalt Pavement. Ministry of Communications: Beijing, China, 2004.

- Wang, H.; Dang, Z.; Li, L.; You, Z. Analysis on fatigue crack growth laws for crumb rubber modified (CRM) asphalt mixture. Constr. Build. Mater. 2013, 47, 1342–1349. [Google Scholar] [CrossRef]

- Mandal, T.; Yin, H.; Ji, R. Correlating laboratory and full-scale reflective cracking tests for airfield pavements. Constr. Build. Mater. 2018, 169, 47–58. [Google Scholar] [CrossRef]

- JTG E20-2011; Ministry of Communications of the People’s Republic of China Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Communications: Beijing, China, 2011.

- DB45/T 1098-2014; Guangxi Zhuang Autonomous Region Quality and Technical Supervision Bureau Technical Specification for Construction of Asphalt Rubber Pavement. Guangxi Zhuang Autonomous Region Quality and Technical Supervision Bureau: Nanning, China, 2014.

- DG/TJ08-2109-2012; Shanghai Urban-Rural Construction and Transportation Commission Technical Code for Asphalt Rubber Pavement. Shanghai Urban-Rural Construction and Transportation Commission: Shanghai, China, 2012.

- Swathi, M.; Andiyappan, T.; Guduru, G.; Amarnatha Reddy, M.; Kuna, K.K. Design of asphalt mixes with steel slag aggregates using the Bailey method of gradation selection. Constr. Build. Mater. 2021, 279, 122426. [Google Scholar] [CrossRef]

- Ge, Z.; Huang, X.; Xu, G. Evaluation of asphalt-mixture’s low-temperature anti-cracking performance by curvature strain energy method. J. Southeast Univ. Nat. Sci. Ed. 2002, 32, 653–655. [Google Scholar]

- Tex-248-F; Texas Department of Transportation Test Procedure for Overlay Test. Texas Department of Transportation: Austin, TX, USA, 2017; pp. 1–13.

- Feng, D.; Cui, S.; Yi, J.; Chen, Z.; Qin, W. Evaluation Index of Low-temperature Asphalt Mixture Performance Based on Semi-circular Bending Test. China J. Highw. Transp. 2020, 33, 50–57. [Google Scholar]

| Technical Indices | Units | Test Results | Test Methods [34] |

|---|---|---|---|

| Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 39.3 | T 0604 |

| Ductility (5 °C, 5 cm/min) | cm | 11.6 | T 0605 |

| Softening point | °C | 75.5 | T 0606 |

| Brookfield viscosity (180 °C) | Pa·s | 2.51 | T 0625 |

| Elastic recovery rate (25 °C) | % | 94.0 | T 0662 |

| Aggregate Types | Technical Indices | Units | Test Results | Requirements [31] | Test Methods | |

|---|---|---|---|---|---|---|

| Coarse aggregate | Crushing value | % | 17 | ≤26 | T 0316 | |

| Apparent specific gravity | 9.5~13.2 mm | — | 2.705 | ≥2.60 | T 0304 | |

| 4.75~9.5 mm | 2.735 | |||||

| 2.36~4.75 mm | 2.63 | |||||

| Bulk specific gravity | 9.5~13.2 mm | — | 2.676 | — | T 0304 | |

| 4.75~9.5 mm | 2.654 | |||||

| 2.36~4.75 mm | 2.611 | |||||

| Water absorption | 9.5~13.2 mm | % | 0.41 | ≤2.0 | T 0304 | |

| 4.75~9.5 mm | 1.11 | |||||

| 2.36~4.75 mm | 0.27 | |||||

| Flat and elongated particles content | 9.5~13.2 mm | % | 13.2 | ≤15 | T 0312 | |

| 4.75~9.5 mm | 10.9 | ≤15 | ||||

| 2.36~4.75 mm | 7.5 | ≤20 | ||||

| Adhesional degree with aggregate | — | 5 | ≥4 | T 0616 | ||

| Fine aggregate | Apparent specific gravity | — | 2.622 | ≥2.50 | T 0304 | |

| Bulk specific gravity | — | 2.620 | — | T 0304 | ||

| Water absorption | % | 0.27 | — | T 0304 | ||

| Sand equivalent | % | 69 | ≥60 | T 0334 | ||

| Angularity (Flow time method) | s | 32.2 | ≥30 | T 0345 | ||

| Gradation Types | Mass Percentage Passing the Following Square-Mesh Sieve (mm)/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 10-A | 100 | 91 | 57 | 40 | 27 | 19 | 13 | 9 | 6 |

| 10-B-1 | 100 | 95 | 35 | 28 | 21 | 17 | 13 | 10 | 8 |

| 10-B-2 | 100 | 98 | 38 | 29 | 23 | 15 | 11 | 8 | 6 |

| Gradation Types | Air Voids/% | Optimal Asphalt–Aggregate Ratio/% | VMA/% | VFA/% | Asphalt Film Thickness/μm |

|---|---|---|---|---|---|

| 10-A | 4.0 | 5.75 | 15.78 | 74.69 | 9.13 |

| 2.5 | 6.10 | 15.11 | 83.41 | 9.70 | |

| 10-B-1 | 4.0 | 5.57 | 15.40 | 74.07 | 8.21 |

| 2.5 | 6.55 | 15.93 | 84.38 | 9.71 | |

| 10-B-2 | 4.0 | 5.89 | 16.04 | 75.13 | 10.46 |

| 2.5 | 6.46 | 15.78 | 84.18 | 11.51 |

| Gradation Types | Improvement of Sft/% | Improvement of Dse/% | ||

|---|---|---|---|---|

| −10 °C | 15 °C | −10 °C | 15 °C | |

| 10-A | 33.2 | 4.7 | 43.4 | 6.0 |

| 10-B-1 | 23.9 | 5.0 | 19.0 | 2.4 |

| 10-B-2 | 46.6 | 2.1 | 34.3 | 6.7 |

| Gradation Parameters | 10-A | 10-B-1 | 10-B-2 | |

|---|---|---|---|---|

| Passing rate of key sieve (2.36 mm)/% | 40 | 28 | 29 | |

| Key sieve aggregate content/% | 4.75–9.5 mm | 34 | 60 | 60 |

| 2.36–4.75 mm | 17 | 7 | 9 | |

| Parameters of Bailey method | CA | 0.40 | 0.11 | 0.15 |

| FAc | 0.48 | 0.61 | 0.52 | |

| FAf | 0.47 | 0.59 | 0.53 | |

| Recommended Test Methods | Recommended Indices | Focus on Evaluating Performance |

|---|---|---|

| −10 °C BBT | Sft, Dse | Low-temperature crack resistance |

| CE-SCB | FI | Crack extension resistance |

| OT | CRI | Fatigue crack resistance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Peng, W.; Tian, S.; Liu, Z.; Liu, J.; Liu, S. Comprehensive Laboratory Evaluation of Crack Resistance for an Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI). Sustainability 2023, 15, 8982. https://doi.org/10.3390/su15118982

Li P, Peng W, Tian S, Liu Z, Liu J, Liu S. Comprehensive Laboratory Evaluation of Crack Resistance for an Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI). Sustainability. 2023; 15(11):8982. https://doi.org/10.3390/su15118982

Chicago/Turabian StyleLi, Ping, Wenju Peng, Shuaituan Tian, Zhaohui Liu, Junbin Liu, and Shende Liu. 2023. "Comprehensive Laboratory Evaluation of Crack Resistance for an Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI)" Sustainability 15, no. 11: 8982. https://doi.org/10.3390/su15118982

APA StyleLi, P., Peng, W., Tian, S., Liu, Z., Liu, J., & Liu, S. (2023). Comprehensive Laboratory Evaluation of Crack Resistance for an Asphalt Rubber Stress-Absorbing Membrane Interlayer (AR-SAMI). Sustainability, 15(11), 8982. https://doi.org/10.3390/su15118982