A Comprehensive Study on the Performance of Various Tracker Systems in Hybrid Renewable Energy Systems, Saudi Arabia

Abstract

1. Introduction

| Location | Goal | System | COE (USD/kWh) | Year | Ref. |

|---|---|---|---|---|---|

| Al-Sulaymania | Optimization to loss of power supply and annualized system cost | PV/WT/Gen/Bat | 0.093 | 2021 | [4] |

| Baha University | Feasibility analysis of HRES to support the college’s energy | PV/WT/FC/Bat | 0.289 | 2020 | [39] |

| Neom | Finding HRES with the minimum NPC | PV/WT/Gen/Bat | 0.164 | 2019 | [40] |

| Arar | Minimizing the COE and the loss of load probability | PV/WT/Gen/Bat | 0.039 | 2021 | [41] |

| Jubail | Technical and economic viability of various hybrid energy system designs is weighed | PV/WT/Gen/Bat | 0.183 to 0.244 | 2019 | [42] |

| Neom | Selection of best configuration to supply the load demand | PV/WT/Gen/Bat PV/Bat | 0.375 0.501 | 2021 | [43] |

| Ad Dulaymiyah | Finding the optimal component sizes and configurations to supply the load demand | PV/Bat | 0.442 | 2021 | [44] |

| Yanbu | Select the best microgrid configuration while minimizing both NPC and LCOE | PV/WT/Gen/Bat | 0.341 to 0.386 | 2021 | [45] |

| Aljouf | Determining the optimal sizing of the HRES | PV/WT/Gen/Bat | 0.134 | 2020 | [46] |

2. Methodology

2.1. Case Study Regions

2.2. Assumptions

2.3. Configurations and Components

3. Results and Discussion

- The results of config 1 are presented as optimal to see the optimal sizing of the components where there is no imposed restriction on the configuration related to using specific components.

- The results of config 2 are presented as 100 kW PV constant, where the size of PV panels in each simulation is considered to be 100 kW. This allows us to see the economic results of the optimization for different tracker systems.

- The results of config 3 are presented as 100% PV to reach the load. This allows us to see how much PV panels under different tracking systems can fulfill the load demand.

- The results of config 4 are presented as 100% Gen to see how much CO2 emission will be emitted where there is no renewable energy producer.

- The results of the sensitivity analysis on the capital cost of PV and the amount of solar GHI where the systems use 100 kW PV are presented in a different section. This allows us to see the influence of changing the capital cost of PV panels or tracker systems and GHI on the COEs for each tracker system.

3.1. The Results of the Config 1

3.2. The Results of the Config 2

3.3. The Results of the Config 3

3.4. The Results of the Config 4

3.5. The Results of the Sens 1

3.6. The Results of the Sens 2

4. Conclusions

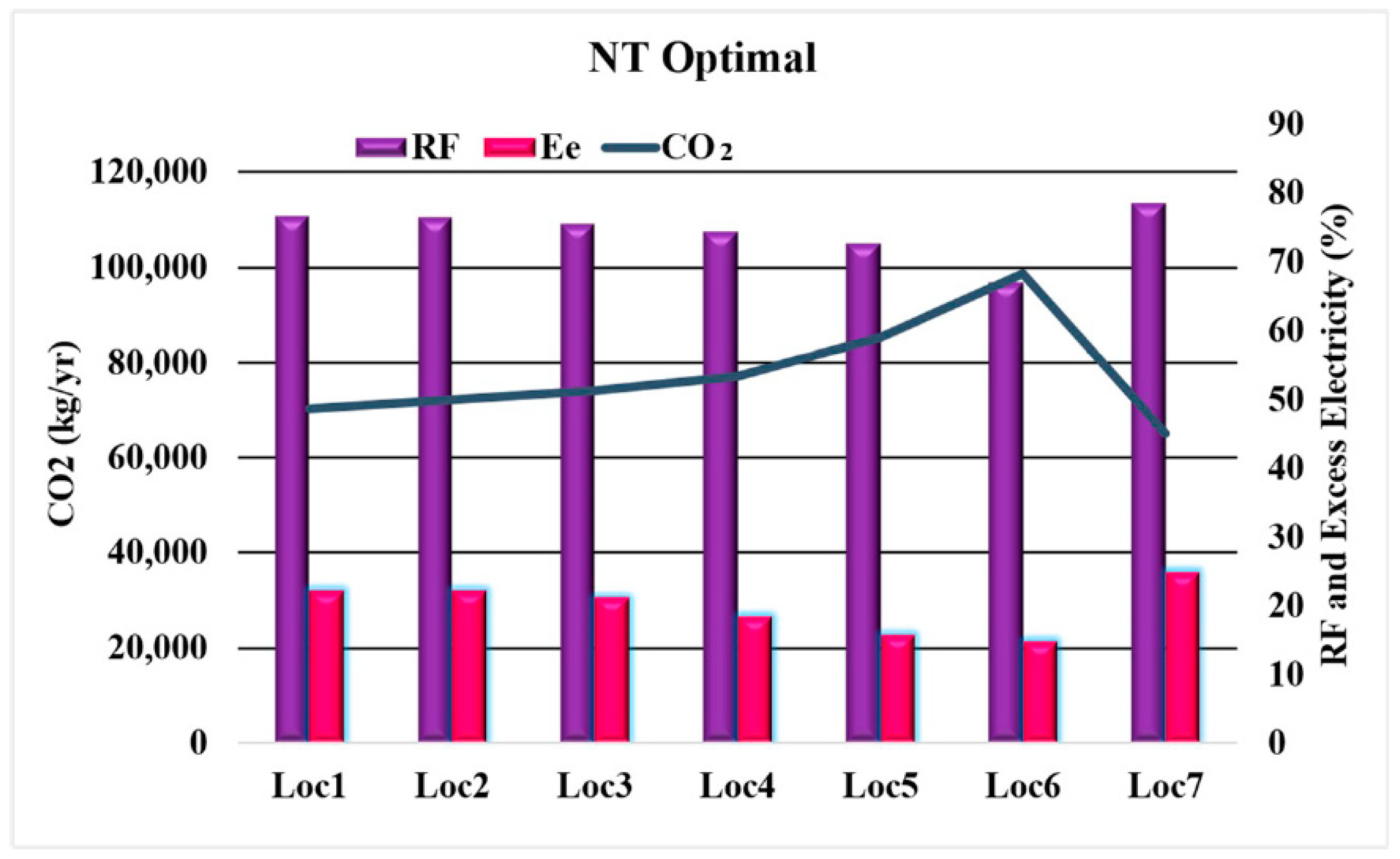

- With changes in location and the same configurations and economic parameters, the best economic tracker and environmentally friendly system in an HRES that can use free sizes of PV, WT, Gen, and Bat would differ.

- Considering the same tracker for different locations in an HRES that can use free sizes of PV, WT, Gen, and Bat, the optimal size of PV panels would differ, resulting in changes in RFs and CO2 emissions.

- If the social cost (penalty) of CO2 emission is considered, with changes in location (where renewable sources would also differ), COEs would differ under various tracking systems such that the higher the RF, the lower the COE.

- The most efficient tracker would be the dual-axis tracking system since it can increase power production by 35% more than PV without a tracker. Additionally, the vertical tracker and horizontal continuous adjustment tracker would increase the power production of the PV by 22% and 8%, respectively.

- In the case of changing the price of PV panels for NT, VT, HT, and DT from 0.7 to 1.2 of the proposed initial capital costs (NT: 1300, VT:1600, HT:1600, and DT: 1800 USD/kW), a vertical tracker would be the best choice and for higher prices up to 1.4 of the initial costs, NT would be more economic.

- For solar GHIs between 5.5 to 6.5 kWh/m2/day, a vertical tracker is more economical while for lower GHIs using a tracker would not be economical.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Bat | Battery |

| COE | Cost of energy |

| Con | Converter |

| CI | Clearness index |

| Config | Configuration |

| da | Day |

| DT | Dual axis tracker |

| Ee | Excess electricity |

| Gen | Generator |

| GHI | Global horizontal irradiation |

| HT | Horizontal tracker |

| HOMER | Hybrid optimization model for multiple energy resources |

| HERES | Hybrid renewable energy system |

| h | Hour |

| Lat | Latitude |

| LCOE | Levelized cost of energy |

| Loc | Location |

| Long | Longitude |

| PV | Photovoltaic |

| NPC | Net present cost |

| NT | No tracking |

| Op | Optimum |

| O&M | Operation and maintenance |

| Qnt | Quantity |

| RF | Renewable fraction |

| Sens | Sensitivity analysis |

| Temp | Temperature |

| VT | Vertical tracker |

| WT | Wind turbine |

| yr | Year |

References

- He, M.; Forootan Fard, H.; Yahya, K.; Mohamed, M.; Alhamrouni, I.; Awalin, L.J. Optimal design of hybrid renewable systems, including grid, PV, bio generator, diesel generator, and battery. Sustainability 2023, 15, 3297. [Google Scholar] [CrossRef]

- Ali, N.; Assad, M.E.H.; Fard, H.F.; Jourdehi, B.A.; Mahariq, I.; Al-Shabi, M.A. CO2 emission modeling of countries in Southeast of Europe by using artificial neural network. In Proceedings of the Sensing for Agriculture and Food Quality and Safety XIV; SPIE: Bellingham, WA, USA, 2022; Volume 12120F. [Google Scholar]

- Sharifpur, M.; Salem, M.; Buswig, Y.M.; Fard, H.F.; Rungamornrat, J. Modeling CO2 Emission in Residential Sector of Three Countries in Southeast of Asia by Applying Intelligent Techniques. Comput. Mater. Contin. 2023, 74, 5679–5690. [Google Scholar] [CrossRef]

- Alturki, F.A.; Al-Shamma’a, A.A.; Farh, H.M.H.; AlSharabi, K. Optimal sizing of autonomous hybrid energy system using supply-demand-based optimization algorithm. Int. J. Energy Res. 2021, 45, 605–625. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Ayar, T.; Yilbas, B.S. Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sustain. Energy Rev. 2017, 69, 33–49. [Google Scholar] [CrossRef]

- Rehman, S. Hybrid power systems–Sizes, efficiencies, and economics. Energy Explor. Exploit. 2021, 39, 3–43. [Google Scholar] [CrossRef]

- Ciupăgeanu, D.-A.; Lăzăroiu, G. Dynamic simulation of a stand-alone photovoltaic/battery energy storage system. In Proceedings of the 2018 International Symposium on Fundamentals of Electrical Engineering (ISFEE), Bucharest, Romania, 1–3 November 2018; IEEE: Piscateville, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Javed, K.; Ashfaq, H.; Singh, R.; Hussain, S.M.S.; Ustun, T.S. Design and performance analysis of a stand-alone PV system with hybrid energy storage for rural India. Electronics 2019, 8, 952. [Google Scholar] [CrossRef]

- Ciupageanu, D.-A.; Barelli, L.; Lazaroiu, G. Design of a fuzzy logic controller for a remote power application. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe), Bucharest, Romania, 29 September–2 October 2019; IEEE: Piscateville, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Xu, A.; Awalin, L.J.; Al-Khaykan, A.; Fard, H.F.; Alhamrouni, I.; Salem, M. Techno-Economic and Environmental Study of Optimum Hybrid Renewable Systems, Including PV/Wind/Gen/Battery, with Various Components to Find the Best Renewable Combination for Ponorogo Regency, East Java, Indonesia. Sustainability 2023, 15, 1802. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Salameh, T.; Sayed, E.T.; Husain, K.S.; Abdelkareem, M.A. Selection guidelines for wind energy technologies. Energies 2021, 14, 3244. [Google Scholar] [CrossRef]

- Rezk, H.; Alghassab, M.; Ziedan, H.A. An optimal sizing of stand-alone hybrid PV-fuel cell-battery to desalinate seawater at saudi NEOM city. Processes 2020, 8, 382. [Google Scholar] [CrossRef]

- Ghenai, C.; Merabet, A.; Salameh, T.; Pigem, E.C. Grid-tied and stand-alone hybrid solar power system for desalination plant. Desalination 2018, 435, 172–180. [Google Scholar] [CrossRef]

- Ali, S.; Jang, C.-M. Optimum design of hybrid renewable energy system for sustainable energy supply to a remote island. Sustainability 2020, 12, 1280. [Google Scholar] [CrossRef]

- El Khashab, H.; Al Ghamedi, M. Comparison between hybrid renewable energy systems in Saudi Arabia. J. Electr. Syst. Inf. Technol. 2015, 2, 111–119. [Google Scholar] [CrossRef]

- Hafez, A.A.; Nassar, Y.F.; Hammdan, M.I.; Alsadi, S.Y. Technical and economic feasibility of utility-scale solar energy conversion systems in Saudi Arabia. Iran. J. Sci. Technol. Trans. Electr. Eng. 2020, 44, 213–225. [Google Scholar] [CrossRef]

- AlOtaibi, Z.S.; Khonkar, H.I.; AlAmoudi, A.O.; Alqahtani, S.H. Current status and future perspectives for localizing the solar photovoltaic industry in the Kingdom of Saudi Arabia. Energy Transit. 2020, 4, 1–9. [Google Scholar] [CrossRef]

- Alkhathlan, K.; Javid, M. Carbon emissions and oil consumption in Saudi Arabia. Renew. Sustain. Energy Rev. 2015, 48, 105–111. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hasan, M.A.; Shafiullah, M.; Rahman, M.S.; Arifuzzaman, M.; Islam, M.K.; Islam, M.M.; Rahman, S.M. A Critical, Temporal Analysis of Saudi Arabia’s Initiatives for Greenhouse Gas Emissions Reduction in the Energy Sector. Sustainability 2022, 14, 12651. [Google Scholar] [CrossRef]

- Ammach, S.; Attia, A. Design and Implementation of Autonomous Energy Efficient Solar Tracking System for PV Power Plants. In Proceedings of the 2019 International Conference on Electrical and Computing Technologies and Applications (ICECTA), Ras Al Khaimah, United Arab Emirates, 19–21 November 2019; IEEE: Piscateville, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Heslop, S.; MacGill, I. Comparative analysis of the variability of fixed and tracking photovoltaic systems. Sol. Energy 2014, 107, 351–364. [Google Scholar] [CrossRef]

- Hariri, N.G.; AlMutawa, M.A.; Osman, I.S.; AlMadani, I.K.; Almahdi, A.M.; Ali, S. Experimental Investigation of Azimuth-and Sensor-Based Control Strategies for a PV Solar Tracking Application. Appl. Sci. 2022, 12, 4758. [Google Scholar] [CrossRef]

- Kambezidis, H.D.; Farahat, A.; Almazroui, M.; Ramadan, E. Solar potential in Saudi Arabia for flat-plate surfaces of varying tilt tracking the sun. Appl. Sci. 2021, 11, 11564. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Addoweesh, K.E.; Bawa, U.; Mohamed, M.A. Economic modeling of hybrid renewable energy system: A case study in Saudi Arabia. Arab. J. Sci. Eng. 2014, 39, 3827–3839. [Google Scholar] [CrossRef]

- Soulayman, S. Economical and Technical Considerations for Solar Tracking: Methodologies and Opportunities for Energy Management: Methodologies and Opportunities for Energy Management; IGI Global: Hershey, PA, USA, 2017; ISBN 1522529519. [Google Scholar]

- Hua, Z.; Ma, C.; Ma, M.; Bin, L.; Pang, X. Operation characteristics of multiple solar trackers under typical weather conditions in a large-scale photovoltaic base. Energy Procedia 2019, 158, 6242–6247. [Google Scholar] [CrossRef]

- Nsengiyumva, W.; Chen, S.G.; Hu, L.; Chen, X. Recent advancements and challenges in Solar Tracking Systems (STS): A review. Renew. Sustain. Energy Rev. 2018, 81, 250–279. [Google Scholar] [CrossRef]

- Sørensen, B.; Watt, G. Trends in Photovoltaic Applications, Survey report of selected IEA countries between 1992 and 2005: Report IEA-PVPS T1-15. 2006. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/tr_2005.pdf (accessed on 1 February 2022).

- Rizk, J.; Chaiko, Y. Solar tracking system: More efficient use of solar panels. World Acad. Sci. Eng. Technol. 2008, 41, 313–315. [Google Scholar]

- Eldin, S.A.S.; Abd-Elhady, M.S.; Kandil, H.A. Feasibility of solar tracking systems for PV panels in hot and cold regions. Renew. Energy 2016, 85, 228–233. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Farzaneh-Gord, M. A sustainable optimal biomass waste-driven CCHP system to boost the nearly zero energy building concept. Energy Convers. Manag. 2023, 277, 116669. [Google Scholar] [CrossRef]

- Abadi, M.K.; Davoodi, V.; Deymi-Dashtebayaz, M.; Ebrahimi-Moghadam, A. Determining the best scenario for providing electrical, cooling, and hot water consuming of a building with utilizing a novel wind/solar-based hybrid system. Energy 2023, 273, 127239. [Google Scholar] [CrossRef]

- Alahmdi, R.; Alansari, A.; Abualkhair, M.; Almoghamisi, A. Empirical Evaluation of Fixed and Single-Axis Tracking Photovoltaic System: Case of ASHRAE Solar Radiation Modelling for Medina, Saudi Arabia. J. Clean Energy Technol. 2021, 9, 33–38. [Google Scholar] [CrossRef]

- Bajawi, A.M.; Nahhas, A.M. Analytical Study of Power Generation Using PV System for Al-Shuaiba and Al-Shuqiq Regions in Saudi Arabia. Am. J. Energy Res. 2021, 9, 21–29. [Google Scholar] [CrossRef]

- Alabdali, Q.A.; Nahhas, A.M. Simulation study of grid connected photovoltaic system using PVsyst Software: Analytical study for Yanbu and Rabigh Regions in Saudi Arabia. Am. J. Energy Res. 2021, 9, 30–44. [Google Scholar] [CrossRef]

- Alzahrani, G.S.; Nahhas, A.M. Analytical Study of Power Generation by Photovoltaic System for Al-Riyadh and Al-Jubail Regions in Saudi Arabia. Am. J. Energy Res. 2021, 9, 45–55. [Google Scholar] [CrossRef]

- Imam, A.A.; Al-Turki, Y.A. Techno-economic feasibility assessment of grid-connected PV systems for residential buildings in Saudi Arabia—A Case Study. Sustainability 2019, 12, 262. [Google Scholar] [CrossRef]

- Al Garni, H.Z.; Awasthi, A.; Ramli, M.A.M. Optimal design and analysis of grid-connected photovoltaic under different tracking systems using HOMER. Energy Convers. Manag. 2018, 155, 42–57. [Google Scholar] [CrossRef]

- Tazay, A.F.; Samy, M.M.; Barakat, S. A Techno-Economic Feasibility Analysis of an Autonomous Hybrid Renewable Energy Sources for University Building at Saudi Arabia. J. Electr. Eng. Technol. 2020, 15, 2519–2527. [Google Scholar] [CrossRef]

- Awan, A.B. Performance analysis and optimization of a hybrid renewable energy system for sustainable NEOM city in Saudi Arabia. J. Renew. Sustain. Energy 2019, 11, 25905. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Alotaibi, M.A.; Alolah, A.I.; Ahmed, M.A. A novel demand response strategy for sizing of hybrid energy system with smart grid concepts. IEEE Access 2021, 9, 20277–20294. [Google Scholar] [CrossRef]

- Baseer, M.A.; Alqahtani, A.; Rehman, S. Techno-economic design and evaluation of hybrid energy systems for residential communities: Case study of Jubail industrial city. J. Clean. Prod. 2019, 237, 117806. [Google Scholar] [CrossRef]

- Salameh, T.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G.; Rezk, H. Optimal selection and management of hybrid renewable energy System: Neom city as a case study. Energy Convers. Manag. 2021, 244, 114434. [Google Scholar] [CrossRef]

- Elmorshedy, M.F.; Elkadeem, M.R.; Kotb, K.M.; Taha, I.B.M.; Mazzeo, D. Optimal design and energy management of an isolated fully renewable energy system integrating batteries and supercapacitors. Energy Convers. Manag. 2021, 245, 114584. [Google Scholar] [CrossRef]

- Kharrich, M.; Kamel, S.; Alghamdi, A.S.; Eid, A.; Mosaad, M.I.; Akherraz, M.; Abdel-Akher, M. Optimal Design of an Isolated Hybrid Microgrid for Enhanced Deployment of Renewable Energy Sources in Saudi Arabia. Sustainability 2021, 13, 4708. [Google Scholar] [CrossRef]

- Fathy, A.; Kaaniche, K.; Alanazi, T.M. Recent approach based social spider optimizer for optimal sizing of hybrid PV/wind/battery/diesel integrated microgrid in Aljouf region. IEEE Access 2020, 8, 57630–57645. [Google Scholar] [CrossRef]

- Dehwah, A.H.A.; Krarti, M. Optimal Hybrid Power Energy Systems for Residential Communities in Saudi Arabia. J. Sol. Energy Eng. 2019, 141, 61002. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Eltamaly, A.M.; Alolah, A.I.; Hatata, A.Y. A novel framework-based cuckoo search algorithm for sizing and optimization of grid-independent hybrid renewable energy systems. Int. J. Green Energy 2019, 16, 86–100. [Google Scholar] [CrossRef]

- Fard, H.F.; Alavi, M.F.; Sharabaty, H.; Ahmadzadeh, M.; Mahariq, I. Technical Design and Economic Investigations for Reducing CO2 Emission considering Environmental Protection Agency Standards by Employing an Optimum Grid-Connected PV/Battery System. Int. J. Photoenergy 2022, 2022, 7360159. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Decision-making between a grid extension and a rural renewable off-grid system with hydrogen generation. Int. J. Hydrogen Energy 2018, 43, 9535–9548. [Google Scholar] [CrossRef]

- Baneshi, M.; Hadianfard, F. Techno-economic feasibility of hybrid diesel/PV/wind/battery electricity generation systems for non-residential large electricity consumers under southern Iran climate conditions. Energy Convers. Manag. 2016, 127, 233–244. [Google Scholar] [CrossRef]

- Razmjoo, A.; Gakenia Kaigutha, L.; Vaziri Rad, M.A.; Marzband, M.; Davarpanah, A.; Denai, M. A Technical analysis investigating energy sustainability utilizing reliable renewable energy sources to reduce CO2 emissions in a high potential area. Renew. Energy 2021, 164, 46–57. [Google Scholar] [CrossRef]

- Jahangir, M.H.; Fakouriyan, S.; Vaziri Rad, M.A.; Dehghan, H. Feasibility study of on/off grid large-scale PV/WT/WEC hybrid energy system in coastal cities: A case-based research. Renew. Energy 2020, 162, 2075–2095. [Google Scholar] [CrossRef]

- Al-Shamma’a, A.A.; Alturki, F.A.; Farh, H.M.H. Techno-economic assessment for energy transition from diesel-based to hybrid energy system-based off-grids in Saudi Arabia. Energy Transit. 2020, 4, 31–43. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, M.; Al-Sulaiman, F.A.; Tahir, S.; Irshad, K.; Zahir, M.H.; Malik, M.Z. Techno-economic study on grid-connected PV system for major cities in Saudi Arabia. E3S Web Conf. 2020, 173, 2005. [Google Scholar] [CrossRef]

- Alturki, F.A.; MH Farh, H.; A. Al-Shamma’a, A.; AlSharabi, K. Techno-economic optimization of small-scale hybrid energy systems using manta ray foraging optimizer. Electronics 2020, 9, 2045. [Google Scholar] [CrossRef]

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CI | 0.56 | 0.59 | 0.58 | 0.59 | 0.65 | 0.71 | 0.69 | 0.68 | 0.67 | 0.66 | 0.60 | 0.54 | |

| Loc1 | GHI | 3.81 | 4.69 | 5.37 | 6.18 | 7.17 | 7.89 | 7.59 | 7.20 | 6.47 | 5.50 | 4.25 | 3.51 |

| Wind Speed | 5.49 | 5.92 | 5.96 | 5.67 | 5.45 | 6.24 | 6.38 | 5.70 | 5.06 | 4.77 | 5.06 | 5.21 | |

| CI | 0.53 | 0.59 | 0.58 | 0.58 | 0.65 | 0.70 | 0.69 | 0.69 | 0.67 | 0.63 | 0.53 | 0.48 | |

| Loc2 | GHI | 3.30 | 4.31 | 5.18 | 6.00 | 7.16 | 7.91 | 7.71 | 7.31 | 6.28 | 4.92 | 3.42 | 2.77 |

| Wind Speed | 5.45 | 5.87 | 5.99 | 5.94 | 6.10 | 7.38 | 7.44 | 6.47 | 5.75 | 5.50 | 5.45 | 5.40 | |

| CI | 0.52 | 0.57 | 0.61 | 0.64 | 0.66 | 0.74 | 0.72 | 0.71 | 0.70 | 0.61 | 0.55 | 0.50 | |

| Loc3 | GHI | 3.02 | 4.07 | 5.30 | 6.57 | 7.37 | 8.41 | 8.08 | 7.45 | 6.39 | 4.59 | 3.33 | 2.70 |

| Wind Speed | 5.23 | 5.77 | 5.90 | 5.76 | 5.62 | 5.61 | 5.91 | 5.11 | 4.86 | 5.13 | 5.04 | 5.04 | |

| CI | 0.62 | 0.65 | 0.65 | 0.65 | 0.66 | 0.71 | 0.70 | 0.68 | 0.67 | 0.62 | 0.62 | 0.61 | |

| Loc4 | GHI | 3.84 | 4.80 | 5.81 | 6.67 | 7.30 | 8.02 | 7.82 | 7.20 | 6.26 | 4.87 | 3.96 | 3.51 |

| Wind Speed | 5.28 | 5.46 | 5.64 | 5.55 | 5.38 | 5.44 | 4.97 | 4.86 | 4.95 | 4.70 | 5.05 | 5.13 | |

| CI | 0.68 | 0.70 | 0.69 | 0.70 | 0.67 | 0.70 | 0.69 | 0.67 | 0.66 | 0.69 | 0.68 | 0.67 | |

| Loc5 | GHI | 4.67 | 5.60 | 6.46 | 7.26 | 7.39 | 7.86 | 7.67 | 7.07 | 6.43 | 5.74 | 4.87 | 4.36 |

| Wind Speed | 4.98 | 4.82 | 4.78 | 4.35 | 4.26 | 4.49 | 4.17 | 4.08 | 4.12 | 3.96 | 4.24 | 4.68 | |

| CI | 0.59 | 0.62 | 0.62 | 0.63 | 0.63 | 0.64 | 0.62 | 0.59 | 0.62 | 0.67 | 0.62 | 0.59 | |

| Loc6 | GHI | 4.39 | 5.20 | 5.95 | 6.60 | 6.85 | 7.08 | 6.81 | 6.22 | 6.09 | 5.84 | 4.76 | 4.23 |

| Wind Speed | 4.55 | 4.54 | 4.64 | 4.25 | 3.71 | 3.88 | 3.88 | 3.41 | 3.64 | 4.47 | 4.26 | 4.34 | |

| CI | 0.58 | 0.62 | 0.59 | 0.59 | 0.62 | 0.69 | 0.69 | 0.67 | 0.65 | 0.61 | 0.55 | 0.55 | |

| Loc7 | GHI | 3.72 | 4.64 | 5.34 | 6.13 | 6.85 | 7.85 | 7.67 | 7.07 | 6.13 | 4.82 | 3.63 | 3.31 |

| Wind Speed | 5.81 | 6.17 | 6.14 | 5.86 | 5.65 | 5.74 | 5.83 | 5.32 | 5.16 | 5.58 | 5.76 | 5.75 | |

| Annual average | Loc1 | Loc2 | Loc3 | Loc4 | Loc5 | Loc6 | Loc7 | ||||||

| Wind speed | 5.58 | 6.06 | 5.42 | 5.2 | 4.41 | 4.13 | 5.73 | ||||||

| GHI | 5.8 | 6 | 5.61 | 5.84 | 6.28 | 5.84 | 6 | ||||||

| Temp | 25.75 | 24.74 | 21.29 | 20.33 | 28.12 | 24.56 | 22.63 | ||||||

| Options | PV | Wind | Gen | Bat | Constraints | Sensitivity | |

|---|---|---|---|---|---|---|---|

| PV Initial Cost (USD) | GHI (kWh/m2/da) | ||||||

| Config 1 | ✓ | ✓ | ✓ | ✓ | |||

| Config 2 | ✓ | ✓ | ✓ | ✓ | 100 kW PV | ||

| Config 3 | ✓ | ✓ | |||||

| Config 4 | ✓ | ||||||

| Sens 1 | ✓ | ✓ | ✓ | ✓ | 100 kW PV | Multiplied by 0.7 to 1.4 | |

| Sens 2 | ✓ | ✓ | ✓ | ✓ | 100 kW PV | From 3.5 to 6.5 |

| Item | Characteristics | Value | Item | Characteristics | Value |

|---|---|---|---|---|---|

| PV | Model name | SunPower E20-327 | Bat | Model name | Surrette 4 KS 25P |

| Panel type | Flat plate | Capacity | 7.55 (kWh) | ||

| Nominal capacity | 0.327 (kW) | Voltage | 4 (V) | ||

| Temperature coefficient | −0.38 | Current | 459 (A) | ||

| Operating temperature | 45 °C | Efficiency | 80 (%) | ||

| Efficiency at STC | 20.4 (%) | Gen | Model name | Generic Genset | |

| Derating factor | 88 (%) | Capacity (kW) | 1 (kW) | ||

| WT | Model name | Eocycle EO10-Class III | Min load ratio (%) | 25 (%) | |

| Rated capacity | 10 (kW) | Fuel | Diesel | ||

| Cut in/off wind speed | 2.75–20 (m/s) | Fuel price | 0.25 (USD/L) | ||

| Hub height | 16 (m) | Con | Model | Generic | |

| Rotor diameter | 15.81 (m) | Efficiency (%) | 95 (%) |

| Module | Lifetime | Capital Cost | Replacement | Maintenance |

|---|---|---|---|---|

| PV | 20 yr | 1300 (USD/kW) | 1300 (USD/kW) | 10 (USD/kW/yr) |

| WT | 20 yr | 3000 (USD/kW) | 3000 (USD/kW) | 600 (USD/kW/yr) |

| Gen | 15,000 h | 450 (USD/kW) | 450 (USD/kW) | 0.018 (USD/op·h) |

| Bat | 20 yr | 1150 (USD/Qnt) | 900 (USD/Qnt) | 40 (USD/Qnt/yr) |

| Con | 15 yr | 300 (USD/kW) | 300 (USD/kW) | 3 (USD/yr·kW) |

| VT | 20 yr | 300 (USD/kW) | 300 (USD/kW) | |

| HT | 20 yr | 300 (USD/kW) | 300 (USD/kW) | |

| DT | 20 yr | 500 (USD/kW) | 500(USD/kW) |

| PV (kW) | Wind (Qnt) | Gen (kW) | Bat (Qnt) | Con (kW) | NPC (USD) | COE (USD/kWh) | 100 kW PV Production (kWh/yr) | COE of 100 kW PV (USD/kWh) | PV to Reach to LOAD (kW) | NPC to Reach to Load (MUSD) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Config 1 | Config 2 | Config 3 | |||||||||

| Loc1 | |||||||||||

| NT | 33 | 6 | 80 | 57 | 35 | 635,429 | 0.12 | 181,938 | 0.124 | 292 | 1.19 |

| VT | 42 | 5 | 80 | 55 | 40 | 632,098 | 0.117 | 221,860 | 0.124 | 268 | 1.19 |

| HT | 27 | 6 | 80 | 49 | 37 | 641,363 | 0.119 | 197,040 | 0.127 | 293 | 1.24 |

| DT | 38 | 5 | 80 | 58 | 39 | 631,343 | 0.117 | 246,087 | 0.127 | 239 | 1.23 |

| Loc2 | |||||||||||

| NT | 12 | 6 | 80 | 38 | 33 | 582,611 | 0.108 | 175,417 | 0.117 | 388 | 1.32 |

| VT | 23 | 6 | 60 | 49 | 74 | 580,814 | 0.108 | 218,231 | 0.119 | 345 | 1.37 |

| HT | 0 | 7 | 70 | 41 | 46 | 583,243 | 0.108 | 190,390 | 0.121 | 380 | 1.42 |

| DT | 21 | 6 | 70 | 51 | 45 | 581,339 | 0.108 | 236,813 | 0.122 | 322 | 1.48 |

| Loc3 | |||||||||||

| NT | 31 | 6 | 80 | 55 | 40 | 647,285 | 0.12 | 181,869 | 0.125 | 369 | 1.31 |

| VT | 40 | 6 | 80 | 55 | 37 | 641,062 | 0.119 | 231,362 | 0.124 | 344 | 1.37 |

| HT | 30 | 6 | 80 | 47 | 39 | 652,672 | 0.121 | 198,197 | 0.128 | 353 | 1.41 |

| DT | 46 | 5 | 80 | 59 | 40 | 639,005 | 0.119 | 250,148 | 0.127 | 327 | 1.46 |

| Loc4 | |||||||||||

| NT | 54 | 5 | 80 | 59 | 42 | 661,349 | 0.123 | 193,297 | 0.126 | 331 | 1.14 |

| VT | 53 | 5 | 70 | 46 | 67 | 654,029 | 0.122 | 239,509 | 0.125 | 264 | 1.13 |

| HT | 50 | 5 | 80 | 62 | 43 | 668,924 | 0.124 | 209,574 | 0.129 | 249 | 1.19 |

| DT | 47 | 5 | 80 | 56 | 41 | 650,629 | 0.121 | 262,266 | 0.128 | 238 | 1.16 |

| Loc5 | |||||||||||

| NT | 94 | 4 | 70 | 64 | 69 | 745,896 | 0.139 | 198,390 | 0.139 | 296 | 1.11 |

| VT | 78 | 4 | 70 | 62 | 67 | 724,888 | 0.135 | 242,464 | 0.136 | 255 | 1.05 |

| HT | 86 | 4 | 70 | 65 | 66 | 753,065 | 0.14 | 215,999 | 0.141 | 276 | 1.12 |

| DT | 71 | 4 | 70 | 58 | 68 | 722,480 | 0.134 | 272,082 | 0.136 | 267 | 1.10 |

| Loc6 | |||||||||||

| NT | 78 | 5 | 80 | 76 | 49 | 759,981 | 0.141 | 183,208 | 0.142 | 346 | 1.23 |

| VT | 71 | 4 | 80 | 77 | 51 | 749,617 | 0.139 | 216,794 | 0.14 | 290 | 1.23 |

| HT | 71 | 5 | 80 | 73 | 49 | 771,475 | 0.143 | 197,770 | 0.145 | 305 | 1.28 |

| DT | 71 | 4 | 80 | 77 | 51 | 745,924 | 0.139 | 244,609 | 0.141 | 245 | 1.27 |

| Loc7 | |||||||||||

| NT | 37 | 6 | 80 | 57 | 36 | 624,767 | 0.116 | 181,684 | 0.122 | 331 | 1.24 |

| VT | 51 | 5 | 80 | 54 | 39 | 619,419 | 0.115 | 223,195 | 0.122 | 293 | 1.25 |

| HT | 19 | 6 | 80 | 46 | 36 | 624,542 | 0.116 | 196,435 | 0.125 | 319 | 1.32 |

| DT | 26 | 6 | 80 | 48 | 38 | 620,620 | 0.115 | 243,815 | 0.125 | 285 | 1.30 |

| Loc1 | Loc2 | Loc3 | Loc4 | Loc5 | Loc6 | Loc7 | |

|---|---|---|---|---|---|---|---|

| The optimality of the trackers | |||||||

| Config 1 | DT | VT | VT | DT | DT | DT | VT |

| Config 2 | DT | VT | VT | VT | DT | NT | VT |

| Config 3 | VT | NT | NT | VT | VT | NT | NT |

| NT (USD/kW) | VT (USD/kW) | HT (USD/kW) | DT (USD/kW) | Economic Optimality |

|---|---|---|---|---|

| 1820 | 2240 | 2240 | 2520 | NT > VT > HT = DT |

| 1690 | 2080 | 2080 | 2340 | NT > VT > DT > HT |

| 1560 | 1920 | 1920 | 2160 | VT = NT > DT > HT |

| 1430 | 1760 | 1760 | 1980 | VT = NT > DT > HT |

| 1300 | 1600 | 1600 | 1800 | VT > NT > VT > HT |

| 1170 | 1440 | 1440 | 1620 | VT > NT > VT > HT |

| 1040 | 1280 | 1280 | 1440 | VT > NT = VT > HT |

| 910 | 1120 | 1120 | 1260 | VT > DT > NT > HT |

| GHI (kWh/m2/day) | Economic Optimality |

|---|---|

| 6.5 | VT > NT > DT > HT |

| 5.5 | VT = NT > DT > HT |

| 4.5 | NT > VT > HT = DT |

| 3.5 | NT > VT > HT > DT |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alanazi, M.; Attar, H.; Amer, A.; Amjad, A.; Mohamed, M.; Majid, M.S.; Yahya, K.; Salem, M. A Comprehensive Study on the Performance of Various Tracker Systems in Hybrid Renewable Energy Systems, Saudi Arabia. Sustainability 2023, 15, 10626. https://doi.org/10.3390/su151310626

Alanazi M, Attar H, Amer A, Amjad A, Mohamed M, Majid MS, Yahya K, Salem M. A Comprehensive Study on the Performance of Various Tracker Systems in Hybrid Renewable Energy Systems, Saudi Arabia. Sustainability. 2023; 15(13):10626. https://doi.org/10.3390/su151310626

Chicago/Turabian StyleAlanazi, Mohana, Hani Attar, Ayman Amer, Ayesha Amjad, Mahmoud Mohamed, Mohammed Sh. Majid, Khalid Yahya, and Mohamed Salem. 2023. "A Comprehensive Study on the Performance of Various Tracker Systems in Hybrid Renewable Energy Systems, Saudi Arabia" Sustainability 15, no. 13: 10626. https://doi.org/10.3390/su151310626

APA StyleAlanazi, M., Attar, H., Amer, A., Amjad, A., Mohamed, M., Majid, M. S., Yahya, K., & Salem, M. (2023). A Comprehensive Study on the Performance of Various Tracker Systems in Hybrid Renewable Energy Systems, Saudi Arabia. Sustainability, 15(13), 10626. https://doi.org/10.3390/su151310626