Assessment of New Bio-Cement Method for Sand Foundation Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

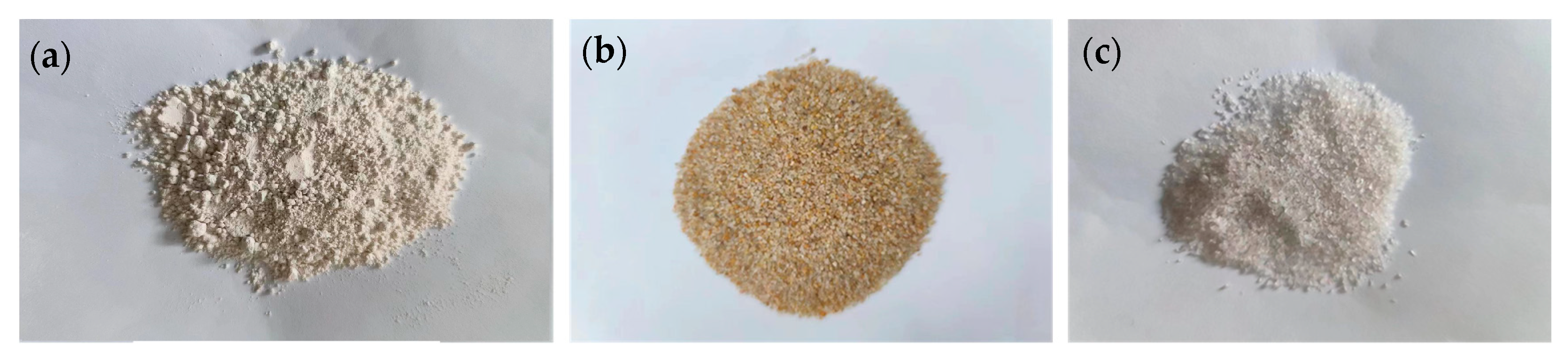

2.1. Sandy Soil and Bio-Cement Composition

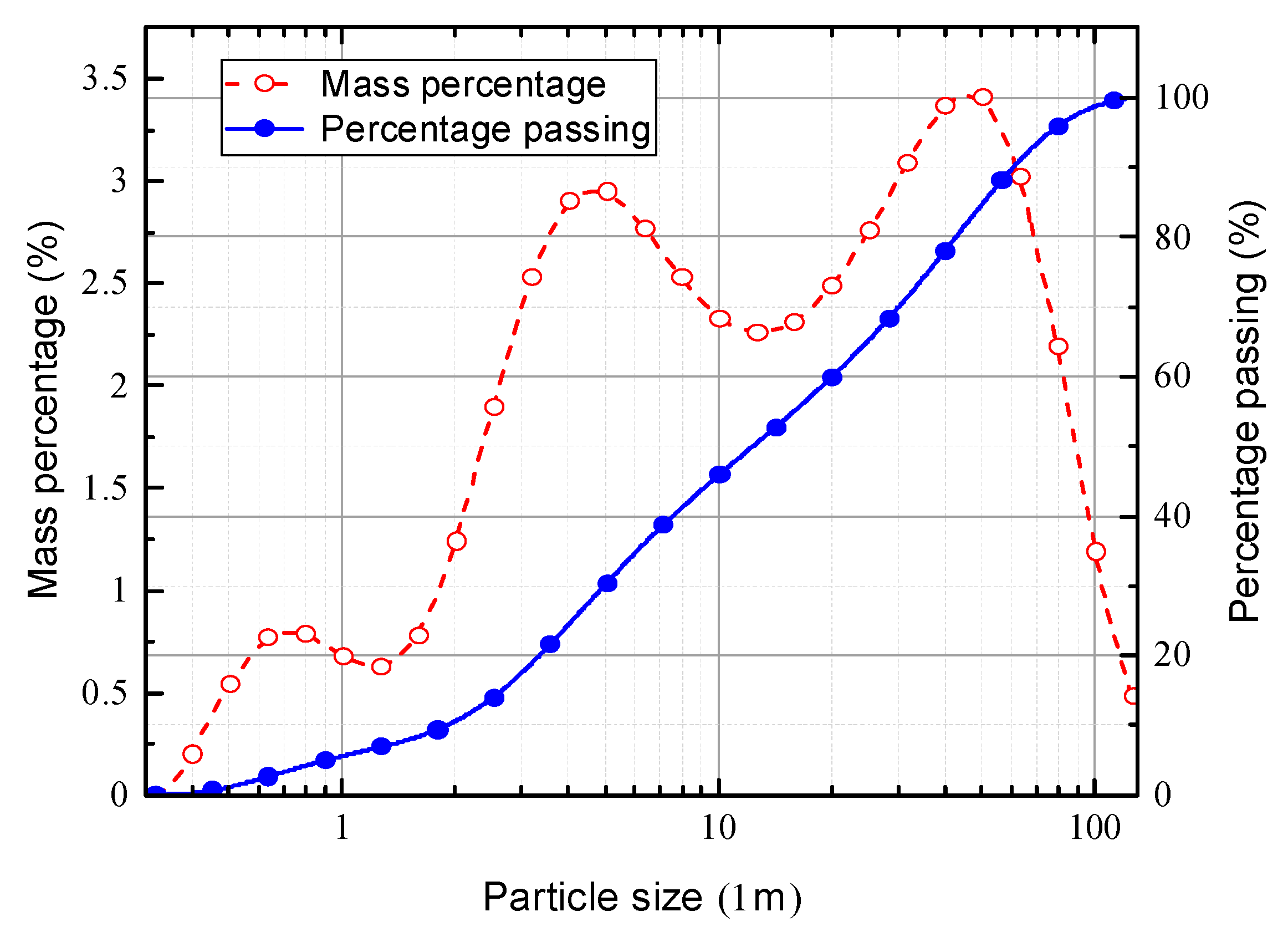

2.1.1. Sandy Soil

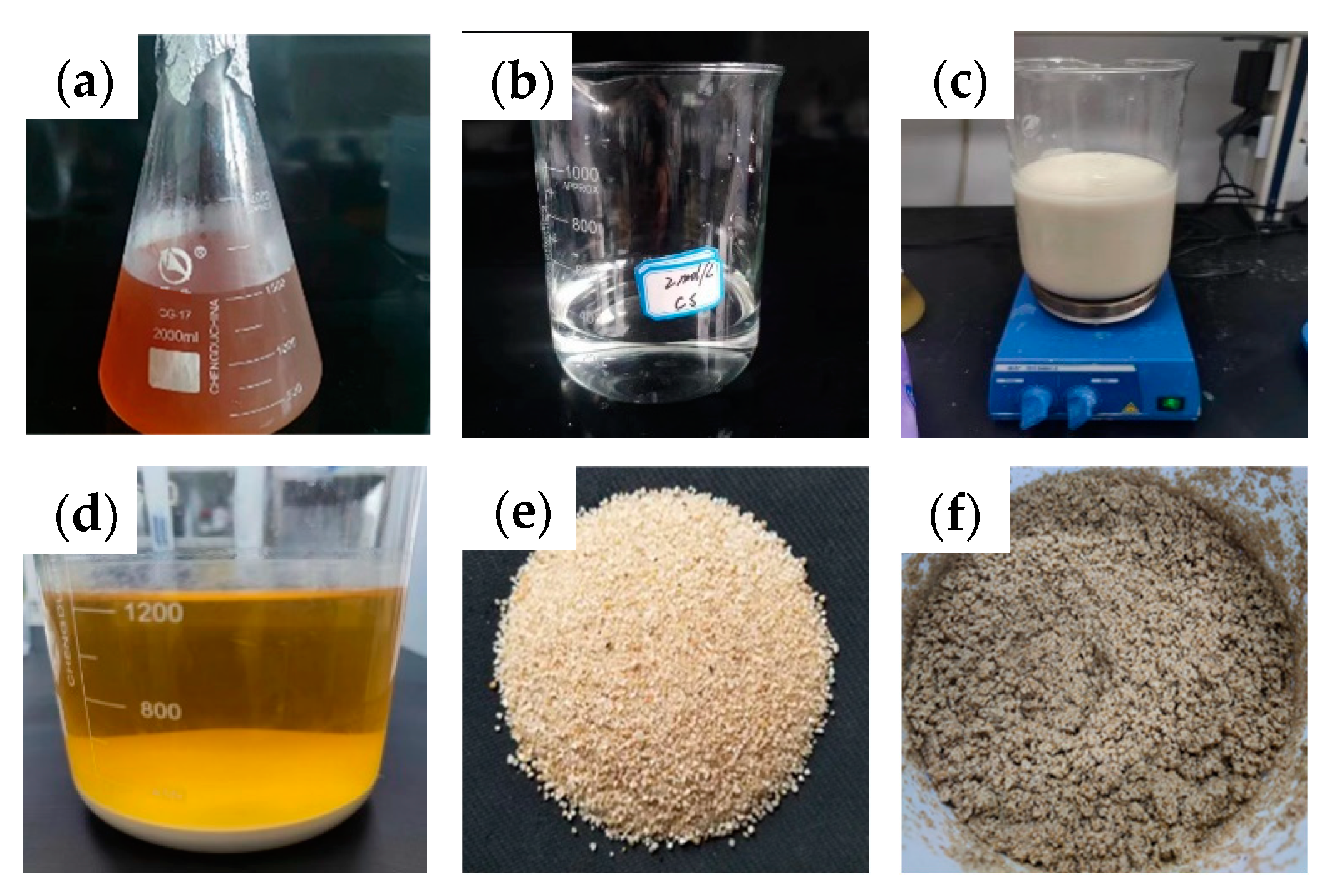

2.1.2. Bio-Cement Composition

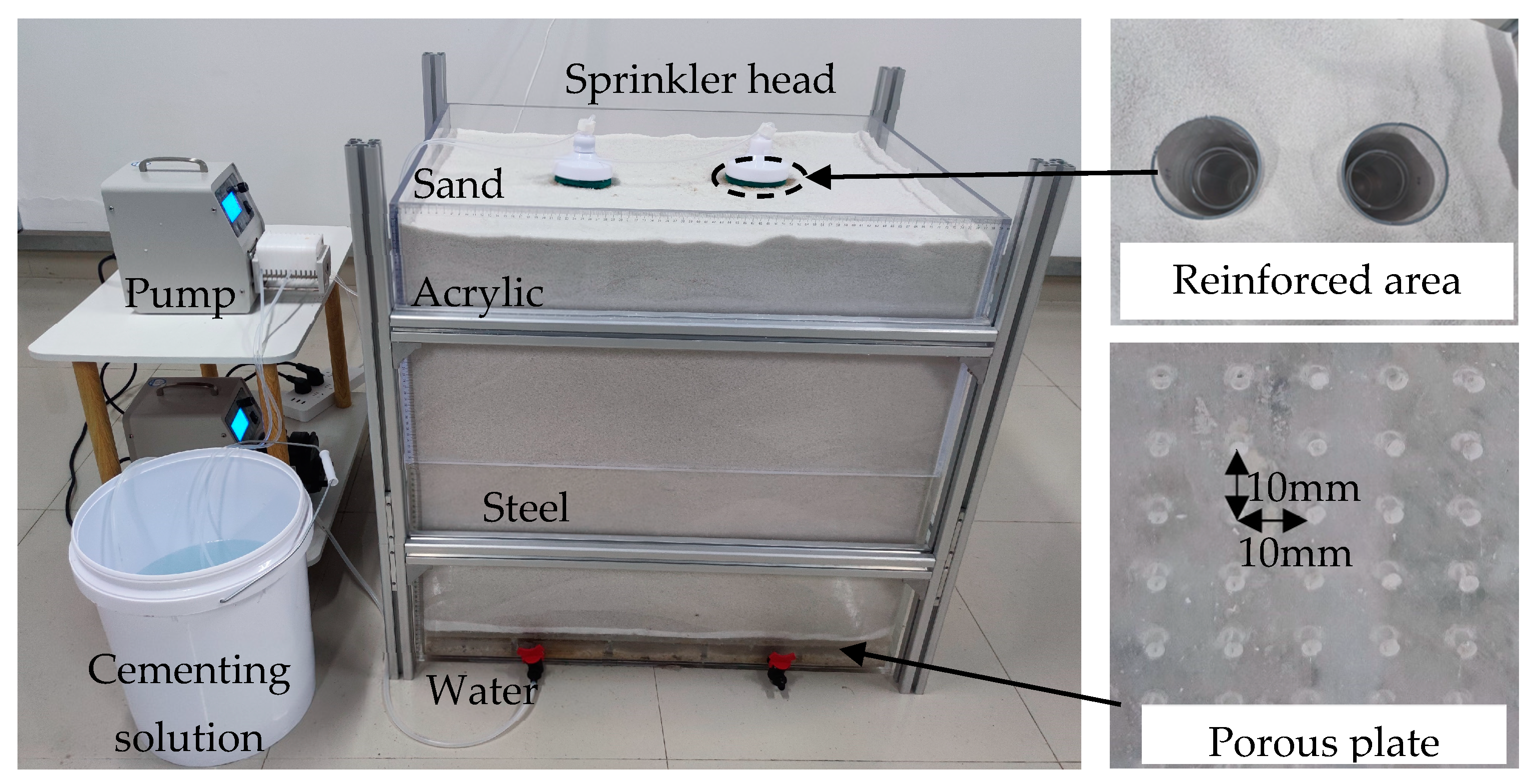

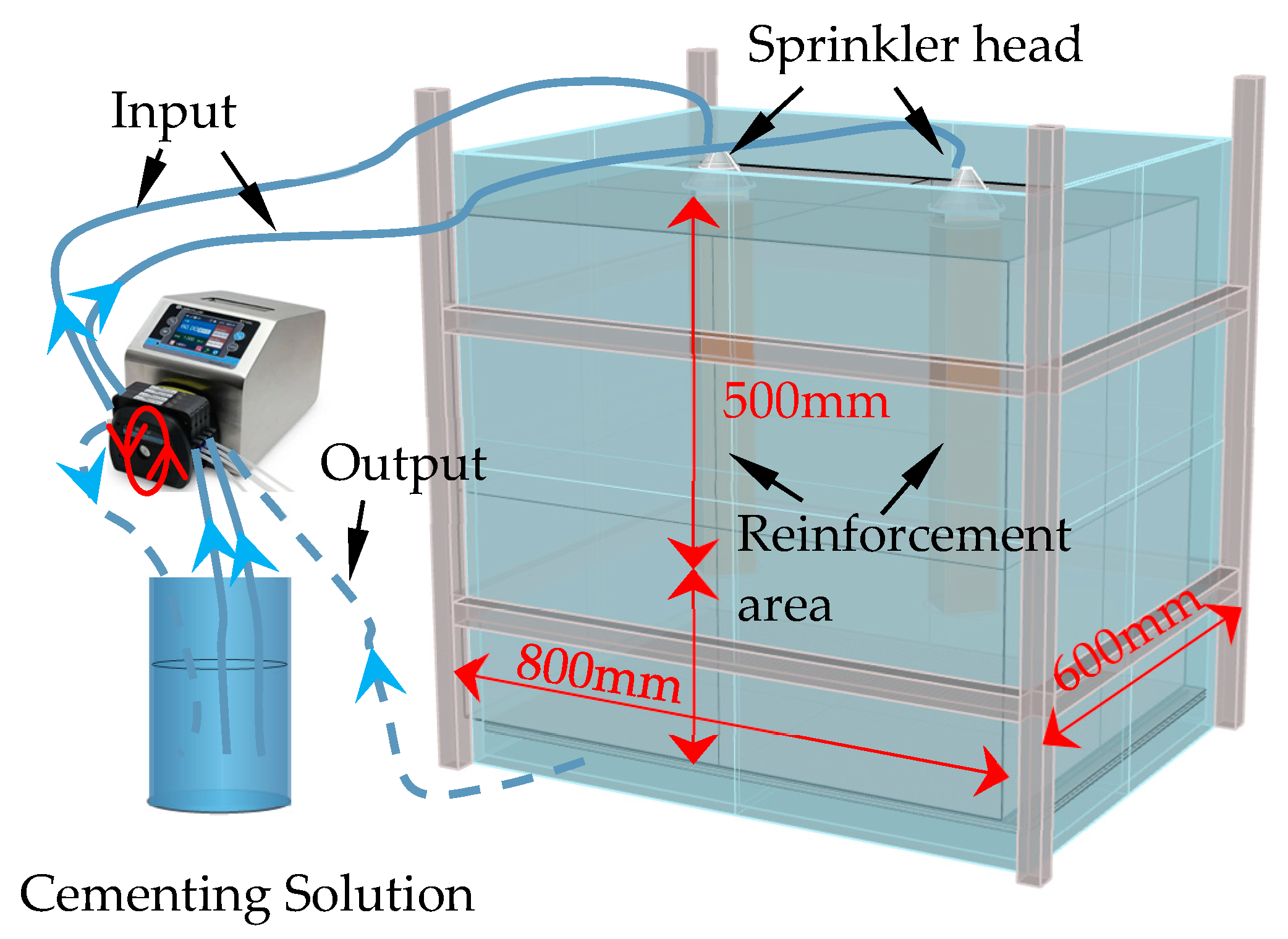

2.2. Model Test Device and Test Procedure

2.2.1. Model Test Device

2.2.2. Test Procedure

2.3. Unconfined Compressive Strength and CaCO3 Content Determination

2.4. Scanning Electron Microscopy Test

3. Results and Discussion

3.1. Sand Foundation Reinforced by the Bio-Cement Infiltration Method

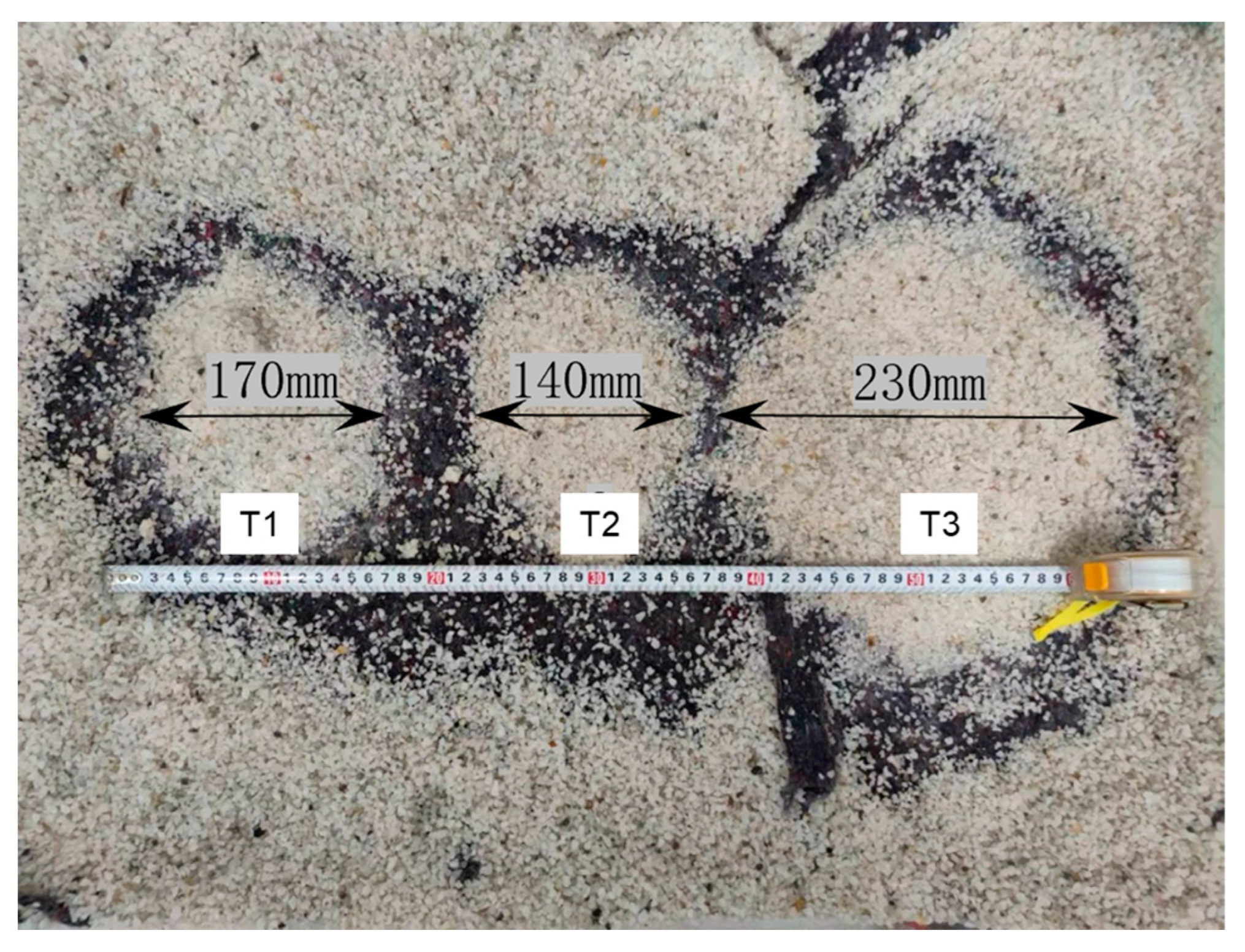

3.1.1. Reinforced Area and Bearing Capacity

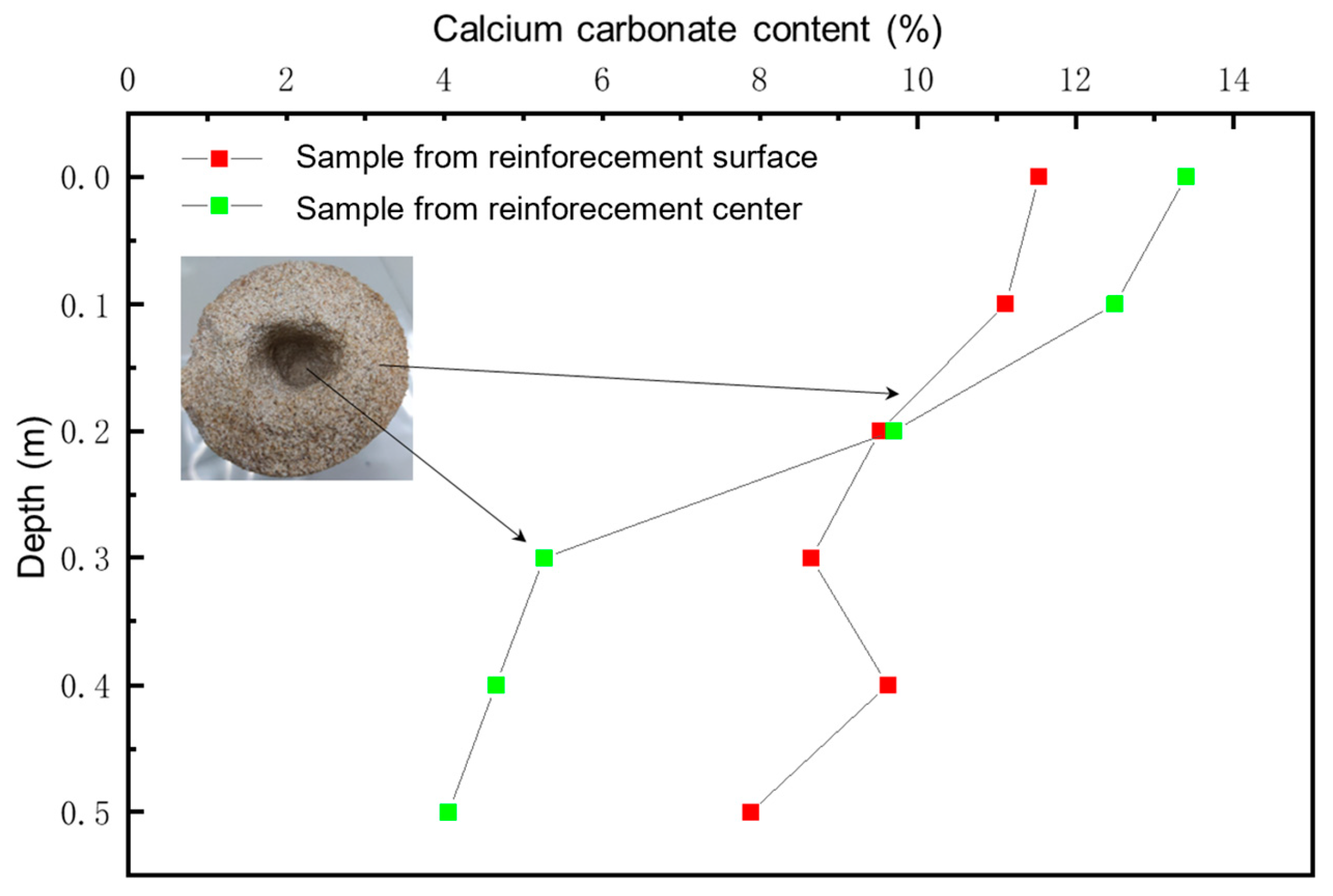

3.1.2. Spatial Distribution of CaCO3

3.2. Sand Foundation Reinforced by the Bio-Cement Mixed Method

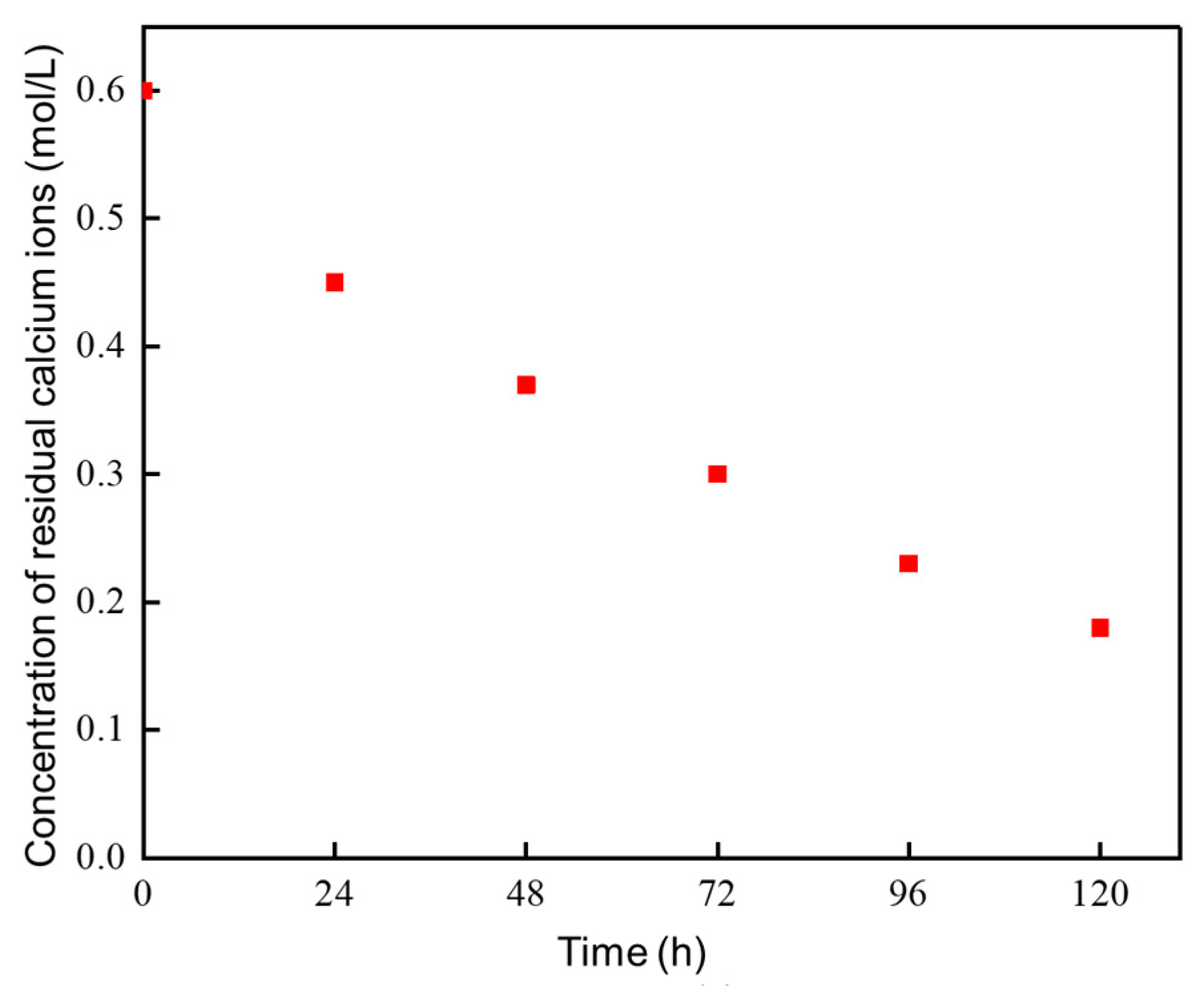

3.2.1. Remaining CS Concentration

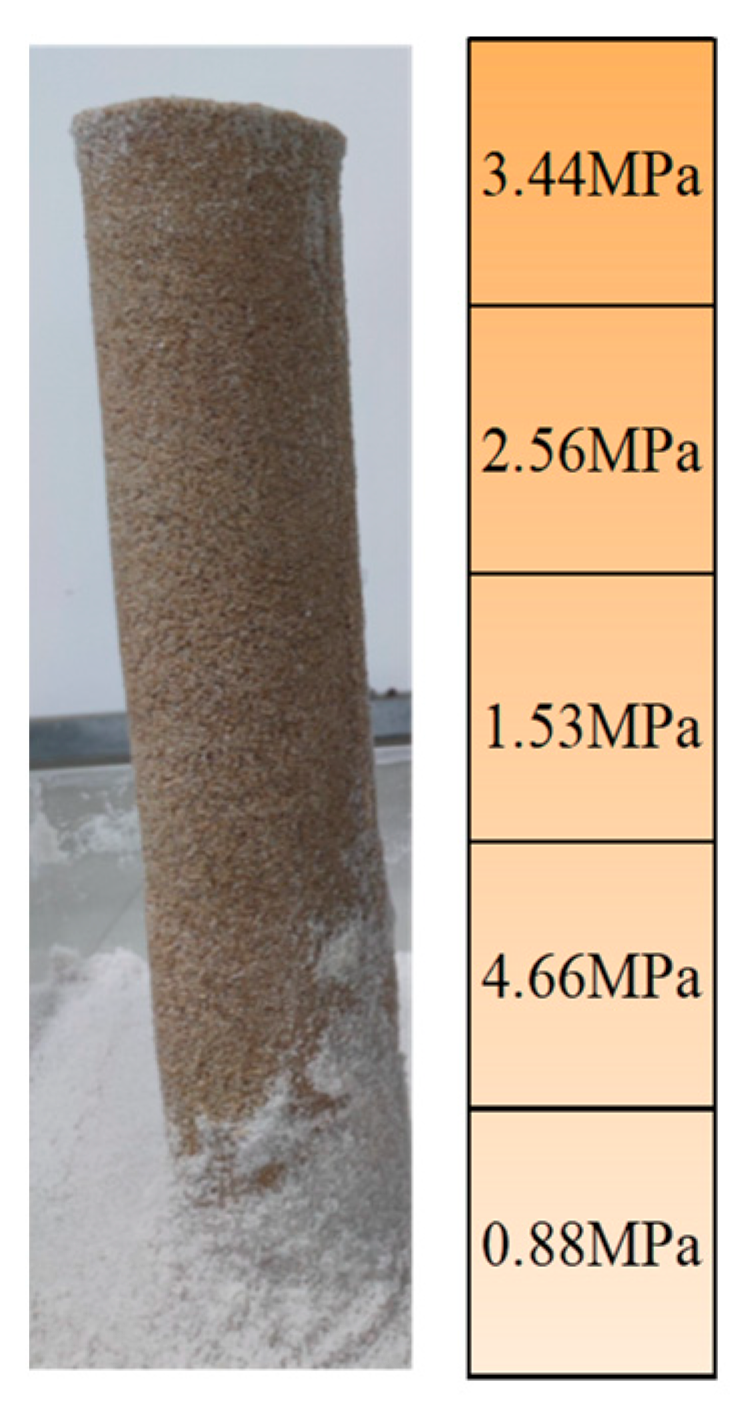

3.2.2. UCS of the Reinforced Area

3.2.3. Spatial Distribution of CaCO3

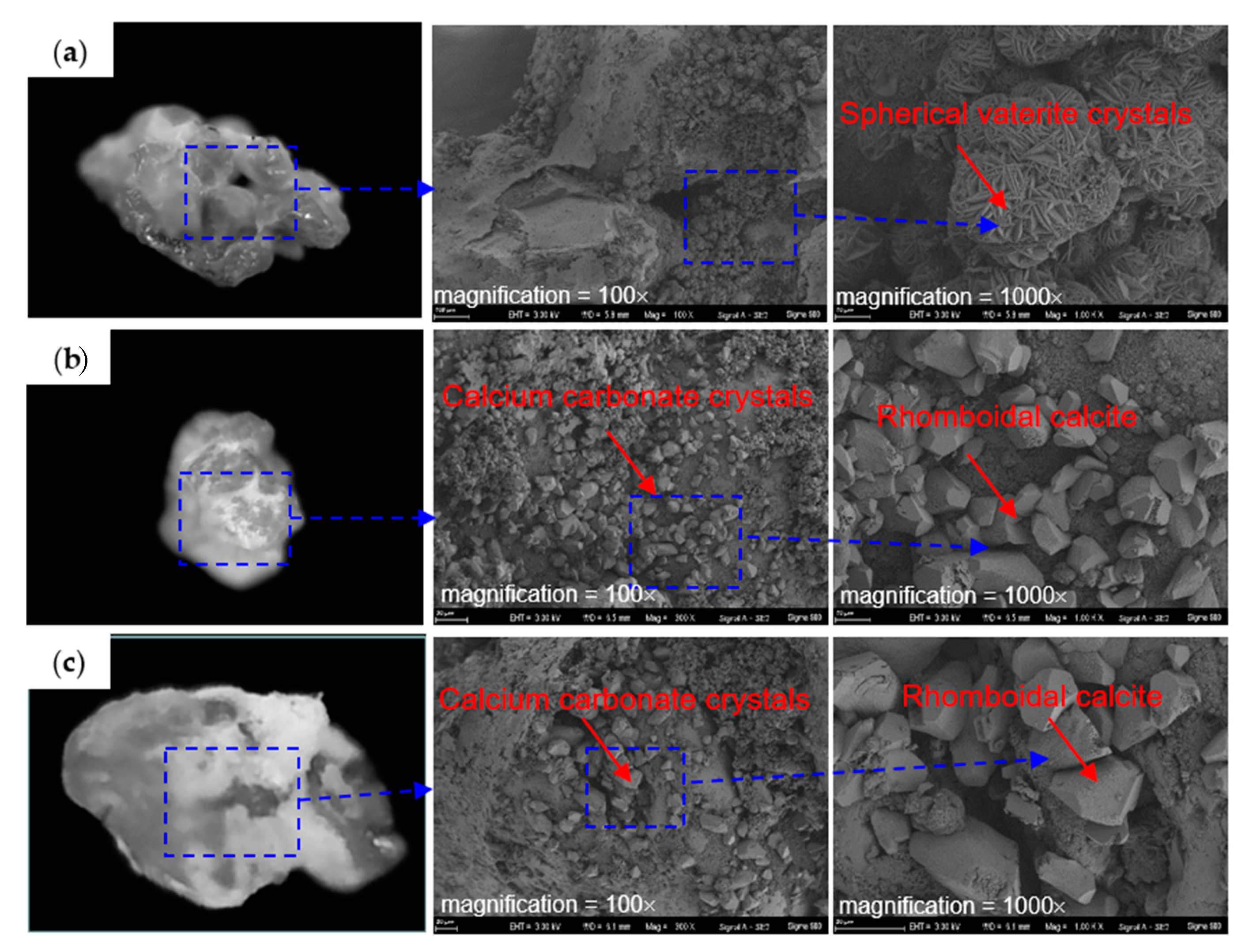

3.2.4. Microscopic Cementation Mechanism

4. Conclusions

- (1)

- The utilization rate of bacterial liquid was maximized, and waste caused by bacteria loss was reduced by the bio-cement, as compared to traditional methods. The bio-cement exhibited long-lasting urease activity of about 5 days and negligible diffusion into the surrounding sand soil.

- (2)

- The sand soil reinforced by the bio-cement infiltration method formed a vertically reinforced area, but the bearing capacity of the reinforced area was small. Both the size of the reinforced area and bearing capacity were controlled by the volume ratio of the bio-cement and calcareous sand powder and the inflow rate.

- (3)

- The UCS of the reinforced area formed by the bio-cement mixed method decreased gradually from 3.44 MPa to 0.88 MPa with depth due to a decrease in the supply of CS from the top to the bottom. Furthermore, the UCS increased with increasing CaCO3 content, indicating that most of the formed CaCO3 crystals had cementation effects.

- (4)

- The CaCO3 crystals were primarily concentrated at the contact points between particles, with most of the crystals appearing as polyhedral shapes. The CaCO3 content decreased with depth, particularly in the central deep part of the reinforcement area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Zhu, C.Q.; Wang, X.Z.; Qin, Y. Study of Dilatancy Behaviors of Calcareous Soils in a Triaxial Test. Mar. Georesources Geotechnol. 2019, 37, 1057–1070. [Google Scholar] [CrossRef]

- Vahdani, S.; Pyke, R.; Siriprusanen, U. Liquefaction of Calcareous Sands and Lateral Spreading Experienced in Guam as a Result of the 1993 Guam Earthquake (Technical Report); NCEE: Washington, DC, USA, 1994. [Google Scholar]

- LaVielle, T.H. Liquefaction Susceptibility of Uncemented Calcareous Sands from Puerto Rico by Cyclic Triaxial Testing; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2008. [Google Scholar]

- Li, Z.Q.; Ma, X.D.; Kong, X.Z.; Saar, M.O.; Vogler, D. Permeability evolution during pressure-controlled shear slip in saw-cut and natural granite fractures. Rock Mech. Bull. 2023, 2, 100027. [Google Scholar] [CrossRef]

- Ronalds, B.; Cole, G. Development of Piled Foundation Bias Factors in the Arabian Gulf; CSIRO: Hobart, Australia, 2005; pp. 1–10. [Google Scholar]

- Montoya, B.M.; DeJong, J.T. Stress-strain behavior of sands cemented by microbially induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Su, Y.H.; Luo, B.; Luo, Z.D.; Xu, F.; Huang, H.; Long, Z.W.; Shen, C.P. Mechanical characteristics and solidification mechanism of slag/fly ash-based geopolymer and cement solidified organic clay: A comparative study. J. Build. Eng. 2023, 71, 106459. [Google Scholar] [CrossRef]

- Wang, H.Y.; Sharma, M.M. Uniquely determine fracture dimension and formation permeability from diagnostic fracture injection test. Rock Mech. Bull. 2023, 2, 100050. [Google Scholar] [CrossRef]

- Soyson, A.; Wiboonluk, P.; Suched, L. Efficiency of microbially-induced calcite precipitation in natural clays for ground improvement. Constr. Build. Mater. 2021, 282, 122722. [Google Scholar]

- Sun, X.H.; Miao, L.C.; Wang, H.X.; Yin, W.H.; Wu, L.Y. Mineralization crust field experiment for desert sand solidification based on enzymatic calcification. J. Environ. Manag. 2021, 287, 112315. [Google Scholar] [CrossRef]

- Wu, C.G.; Zhang, J.; Zhou, M.L.; Wang, L. Resistance factors for design of slopes in a homogenous soil layer. Rock Mech. Bull. 2023, 2, 100022. [Google Scholar] [CrossRef]

- Kou, H.L.; Liu, J.H.; Zhang, P.; Wu, C.Z.; Ni, P.P.; Wang, D. Ecofriendly improvement of coastal calcareous sandy slope using recycled shredded coconut coir (RSC) and bio-cement. Acta Geotech. 2022, 17, 5375–5389. [Google Scholar] [CrossRef]

- Hu, X.; Chen, M.; Hu, B.; Du, G.Z.; Li, K.H. Experimental Study on the Mechanical Behavior of Sandy Soil Reinforced by Disposable Face Mask Chips under Different Stress Paths. Sustainability 2023, 15, 4059. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nüsslein, K. Microbially induced cementation to control sand response to undrained shear. J. Geotech. Geoenviron. Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Jiang, N.J.; Soga, K. The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel–sand mixtures. Géotechnique 2017, 67, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.Z.; Song, Z.C.; Jang, B.A.; Song, H.G.; Ni, P.P. Strength improvement of rock fractures and aggregates cemented with bio-slurry. Mater. Lett. 2021, 305, 130866. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement; Murdoch University: Perth, Australia, 2004. [Google Scholar]

- Montoya, B.M.; Dejong, J.T.; Boulanger, R.W. Dynamic response of liquefiable sand improved by microbial-induced calcite precipitation. Geotechnique 2013, 63, 302–312. [Google Scholar] [CrossRef]

- Cheng, X.H.; Ma, Q.; Yang, Z.; Zhang, Z.; Li, M. Dynamic response of liquefiable sand foundation improved by bio-grouting. Chin. J. Geotech. Eng. 2013, 35, 1486–1495. [Google Scholar]

- Gomez, M.G.; Anderson, C.M.; Graddy, C.M.R.; DeJong, J.T.; Nelson, D.C.; Ginn, T.R. Large-scale comparison of bioaugmentation and biostimulation approaches for biocementation of sands. J. Geotech. Geoenviron. Eng. 2017, 143, 04016124. [Google Scholar] [CrossRef]

- Zamani, A.; Montoya, B.M. Undrained cyclic response of silty sands improved by microbial induced calcium carbonate precipitation. Soil Dyn. Earthq. Eng. 2019, 120, 436–448. [Google Scholar] [CrossRef]

- Yin, J.; Wu, J.X.; Zhang, K.; Shahin, M.A.; Cheng, L. Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation. Sustainability 2022, 15, 434. [Google Scholar] [CrossRef]

- Lee, C.; Lee, H.; Kim, O.B. Biocement fabrication and design application for a sustainable urban area. Sustainability 2018, 10, 4079. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R. In situ soil cementation with ureolytic bacteria by surface percolation. Ecol. Eng. 2012, 42, 64–72. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.Z.; Chu, J.; Cheng, L.; Wu, S.F. Biogrouting of aggregates using premixed injection method with or without pH adjustment. J. Mater. Civ. Eng. 2019, 31, 06019008. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Y.; Wang, S.; Evans, T.M.; Stuedlein, A.W.; Chu, J.; Zhao, C.; Wu, H.R.; Liu, H.L. Homogeneity and mechanical behaviors of sands improved by a temperature-controlled one-phase MICP method. Acta Geotech. 2021, 16, 1417–1427. [Google Scholar] [CrossRef]

- Cheng, L.; Kobayashi, T.; Shahin, M.A. Microbially induced calcite precipitation for production of “bio-bricks” treated at partial saturation condition. Constr. Build. Mater. 2020, 231, 117095. [Google Scholar] [CrossRef]

- Lv, C.; Zhu, C.; Tang, C.S.; Cheng, Q.; Yin, L.Y.; Shi, B. Effect of fiber reinforcement on the mechanical behavior of bio-cemented sand. Geosynth. Int. 2021, 28, 195–205. [Google Scholar] [CrossRef]

- Wu, C.Z.; Chu, J. Biogrouting method for stronger bond strength for aggregates. J. Geotech. Geoenviron. Eng. 2020, 146, 06020021. [Google Scholar] [CrossRef]

- Gowthaman, S.; Koizumi, H.; Nakashima, K.; Kawasaki, S. Field experimentation of bio-cementation using low-cost cementation media for preservation of slope surface. Case Stud. Constr. Mater. 2023, 18, e02086. [Google Scholar] [CrossRef]

- Xu, L.; Xu, R.; Shashank, B.S.; Chen, X.H.; Yu, J.L.; Wu, C.Z. An improved quantification method for characterisation of clay microstructure using SEM. Environ. Geotech. 2022, 40, 1–20. [Google Scholar] [CrossRef]

- Shen, D.Y.; Liu, Z.Y.; Song, Z.C.; Wu, C.Z. Reinforcement Mechanism and Erosion Resistance of Loess Slope Using Enzyme Induced Calcite Precipitation Technique. Sustainability 2023, 15, 1044. [Google Scholar] [CrossRef]

- Zhang, F.Y.; Kong, R.; Peng, J.B. Effects of heating on compositional, structural, and physicochemical properties of loess under laboratory conditions. Appl. Clay Sci. 2018, 152, 259–266. [Google Scholar] [CrossRef]

- Qabany, A.A.; Soga, K.; Santamarina, C. Factors affecting efficiency of microbially induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Gowthaman, S.; Mitsuyama, S.; Nakashima, K.; Komatsu, M.; Kawasaki, S. Biogeotechnical approach for slope soil stabilization using locally isolated bacteria and inexpensive low-grade chemicals: A feasibility study on Hokkaido expressway soil, Japan. Soils Found. 2019, 59, 484–499. [Google Scholar] [CrossRef]

- Danjo, T.; Kawasaki, S. Microbially Induced Sand Cementation Method Using Pararhodobacter sp. Strain SO1, Inspired by Beachrock Formation Mechanism. Mater. Trans. 2016, 57, 428–437. [Google Scholar] [CrossRef] [Green Version]

- Paassen, L.A.V.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; Zon, W.V.D.; Loosdrecht, M.C.M.V. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar] [CrossRef]

- Yu, X.; Qian, C.; Jiang, J. Desert sand cemented by bio-magnesium ammonium phosphate cement and its microscopic properties. Constr. Build. Mater. 2019, 200, 116–123. [Google Scholar] [CrossRef]

- Somani, R.S.; Patel, K.S.; Mehta, A.R.; Jasra, R.V. Examination of the polymorphs and particle size of calcium carbonate precipitated using still effluent (ie, CaCl2 + NaCl solution) of soda ash manufacturing process. Ind. Eng. Chem. Res. 2006, 45, 5223–5230. [Google Scholar] [CrossRef]

| Sample No. | Volume Ratio of Bio-Cement/Calcareous Sand Powder | CS Concentration (mol/L) | Inflow Rate (mL/min) |

|---|---|---|---|

| T1 | 200/40 | 1 | 40 |

| T2 | 200/40 | 20 | |

| T3 | 400/80 | 20 |

| Parameter | Value |

|---|---|

| Reinforcement area, d × h (mm) | 100 × 500 |

| Sand size (mm) | 0.5–1 |

| Bacteria solution volume (L) | 12 |

| CS concentration (mol/L) | 0.6 |

| Cement solution volume (L) | 40 |

| Duration of injection (d) | 5 |

| Injection rate (mL/min) | 15 |

| Depth (cm) | CaCO3 Content (%) | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| 0 | 8.3 | 12.8 | 10.8 |

| 10 | 9.8 | 10.5 | 8.6 |

| 20 | 8.3 | 9.6 | 7.4 |

| 30 | 21.1 | 20.2 | 22.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Song, Z.; Zhang, R.; Shen, D.; Wu, C. Assessment of New Bio-Cement Method for Sand Foundation Reinforcement. Sustainability 2023, 15, 9432. https://doi.org/10.3390/su15129432

Sun J, Song Z, Zhang R, Shen D, Wu C. Assessment of New Bio-Cement Method for Sand Foundation Reinforcement. Sustainability. 2023; 15(12):9432. https://doi.org/10.3390/su15129432

Chicago/Turabian StyleSun, Jinzheng, Zhichao Song, Rongzheng Zhang, Danyi Shen, and Chuangzhou Wu. 2023. "Assessment of New Bio-Cement Method for Sand Foundation Reinforcement" Sustainability 15, no. 12: 9432. https://doi.org/10.3390/su15129432